Hotpoint WD52 User Manual

INSTRUCTIONS FOR INSTALLATION & USE

WD52

Hotpoint recommends,for your own safety and to ensure you get the best possible results from your Washer

Dryer,you read through this booklet and follow these steps thoroughly.

Choose a location for your washer dryer,

where possible on a solid floor,with the

electrical sockets and water supply taps

easily accessible.

Allow sufficient space: 600mm width,

600m depth and 900mm height.

DO NOT install in a bath or shower

room.

Dispose of packaging material in a safe

place and remove any labels.

Please read through thoroughly to

ensure you understand each stage

before you begin.

Read the rest of these instructions to get the best from your appliance, remember to fill in your guarantee registration.

Keep these instructions in a safe place for quick reference.

STEP 1 STEP 2

A wash chart is provided to help you to

select your required programme.

Examples given for the maximum

washing load weight for different fabric

types.

STEP 4

WARNING: This appliance must be earthed.

Remember you may be charged for a service call if a

problem with your washer dryer is caused by

incorrect installation or misuse.

Electrical Guide Installation Guide

Wash Guide

Read through this section to familiarise

yourself with the different

compartments within the dispenser

drawer.

STEP 3

Dispenser Drawer

NOTE: Always follow manufacturer’s dosage

recommendations.

A guide to drying times is provided for

independent drying programmes, along

with a list of items not suitable for

tumble drying.

Examples given for the maximum drying

load weight for different fabric types.

STEP 6

Drying Guide

All available optional wash features are

explained within this section - These

allow you to adjust your selected wash

programme to suit your needs.

STEP 5

Options Guide

NOTE: In addition to the temperature of the

incoming water,the selection of optional wash

features will affect the programme times.

Hotpoint recommend the Persil range of

detergent products.

STEP 8

Troubleshooting

A picture guide provides a clear

explanation how to set a wash and auto

dry programme.

DO NOT overload the washer dryer.

STEP 7

Wash & Auto Dry Programme

NOTE: Hotpoint recommend, on completion of

your programme, that you switch off both the

electricity and water supply to the appliance.

Please refer to the Troubleshooting

section if you have any problems when

using your washer dryer.

There may be nothing wrong!

NOTE: Always make sure the mains button is in the

OFF position before selecting an independent

drying programme.

READ BEFORE

CONTACTING

SERVICE!

Electricity Supply

STEP 1

WARNING: The appliance must be earthed.

CE marking certifies that this appliance conforms to the following

EEC directives:

