Hotpoint WT540 Installation

Instructions for Installation and Use

7kg Washing Machine

Aquarius

To the Installer:

Before installation, fill in the product details on the back cover of this

book. The information can be found on the rating plate.

To the User:

You must read these instructions prior to installing and using the

appliance and then retain them for future reference.

GB

Description

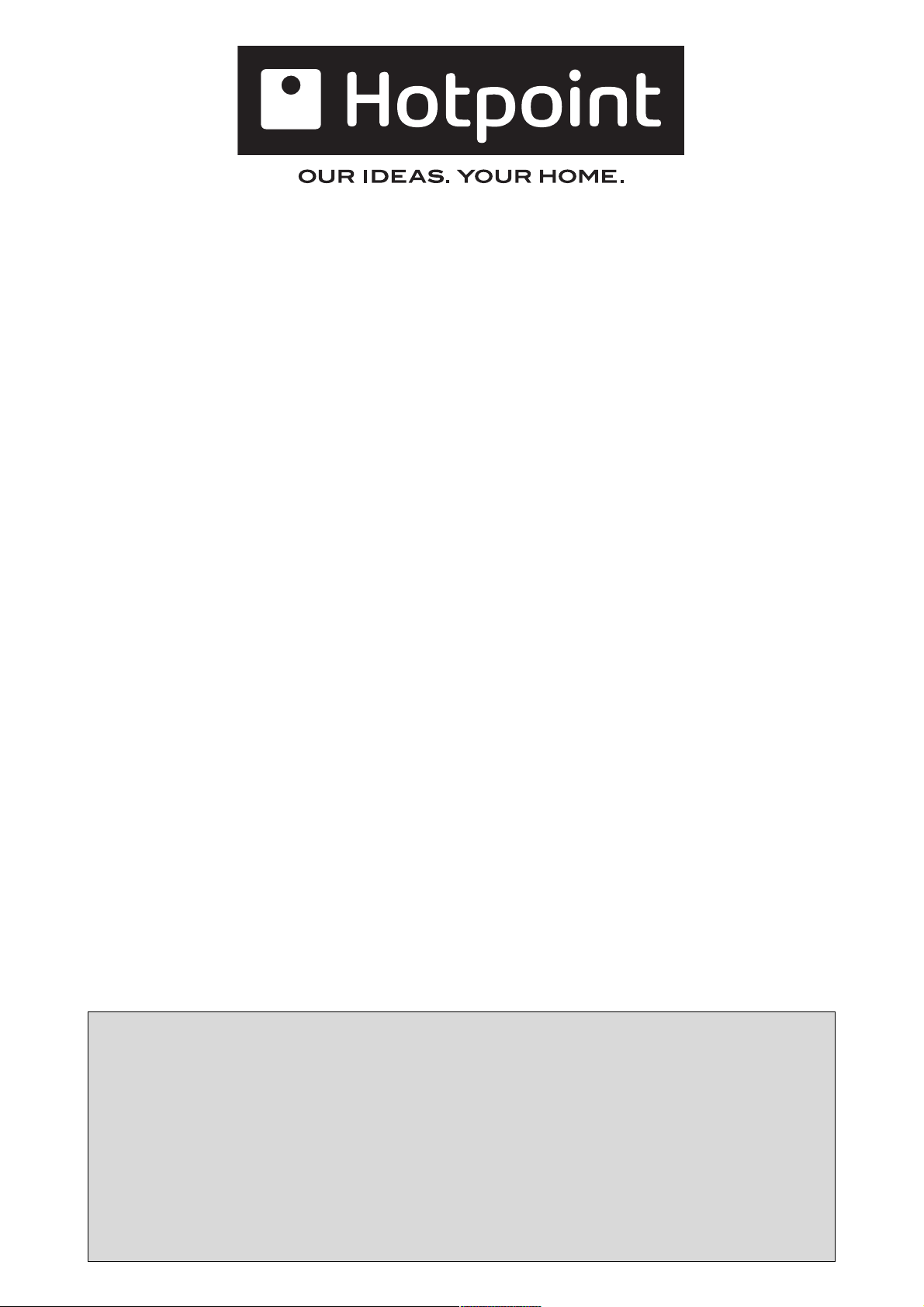

Dispenser drawer

Control panel

●

Interlocking door and

release lever.

