Hotpoint WD420P, WD420G, WD420T, WD440P, WD440G Service Information

Information

Indesit Company UK Ltd

© 2006 Reg. Office: Peterborough PE2 9JB. Registered in London: 106725

Service

Hotpoint

Aquarius

Washer

Dryers

Models Commercial

Code

WD420P 31127

WD420G 31128

WD420T 31126

WD440P 34189

WD440G 36234

5407170 Issue 6 Aug. 2006

2

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable

product knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected

(unplugged) from the electrical supply.

4. Servicing must be preceded by Earth Continuity and Insulation Resistance checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges

on metal and plastic parts.

6. After servicing the appliance must be rechecked for Electrical Safety. In the case of appliances

which are connected to a water supply (i.e.: Washing Machines, Dishwashers & Food Centres

etc.) checks must be made for leaks from seals gaskets and pipe work and rectification carried

out where necessary.

7. It can be dangerous to attempt 'DIY' repairs / maintenance on complex equipment and the

Company recommends that any problem with the appliance is referred to its own Service

Organisation.

8. Whilst the Company has endeavoured to ensure the accuracy of the data within this publication

they cannot hold themselves responsible for any inconvenience or loss occasioned by any error

within.

3

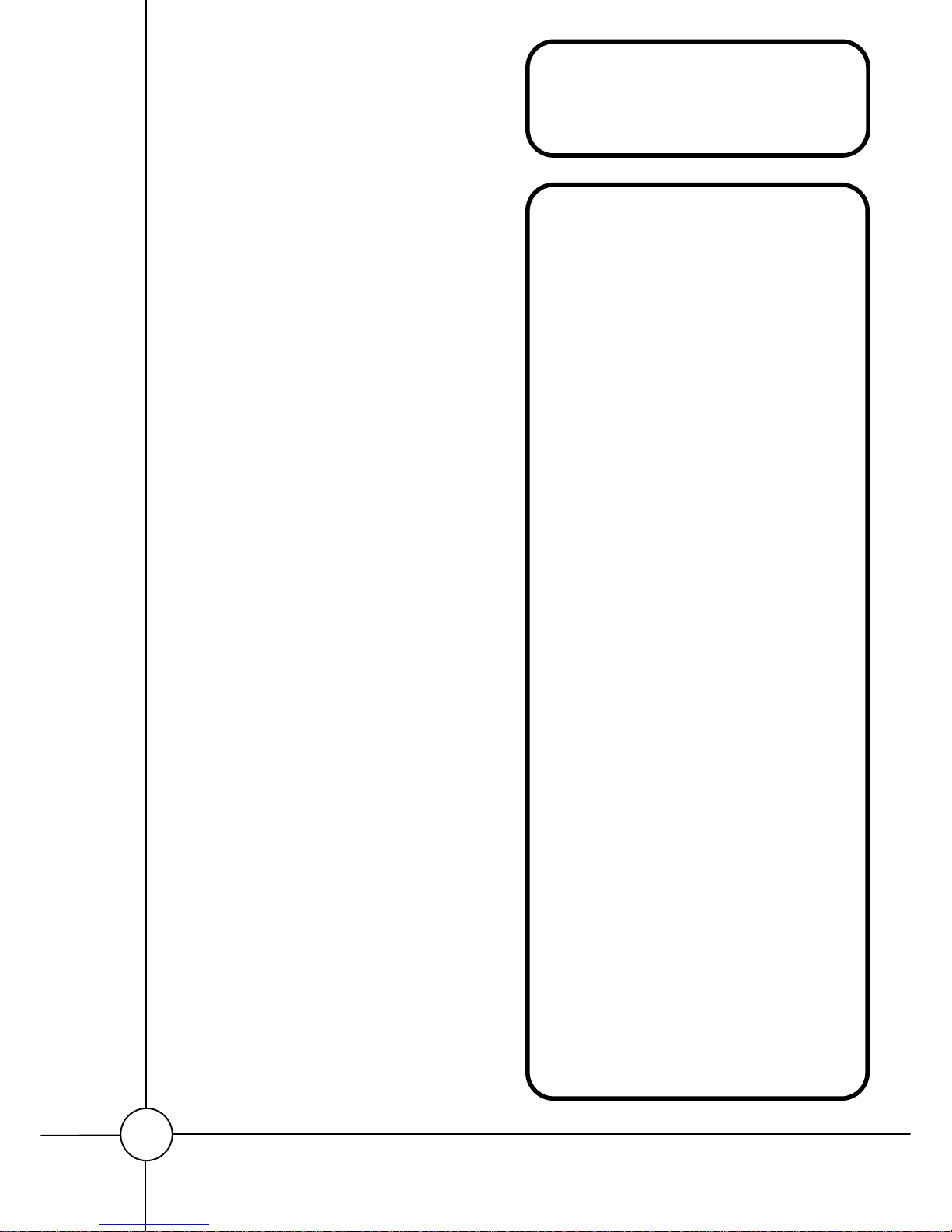

MANUFACTURING DATE CODE REFERENCE CHART

This example shows that the machine was

manufactured in MARCH 2004.

SERIAL NUMBER / INDUSTRIAL CODE EXPLANATION

1986 1987 1988 1989 1990 1991 1992 1993

1994 1995 1996 1997 1998 1999 2000 2001

2002 2003 2004 2005 2006 2007 2008 2009

Jan 01 13 25 37 49 61 73 85

Feb 02 14 26 38 50 62 74 86

March 03 15 27 39 51 63 75 87

April 04 16 28 40 52 64 76 88

Ma

y

05 17 29 41 53 65 77 89

June 06 18 30 42 54 66 78 90

Jul

y

07 19 31 43 55 67 79 91

Aug 08 20 32 44 56 68 80 92

Sept 09 21 33 45 57 69 81 93

Oct 10 22 34 46 58 70 82 94

No

v

11 23 35 47 59 71 83 95

Dec 12 24 36 48 60 72 84 96

First 2 digits of the serial number indicate production date

Date Code 27 120054

Serial Number Example

3 10 02 0895

Four remaining digits = Build number that day 895

th

built

Third two digits = Day of manufacture 2

nd

of month

Second two digits = Month of manufacture October

First digit = Year of manufacture 2003

Industrial Code Example

37 24455 0010

Last four digits = 0000 original production.

Second five digits = COMMERCIAL CODE*

First two digits = Factory of origin

