Page 1

PZ 640T GH NG and PZ 750R GH NG

Operating, Care and

Installation Instructions

Contents

Safety Warnings 2

Using Your Cooker 3

Installation 4-5

Service Details 6

Troubleshooting 7

Care And Maintenance 8

Installer - Ensure these instructions remain with the consumer.

This cooktop has been certifi ed for use by SAI-Global

Page 2

Safety Warnings

This appliance has been designed and manufactured

in compliance with Australian and international safety

standards. The following warnings are provided for safety

reasons and must be read carefully.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHILE IT IS IN OPERATION.

DO NOT MODIFY THIS APPLIANCE.

DO NOT USE OR STORE FLAMMABLE MATERIALS

NEAR THIS APPLIANCE.

This appliance is not suitable for marine craft, caravans or

recreational vehicles

This appliance is not intended to be used by young children, the elderly or infi rm without supervision.

Young children should be supervised at all times when

near this appliance.

If the appliance fails to operate correctly, contact place of

purchase or their appointed agent for advice and service.

Do not touch hot surfaces. Allow hob to cool before wiping

spillage.

There are no user serviceable parts within this appliance.

For any service, contact the place of purchase or the

nominated service agent. Do not attempt repairs yourself.

The appliance was designed for domestic use inside the

home and is not intended for commercial or industrial use.

The appliance must not be installed outdoors, even in

covered areas. It is extremely dangerous to leave the appliance exposed to weather.

Always make sure the knobs are in the OFF position when

the appliance is not in use.

Always make sure that pan handles are turned towards

the centre of the hob in order to avoid accidental burns.

Gas appliances require a regular air supply to maintain

effi cient operation. Always ensure that the kitchen is ad-

equately ventilated whilst the appliance is in use.

Never leave cooking food unattended. Do not allow the

liquid to boil dry

Do not use asbestos mats or heat diffusers, as these

trap the heat and can cause damage to the cooktop from

overheating.

Don’t wear loose clothing while cooking, as garments may

catch utensil handles or catch fi re.

Use dry utensil holders. Wet pot holders can build up

steam. Do not use towels or other large pieces of cloth to

pick up cooking utensils, as these may touch the heating

element and catch fi re.

Do not allow pot handles to overhang other burners that

are in use, as this will cause scorching of the handle, and

potential handling burns.

Rapid

Burner

Auxiliary

Burner

Semi Rapid

Burner

Wok

Burner

Rapid

Burner

Auxiliary

Burner

Double Crown

Double Ring

Burner

Semi Rapid

Burner

Semi Rapid

Burner

2

Page 3

Using Your Cooker

Controlling the burners

Each control knob is marked to indicate which burner it

controls. Each control knob also has markings to indicate the

three main settings:

