Hotpoint WD71 User Manual

Congratulations on the purchase of

your new Ultima Washer Dryer.

IMPORTANT INFORMATION

Please read this instruction book

thoroughly before installing and using

your appliance for the first time.

ULTIMA

Instruction Manual

For Model WD71

Electricity Supply

WARNING: This appliance must be earthed.

Fuses

Your appliance comes fitted with a plug and a 13A fuse. If you need to replace the fuse, only

those rated at 13A and ASTA approved to BS1362 should be used. To change fuse lift

holder to vertical position and lift fuse out. To replace, insert fuse and push fuse holder down

into locked position. Correct replacement is identified by colour coding or the marking on

base of plug.

WARNING: Do not use plug unless fuse holder is in locked position.

Changing the Plug

Cut off and dispose of the supplied plug if it does not fit your socket.

WARNING: To avoid a shock hazard do not insert the discarded plug into a socket

anywhere else.

IMPORTANT: WIRES IN THE MAINS LEAD

ARE COLOURED IN ACCORDANCE WITH

THE FOLLOWING CODE:

Green/Yellow - Earth

Blue - Neutral

Brown - Live

If you change the plug, the colour of

wires in the mains lead may not

correspond with the colour of the

markings identifying terminals in the

plug. You should therefore wire it as

shown (Fig 1).

Green and yellow (Earth)

wire to terminal

marked ‘E’,

symbol , or

coloured green

and yellow.

Blue (Neutral)

wire to terminal

marked ‘N’ or

coloured black.

13A ASTA

approved fuse to

BS1362.

Brown (Live)

wire to terminal

marked ‘L’ or

coloured red.

Cord clamp

Fig 1

Changing the Mains Lead

A special lead can be ordered from Hotpoint Service UK: 08709 066 066 or

Republic of Ireland: 1850 302 200

If you have damaged the existing lead or require a longer one a charge will be made. It is

strongly advised that this work is carried out by a qualified electrician.

CE marking certifies that this appliance conforms to the following EEC directives:Low Voltage Equipment - 72/23/EEC & 93/68 EEC

Electromagnetic Compatibility - 89/336/EEC, 92/31/EEC & 93/68/EEC

2

Contents

Electricity Supply ...................................... 2

Recycling & Disposal Information .............. 3

Installation Instructions

1. Choose a Location................................ 4

2. Remove Transit Brackets ...................... 5

3. Connect to the Water Supply ............... 6

4. Connect to a Drainage System

5. Adjust the Feet ..................................... 7

When you have installed your appliance,

ensure it is ready to use by following the

10 Step Check List on page 7

Getting to know your

Appliance

Index ........................................................ 8

Button Selection

Interlocking Door System

Automatic Features ................................... 9

Wash & Auto Dry

Programme

.................................... 10

Choosing a Dry Programme

Drying Weight Loads

Removal Of Fluff

Items Not Suitable for Tumble Drying

Drying Tips .............................................. 14

Optional Wash/Dry Features

Option Buttons

Automatic Features ............................15-16

The Dispenser Drawer

Index

Choose a Suitable Detergent....................17

Changing the Main Wash Indicator

Dispensing Powder Detergent

Dispensing Liquid Detergent

Dispensing Fabric Conditioner

Using a Dosing Ball.................................. 18

Cleaning

Maintenance Wash

.....................19

Independent Dry

Programme

......................................11

Troubleshooting

Error Messages

............................ 20

............................ 21

Choosing a Wash Programme

Selecting a Prewash

Washing Weight Loads ............................12

Gentle Wash, Rinse & Spin

Hotpoint After Sales

Service

Hotpoint Guarantee

Guarantee Terms & Conditions ............... 23

.............................................. 22

Options for Programme ‘G’

Washcare tips...........................................13

Key Contacts

.................. Back Page

Recycling & Disposal Information

As part of Hotpoint’s continued commitment to helping the environment, Hotpoint reserves the right to use

quality recycled components to keep down customer costs and minimise material wastage.

Please dispose of packaging and old appliances carefully. To minimise risk of injury to children,

remove the door, plug and cut mains cable off flush with the appliance. Dispose of separately to

ensure that the appliance can no longer be plugged into a mains socket.