Drainage hose

Please record the Model number and

Serial number of your machine on the

back cover of this book for future

reference.

- The Serial number can be found on

the inside door trim.

Cold water inlet point and

attached fill hose

(blue connector)

Mains cable

Front adjustable feet

Hooked end support

Plumbing indicator line

TWO transit fixings.

Comprising of: two bolts, two washers,

two rubber grommets and two nylon spacers

! BOTH transit fixings must be removed BEFORE

you use your machine (

sseeee ppaaggee 55

Rating plate

).

Back feet

2

Contents

WASHING MACHINE

GB

Description, 2

Installation, 4-7

Unpacking

Remove the transit fixings

Location

Levelling

Water connection

Drainage connection

Electrical connection

Before you start using your machine

Control Panel Features, 8

Aquarius

Programmes and Option Modifiers, 9-13

Starting a programme

Programme table

Wash labels and tips

Option modifiers and special features

Detergents, 14

Detergent dispenser

Care and Maintenance, 15

Cleaning your machine

Fuses

Changing the plug

Cleaning the pump

Description

Contents

Control Panel

FeaturesInstallation

Programmes

and Option

Modifiers

and Laundry

Detergents

Precautions and Advice, 16-17

General safety

Saving energy and respecting the environment

Disposal

Something Wrong? - Troubleshooting, 18-19

Service, 20

Before calling for assistance

Spare parts

Key Contacts

! Keep this instruction book on hand in order to refer to it when necessary. Take it with you when you move,

and should you sell this appliance or pass it on to another party, make sure that this booklet is supplied

along with the appliance so that the new owner may be informed about warnings and suggestions on how

the machine works.

Maintenance

Care and

Precautions

and Advice

Troubleshooting Service

Wrong? -

Something

3

Installation

GB

! Read these instructions carefully: the following

pages contain important information on installation

and suggestions on how the appliance works.

