Hotpoint MSZ900DFUK, MSZ902DFUK, MSZ906DFUK, MSZ906NDFUK, MSZ900NDFUK Service Information

...

Indesit Company UK Ltd

© 2012 Reg. Office: Peterborough PE2 9JB Registered in London: 106725

Service

Information

HOTPOINT

SIDE-BY-SIDE

FRIDGE

FREEZERS

(7 ~ Segment Version)

Models Comm.

Covered Code

Energy Band 'A' Models

MSZ900DFUK 71629

MSZ902DFUK 71622

MSZ906DFUK 71630

MSZ900NDFUK 76246

MSZ902NDFUK 76244

MSZ906NDFUK 76240

5407573 Issue 2 March 2012

2 of 61

Service Manual UK

Indesit

Company

English

HEALTH AND SAFETY

For the servicing of refrigeration products, containing R134a refrigerant.

These instructions are in addition to any other Company procedures already published.

Published primarily for Indesit Company engineers working in the UK or Southern Ireland, for

which these instructions are MANDATORY.

General

1. This manual is not intended as a comprehensive repair/maintenance guide to the appliance.

2. It should only be used by suitably qualified persons having technical competence, applicable product

knowledge, suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected. (unplugged

from the electrical supply).

4. Servicing must be preceded by earth continuity and insulation checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on

metal and plastic parts.

6. After servicing, the appliance must be rechecked for electrical safety.

Refrigerant R134a - Safe Handling - Transporting & Storage

1. Work areas should be well ventilated and any immediate heat sources turned off.

2. Do not smoke where there is a possibility of refrigerant in the atmosphere. Customer/s should also

be advised.

3. Cylinders must not have heat applied, or stand close to a heat source, and should be stored out of

direct sunlight.

4. Should a sudden release of refrigerant occur, open windows or outside doors in the immediate

vicinity, then evacuate for a few minutes.

5. It is illegal to intentionally vent R134a refrigerant to atmosphere. Follow the company procedure on

collection and reclamation.

6. If a leak is identified the appliance must be repaired immediately if possible.

7. Where it is not possible to repair the appliance immediately the customer should be advised:

Appliance should be turned off and the refrigerant recovered.

8. Returned compressors must be sealed to prevent the escape of oil and refrigerant. Refer to the

Environmental responsibilities for service engineers in your Health and Safety booklet.

9. Cylinders (R134a) being transported must be in an upright position on the floor of the vehicle and

prevented from movement.

10. A green compressed gas label Part No. 8100062 should be displayed on the rear of the vehicle.

3 of 61

Indesit Company

Service Manual UK English

CONTENTS

Health & Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Star Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Appliance Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Removing the Appliance Furniture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Detailed Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Water Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ice Maker Operation & Water Flow System . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 20

Power Module Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 - 22

Display Panel Functions & Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 - 27

Component Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 - 30

Alarm Conditions, Temperature Tables & Auto Test . . . . . . . . . . . . . . . . . . . . 31 - 35

Ice Maker & Ice Dispensing Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . 36 - 38

Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 - 40

Thermistor (NTC) Sensor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Servicing & Dismantling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 - 49

Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Compressor Connection Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Power Module Edge Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 - 53

Theoretical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 - 55

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 - 60

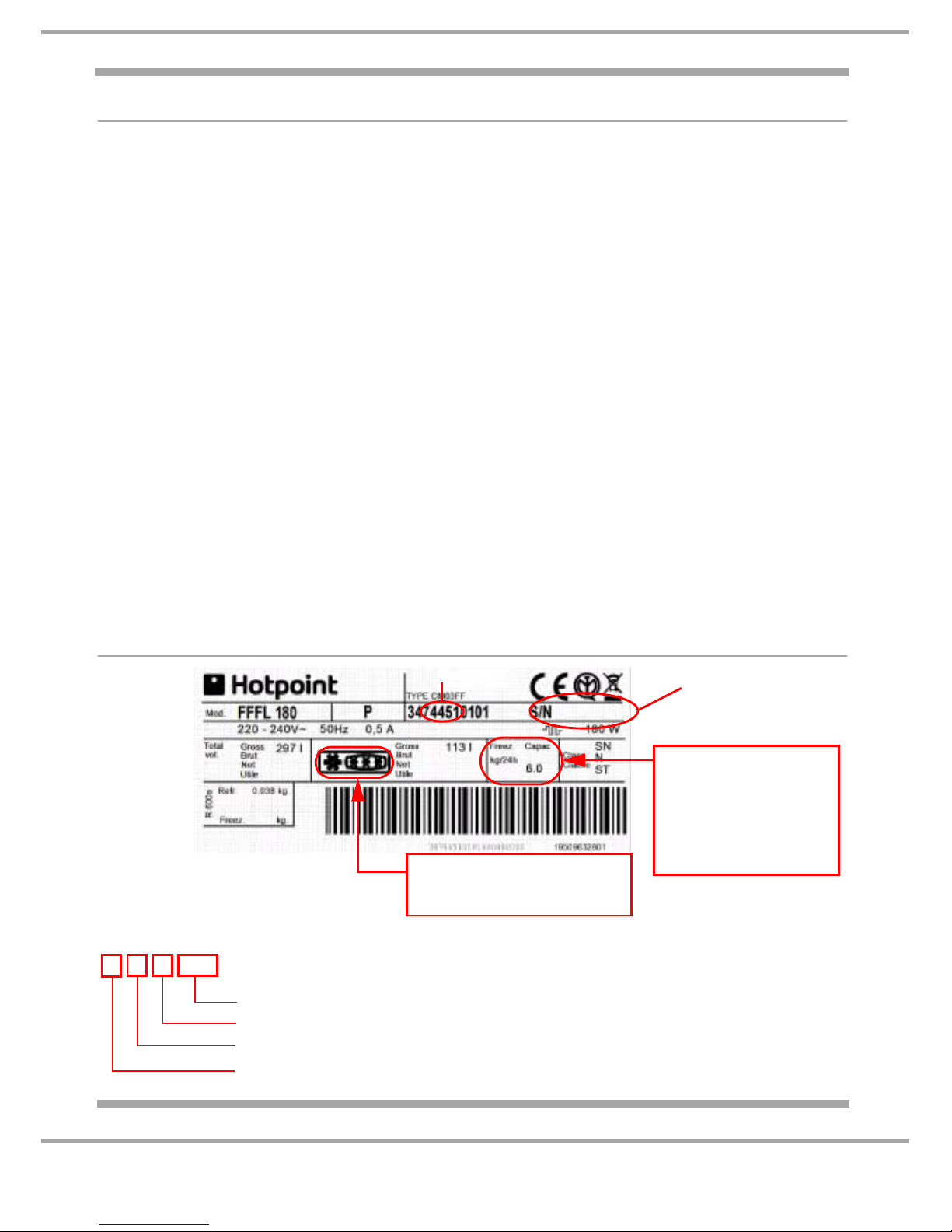

PRODUCT IDENTITY

Example

1 Commercial Code: 74451

2 Serial Number:

Printed on a separate label below the Rating Plate

Build number that day, e.g. 8689th built

Day of manufacture, e.g. 10

th

of month

Month of manufacture, e.g. June

Year of manufacture, e.g. 2010

1

2

00610 8689

006108689

Example Shown:

This appliance is rated as 4 star

indicated by the logo

Example shown:

This appliance has the

capacity to freeze 6 kg of

fresh food from +25°C to

-18°C in 24 hours without

affecting the frozen food

already being stored.