Retention of this

Instruction Manual

Keep this instruction manual in a

handy place for reference.

It contains important details on

the safe and proper use of your

appliance. If you sell the

appliance, pass it on to someone

else, move house and leave it

behind, make sure that you

provide this manual so that the

new owner can become familiar

with the appliance and safety

warnings.

3

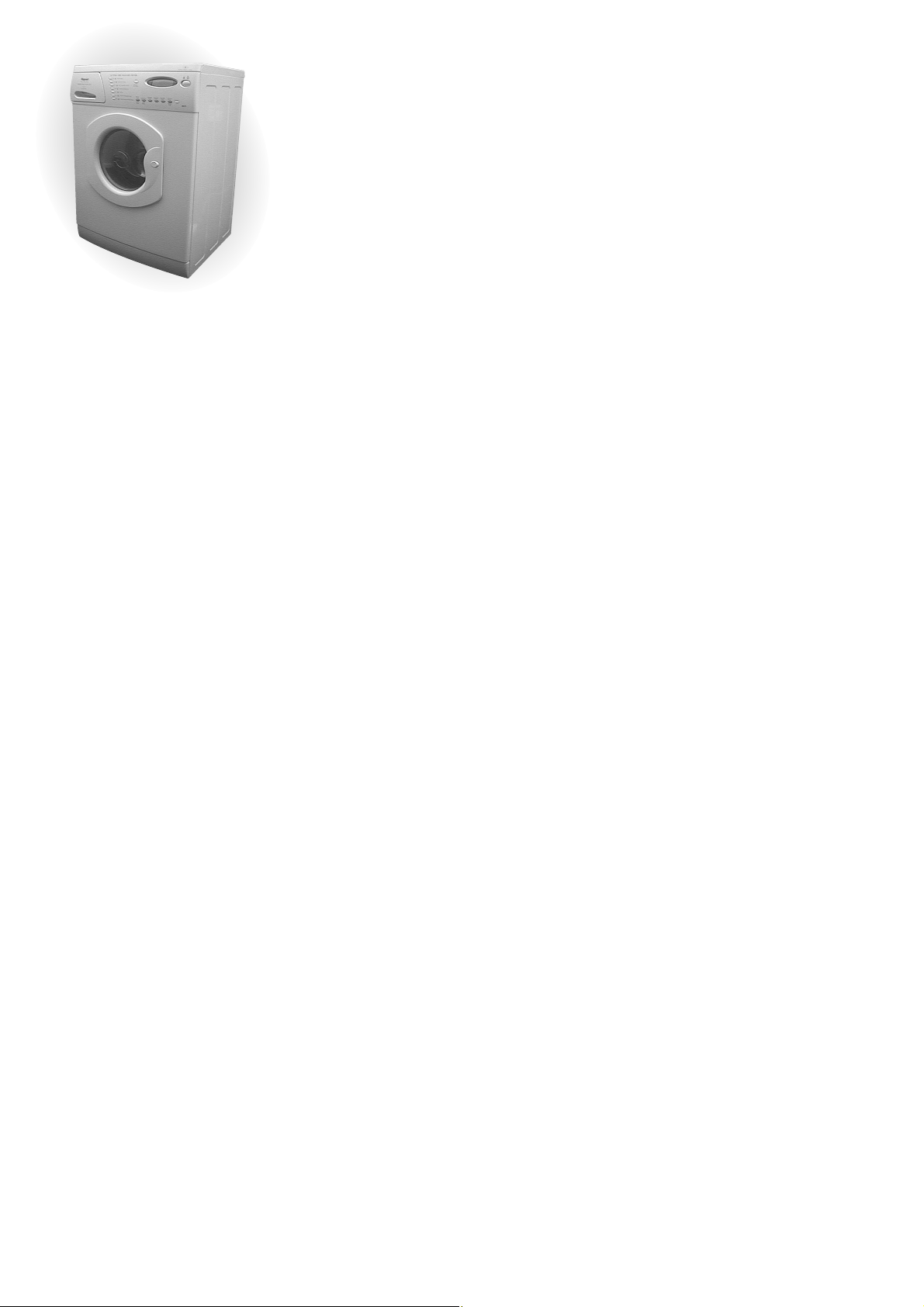

Installation Instructions

IMPORTANT INFORMATION:

●

Do not plug in and switch appliance on at the mains until installation is complete.

