Hottinger Baldwin Messtechnik T40S2TOS6 User Manual

Mounting Instructions | Montageanleitung

English Deutsch

T40B

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

Email: info@hbm.com

Internet: www.hbm.com

Mat.: 7-2002.3452

DVS: A3452-10.0

11.2014

E Hottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie im Sinne des §443 BGB dar.

Mounting Instructions | Montageanleitung

English Deutsch

T40B

English

1 Safety instructions 4........................................

2 Markings used 12............................................

2.1 Symbols on the transducer 12..................................

2.2 The markings used in this document 12..........................

3 Application 14...............................................

4 Structure and mode of operation 15...........................

5 Mechanical installation 21....................................

5.1 Important precautions during installation 21......................

5.2 Conditions on site 22..........................................

5.3 Installation orientation 23......................................

5.4 Installation options 23.........................................

5.4.1 Installation without dismantling the antenna ring, Option 7, Code U with

antenna shielding cover 24.....................................

5.4.2 Installation with subsequent stator mounting, Option 7, Code S 25...

5.5 Installing the rotor 26..........................................

5.6 Installing the stator 29.........................................

5.7 Rotational speed measuring system, reference signal (optional) 37..

6 Electrical connection 39......................................

6.1 General information 39........................................

6.2 EMC protection 39............................................

6.3 Connector pin assignment 41...................................

6.4 Supply voltage 47.............................................

7 Shunt signal 49..............................................

8 Functionality testing 50......................................

8.1 Rotor status, LED A (upper LED) 51.............................

8.2 Stator status, LED B (lower LED) 52............................

2 A3452-10.0 T40B

9 Load‐carrying capacity 53....................................

10 Maintenance 54..............................................

11 Waste disposal and environmental protection 55..............

12 Ordering numbers, accessories 56............................

13 Specifications 58............................................

13.1 Nominal (rated) torque 50N·m to 500N·m 58....................

13.2 Nominal (rated) torque 1kN·m to 10kN·m 66.....................

14 Supplementary technical information 76......................

T40B A3452-10.0 3

Safety instructions

1 Safety instructions

FCC Compliance & Advisory Statement for Option 7,

Code U

Important

Any changes or modification not expressly approved in

writing by by the party responsible for compliance could

void the user’s authority to operate the device. Where

specified additional components or accessories else

where defined to be used with the installation of the prod

uct, they must be used in order to ensure compliance

with FCC regulations.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2)

this device must accept any interference received, includ

ing interference that may cause undesired operation.

The FCC identifier or the unique identifier, as appropri

ate, must be displayed on the device.