4 of 61

Service Manual UK

Indesit

Company

English

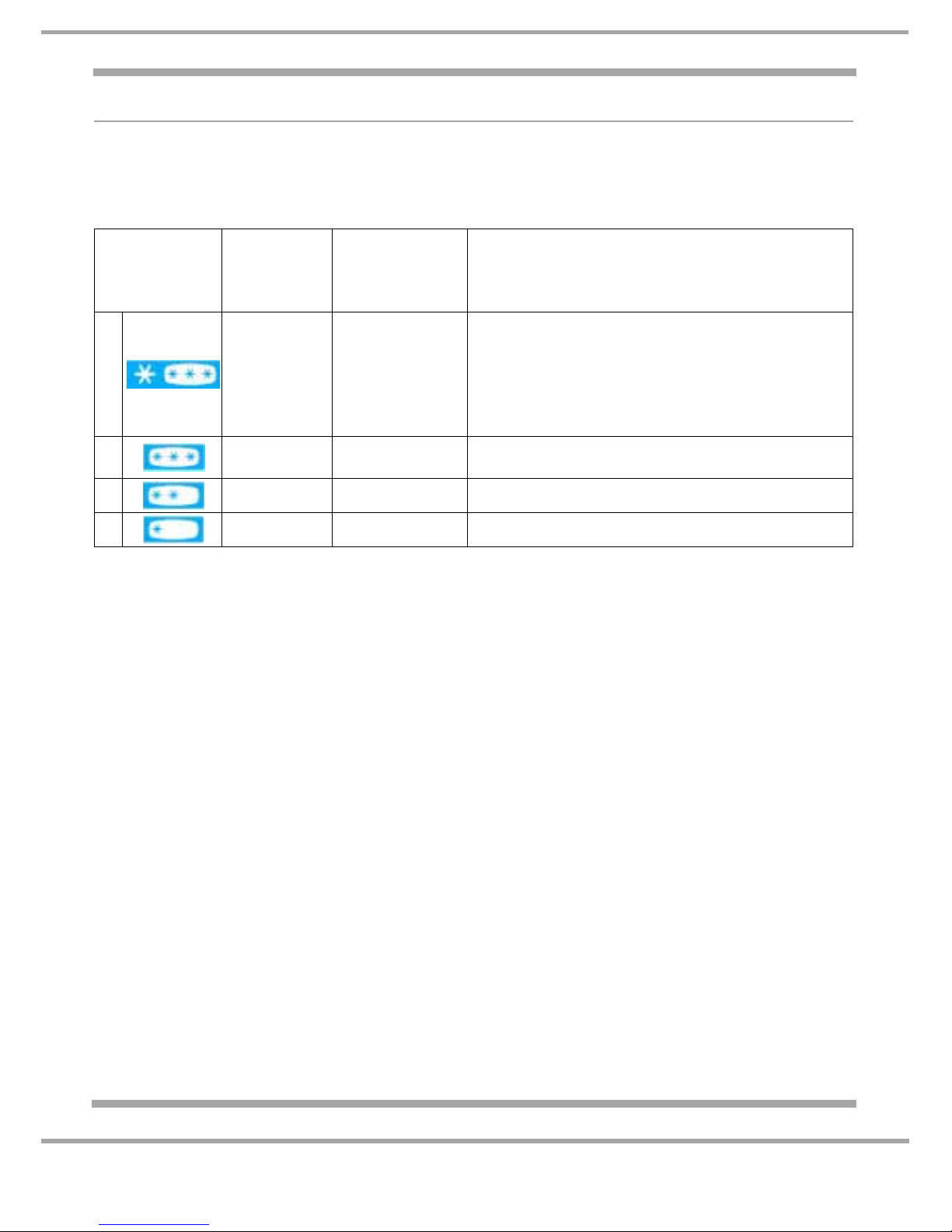

STAR RATING

UK and EU freezers and refrigerators with freezer compartments are star rated with regard to their

capacity to store or freeze food.

The temperatures for the freezer compartment relating to these star ratings are as follows:

Although both the three and four star ratings specify the same storage times and same minimum

temperature of -18°C, only a four star freezer is intended to be used for freezing fresh food, and may

include a 'fast freeze' function (runs the compressor continually, down to as low as -26°C) to facilitate

this.

Three (or fewer) stars are used for frozen food compartments which are only suitable for storing frozen

food; introducing fresh food into such a compartment is likely to result in unacceptable temperature

rises.

This difference in categorisation is shown in the design of the star logo, where the 'standard' three stars

are displayed in a box using 'positive' colours, denoting the same normal operation as a 3-star freezer,

and the fourth star showing the additional fresh food/fast freeze function is prefixed to the box in

'negative' colours or with other distinct formatting.

STAR Rating

Minimum

Temperature

°C (°F)

Maximum

Storage Time for

Per-Frozen

Foods

Maximum Storage Time for Frozen from Fresh

Foods

4 -18°C (0°F)

Between 3 and 12

months

Between 3 and 12 months.

Has the capacity to freeze a specified quantity of fresh

food from +25°C to -18°C in 24 hours

without affecting the frozen food already being stored.

(Refer to the rating plate on the appliance for

specific quantity.)

3 -18°C (0°F)

Between 3 and 12

months

N/A

2 -12°C (10°C) 1 month N/A

1 -6°C (21°F) 1 week N/A

5 of 61

Indesit Company

Service Manual UK English

MODEL INTRODUCTION

The models included in this manual are 1774 mm high Side by Side fridge and freezer, one

compressor Frost Free appliances. There are two different ranges of the same model, the first range

was first introduced during March 2010 and the second range during September 2011. All models are

similar with regard to the furniture design, refer to Technical Specification Pages 6 and 7 for the

models, colour variants and specifications. The two ranges are referred to in this manual as either

2010 DF Models or 2011 NDF models. Where no specific range is noted, the information will be

generic for both ranges.

Interior:

The interior of the fridge has safety glass shelves, one meat drawer (chiller) and one humidity

controlled salad bin (crisper) with a glass cover. The door has two deep shelves, a dairy shelf with a lid

and a lower bottle shelf.

The interior of the freezer section has two drawers of varying sizes and two safety glass shelves of

varying sizes. The door has two commodity shelves and an ice storage bucket.

The interior differences between the DF and NDF model are shown below:

MSZ900DF, MSZ902DF and MSZ906DF (2010 DF Models):

1. The Icemaker (with blue rake) is located at the top inside section of the freezer compartment.

2. Has two roller wheels at the rear and two wheels and two adjustable feet at the front.

MSZ900NDF, MSZ902NDF and MSZ906NDF (2011 NDF Models)

1. Sankyo IDI2 (In-Door-Ice) Icemaker is located in the freezer door above the ice storage bucket.

2. A new upper hinge with “cut-out” for a door removal without removing the connectors and modified

top connectors with pin lock system.

3. New water piping guidance for the ice maker. Both pipes are now located in the base of the

appliance. Blue pipe for the ice-maker. Transparent pipe for the water.

4. Has two feet at the rear and two feet at front.

5. Has an ice maker fill tube heater.

6. LED light in the water dispensing area.

The appliance is 'frost free' design so defrosting is automatic.

The digital display interface module (7 ~ segment LED) is mounted in the front of the freezer door with

the drinks dispenser, the fast freeze button and ice maker controls are also mounted in the same area.

The fridge and freezer temperature settings are adjusted by selecting the + / - buttons next to the

relevant temperature display window. All functions are monitored and actioned by the power module

mounted at the rear of the appliance within the compressor compartment.

The climate class is N / ST signifying that it is designed to operate in ambient temperatures between

+16°C to +38°C.

As with many refrigeration appliances, it is important that it is installed and operated within the

recommended ambient temperature range and that there is adequate ventilation.

All appliances equipped with an automatic ice-maker and water dispenser must be connected to a

water supply that only delivers drinking water. See Specification page for pressure requirements.

6 of 61

Service Manual UK

Indesit

Company

English

SPECIFICATIONS

Key: DF = Ice and Water Dispenser

GENERAL:

Appliance Type: Side by Side

Static / Frost Free: Frost Free

Door Hinging - Freezer L/H & Fridge R/H

Reversible: No

Plug/Cable: UK / 2.45m

Water Pipe: 1.65m

Noise Level: 'A' Class band models ~ 45dB

Climate Class: (Rating Plate) N.ST = 16°C to 38°C

Star Rating 4 Star

Refrigeration Type: Frost Free - Fin On Tube (FOT)

DIMENSIONS & WEIGHT:

*Height - Maximum: 1775 mm 1744 mm rear cabinet height only

*Width: 902 mm

*Depth: 752 mm

Weight Gross: 146 kg

Weight Net: 140 kg

To allow product handling and sufficient air circulation, leave at least 10 mm clearance at the sides,

above the appliance and between the rear panel and the wall.

* For further dimensions please refer to Page 8.

