Page 1

Instructions

WD440

WD420

Page 2

Instruction booklet

WASHER DRYER

GB

GB

English

Contents

Installation, 2-3

Unpacking

Remove the transit fixings

Levelling

Water connections

Drainage and electrical connections

Technical details

Washer dryer description, 4-5

The front

The back

Control panel

Indicator lights

Starting and programmes, 6-9

Briefly: how to start a programme

To stop or change a programme

Programmes table

Reducing the wash temperature

Options

Drying

Automatic features

Detergents and laundry, 10

Detergent dispenser

Washcare Tips

Preparing your laundry

Precautions and Advice, 11

General safety

Disposal

Saving energy and respecting the environment

Care and Maintenance, 12

Switching off the water or electricity supply

Cleaning

Checking the water inlet hoses

Fuses

Changing the plug

Troubleshooting, 13

Service, 14

Before calling for assistance

Spare parts

1

Page 3

Installation

! Keep this instruction manual in a safe place for

future reference. Should the appliance be sold,

transferred or moved, make sure the instruction manual

accompanies the washer dryer to inform the new

owner as to its operation and features.

! Read these instructions carefully: they contain vital

information on installation, use and safety.

Unpacking

1. Unpack the machine.

2. Check whether the washer dryer has been

damaged during transport. If this is the case, do

not install it and contact your retailer.

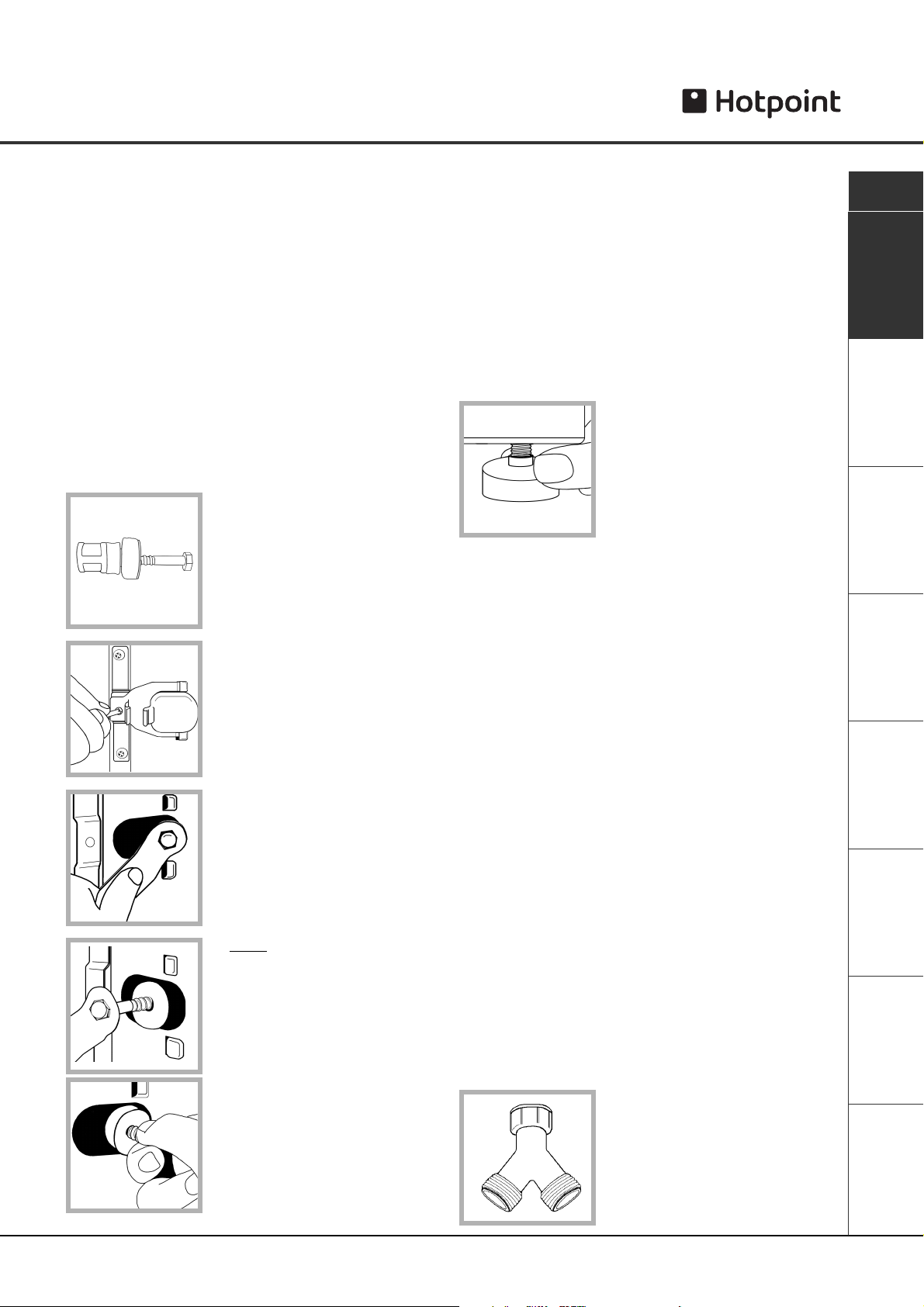

Remove the transit fixings

IMPORTANT: Follow these instructions to remove the

TWO transit fixings (see Description for location).

Situated one either side of the

rear panel, BOTH transit bolts

MUST be removed before use.

! Failure to do so may cause

damage to your machine.

It is important the transit bolt

and spacer (see pic) come out

intact.

1. Use a crosshead screwdriver to remove the yellow plastic

cover.

2. Unscrew the bolt using a

13mm spanner.