* Vital for correct model information and system identification

Other numbers denote major production changes

4

INDEX

Safety & Servicing Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manufacturing Date Code Chart & Serial Number Information . . . . . . . . . . . 3

Development History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Controls, Options and Wash Programme details . . . . . . . . . . . . . . . . . . 9 - 13

Wiring Details

Wiring Connections & Wiring Diagram - Before D.C. 40 . . . . . . . . . 14 - 15

Wiring Connections & Wiring Diagram - After D.C. 39. . . . . . . . . . . 16 - 17

Wiring Diagram - After Serial Number 60508.0000 . . . . . . . . . . . . . . . . . . 18

Wiring Diagram Legend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Auto Test Set Up, Test Sequence, Diagnostics & Error Codes . . . . . . 20 - 23

Dismantling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 - 30

EEProms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DEVELOPMENT HISTORY

September 2004

Date Code 33 Aquarius versions WD420 enter full production.

November 2004

Date Code 35 WD440P - General tactical model, same as WD420 but with 1400 rpm spin.

February 2005

Date Code 38 WD440G first produced.

April 2005 Models WD420 & WD440

Date Code 40 Change to Cold Fill and deletion of heater box fluff filter.

On 25

th

April 2005 (Date Code 40), this range of washer dryers changed from

Hot and Cold Fill to Cold Fill only. Along with this change a modification was

made to the tumble dryer heater box assembly with the introduction of a

straight heating element, this to improve the air flow through the heater box.

This change enables the removal of the heater box fluff filter and deletion of the

flushing valve and hose. The thermistor, one-shot cut out and fan assembly are

not affected. The 4-way valve is replaced by a 3-way valve and the hot supply

hose is deleted.

A new file setting (EEPROM) is used for cold fill machines, but the consumer

programmes remain the same for both Hot and Cold and Cold fill machines.

The changes to the heater box assembly does not effect the EEPROM file

settings.

May 2006 Model WD420 & WD440

(S/N 60508.0000) Re-introduction of flushing valve style heater box assembly.

On 8 May 2006 (S/N 60508.0000), the flushing valve and fluff filter was

re-introduced in production, along with spiral element, metal fan, externally

mounted dryer motor and thermal fuse cable, which is attached to the heater

box upper casing in place of the one shot cut-out device.