CAPACITIES / VOLUME: Gross Volume Net Volume

Fridge: 340 litre 335 litre

Freezer: 206 litre 155 litre

Freezing Capacities (per 24 hrs):12 kg

Conservation Time: 5 hours

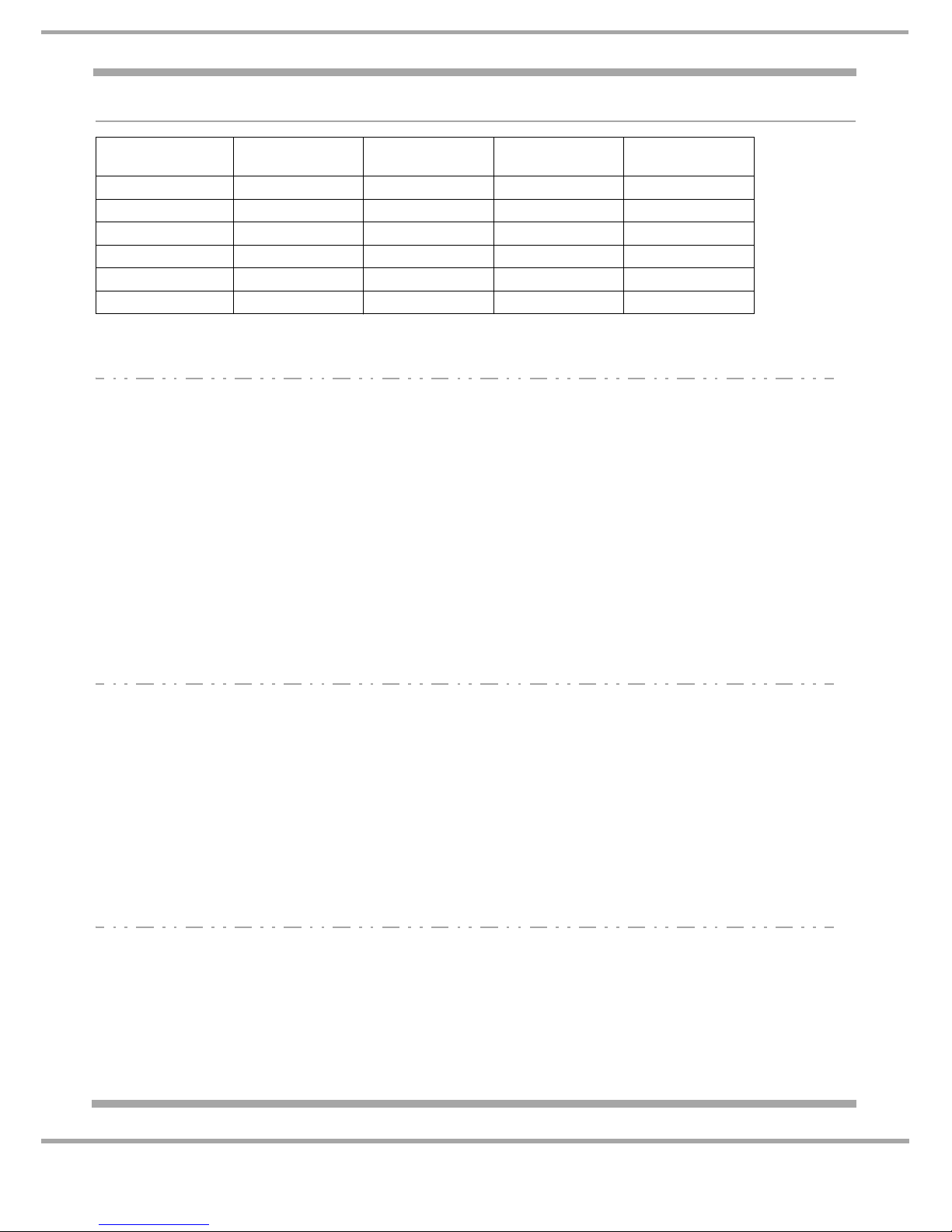

Model Colours

Commercial

Code

Manufactured

Introduction

Date

MSZ906DF Black 71630 Italy March 2010

MSZ900DF Silver 71629 Italy March 2010

MSZ902DF Stainless Steel 71622 Italy March 2010

MSZ900NDFUK Silver 76246 Italy Sept. 2011

MSZ902NDFUK Stainless Steel 76244 Italy Sept. 2011

MSZ906NDFUK Black 76240 Italy Sept. 2011

7 of 61

Indesit Company

Service Manual UK English

TECHNICAL DATA:

Power Supply Voltage: 220/240 V

Power Supply Frequency: 50 Hz

Mains Water Supply: Min. 1.38 bar

Max. 8.27 bar

Freezer Lamp: T-Click 40W 220V - 240V

Fridge Lamp: T-Click 40W 220V - 240V

ENERGY

Energy Class: A

Power Consumption: 1.39 kWh/24hr

Annual Consumption: 507.35 kWh/yr

COMPRESSOR WINDING

Manufacturer: Embraco

Type I/D: EGYS 90 HLP

Winding Resistance: Start: 21.3:

Run: 12.3:

Refrigerant/ Grams: R134a / 160g - Refer to the appliance rating plate

Insulation: C-Pentane

HEATER RESISTANCES

Evaporator Defrost Heater: 86:

Ice Maker (2010 DF Models):

Motor Power 8W

Sankyo IDI (2011 NDF Models):

Fill Tube Heater: 65.85 - 73.17:

Motor Power: 2W

ICE PRODUCTION:

ICEMAKER SANKYO IDI (IDI= In Door Ice) located in the freezer door of 2011 NDF models:

Approximately six or seven loads or 0.8kg.

ICEMAKER (2010 DF Models): Approximately 200 ice cubes per 24 hours running at optimum capacity

COMPONENT RESISTANCES

Condenser Fan Motor: 220 - 240V, 1100 rpm

Evaporator Fan Motor: 256:

Water Dispenser Solenoid Valve: 8.68k:

Water Ice Maker Solenoid Valve: 8.71k:

Ice Chute Motor (Dispenser) 50: ± 7%

8 of 61

Service Manual UK

Indesit

Company

English

DIMENSIONS

Dimensions are an approximate guidance as doors can be adjusted horizontally and vertically.

PLAN VIEW DIMENSIONS (mm)

Door opening with Handle (Fridge Side, door in relaxed natural open position.

NOTE: - To allow full removal of the two lower drawers and shelves, the door

requires further opening past the relaxed natural stop position.

270

Maximum door opening with Handle (Fridge Side, door fully open pushed past

its stop position to allow full removal of the two lower drawers and shelves).

312 as shown in PLAN VIEW above

Tot al Depth including Handles 780

Total Depth without Handles (Fridge Side) 700 (cabinet 598 + door 90 + rear panel 12)

Tot al Depth including Dispenser but without Handles (Freezer Side) 705 (cabinet 598 + dispenser 5 + rear panel 12 + door 90)

Tot al Depth of Cabinet without Doors 610 (cabinet 598 + rear panel 12)

Total Height of Cabinet without Upper Hinges and Doors 1744

Total Height of Cabinet including Upper Hinges and Doors 1755

APERTURE MEASUREMENTS PLAN VIEW

(With door open 90° and fully)(Measurements below are the minimum requirement in mm.

Dimensions include the 10 mm space required on both

sides, back and above)

355

922

1754

620

410

1064

902

240

82

7

312

88

7

1137

9 of 61

Indesit Company

Service Manual UK English

REMOVING THE REFRIGERATOR & FREEZER FURNITURE

Removing the Fridge and Freezer Shelves

1. Pull the shelf out until it reaches its stop point then lift the shelf from the front to remove it.

2. NOTE: - For the easiest recommended removal of some fridge shelves and drawers, lift the front

end up to nearly a vertical position whilst pushing the fridge door fully open.

Removing the Crisper or Meat Drawer from the Fridge Compartment

1. Slide the drawer out until it reaches its stop;

2. With one hand underneath the drawer, lift from the front and pull it past the stops; the drawer will

come off the runners and can be pulled out further;

3. To remove it completely, lift the front end up (rear end down) and turn and manoeuvre the drawer

out. NOTE: The fridge door may require pushing to its fully open position.

Crisper Moisture Control Device

• Moving the slider to the far right opens the small vent, eliminating

humidity from the compartment. this setting is best for preserving

fruits and vegetables with skin.

• Moving the slider to the far left closes the small vent, maintaining

humidity inside the compartment. This setting is best for preserving

salads and leaf vegetables.

