Page 1

Instructions for use

WASHER-DRYER

GB

English,1

RG 964 J

! This symbol reminds you to read this instruc-

tion manual.

Contents

Installation, 2-3-4-5

Unpacking and levelling

Connecting the electricity and water supplies

The first wash cycle

Technical data

Care and maintenance, 6

Cutting off the water and electricity supplies

Cleaning the washer-dryer

Cleaning the detergent dispenser drawer

Caring for the door and drum of your appliance

Cleaning the pump

Checking the water inlet hose

Precautions and tips, 7

General safety

Disposal

GB

Description of the washer-dryer, 8-9

Control panel

Display

How to run a wash cycle or a drying cycle, 10

Wash cycles, 11

Table of programmes and wash cycles

Detergents and laundry, 12

Detergent dispenser drawer

Preparing the laundry

Special wash cycles

Load balancing system

Troubleshooting, 13-14

Product Guarantee and Repair Information, 15

1

Page 2

Installation

GB

! Keep this instruction manual in a safe place

for future reference. Should the appliance

be sold, transferred or moved, make sure

the instruction manual accompanies the

washer-dryer to inform the new owner as to its

operation and features.

! Read these instructions carefully: they contain

vital information on installation, use and safety.

Unpacking and levelling

Unpacking

! This is a separate

part of the polystyrene

base and should be

removed with the

base.

! IMPORTANT check

when unpacking

your machine.

1. Unpack the washerdryer.

2. Check whether

the washer-dryer has

been damaged during

transport. If this is the

case, do not install

it and contact your

retailer.

3. Remove the 4

protective screws and the rubber bush with

the respective spacer, situated on the rear of

the appliance (see also the installation leaflet).

4. Seal the gaps using the plastic plugs provided.

5. Keep all the parts: you will need them again

if the washer-dryer needs to be moved to

another location.

! Packaging materials are not children’s toys.

Levelling

Your machine may make a considerable

amount of noise if the two front feet have not

been adjusted correctly.

1. Install the washerdryer on a flat sturdy

floor, without resting it up

against walls, cabinets

or anything else.

2. If the floor is not perfectly level, compensate

for any unevenness by tightening or loosening

the adjustable front feet (see figure); the angle

of inclination, measured according to the

worktop, must not exceed 2°.

Levelling your appliance correctly will provide

it with stability and avoid any vibrations, noise

and shifting during operation. If it is placed on

a fitted or loose carpet, adjust the feet in such

a way as to allow enough room for ventilation

beneath the washer-dryer.

Electric and water connections

Connecting the water inlet hose

1. Connect the supply

pipe by screwing it to

a cold water tap using

a 3/4 gas threaded

connection (see

figure).

Before performing

the connection, allow

the water to run freely

until it is perfectly

clear.

2. Connect the other

end of the water inlet

hose to the washerdryer,

screwing it onto the

appliance’s cold water

inlet, situated on the

top right-hand side

on the rear of the

appliance (see figure).

3. Make sure there are no kinks or bends in the

hose.

! The water pressure at the tap must be within

the values indicated in the Technical details

table (on the page 5).

! If the water inlet hose is not long enough,

contact a specialist store or an authorised

serviceman.

! Ensure that the supply taps are allowing

water through. Old taps may seize in the

closed position and thus prevent water

reaching the machine.

! Never use second-hand or old inlet hoses;

use the products supplied with the machine.