●

repeat steps 1 to 5 to remove the second transit

bolt.

! Packaging materials are not children's toys.

Levelling

Your machine will be noisy if the two front feet are not

adjusted so that the machine stands firm and level.

! The inclination of the machine, measured on the

top, must not exceed 2˚.

1. Move your machine into its final location.

- Take care not to trap or kink the hoses.

2. Turn one or both front feet

clockwise until the machine

stands firm and level. The

spring on each foot will stop

them coming loose.

If it is placed on a fitted or loose carpet, adjust the

feet in such a way as to allow enough room for

ventilation beneath the machine.

Water connection

Connecting the water inlet hoses.

Remember, please use the new hoses supplied, fitted

to the machine. Old hoses may cause leaks due to

worn out washers or may split due to water pressure.

1. Before making connections to both hot and cold

water supplies, allow the water to run freely from the

supply tap until it is perfectly clear.

2. Connect the new fill hoses to the water supply taps:

- Red or Grey hose end to Hot

- Blue Hose end to Cold

3. Turn both supply taps on and check for leaks,

tighten if necessary.

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

Precautions and

advice

Maintenance Troubleshooting Service

Care and

3. STOP

be seen.

4. Hold, slide and pull to remove.

5. For safety, replace both

yellow plastic covers over the

holes left by removing the two

bolts.

when 3 threads can

! Make sure there are no kinks or bends in the hoses.

! The water pressure at the tap must be within the

values indicated in the Technical details table (next

page).

! If the water inlet hoses are not long enough, contact

a specialist store or an authorised serviceman.

! Always use new hoses.

! Check the water hoses at least once a year, replace

any that are cracked as worn hoses could split under

water pressure.

! If you have no hot water

supply, a ‘Y’ piece adaptor is

available from your local

Hotpoint authorised Service

Centre or by calling the

Genuine Parts & Accessories

Hotline (see KEY CONTACTS).

2

Page 4

Installation

GB

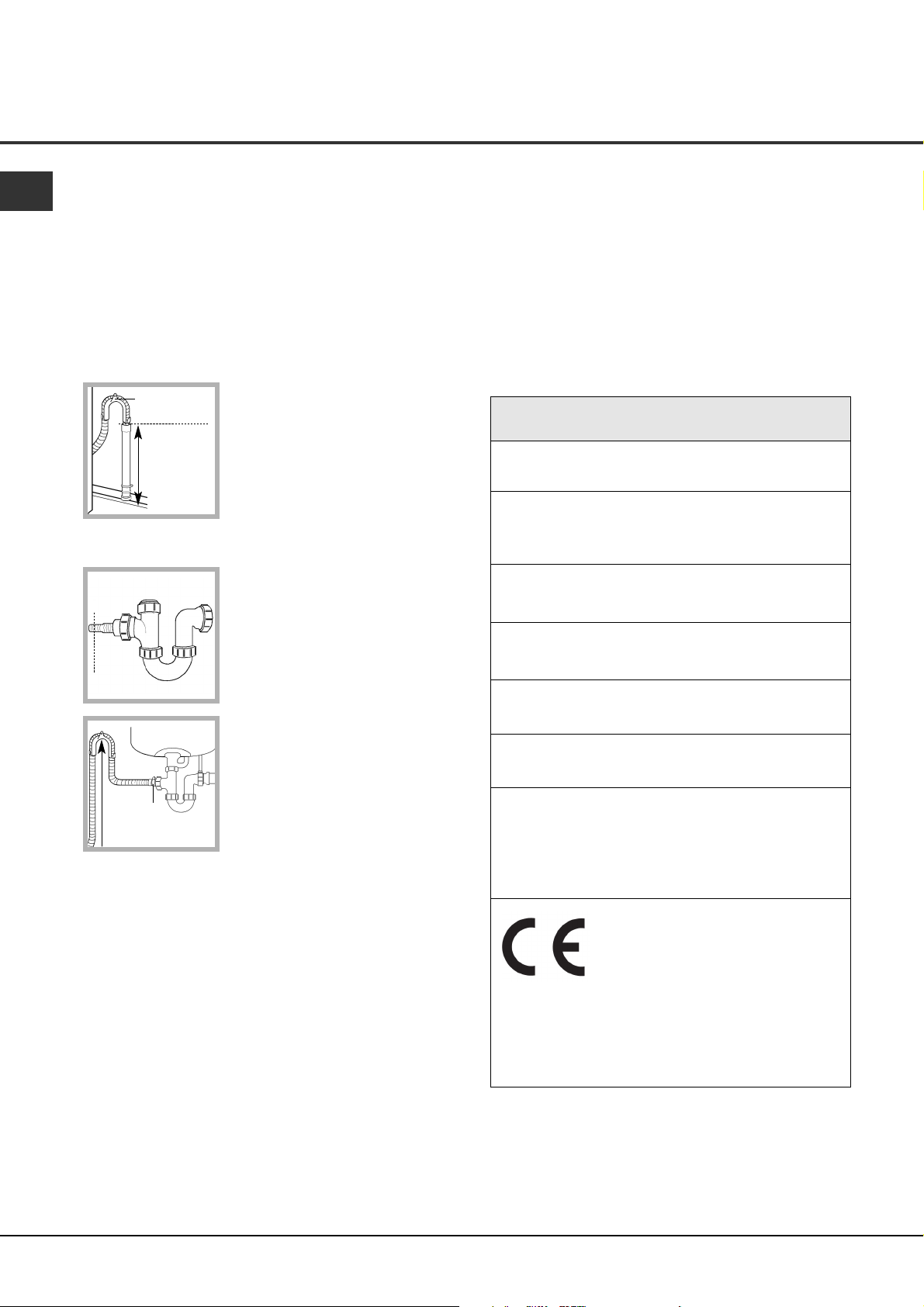

Drainage connections

We recommend one of the following:

! Although you may need to move the hooked end

support along the grey drainage hose, DO NOT

remove it.