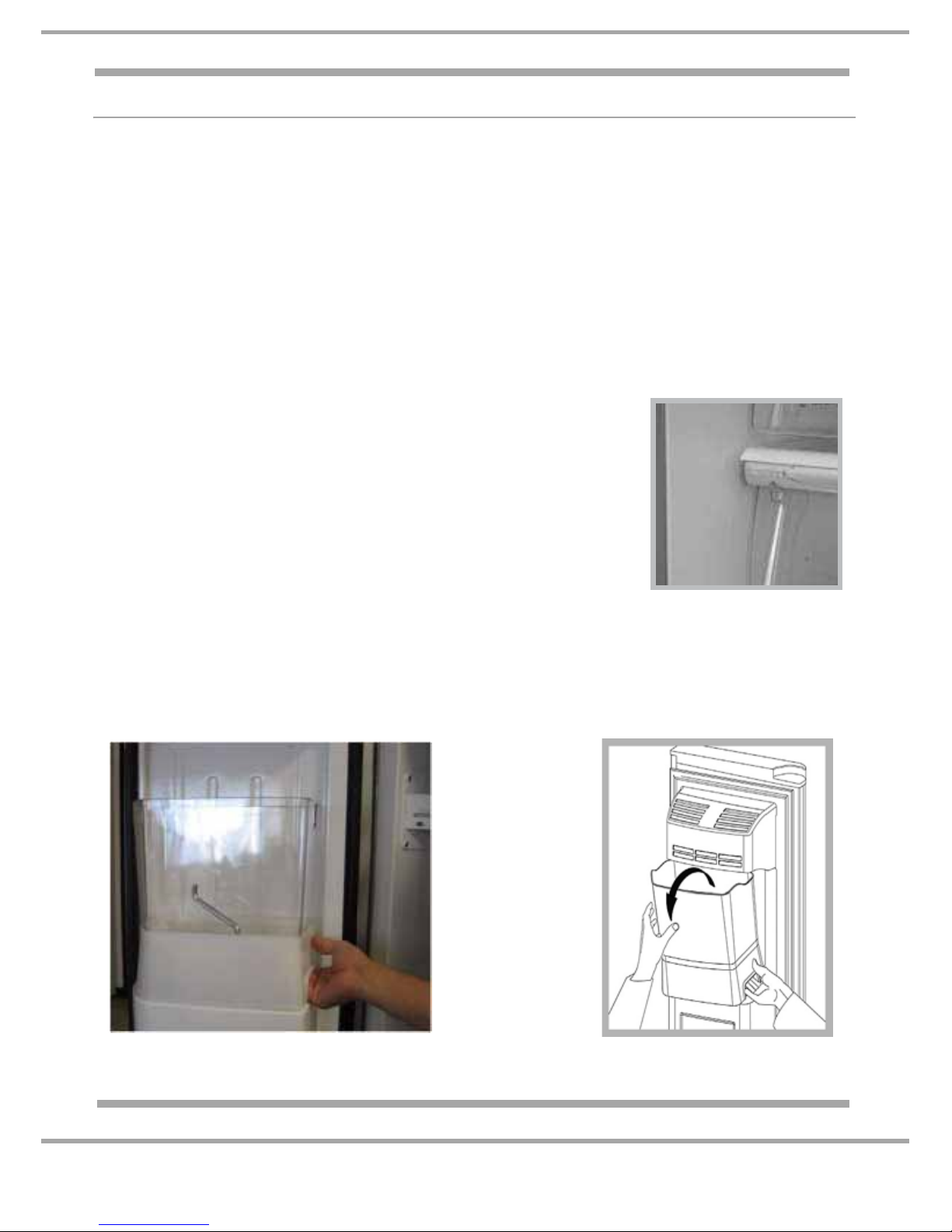

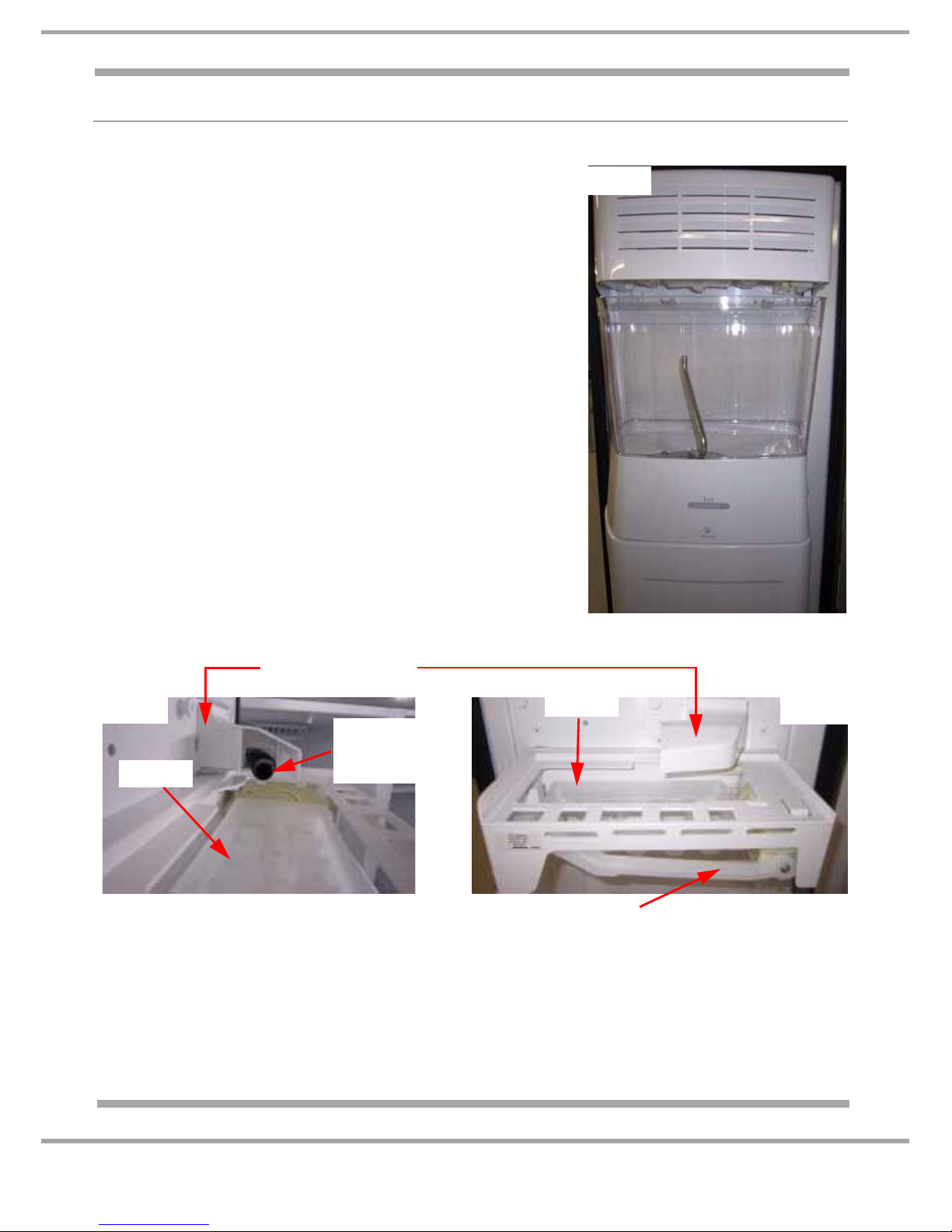

Removing the Ice Storage Bucket / Container

Locate the handle inside the opening at the base of the container (right hand side). Pull the lever and lift

the container upwards and outwards (see Figs. A and B). To reposition it, rest the base of the container

on the ledge in the inner door and lower it into position. Note: Switch the icemaker off before removing

the container to prevent accidental discharge of ice cubes.

