A I R S W I N G E R

O P E R A T O R’ S M A N U A L

Safety Instructions

When using your heat press,

basic precautions should always be followed,

including the following:

Read all instructions.

1.

Use heat press only for its intended use.

2.

To reduce the risk of electric shock, do not immerse the heat press in water or other liquids.

3.

Never pull cord to disconnect from outlet, instead grasp plug and pull to disconnect.

4.

Do not allow cord to touch hot surfaces, allow heat press to cool completely before storing.

5.

Do not operate heat press with a damaged cord or if the equipment has been dropped or damaged.

6.

To reduce the risk of electric shock, do not disassemble or attempt to repair the heat press. Take it

to a qualified service person for examination and repair. Incorrect assembly or repair could increase

the risk of fire, electric shock, or injury to persons when the equipment is used.

This appliance is not intended for use by persons (including children) with reduced physical, sensory

7.

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

Close supervision is necessary for any heat press being used by or near children. Do not leave

8.

equipment unattended while connected.

Burns can occur when touching hot metal parts.

9.

To reduce the likelihood of circuit overload, do not operate other high voltage equipment on the same

10.

circuit.

If an extension cord is necessary, then a 20 amperage rated cord should be used. Cords rated for

11.

less amperage may overheat. Care should be taken to arrange the cord so that it cannot be pulled

or tripped over.

S A V E T H E S E I N S T R U C T I O N S

Product Warranty Registration

Log onto www.Hotronix.com/registration

You must provide the Hotronix® heat press

serial number and model information.

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

HOTRONIX® AIR SWINGER

Table of Contents

Important Safety Notice

Machine View

Operating Instructions

Connecting the System

Turning the System On

Adjusting the Pressure

Adjusting Dual Time

Adjusting the Temperature

Printing and Pressing

Setting the System

Stored Settings

Retrieving Settings

Parts List and Location Guide

4

5

6-17

6

7

8

9

10

11

12-14

15-16

17

18-20

Electrical Schematic

Accessories

Contact

21

22

23

HOTRONIX® AIR SWINGER

Important Safety Notice

The Hotronix® Air Swinger is equipped with a lighted Quick Release Button. When pressed, this button activates a quick

release of the heat platen when in the print position and automatically returns the platen to the “UP” position.

Once activated, the button can be reset by pushing it in. The press will then return to the previous mode

(Normal Operation Mode).

Light On = Normal Operation Mode

Light Off = Quick Release Mode

PAGE 4

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

HOTRONIX® AIR SWINGERHOTRONIX

Pressure Regulator Knob

LCD Display

Machine View

Tack Button

ON/OFF Switch &

Circuit Breaker

Pressure Gauge

Left Print Button

Swing Arm

Right Print Button

Keypad

Air Filter

(Located in Back)

Quick Release Button

PAGE 5

HOTRONIX® AIR SWINGER

Operating Instructions

H O T R O N I X ® A I R S W I N G E R

The Hotronix® Air Swinger Operating Instructions are designed with the user in mind. Carefully read and follow the

step-by-step instructions for best results.

To avoid burns, do not touch the heated platen

during use.

Keep hands clear of the upper platen of the press

during platen lock down as the pressure may

cause injury.

Press should be placed on a sturdy, suitable stand

at least 36”L x 24”W x 29”H.

Work area must be kept clean, tidy and free of

obstructions.

Power supply cord must be disconnected before

cleaning or servicing press.

Connecting the System

CONNECT THE POWER CORD

1.

1.1

Connect the power cord into a properly grounded electrical outlet with a sufficient amperage rating.

VOLTAGE

120 Volt - The Hotronix

220 Volt - The Hotronix

EXTENSION CORDS If used, should be as short as possible and not less than 12 gauge.

Heavy duty cords are recommended.

CIRCUITS that have less than 15 amps or that have other high demand equipment or appliances (especially

more than one heat seal machine) plugged in, should not be used.

NOTE: If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or a similarly

qualified person in order to avoid hazard. Use SJT type rated 300 V cord for replacement.