●

You may be charged for a service call if a problem with your appliance is caused

by incorrect installation or misuse.

Follow these 5 steps for a trouble free installation:

1. Choose a Location...

2. Remove Transit Brackets...

3. Connect to the Water Supply...

4. Connect to a Drainage System...

5. Adjust the Feet...

1. Choose a Location...

The choice of location for your appliance will influence its performance.

●

Position where possible on a solid floor. Vibration may occur with a wooden floor.

●

Take care with vinyl floor coverings. The weight of the appliance may cause indentations

in some vinyl floor coverings.

●

For your safety and to comply with IEE regulations, you should not install your appliance

in a bath or shower room. Seek professional advice if you wish to do so.

●

Ensure sufficient space is allowed for the appliance. The dimensions should be a

minimum of 600 mm wide, 600 mm deep and 900 mm high.

●

Ensure the electrical socket and water taps are easily accessible and that the water

supply can be isolated if necessary.

4

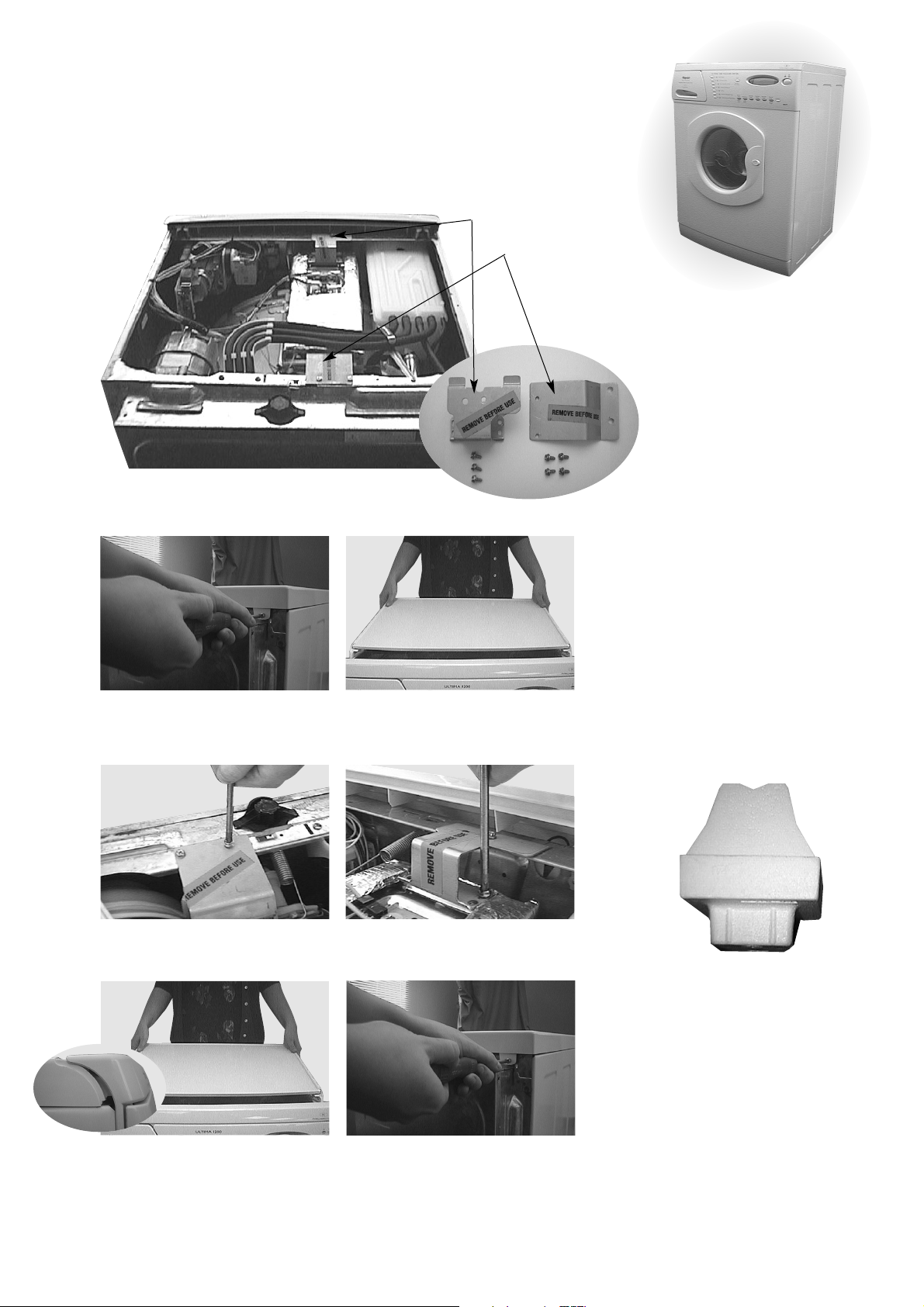

2. Remove Transit Brackets...

Your appliance is fitted with internal transit brackets (Fig 1) which prevents damage to the

appliance during transit. Remove parts (Fig 2) following the instructions below.

Note: It is normal for the door seal to look creased, it will not affect its use.

Front Transit Bracket

Fig 1

Remove 3 screws from back of

1

work top lid, retain.

From rear of appliance, grip