OFF

High

Low

Lighting the burners

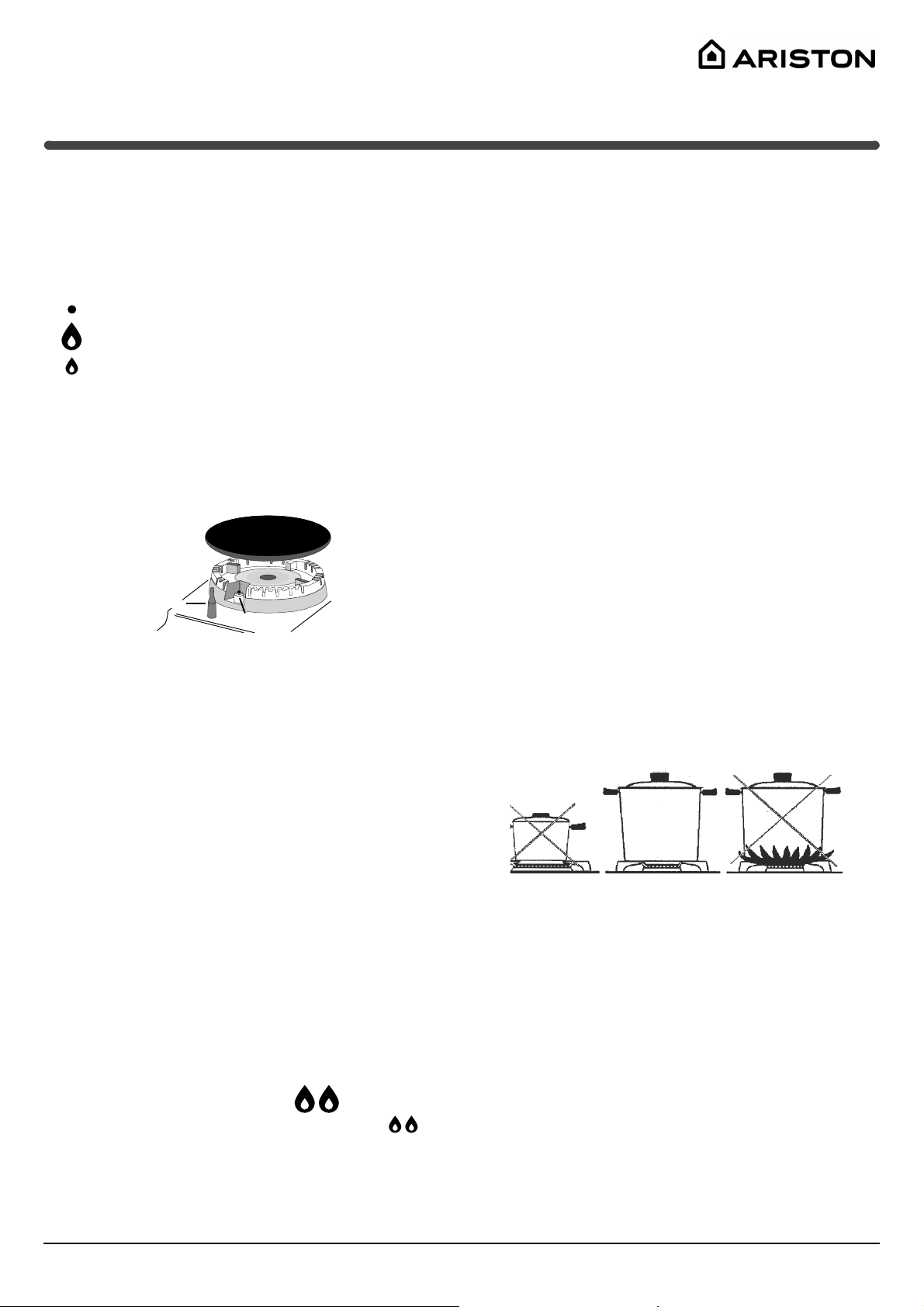

Your Arisit hobs are equipped with a safety probe that prevents the gas from fl owing unless there is a fl ame.

To ignite a burner, press and turn the control knob counterclockwise until the knob points to High. Keep pressing the

knob inwards until the probe heats up. Release the knob.

safety probe

ignitor

Check that the gas has been lit. If the burner fails to ignite try

again. If the burner fails to ignite after 3 attempts, wait a few

minutes for the gas to disperse before making any further

attempts.

If the burner still fails to ignite, a match or lighting device can

be used, but care must be taken. If the problem persists, contact place of purchase or their appointed agent for service.

Lighting the burners for the fi rst time

If the appliance is being used for the fi rst time, or if it has not

been used for a long period of time, it may be necessary to

purge the gas lines of excess air before you can successfully

light the burners.

To do this, turn each burner to high for 10-15 seconds and

press the ignition button several times. If the burner does not

light, repeat this procedure twice more. Wait 1-2 minutes for

any gas build up to disperse before allowing any further gas

fl ow.

Cookware

Use appropriate cookware for each burner

Always use a vessel for cooking that is appropriate in size

for the size of burner. Ensure the fl ames do not extend

beyond the bottom of the pot.

Never use pots that are too small or too large. For wok

cooking it is recommended that a domestic size wok, no

larger than 400 mm in diameter be used.

Always use cookware with a fl at base. Do not use pans

which are unstable or which have a warped or damaged

base.

Ensure the pot sits securely on the trivet and is centred

above the burner.

Small pots can be used on the inner ring of the double

crown double ring burner.

Controlling the fl ame height

Any fl ame height can be achieved between High and Low by

rotating the control knob between the two positions:

Avoid operating the burner with the control knob set between

Off and High.

If a fl ame is accidentally extinguished, turn off the control

knob and wait for at least 1 minute before relighting.

Double Crown Double Ring Burner (PZ750

only)

Double ring burners have two independent gas rings controlled by the one control knob. Turning the knob anticlockwise

from the Off position controls the smaller inner ring only.

To switch on the outer ring, keep turning the knob anticlockwise past the 6 O’Clock position. The outer ring will ignite

as well, and both rings will be on High

rotate the knob until both rings are operating on Low

.. Continue to

..

To turn off the burner

To switch off the burner, turn the knob in a clockwise direction

until it reaches the 0ff position.