CAUTION: Failure to follow these instructions will cause:

1. Erratic controller functions. 2. Inaccurate displays and slow heat-up. 3. The circuit breaker to disengage.

®

Air Swinger requires a full 20 amp grounded circuit for 120 volt operation.

®

Air Swinger requires a full 10 amp grounded circuit for 220 volt operation.

CONNECT AIRLINE

2.

2.1

Connect the air line from your Hotronix

The Air Swinger requires 1CFM of air at 90 PSI to print continuously. A 1/2 hp compressor with a 1 gallon

tank or larger is recommended. The motor should be rated for continuous operation.

PAGE 6

®

Air Swinger to the standard port on your air compressor.

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

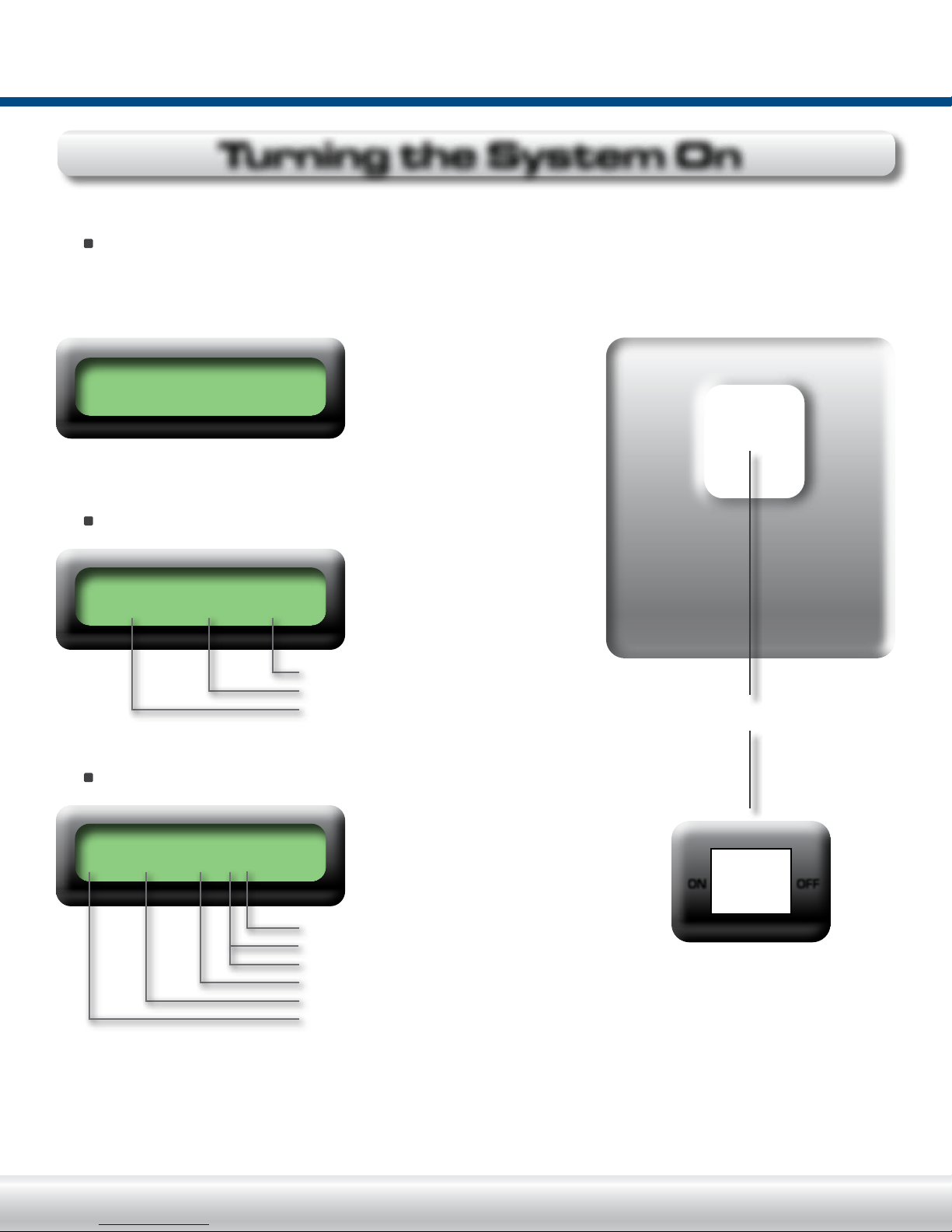

HOTRONIX® AIR SWINGERHOTRONIX

SWITCH THE SYSTEM ON

3.