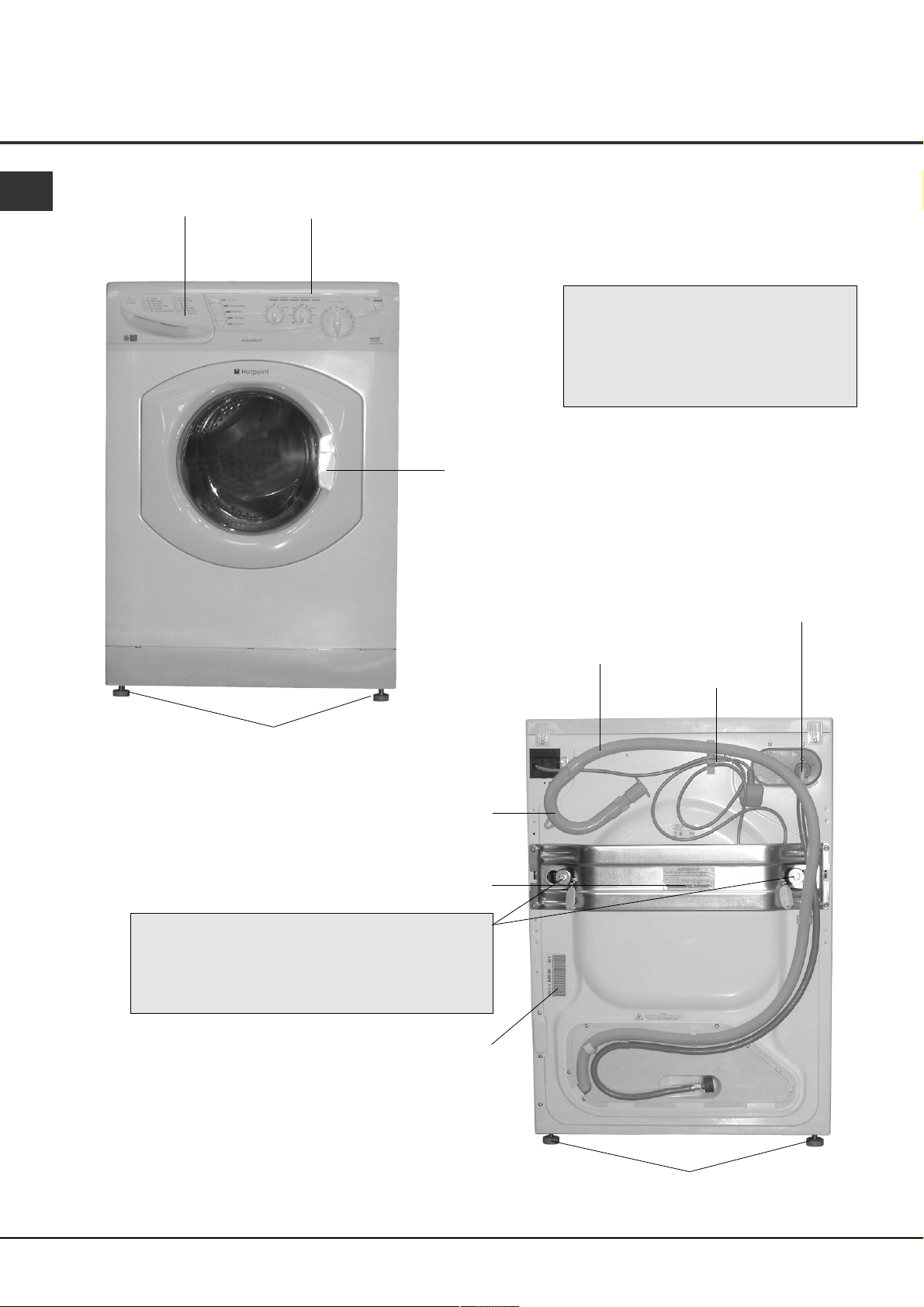

Unpacking

1. Using scissors, cut

carefully along one corner

post to remove the film.

2. Lift off the polystyrene

top cap and remove the

four corner posts.

4. Remove the

polystyrene base.

! IMPORTANT check

when unpacking your

machine:

5. Stand the machine

upright.

! This is a part of the

polystyrene base and

should have stayed intact

when you removed the

base.

! If it has broken off and

is still in the machine...

ve it... while the

remo

machine is still laying on

its side on the top cap.

3. Carefully lay the left

side of the machine down

onto the top cap.

! We recommend that a

second person helps to raise

and lower the machine.

! We recommend that a

second person helps to raise

and lower the machine.

! Continue to read the rest

of these instructions

carefully; the following

pages contain important

information on installation

and troubleshooting.

! Protect the environment - please dispose of the

packaging material carefully and considerately.