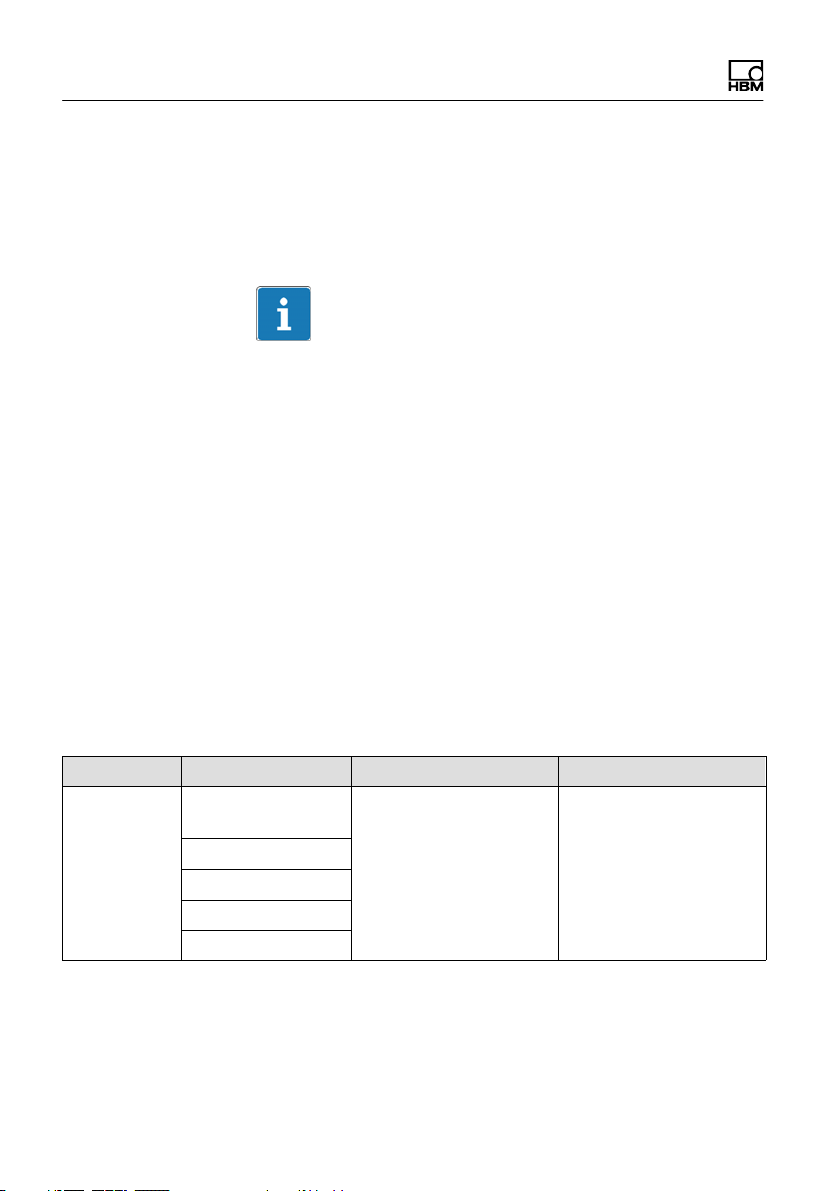

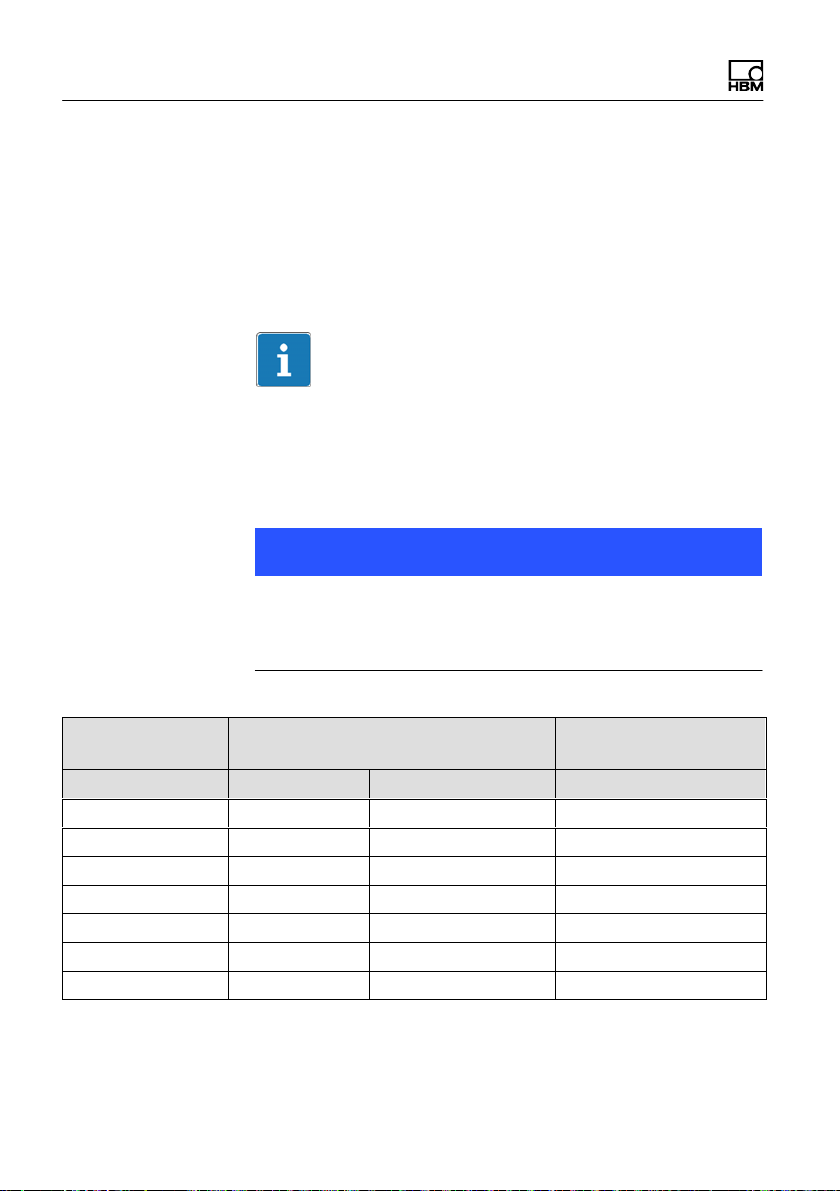

Model Measuring range FCC ID IC

50 Nm, 100 Nm,

200 Nm

500 Nm, 1 kNm

T40S2TOS6

2 kNm, 3 kNm

5 kNm

10 kNm

2ADAT−T40S2TOS6 12438A−T40S2TOS6

4 A3452-10.0 T40B

Safety instructions

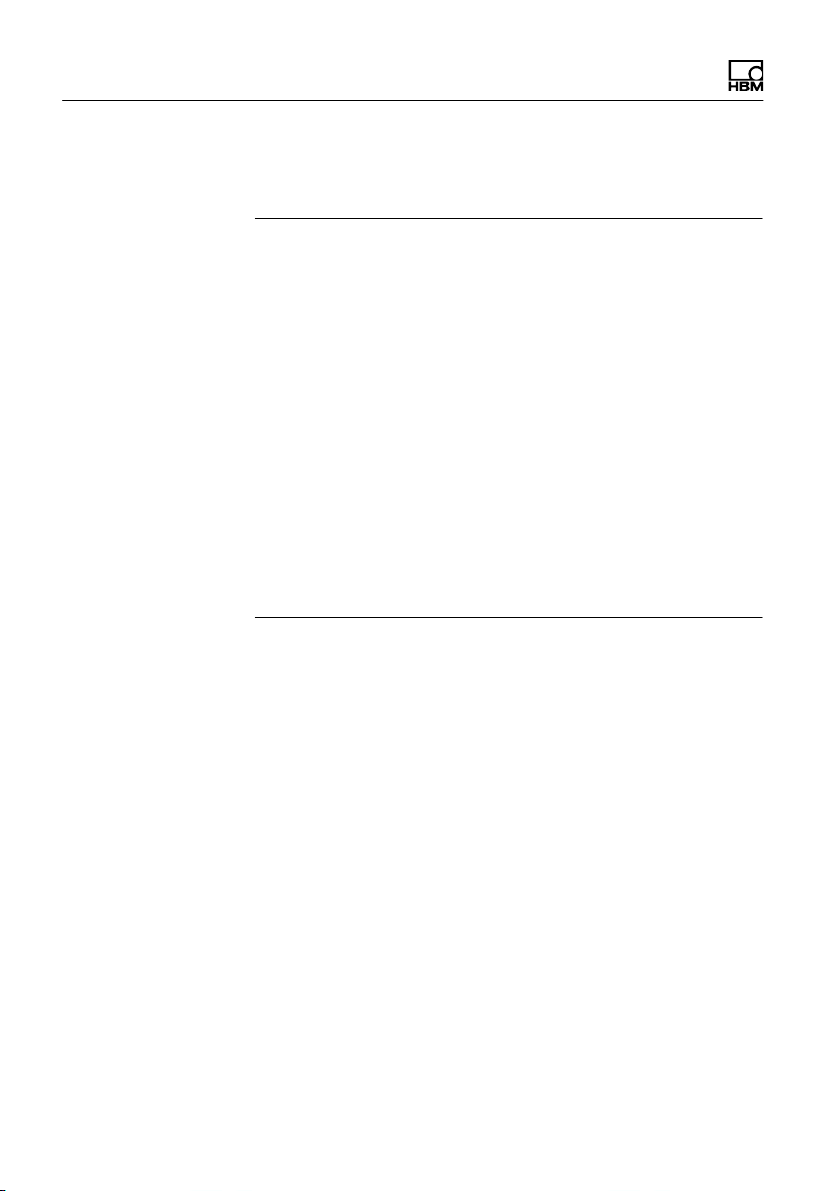

Label example with FCC ID and IC number.

