A U T O O P E N S E R I E S

6 x 6 P R E S S

O P E R A T O R’ S M A N U A L

Safety Instructions

When using your heat press,

basic precautions should always be followed,

including the following:

Read all instructions.

1.

Use heat press only for its intended use.

2.

To reduce the risk of electric shock, do not immerse the heat press in water or other liquids.

3.

Never pull cord to disconnect from outlet, instead grasp plug and pull to disconnect.

4.

Do not allow cord to touch hot surfaces, allow heat press to cool completely before storing.

5.

Do not operate heat press with a damaged cord, or if the equipment has been dropped or

6.

damaged. To reduce the risk of electric shock, do not disassemble or attempt to repair the heat

press, take it to a qualified service person for examination and repair. Incorrect reassembly or

repair could cause a risk of fire, electric shock, or injury to persons when the equipment is used.

Close supervision is necessary for any heat press being used by or near children. Do not leave

7.

equipment unattended while connected.

Burns can occur when touching hot metal parts.

8.

To reduce the likelihood of circuit overload, do not operate other high voltage equipment on the same

9.

circuit.

If an extension cord is necessary, then a 20 amperage rated cord should be used. Cords rated for

10.

less amperage may overheat, care should be taken to arrange the cord so that it cannot be pulled or

tripped over.

S A V E T H E S E I N S T R U C T I O N S

AUTO OPEN SERIES

Table of Contents

Machine View

Control Panel Guide

Operating Instructions

Connecting the System

Turning the System On

Adjusting the Temperature

Adjusting the Time

Adjusting the Pressure

Pressing

Replacement Parts List

Parts Location Guide

4

5

6-11

6

7

8

9

10

11

12

13

Electrical Schematic

Contact

14

15

AUTO OPEN SERIES

Machine View

FRONT VIEW

LED Display

Circuit Breaker

Power Supply

SIDE VIEW

Located on the opposite

side of the press

Lift Handle

Pressure Adjustment Knob

12V Magnet

Power ON/OFF Switch

ON OFF

PAGE 4

AUTO OPEN SERIESAUTO OPEN SERIES

Control Panel Guide

Digital Display

Temperature Indicator

Set Indicator

Time Indicator

Pressure Indicator

Increase

Mode Select

Decrease

PAGE 5

AUTO OPEN SERIES

Operating Instructions

A U T O O P E N 6 x 6 P R E S S

The Auto Open 6x6 Press Operating Instructions are designed with the user in mind.

Carefully read and follow the step-by-step instructions for best results.

To avoid burns, do not touch the heated platen

during use.

Keep hands clear of the upper platen of the press

during platen lock down as the pressure may

cause injury.

Press should be placed on a sturdy, suitable stand

at least 36”L x 24”W x 29”H.

Work area must be kept clean, tidy and free of

obstructions.

Power supply cord must be disconnected before

cleaning or servicing press.

Connecting the System

CONNECT THE POWER CORD

1.

1.1

Connect the power cord into a properly grounded electrical outlet with a sufficient amperage rating.

VOLTAGE

120 Volt - The Auto Open 6x6 Press requires a full 10 amp grounded circuit for 120 volt operation.

240 Volt - The Auto Open 6x6 Press requires a full 10 amp grounded circuit for 240 volt operation.

EXTENSION CORDS If used, should be as short as possible and not less than 12 gauge.

Heavy duty cords are recommended.

CIRCUITS that have less than 10 amps or that have other high demand equipment or appliances

(especially more than one heat seal machine) plugged in, should not be used.

NOTE: If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or a

similarly qualified person in order to avoid hazard. Use HSJ type, rated 250 V - 10 AMP for replacement.

CAUTION Failure to follow these instructions will cause:

1. Erratic controller functions. 2. Inaccurate displays and slow heat-up. 3. The circuit breaker to disengage.

PAGE 6

SWITCH THE SYSTEM ON

2.

See the diagram below for switch placement.