2

Page 3

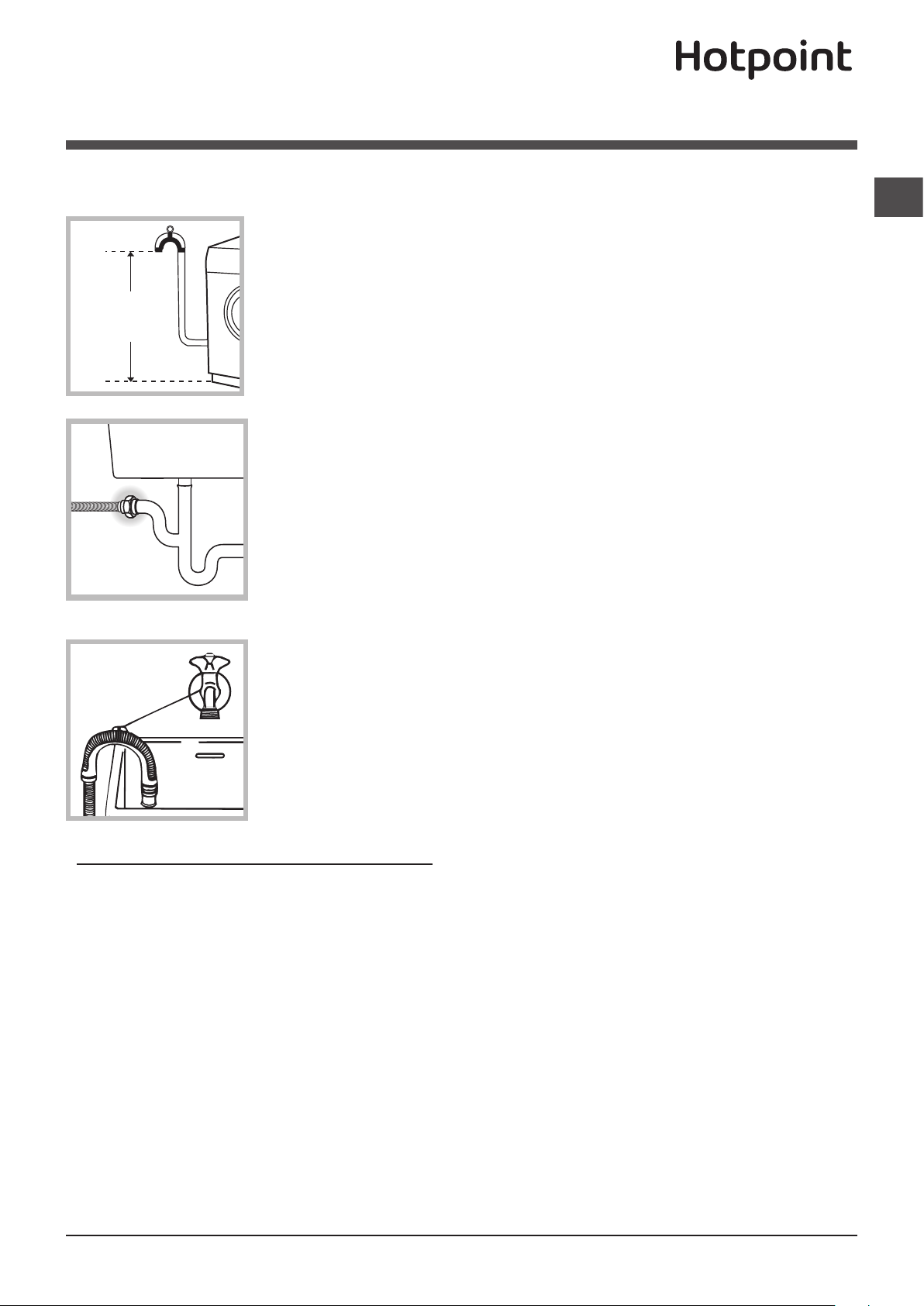

Connecting the drain hose

65 - 100 cm

Where it connects to

the waste water pipe

cut end off spigot or

remove the blanking cap

Connect the drain

hose, without bending

it, to a draining

duct or a wall drain

situated between 65

and 100 cm from the

floor;

The drain hose may

be connected to

an under-sink trap.

Before connecting

the drain hose from

the machine ensure

that any blanks or

removable ends have

been taken off the

spigot.

If it is placed over

the edge of a basin

or sink be sure

the free end of the

hose should not be

underwater.

! We advise against the use of hose extensions;

in case of absolute need, the extension must

have the same diameter as the original hose

and must not exceed 150 cm in length.

Ensure that if the drain hose is pushed into

a standpipe, that the end does not go down

more than 15cms (6 inches). If the hose is

pushed down too far, this may cause the

machine to self -syphon ie. continuously empty

as it is filling.

Electric connection

Before plugging the appliance into the mains

socket, make sure that:

• the socket is earthed and in compliance with

the applicable law;

• the socket is able to sustain the appliance’s

maximum power load indicated on the

Technical Data Plate fixed on the machine;

• the supply voltage is included within the

values indicated on the Technical Data Plate

fixed on the machine.

• the socket is compatible with the washer-

dryer’s plug. If this is not the case, replace

the socket or the plug.

Your appliance is now supplied with a 13 amp

fused plug it can be plugged into a 13 amp

socket for immediate use. Before using the

appliance please read the instructions below.

WARNING - THIS APPLIANCE MUST BE

EARTHED.

THE FOLLOWING OPERATIONS SHOULD

BE CARRIED OUT BY A QUALIFIED

ELECTRICIAN.

Replacing the fuse:

When replacing a faulty fuse, a 13 amp ASTA

approved fuse to BS 1362 should always be

used, and the fuse cover re-fitted. If the fuse

cover is lost, the plug must not be used until a

replacement is obtained.

Replacement fuse covers:

If a replacement fuse cover is fitted, it must

be of the correct colour as indicated by

the coloured marking or the colour that is

embossed in words on the base of the plug.

Replacements can be obtained directly from

your nearest Service Depot.

Removing the plug:

If your appliance has a non-rewireable

moulded plug and you should wish to re-route

the mains cable through partitions, units etc.,

please ensure that either:

the plug is replaced by a fused 13 ampere

rewireable plug bearing the BSI mark of

approval.

or:

the mains cable is wired directly into a 13

amp cable outlet, controlled by a switch, (in

compliance with BS 5733) which is accessible

without moving the appliance.

Disposing of the plug:

Ensure that before disposing of the plug itself,

you make the pins unusable so that it cannot

be accidentally inserted into a socket.

Instructions for connecting cable to an alternative

plug:

Important: the wires in the mains lead are

coloured in accordance with the following

code:

Green & Yellow Earth

Blue Neutral

Brown Live

GB

3

Page 4

GB

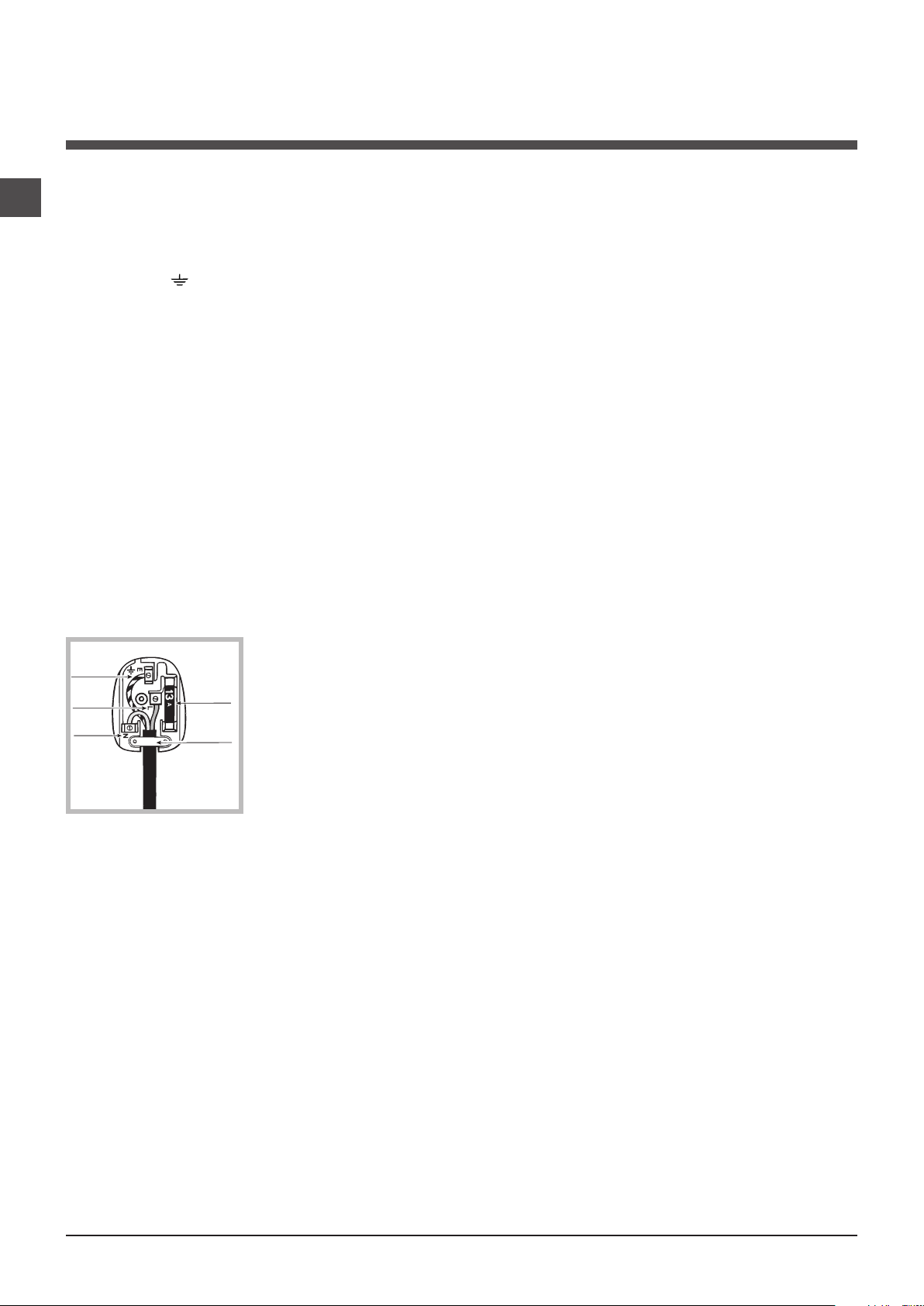

GREEN &

YELLOW

BROWN

BLUE

13 ampere fuse

CROSS-BAR

CORD GRIP

As the colours of the wires in the lead may

not correspond with the coloured markings

identifying the terminals in your plug, proceed

as follows:

Connect Green & Yellow wire to terminal

marked E or or coloured Green or Green &

Yellow.

Connect Brown wire to terminal marked L or

coloured Red.

Connect Blue wire to terminal marked N or

coloured Black.

If a 13 amp plug (BS 1363) is used it must be

fitted with a

13 amp fuse, either in the plug or adaptor or

at the distribution board.

If you are in any doubt regarding the electrical

supply to your machine, consult a qualified

electrician before use.

How to connect an alternative plug:

The wires in this mains lead are coloured in

accordance with the following code:

BLUE NEUTRAL (N)

BROWN LIVE (L)

GREEN & YELLOW EARTH (E)

! The power supply cable must only be

replaced by an authorised serviceman.

Warning! The company denies all liability if and

when these norms are not respected.

The first wash cycle

Once the appliance has been installed, and

before you use it for the first time, run a wash

cycle with detergent and no laundry, using

wash cycle number auto clean (see “Cleaning

the washer-dryer”).

Disposing of the appliance:

When disposing of the appliance please

remove the plug by cutting the mains cable

as close as possible to the plug body and

dispose of it as described on the previous

page.

! The washer-dryer should not be installed

in an outdoor environment, not even where

the area is sheltered, because it may be very

dangerous to leave it exposed to damp, rain

and thunderstorms.

! When the washer-dryer is installed, the mains

socket must be within easy reach.

! Do not use extensions or multiple sockets.

! The power supply cable must never be bent

or dangerously compressed.

