Hotpoint FF175BP Service Information

. - -

Service

Information

5407324 Issue 2 Jan. 2007

HOTPOINT

FREESTANDING

FROST FREE

FRIDGE

FREEZER

Model Comm.

Covered Code

FF175BP 39772

lndesit

Company

UK Ltd

© 2007 Reg. Office: Peterborough PE2 9JB. Registered

in

London: 106725

VVPL00003242_0001

Health & Safety Information applicable to Servicing Refrigeration Products

containing lsobutane Refrigerant R600a

General

The following Health & Safety instructions are an addition to other Company Health Safety

Procedures already published:-

1.

Only engineers who have been trained on the safe handling

of

lsobutane R600a refrigerant are

authorised to transport, store or carry out system repairs.

2.

This manual is not intended

as

a comprehensive repair/maintenance guide to the appliance.

3.

It should only be used by suitably qualified persons having technical competence, applicable

product knowledge, suitable tools and test equipment.

4.

Servicing

of

electrical appliances must be undertaken with the appliance disconnected.

(unplugged from the electrical supply).

5.

Servicing must be preceded

by

earth continuity and insulation checks, plus refrigerant leak

detection.

6.

Personal safety precautions must be taken to protect against accidents caused

by

sharp edges

on metal and plastic parts.

7.

After servicing, the appliance must be rechecked for electrical safety.

8.

Smoking, naked flames, or operating gas and/or electrical equipment (including cordless power

tools) are forbidden within the storage area, working area and vehicles used to transport

lsobutane.

9.

The carrying case for the scales and refrigerant must display a red flammability label

Part Number 8100063 which should be visible and readable at all times.

10.

The vehicle and storage area must

be

ventilated as far

as

is reasonably practicable and the

aluminium case kept out

of

direct sunlight. The storage temperature of lsobutane should not

exceed 50°C.

11.

The vehicle transporting lsobutane (R600a) refrigerant must display a

Red

Flammable Gas

warning sticker (Part Number 8100063).

12.

Engineers should not wear clothes that are liable to cause static discharge ("electrostatic

sparking").

13.

Avoid working

in

small rooms.

14.

Do not work

in

cellars.

15.

Whenever possible move the appliance into a larger open area away from possible ignition

sources.

16.

Request the customer to turn off all other electrical and gas appliances

in

the near vicinity

of

the

repair and note that it

is

done.

Customers should be advised to restrict activity within the near vicinity for a short time.

17.

lsobutane refrigerant must be vented to atmosphere, (outside

of

the premises e.g. via open

window through the clear plastic hose supplied).

continued ....

2

VVPL00003242_0002

Health & Safety Information applicable to Servicing Refrigeration Products

containing lsobutane Refrigerant R600a

18.

lsobutane

is

heavier than air and must not

be

vented within 3 metres

of

the following: sewer

cover, cellar, drain or any similar construction lower than ground level, boiler air inlet/outlet, or

near any possible source

of

ignition.

19.

Working with a naked flame i.e. soldering or brazing is forbidden. Unless otherwise stated,

pipework connections must only be made using the Lokring coupling system.

20. Electronic leak detectors with high voltage tips must NOT be used with any lsobutane (R600a).

21. All equipment used for this activity must be checked regularly and maintained

in

a safe working

condition; parts must be replaced as required.

Information regarding

lsobutane Canisters

1.

The maximum quantity

of

lsobutane

an

engineer should hold or store at any one time

is

two 420

gramme aluminium canisters, supplied individually

as

Part Number 2602600.

2.

Canisters must be stored inside the aluminium case with the weighing scales for protection from

possible damage and heat.

The aluminium case must NEVER be placed next to a heat source or

in

direct sunlight.

3.

lsobutane must only

be

dispensed to the appliance from the 420 gramme aluminium canister

placed

in

an

upright position on the weighing scales provided.

4.

A blue returns label

RS

5647 must then

be

attached and the individual canister/s left out for the

driver to collect and return for disposal.

5.

Canisters must not be punctured or the internal valve damaged.

6.

Before storing the canister it must have the extraction tap valve removed and the internal valve

of

the canister checked for leakage using leak detector. (Leak Detector Part Number 5700043).

7.

All used canisters and those found to

be

leaking should

be

exhausted to atmosphere to ensure

they are completely empty

in

the following manner:

Refit the extraction tap if necessary, open the tap and then invert the canister.

This must

be

done outside

in

open air away from buildings and ignition sources and complying

with Item 18 above.