2

sides of work top lid, lift, slide

and pull towards you.

Rear Transit Bracket

Fig 2

WARNINGS

●

Before using appliance,

remove transit brackets,

clamps and screws

Retain parts for future

transportation.

●

After removing the

packaging from the

machine, ensure that

the polystyrene pyramid (shown below) has

come away from the

underside of the

machine, with the

polystyrene base.

Remove 4 screws and rear

3

transit bracket, retain.

Slide and push work top lid into

5

position, ensuring front edge is

correctly located into console.

Remove 3 screws and front

4

transit bracket, retain.

Replace work top lid and 3

6

screws.

If it has not come away,

remove it by tilting the

machine backwards until

the pyramid can be seen

and then remove.

Remember you may be

charged for a service call

if a problem with your

appliance is caused by

incorrect installation or

misuse.

5

3. Connect to the Water Supply...

●

Incoming hot and cold water pressure should be between 3 and 150 psi (21 - 1034 Kpa).

●

The temperature of the incoming household hot water supply should ideally be 60°C and

no higher than 70°C as this could cause damage to both your laundry and appliance.

●

The water supply taps must be easily accessible when the appliance is installed.

●

The appliance must be connected to the appliance water supply using the new hose set

supplied, old hose sets should not be used.

WARNING

●

Do not connect

appliance to a single

outlet instantaneous

water heater.