! Whichever drainage method you use, make sure that

the hooked end support is fixed level to, or above the

‘Plumbing Indicator Line’ (see Description).

Standpipe method:

Hooked end

support

minimum:

500mm

Under sink method:

1. Make sure the standpipe

height is a minimum 500mm from

the floor.

2. Insert the drainage hose

approximately 100mm into the

standpipe.

1. Cut off the blocked end of the

under sink drainage unit.

! When the machine is installed, the mains socket

must be within easy reach and should be connected

to a suitable electrical supply.

! Do not use extensions or multiple sockets.

! The power supply cable must never be bent or

dangerously compressed.

! The power supply cable must only be replaced by

an authorised serviceman.

! The company denies all liability if and when these

norms are not respected.

Technical Details

Models WD440,

WD420

59.5cm wide

Dimensions 85cm high

60cm deep

Capacity from 1 to 6kg Wash

from 1 to 5kg Dry

2. Fix the hooked end support a

minimum of 800mm from the

floor.

Hose clip

minimum:

800mm

from floor

3. Use a hose clip to securely

attach the grey drainage hose

end to the under sink drainage

unit using a hose.

Electrical connections

Before plugging the appliance into the mains socket,

make sure that:

●

the socket is earthed and in compliance with the

applicable law.

●

the socket is able to sustain the appliances

maximum power load indicated in the Technical

Details table (on the right).

●

the supply voltage is included within the values

indicated in the Technical Details table (on the right).

●

the socket is compatible with the machines plug.

If this is not the case, replace the socket or the

plug.

! The machine should not be installed in an outdoor

environment, not even when the area is sheltered,

because it may be very dangerous to leave it exposed

to rain and thunderstorms.

Electric voltage 220/230 Volts 50Hz

connections maximum absorbed power 1700W

Water maximum pressure 1 MPa (10 bar)

connections minimum pressure 0.05 MPa (0.5 bar)

Spin Speed up to 1400 rpm - WD440

up to 1200 rpm - WD420

Control programme D

programmes temperature 60˚C

according to

IEC456 - Wash run with a 6kg load

directive - Dry run with 5kg & 1kg loads

This appliance is compliant with the

following European Community

Directives:

- 72/23/EEC & 93/68/EEC

(Low Voltage) and subsequent amendments.

- 89/336/EEC,92/31/EEC & 93/68/EEC

(Electromagnetic Compatibility) and subsequent

amendments.

The first wash cycle

Once the appliance has been installed and before you

use it for the first time, run a wash cycle without

detergent and no laundry, setting the 95˚C

programme B without a pre-wash cycle. This will take

approximately 2 hours 30 minutes to complete.