5

SPECIFICATIONS

Models Covered WD420 Washer Dryer

WD440 Washer Dryer

Colours P = Polar, G = Graphite, T = Sandstone

Country of Origin Great Britain

Electrical Supply 230 Volts AC @ 50Hz Fuse 13amp

Energy Energy Class: B

Washing Performance Class: A @ 40°C

Energy Consumption 1.02 KWh / Cycle @ 60°C Cotton

Water Consumption Washing Only = 55 Litres @ 60°C Cotton

Wash Load 6 kg Cottons

Washing & Drying Load 5.0 kg + 5.0 kg Cottons

Spin Speed WD420 - 1200 rpm maximum WD440 - 1400 rpm maximum

Control PCB 220/230Volt 50/60Hz Type Merloni EVO 2

Wash Heater 1800 Watts @ 230 volts Resistance 30 Ω approx.

Dryer Heater 1200 Watts @ 230 volts Resistance 43 Ω approx.

Thermistor NTC - Wash Resistance: 20 KΩ @ 20°C

Thermistor NTC - Dryer Resistance: 26 KΩ @ 20°C

Water Supply Hot & Cold Valves - Coil Resistance 3.8 KΩ

Max Pressure = 1 Mpa (10bar)

Minimum Pressure = 0.05 Mpa (0.5bar)

Motor - Wash Universal Series Wound 230V 50Hz AC with tapped field

Motor - Dryer Fan 230 Volt 50 Hz Resistance approx. 45 Ω

Pump 2 Pole Synchronous

220 / 240 Volt 25 Watt, Resistance = 165 Ω

Maximum Head 1.4 metres

Flow rate @ 0.9 metres / 30 Litres per minute

Door Lock P.T.C. Bimetallic - Time Delay approx 2 minutes

Torque Settings Outer Drum = 8Nm

Upper Balance Weight = 18 Nm

Lower Balance Weight = 24 Nm

Heater Box to Drum = 12Nm

Heater Box Top to Bottom = 8Nm

Dimensions Height 850 mm Width 595 mm

Depth 600 mm Weight 66 kg. Packed approx 69 kg

Pins Resistances FHP CESET

5-6 Armature Varies with brush-gear 1.5 Ω ± 8% 1.78 Ω ± 7%

3-4 Full Field 1.26 Ω ± 8% 1.25 Ω ± 7%

3-7 Tapped Field 0.47 Ω ± 10% 0.41 Ω ± 7%

1-2 Tacho 16 Pole (8 pairs) 135 Ω ± 10% 68.7 Ω ± 7%

6

INSTALLATION

Unpacking

1. Unpack the washing machine.

2. Check whether the washing machine has

been damaged during transport. If this is the

case, do not install it.

Remove the polystyrene base

The vertical block part of the base (see below)

should have stayed intact when the base was

removed. If it has broken off and is still inside

the machine, carefully lay the machine on its

side, onto the polystyrene top cap and then

remove the block.

Warning:

Packaging materials are not childrens toys.