Hot and Cold Fill

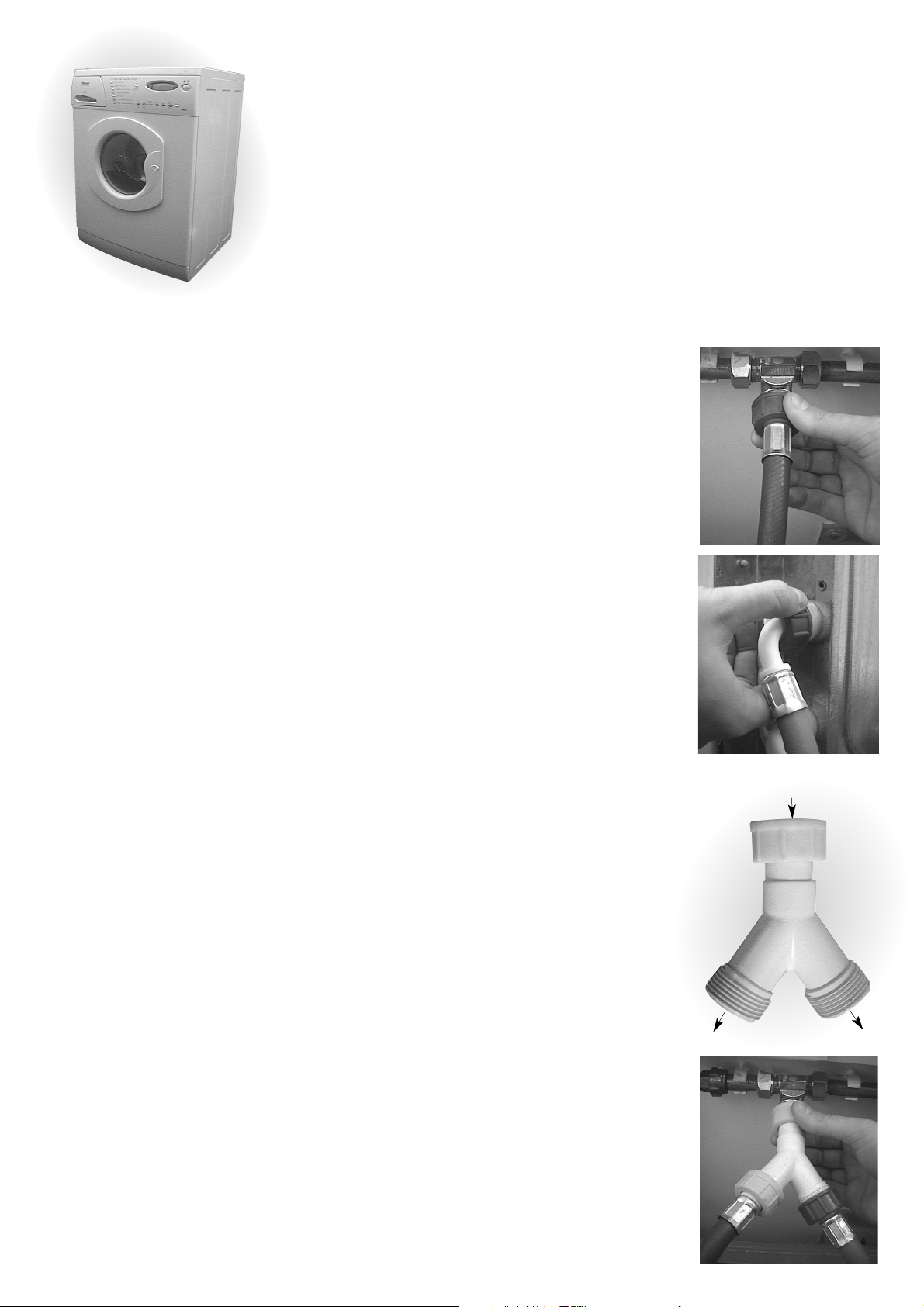

1. Connect straight end of supplied red or grey hose to the

HOT water supply tap (Fig 1). Connect straight end of

supplied blue hose to the COLD water supply tap.

2. Hand tighten connectors sufficiently to ensure water

does not leak from the hose connections.

3. Before connecting each of the hoses to the appliance,

confirm water supply is flowing by holding the free end

of each hose in a bucket, turn the relevant water supply

taps on and then off.

4. Connect angled end of red or grey hose to white plastic

inlet valve marked ‘H’ (Fig 2) and angled end of blue

hose to white plastic inlet valve marked ‘C’ at the back

of the appliance.

5. Hand tighten connectors sufficiently to ensure water

does not leak from the hose connections.

6. Turn on water supply taps and check for leaks from the

connectors. In the event of a leak, turn off supply tap,

remove connector and check sealing washer is in place.

Refit connector and tighten. Turn on water supply taps.

Fig 1

Fig 2

Cold Water Supply

Remember you may be

charged for a service call if

a problem with your

appliance is caused by

incorrect installation or

misuse.

6

If you have no hot water supply...

A Cold Fill Adaptor (Fig 3) is available from your local

Hotpoint authorised Service Centre or by calling the

Genuine Parts & Accessories Mail Order Hotline

UK: 08709 077 077 or Republic of Ireland: (01) 842 6836.

Fitting a Cold Fill Adaptor

1. Connect straight ends of supplied hoses to the Cold Fill

Adaptor (Fig 3).