3

Page 5

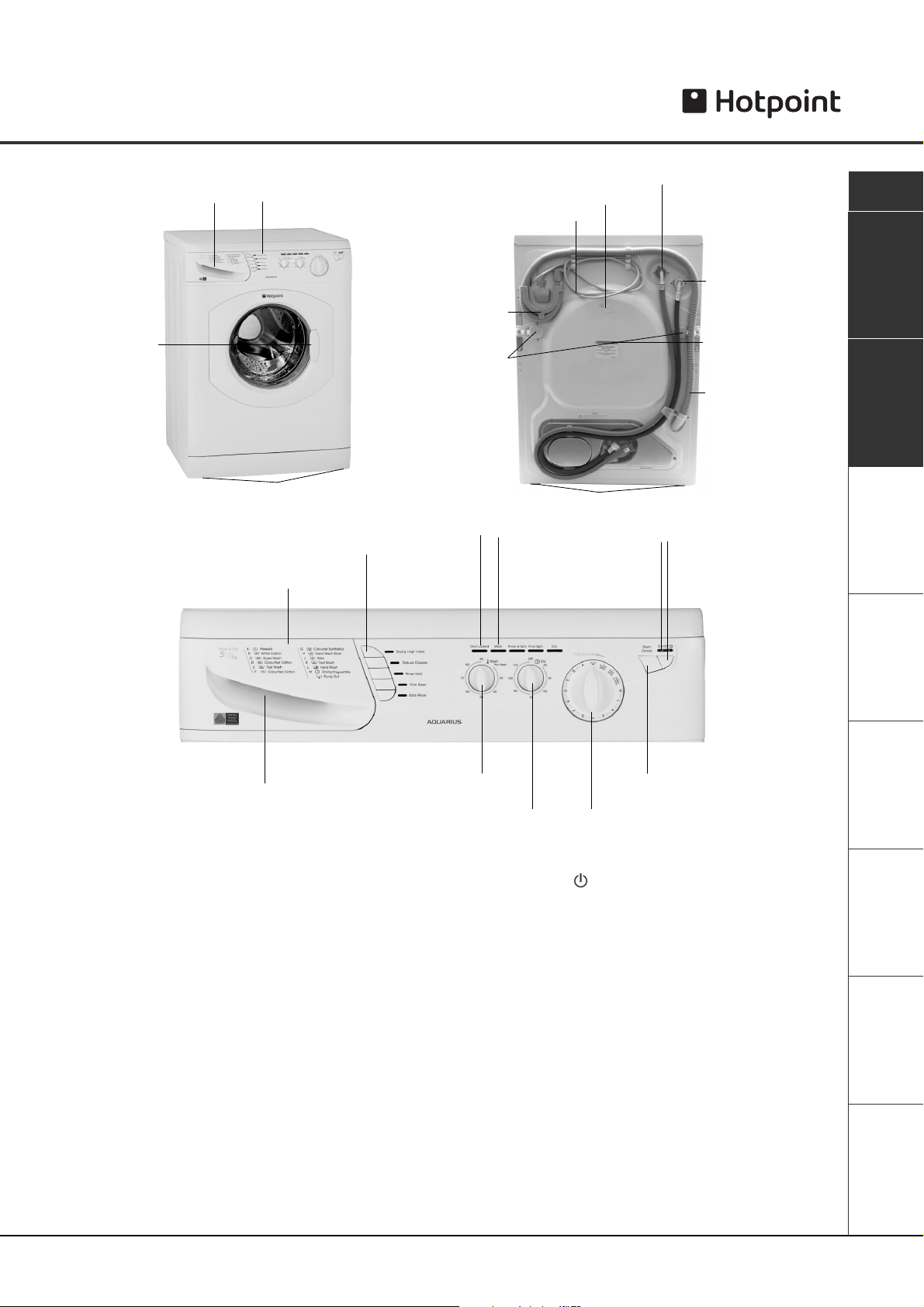

Washer Dryer Description

The front The back

Dispenser Drawer

Interlocking

door and

release lever

Front Adjustable Feet

Control Panel

Mains cable

Hooked end

support

Two transit fixings,

located under yellow

plastic covers, one

either side of the rear

panel.

(! both must be

removed before using

your machine).

Control panel

Buttons and lights

Programme listing

OPTION

DOOR LOCKED

Indicator light

PROGRESS

Indicator lights

Rating Plate

Rear Feet

ON/OFF

Light

Hot water inlet point and

supplied hose

(Red or Grey end)

Cold water inlet

point and supplied

hose (Blue end)

Plumbing

Indicator Line

Drainage Hose

ON/OFF

Button

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

VARIABLE TEMPERATURE

Detergent dispenser

Detergent dispenser: To add detergent and fabric

softener (see Detergents and Laundry).

Programme listing: To consult a straightforward

chart of the different programmes available.

PROGRESS Indicator lights: To find out which cycle

phase is under way. The corresponding light for the

cycle in progress is illuminated.

DRYING TIMES dial: To set the drying time. The knob

stays still during the cycle. When the programme has

finished, return the dial to its original setting.

OPTION buttons: To select the options available (see

Personalisation).

OPTION lights: When an option is selected, the

corresponding light is illuminated.

VARIABLE TEMPERATURE dial: To reduce the

selected programmes wash temperature (see

START/CANCEL

Dial

DRYING TIMES

Dial

Personalisation). When the programme has finished,

return the dial to its original setting.

ON/OFF button: To turn the machine on and off.

ON/OFF light: Signals that the machine is in use or

ready to select a programme

START/CANCEL button: To start the programme or

cancel any incorrect settings.

DOOR LOCKED Indicator light: When lit your selected

programme is in progress and the door cannot be

opened. The door can be opened when the programme

has finished and this light has switched off.

This light will also flash to indicate the door has not

been shut properly.

PROGRAMME SELECTOR dial: To select the

programme you require. The knob stays still during

the cycle.

PROGRAMME SELECTOR

Dial

Button

Precautions and

advice

Maintenance Troubleshooting Service

Care and

4

Page 6

Washer Dryer Description

GBGB

PROGRESS INDICATOR lights:

These will light up to indicate the

progress of the selected

programme.

When the programme is started the light corresponding

to the first cycle is lit and as the programme

progresses, successive lights will come on until the

programme finishes.

OPTION buttons / lights:

When an option is selected, the

corresponding light is illuminated.

DOOR LOCKED light:

This light will come on two seconds after the

Start/Cancel button has been pressed and will stay lit

throughout the programme.

If this light is on, the appliance door is locked to

prevent it from being opened accidentally; to avoid

any damage. Wait for the light to go out before you

open the door.

! The DOOR LOCKED light will flash to indicate the

door has not been closed properly and the selected

programme will not start. Push the door shut until you

hear the catch click, the DOOR LOCKED light will

stop flashing and the selected programme will start.

●

If the option selected is incompatible with the

programme set, the button will flash and the option

will not be enabled.

●

If you set an option that is incompatible with an

option selected previously, only the last option

selected will be enabled.

5

Page 7

Starting and Programmes

On-Off / Selecting a programme

To stop or change a programme

1. Switch the machine on by pressing the ON/OFF

button , for 2 seconds. All the indicator lights

will light up for a few seconds and the DOOR

LOCKED indicator light will flash once.

2. Load your laundry into the machine and shut the

door.

3. Add the detergent and any fabric softener (see

Detergents and Laundry).

4. Turn the PROGRAMME SELECTOR dial to the

required programme.

5. Select any options you require (see Personalisation).

6. If no drying cycle is required (ie. wash programme

1. Press the Start/Cancel button for 2 seconds

2. Select ‘Pump Out’ on the programme selector

dial.

3. When the machine has finished emptying, turn the

programme selector dial to the new programme

required, you may need to add detergent (see

Detergents and Laundry).

4. Press the Start/Cancel button for 2 seconds to

start the programme.

! If you cancel a hot wash programme, take care

when removing the laundry, it might still be very hot.

only) ensure that the Drying Times dial is set to ‘Off’.

7. Press the Start/Cancel button for 2 seconds to

start the programme.

IMPORTANT INFORMATION: The temperature of the incoming water supply,load size and selection of any Optional Wash Feature,

ie.Time Saver, will affect the programme times*.