Low Voltage Equipment - 72/23/EEC & 93/68/EEC

Electromagnetic Compatibility - 89/336/EEC, 92/31/EEC & 93/68/EEC

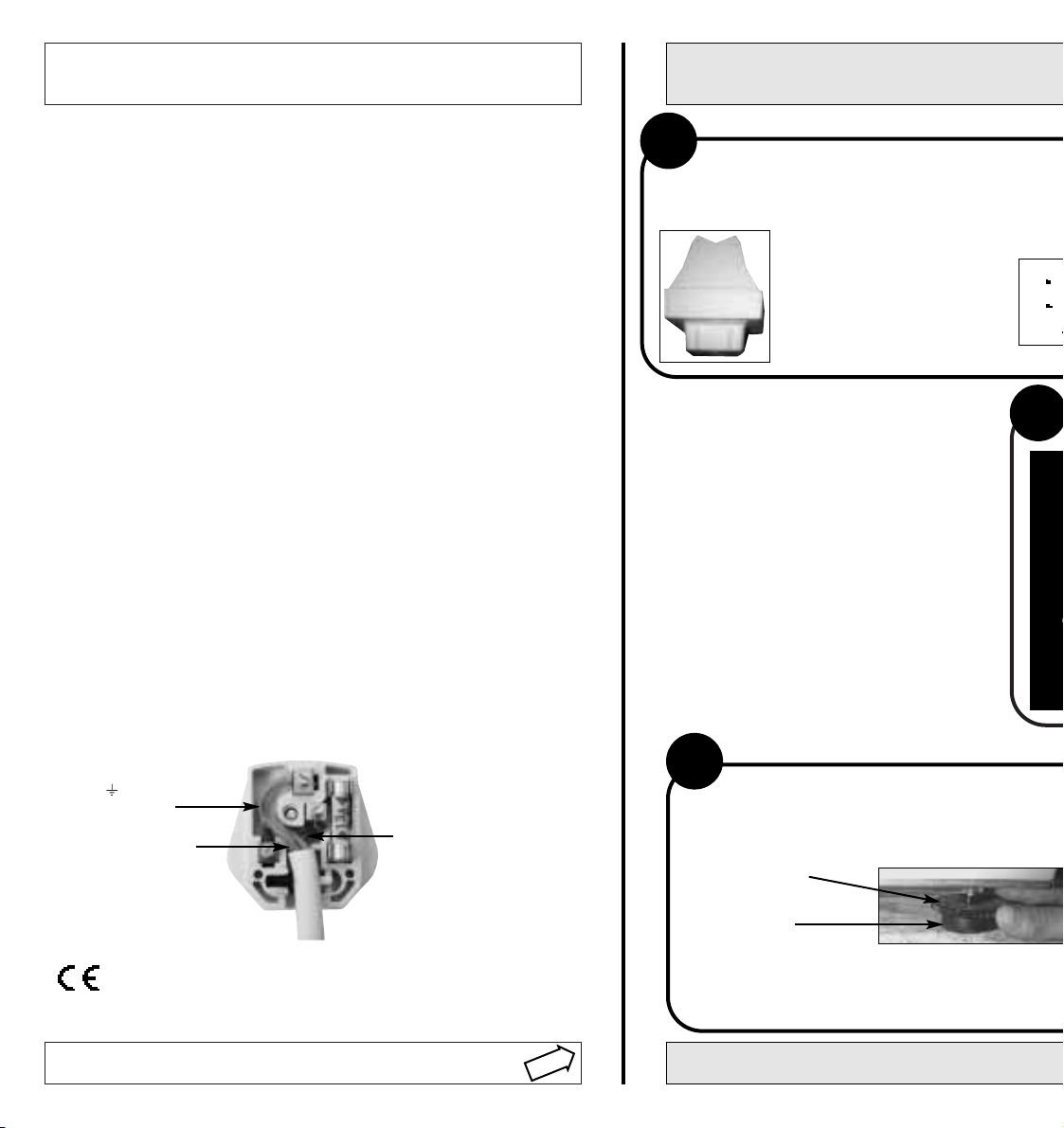

Fuses

Your appliance comes fitted with a plug and a 13A fuse. If you need to

replace the fuse,only those rated at 13A and ASTA approved to

BS1362 should be used.To change fuse lift holder to vertical position

and lift fuse out.To replace, insert fuse and push fuse holder down

into locked position. Correct replacement is identified by colour cod-

ing or the marking on base of plug.

WARNING: Do not use plug unless fuse holder is in locked position.

Changing the Mains Lead

A special lead can be ordered from Hotpoint Service

UK: 08709 066 066 or Republic of Ireland: 1850 302 200

If you have damaged the existing lead or require a longer one a

charge will be made. It is strongly advised that this work is carried out

by a qualified electrician.

Changing the Plug

Cut off and dispose of the supplied plug if it does not fit your socket.

WARNING:To avoid a shock hazard do not insert the discarded plug into

a socket anywhere else.

IMPORTANT: WIRES IN THE MAINS LEAD ARE COLOURED IN

ACCORDANCE WITH THE FOLLOWING CODE:

Green/Yellow - Earth

Blue - Neutral

Brown - Live

If you change the plug, the colour of wires in the mains lead may not

correspond with the colour of the markings identifying terminals in

the plug.You should therefore wire it as shown:

Green and yellow (Earth)

wire to terminal marked ‘E’,

symbol , or coloured

green and yellow.

Blue (Neutral) wire to

terminal marked ‘N’or

coloured black.

13A ASTAapproved fuse to

BS1362.

Brown (Live) wire to terminal

marked ‘L’ or coloured red.

4

1

POLYSTYRENE BLOCK...

5

LEVEL?...