3

Page 4

Installation

WARNING: Before installation, check that the gas type (natu-

ral gas or LPG/Propane) of the cooker is suitable for the gas

type available to the installation. It is extremely dangerous to

use the wrong gas type with any appliance, as fi re or serious

injury can result.

These instructions have been prepared for use by authorised

persons. This unit must only be installed by an authorised

person.

This appliance must not be installed in marine craft or recreational vehicles.

Compliance with standards

This cooktop must be installed in accordance with the requirements of local gas and electrical authorities, as well as

the latest published versions of the following standards:

AS/NZS 5601 Gas Installation code

SAA Wiring Rules

Dimensions of cutout

The following diagram indicates the dimensions of the required cutout.

In placing the cooktop, suitable insulation between the cooktop undersurface and the top of the bench should be used.

Wherever possible, the cooktop should be secured to the

benchtop using clamps.

Fitting the cooktop into cabinetry

The following minimum clearances to combustible materials

must be observed:

Minimum clearance from edge of burner to side wall must

be 200 mm.

Minimum clearance from edge of burner to rear wall must

be 200 mm.

Minimum clearance from top of highest burner to cupboard

above hob burners must be 600 mm.

555 mm

55 mm

475 mm

INSTALLER: Please also ensure that the duplicate data label

supplied, be affi xed in a suitable easily accessible location

such as an adjacent cupboard or drawer, for future reference.

Dimensions (mm) PZ640 PZ750

length (side to side) 600 750

width (front to back) 510 510

depth 44 44

Fixing to the housing unit

Proceed with fi xing to the housing unit as follows (see fi gure

above).

Mount the hooks, partly tightening the screws into the

holes.

Position the sealing gasket approximately 5-6 mm from

the edge of the installation hole, matching up the two ends

of the seal without overlapping.

Insert the hob into the cutout, making sure it is positioned

centrally and that the edge adheres to the sealant

Position the hooks correctly, as shown in the fi gure, and

then tighten the screws to hold them in place.

Range hoods

Range hoods and overhead exhaust fans must be installed

according to manufacturers’ instructions but in no case shall

clearance from hob burners be less than 600 mm for range

hoods and 750 mm for overhead exhaust fans.

Adjacent cabinetry

It is recommended that the adjacent kitchen surfaces should

be capable of withstanding temperatures of 100°C.

4

Page 5

Installation

Fitting the cooktop above an oven

When installing the cooktop above an oven, both the electricity supply cable and the gas pipe or fl exible hose must not

touch hot parts of the oven housing.

When installing above a built-under oven without forced cooling ventilation, suitable air vents should be provided for as

shown in the fi gure (inlet at least 200 cm² from the bottom,

outlet at least 120 cm²

from the top part) to

allow adequate ventilation inside the housing

unit.

Also a wooden panel

“A” should be installed

beneath the hob as insulation, positioning it

at a minimum distance

of 15 mm from the hob

housing

200 cm²

Gas connection

Electrical connection

The electrical supply for the cooktop must be a 240 Volt 50

Hz.

The fuse and electrical wiring of the home/premises must

support the load of the appliance.

The appliance must be earthed. A 3 pin fl exible power cord

is supplied with the appliance to allow the cooktop to be

connected to a properly earthed and rated power socket.

The fl exible cord of the appliance must not be subject to

direct heat and must be positioned after installation of the

appliance so that its temperature does not exceed 75°C.

IMPORTANT If a power socket needs to be installed or

relocated, the work must be done by a licensed electrician.

Gas type conversion

If the hob is to be converted for use with a type of gas other

than that for which it was set in the factory (indicated on the

cooktop data plate), the burner injectors must be replaced as

follows:

Remove the pan supports and the burners.

Unscrew the injectors (“A” in fi ugure below) using a 7 mm

socket wrench, and replace them with injectors of suitable

orifi ce diameter, as indicated on the appliance data plate.

Reassemble the parts.

This appliance is suitable for use with either a fl exible con-

nection or rigid copper connection. If installing the appliance

with a fl exible connection, the fl exible connection must be

approved to class B or D of AS/NZS1869 as a minimum.

Fit regulator supplied for Natural Gas (if applicable) at rear

of appliance, and as close as practicable to the appliance.

It is recommended that an isolating valve and union be

fi tted, to enable simple disconnection for servicing. These

are to be in an accessible location.

Flexible hose

If a fl exible hose is used, it should be as short as possible

with a maximum length of 1.5 metres;

it should not be bent or kinked;

it should not be in contact with the rear wall of the appliance or in any case with parts which may reach a temperature of 50°C;

it should not come into contact with pointed parts or sharp

corners;

it should be easy to inspect along its entire length in order

to be able to check its condition.