Programmes Fabric Temp. Max. Approx. Spin

table ˚C dry programme speed

A

B

C

D

E

F

G

G

H

Wash weight time*

label load

Mixed Prewash 30 6kg 20 minutes Slow

White Cotton & Linen

without special finishes. 95 6kg 2 hours 30minutes Fast

Super Wash 60 6kg 2 hours 20minutes Fast

White Cotton & Linen

Colourfast Cotton, Linen

or Viscose without special 60 6kg 2 hours Fast

finishes.

Fast Wash

Colourfast Cottons & Linen 60 5kg 1 hour Fast

Colourfast Cottons,

Linen & Viscose 40 6kg 1 hour 45minutes Fast

Coloured Synthetics:

coloured Nylon, Polyester,

Acrylic and Cotton mixtures,

Cotton or Viscose with special 50 3kg 1 hour 10minutes Slow

finishes,

coloured Polyester and Cotton

mixtures.

Acrylics: Set the wash temperature to 40˚C using the Variable Temperature dial.

Acrylics and tri-acetate 40 3kg 1 hour Slow

blends of these fabrics with

Wool,Polyester and Wool blends.

Handwash Wool 40 1kg 45minutes Slow

WEIGHT OF

WASH LOAD

Two examples of

maximum wash loads

for different types of

fabric:

COTTON

2 Bath Towels

1 Hand Towel

6 Shirts

6 Blouses

1 Sets of Pyjamas

4 Items of

Underwear

= 6kg

SYNTHETIC

2 Children’s Dresses

4 Shirts

4 Blouses

1 Sets of Pyjamas

4 Items of

Underwear

= 3kg

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

Precautions and

advice

Maintenance Troubleshooting Service

Care and

J

K

L

M

Rinse and Spin Mixed 3kg 30minutes Slow

Fast Spin Cotton 6kg 15minutes Fast

Slow Spin Delicates 3kg 13minutes Slow

Pump Out All 2minutes

Silks 30 3kg 55minutes Gentle

Fast Wash 30 3kg 30minutes Slow

Handwash 25 3kg 45minutes Gentle

Drying Programmes Options: select Drying High Heat for cottons.

Handwash Wool Approved

‘The wool wash cycle on

Hotpoint machines has been

tested and approved by the

Woolmark Company for

washing garments labelled

as “hand wash”, provided that

the garments are washed in

accordance to the instructions

issued by the manufacturer

of this machine.’

Note: We recommend

using a wool wash liquid

when using Programme H.

6

Page 8

Personalisation

GB

Reducing the temperature

Use the ‘Variable Temperature’ dial, to reduce

programme wash temperature.

If you leave this dial on the maximum position (95),

the actual wash temperature will be the maximum that

is appropriate for the wash programme you have

chosen.

●

When the programme has finished, return the dial

to its original setting.

Option table

Option

Drying High

Heat

Reduce

Creases

Effect

Allows you to

select HIGH heat

for tumble drying.

Reduces wash

action and spin

speed.

Comments

Default is low heat.

Meaning less ironing for delicate clothes.

Optional Features

Button selection:

1. press the button corresponding to the desired

option, according to the table below.

2. the option is selected when the corresponding

LED is illuminated.

Available with

programmes

B,C,D,E,F

& M

C, E, G

plus

Rinse and Spin

Rinse Hold

Time Saver

Extra Rinse

Clothes will be

held in the final

rinse water,

keeping them

fresh until you are

ready to complete

the programme.

Reduces

programme time.

Adds one extra

rinse cycle.

Complete the final spin by pressing the Rinse Hold button

when the light is flashing.

Saves up to a third on the programme time.

For larger wash loads, to wash items for young children and

people with sensitive skin.

Remember - you will use more water than with a standard

cycle.

B, C, D, F, G, J

plus

Rinse and Spin

B, D and G

B, C, D, E, F, G

plus

Rinse and Spin

7

Page 9

Drying

Drying programmes

Independent drying only programme:

1. Remove the wet laundry and in drum dosing ball

(if used) until the correct ‘Drying Weight Load’

(see table below) is left in the drum.

Close the door until it clicks shut.

2. Turn the programme selector dial to drying

programme M (see Programmes).

3. Select HIGH heat, if drying cottons by pressing

the Drying High Heat option button: the

corresponding light will show selection.

4. Turn the Drying Times dial to the required time.

5. When all selections have been made press the

Start/Cancel button. The door will lock.

6. A short time after the programme has finished the

DOOR LOCKED indicator light will go out and the

door can be opened.

Drycare tips

Items not suitable for tumble drying:

●

Garments with the ITCL code - DO NOT

TUMBLE DRY.

●

Woollens.

●

Large, bulky items eg. quilts, bedspreads,

pillows etc... expand when dry, preventing air

flow through the appliance.

●

Items containing plastic film, foam rubber or

rubber like materials eg. pillows, cushions, PVC

rainwear or inflammable articles which contain

inflammable substances eg. towels contaminated

with hair lacquer.

●

Fibreglass (eg. some types of curtains).

●

Items which have been dry cleaned.

Important information:

! To improve the life expectancy of your machine,

it is recommended that you do not stop or cancel

your programme during the drying cycle.

! It is recommended that you allow the programme to

complete its full cycle, which includes completing the

‘cool tumble’ (see below).

A 20 minute ‘cool tumble’ is included at the end

!

of drying, allowing fabrics to cool down, minimising

creasing - The load may still be warm when

removed from the machine.

! If your machine is not permanently plumbed in, turn

on the cold water supply and hook the drain hose

over the sink to enable the condensing action to

work.

! The dryer is intended for use only where water is

used for the cleaning process.

! Be careful not to touch the drum at the top as this

area does get hot during drying.

! On no account should liquid fabric conditioner be

added during the drying process.

! Misuse of the dryer may create a fire hazard.