Fig. A

Fig. B

2010 DF MODELS 2011 NDF MODELS

10 of 61

Service Manual UK

Indesit

Company

English

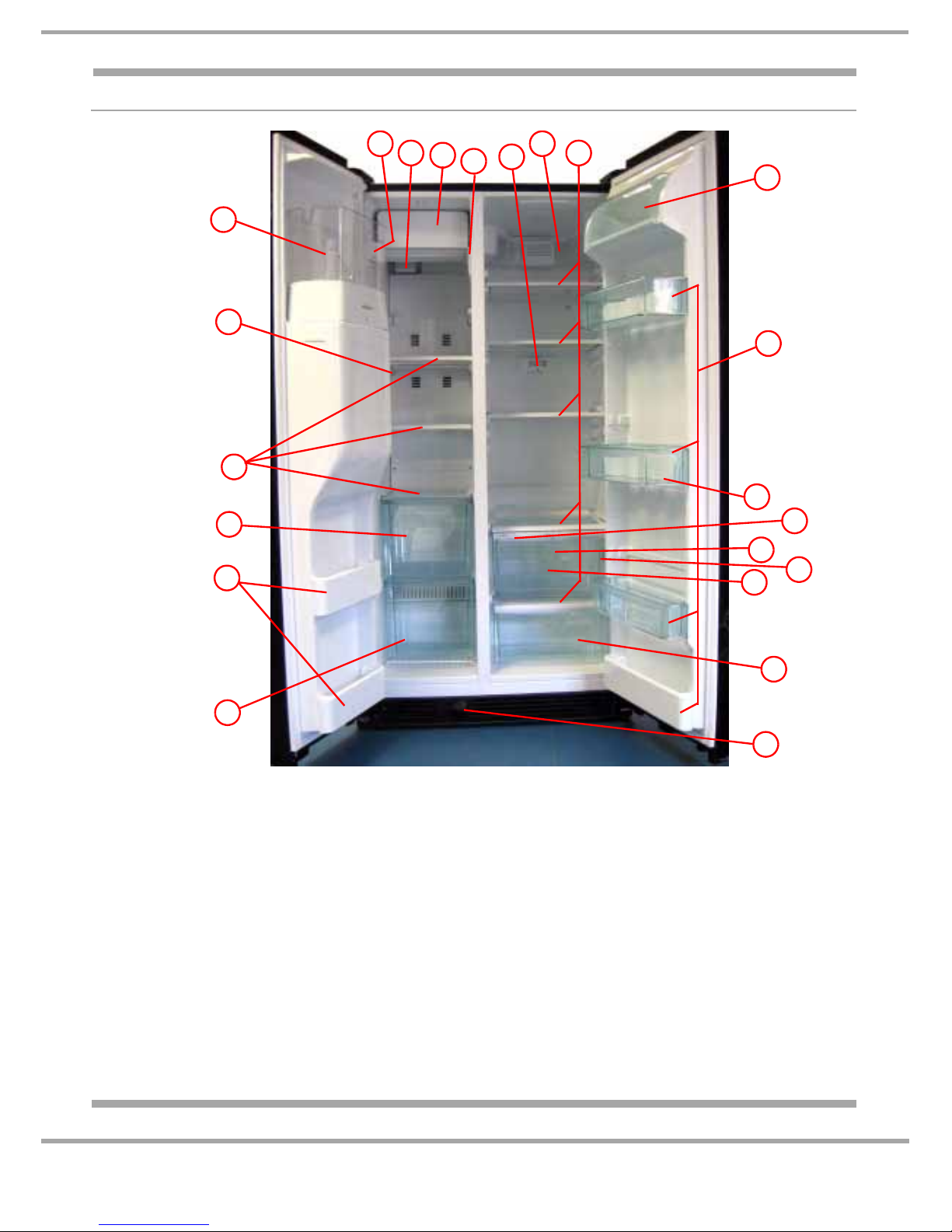

2010 DF MODELS

Refrigeration Compartment Freezer Compartment

A. Interior light located within the damper

housing/light box

B. Shelves

C. Fridge sensor support

D. Crisper drawer moisture control

E. Crisper drawer

F. Rating plate located on inner fridge liner

G. Water tube (coiled reservoir part of the

water tube located on back wall behind

crisper drawer

H. Meat/chiller drawer

I. Dairy compartment

J. Door bottle shelves

K. Door shelf bottle separator

L. Water filter

M. Automatic icemaker located behind cover

N. Interior light located on the back wall

O. Icemaker emitter (left liner)

P. Icemaker receiver (right liner)

Q. Ice cube container/bucket and auger

R. Freezer sensor on left freezer liner

S. Glass shelves

T. Drawer (upper)

U. Drawer (lower)

V. Door shelves

A

C

M

N

O

Q

R

S

T

V

U

J

K

E

F

G

H

D

I

B

DETAILEDVIEW

P

L

11 of 61

Indesit Company

Service Manual UK English

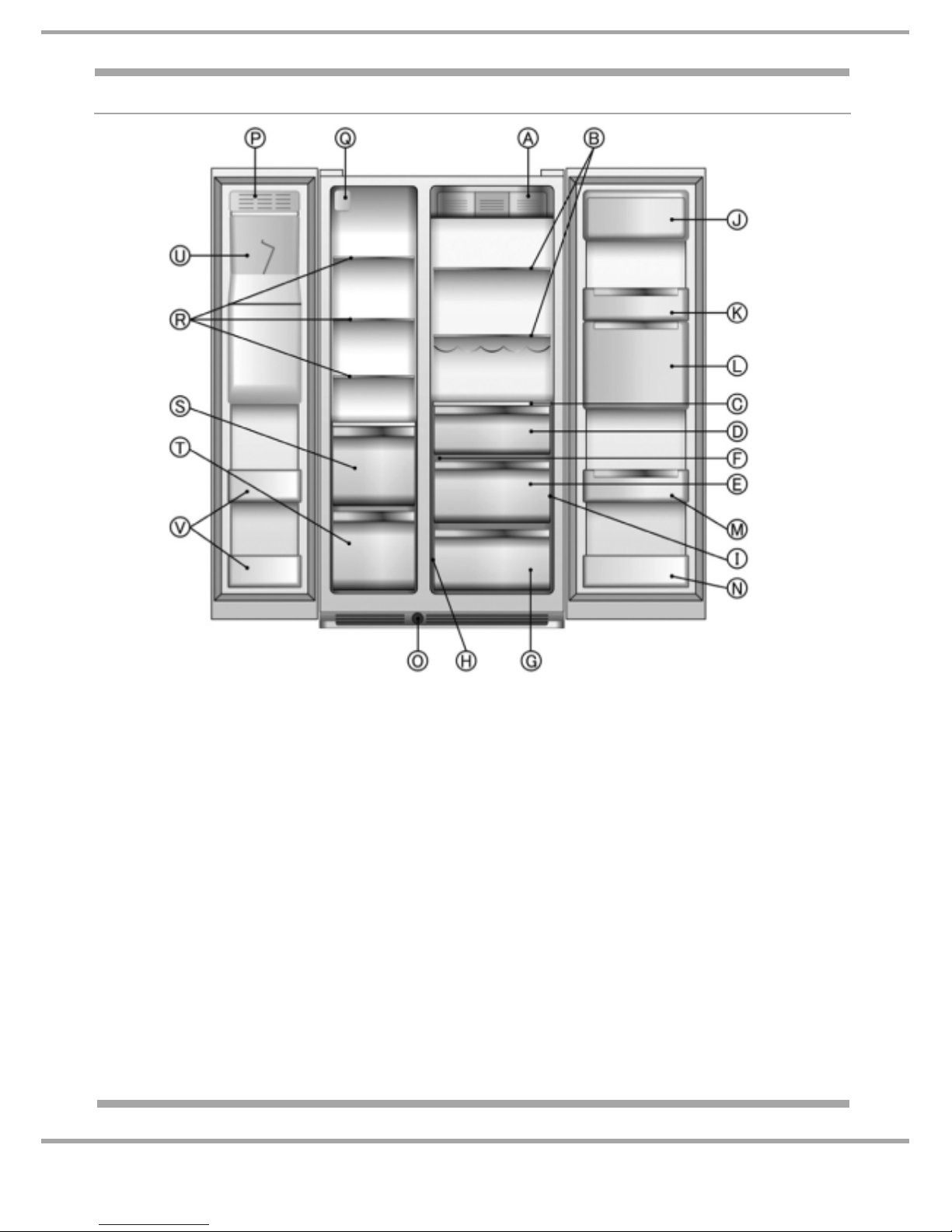

2011 NDF MODELS

Refrigeration Compartment Freezer Compartment

A. Inside light

B. Shelves

C. Shelf - drawer lid

D. Snack drawer (depending on model)

E. Crisper drawer

F. crisper drawer moisture control (where provided)

G. Meat / crisper drawer

H. Meat / cripers drawer temperature control (where

provided)

I. Rating plate

J. Dairy compartment

K. Door trays

L. Fresh compartment and Nature Fresh (where

provided)

M. 2 litre door tray with bottle holder (where

provided)

N. 0.75 litre door tray

O. Water filter (depending on model)

P. Automatic ice maker

Q. Inside light

R. Glass shelves / racks (depending on model)

S. Drawer / top basket (depending on model)

T. Drawer / bottom basket (depending on model)

U. Ice container

V. Door trays

12 of 61

Service Manual UK

Indesit

Company

English

WATER FILTER

REMOVAL OF THE FILTER

1. Locate the water filter cartridge cap in the base plinth grille below the freezer compartment door.

Rotate the cap counter clockwise to a vertical position (¼ turn) and pull the cap and filter cartridge

from the filter housing out through the base grille.