4

Page 5

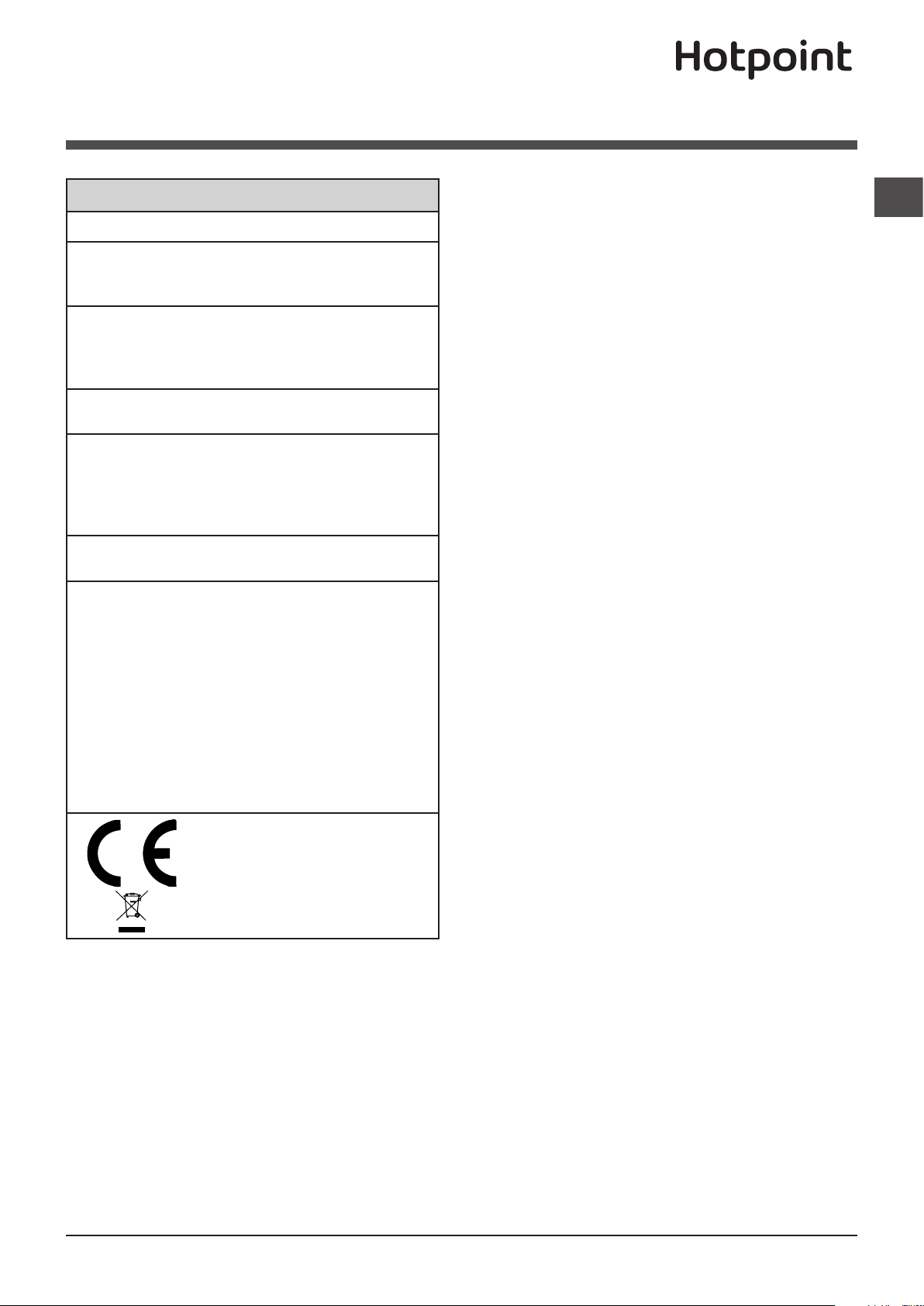

Technical data

GB

Model

Dimensions

Capacity

Electrical

connections

Water connections

Spin speed

Energy rated

programmes

according to

regulation

EN 50229

RG 964 J

width 59.5 cm

height 85 cm

depth 54 cm

from 1 to 9 kg for the wash

programme

from 1 to 6 kg for the drying

programme

please refer to the technical

data plate fixed to the machine

maximum pressure

1 MPa (10 bar)

minimum pressure

0.05 MPa (0.5 bar)

drum capacity 58 litres

up to 1400 rotations per

minute

Wash: programme 8; temperature 60°C; using a load

of 9 kg.

Drying: the greater load

(6kg) must be dried by

selecting the “A3” dryness

level. The remainder of the

load must be dried by selecting the “A3” dryness level:

the load must consist of 3

sheets, 2 pillowcases and 1

hand towel.

This appliance conforms to

the following EC Directives:

- 2004/108/EC (Electromagnetic Compatibility)

- 2006/95/EC (Low Voltage)

- 2012/19/EU (WEEE)

5

Page 6

Care and maintenance

1

2

GB

Cutting off the water and

electricity supplies

• Turn off the water tap after every wash cycle.

This will limit wear on the hydraulic system

inside the washer-dryer and help to prevent

leaks.

• Unplug the washer-dryer when cleaning it

and during all maintenance work.

Cleaning the washer-dryer

• The outer parts and rubber components

of the appliance can be cleaned using a soft

cloth soaked in lukewarm soapy water. Do not

use solvents or abrasives.

• The washer-dryer has a auto clean

programme for its internal parts that must be

run with no load in the drum.

A

programme every 40 wash cycles.

To start the programme press button A for 5

seconds (see figure).

The programme will start automatically and will

run for about 70 minutes. To stop the cycle

press the START/PAUSE button.

To help the wash cycle

you may want to use

either the detergent

(i.e. a quantity 10% the

quantity specified for

lightly-soiled garments)

or special additives

to clean the washerdryer. We recommend

running a cleaning

Caring for the door and drum of

your appliance

• Always leave the porthole door ajar in order

to prevent unpleasant odours from forming.

Cleaning the pump

The washer-dryer is fitted with a self-cleaning

pump which does not require any maintenance.

Sometimes, small items (such as coins or

buttons) may fall into the pre-chamber which

protects the pump, situated in its bottom part.

! Make sure the wash cycle has finished and

unplug the appliance.

To access the pre-chamber:

1. using a

screwdriver, remove

the cover panel on

the lower front part of

the washer-dryer (see

figure);

2. unscrew the lid

by rotating it anticlockwise (see figure):

a little water may

trickle out. This is

perfectly normal;

Cleaning the detergent dispenser

drawer

Remove the dispenser

by raising it and

pulling it out (see

figure).

Wash it under running

water; this operation

should be repeated

frequently.

6

3. clean the inside thoroughly;

4. screw the lid back on;

5. reposition the panel, making sure the hooks

are securely in place before you push it onto

the appliance.

Checking the water inlet hose

Check the inlet hose at least once a year. If

there are any cracks, it should be replaced

immediately: during the wash cycles, water

pressure is very strong and a cracked hose

could easily split open.

! Never use second-hand hoses.

Page 7

Precautions and tips

! This washer-dryer was designed and constructed in

accordance with international safety regulations. The

following information is provided for safety reasons and

must therefore be read carefully.

General safety

• This appliance was designed for domestic use only.

• This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they

have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved. Children

shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

– Do not dry unwashed items in the tumble dryer.

– Items that have been soiled with

substances such as cooking oil, acetone,

alcohol, petrol, kerosene, spot removers,

turpentine, waxes and wax removers should

be washed in hot water with an extra

amount of detergent before being dried in

the tumble dryer.

– Items such as foam rubber (latex foam),

shower caps, waterproof textiles, rubber

backed articles and clothes or pillows fitted

with foam rubber pads should not be dried in

the tumble dryer.

– Fabric softeners, or similar products,

should be used as specified by the fabric

softener instructions.

– The final part of a tumble dryer cycle occurs

without heat (cool down cycle) to ensure that

the items are left at a temperature that ensures

that the items will not be damaged.

WARNING: Never stop a tumble dryer before

the end of the drying cycle unless all items

are quickly removed and spread out so that

the heat is dissipated.

• Do not touch the machine when barefoot or with wet or

damp hands or feet.

• Do not pull on the power supply cable when unplugging

the appliance from the electricity socket. Hold the plug

and pull.

• Do not open the detergent dispenser drawer while the

machine is in operation.

• Do not touch the drained water as it may reach

extremely high temperatures.

• Never force the porthole door. This could damage the

safety lock mechanism designed to prevent accidental

opening.

• If the appliance breaks down, do not under any

circumstances access the internal mechanisms in an

attempt to repair it yourself.

• Always keep children well away from the appliance while

it is operating.

• The door can become quite hot during the wash cycle.

• If the appliance has to be moved, work in a group of two

or three people and handle it with the utmost care. Never

try to do this alone, because the appliance is very heavy.

• Before loading laundry into the washer-dryer, make sure

the drum is empty.

• During the drying phase, the door tends to get quite hot.