Select HIGH heat by pressing the Drying High

!

Heat option button. If this option is not selected

the programme will automatically default to LOW

heat.

!

A spin cycle may be carried out during the

drying programme.

!

Your machine is fitted with a revolutionary selfclean filter, which will flush with water during

drying - therefore you may hear water entering the

machine during the drying cycle.

!

The Drying Times dial DOES NOT rotate - Return

the dial to the ‘Off’ position at the end of each

drying cycle.

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

Precautions and

advice

Drying table

Fabric Programme Dry Weight load Heat setting Time Setting*

(approx)

Cottons

Synthetics

●

It is recommended that you separate your drying loads into similar fabric types,

B,C,D,E & F

G & K

5kg max.

3kg max.

HIGH

LOW

max.

3 hours

max.

2 hours

as this will increase the drying efficiency.

DRYING WEIGHT

LOADS

Two examples of typical

loads for drying different

types of fabric:

COTTON

2 Bath Towels 4 Items of

6 Shirts Underwear

6 Blouses 2 Pillow cases

2 Sets of Pyjamas

SYNTHETIC

3 Children’s Dresses 2 Sets of

5 Shirts Pyjamas

6 Blouses 4 Items of

= 5kg

*for smaller loads

reduce the drying

time accordingly.

Underwear

= 3kg

8

Maintenance Troubleshooting Service

Care and

Page 10

Drying

GB

A wash and dry programme:

1. Sort your laundry into groups with the same wash

and dry care labels.

2. Load the machine, making sure that items are not

trapped in the door. Close the door by pushing it

until it clicks.

3. Add detergent and fabric conditioner (if required), to

the dispenser drawer. Refer to the detergent

manufacturer’s dosage instructions.

4. Switch the machine on by pressing the ON/OFF

button . The DOOR LOCKED indicator light will

illuminate.

5. Turn the Programme Selector dial to the desired

wash programme (see Programmes).

6. Select any optional wash feature(s) that you may

require by pressing the appropriate button/s (see

‘Personalisation Option Chart’ ).

The corresponding light will illuminate to show

what you have chosen.

7. Turn the Drying Times dial to the required time.

8. Reduce the selected programmes wash temperature

(if required) by turning the Variable Temperature

dial.

9. Press the Start/Cancel button to begin the

programme.

- During the programme, progress indicator lights

will illuminate to indicate what stage in the cycle

the programme has reached.

10.A short time after the programme has finished the

DOOR LOCKED indicator light will go out and the

door can be opened.

- Take out your laundry and leave the appliance

door ajar to allow the drum to dry thoroughly.

- Return the Drying Times dial to its ‘Off’ position.

- Turn the machine off by pressing the ON/OFF

button .

We also recommend that you switch off the

!

electricity and water supply.

Automatic features

Auto half load:

Auto half load saves you time and money when

washing smaller loads.

Water levels are automatically adjusted to cater for the

different loads.

Unbalanced load:

Your machine has an inbuilt feature to prevent it

spinning with an unbalanced load. If the machine is

unable to balance the load it will abort the spin

process.

If this safety feature is encountered you can spin the

load, after first opening the door, redistributing the

load and selecting a spin only programme.

! Do not allow children to play with the appliance or

tamper with the controls.

! Do not overload the appliance. It may damage the

laundry and reduce the quality of the wash.

! When in operation, remember that the door glass

may become hot to the touch.

! Do not open the dispenser drawer during any

programme.

! Do not try to open the door when the DOOR

LOCKED indicator light is on.

! If you stop a programme part way through a wash or

there is a power cut, take care when opening the door

the machine may contain hot water.

9

Page 11

Detergents and Laundry

Detergent dispenser

! Do not put any items into the drawer, other than

detergents designed to be released from the drawer,

as they may cause damage or blockage.

1

2

3

4

5

1 Drawer release catch.

2 Pre-wash detergent compartment:

Maximum 200ml powder or

100ml liquid

3 Main wash detergent compartment:

Maximum 400ml powder

or 200ml liquid

4 Grate

5 Fabric conditioner compartment:

Maximum 120ml

Dispensing powder detergent

To achieve the best wash results the manufacturer’s

recommended amount of detergent should be

measured and added to the main detergent

compartment.

Dispensing liquid detergent

We recommend the use of a detergent dosing ball,

as provided by your detergent manufacturer.

Adding fabric conditioner

Pour the recommended amount of fabric conditioner

into the compartment. Do not exceed the maximum

fill line.

Pre-Wash programme A

When selecting programme A, add detergent to both

the pre-wash and the main wash compartments.

! DO NOT use in drum dosing devices with Pre-wash

programme A.

How much does your laundry weigh?

1 sheet 400-500g

1 pillow case 150-200g

1 tablecloth 400-500g

1 bathrobe 900-1200g

1 towel 150-250g

Washcare Tips

●

Do not overload the machine (maximum load:

Wash 6kg and Dry 5kg), in addition to reducing

the quality of the wash this may also damage you

laundry and the machine.

●

We strongly recommend that you do not wash

underwired bras in this machine. Should the wires

become detached it could cause damage to your

laundry and the machine. If the washcare label

states that the bra is machine washable, then we

advise placing it in a sealed pillow case or a

similar washbag.

Remember you will be charged for a service call

!

resulting from a detached bra wire.

●

Do not use the machine if the item to be washed

does not have a wash label.

Before washing laundry we recommend you:

●

Pre-treat awkward stains with washable treatments.

Do not wash any items that have previously been

treated with solvents.

●

Close zips, fasten belts, tie strings and close

press studs to prevent tangling.

●

Empty all objects from pockets as they may

damage the laundry and the machine.