NOTE:

MOV

ALON

WHI

YOU

HOO

LEVEL

DRA

(*see

This is part of the packaging

and should have come away

with the polystyrene base -

IF IT HAS NOT... REMOVE IT!

NOTE: YOU MAY NEED A SECOND PERSON TO HELP YOU

RAISE AND LOWER THE APPLIANCE.

YOUR MACHINE WILL BE NOISY IF THE TWO

NOT ADJUSTED SO THE MACHINE STANDS F

Each foot has two parts: The Locking Disk a

ii

i

Release the locking disk on the

two front feet and screw the feet

in or out until the machine stands

firm and level.

Turn ON

on the t

each is

of the m

Locking

Disk

Foot

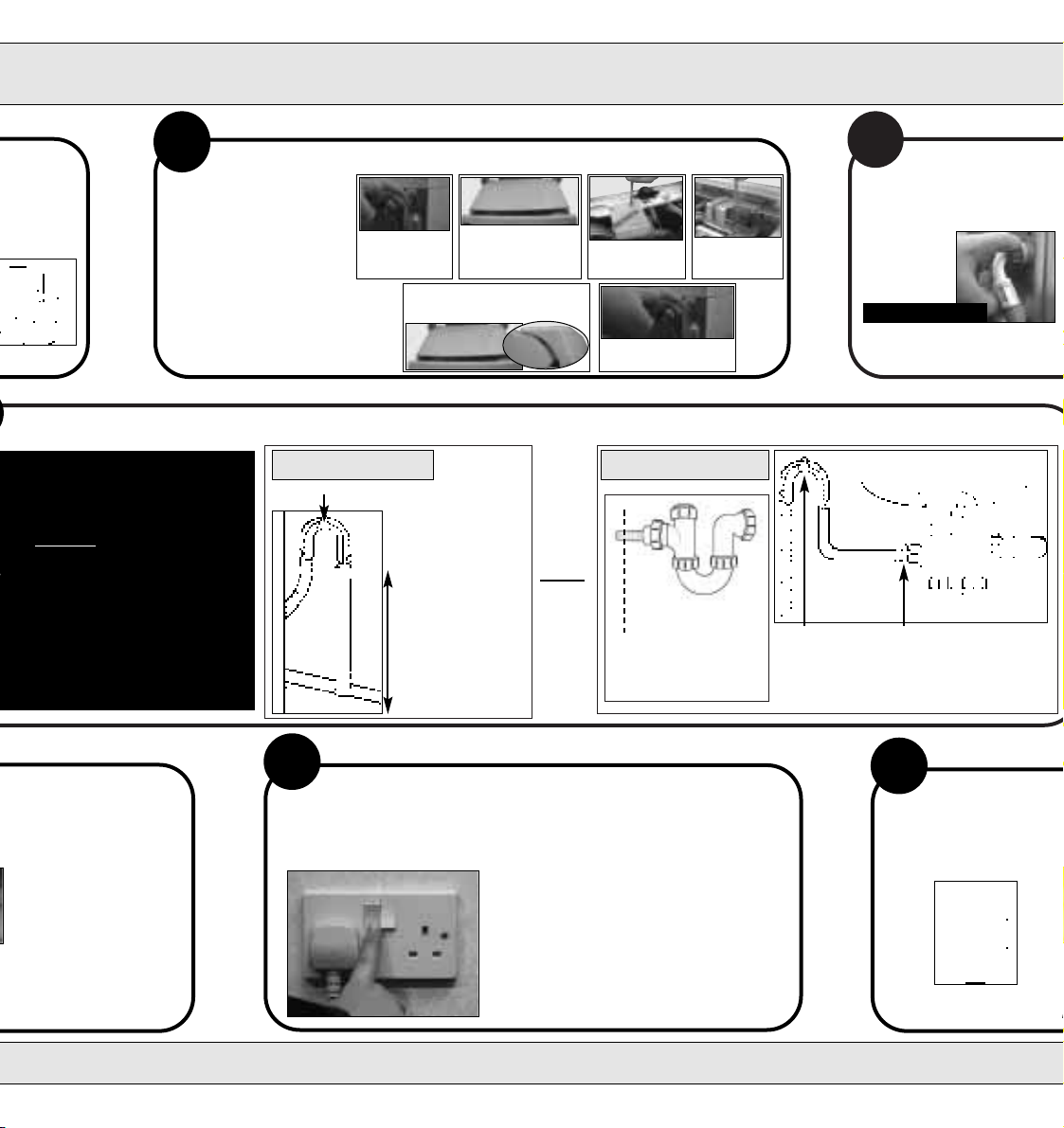

STEP 2

3

CONNECT TO THE

Installation

DRAINAGE SYSTEM...we recommend one of the following:

DO NO

T REMOVE IT.

2

REMOVE TRANSIT BRACKETS...

IMPORTANT:

Internal transit brackets

are fitted to prevent

damage during transit

and MUST be removed

before use...

Failure to do so may

cause damage to your

machine!

STANDPIPE METHOD

UNDER SINK METHOD

OR

Attach the GREY

drainage hose to the

under sink drainage

unit securely,using a

hose clip.

Fix the hooked

end support at

a minimum

800mm from

the floor.

cut off the blocked