• Do not use the appliance to dry clothes that

have been washed with flammable solvents

(e.g. trichlorethylene).

• Do not use the appliance to dry foam rubber

or similar elastomers.

• Make sure that the water tap is turned on during

the drying cycles.

• Children of less than 3 years should be kept

away from the appliance unless continuou sly supervised.

• Remove all objects from pockets such as

lighters and matches.

Disposal

• Disposing of the packaging materials: observe local

regulations so that the packaging may be re-used.

• The European Directive 2012/19/EU on Waste

Electrical and Electronic Equipment, requires that

old household electrical appliances must not be

disposed of in the normal unsorted municipal waste

stream. Old appliances must be collected

separately in order to optimise the recovery and

recycling of the materials they contain and reduce

the impact on human health and the environment.

The crossed out “wheeled bin” symbol on the

product reminds you of your obligation, that when

you dispose of the appliance it must be separately

collected.

Consumers should contact their local authority or

retailer for information concerning the correct

disposal of their old appliance.

GB

7

Page 8

GB

Description of the washer-dryer

DIRECT

Control panel

ON/OFF

button

TEMPERATURE

button

DRY ONLY

button

DISPLAY

KEY

LOCK

button

INJECTION

button and

indicator light

Detergent dispenser drawer

Detergent dispenser drawer: used to dispense

detergents and washing additives (see “Detergents and

laundry”).

Programme Key: the Programme Key inside the

detergent dispenser shows all the available programmes

together with a graphical guide on how to use the

individual dispenser compartments.

ON/OFF button: press this briefly to switch the

machine on or off. The START/PAUSE indicator light which

flashes slowly in a green colour shows that the machine

is switched on. To switch off the washer-dryer during the

wash cycle, press and hold the button for approximately 3

seconds; if the button is pressed briefly or accidentally the

machine will not switch off.

If the machine is switched off during a wash cycle, this

wash cycle will be cancelled.

WASH CYCLE SELECTOR KNOB: used to set the

desired wash cycle (see “Table of programmes and wash

cycles”).

DIRECT INJECTION button and indicator light: press to

select the DIRECT INJECTION option.

TEMPERATURE button: press to reduce or completely

exclude the temperature; the value appears on the display.

SPIN button: press to reduce or completely exclude

the spin cycle; the value appears on the display.

DELAY button: press to set a delayed start for the

selected wash cycle; the delay period appears on the

display.

Programme

Key

WASH

CYCLE

SELECTOR

KNOB

SPIN

button

START/PAUSE button and indicator light: when the green

indicator light flashes slowly, press the button to start a

wash cycle. Once the cycle has begun the indicator light

will remain lit in a fixed manner. To pause the wash cycle,

press the button again; the indicator light will flash in an

amber colour. If the symbol is not illuminated, the door

may be opened. To start the wash cycle from the point at

which it was interrupted, press the button again.

KEY LOCK button: to activate the control panel lock,

press and hold the button for approximately 2 seconds.

When the symbol is illuminated, the control panel

is locked (apart from the ON/OFF button). This means it

is possible to prevent wash cycles from being modified

accidentally, especially where there are children in the

home. To deactivate the control panel lock, press and hold

the button for approximately 2 seconds.

Standby mode

This washer-dryer, in compliance with new energy saving

regulations, is fitted with an automatic standby system

which is enabled after about 30 minutes if no activity is

detected. Press the ON-OFF button briefly and wait for the

machine to start up again.

Consumption in off-mode: 0,5 W

Consumption in Left-on: 8 W

DELAY

button

DRYING

button

START/PAUSE

button and indicator

light

DRYING button : press to decrease or exclude drying;

the selected drying level or time will appear on the display.

DRY ONLY button : press to run the drying cycle

only.

8

Page 9

Display

B

A

C

The display is useful when programming the machine and provides a great deal of information.

The duration of the available wash cycles and the remaining time of a running cycle appear in section A (the display will show

the maximum duration of the cycle chosen, which may decrease after several minutes, since the effective duration of the

programme varies depending on the wash load and the settings chosen); if the DELAY option has been set, the countdown

to the start of the selected wash cycle will appear.

Moreover, pressing the relative button allows for visualising the maximum values for the temperature, spin speed or type of

drying relative to the selected programme or the most recently selected ones, if compatible with the selected programme.

GB

The “wash cycle phases” corresponding to the selected wash cycle and the “wash cycle phase” of the running wash cycle

appear in section B:

Main wash

Rinse

Spin/Pump out

Drying

The icons corresponding to “temperature”, “spin” and “drying” (working from the left) are displayed in section C.

The “temperature” bars indicate the maximum temperature level which may be selected for the set cycle.

The “spin” bars indicate the maximum spin level which may be selected for the set cycle.

The symbol lights up while the drying settings are being adjusted.

DOOR LOCKED indicator light:

The lit symbol indicates that the door is locked. To prevent any damage, wait until the symbol turns off before opening the door.

To open the door while a cycle is in progress, press the START/PAUSE button; if the DOOR LOCKED symbol is switched

off the door may be opened.

9

Page 10

How to run a wash cycle or a

drying cycle

GB

1. SWITCH THE MACHINE ON. Press the button;

the START/PAUSE indicator light will flash slowly in a

green colour.

2. LOAD THE LAUNDRY. Open the porthole door.

Load the laundry, making sure you do not exceed

the maximum load value indicated in the table of

programmes and wash cycles on the following page.

3. MEASURE OUT THE DETERGENT. Pull out the

detergent dispenser drawer and pour the detergent into

the relevant compartments as described in “Detergents

and laundry”.

4. CLOSE THE DOOR.

5. SELECT THE WASH CYCLE. Use the WASH CYCLE

SELECTOR knob to select the desired wash cycle. A

temperature and spin speed is set for each wash cycle;

these values may be adjusted. The duration of the cycle

will appear on the display.

6. CUSTOMISE THE WASH CYCLE. Use the relevant

buttons:

Modify the temperature and/or spin speed.

The machine automatically displays the maximum

temperature and spin speed values set for the selected

cycle, or the most recently-used settings if they are

compatible with the selected cycle. The temperature

can be decreased by pressing the button, until

the cold wash “OFF” setting is reached. The spin

speed may be progressively reduced by pressing

the button, until it is completely excluded (the

“OFF” setting). If these buttons are pressed again, the

maximum values are restored.