Remember you will be charged for a service call

!

to rectify malfunction resulting from objects such

as coins, pens, hair grips etc. falling from pockets.

●

Limit the size of absorbent loads ie. towels, to 3kg

(7lb) to give good washing and rinsing results.

●

Place small items in a wash bag.

●

Always follow the care label on items when

choosing the wash programme.

●

Wash non-colourfast items or really dirty items

separately as they may affect other laundry.

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

Precautions and

advice

Maintenance Troubleshooting Service

Care and

10

Page 12

Precautions and advice

GB

! The machine was designed and built in compliance

with the applicable international safety regulations.

The following information is provided for your safety

and should consequently be read carefully.

General safety

●

This machine should only be used by adults and

in accordance with the instructions provided in this

manual.

●

Do not overload the machine.

reducing the quality of the wash, this may also

damage your laundry and the machine.

●

Never touch the machine when barefoot or with

wet or damp hands or feet.

●

Do not pull on the power supply cable to unplug

the appliance from the electricity socket. Pull the

plug out.

●

Do not open the machine door while the

appliance is in operation.

●

Do not open the detergent dispenser while the

appliance is in operation.

●

Do not touch the drain water as it could reach very

high temperatures.

●

Never force the machine door: this could damage

the safety lock mechanism designed to prevent

any accidental opening.

●

In the event of a malfunction, do not under any

circumstances touch internal parts in order to

attempt repairs.

●

Always keep children well away from the

appliance while in operation. Do not let children

play with the machine or tamper with the controls.

In addition to

Saving energy and respecting the

environment

Environmentally-friendly technology

If you only see a little water through your appliance

door, this is because thanks to the latest Hotpoint

technology, your machine only needs less than half

the amount of water to get the best results: an

objective reached to respect the environment.

Saving on detergent, water, energy and time

●

To avoid wasting resources, the machine should

be used with a full load. A full load instead of two

half loads allows you to save up to 50% on energy.

●

The pre-wash cycle is only necessary on

extremely soiled garments. Avoiding it will save

on detergent, time, water and between 5 and

15% energy.

●

Treating stains with a stain remover or leaving

them to soak before washing will cut down the

need to wash them at high temperatures.

A programme at 60˚C instead of 90˚C or one at

40˚C instead of 60˚C will save up to 50% on

energy.

●

Use the correct quantity of detergent, depending

on the water hardness, how soiled the garments

are and the amount of laundry you have, to avoid

wastage and to protect the environment: despite

being biodegradable, detergents do contain

ingredients that alter the natural balance of the

environment. In addition, avoid using fabric

softener as much as possible.

●

If you use your machine between late in the

afternoon and the early hours of the morning, you

will help reduce the electricity board’s peak load.

Recycling and Disposal information

●

The appliance door tends to get quite hot during

the cycle.

●

Should it have to be moved, proceed with the

help of two or three people and handle it with the

utmost care. Never try to do this alone, because

the appliance is very heavy.

●

Before loading your laundry into the machine,

make sure the drum is empty.

●

In the unlikely event of something not working see the Troubleshooting section.

11

As part of Hotpoint’s continued commitment to helping

the environment, Hotpoint reserve the right to use

quality recycled components to keep down customer

costs and minimise material wastage.

●

Please dispose of packaging and old appliances

carefully.

●

To minimise risk of injury to children, remove the

door and plug - then cut off mains cable,flush with

the appliance. Dispose of these parts separately to

ensure that the appliance can no longer be

plugged into a mains socket, and the door cannot

be locked shut.

Page 13

Care and maintenance

Switching off the electricity

●

Turn off the water tap after every wash. This will

limit the wear of your appliances water system

and also prevent leaks.

●

Unplug your appliance when cleaning it and

during all maintenance operations.

Cleaning

Cleaning the exterior

Use a damp cloth or silicon polish to clean the exterior

surfaces of the appliance.

Cleaning the dispenser drawer and compartments

It is advisable to clean the dispenser drawer regularly.

! Do not try to clean any part of the dispenser drawer

while the machine is running.

1. Pull out the drawer until it reaches its stop.

2. Press the drawer release

button to remove the dispenser

drawer (see pic).

Cleaning the door bowl

Clean the internal surface of the door bowl regularly

with a soft cloth. A build up of soap powder and water

hardness residue may result in water leaking from the

door.

●

Always leave the appliance door ajar to prevent

unpleasant odours from forming.

Checking the water inlet hoses

Check the water fill hoses at least once a year. If you

see any cracks, replace them immediately:

during the wash cycles, high water pressure could

cause a cracked hose to split open.

! Never use hoses that have already been used.

Moulded plug

! The plug must not be used

without the fuse cover in place.

If a replacement fuse

holder/cover is required, it must

be of the same colour coding or

wording as shown on the base

of the plug.

Replacements are available

from authorised dealers.

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

3. Clean and dry the dispenser

drawer, syphons, grate and

fabric conditioner exit channel

(A). Also regularly clean the

outlet pipe area (B).

A

B

4. Relocate the dispenser drawer and push it firmly

back into place.

! Do not clean any part of the machine with abrasive

cleaners, scouring agents, acids, any bleach or metal

polish as they may cause damage.

! We recommend a maintenance wash 2 or 3 times a

year, to avoid a build up of greasy deposits and

water hardness residue. Run Programme B, without

laundry and without detergent.

●

Where the drying only option is regularly used, do

this on a monthly basis.

Changing the plug

The wires in the power cord are coloured in accordance

with the following:

Green and Yellow

(Earth) wire to terminal

marked ‘E’, symbol ,

or coloured green and

yellow.

Blue (Neutral) wire to

terminal marked ‘N’ or

coloured black.