Label

Model: T40S2TOS6

FCC ID: 2ADAT-T40S2TOS6

IC: 12438AT40S2TOS6

This device complies with part 15 of the FCC Rules. Opera

tion is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must

accept any interference received, including interference that

may cause undesired operation.

Fig. 1.1 Location of the label on the stator of the device

Model: T40S2TOS6

FCC ID: 2ADAT-T40S2TOS6

IC: 12438AT40S2TOS6

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Fig. 1.2 Example of the label

T40B A3452-10.0 5

Safety instructions

Industry Canada for Option 7, Code U

Darmstadt, 2014-11-13

This product has not yet received IC (Industry Canada)

approval. The certification process for this product is still

under way. HBM currently expects that IC approval will

be granted by the end of December 2014.

Your local HBM contact looks forward to answer any

questions you may have regarding IC approval.

Darmstadt, le 13 novembre 2014

Ce produit n'a pas encore obtenu l'approbation IC (Indus

trie Canada). Le produit est encore en processus de

certification. Actuellement, HBM suppose que l'appro

bation IC sera accordée jusqu'à fin décembre 2014.

Si vous avez des questions au sujet de l'approbation IC,

veuillez vous adresser à votre représentation HBM sur

place.

This device complies with Industry Canada standard

RSS210.

This device complies with Industry Canada

license−exempt RSS standard(s).Operation is subject to

the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any

interference, including interference that may cause unde

sired operation of the device.

Cet appareil est conforme aux norme RSS210 d’Industrie

Canada.

Cet appareil est conforme aux normes d’exemption de

licence RSS d’Industry Canada. Son fonctionnement est

soumis aux deux conditions suivantes : (1)cet appareil ne

doit pas causer d’interférence et (2) cet appareil doit

6 A3452-10.0 T40B

Safety instructions

accepter toute interférence, notamment les interférences

qui peuvent affecter son fonctionnement.

Appropriate use

The T40B torque flange is used exclusively for torque,

angle of rotation and power measurement tasks within

the load limits stipulated in the specifications. Any other

use is not appropriate.

Stator operation is only permitted when the rotor is

installed.

The torque flange may only be installed by qualified per

sonnel in compliance with the specifications and with the

safety requirements and regulations of these mounting

instructions. It is also essential to observe the applicable

legal and safety regulations for the application con

cerned. The same applies to the use of accessories.

The torque flange is not intended for use as a safety

component. Please also refer to the “Additional safety

precautions" section. Proper and safe operation requires

proper transportation, correct storage, siting and mount

ing, and careful operation.

Load carrying capacity limits

The data in the technical data sheets must be complied

with when using the torque flange. In particular, the

respective maximum loads specified must never be

exceeded. For example, the values stated in the specifi

cations must not be exceeded for

S limit torque,

S longitudinal limit force, lateral limit force or limit bend

ing moment,

S torque oscillation width,

T40B A3452-10.0 7

Safety instructions

S breaking torque,

S temperature limits,

S the limits of the electrical load‐carrying capacity.

Use as a machine element

The torque flange can be used as a machine element.

When used in this manner, it must be noted that, to favor

greater sensitivity, the transducer is not designed with

the safety factors usual in mechanical engineering.

Please refer here to the section “Load carrying capacity

limits" and to the specifications.

Accident prevention

According to the prevailing accident prevention regula

tions, once the transducers have been mounted, a cover

ing agent or cladding has to be fitted as follows:

S The covering agent or cladding must not be free to

rotate.

S The covering agent or cladding should prevent

squeezing or shearing and provide protection against

parts that might come loose.

S Covering agents and cladding must be positioned at a

suitable distance or be so arranged that there is no

access to any moving parts within.

S Covering agents and cladding must still be attached

even if the moving parts of the torque flange are

installed outside people's movement and working

range.

The only permitted exceptions to the above requirements

are if the torque flange is already fully protected by the

design of the machine or by existing safety precautions.

8 A3452-10.0 T40B

Safety instructions

Additional safety precautions

The torque flange cannot (as a passive transducer)

implement any (safety‐relevant) cutoffs. This requires

additional components and constructive measures, for

which the installer and operator of the plant is responsi

ble. The electronics conditioning the measurement signal

should be designed so that measurement signal failure

does not subsequently cause damage.

The scope of supply and performance of the transducer

covers only a small area of torque measurement technol

ogy. In addition, equipment planners, installers and oper

ators should plan, implement and respond to safety engi

neering considerations in such a way as to minimize

residual dangers. Pertinent national and local regulations

must be complied with.

General dangers of failing to follow the safety

instructions

The torque flange corresponds to the state of the art and

is reliable. Transducers can give rise to residual dangers

if they are incorrectly operated or inappropriately

mounted, installed and operated by untrained personnel.

Every person involved with siting, starting‐up, operating

or repairing a torque flange must have read and under

stood the mounting instructions and in particular the tech

nical safety instructions. The transducers can be dam

aged or destroyed by non‐designated use of the

transducer or by non‐compliance with the mounting and

operating instructions, these safety instructions or any

other applicable safety regulations (BG safety and acci

dent prevention regulations), when using the transducers.

Transducers can break, particularly in the case of over

loading. The breakage of a transducer can also cause

damage to property or injury to persons in the vicinity of

the transducer.

T40B A3452-10.0 9

Safety instructions

If the torque flange is not used according to the desig

nated use, or if the safety instructions or specifications in

the mounting and operating instructions are ignored, it is

also possible that the transducer may fail or malfunction,

with the result that persons or property may be adversely

affected (due to the torques acting on or being monitored

by the torque flange).

Conversions and modifications

The transducer must not be modified from the design or

safety engineering point of view except with our express

agreement. Any modification shall exclude all liability on

our part for any damage resulting therefrom.

Selling on

If the torque flange is sold on, these mounting instruc

tions must be included with the torque flange.

Qualified personnel

Qualified personnel means persons entrusted with siting,

mounting, starting up and operating the product, who

possess the appropriate qualifications for their function.

This includes people who meet at least one of the three

following requirements:

1. Knowledge of the safety concepts of automation tech

nology is a requirement and as project personnel, you

must be familiar with these concepts.