! Exception: if the 5 programme is selected, the

temperature can be increased up to a value of 40°C.

! Exception: if the 7 programme is selected, the

temperature can be increased up to a value of 90°C.

! Exception: if the 9 programme is selected, the

temperature can be increased up to a value of 60°C.

Setting the drying cycle

The first time the button is pressed, the machine will

automatically select the maximum drying cycle which is

compatible with the selected wash cycle. Subsequent

presses will decrease the drying level and then the drying

time, until the cycle is excluded completely (“OFF”).

Drying may be set as follows:

A- Based on the desired laundry dryness level:

Iron “A1”: suitable for clothes which will need ironing

afterwards. the remaining dampness softens creases,

making them easier to remove.

Hanger “A2”: ideal for clothes which do not need to be

dried fully.

Cupboard “A3”: suitable for laundry which can be put

back in a cupboard without being ironed.

B - Based on a set time period: between 45 and 210

minutes.

If your laundry load to be washed and dried is much

greater than the maximum stated load, perform the

wash cycle, and when the cycle is complete, divide the

garments into groups and put some of them back in

the drum. At this point, follow the instructions provided

for a “Dry only” cycle. Repeat this procedure for the

remainder of the load. A cooling-down period is always

added to the end of each drying cycle.

Dry only

Press button to perform the drying-only cycle.

After selecting the desired cycle (compatible with the type

of garments), press button to exclude the washing

phase and start the drying phase at the maximum level

for the selected cycle. The drying level or time may be

set and changed by pressing the drying button . (Not

compatible with cycles 1-2-3-4 and 14).

Setting a delayed start.

To set a delayed start for the selected cycle, press the

corresponding button repeatedly until the required delay

period has been reached. To remove the delayed start

setting, press the button until the text “OFF” appears on

the display.

7. START THE WASH CYCLE. Press the START/

PAUSE button. The corresponding indicator light will

turn green, remaining lit in a fixed manner, and the

door will be locked (the DOOR LOCKED symbol will

be lit). To change a wash cycle while it is in progress,

pause the washer-dryer using the START/PAUSE

button (the START/PAUSE indicator light will flash

slowly in an amber colour); then select the desired cycle

and press the START/PAUSE button again.

To open the door while a cycle is in progress, press

the START/PAUSE button; if the DOOR LOCKED

symbol is switched off the door may be opened. Press

the START/PAUSE button again to restart the wash

cycle from the point at which it was interrupted.

8. THE END OF THE WASH CYCLE. This will be

indicated by the text “END” on the display; when the

DOOR LOCKED symbol switches off the door may

be opened. Open the door, unload the laundry and

switch off the machine.

! If you wish to cancel a cycle which has already begun,

press and hold the button. The cycle will be stopped

and the machine will switch off.

Direct Injection

The washer-dryer is equipped with the innovative

technology «Direct Injection» which pre-mixes water and

detergent, thus immediately activating the detergent’s

cleaning principles. This active emulsion is directly

introduced into the drum of the washer-dryer and

penetrates the fibres with more efficacy in cleaning

even heavily soiled garments at low temperatures, fully

preserving colours and fabrics.

The mode «Power» ensures the best cleaning performance

and the mode «EcoEnergy» allows more energy saving.

10

Page 11

Wash cycles

60°/40°

Table of programmes and wash cycles

Description of the wash cycle

Wash cycles

ANTI CREASE

Daily Wash & Dry

1

Shirts Wash & Dry

2

Pre Iron

3

Steam Refresh

4

DAILY CLEAN

5 Anti-Stain Turbo 45’

6 Anti-Stain Power 20°C

7

Cotton: lightly soiled resistant and delicate colours.

8

Eco Cotton

9

Synthetics (3): lightly soiled resistant colours.

SPECIALS

10 Multicolor

Ultradelicates

11

Wool: for wool, cashmere, etc.

12

Sport

13

Fast (**): to refresh lightly soiled garments quickly (not suitable for wool, silk and

14

clothes which require washing by hand).

Partial Programmes

Rinse

Spin + Pump out

Pump out only *

(1-2): heavily soiled whites and resistant colours.

Detergents

Max.

temp.

(°C)

40°

40°

Max.

speed

(rpm)

800

1000

Drying

Wash

- - - - - 1,5

- - - - - 2

20°

(Max. 40°C)

20°

40°

(Max. 90°C)

60° 1400

40°

(Max. 60°C)

40° 1400

30° 0

40° 800

40° 600

30° 800

- 1400

- 1400

-

1200

1400

1400

1000

OFF

-

- - 9

- - - 9

Fabric

softener

(kg)

Max. load

3

2

The duration of the wash cycle can be checked on the display.

4

9

9

9

4,5

9

1

2

4

3,5

9

GB

tion

Cycle dura-

* If you select programme and exclude the spin cycle, the machine will drain only.

** If a drying cycle is also programmed, the machine will run a “wash+dry” programme lasting 45’ with maximum spin speed and a 1kg laundry load.

The length of cycle shown on the display or in this booklet is an estimation only and is calculated assuming standard working conditions. The actual duration can vary according to factors such as water temperature and pressure, the amount of detergent used, the amount and type of load inserted, load balancing and any wash options selected.

1) Test wash cycle in compliance with regulation EN 50229: set wash cycle 8 with a temperature of 60°C.

2) Long wash cycle for cottons: set programme 8 at temperature 40°C and press the DIRECT INJECTION button under “Power” mode.

3) Long wash cycle for synthetics: set wash cycle 9 with a temperature of 40°C.

11

Page 12

Detergents and laundry

1

2

A

B

*

GB

Detergent dispenser drawer

Successful washing results also depend on the correct

dose of detergent: adding too much detergent will not

necessarily result in a more efficient wash, and may in

fact cause build up on the inside of your appliance and

contribute to environmental pollution.

! Use powder detergent for white cotton garments, for prewashing, and for washing at temperatures over 60°C.

! Follow the instructions given on the detergent packaging.

! Do not use hand washing detergents; they create too

much foam.

Open the detergent

dispenser drawer and pour

in the detergent or washing

additive, as follows.