4

Installation

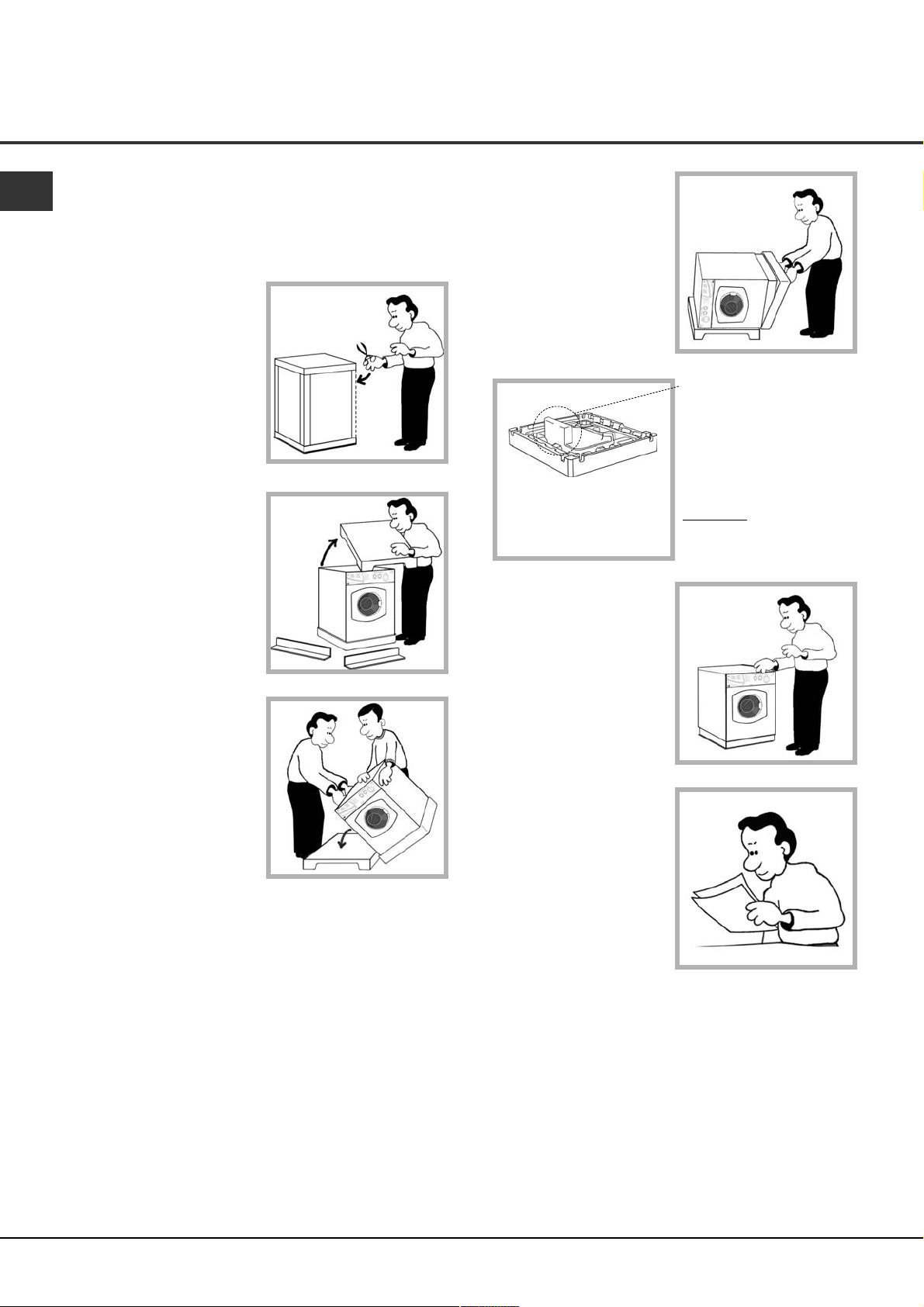

Remove the transit fixings

IMPORTANT: Follow these instructions to remove the

TWO transit fixings (see Description for location).

! Situated one either

side of the rear panel,

BOTH transit bolts

MUST be removed

before use.

Location of transit bolts.

! Failure to do so may cause damage to your machine.

! It is important the TWO transit fixings come out intact.

! Be sure to remove TWO bolts,

TWO washers, TWO rubber

grommets and TWO nylon

spacers (see pic).

1. Unscrew the bolt using a

13mm spanner.

2. STOP

seen.

when 3 threads can be

3. Hold, slide sideways and pull to

remove.

4. For safety, insert one of the

the plastic covers (supplied

with your machine) over the

hole.

! Repeat steps 1 to 4 to remove the second transit bolt.

PPaacckkaaggiinngg mmaatteerriiaallss aarree nnoott cchhiillddrreenn''ss ttooyyss..

!

Location

Where you install your machine will affect its

performance:

! For your safety and to comply with electrical

regulations, seek professional advice if you want to

install your machine in a bath or shower room.

●

Make sure that the electrical socket and water

taps are easily accessible. You should switch off

the machine’s electrical and water supplies

when you are not using it for extended periods.