Remove the transit fixings

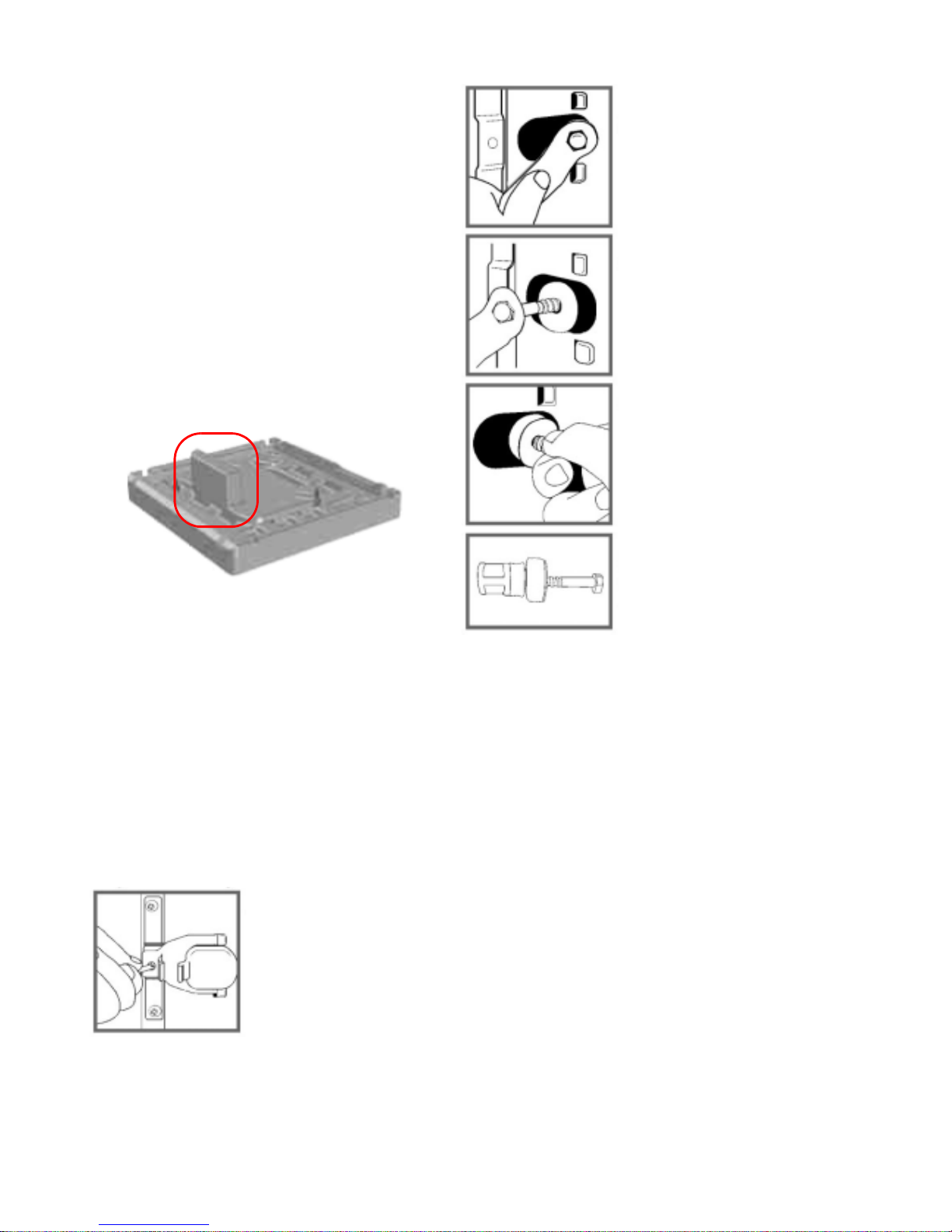

Follow these instructions to remove the TWO

transit fixings. IMPORTANT: Situated one either

side of the rear panel, both transit bolts (complete

with spacers) MUST be removed before use.

Failure to do so may cause damage to the

machine!

1. Use a crosshead

screwdriver to

remove the plastic

cover.

Vertical block

polystyrene

base

For safety, replace both plastic covers over the

holes left by removing the two bolts.

Levelling

1. Install the washing machine on a flat sturdy

floor, without resting it up against walls,

cabinets etc.

2. Compensate for any unevenness by

tightening or loosening the adjustable front

feet. The angle of inclination, measured

according to the worktop must not

exceed 2°.

Levelling the appliance correctly will provide it

with stability and avoid any vibrations, noise

and shifting during operation. If it is placed on

a fitted or loose carpet, adjust the feet in such

a way as to allow enough room for ventilation

beneath the washing machine.

2. Unscrew the bolt

using a 13 mm

spanner.

3. STOP when 3

threads can be

seen.

4. Hold, slide and pull

to remove.

! It is important the

transit bolt and

spacer come out

intact

(see image left).

7

Connecting to the Water Supply

WARNINGS:

The temperature of the hot water supply

should ideally be 60°C and no higher than

70°C as this could cause damage to the

laundry and the machine. Applies to

products produced prior to Date Code 40.

Do not connect the machine to a single

outlet instantaneous water heater.

The hot and cold water pressure should be

between 3 and 150 psi (21 - 1034 kPa).

Incorrect pressures could lead to flooding.

The water supply taps should be accessible

when the machine is installed.

Before connecting the fill hoses, check that

water is running from the water supply taps

you will use for the machine.

Connect the washing machine to the water

supply using the fill hoses fitted to the

machine.

Do not use old hoses.

Hot & Cold Fill - Cold fill only from D.C. 40

1 Unclip the grey and blue fill hoses from

the back of the machine.

2 Connect the free end of the grey fill hose

to the HOT water supply (see figure1).

Connect the free end of the blue fill hose

to the COLD water supply.

3 Turn on the water supply and check for

leaks. If there is a leak, turn off the water

supply, remove the connector and check

that the sealing washer is in place.

Refit the connector and tighten it.