2. As automation plant operating personnel, you have

been instructed how to handle the machinery. You are

familiar with the operation of the equipment and tech

nologies described in this documentation.

3. As system startup engineers or service engineers,

you have successfully completed the training to qual

10 A3452-10.0 T40B

Safety instructions

ify you to repair the automation systems. You are also

authorized to ground and label circuits and equipment

and place them in operation in accordance with safety

engineering standards.

T40B A3452-10.0 11

Markings used

2 Markings used

2.1 Symbols on the transducer

Read and note the data in this manual

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rele

vant EC directives (the Declaration of Conformity can be

found on the HBM website at www.hbm.com under

HBMdoc).

Model: T40S2TOS6

FCC ID: 2ADAT-T40S2TOS6

IC: 12438AT40S2TOS6

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions: (1) This device

may not cause harmful interference, and

(2) this device must accept any interfer

ence received, including interference

that may cause undesired operation.

Label example

Label example with FCC ID and IC number, Option 7

Code U. Location of the label on the stator device.

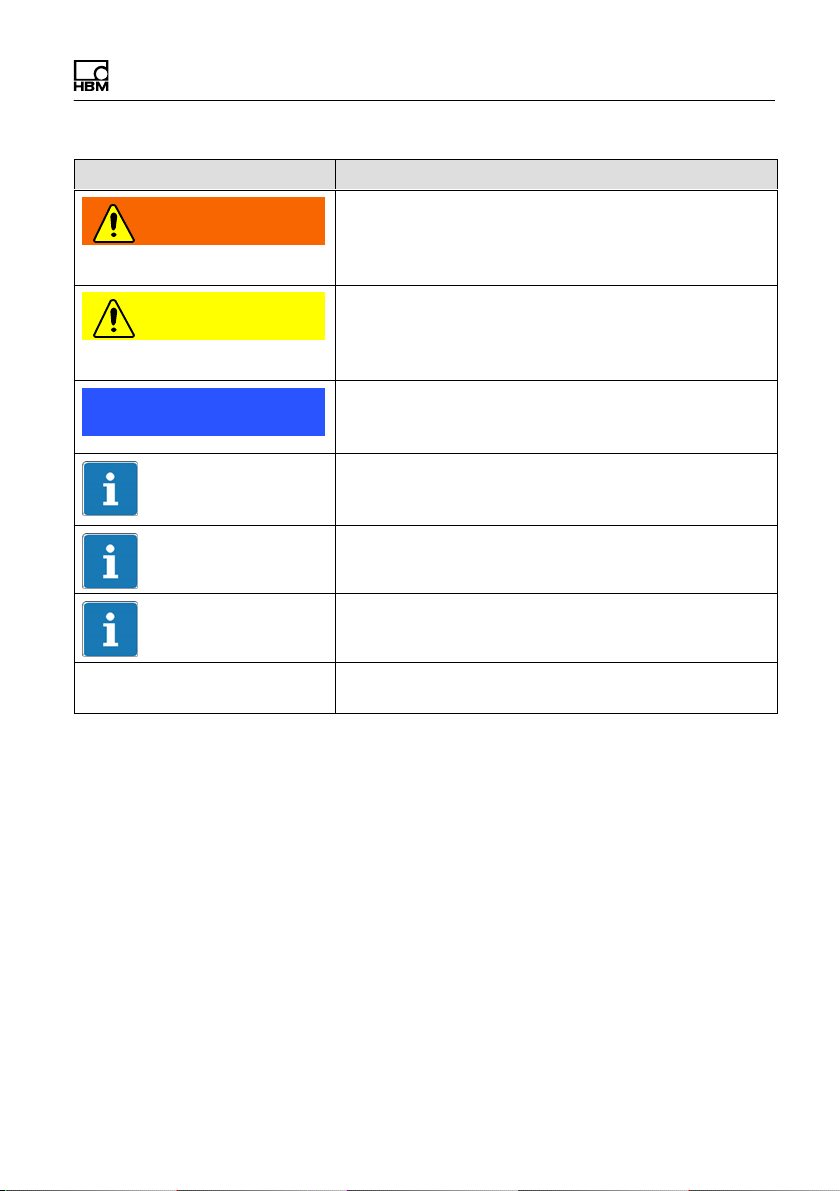

2.2 The markings used in this document

Important instructions for your safety are specifically

identified. It is essential to follow these instructions in

order to prevent accidents and damage to property.

12 A3452-10.0 T40B

Symbol Significance

WARNING

CAUTION

Note

Important

This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in death or serious physical

injury.

This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

This marking draws your attention to important

information about the product or about handling the

product.

This marking indicates application tips or other

information that is useful to you.

Tip

This marking draws your attention to information

about the product or about handling the product.

Information

Emphasis

See….

Italics are used to emphasize and highlight text and

references to other chapters and external documents.

Markings used

T40B A3452-10.0 13

Application

3 Application

The T40B torque flange measures static and dynamic

torques on stationary and rotating shafts. Test beds can

be extremely compact because of the compact design of

the transducer. This offers a very wide range of applica

tions.

The T40B torque flange is reliably protected against elec

tromagnetic interference. It has been tested according to

harmonized European standards and/or complies with

US and Canadian standards. The product carries the

CE mark and/or FCC label.

14 A3452-10.0 T40B

Structure and mode of operation

4 Structure and mode of operation

The torque flange consists of two separate parts: the

rotor and the stator. The rotor comprises the measuring

body and the signal transmission elements.

Strain gages (SGs) are installed on the measuring body.

The rotor electronics for transmitting the bridge excitation

voltage and the measurement signal are located centrally

in the flange. The transmitter coils for contactless trans

mission of excitation voltage and measurement signal are

located on the measuring body's outer circumference.

The signals are sent and received by a separable

antenna ring. Separable antenna ring not for Option 7,

Code U. The antenna ring is mounted on a housing that

contains the electronics for voltage adaptation and the

signal conditioning.

Connector plugs for the torque and rotational speed sig

nals, the voltage supply and digital output, are located on

the stator. The antenna segments (the antenna ring)

must be mounted concentrically around the rotor (see

chapter 5).