NOTE: The Auto Open 6x6 Press is equipped with an Auto Sleep Mode. When the machine is not in use for a

period of two hours, it will enter an energy saving sleep mode. To restore to normal operating mode, press any

button on the display panel and allow the heat press to return to the target temperature

Locate the packaging bolt positioned on the top-center of the press.

Packaging bolt must be removed prior to turning the press on or

operating the press.

AUTO OPEN SERIESAUTO OPEN SERIES

Turning the System On

Now, locate the Power ON/OFF

Switch on the side of the press,

then turn the Power Switch on.

Power ON/OFF Switch

ON OFF

PAGE 7

AUTO OPEN SERIES

Adjusting the Temperature

ADJUST THE TEMPERATURE

3.

Locate the LED Display on the Press.

3.1

Press the Mode Select button located in the center of the Control Panel.

The (SET) and (TEMP) lights located next to the display will illuminate indicating you are in the adjust

temperature mode.

3.2

Next, press the (-) button located to the left of the Mode Select button to lower the temperature setting,

or press the (+) button located to the right of the Mode Select button to raise the temperature setting.

The temperature can be set from 176° F (79° C) to 430° F (220° C).

The LED will display changes as you make them.

Digital Display

Temperature Indicator

Set Indicator

Time Indicator

Pressure Indicator

Increase

Mode Select

PAGE 8

Decrease

ADJUST THE TIME

4.

Your Auto Open, 6 x 6 Press has two time settings. This will allow you to set different times when a two hit

application is required. For single hit applications, you simply set both time settings the same.

Once you have adjusted the temperature, press the Mode Select button again. This will advance you to the Time

#1 mode. The set and time lights will illuminate, indicating that you are in the Time # 1 mode.

Adjust the time in the same manner that you adjusted the temperature. Once you have the Time # 1 set, push

the Mode Select button again to advance to the Time # 2 setting. All three red LED lights will illuminate

indicating that you are in the Set Time # 2 Mode. Select the desired time and push the Mode Select button

again to exit the time settings. All lights will be off and the press will return to the print mode.

AUTO OPEN SERIESAUTO OPEN SERIES

Adjusting the Time

REMEMBER: Press the Mode Select button

ONCE to advance to the Adjust

Temperature Mode

Press the Mode Select button

A SECOND TIME to advance to

the Time #1 mode.

Press the Mode Select button

A THIRD TIME to advance to

the Time #2 Settings.

Press the Mode Select button

A FOURTH TIME to return to

the Heat Up/Operating Mode.

PAGE 9

AUTO OPEN SERIES

Adjusting the Pressure

ADJUST THE PRESSURE

5.

First, locate the LED Display on the Press.

(See figure 1)

The Pressure Adjustment Knob is located in

the center of the heat platen

(See figure 2)

Adjust the pressure by turning the knob

clockwise to increase pressure and counter

clockwise to decrease pressure.

PRESSURE READOUT

A visual Pressure Readout is located on the lower right side of the LED Display.

When the handle is locked into the Print Position, a pressure number will be

displayed. Readout will be on a scale of 0 - 9. A 0 Pressure readout would

indicate no pressure at all and 9 would indicate very heavy pressure.

(See figure 1)

1 - 3 = Light Pressure

4 - 7 = Medium Pressure

8 - 9 = Heavy Pressure

To adjust the Pressure, simply turn the Pressure Adjustment

Knob to the right or clockwise to increase the Pressure and to

the left or counter clockwise to decrease the Pressure. The

readout will display the Pressure when locked down in the

print position.

REMEMBER: To allow for the thickness of your garment

when adjusting the pressure.

Figure 1

Pressure Adjustment Knob

Figure 2

WARNING: Structural damage caused by excessive pressure is not covered under the limited warranty!

PAGE 10

6.

AUTO OPEN SERIESAUTO OPEN SERIES

Pressing

PRESS

Once your equipment has reached the designated temperature:

Position the garment and application and proceed to press.

Lower and lock the heat platen into the press position.

This procedure will start the automatic timing process.