Turn on the water supply.

4 When moving the machine into its final

position, make sure that the hoses are not

trapped or kinked.

Fig. 1 Fig. 2

If the fill hoses are too short:

Longer fill hoses are available. Remove the

existing fill hoses from the inlet valves on the

back of the machine and fit the new longer fill

hoses as shown above with the angled ends

of the hoses connected to the machine

(see Fig. 2).

If no hot water supply is available or the hot

water pressure is low, a cold fill adaptor

(Fig. 3) and fitting instructions are available.

Applies to products produced prior to D.C. 40.

Electrical connections

Before plugging the appliance into the

mains socket, make sure that:

- the socket is earthed and in compliance

with the applicable law.

- the supply voltage is included within the

values indicated in the Specifications page.

- the socket is compatible with the washing

machines plug. If this is not the case,

replace the socket or the plug.

Location

! The washing machine should not be

installed in an outdoor environment, not

even when the area is sheltered, because it

may be very dangerous to leave it exposed

to rain and thunderstorms.

! When the washing machine is installe d, the

mains socket must be within easy reach.

! Do not use extensions or multiple sockets.

! The power supply cable must never be

bent or dangerously compressed.

! The power supply cable must only be

replaced by an authorised engineer.

8

Drainage Connections

Take care when you remove the drain hose

from the clips on the back of the machine.

All machines are tested with water before they

leave the factory so a small amount of water

may still be in the hose.

Do not remove the hooked end support from

the GREY drainage hose when using any of

the drainage methods detailed below. You

may need to reposition it as required along the

drainage hose.

For drainage into a standard work top sink,

ensure the outlet pipe has a minimum

diameter of 32 mm. If the sink is inset, the front

edge of the basin must be less than

75 mm from the front edge of the worktop, so

that the drain hose will hook securely into the

sink.

Unclip the drainage hose from the back of the

machine and hook over into the sink. Make

sure that the sink is free of any obstructions

and that the sink plug can not fall into the sink,

preventing the water from draining away

freely. Pumped out water may be very hot.

We recommend one of the following drainage

methods:

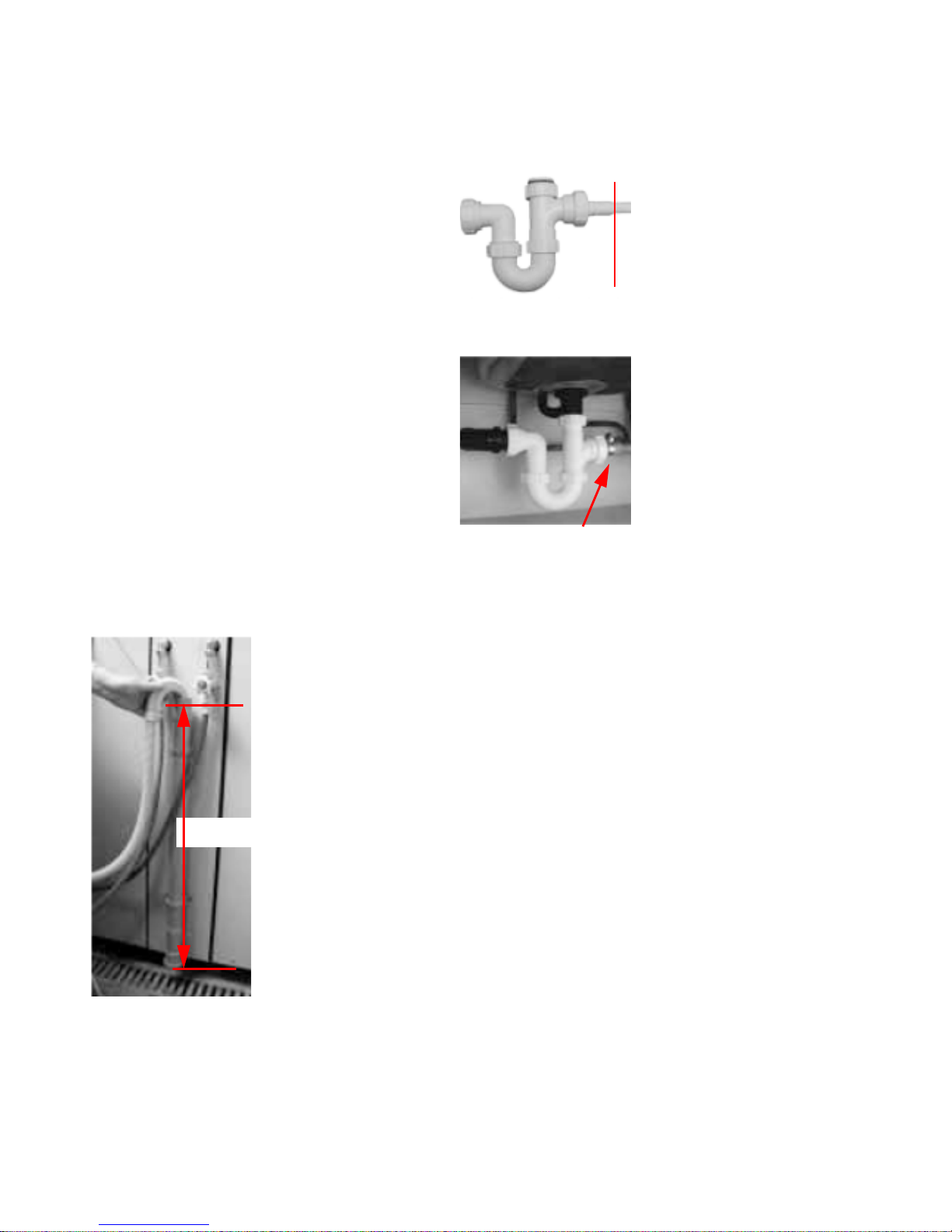

Stand pipe Fig. 1 1 Make sure that the

standpipe has a

minimum diameter

of 38 mm.

2 Remove the

drainage hose from

the clips on the

back of the

machine.

3 Make sure that the

top of the standpipe

is positioned at

least 500 mm from

the floor (see

Fig.1).

Use the plumbing

indicator line label

on the back of the

machine as a

guide.

4 Place the drainage hose approximately

100 mm into the standp ipe.

500 mm

Extending the drainage hose

If the GREY drainage hose is too short, a

longer drainage hose is available from our

Genuine Parts & Accessories Mail Order

Hotline.

WARNING!

The company denies all liability if and when

these warnings are not respected.

The first wash cycle

Once the appliance has been installed and

before you use it for the first time, run a

wash cycle without detergent and no

laundry, setting the 90°C programme

without a pre-wash cycle.

Under Sink

Waste System

Fig.2

Fig.3

1 Cut out the

membrane, bung or

blanking plug (see

Fig. 2).

2 Unclip the drainage

hose from the back

of the machine.

3 Move the hooked

end support along

the drainage hose

as required.

4 Attach the drainage

hose securely to

the under sink

drainage unit, using

a hose clip (see

Fig. 3).

5 Raise the hooked

end support up to at

least 800 mm to

avoid water being

drawn back into the

machine.