3

VVPL00003242_0003

INDEX

Health & Safety Information

for

R600a Charged Appliances

................

2 - 3

Industrial Code & Serial Number Format

...................................

4

Introduction

...........................................................

5

Technical Specifications

.............................................

6 - 7

Detailed

View

.........................................................

8

Component Function

...............................................

9 - 10

Auto

Test

............................................................

11

Air

Flow

.........................................................

12

- 13

Control Module Parameters

.........................................

14 - 15

Fault Diagnosis Quick Guide

........................................

16 -

17

Servicing & Dismantling

Instructions

.................................

18

- 19

Door Reversal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 -21

Wiring Connection Chart

...............................................

22

Control Module Connections

...........................................

23

Wiring Diagram

.......................................................

24

Thermistor Sensor Location

............................................

25

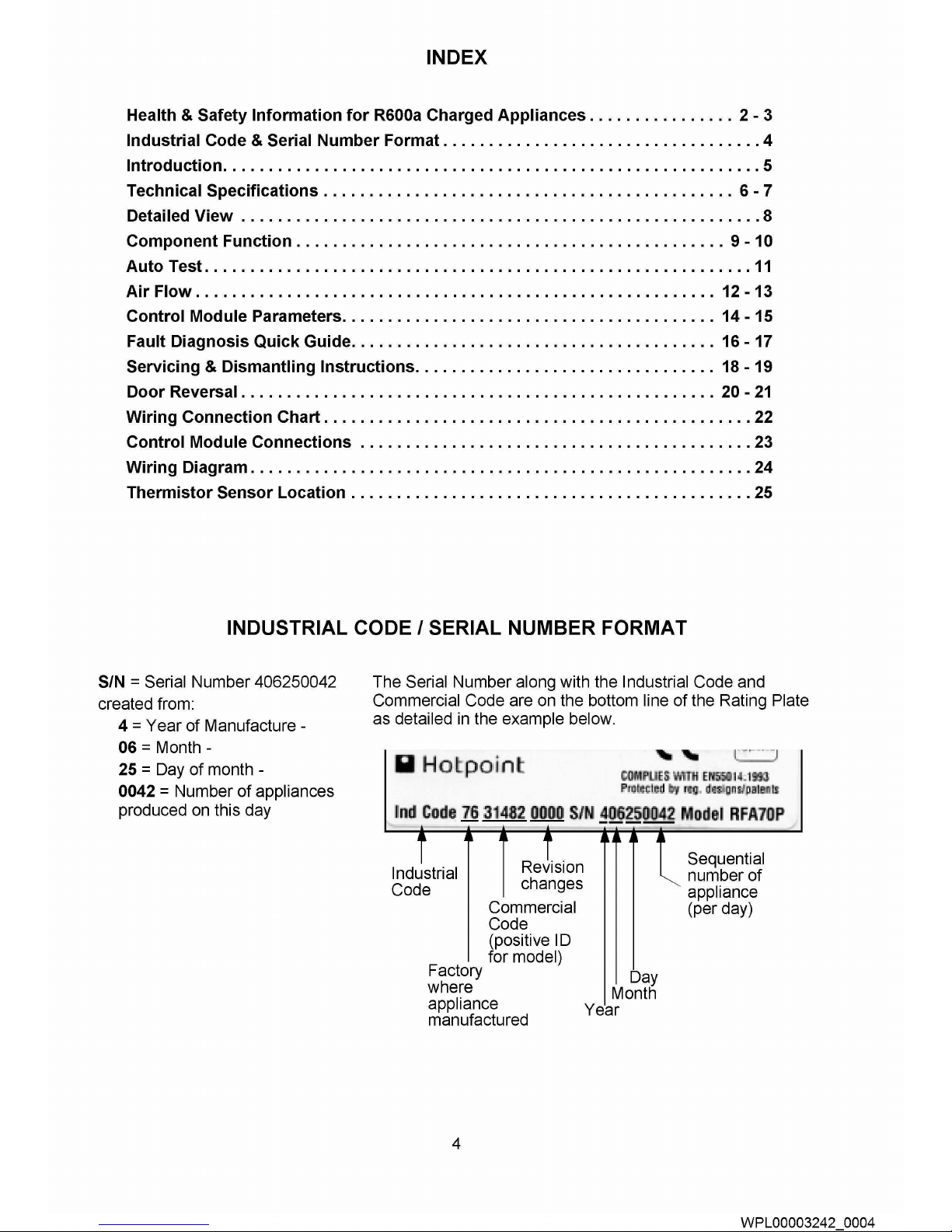

INDUSTRIAL CODE I SERIAL NUMBER FORMAT

SIN = Serial Number 406250042

created from:

4

=Year

of Manufacture -

06

=Month

-

25

= Day

of

month -

0042 = Number

of

appliances

produced

on

this day

The Serial Number along with the Industrial Code and

Commercial Code are on the bottom line

of

the Rating Plate

as detailed

in

the example below.