T40B A3452-10.0 15

Structure and mode of operation

Connect

or plugs

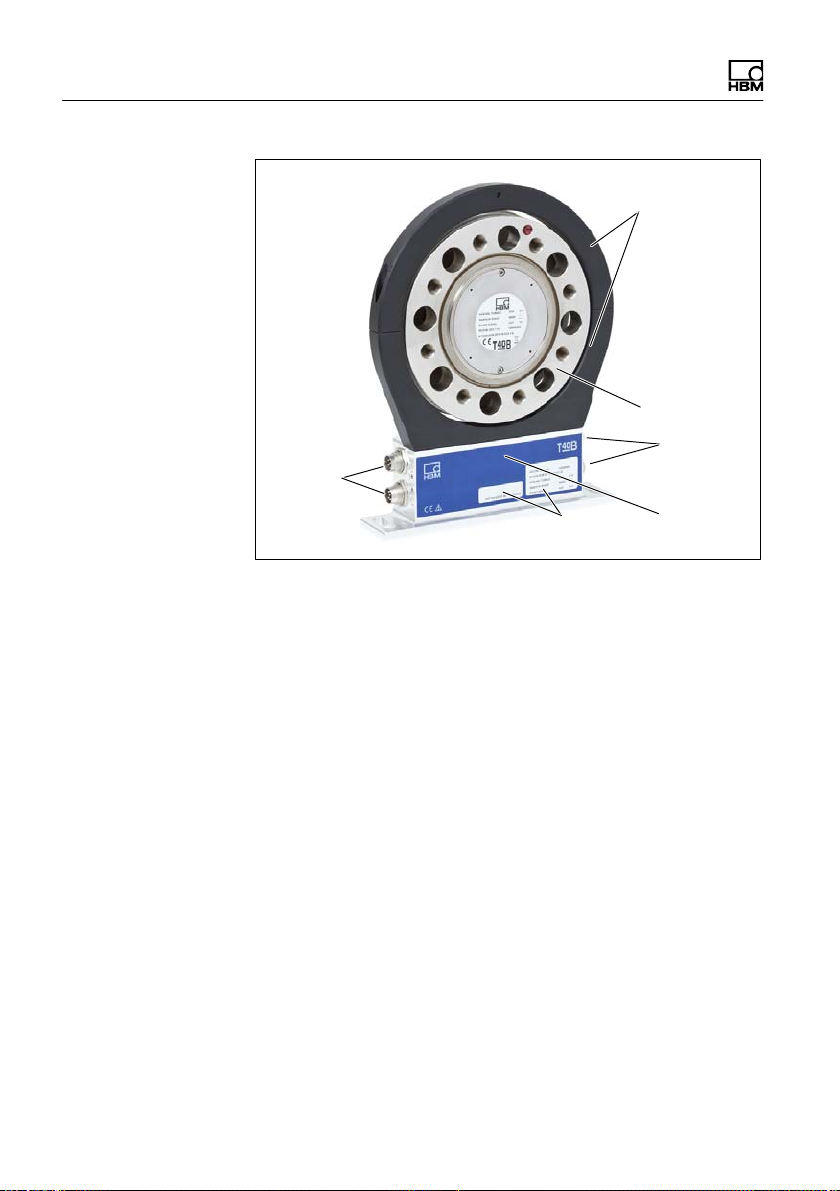

Fig. 4.1 Mechanical construction without a rotational speed

measuring system, Option 7, Code S

The rotational speed sensor is mounted on the stator in

Option 6 with a rotational speed measuring system. The

rotational speed is measured magnetically via an AMR

sensor and a magnetic ring. The magnetic ring for mea

suring the rotational speed is welded to the flange.

Type plate

Antenna

segments

Rotor

Connect

or plugs

Stator

housing

16 A3452-10.0 T40B

Antenna segments

Magnetic ring for rotational

speed measurement

Structure and mode of operation

Rotor

Sensor head for measuring

rotational speed

Connector plugs

Fig. 4.2 Mechanical construction with a rotational speed

In the version with a rotational speed measuring system,

the transducer can also be fitted with a sensor head for a

reference signal (zero index) for measuring the angle of

rotation. The magnet to be used for this is located on the

inner surface of the flange. The sensor head for sampling

the reference signal is located in the bracket above the

rotational speed sensor.