Note: Since there is water in the cartridge, some spilling may occur.

2. Remove the cartridge cap by sliding it off the end of the old cartridge.

DO NOT DISCARD THE CAP.

3. Take the new cartridge out of its packaging and remove the protective cover from the O-rings.

Make a note of the installation date in the space provided on the new cartridge.

4. Slide the cartridge cap onto the new cartridge.

5. With the cartridge cap in the vertical position, push the new filter cartridge into the base grille until

it stops. Rotate the cartridge cap clockwise to a horizontal position (¼ turn).

6. RUN WATER THROUGH THE DISPENSER UNTIL THE WATER RUNS CLEAR (about 9-14 litres

or 6-7 minutes). This will clean the system and clear air from the lines. Note: As air is cleared from

the system, water may spurt out of the dispenser.

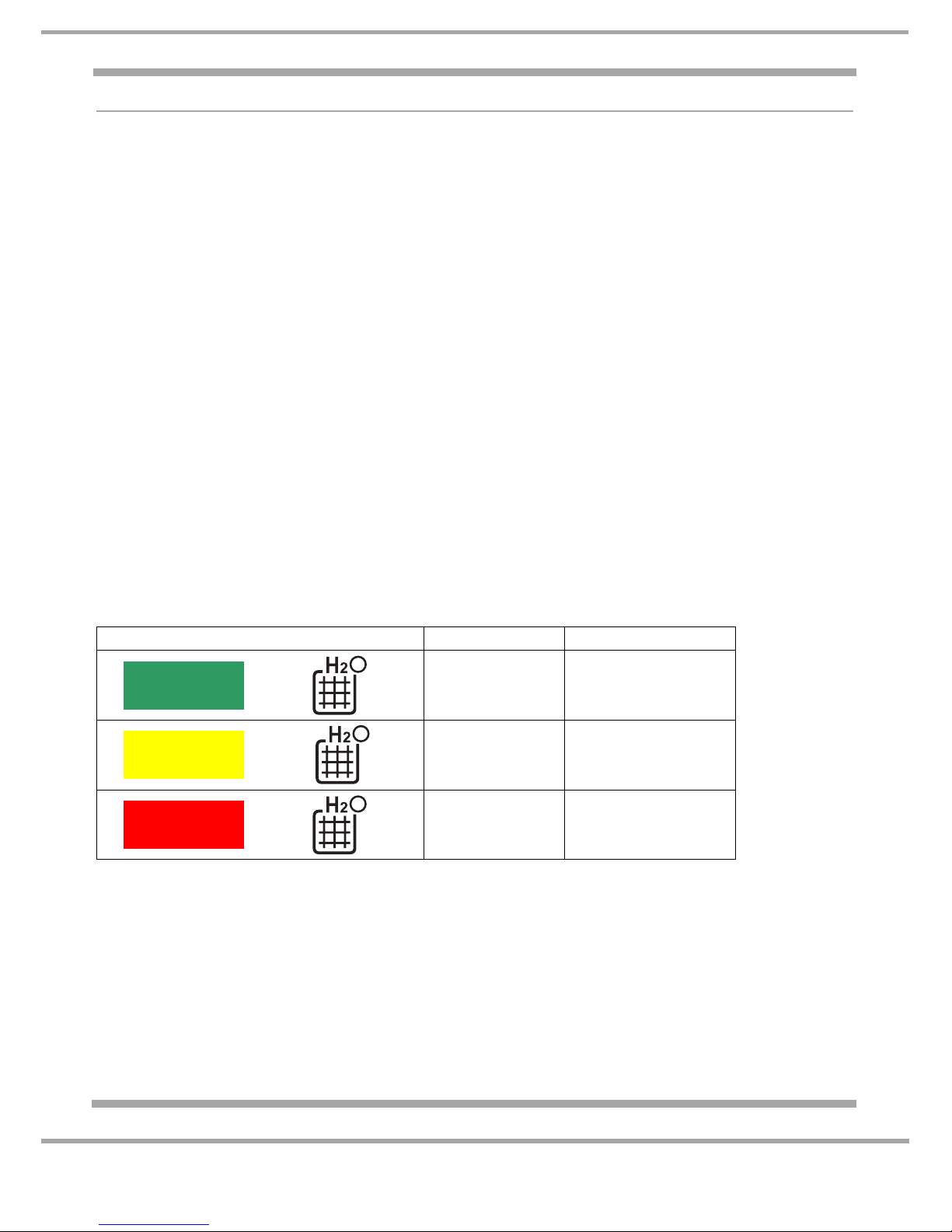

OPERATION

The water filter control will calculate and record the total volume of water flowed through the valve

during the opening periods. The flow rate for the dispenser water valve is 1.51 litres per minute

(24-58 cc per second).

The total litres flow is calculated by using the flow rates for Ice Maker valve and Water Dispenser

valve. The valve flow rate in litres is multiplied by the corresponding open time. The total litres will be

obtained adding the litres of each valve. The litres and time usage data will be recorded even after a

power black out. This data is updated daily. The table below shows the relationship between water flow

and time. The H

2

O symbol located on the user interface changes colour accordingly.

The MID Yellow usage state indicates that the filter is almost exhausted and the user should order a

new filter. When the filter indicator is in its RED alarm usage state the filter should be changed.

Once the filter has been changed the user should press the 'RESET' button on the display panel for at

least 3 seconds until the audible beep sounds. The water filter icon switches back to the low usage

state. This normal RESET operation will not work in the LOW Green usage state. It is however

possible to reset the water filter during any of the usage states after an autotest if the filter was

changed during the green stage (refer to Page 34 for the Autotest). When the autotest has finished,

indicated by 00 in the display, press the water dispenser paddle 4 times (within 10 seconds).

The symbol F will display on the fridge side to confirm the operation. If an alarm error code is displayed

it will cycle together with the F symbol.

USAGE STATE AND ICON

LITRES TIME (DAYS)

0 - 1350 0 - 250

>1350 >250

>1500 >270

NEW / LOW

USAGE (Green)

MID-HIGH

USAGE (Yellow)

ALARM STAGE

(Red)

13 of 61

Indesit Company

Service Manual UK English

ICE MAKER OPERATION - 2010 DF MODELS

To operate ensure:

• The appliance has reached -9°C for a minimum of 2 hours.

• Crushed ice or cubed ice mode is selected on the user control display.

• The appliance has been on for approximately 12-24 hours at initial start up.

A. Ice Maker Circuit Module. The ice maker has its own circuit module which controls the load, the

heater on the underside of the ice maker and ice maker solenoid valve at the base of the

appliance. (To prevent overfilling the ice maker module will only allow the ice maker solenoid valve

to open up to a maximum of 20 seconds).

B. Emitter and Receiver Sensors. The electronic

control consists of two separate printed circuit

boards mounted on opposite sides of the

freezer liner below the ice maker. The board

mounted on the left hand side of the freezer

liner is referred to as the 'emitter board', and the

board mounted on the right hand side (mullion)

is referred to as the 'receiver board' (Fig. 1).

The electronic control will periodically check to see if the ice

maker is at the home/park position. (Fig. 2 shows the rake in

blue in the home position at the 2 o’clock position). When the

rake is at the home position the relay will de-energize removing

power from the ice maker until the next harvest of ice. When the

ice maker thermostat closes and signals the ice is ready to be

harvested, the emitter board sends out an infrared (IR) pulse.

If the path of the pulse is unobstructed to the receiver board, the phototransistor on the receiver

board will 'sense' the pulse. The control will then energise a relay, which applies power to the ice

maker. A harvest begins.