The supply connection point must be accessible with the

appliance installed.

If a regulator is required for the new gas type, instal an ap-

proved regulator of appropriate pressure setting and fl ow

capacity.

Replace the gas type label with one suitable for the new

gas type.

Perform the post installation checks as described later in

this manual. In particular, check the turn down setting of

each burner and adjust where necessary.

Perform post installation checks and ensure proper and safe operation

before leaving. Test all burners individually and in combination.

5

Page 6

Service Details

Post installation checks

Leak Check

Ensure all gas control knobs are in the Off position.

Ensure the gas supply is switched on.

Spray a solution of soapy water onto all gas joints as well

as the full length of any fl exible hoses.

UNDER NO CIRCUMSTANCES USE A NAKED FLAME

IN CHECKING FOR LEAKS.

If bubbles appear anywhere, turn the gas supply off, check

all connections and retest. If satisfactory operation cannot be

achieved, contact place of purchase or their appointed agent

for service.

Flame check

Turn each burner on, and ensure that the fl ame is blue with

minimal yellow tipping. If there is signifi cant yellow tipping,

fl ame lift off or excessive noise, check pressure and adjust at

the regulator if necessary.

If satisfactory operation cannot be achieved, contact place of

purchase or their appointed agent for service.

Igniter operation

Check that the igniter for each burner successfully ignites the

gas.

If an igniter fails to work, fi rst remove the plug from the

electrical power outlet, and then check that all the electrical

connections are in place.

If satisfactory operation cannot be achieved, contact place of

purchase or their appointed agent for service.

Low fl ame setting

Check the low fl ame setting for each hob burner to ensure

that the minimum fl ame will not be extinguished by air

draughts.

Light the burner.

Turn the control until it engages in the minimum position.

Ensure the fl ame is stable and will not be extinguished by

air draughts.

To adjust the minimum fl ame:

Follow the procedure described in the gas conversion instruction.

Electrical equipment and components

To check or replace the ignition module

Electrical components are located below the hob surface. To

access the components:

IMPORTANT: First ensure that gas and electrical power

are disconnected before performing any service to this

appliance.

Remove the control knobs, trivets, burner caps and burner

head assembly.

Invert the cooktop and remove the two screws on the base

near the gas manifold.

Lift the base upwards. Take care to ensure that no damage occurs to the spark ignition leads or the igniter components.

The electronic ignition module is now easily accessible for

service or replacement.

Assembly is a reversal of the above procedure.

To check or replace the gas controls and gas manifold

Gas components are located below the hob surface.

Access the components underneath the surface of the hob

as described in the previous section.

Disconnect all ancillary gas piping, wiring and any screws,

as appropriate.

The gas manifold may then be extracted.

Replacement is a reversal of the above procedure.

ALWAYS PERFORM A LEAK CHECK AFTER PERFORMING ANY SERVICE. Correct procedure is at the top of

this page.

Adjust turn down setting

Put the tap to the low fl ame position;

Remove the tap knob and turn the adjusting screw, situ-

ated inside the tap stem (fi g.11), using a screwdriver

(loosening the screw increases the height of the fl ame,

tightening decreases it). note: the adjusting screw must be

fully screwed down for liquid gas.

Having obtained the low fl ame setting required and with

the burner lit, abruptly change the position of the knob

several times from minimum to maximum and vice versa

and check that the fl ame does not go out.

DO NOT MODIFY THIS APPLIANCE IN ANY WAY.

6

Page 7

Troubleshooting

It may happen that the appliance does not function properly or at all. Before calling the service centre for assistance, check if

anything can be done. First, check to see that there are any interruptions in the gas and electrical supplies, and, in particular,

that the gas valves for the mains are open.

Problem Likely cause

The burner does not light or the fl ame is not even around the

burner.

The burner does not remain lit when set to minimum. The gas holes are blocked.

The cookware is unstable. The bottom of the cookware is warped.

The gas holes on the burner are clogged.

The removable parts that make up the burner are mounted

incorrectly.

There are draughts near the appliance.

There are draughts near the appliance.

The minimum setting has not been adjusted properly.

The cookware is not positioned correctly at the centre of

the burner.

The pan support grids have been positioned incorrectly.