The timer will automatically count

down and lift the heat platen into the “UP”

position when the press cycle is complete.

NOTE: Please be aware after time

is complete, gas shocks will

automatically release the platen

into the “UP” position.

The time will automatically re-set

and you are ready to continue

with the next application.

PAGE 11

AUTO OPEN SERIES

Replacement Parts List

Item #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Part Name

Hex Soc Button HD #10-32 x 1/2”

Rubber Foot

Acorn Hex Nut

Adjustment Spindle

Lower Platen 6 x 6

Silicone Pad Gray 6 x 6 Blue

Heat Platen 6 x 6

Heat Platen Cover 6 x 6

Finish Washer

Cover Screw 10-24x1/2”

Shoulder Bolt

Hex Soc HD Cap Screw 1/2” - 13 x 3/4”

All Thread Pin 1/4 - 20 x 4 3/4”

PVC Spacer 1/2” I.D. x 5”

Blue Foam Grip

JCN Nut

Electromagnet

Silicone Pad 5/16” I.D. x 1 3/4” O.D.

End Cap

Hex Soc HD Shoulder Screw 5/16” x 1/2”

6 x 6 Heater Arm

PVC Spacer 1/2” I.D. x 3.30”

Lift Links

Steel Pin 1/2” Dia. x 5 7/8”

Nylon Washer

Steel Spacer

Hub Cap 1/2”

Probe

Conduit 12”

Nylon Hex Nut

Gas Spring

Ball Stud 10mm

Phillips Pan HD Screw #6 - 32 x 1/2”

Steel Pin 1/2” Dia. x 6.45”

PVC Spacer 1/2” I.D. x 3.80”

PVC Spacer 1/2” I.D. x .7”

Base 6 x 6

Proximity Switch

Circuit Breaker

STX Housing

On/Off Switch

Display Overlay

Terminal Block

Triac

Controller Bracket

SSTT Control Board

Handle Assembly 6 x 6

Steel Pin 1/2” Dia. x 4.69”

Part #

3-1011-164

1-1256

3-1011-182

1-1023

KIT 3-6911

1-2138

3-1334

2-1662

1-1063

3-1011-217

3-1011-121

3-1011-236

1-1042-1

1-2096

1-2115

2-1006-2

1-1945-1

1-2104

1-1999

3-1011-233

KIT 3-6912

1-1049-1

KIT 3-6909

2-1055-9

1-1048-3

1-2114

1-1107-1

1-1272-1

1-1048-2

2-1006-20

1-2246

1-1939

3-1011-152

2-1055-11

1-1049-5

1-1049-4

KIT 3-6907

1-1211

1-1456

4-1172

1-2087

1-2018-1

1-1290

1-1059

2-1661

1-2129

KIT 3-6910

2-1055-15

Qty.