end of the under sink

drainage unit.

7

READY...

TO CHECK ALL PARTS OF

CLEAN THE INSIDE OF YO

SELECT A 95˚ WHITE CO

6

CONNECT TO THE POWER SUPPLY...

PLUG YOUR MACHINE INTO AN ELECTRICAL SOCKET WHICH IS

EASILY ACCESSIBLE. SWITCH ON

NOTE: Hotpoint recommend

extension leads are not used.

Move your machine into position,

take care not to trap or kink the

hoses.

WITHO

THIS WILL TAKE APP

.............................

Standpipe height:

minimum 500mm

from the floor.

Insert drainage hose

approximately 100mm

into the standpipe.

✗

Slide and push worktop lid back

into position, ensuring front edge is

correctly located into the console.

Replace the work top lid

using the 3 original screws.

Remove and

retain 3 screws

from the back of

the worktop lid

From the rear of the

machine, grip sides of

the worktop lid, lift,slide

and pull towards you.

Remove 4 screws

and the rear transit

bracket - retain.

Remove 3 screws

and front transit

bracket - retain.

800mm

from floor

Hooked End Support

PLEASE USE THE NEW HOSES

SUPPLIED, FITTED TO THE

MACHINE.

Old hoses may cause leaks

due to worn out washers.

DO NOT REMOVE!