Cord clamp

13A ASTA approved

fuse to BS1362.

Brown (Live) wire to

terminal marked ‘L’ or

coloured red.

! If the plug being replaced is a non-rewirable type,

then the cut-off plug must be disposed of safely.

DO NOT leave it where it can be inserted into a socket

and create a shock hazard.

! The power supply cord should be checked periodically

and replaced by a cord specially prepared for this

machine and fitted only by authorised technicians (see

Service). New or longer power cords are supplied at

an extra charge by authorised dealers.

! The manufacturer denies any responsibility should

any of these rules not be followed.

! If in doubt about any of the above consult a

qualified electrician.

Precautions and

advice

Maintenance Troubleshooting Service

Care and

12

Page 14

Troubleshooting

GB

One day your machine seems not to be working. Before you call your Service Centre (see Service), go through the

following troubleshooting suggestions:

Problem: Possible causes / Solution:

The machine won’t start?

The wash cycle won’t

start?

The machine fails to fill

with water?

The machine does not

drain or spin?

●

Check the appliance is fully plugged into the socket and switched on.

●

Is the socket ok? Try another appliance in the socket to check.

●

Is the fuse in the plug ok? If not, replace it (see Care and Maintenance).

●

There has been a power failure.

●

The appliance door is not shut properly.

●

The ON/OFF button has not been pressed, for at least 2 seconds.

●

The Start/Cancel button has not been pressed for at least 2 seconds.

●

The water supply taps are not turned on.

●

The water inlet hoses are not connected to the tap.

●

The hoses are kinked.

●

The water supply taps are not turned on.

●

There is a water shortage.

●

The water pressure is insufficient.

●

The Start/Cancel button has not been pressed, for at least 2 seconds.

●

There has been an unbalanced load and the machine could not spin

(see ‘Automatic Features’, Starting and Programmes).

●

Has the drain hose been installed correctly (see Installation)?

●

Are the drain hose, standpipe or undersink connections blocked?

●

Has ‘Rinse Hold’ option been selected? If so press the Rinse Hold button.

The machine makes a

noise or vibrates too much

during the spin cycle?

The machine leaks?

The laundry is not dry after

using the dry programme?

Steam is coming from the

dispenser drawer

There is too much foam?

The detergent dispenser

will not close properly or is

collecting water?

●

The transit fixings were not removed correctly (see Installation).

●

The washing machine is not level (see Installation).

●

The washing machine is closed in, between furniture cabinets and the

wall (see Installation).

●

Check all loose items, such as coins were removed from the laundry.

●

The water inlet hoses are not connected correctly (see Installation).

●

Is your water pressure within limits?

●

The detergent dispenser is obstructed, clean it (see Care and Maintenance).

●

The drain hose is not secured properly or is blocked (see Installation).

●

Is the cold water turned on at the tap?

●

Did your load fabric type require a high heat setting (eg. Cottons)?

If so, was Drying High Heat option selected?

●

Did you select a long enough drying time?

●

Was the laundry spun dry at the end of the wash programme, if not select

the spin and dry option to suit the type of fabric?

●

This is not a fault, we have designed the machine to release steam from the

dispenser drawer during hot washes. It may also vent during drying.

●

The detergent is not suitable for machine washing. If you have used the

wrong type of detergent, select a Rinse programme to flush out your machine.

●

You used too much detergent. Refer to the manufacturer’s recommendations.

●

Check the drawer is properly aligned.

●

Clean the dispenser drawer (see Care and Maintenance).

Not all the detergent has

been flushed away?

13

●

Check the water supply taps are turned on fully.

●

Check the water inlet hoses are not kinked.

●

Is your water pressure too low? You may need a ‘Y’ piece adaptor to run

your machine as cold fill only.

Page 15

Service

Before calling the Service Centre:

●

Use the troubleshooting guide to see if you can

solve the problem yourself (see Troubleshooting).

●

If not, turn off the machine and call the Service

Centre closest to you.

What to tell the Service Centre:

●

name, address and post code.

●

telephone number.

●

the type of problem.

●

the date of purchase.

●

the appliance model (Mod.).

●

the serial number (S/N).

This information can be found on the data label

inside the door of the machine.

Spare Parts

This washer dryer is a complex machine. Repairing it

yourself or having a non-authorised person try to

repair it could cause harm to one or more persons,

could damage the machine and could invalidate the

spare parts warranty.

Call an authorised technician if you experience

problems while using the machine.

The spare parts have been designed exclusively for

this appliance and not for other uses.

GB

Installation

Description

Programmes

Starting and

Detergent and

Laundry

Precautions and

advice

Maintenance Troubleshooting Service

Care and

14

Page 16

Key Contacts

After Sales Service

Over 1100 trained specialists, directly employed by us, ensure that you can have complete

confidence in both the appliances and services we offer.

Repair Service and Information Help Desk

UK: 08709 066 066

Monday to Friday, 8am to 7.30pm

Saturday, 8.30am to 5.30pm

Sunday, 9.30am to 3.30pm

www.hotpoint

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

Model number

Serial number

service.co.uk

Extended Warranties

UK: 08709 088 088

Monday to Sunday, 8am to 8pm

www.hotpointservice.co.uk

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

UK: 08709 077 077

Monday to Friday, 8.30am to 5pm

Saturday, 8.30am to 12noon

www.hotpointservice.co.uk

Republic of Ireland: (01) 842 6836

www

.hotpoint.co.uk

Indesit Company UK Limited, Morley Way, Peterborough, PE2 9JB

PRINTED BY SIMLEX.FOUR ASHES,WOLVERHAMPTON. 01/2005 195046049.01

02/2005 195048896.00

Loading...

Loading...