●

Make sure that you allow enough space for the

machine. Select a space at least 60cm wide,

60cm deep and 85cm high. Also leave enough

space to open the door fully, so that you can load

and unload it easily.

●

Where possible, the machine should be positioned

on a solid floor to minimise vibration.

GB

Description Contents

Installation

Control Panel

Features

Programmes

and Option

Modifiers

and Laundry

Detergents

Maintenance

Care and

Precautions

and Advice

! Take care when you move the machine not to rip any

floor coverings. The weight of the machine may cause

indentations in some floor coverings.

Did you know?...

●

...the transit fixings are fitted to ensure that your machine is undamaged during delivery.

●

...both of the transit fixings MUST BE removed before using the machine, be sure to remove TWO bolts,

TWO washers, TWO rubber grommets and TWO nylon spacers, not doing so will lead to excessive

vibration, movement of the machine and could eventually lead to internal damage.

●

...the majority of problems with noisy machines are due to the transit fixings not being removed.

●

...you will be charged for a service engineers visit if a problem with your machine is caused by incorrect

installation or misuse.

Troubleshooting

Something

Wrong? -

Service

5

Installation

GB

Levelling

Your machine will be noisy if the two front feet are not

adjusted so that the machine stands firm and level.

! The machine must be levelled from side to side and

from front to back.

1. Move your machine into its final location, taking

care not to trap or kink the hoses.

2. Turn one or both front feet

anti-clockwise by hand until the

feet cannot be turned any more.

When adjusting the feet, use a

spirit level to check the machine

stands level, from side to side

and from front to back.

The spring on each foot will stop

them coming loose.

! If it is placed on a fitted or loose carpet, adjust the

feet in such a way as to allow enough room for

ventilation beneath the machine.