Connector

plugs

Stator housing

Type plate

measuring system, Option 7, Code S

T40B A3452-10.0 17

Structure and mode of operation

Sensor head for

measuring

rotational speed

Connector plugs

Stator housing

Fig. 4.3 Mechanical construction with rotational speed

measuring system and sensor for the reference

signal (zero index), Option 7, Code S

Rotor

Antenna segments

Magnetic ring for rotational

speed measurement

Sensor head for the

reference signal

Connector

plugs

Type plate

18 A3452-10.0 T40B

Structure and mode of operation

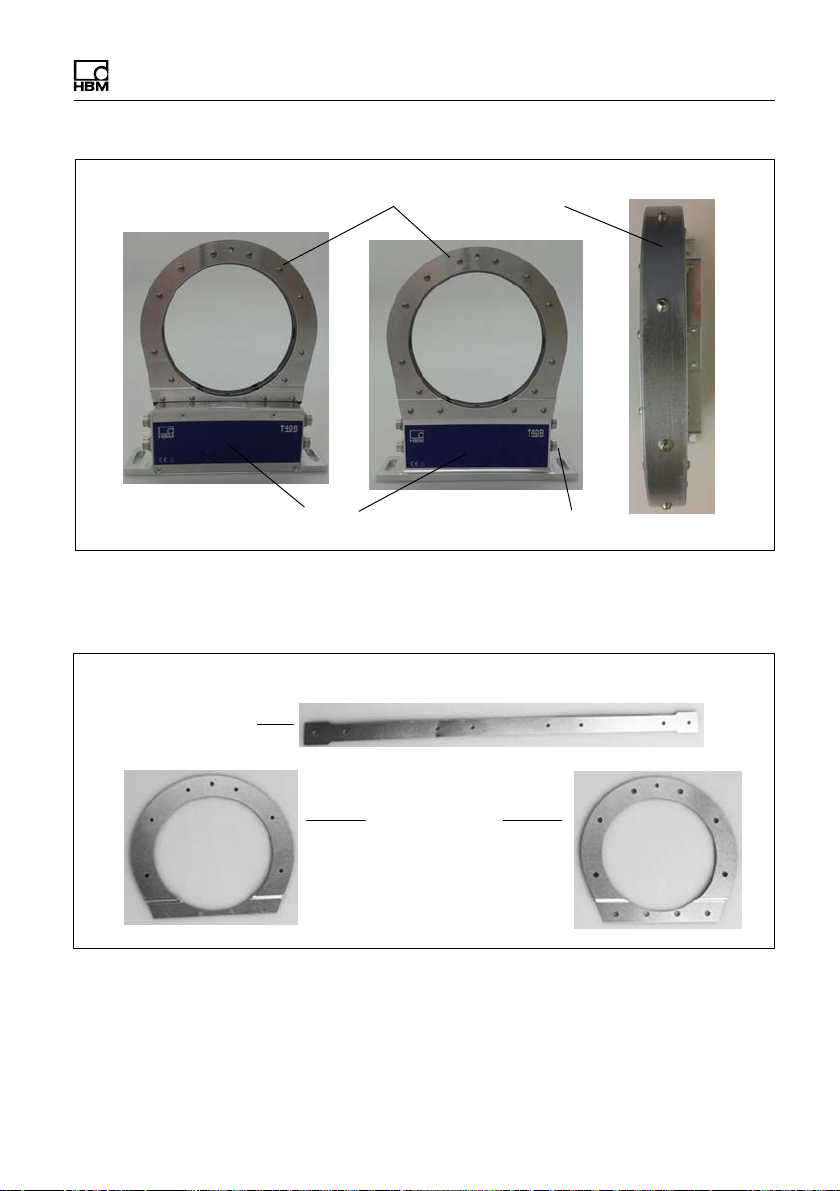

Antenna segments with mounted shielding plates

Stator housing

Connector plugs

Fig. 4.4 Mechanical construction of Stator with mounted

shielding plates without rotational speed Option 7,

Code U

Dismounted shielding plates

Radial shielding

plate

Axial shielding

plates

Fig. 4.5 Individual shielding plates, Option 7, Code U

T40B A3452-10.0 19

Structure and mode of operation

Information

Mechanical construction with rotational speed measuring

System is the same as in Fig. 4.2 with additional shield

ing plate of antenna ring see Fig. 4.4.

Important

The use of the shielding plates are important to ensure

compliance with FCCregulations. If the shielding plates

has to be removed for any purpose (e.g. in-stallation or

maintenance), they must be replaced in the original posi

tion be-fore the product is used.

20 A3452-10.0 T40B

5 Mechanical installation

5.1 Important precautions during installation

Note

A torque flange is a precision measuring element and

therefore needs careful handling. Dropping or knocking

the transducer may cause permanent damage. Make

sure that the transducer cannot be overloaded, including

while it is being mounted.

S Handle the transducer with care.

S Check the effect of bending moments, critical rota

tional speeds and natural torsional vibrations, to pre

vent the transducer being overloaded by resonance

sharpness.

Mechanical installation

S Make sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is over

loaded. This can cause danger for the operating person

nel of the system in which the transducer is installed.

Implement appropriate safety measures to avoid over

loads and to protect against resulting dangers.

S Use a threadlocker (medium strength, e.g. LOCTITE)

to glue the screws into the counter thread to exclude

T40B A3452-10.0 21

Mechanical installation

S Comply with the mounting dimensions to enable cor

An appropriate shaft flange enables the T40B torque

flange to be mounted directly. It is also possible to mount

a joint shaft or relevant compensating element directly on

the rotor (using an intermediate flange when required).

Under no circumstances should the permissible limits

specified for bending moments, lateral and longitudinal

forces be exceeded. Due to the T40B torque flange's

high torsional stiffness, dynamic shaft train changes are

kept to a minimum.

Even if the unit is installed correctly, the zero point

adjustment made at the factory can shift by up to

approx. 2% of the sensitivity. If this value is exceeded,

we advise you to check the mounting conditions. If the

residual zero offset when the unit is removed is greater

than 1% of the sensitivity, please send the transducer

back to the Darmstadt factory for testing.

prestressing loss due to screw slackening, in the

event of alternating loads.

rect operation.

Important

5.2 Conditions on site

The T40B torque flange must be protected against

coarse dirt particles, dust, oil, solvents and moisture.

There is wide ranging compensation for the effects of

temperature on the output and zero signals of the trans

ducer (see “Specifications" section). If there are no static

temperature ratios, for example, because of the tempera

ture differences between the measuring body and the

22 A3452-10.0 T40B

Mechanical installation

flange, the values given in the specifications can be

exceeded. In this case, ensure static temperature ratios

by cooling or heating, depending on the application. As

an alternative, check if thermal decoupling is possible,

e.g. by means of heat radiating elements such as multi

ple disc couplings.

5.3 Installation orientation

The torque flange can be installed with any orientation.

With clockwise torque, the output frequency is 60 to

90 kHz for Option 5, Code DU2 (Option 5, Code SU2: 10

to 15 kHz; Option HU2: 240 to 360kHz). In conjunction

with HBM amplifiers or when using the voltage output, a

positive output signal (0 V to +10 V) is present. In the

case of the rotational speed measuring system, an arrow

is attached to the stator housing to clearly define the

direction of rotation: if the measurement flange turns in

the direction of the arrow, connected HBM measuring

amplifiers deliver a positive output signal.

5.4 Installation options

There are basically two options for mounting the torque

flange: with or without dismantling the antenna ring. We

recommend mounting as described in Chapter 5.4.1. If

mounting in accordance with Chapter 5.4.1 is not possi

ble, (e.g. in the case of subsequent stator replacement),

you will have to dismantle the antenna ring (only possible

for Option 7, Code S). It is essential in this case to com

ply with the notes on assembling the antenna segments

(see Chapter 5.4.2).