Closing the freezer door forces the emitter flap to fold

flat to the liner, allowing the IR beam to travel through

the cut out section at the top of the Ice Bucket (Fig. 3).

If ice reaches this point in the bucket, the ice acts as a

barrier to the beam and prevents the IR beam hitting

the receiver sensor on the right. Note: If the door is

open the emitter flap springs open which obstructs the

IR beam travel to the receiver.

The emitter and receiver’s electronic boards control

power to the Ice Maker. These boards can also be

used for the Optics Diagnostic Mode Test

(see Page 38).

The auto test (see Page 34) will not test the ice solenoid valve, the two emitter and receiver

sensors, nor the Ice Maker itself. Refer to Pages 36 - 38 for the Optics Diagnostic Mode Test.

Ice Maker - view from behind cover

Emitter

Receiver

Fig. 1

Fig. 2

Emitter

Ice Maker Cover

Ice

Bucket

Fig. 3

14 of 61

Service Manual UK

Indesit

Company

English

C. Ice Harvesting. The harvesting process begins when the Ice Maker thermostat closes and signals

that the harvest temperature has been reached. The closed thermostat applies power to the ice

maker motor and to the heater. As the heater melts the outer layer of the ice, the motor rotates a

rake (rake in blue in Fig. 2 on previous page), which sweeps the ice cubes out of the mould, and

pushes them forward into the Ice Storage container/ bucket in the freezer door. The harvest lasts

approximately 5 minutes. To prevent an early harvest from occurring after the last harvest is

completed; a minimum of 40 minutes must pass before another harvest will be initiated.

Note: When the water supply is turned off the Ice Mode should be disabled on the user control

display interface.

For Ice Maker Troubleshooting see Page 36.

15 of 61

Indesit Company

Service Manual UK English

ICE MAKER OPERATION - 2011 NDF MODELS

ICE MAKER SANKYO IDI2 (FIG. 4) OPERATION - 2011 NDF MODELS:

To operate ensure:

• The appliance has reached -10°C for a minimum of 2 hours.

• Crushed ice or cubed ice mode is selected on the user

control display.

• The appliance has been on for approximately 12-24 hours at

initial start up. Note: After a period of no use, the icemaker

needs to be run overnight before it will deliver the first cubes.

Ice Maker ON / OFF manager (IDI2 Sankyo):

The Icemaker system is managed by the main power module

determined by ICE mode selected on the user module.

Ice water solenoid activates, this activates the ice fill tube heater

and fills the ice tray with water (See Figs. 5 and 6). Once the

ice-sensor (Fig. 7) signals that the harvest temperature has been

reached, it begins to harvest the ice by twisting the tray (no

heating element inside). The Guide “Ice-Full” arm (Fig. 6) turns

every 2 hours in the down position (30° angle). When the arm

reaches the 30° angle the internal contact inside of the icemaker

gives a signal to the main module. The signal allows ice

production to activate. If the arm cannot go completely down due

to the ice storage container being full (i.e ice is restricting the arm

to lower completely), the feedback signal is therefore missing and ice production is stopped.

Fig. 4

Ice Fill Tube Cover

Guide Ice-full Arm

Ice Maker: side view from the left of freezer

door with ice maker cover removed.

Ice Maker: straight on view of internal freezer

door with ice maker cover removed

Fig. 5

Fig. 6

Fill Tube

& Foil

Heater

Ice Tray

Ice Tray

16 of 61

Indesit Company

Service Manual UK English

To avoid water overflow, the main module will switch

OFF the relay K002 if the ice valve feedback lasts

more than 20 seconds. The Icemaker system will then

be switched OFF until the following points will be

satisfied:

1) The power has been removed (Power-OFF)

2) The main power has been re-applied (Power-UP)

During this failure condition the main power module will

send the alarm code to the User Interface. (See Alarm

Codes on Pages 31 & 32 Ice maker checks can be

done using the Autotest, see Page 34).

Note: When the water supply is turned off the Ice

Mode should be disabled on the user control display

interface.

For Ice Maker Troubleshooting see Page 36

SOLENOID VALVE - SANKYO

WATER SOLENOID VALVE MANAGEMENT:

The water solenoid is activated by the display control board passing the information to the Main board.

The control calculates and recorded the total volume of water flowed through the valve during the

opening periods.

The flow rate is: 1.51 litres per minute (24 – 58 cc per second)

Supply voltage (nominal): 220 V AC; 50Hz

Power dissipation for each coil: 20W

Opening voltage: 190 V; 50Hz (at 862 Kpa, 125 psi)

Water pressure range: 1,38 - 8,27 bar

Flow rate outlet Ice Maker: 65cc / 7.5 sec.

Flow rate outlet water dispenser: 237cc / 7.5 sec.

The diagram on Page 18 shows the water flow system:......

Water Solenoid:

8 mm

Blue collar

Ice Maker Solenoid:

6 mm

Yellow collar

Water inlet from filter

Fig. 8

17 of 61

Indesit Company

Service Manual UK English

ICE SOLENOID WATER VALVE MANAGEMENT (2010 DF MODELS):

The icemaker water solenoid valve will be automatically controlled and driven by the Icemaker.

The flow rate for the icemaker water valve:1.13 litres per minute (140cc per 7.5 seconds +11cc –17cc)

Supply voltage (nominal): 12V

Motor power dissipation: 8 W

Ice production per 24 Hours: Approximately 200 ice cubes

Condition to start ice production: -9°C appliance temperature for min. 2 hours

Condition to stop ice production: -10°C temperature in the mould (ice-sensor)

(The above could vary depending on water pressure, usage of appliance and temperature etc.).

ICE SOLENOID WATER VALVE MANAGEMENT (2011 NDF MODELS)

The icemaker water valve will be automatically controlled and driven by the Main Power Module.

The flow rate for the icemaker water valve: 1.51 litres per minute

Opening time of the icemaker water valve: 5 seconds = ~100cc (+/- 3cc)

Ice valve ALARM indication for opening time: 20 seconds

Water pressure range with filter cartridge: 2.07 bar till 8.27 bar

Water pressure range without water filter: 1.38 bar till 8.27 bar

General Requirements

Supply voltage (nominal): 12V

Motor power dissipation: 8 W

Ice production per 24 Hours: 0.8 kg (six or seven loads)

Condition to start ice production: -10°C appliance temperature for min. 2 hours

Condition to stop ice production: -9°C temperature in the mould (ice-sensor)