! Do not pour detergent into

the middle compartment (*).

compartment 1:

Detergent for the wash

cycle (powder or liquid)

If liquid detergent is used,

it is recommended that the removable plastic partition A

(supplied) be used for proper dosage. If powder detergent

is used, place the partition into slot B.

compartment 2: Additives (fabric softeners, etc.)

The fabric softener should not overflow the grid.

Preparing the laundry

• Divide the laundry according to:

- the type of fabric/the symbol on the label

- the colours: separate coloured garments from whites.

• Empty all garment pockets and check the buttons.

• Do not exceed the listed values, which refer to

the weight of the laundry when dry: see “Table of

programmes and wash cycles”.

How much does your laundry weigh?

1 sheet 400-500 g

1 pillow case 150-200 g

1 tablecloth 400-500 g

1 bathrobe 900-1,200 g

1 towel 150-250 g

Special wash cycles

Daily Wash & Dry: use programme 1 to wash and dry

mixed garments (cotton and synthetics). This cycle may be

used to wash and dry loads of up to 3 kg; we recommend

the use of liquid detergent.

The use of the steam in this programme is optimised to

reduce the formation of creases on garments, making

them easier to iron.

Shirts Wash & Dry: use programme 2 to wash and dry

shirts and T-shirts in different fabrics and colours to ensure

maximum care. This cycle may be used to wash and dry

loads of up to 2 kg. To achieve optimum results, use liquid

detergent and pre-treat cuffs, collars and stains. The use

of the steam in this programme is optimised to reduce the

formation of creases on garments, making them easier to

iron.

Pre Iron: use this programme immediately before ironing;

max. 1.5 kg load. The use of the steam in this programme

is optimised to reduce the formation of creases on

garments, making them easier to iron.

Steam Refresh: for refreshing garments, neutralised

unpleasant odours and relaxing the fibres by delivering

steam into the drum. The garments will be damp at the

end of the cycle.

Anti-Stain Turbo 45’: this cycle ensures excellent stain

removal capacity even at 20°C in just 45 minutes. The

temperature of this cycle can be increased up to 40°C.

Anti-Stain Power 20°C: this programme ensures

maximum stain removal capacity with no need for pretreatment at low temperatures, preserving fabrics and

colours.

Multicolor: for washing coloured cotton garments. This

programme is optimised to keep colours bright even after

repeated washing.

Ultradelicates: use programme 11 to wash very delicate

garments having strasses or sequins.

We recommend turning the garments inside out before

washing and placing small items into the special bag

for washing delicates. Use liquid detergent on delicate

garments for best results.

When selecting an exclusively time-based drying function,

a drying cycle is performed at the end of the wash cycle

that is particularly delicate, thanks to light handling and

appropriate temperature control of the water jet.

The recommended durations are:

1 kg of synthetic garments --> 150 min

1 kg of synthetic and cotton garments --> 180 min

1 kg of cotton garments --> 180 min

The degree of dryness depends on the load and fabric

composition.

Wool - Woolmark Apparel Care - Green:

the wool wash cycle of this machine has been approved

by The Woolmark Company for the washing of wool

garments labelled as “hand wash” provided that the

products are washed according to the instructions on the

garment label and those issued by the manufacturer of this

washer-dryer

Sport: for washing lightly soiled sports clothing (tracksuits,

shorts, towels, etc.); for best results, we recommend not

exceeding the maximum load indicated in the “Table of

programmes and wash cycles”. We recommend using

liquid detergent, and adding the amount suitable for a halfload.

Load balancing system

Before every spin cycle, to avoid excessive vibrations

before every spin and to distribute the load in a uniform

manner, the drum rotates continuously at a speed which

is slightly greater than the washing rotation speed. If,

after several attempts, the load is not balanced correctly,

the machine spins at a reduced spin speed. If the load is

excessively unbalanced, the washer-dryer performs the

distribution process instead of spinning. To encourage

improved load distribution and balance, we recommend

small and large garments are mixed in the load.

12

Page 13

Troubleshooting

Your washer-dryer could occasionally fail to work. Before contacting the Technical Assistance Service (see “ Product

Guarantee and Repair Information”), make sure that the problem cannot be solved easily using the following list.

Problem:

The machine does not switch on.

The wash cycle does not start.

The machine does not dry.

The clothes are too hot when the

drying cycle is finished.

The machine does not fill with

water (the text “H2O” flashes on

the display).

The machine continuously fills with

water and continually drains away

or Water left in the drum

or Stuck on wash.

The machine does not drain or spin

- (error lights flashing).

Possible causes / Solutions:

• The appliance is not plugged into the socket fully, or not enough to make contact.

• There is no power to the socket, or the fuse has blown in the mains plug.

• The door is not closed properly.

• The ON/OFF button has not been pressed.

• The START/PAUSE button has not been pressed.

• The water tap has not been turned on to allow water to flow into the machine.

• A delayed start has been set.

• Check the 2 sections above.

• DRYING is in the OFF position.

• A cooling-down period is always added to the end of each drying cycle. If the

clothes appear too hot to handle leave the door open to allow to cool further

before removing from the machine.

• The water inlet hose is kinked.

• The water inlet hose is not connected to the water supply.

• The water pressure is too low.

• The water tap has not been turned on to allow water to flow into the machine.

• There is no water supply to the house.

• The inlet valve filter is blocked.

• The START/PAUSE button has not been pressed.

• The top of the drain hose is too low - It must be fitted at a height between 65

and 100 cm from the floor (see “Installation”).

• The drain hose is connected incorrectly to the sink trap allowing water to run

into the machine, the drain hose must be positioned higher than the bottom of

the sink to prevent water flowing down the drain hose.

• The end of the drain hose has been pushed too far down the standpipe, the

‘U’ bracket should be fitted 100 mm from the end of the drain hose.

• The Pump filter is blocked.

• The drain hose is kinked (see “Installation”).

• New Installation - The blanking cap or spigot has not been removed if

connected under a sink.

• The drain hose or sink trap is blocked.

GB

The machine does spin.

The machine does not heat or poor

wash results.

The programme takes too long.

The Display sticks at one ‘time to

end’ for more than 1 Minute or the

Display changes the estimated ‘Time

to End’ during the programme.