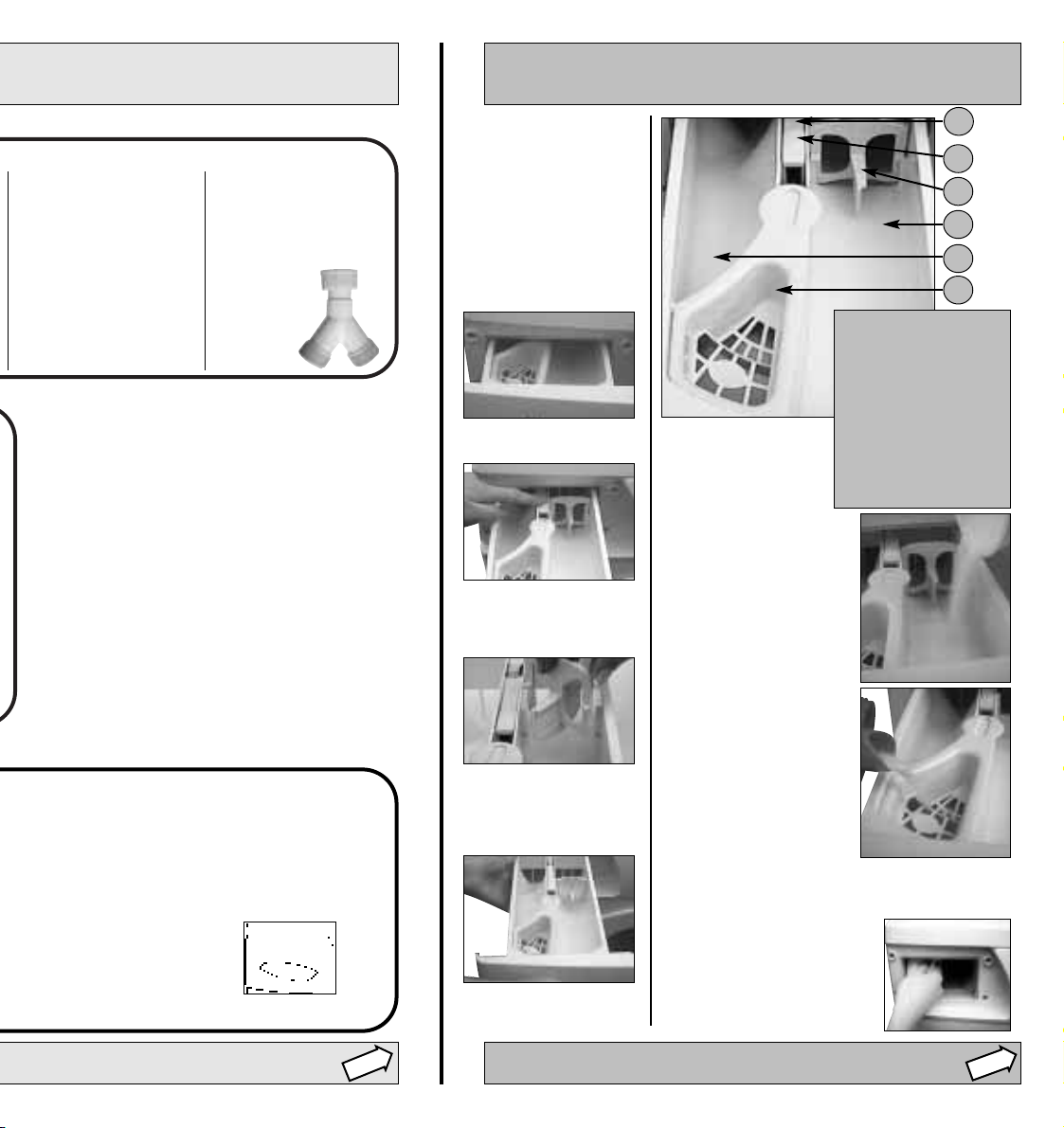

The Dispenser Drawer

STEP 3

Changing the Main

Wash Indicator:

Cleaning the Dispenser Drawer &

Compartments:

Dispensing Powder

Detergent

Dispensing Fabric

Conditioner

The main wash indicator

has been fitted to

dispense powder

detergent only.

If you wish to use liquid

detergent, reposition the

main wash indicator as

shown below:

1

ii

i

Pull the drawer out until

it reaches its stop.

2

Press down on button,

to release the drawer

latch and remove the

drawer.

4

Relocate the drawer and

push back into place.

3

Lift the main wash

indicator out of slots,

rotate and reposition for

Liquid, ensuring it is

secure.

Index:

1. Drawer latch

2. Button

3. Main wash

indicator

4. Main wash

compartment

5. Prewash

compartment

6. Fabric conditioner

compartment.

1

2

3

4

5

6

To achieve optimum wash

results we recommend that

you use the detergent

manufacturers dispensing

cup, to dispense no more

than 300ml of powder.

Pour fabric conditioner into

the compartment.

We recommend that you do

not exceed the maximum

level indicated.

It is advisable to clean the dispenser

drawer regularly:

Remove the drawer, see ‘Changing

the Main Wash Indicator’, wash

the dispenser drawer and clean

out the compartment.

Dry thoroughly and relocate.

If you have no hot water

supply...

Check both hot and

cold water supplies

are running freely...

A cold fill adaptor is

available from your local

Hotpoint authorised Service

Centre or by

calling the

Genuine

Parts &

Accessories

Hotline

(see KEY

CONTACTS).

Connect fill hoses to

water supply taps:

- Red or Grey Hose

end to Hot

- Blue Hose end to

Cold

TURN ON BOTH TAPS

WITHOUT ANY DETERGENT

and

✗

Loading...

Loading...