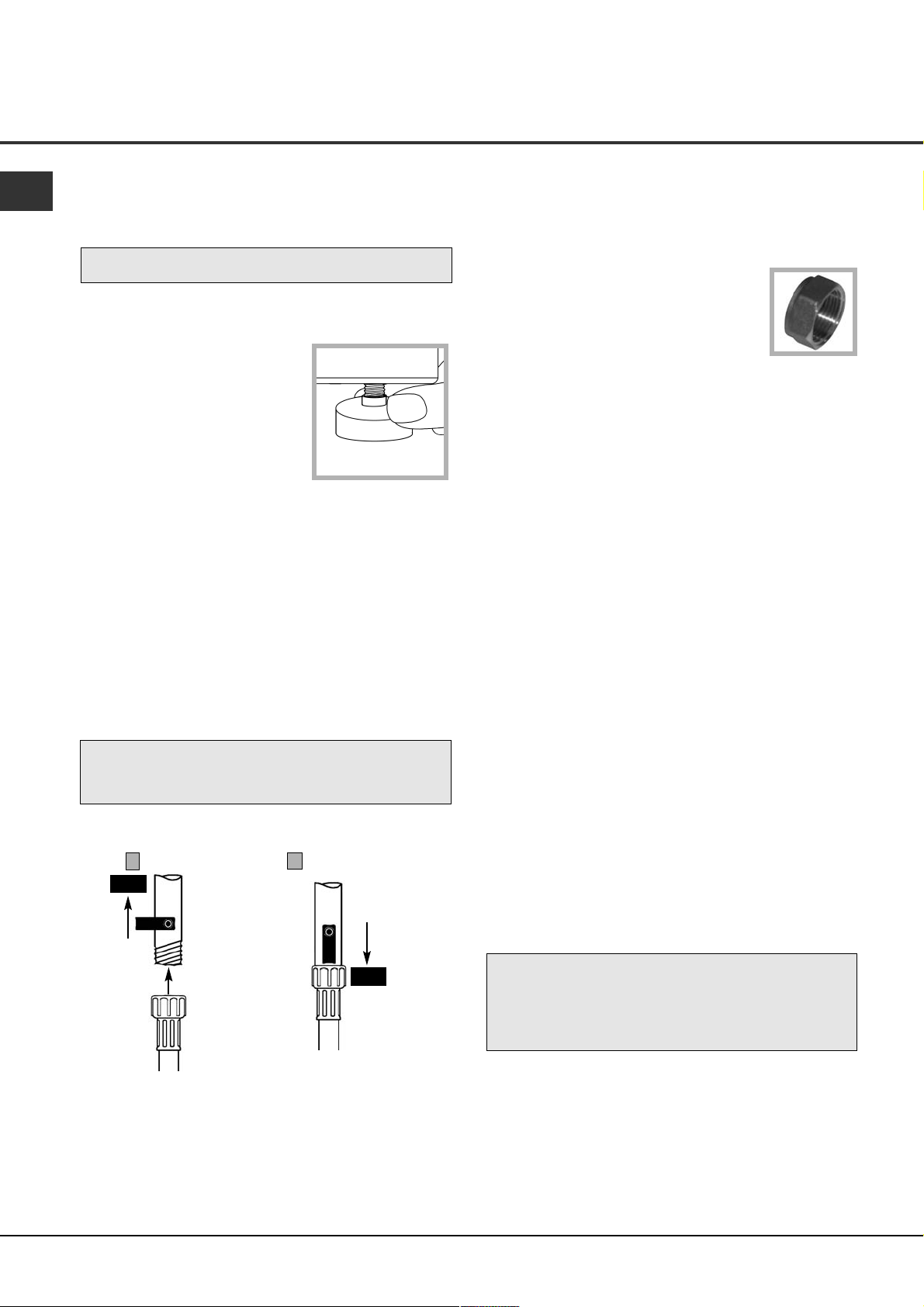

Water Connection

Remember this is a cold fill machine.

! Please use the new hose supplied, fitted to the

machine. Old hoses may cause leaks due to worn out

washers or may be split due to water pressure.

! Before making connections to the cold water supply,

allow the water to run freely from the supply tap until

it is perfectly clear.

Connecting the cold water inlet hose to the COLD

WATER SUPPLY:

1

OFF

COLD

WATER

SUPPLY

Cold water

fill hose (Blue

Connector)

2

COLD

WATER

SUPPLY

ON

1. Screw the cold water fill hose (blue connector) onto

the cold water supply until tight.

2. Turn on the cold water supply and check for leaks,

tighten if necessary.

3

! We recommend fitting a

/4" sealing cap

to the hot water supply tap (if present), to

ensure there are no leaks. Sealing caps

can be purchased from Hotpoint Service

on 08709 077 077 or all good DIY and

Plumbing outlets.

Benefits of cold fill

●

Modern detergents are designed to give the best

cleaning results at low temperatures. Biological

detergents contain enzymes which are active

between 30˚C and 53˚C, giving greater results at

lower temperatures.

●

Cold water relaxes fabrics, whilst hot water can

seal in stains.

●

Improved stain removal with cold water.

●

The most commonly used programme at present is

40˚C, which will take on cold water even if hot and

cold were available.

●

You can heat the water required to finish the wash

cycle, which makes it more economical than taking

water heated in a tank by an immersion heater or

gas boiler.

Hints and tips

! Make sure there are no kinks or bends in the hose.

! The water pressure at the supply tap must be within

the values indicated in the Technical Details table

(see page 17).

! If the water inlet hose is not long enough, you can

purchase an extended hose from Hotpoint Service on

08709 077 077.

! Always use a new inlet hose.

! Check the water inlet hose at least once a year,

replace if cracked as worn hoses could split under

water pressure.

! Turn on the water supply and check that the

connections do not leak. If there is a leak, turn off

the water supply, disconnect the hoses and check

that the sealing washers are in place. Refit the hoses

and turn on the water supply.

Did you know?...

●

...the most common cause of problems with water connection is that the customer has not turned the

supply tap on..

●

...it is very important to ensure that your hoses or cables are not kinked or squashed when the machine

is pushed back into its location, as this can lead to your machine failing to fill or empty the water.

●

...the majority of problems with noisy machines are due to the feet not being adjusted correctly to

level the machine.

6

Loading...

Loading...