T40B A3452-10.0 23

Mechanical installation

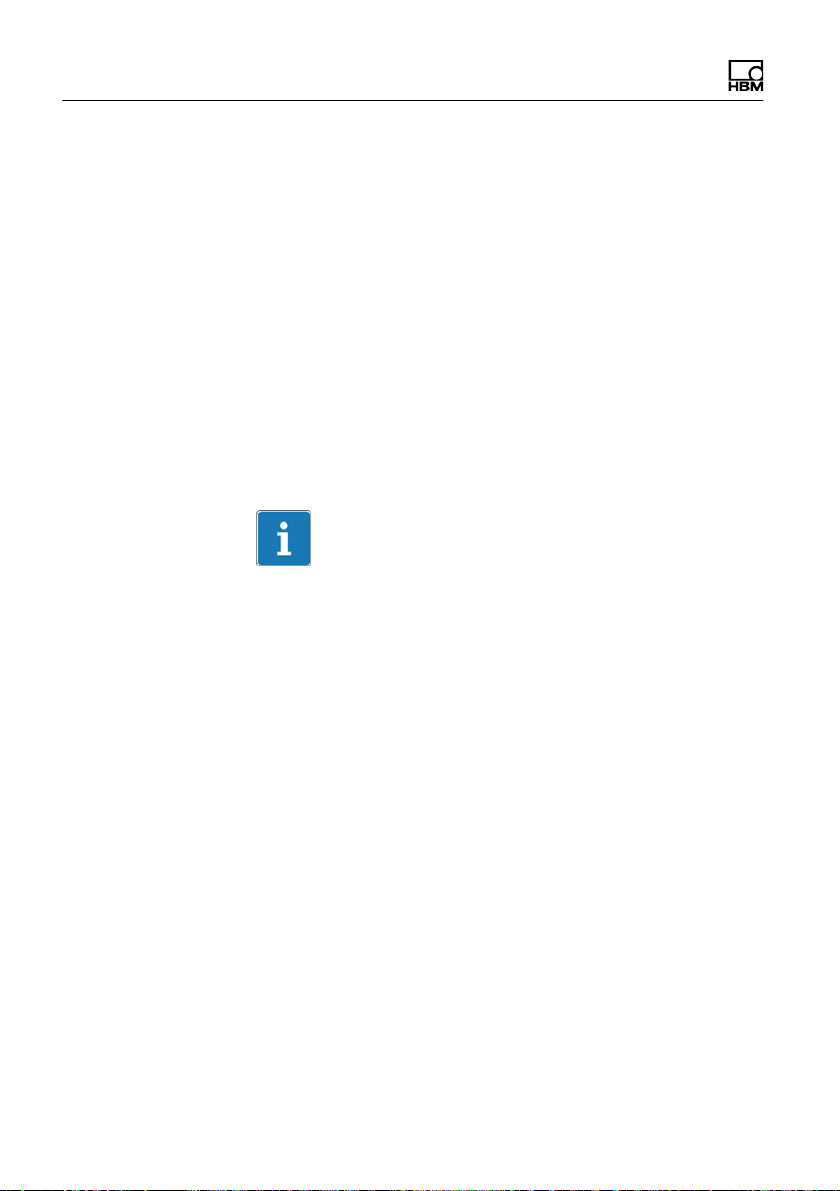

5.4.1 Installation without dismantling the antenna

1. Install rotor 2. Install stator

ring, Option 7, Code U with antenna shielding

cover

Mounting supplied

by customer

Support supplied

by customer

3. Finish shaft train installation 4. Fit support

24 A3452-10.0 T40B

Mechanical installation

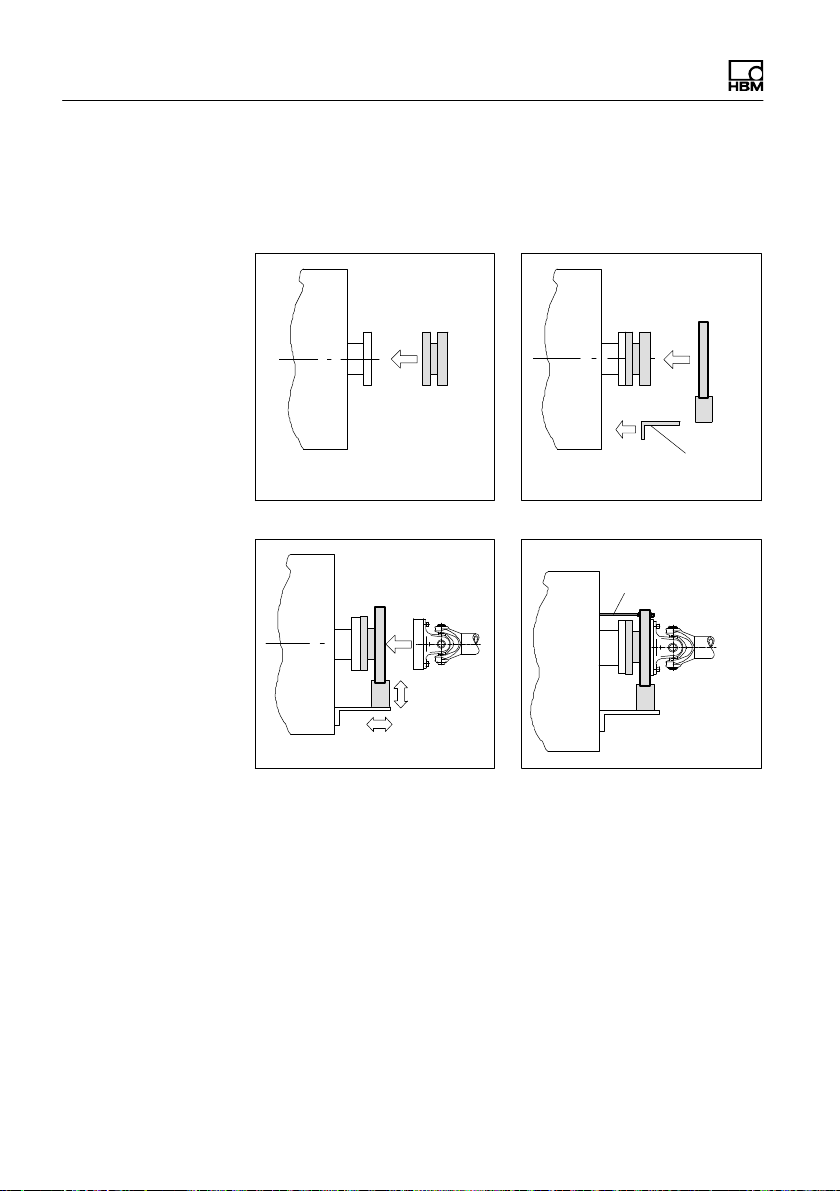

5.4.2 Installation with subsequent stator mounting, Option 7, Code S

1. Install rotor 2. Install shaft train

Washers

Fan‐type

lock

washers

3. Dismantle antenna segment 4. Install antenna segment

Support supplied

by customer

5. Fit support

T40B A3452-10.0 25

Mechanical installation

5.5 Installing the rotor

Usually the rotor type plate is no longer visible after

installation. This is why we include with the rotor addi

tional stickers with the important characteristics, which

you can attach to the stator or any other relevant

test‐bench components. You can then refer to them

whenever there is anything you wish to know, such as

the shunt signal. To explicitly assign the data, the identifi

cation number and the size are engraved on the rotor

flange, where they can be seen from outside.