See the diagram below for switch placement.

(The Power ON/OFF Switch is located on the top of the control housing).

3.1

Flip the Switch to the ON position. The machine will display “HELLO” for 3 seconds.

HELLO!

Turning the System On

The Date, Day, and Time message will automatically appear.

04/01 WED 16:00

Time

Day

Date (Month/Day)

The Temperature message will automatically appear.

T = 180/375F t = 008

t = Actual dwell time in seconds

F = Fahrenheit

C = Centigrade (Refer to page 10)

Target Temperature

Actual Platen Temperature

T = Temperature

Power ON/OFF Switch

ON OFF

NOTE: 180 F (82.2C) is the lowest number the temperature sensor will read. Once the actual platen

temperature reaches a temperature of 180 F (82.2C) degrees, the display will then increase as the actual

temperature rises. Now the Hotronix

machine was last turned off.

®

press will automatically recall the previous settings at the time the

PAGE 7

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGER

Adjusting the Pressure

ADJUST THE PRESSURE

4.

While the platen is heating, Adjust the Pressure by turning the

Pressure Adjustment Knob clockwise to increase the Pressure and

counter clockwise to decrease the Pressure.

NOTE: The machine may not operate properly at pressure settings

below 20 PSI.

Refer to the Pressure Gauge for the actual pressure setting.

(see diagram to the right).

IMPORTANT: The display on the Pressure Gauge will follow the

actual pressure when increasing the pressure. When decreasing

the pressure, adjust below the target pressure and turn back up.

Failure to follow this procedure will result in poor print quality.

Pressure Adjustment Knob

Optional: If you desire to store

a Reference Pressure, press

REF PRESSURE = 00

REF PRESSURE = C 00

NOTE: Press the Pressure Key once to review Reference Pressure.

30 - 45 PSI = Light Pressure

(Pressure will be displayed and automatically return to the “Ready To

45 - 60 PSI = Medium Pressure

Print Mode.”) Or press the Pressure Key twice to enter a Reference

60 - 90 PSI = Heavy Pressure

Pressure.

the Pressure Key.

(Press for two seconds)

Press the Pressure Key again.

(Press for two seconds)

The “C” signals that a

pressure may be entered.

Enter your reference

pressure from 01 to 99 PSI.

Press the “E” Enter Key

when completed.

(Press for two seconds)

PAGE 8

Press the “E” Key to exit the Pressure Mode and to return to the

Print Mode.

WARNING: Structural damage caused by excessive pressure is not covered under the limited warranty!

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

ADJUST DUAL TIME

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

5.

Dual Time will allow you to enter two times which will alternate between print cycles.

SET TIME: 008

Key in desired time. To enter time, key in 3 digits within a range of

001 to 999 seconds (i.e. 008 seconds). To accept time withought

changing it, press the “E” Key and begin entering second time.

NOTE: The press will not accept times below 001 or above 999

seconds. If you mistakenly attempt to key in a time beyond the

allowable range, the press will beep to alert you of your error.

HOTRONIX® AIR SWINGERHOTRONIX

Adjusting Dual Time

Press the Time Key.

(Hold for two seconds)

Press “E” Enter Key to enter the time (press for 2 seconds).

Your time has now been programmed and will appear in the display.

SET TIME: 2 010

Key in second desired time (i.e. 010 seconds)

To accept time withought changing it, Press the “E” Key. The

Machine will turn to normal operating mode.

To enter time, key in 3 digits within a range of 001 to 999

seconds.

T = 360/360 t = 010

The Air Swinger will automatically return to the “READY TO PRINT”

cycle.