The machine vibrates a lot during

the spin cycle.

• The Spin Speed is set to “OFF”.

• The ‘Temperature’ is set to “OFF”.

• Programme times will vary due to water pressure, the incoming water temperature

and if the wash load goes out of balance. This will increase the programme times

accordingly (see ‘ The machine wont spin properly’ next page).

• The display time is for guidance only - it is not a precise time to finish and

may vary.

• The feet have not been adjusted, enabling the machine to rock.

• New Installation - Either the Transit Bolts including the plastic spacers, or the

Polystyrene Packaging have not been removed when installing the machine.

• The machine is trapped between cabinets and/or walls.

• The load is in a slight out of balance condition and machine is spinning, but at

a lower speed.

13

Page 14

GB

The machine is noisy.

The machine wont spin properly.

• There will always be some motor, pump and drum noise during spin.

• Out of Balance detected when attempting to go into a spin cycle - If this

happens the machine will continue to try to repeat the distribution of the load

required before the machine will go into higher spin speeds - This will increase

the programme time accordingly. This is a safety feature to prevent damage.

Out of Balance can be caused by washing a single heavy item (eg duvet, quilt,

etc). - Try the programme again using a different load.

The machine leaks from the

dispenser.

The machine leaks (other than

dispenser).

The START/PAUSE indicator light

flash rapidly and an error code

appears on the display (e.g.: F-01,

F-..).

The machine smells.

The machine door cannot be

opened.

Door Seal damaged at the bottom.

The water level is too low when

the machine is washing.

• The dispenser drawer is blocked with detergent and requires cleaning.

• The water pressure is too high and requires turning down - turn down the tap

on the water supply pipe slightly and try again.

• The machine is tilting forwards - It must be level when in its final position.

• The fill hose is loose, check both the cabinet and tap ends.

• The fill hose is tight but still leaks, if so replace the rubber washers, or the fill

hose is missing the rubber washer.

• The drain hose is not fixed in properly.

• Switch off the machine and unplug it, wait for approximately 1 minute and then

switch back on again. If the problem persists contact Technical Assistance

Centre.

• The machine requires a service wash. Run a auto clean wash cycle with

detergent and no laundry.

• The door will not open until the door lock indicator light goes out shortly after

the program has finished.

• If there is no power to the machine you need to perform the manual unlocking

procedure.

• The door seal has drainage holes at the bottom - This is normal.

• The water level is correct if it can be seen at the bottom of the door.

There is too much foam.

• The detergent is not suitable for machine washing (it should display the text

‘for washer-dryers’ or ‘hand and machine wash’ or the like).

• Too much detergent was used - less detergent is required in soft water.

The machine just ‘beeps’ when a

programme or option is selected

• Deactivate the Key Lock feature by pressing and holding in the ‘KEY LOCK’

button for 2 seconds.

(Key Lock led is lit).

After completing the programme,

or before starting a programme,

the machine has turned itself off

• To comply with new energy saving regulations the machine is fitted with an

automatic standby system. Press ‘ON/OFF’ button for 3 seconds to activate

the machine, it can then either be switched off or a new programme selected.

(no lights).

General.

• Your washer-dryer contains sensors that monitor progress during the wash cycle

(eg: Water Levels, Temperatures, Out of Balance loads, Wash time/progress).

Normally, if your machine successfully completes the cycle, there is unlikely to

be anything wrong!

Remember, you will be charged for a service call for problems caused by incorrect installation, as indicated on

pages 2 to 4.

Not emptying contents from pockets may cause pump or drain blockages, or may damage the machine.

Do not wash items which do not have a wash label, or wash items that are not intended as machine washable.

14

Page 15

Product Guarantee and

Repair Information

Guarantee

12 Months Parts and Labour Guarantee

Your appliance has the benefit of our manufacturer’s

guarantee, which covers the cost of breakdown

repairs for twelve months from the date of purchase.

This gives you the reassurance that if, within that

time, your appliance is proven to be defective

because of either workmanship or materials, we will,

at our discretion, either repair or replace the appliance

at no cost to you:

This guarantee is subject to the following conditions:

- The appliance has been installed and operated

correctly and in accordance with our operating and

maintenance instructions.

- The appliance is used only on the electricity or gas

supply printed on the rating plate.

- The appliance has been used for normal domestic

purposes only.

- The appliance has not been altered, serviced,

maintained, dismantled, or otherwise interfered with

by any person not authorised by us.

- Any repair work must be undertaken by us or our

appointed agent.

- Any parts removed during repair work or any

appliance that is replaced become our property.

- The appliance is used in the United Kingdom or

Republic of Ireland.

The guarantee does not cover:

- Damage resulting from transportation, improper

use, neglect or interference or as a result of improper

installation.

- Replacement of any consumable item or accessory.

These include but are not limited to: plugs, cables,

batteries, light bulbs, fluorescent tubes and starters,

covers and filters.

- Replacement of any removable parts made of glass

or plastic.

Recycling and Disposal Information

As part of Hotpoint’s continued commitment to

helping the environment, Hotpoint reserves the right

to use quality, recycled components to keep down

customer costs and minimise material wastage.

Please dispose of packaging and old appliances

carefully. To minimise the risk of injury to children,

remove the door, plug, and cut the mains cable

off flush with the appliance. Dispose of these parts

separately to ensure that the appliance can no longer

be plugged into mains socket, and the door cannot

be locked shut.

Repairs and After Sales

For product help and advice, repairs, spare parts or

accessories, we’re here to help.

For local repair engineers - 03448 111 606

ROI - 0818 313 413

UK standard local rate applies

ROI local Irish rate applies

For Parts and Accessories visit:

parts.hotpoint.co.uk/shop

Please remember to register your appliance at

www.hotpointservice.co.uk to activate your 10 year

parts guarantee.

How to find your model and serial number:

GB

THIS GUARANTEE WILL NOT APPLY IF THE

APPLIANCE HAS BEEN USED IN COMMERCIAL

OR NON-DOMESTIC PREMISES.

15

Page 16

GB

195140320.03

10/2016

Indesit Company Spa

Viale Aristide Merloni, 47

60044 Fabriano (AN)

Italy

www.hotpoint.co.uk

16

Loading...

Loading...