4

4

4

1

1

1

1

1

4

4

1

1

1

1

1

2

1

1

2

1

1

1

2

1

8

2

8

1

1

2

1

2

4

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

PAGE 12

AUTO OPEN SERIESAUTO OPEN SERIES

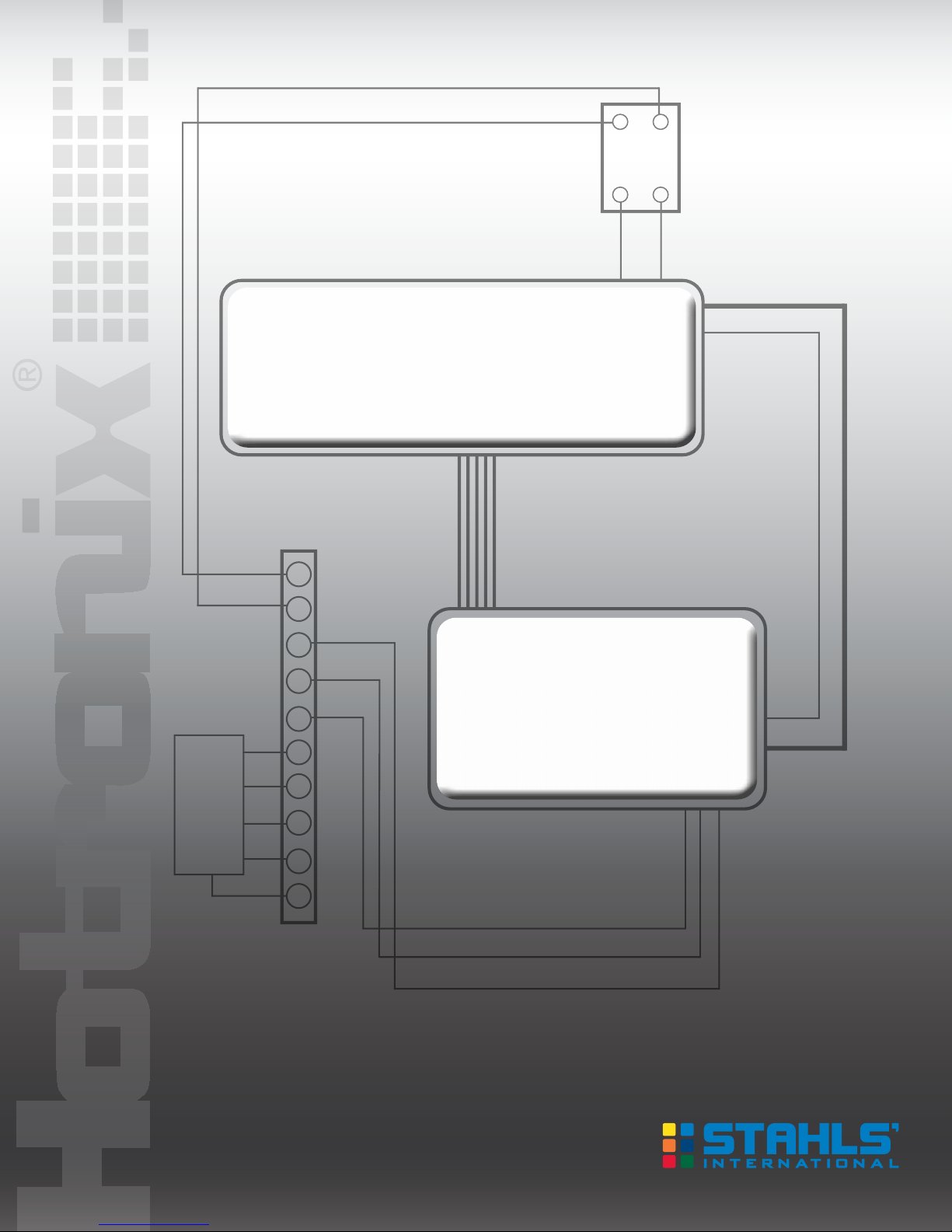

Parts Location Guide

PAGE 13

AUTO OPEN SERIES

Electrical Schematic

US 120 V VERSION

US 240 V VERSION

GERMAN 240V VERSION

PAGE 14

PAGE 14

Contact

STAHLS’ International

20600 Stephens Street

St. Clair Shores, MI 48080

U.S.A.

phone

(001) 586 . 772 . 5551

fax

(001) 586 . 772 . 6237

email

info@stahlsinternational.com

web

StahlsInternational.com

This document includes multiple trademarks and describes equipment covered by many patents

that are owned by GroupeSTAHL and/or its subsidiaries. GroupeSTAHL enforces its rights

to protect these intellectual properties. © 2012

2 0 6 0 0 S t e p h e n s S t r e e t S t . C l a i r S h o r e s , M I 4 8 0 8 0 , U . S . A .

t ( 0 0 1 ) 5 8 6 . 7 7 2 . 5 5 5 1 f ( 0 0 1 ) 5 8 6 . 7 7 2 . 6 2 3 7

e i n f o @ s t a h l s i n t e r n a t i o n a l . c o m w S t a h l s I n t e r n a t i o n a l . c o m

Proudly made in the U.S.A.

Loading...

Loading...