Note

Make sure during installation that you do not damage the

measuring zone marked in Fig. 5.1 by using it to support

tools, or knocking tools against it when tightening screws,

for example. This can damage the transducer and pro

duce measurement errors, or even destroy the trans

ducer.

Tip

26 A3452-10.0 T40B

Mechanical installation

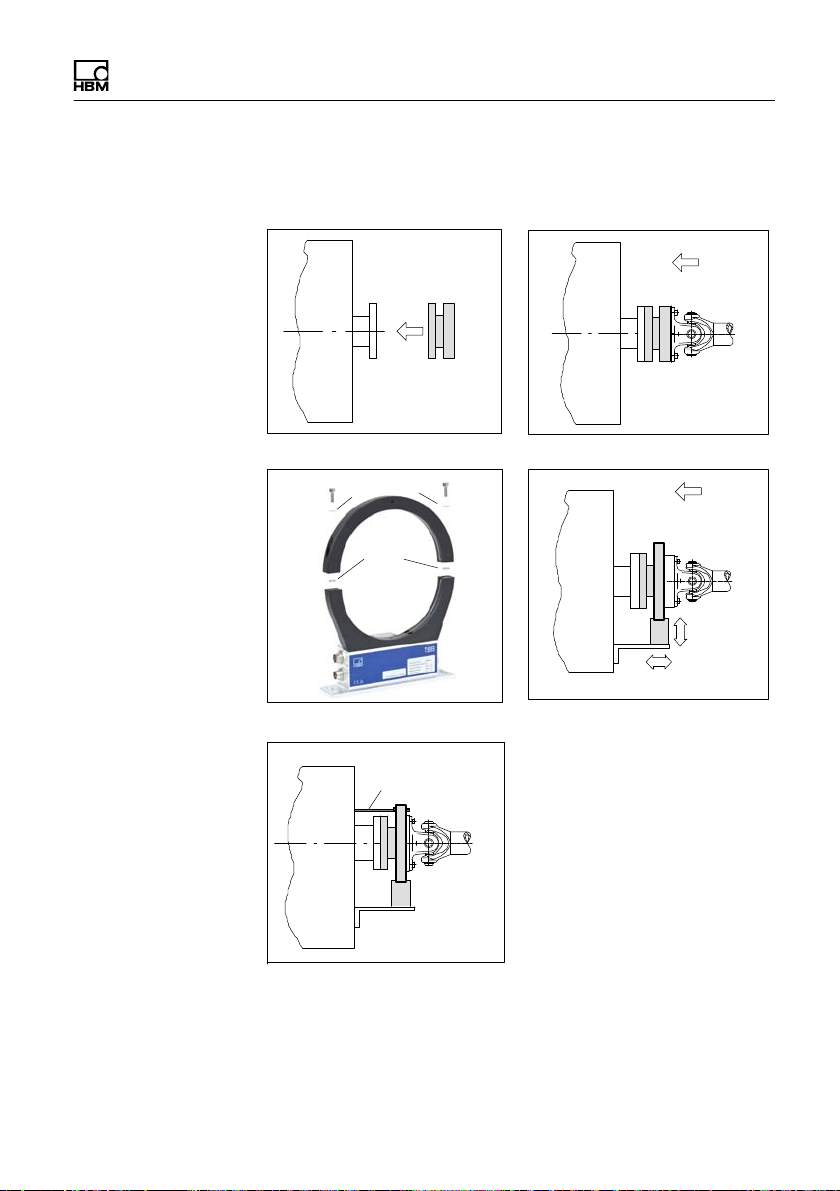

Transmitter winding

Measuring

zone

without rotational speed

measuring system

Fig. 5.1 Bolted rotor connection

1. Prior to installation, clean the plane faces of the trans

Rotational speed measuring system

with rotational

Flange plane faces

speed measuring

system

ducer flange and the counter flange.

For safe torque transfer, the faces must be clean and

free from grease. Use a piece of cloth or paper

soaked in solvent. When cleaning, make sure that you

do not damage the transmitter winding or the rota

tional speed measuring system.

2. For the bolted rotor connection (see Fig. 5.1), use six

or eight DIN EN ISO 4762 hexagon socket screws of

the property class stated in Tab. 5.1, in a suitable

length (dependent on the connection geometry, see

Tab. 5.1 on page 29).

We recommend DIN EN ISO 4762 socket head cap

screws, blackened, smooth‐headed, permitted size

and shape variance in accordance with DIN

ISO 4759, Part 1, product class A.

T40B A3452-10.0 27

Mechanical installation

3. Fasten all screws with the specified torque (Tab. 5.1

4. There are six or eight tapped holes on the rotor for

Use a threadlocker (medium strength, e.g. LOCTITE) to

glue the screws into the counter thread to exclude pre

stressing loss due to screw slackening, in the event of

alternating loads.

Note

Comply with the maximum thread reach as per Tab. 5.1.

Otherwise significant measurement errors may result

from torque shunt, or the transducer may be damaged.

on page 29).

continuing the shaft train mounting. Again use screws

of property class 10.9 or 12.9 and tighten them with

the prescribed torque, as specified in Tab. 5.1.

Important

Measuring range Fastening screws Prescribed tightening

moment

NVm Z

50 M8 10.9 34

100 M8 10.9 34

200 M8 10.9 34

500 M10 10.9 67

1 k M10 10.9 67

2 k M12 10.9 115

3 k M12 12.9 135

1

Property class NVm

28 A3452-10.0 T40B

Loading...

Loading...