Indesit Company

18 of 61

Service Manual UK English

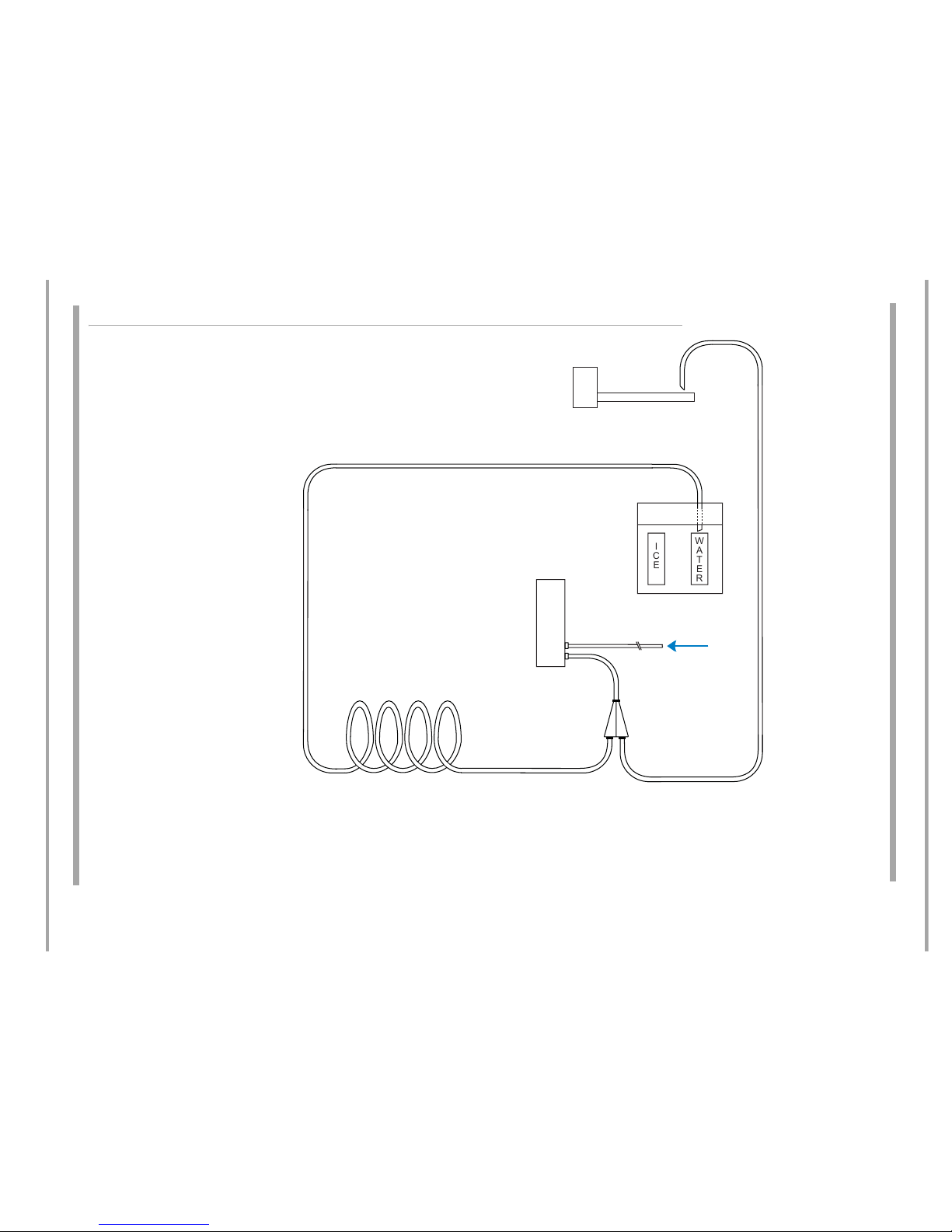

WATER FLOW SYSTEM

Underneath the ice and water dispenser is a grille and sump to catch any spillage that may occur. This is not a drain.

WATER RESERVOIR

LOCATED IN FRIDGE

FILTER

HOUSING

FRONT

REAR

FILL

VALV E

DISPENSER

INTERFACE

ICEMAKER

WATER

INLET

,&(

:$7(5

BLUE/GREEN

YELLOW/WHITE

water flow.ai

19 of 61

Indesit Company

Service Manual UK English

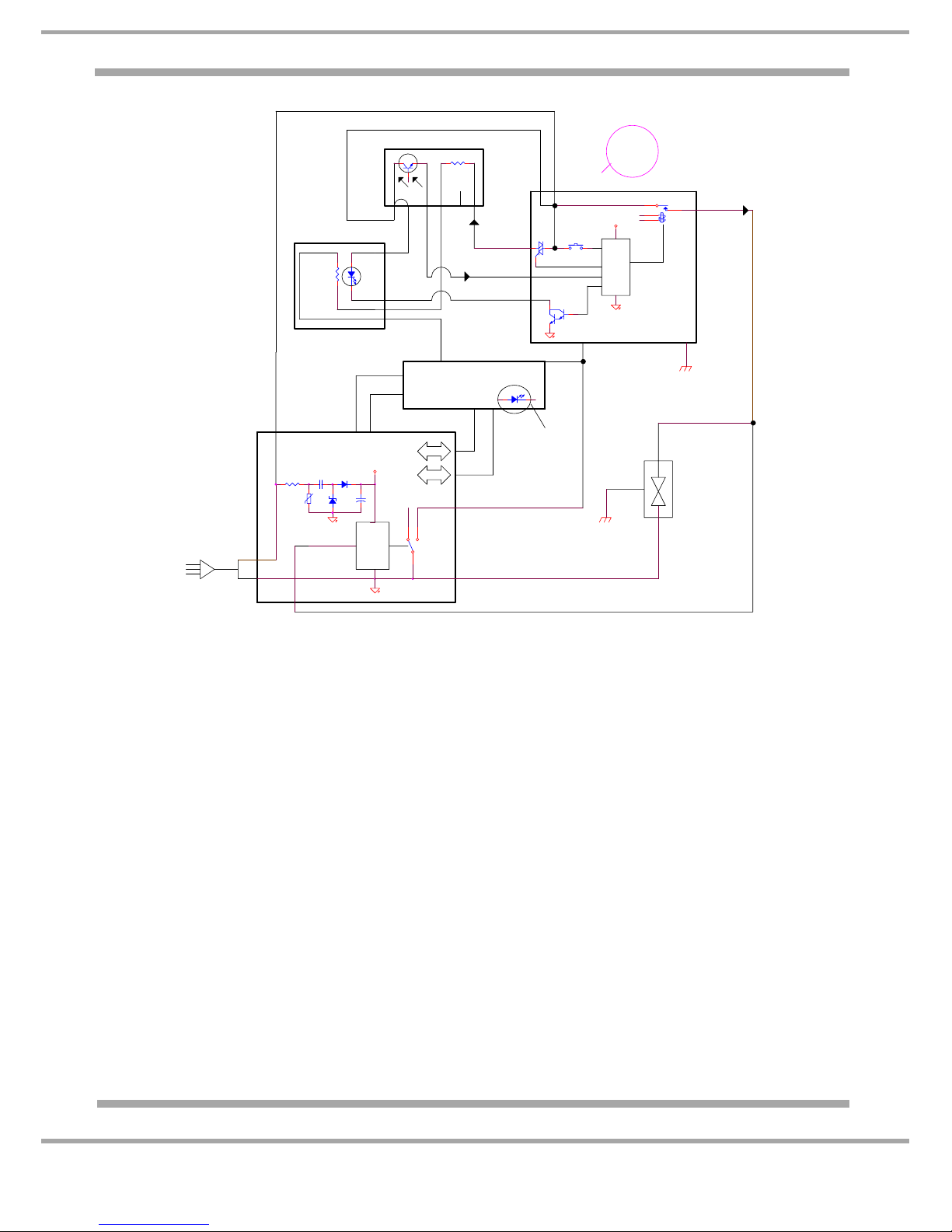

Ice Maker Circuit through the Display, Main Control, Emitter and Receiver Boards

Ice Maker Solenoid Valve Feedback Description

The feed-back circuit mainly gives the information to the microprocessor on how many times the Ice

Maker Valve has been energised. This is recorded by the microprocessor and it is multiplied by the

valve flow rate in order to record how many litres of water flows through the valve and consequently

through the filter.

So, the Water Filter Indicator can be updated accordingly. The feed-back is also used by the Main

Board in order to understand if the Ice Maker is stuck at water fill position and to avoid water overflow.

The following describes how the feed-back works: If the Ice Maker Valve command lasts more than 20

seconds the Ice-Maker equipment will be switched OFF until the following points are satisfied in the

following sequence:

1) Press the reset button (alarm and buzzer OFF/Ice-Maker OFF).

- When the alarm is enabled the buzzer will sound and the Ice Mode LEDs will blink alternately.

2) Unplug the appliance from the electricity supply.

3) Plug the appliance back into the electricity supply.

Note:

a) If the user tries to switch ON the Ice-Maker before executing point 2, the alarm will re-start again

and the relay will remain in the OFF state.

b) If after point 3) the situation persists and the above alarm will restart., further diagnosis will be

required. Refer to Page 36.

+5VDC

+5VDC

+

321

4

3

1

2

User Interface

N

Main plug

220Vac

N

Main Board

TX

RX

Feed-back

Ice valve

Water Filter

Indicator

L

L

Neutral

Line

uP

Relè

Ice-Maker

Line

Neutral

Ice

Valve

(black)

(IR_Emitter)

3

Short

(Line/Phase)

Pole 3 of 10

Line21

Heater

De-Frost

Ice-Maker

Neutral

Emitter

4

(Neutral)

Receiver

(Line/De-Frost)

3

Pole 1 and 9 not connected

(IR_Line)

Pole 5 of 10

2

5

6

(IR_Receiver)

Pole 4 of 10

(Physical GND)

Heater De-Frost

Pole 2 of 10

(Water_valve)

4

Line

This is Pole

1 of 10 for

NAR 120V

version

n.c.

Pole 8 of 10

Pole 10 of 10

Pole 7 of 10

uP

1

Bimetal

Pole 6 of 10

DF 2010 Models

Loading...

Loading...