cut

off

end

Hose clip

9

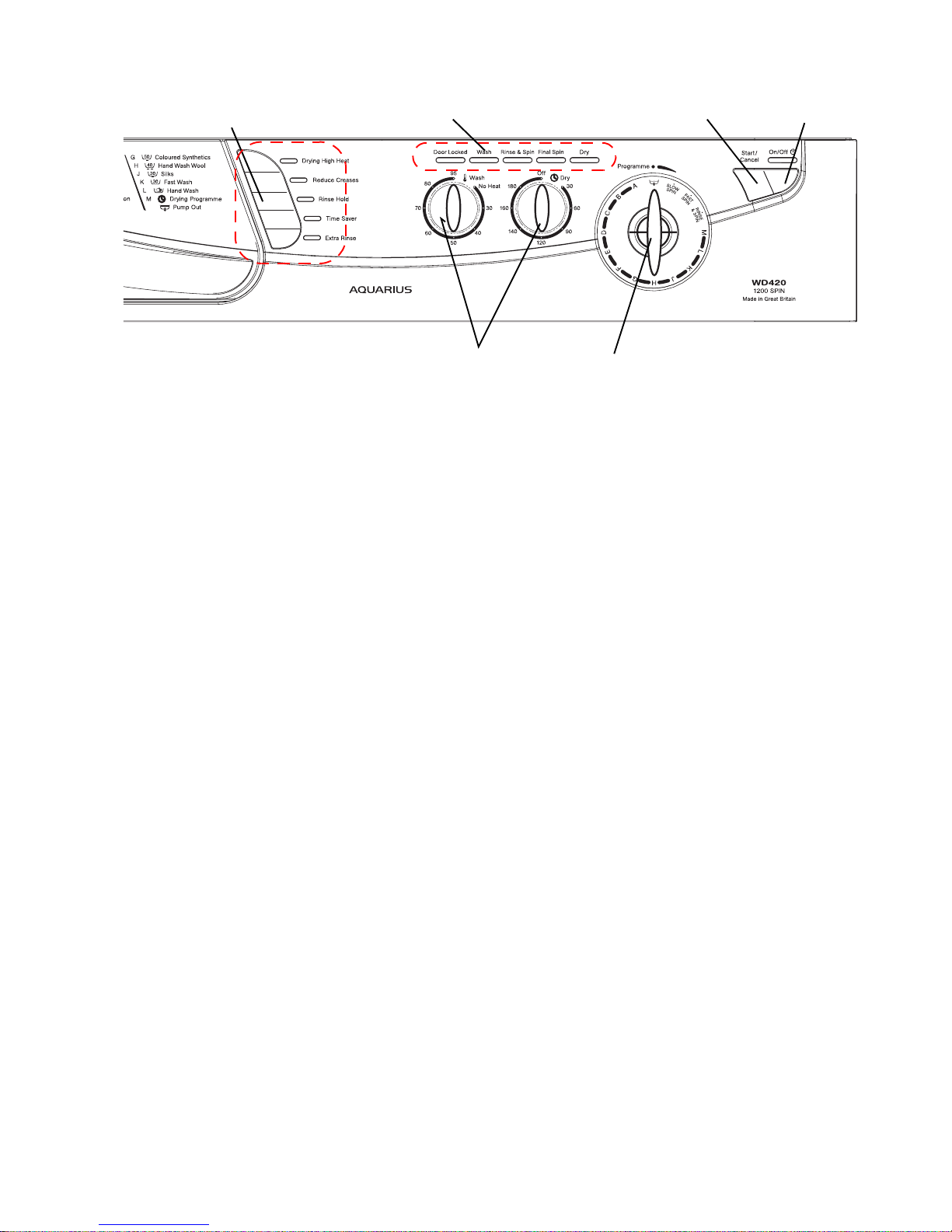

Controls

On-Off / Selecting a programme

The machine is switched on by pressing the 'On/Off' button for 2 seco nds. All the indicator lig hts will

light up for a few seconds and the 'Door Locked' indicator light will flash once.

Turn the programme selector dial to the desired programme. Load the laundry and detergent.

Select the options you require.

Press the 'Start/Cancel' button for 2 seconds to start the programme.

To stop or change a programme

Press the 'Start/Cancel' button for 2 seconds.

Select 'Pump Out' on the programme selector dial.

When the machine has finished emptying, turn the programme selector dial to the new pr ogramme.

Press the 'Start/Cancel' button to start the programme.

If you cancel a hot wash programme, take care when removing the laundr y, it migh t still be ve ry hot.

Progress indicator lights

These will light up when you choose a programme, to indicate the progress of the selected

programme. When started, the first light in the cycle will stay lit and as the programme progresses,

successive lights will come on until the programme finishes.

Door Locked indicator light

The ‘Door Locked’ indicator light will c ome on two sec onds afte r yo u p res s the 'Star t/Cance l' butto n

and will stay lit throughout the programme. A short time after the programme has finished the

indicator light will go out and you can then open the door.

Selected programmes will not start if the door is not cl osed properly, the 'Door Lo cked' indicator light

will flash to show this. Push the door shut until you hear the catch click.

Button Selection:

To select an option, press the button and you will see a light come on alongside the button.

Press again to cancel, and the light will go out.

Option Buttons

Progress Indicator Lights Start/Cancel

On/Off

Programme Selector Dial

Variable Control(s)