Industrial

Code

Revision

changes

Commercial

Code

(positive ID

for model)

Factory

where

appliance

manufactured

4

.. I..

r~~-·

~j

iOOMP.

ES

iJI

EN

_ I .1

9'3

l?f(I eltd

11D

d

11nil'pBll!

II

Day

Month

Year

odel

RFA70P

'

Sequential

number

of

appliance

(per day)

VVPL00003242_0004

INTRODUCTION

OF

COMBINATION FROST FREE FRIDGE FREEZER

The FF1758 model was introduced during May 2006 for the UK market.

The interior

of

the fridge has 2 glass shelves and 2 salad bins with a glass cover. The door has a

bottle shelf, dairy shelf with a lid, egg tray and a commodity shelf. The freezer section has three

drawers

of

varying sizes, the drawers have ice cube compartments inserted

in

the top of the drawer

fronts, these are complete drawers.

The electronic thermostat is part

of

the control module mounted

in

the top facia

of

the appliance.

The freezer temperature settings are adjusted

by

operating the control knob mounted

in

the facia.

The fridge temperature settings are adjusted by operating the control knob mounted

on

the multi-flow

in

the fridge.

All functions except the fridge baffle are monitored and actioned

by

the control module mounted

in

the facia

of

the appliance. The fridge baffle is

of

a mechanical type, mounted

in

the multi-flow unit,

the phial

of

which

is

located

in

the exhaust duct

in

the fridge. The freezer cabinet temperature is

monitored by a sensor mounted

in

the lower right side

of

the freezer cabinet liner.

The thermistor sensor is manufactured to a very high specification, it

is

not replaceable because it is

for the most part, foamed behind the liner where it

is

not affected

by

moisture.

The sensor

is

double insulated and

in

the unlikely event

of

failure a section

of

the control module is

programmed to respond and control the functions on a timed basis from there on

in.

Defrosting is automatic (Full Frost-Free).

All models have rear wheels located

in

the compressor base plate with adjustable feet fitted to the

front.

The climate class

is

SN I ST signifying that it is designed to operate

in

ambient temperatures between

+ 10°C to +38°C.

As with many refrigeration appliances, it

is

important that it

is

installed and operated within the

recommended ambient temperature range and that there is adequate ventilation.

The doors are reversible.

MICROBAN® (Hygiene Control)

Some models have Microban®- built

in

protection for life of the product. Food safety is becoming

increasingly important to consumers with more and more cases

of

food poisoning. Microban® is the

number one brand name

in

antibacterial products. Microban®

is

built into the plastic of the fridge

interior during manufacture so it cannot wash or wear out.

It provides permanent protection against bacteria as it reduces

on

contact the spread

of

food

poisoning bacteria, which can cause contamination and odour.

It gives extra hygiene reassurance as it kills or inhibits the growth

of

any bacteria, which may come

into contact with the interior surfaces of the fridge.

Microban® is approved safe for use

in

food contact applications

by

the European Scientific

Committee for Food and has proven safe over many

in

personal care and household cleaning

products.