REMEMBER: If a beep is heard at anytime during programming, you

have made an error. Please re-read the instructions and try again.

Press “E” Enter Key to

enter the second time

(press for 2 seconds)

The second time has now

been programmed.

NOTE: Your Hotronix

®

Air Swinger will automatically return to normal operating mode.

PAGE 9

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGER

Adjusting the Temperature

ADJUST THE TEMPERATURE

6.

6.1

First, locate and press the Temperature Key on the Control Panel.

(Press for 2 seconds)

The displayed message will illuminate in the LCD display indicating

you are in the Adjust Temperature Mode.

SET TEMP F 330

6.2

Key in desired temperature (i.e. 330°).

6.3

To enter a temperature in fahrenheit, key in 3 numbers.

6.4

To enter a temperature in centigrade, key in 4 numbers.

NOTE: The press will not accept temperatures below 205° F (096° C) or above 430° F (221.6° C). If you

mistakenly attempt to key in a temperature beyond the allowable range, the press will beep to alert you of your

error.

6.5

Press “E” Enter Key to enter the temperature.

(Press for 2 seconds)

Your temperature has now been programmed and the heat platen

will begin to heat or cool to obtain the new temperature.

PAGE 10

REMEMBER: If a beep is heard at any time during programming, you have made an error. Please re-read the

instructions and try again.

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

7.

PREPARE TO PRINT

When the targeted press temperature is reached, the display will prompt you with the message

“READY TO PRINT”. This display will flash alternately with the “Temperature/Time” display.

Position garment and application. Gently swing the top platen in a smooth continuous motion, until it lines up

with the lower platen. With both hands, press the Print Buttons located on the side of the press. The heat

platen will lower to the print position and remain lowered for the number of seconds indicated by the timer.

HOTRONIX® AIR SWINGERHOTRONIX

Pressing

Alternating Displays

CAUTION: When the print cycle is complete, the heat platen will return to the UP position and audibly signal.

Gently swing the top platen to the side and proceed according to the application’s instructions.

The display will then

show this message

Example: 005, 004, 003, 002, 001

8.

OPTIONAL GARMENT PRE-PRESS TACK MODE

Position the garment and

press the Tack Button

located on top of the

Control Housing.

Gently swing the top platen in a smooth continuous motion until it

lines up with the lower platen. With both hands, press the Print

Buttons located on each side of the press. The top platen will lower

to the print position and remain there until you release the buttons.

CAUTION: Once the Print Buttons are released, the top platen will

return to the UP position.

To exit the Tack Mode simply press the Tack Button.

PAGE 11

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGER

Setting the Date and Time

SWITCH THE SYSTEM ON

9.

The Power ON/OFF Switch is located on the top of the control housing. Flip the switch to the ON position. The

machine will display “HELLO” for 3 seconds.

The Date, Day and Time

message will automatically

HELLO!

NOTE: If the Time and Temperature screen appears before a

decision is made, turn the press off and begin with Step 9.1.

appear.

Immediately press the

“E” Key while the Date, Day

and Time message is being

displayed.

(Press for 2 seconds)

04/01 WED 16:00

# = Set Clock E = OK

This message will automatically appear

Key in the two digits for the month (MOMO)

(01= January, 12=December)

Next, key in one digit for the day (DAY) (1= Monday, 7= Sunday)

Then, key in two digits for the date (DD) (01 - 31)

When the final number is keyed in, the LCD screen will display

this message:

NOTE: If too much time is taken, the controller will return to the original display and you will need to start the

sequence again. Turn machine off and begin with Step 9.1.

Key in four digit hours (HH) and minutes (MM) using the 24-hour

clock. Example: 08:00 = 8 am 16:49 = 4:49 pm. When the final

number is keyed in, the LCD screen will display this message:

NOTE: If a blank screen appears, simply press the “C” Key followed

by the “E” Key.

Press the “E” Key to store your new time and date and to return the press to the Print Mode or press the “C”

Key to set the Automatic ON/OFF Function (Where time and date will automatically be stored).

Press the “#” Key.