10

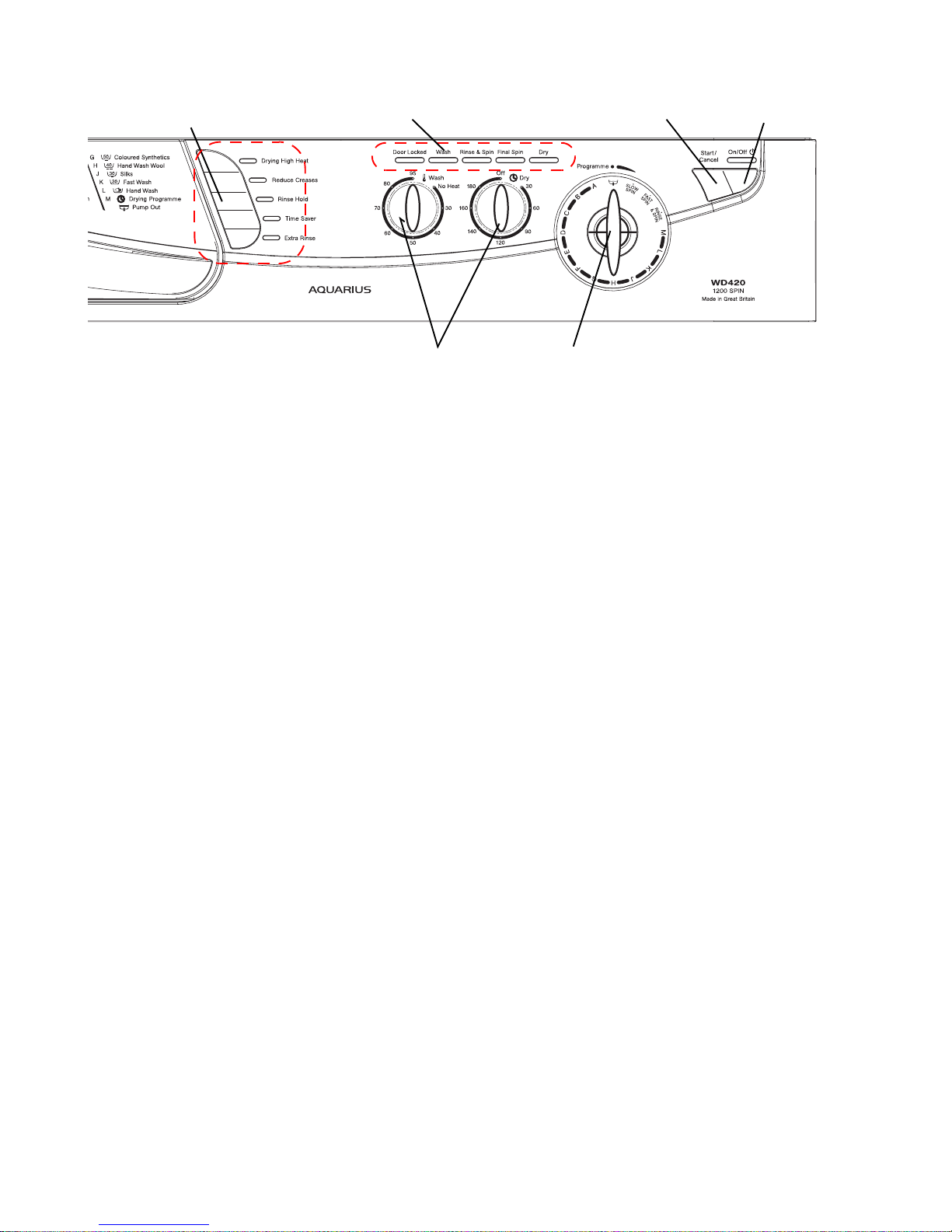

Options

Options are selected by pressing the button and confirmed by illumination of the LED.

Drying High Heat

The default setting is LOW heat. By selecting this allows HIGH heat for tumble drying.

Reduced Creases

Changes wash action and slightly increases drum speed on cotton programmes and removes end

of wash spin with a reduced speed on final spin on synthetic programmes.

Available on programmes C, E, G and Rinse and Spin programmes

Rinse Hold

Clothes will be suspended in cold water at the end of the final rinse. To complete the programme,

press the button when the LED is flashing

This option is not available on programmes A, H, K, L and Spin only

Time Saver

Saves programme time by up to a third depending on programme selected and is achieved by

reducing wash run times.

This option is only available on programmes B, D, G and H.

Extra Rinse

Adds an extra rinse to the programme

This option is not available on programmes A, E, H, J, K, L or Spin only

Variable Wash Temperature Control - Selected by Rotary Knob

Enables a lower wash temperature and No Heat to be selected

Note; if the dial is left at the maximum temperature setting the programme will be washed at the

maximum temperature for the programme selected

Variable Tumble Drying Time - Selected by Rotary Knob

Enables the required drying time to be chosen.

Maximum 180 minutes plus 20 minutes Cool Tumble.

Option Buttons

Progress Indicator Lights Start/Cancel

On/Off

Programme Selector Dial

Variable Control(s)

Loading...

Loading...