2. Connect adaptor to the cold water supply tap (Fig 4).

3. Before connecting the hoses to the appliance hold the

free end of each hose in a bucket, gently turn on the tap

to confirm the water supply is flowing. Turn off the tap.

4. Connect angled end of the supplied hoses to white

plastic inlet valves marked ‘H’ and ‘C’ at the back of the

appliance.

5. Hand tighten the connectors sufficiently to ensure water

does not leak from the hose connections. Turn on water

supply taps.

Inlet to

machine

Fig. 3

Inlet to

machine

Fig. 4

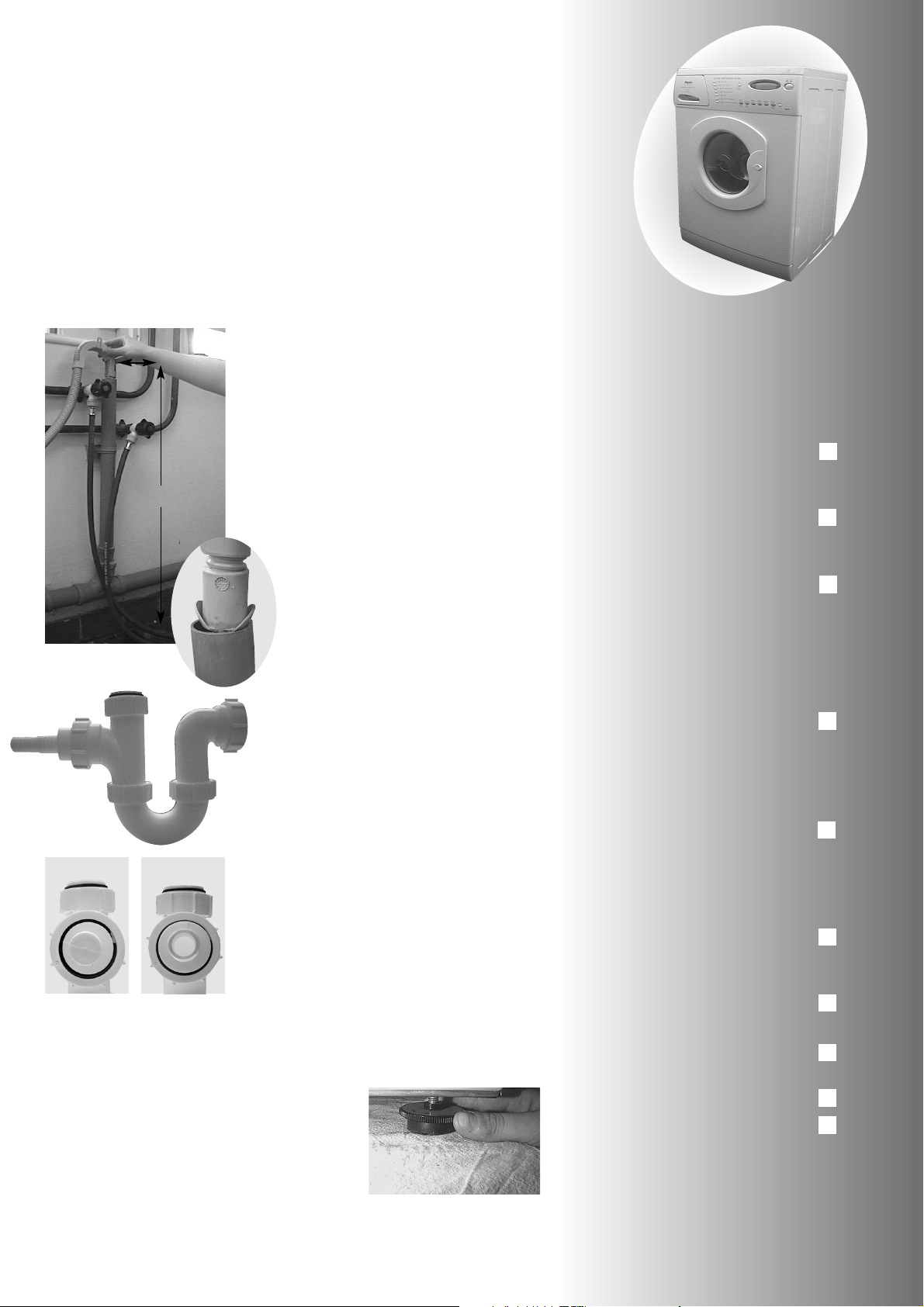

4. Connect to a Drainage

System...