(Press for 2 seconds)

DATE: MOMO, DAY, DD

This message will automatically appear

TIME: HH, MM

# = Set Clock E = OK

PAGE 12

NOTE: If the Automatic ON/OFF Function is not used, your Hotronix

conserving feature which automatically shuts off the machine’s heat at 12:00 AM in case the machine was left

on. To override simply press the “#” Key.

®

press is equipped with an energy

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGERHOTRONIX

Setting the Auto ON/OFF

10.

1 = Monday 00:00 = OFF Time, Hour: Minute

PREPARE TO PRINT

The Automatic ON/OFF feature allows you to make the most of every business day. By using the Automatic

ON/OFF feature your equipment may be programmed to turn on, pre-heat the platen, and be ready to print

when you arrive to work. Also, your equipment may be programmed to automatically turn itself off each evening

at any time you desire.

1 = 00:00 00:00

00:00 = ON Time, Hour: Minute

Press the “#” Key.

(Press for 2 seconds)

The LCD screen will go

blank as displayed.

0800 1600

NOTE: If you do not want to have your machine turn on and off for a

particular day, then simply key in eight zeros for that day.

2 = 00:00 00:00

Key in the desired settings. Using the 24-hour clock, key in Four digit

hours (HH) and minutes (MM). This example shows the press

automatically turning on at 8 AM and automatically turning off at 4PM.

When the eighth

number is keyed in,

the next day will

automatically be

displayed.

PAGE 13

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGER

Setting the Auto ON/OFF - Cont.

Repeat the previous step until all seven days are entered. This message will be displayed:

NOTE: You must continue through all seven days in this

# = Set Clock E = OK

If you make an error in entering the times, do not panic. Finish the settings for the remaining days, then return

to the error by repeating the Time Set and Automatic ON/OFF programming steps. (Refer to Step 10.6)

manner for the Automatic ON/OFF Function to work.

If you press the “E” Key during the programming of any of the seven

days, the memory will be erased and the procedure for Time Set and

Automatic ON/OFF will have to be repeated.

Now your Hotronix

time.

IMPORTANT: When using the Automatic ON/OFF function, you must leave the press plugged in and have the

power switch in the “ON” position. The press will automatically heat itself to the previous day’s final temperature

setting.

Press the “E” Key to exit the automatic ON/OFF programming mode

and to save your settings into memory or press “#” to reset the time

and then correct errors for the Automatic ON/OFF.

When resetting Automatic ON/OFF times, it is not necessary to reset

each day. Pressing the “C” Key instead of the “#” Key will retain the

displayed information and advance to the next day’s settings.

Pressing the “#” Key will allow you to change the time for the desired

day. (Refer to step 10.2).

®

press will automatically turn on each morning and turn off each evening at your designated

PAGE 14

If the press should turn itself off while you are working, simply press the “#” Key to override the Automatic

ON/OFF function. Once your work is completed, press the “#” Key again to return your press to the Automatic

ON/OFF Mode.

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGERHOTRONIX

Storing Settings

11.

STORE FREQUENTLY USED SETTINGS

®

Frequently used press settings (Time, Temperature, and Pressure), can be stored into the Hotronix

memory and may be instantly recalled at any time. For your convenience, Hotronix

most commonly used settings. The preset programs are as follows:

Seconds

4

6

8

10

15

20

25

The numbers 0 through 9 are pre-set programs. For example, Program Number 9 is the only pre-set program

for 15 seconds at 375° F (190° C). A pre-set program sticker has been enclosed for your convenience. To

store the setting you are currently using as a pre-set program, follow the instructions below.

A 330/165

0

1

2

B 350/180

3

4

5

6

7

8

®

has already pre-set the ten

C 375/190

9

press

Set the Temperature.

(Refer to page 10)

Set the Time.

(Refer to page 9)

Set the Pressure.

Press the “pressure” key.

(Refer to page 8)

This message will automatically appear

ADJ PRESSURE = 0 0

Target Pressure

Actual Platen Pressure

PAGE 15

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

0F0

C

HOTRONIX® AIR SWINGER

Storing Settings - cont.