Technical Specifi cations

Gas consumption

PZ 750 Injector

diameter

Natural Gas (1.0 kPa) Propane (2.75 kPa)

Auxiliary 0.85 mm 3.3 MJ/hr 0.50 mm 3.3 MJ/hr

Semi Rapid (2) 1.10 mm 6.0 MJ/hr 0.64 mm 5.5 MJ/hr

Rapid 1.25 mm 9.4 MJ/hr 0.85 mm 9.0 MJ/hr

Wok Burner (Double

Crown Double Ring)

total 39.7 MJ/hr 38.3 MJ/hr

PZ 640 Injector

Auxiliary 0.85 mm 3.3 MJ/hr 0.50 mm 3.5 MJ/hr

Semi Rapid 1.10 mm 6.0 MJ/hr 0.64 mm 5.5 MJ/hr

Rapid 1.25 mm 9.4 MJ/hr 0.85 mm 9.0 MJ/hr

Wok Burner 1.75 mm 13.0 MJ/hr 1.01 mm 13.0 MJ/hr

total 31.7 MJ/hr 31.0 MJ/hr

0.85 mm +

2 x 1.25 mmm

diameter

Natural Gas (1.0 kPa) Propane (2.75 kPa)

gas input Injector

diameter

15 MJ/hr 0.5 mm +

2 x 0.75 mm

gas input Injector

diameter

gas input

15 MJ/hr

gas input

Connections

PZ 640 PZ 750

Gas Inlet fi tting 1/2” BSP (male) thread 1/2” BSP (male) thread

Location of gas inlet 40 mm from rear edge

60 mm from right side edge

Electrical input Flexible cord and earthed 10

Amp 3 pin plug

Location of Electrical Connection 55 mm from rear edge

200 mm from left side edge

40 mm from rear edge

145 mm from right side edge

Flexible cord and earthed 10 Amp

3 pin plug

50 mm from rear edge

250 mm from left side edge

7

Page 8

Care And Maintenance

04/2008 - 195071001.00

XEROX BUSINESS SERVICES

General cleaning notes

DO NOT TOUCH HOT SURFACES, ALLOW COOKTOP TO

COOL COMPLETELY BEFORE CLEANING.

Always wipe spills up when they occur. Do not leave spills

to dry onto the surface of the hob.

It is usually enough to wash the hob with a damp sponge

and dry it with absorbent kitchen roll.

NOTE: Do not put hot components in cold water. The

sudden temperature shock could cause the component to

crack.

Do not use abrasive or corrosive detergents such as

stain removers, anti-rust products, powder detergents or

sponges with abrasive surfaces: these may scratch the

surface beyond repair.

Burners

Wait for the cooktop to cool completely. Remove the

burner cap and check the gas outlet holes for blockages.

Clean with a soft bristle brush and warm soapy water.

The removable parts of the burners should be washed

frequently with warm water and soap and any burnt-on

substances removed.

Ignitors

The terminal part of the electronic instant lighting devices

should be cleaned frequently,

Enamelled parts (trivets)

Never use abrasives, scouring pads or sharp objects. This

will cause irreparable damage to the enamel.

Clean the enamelled parts with soapy water when cold

and wipe off with a clean, dry cloth. The enamel could dull

if cleaned while still hot.

Stainless steel and chromed parts

Stainless steel can be marked by hard water that has

been left on the surface for a long time, or by aggressive

detergents containing phosphorus. After cleaning, rinse

and dry any remaining drops of water.

Use commercial products designed for cleaning stainless

steel and chromed steel, and follow the maker’s instructions. Care should be taken when cleaning around graphics.

Never use steam cleaners or pressure cleaners on the

appliance.

Service Schedule

To keep your cooker running smoothly, we recommend that

you have your cooker serviced every 5 years by an authorised service agent.

Never use unauthorised technicians and never accept replacement parts which are not original.

ARISTON

PRIORITY SERVICE

If you are not completely satisfi ed

with your appliance or require

service call:

Australia

Phone: 1300 815 589

New Zealand

Phone: (09) 306 1020

AUSTRALIA

ARISIT PTY LIMITED

40-44 Mark Anthony Drive, Dandenong South,

VIC 3175, Australia

Fax: Service & Sales (03) 9768 0838

Email: consumer.care@arisit.com

Service and spare parts are available on the numbers below.

Please have the following information handy:

The appliance model (Mod.).

The serial number (S/N).

This information can be found on the data plate located on

the appliance and/or on the packaging.

GENUINE ACCESSORIES

& SPARE PARTS

A wide range of genuine

accessories are available for

your appliance call:

Australia

Phone: 03 9768 0888

New Zealand

Phone: (09) 306 1020

NEW ZEALAND

ARISIT PTY LIMITED

PO Box 68-140 Newton, Auckland

1145, New Zealand

Fax: (09) 302 0077 Email: sales@aristonappliances.co.nz

PZ-0408

8

Loading...

Loading...