●

Do not remove hooked end support from drainage hose.

●

Do not position standpipe near an electrical outlet.

●

For drainage into a standard work top sink ensure outlet pipe has a

minimum bore of 32 mm. To avoid syphoning ensure the end of the

drainage hose is above the water level in the sink. If your sink is inset, the

front edge of the basin must be less than 75 mm from the front edge of

your work top.

Fig 1

Fig 3

Fig 4 - Before

500 mm

Fig 4a - After

Fig 2

We recommend one of the following

drainage methods:-

Standpipe

Note: Ensure the standpipe has a

minimum diameter of 38 mm.

1. Ensure top of standpipe is positioned

at least 500 mm from the floor (Fig 1).

2. Untie the end of the GREY drainage

hose from the rear of the appliance

and place approximately 100 mm into

the standpipe.

3. If the end of GREY drainage hose is

fitted with ‘Retaining Flaps’, ensure

that they are fully inserted into the

standpipe as shown (Fig 2).

Sink Waste System

Note: Ensure the sink outlet pipe has a

minimum diameter of 32 mm.

1. Untie the end of the GREY drainage

from the rear of the appliance.

2. Reposition ‘Hooked End Support’ as

required along GREY drainage hose.

3. If fitting an under sink waste disposal

unit (Fig 3), cut out the membrane,

bung or blanking plug (Fig 4 and 4a).

4. Attach the GREY drainage hose to

the under sink waste disposal unit

securely, using a Jubilee clip.

5. Raise the hose to a minimum height

of 800 mm to avoid syphoning.

When you have installed your

appliance, ensure it is ready to use by

following this 10 Step Check List

1. Dispose of packaging safely,

see ‘Recycling Information’

on page 3.

2. Position appliance close to

electrical/water supply see

‘Location’ on page 4.

3. Remove transit brackets, screws

and spacers see ‘Remove

Transit Brackets’ on page 5.

4. Connect supplied hoses to

appliance water supply, confirm

water is flowing before connecting

to the appliance inlet valves

see ‘Water Supply’ on page 6.

5. Untie drainage hose at rear of

appliance and connect to either

a standpipe or sink waste drainage

system see ‘Drainage’ opposite.

6. Untie mains lead at rear of

appliance and plug into

electrical supply via a switched

socket, see ‘Electrical Supply’ on

page 2.

7. Position appliance, taking care

not to kink or damage hoses

at rear of appliance.

8. Stabilise the appliance, see

‘Adjusting the feet’ opposite.

Check List

Check List

5. Adjust the Feet...This must

only be done when the machine is upright

●

Release locking rings on the two front feet.

●

Screw feet in or out until appliance is

standing firm and level.

●

Ensure all feet are in firm contact with the

floor and the machine is not leaning forward.

●

Tighten the locking rings on the front feet to the underside of the cabinet.

Note: Your appliance may become noisy or move about the floor if it has

not been stabilised.

9. Turn on the water supply

to the appliance.

10.Switch on at plug socket.

Your appliance is now ready to use,

refer to ‘Getting to Know your

Appliance’ on page 8 to familiarise

yourself with the appliance.