IMPORTANT: The Actual Pressure must be re-checked each time a pressure change is desired.

Press the Temperature

Key (Press for 2 seconds).

The “Ready to Print”

message will stop blinking.

Press the Temperature Key a second time.

(Press for 2 seconds)

This signals the controller that you are about to store the settings

that you are currently using. The controller is now ready to accept

the next command.

SET TEMP F 330

SET TEMP F 33A

Press the “C” Key (Press for two seconds).

Press the Number Key (0-9) that you desire to assign your new

stored program. Once the new program is stored into memory, your

press will return to the “READY TO PRINT” mode.

PAGE 16

REMEMBER: Keep a written record of your new preset programs as well as notes on the best temperature,

time, and pressure for each garment type and applications.

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

1 2 3

4 5 6

7 8 9

C

0

E

#

0F0

C

HOTRONIX® AIR SWINGERHOTRONIX

12.

TO RETRIEVE A PRESET PROGRAM

Press the “C” Key. (Press for 2 seconds)

This turns the retrieve function on and the “READY TO PRINT” display will stop blinking.

READY TO PRINT

NOTE: Make sure the display has stopped blinking before proceeding to the next step. Failure to do this will

result in the controller advancing into an incorrect mode when you perform Step 2.

Press the “#” Key. (Press for 2 seconds)

This signals the controller that you are about to retrieve a pre-set

program.

Press the particular

Number Key (0-9) of the

pre-set program which you

desire to retrieve Once you

have pressed the recall

number, your machine will

return to the “READY TO

PRINT”mode and will display

the pre-set program you

retrieved.

The LCD Screen will

display your Actual

Temperature, new Target

Temperature, and new

Time as follows:

Check the pressure setting

before you begin to print.

(Refer to page 8 for instructions on setting your pressure).

READY TO PRINT

T = 350/375 t = 015

PAGE 17

HOTRONIX® AIR SWINGER

Parts location Guide

Air Line Diagram

Air Filter

Air Cylinder

Mac Valve

23

21

20

22

24

18

28

25

26

27

15

30

30

29

49

14

13

12

Air Gauge

Pressure

Regulator

17

16

47

19

11

10

9

8

5

4

3

2

1

3

7

6

PAGE 18

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

HOTRONIX® AIR SWINGERHOTRONIX

Parts Location Guide

39

35

36

31

37

32

33

38

41

34

39

40

43

46

48

42

30

30

31

45

47

44

PAGE 19

HOTRONIX® AIR SWINGER

Replacement Parts List

Item #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29/49

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49/29

Part Name

Nylon Lock Nuts 5/16-18

Lock Spring Washer 3/8”

Table Top Stand

Platen Thumb Screw

Base Weldment with Spindle

Hex Soc Screw 1/4-20x3/4”

Lock Spring Washer 1/4”

Post Casting

Lower Platen 16x20

Silicone Pad Grey 16x20

Heat Platen 16x20

Heat Platen Cover

Finish Washer

Cover Screw 10-24x1/2”

Probe

Quick Disconnect

Air Filter

Heater Triac

Proximity Switch

Magnet

Top Weldment

Bulkhead Fitting 3/8”

Power Cord

IEC Inlet

Air Triac

Safety Bolt 3/8-16x7”

Jam Nut 1”-12

Air Cylinder

Control Housing/Back

Elbow Fitting 1/4”x1/4”

Pressure Regulator

Tack Button

ON/OFF Switch

Ciruit Breaker

LCD Display

Pressure Gauge

E-Stop

Keypad

Print Switch

Counter

Terminal Block 5 Position

Stone Filter

Mac Valve

Safety Valve 100 PSI

Elbow Fitting 1/8”x1/4”

Control Board

Elbow Fitting 1/4”x3/8”

Terminal Block

Control Housing

Part #

2-1006-20

2-1006-43

Kit 3-6918

1-1016

Kit 3-1225

3-1011-106

2-1006-44

2-1033

2-1029

1-1011

2-1002-3

4-1117

1-1063

3-1011-217

1-1272-1

1-1791

1-1215

1-1059

1-1211

1-1219

Kit 3-1257

1-1892

2-1013-1

1-1759

1-1059-1

3-1011-230

No Number

1-2074

4-1161

4-1015-12

1-1213

1-1587

1-2087

1-1331

1-1031

1-1214

1-1588-1

2-1014

1-1670

1-2067

1-1290

4-1015-36

1-1231 IN

1-1581

4-1015-13

1-2021

4-1015-4

1-1762

4-1161

Qty.

4

4

1

2

1

4

4

1

1

1

1

1

4

4

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

7

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

Each

PAGE 20

S E R V I C E H O T L I N E : 8 0 0 . 7 2 7 . 8 5 2 0 H O T R O N I X . C O M

HOTRONIX® AIR SWINGERHOTRONIX

Electrical Schematic

TO COUNTDOWN

PROXIMITY SWITCH S6

J4

J5

LCD DISPLAY

EMERG.

TS1

STRIP

TERMINAL

CONNECTIONS

220 VOLT

CONNECTIONS

120 VOLT

J9

WHITE

GREEN

BLACK

JUMPER

RED

WHITE

WHITE

BLACK

BLACK

GREEN

V1

AIR VALVE

PLATEN

T1

RED

TRIAC

VALVE

WHITE

BLACK

S2

STOP

SWITCH

4

2

1

7

6

5

4

3

2

1

345

2

1

6

7

8 8

WHITE

BLACK

HEATER

J8

BROWN

3 CONDUCTOR CABLE

BROWN

T2

TRIAC

BLACK

BLACK

RED

RED

J7

BROWN

BROWN

RTD

RED

BLACK

3 CONDUCTOR CABLE

BROWN

ORANGE

J10

4 CONDUCTOR CABLE

BLACK

BLACK

J2

RED

BLACK

BROWN

J1

ORANGE

TERMINAL

TS2

STRIP

54

3

2

1

JUMPER

KEYPAD

TO MODE SELECTOR (TACK) SWITCH S5

TO PRINT SWITCH (RIGHT) S4

TO PRINT SWITCH (LEFT) S3

BLACK

S1

ON-OFF

WHITE

BLACK

BLACK

CB1

SWITCH

20 AMP

CIRCUIT

BREAKER

WATT HEATER

FILTER

2250 WATT HEATER

WIRED FOR 220 VOLTS

TO POS. #4

TO POS. #2

S1

BLK

L

GREEN

ON-OFF

SWITCH

WHT

N

IEC

INLET

WIRED FOR 120 VOLTS

1800

GREEN

WHITE

POWER CORD

TO POS. #2

TO POS. #4

WHITE

WHITE

GREEN

BLACK

S1

US 220V UNITS ONLY

ON-OFF

CB1

SWITCH

10 AMP

BREAKER

CIRCUIT

CB2

10 AMP

CIRCUIT

BREAKER

BLACK

CE 220V VERSION

POWER CORD

CIRCUIT BREAKER

10 AMP

RFI

CB1

PAGE 21

HOTRONIX® AIR SWINGER

Models/Accessories

This fitted, non-stick cover slips snugly over the bottom

platen

PAGE 14

PAGE 22

Contact us

Stahls’ Hotronix

®

One Paisley Park

Carmichaels, PA 15320

U.S.A.

Technical Support

800 . 727 . 8520

Monday - Friday

8am - 7pm EST

Customer Service

800 . 727 . 8520

Monday - Friday

8am - 5pm EST

Replacement Parts

800 . 727 . 8520

8am - 7pm EST

Web

Hotronix.com

This document includes multiple trademarks and describes equipment covered by many patents

that are owned by GroupeSTAHL and/or its subsidiaries. GroupeSTAHL enforces its rights

to protect these intellectual properties. © 2012

Rev. A 9-12 Doc. XRS 9-12

One Paisley Park . Carmichaels, PA 15320, U.S.A.

Tech Support - Customer Service - Replacement Parts: 800 . 727 . 8520

Proudly made in the U.S.A.

Web: Hotronix.com

Loading...

Loading...