10 Step

10 Step

7

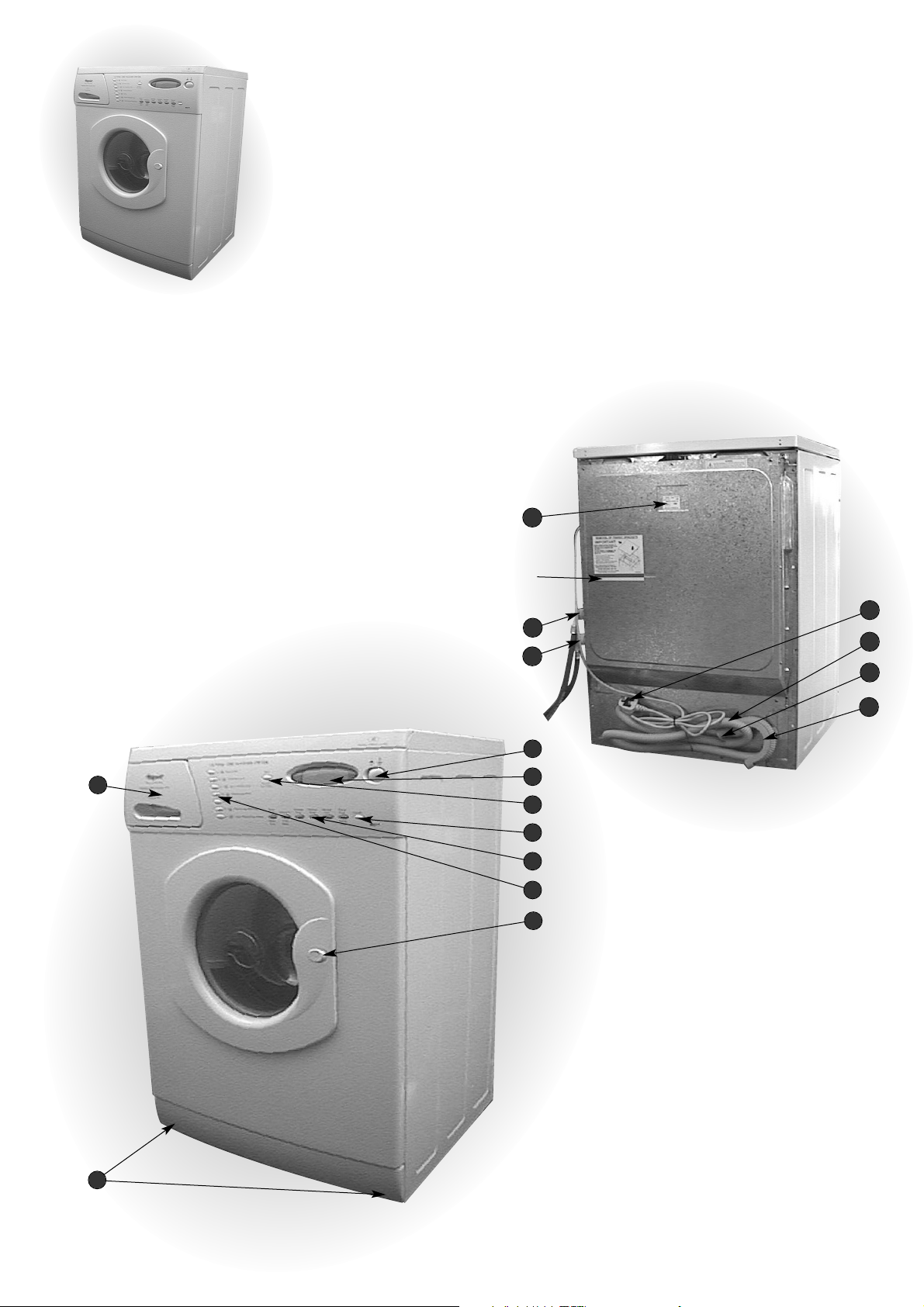

Getting to Know Your

Appliance

10

Red line indicates minimum

height of drainage hose

11

Model WD71

8

12

1

2

3

13

14

15

16

4

5

6

7

9

8

Index

Front

1. Mains On/Off Button

2. Infobubble™ Display

3. Start, Buzzer/Time Delay Button

4. Cancel Button

5. Optional Wash/Dry Feature Buttons

6. Wash Programme Buttons

7. Door Handle & Release Button

8. Detergent/Fabric Conditioner Drawer

9. Adjustable Feet

Back

10. Rating Plate

11. Hot Water Inlet Point and supplied Hose

(Red or Grey)

12. Cold Water Inlet Point and supplied Hose (Blue)

13. Mains Cable

14. Drainage Hose

15. Retaining Flaps

16. Hooked End Support

Loading...

Loading...