5

VVPL00003242_0005

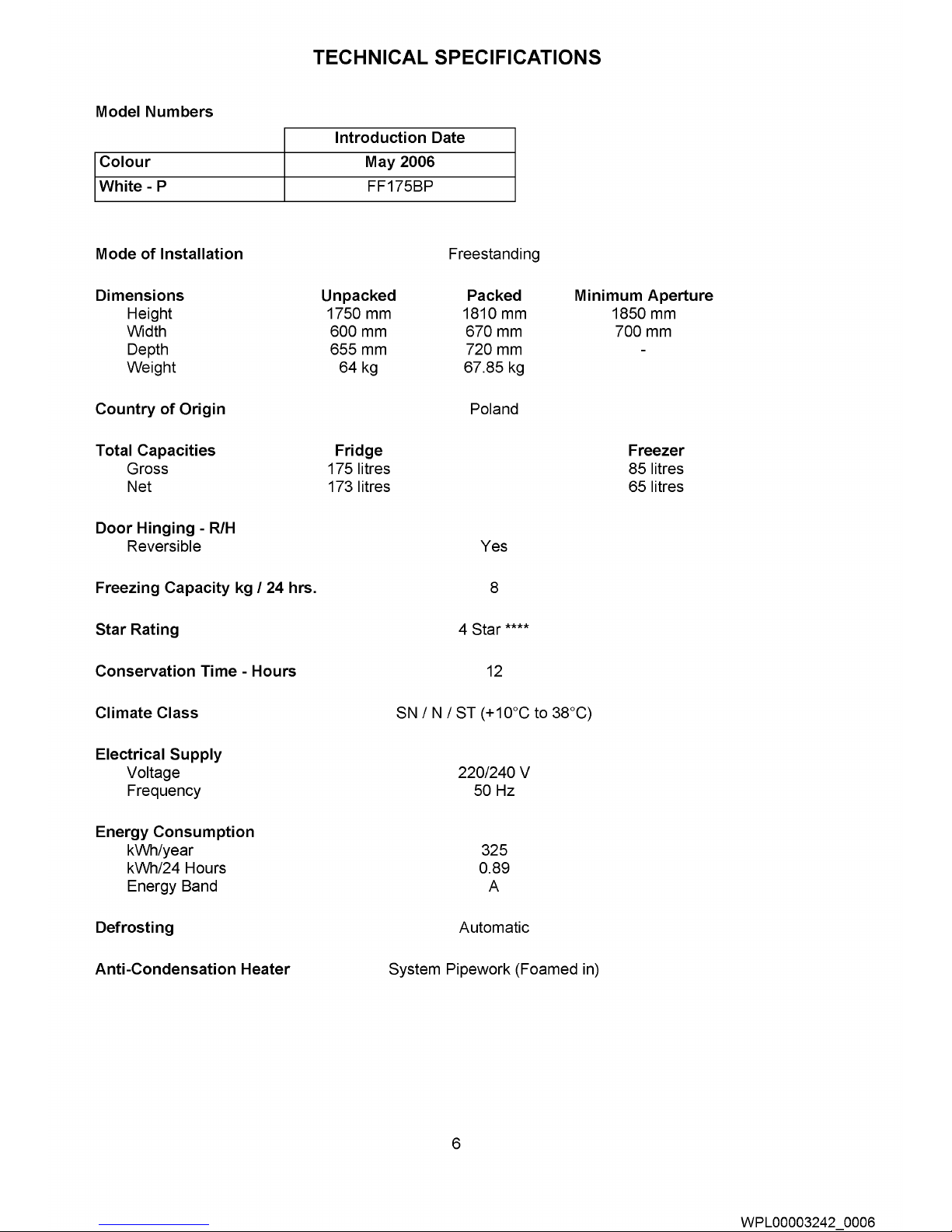

TECHNICAL SPECIFICATIONS

Model

Numbers

Colour

White

- P

Mode

of

Installation

Dimensions

Height

Width

Depth

Weight

Country

of

Origin

Total Capacities

Gross

Net

Door

Hinging -R/H

Reversible

Freezing Capacity kg I 24 hrs.

Star

Rating

Conservation

Time -

Hours

Climate Class

Electrical

Supply

Voltage

Frequency

Energy

Consumption

kWh/year

kWh/24 Hours

Energy Band

Defrosting

Anti-Condensation

Heater

Introduction

Date

May 2006

FF175BP

Unpacked

1750

mm

600mm

655mm

64

kg

Fridge

175 litres

173 litres

Freestanding

Packed

1810

mm

670mm

720mm

67.85

kg

Poland

Yes

8

4 Star****

12

Minimum

Aperture

1850

mm

700mm

Freezer

85 litres

65 litres

SN

IN

I ST (+10°C to 38°C)

220/240 v

50 Hz

325

0.89

A

Automatic

System Pipework (Foamed

in)

6

VVPL00003242_0006

TECHNICAL SPECIFICATIONS cont.

Evaporator

Defrost

Heater

(Q)

Gutter

Heater

(Q)

(Foamed In)

Freezer

Inlet

Duct

Heater

(Q)

(Foamed In)

Defrost

Thermostat

(Protector)

Cut-In

-5°C (+/-5°C)

Thermal

Fuse

Refrigerant

Charge

- R600a

Compressor

Winding

Resistance

(Q)

Start

Run

Capacitor

387.2

1.61k

16.13k

72°C

Refer to Rating Plate

Tecumseh

TWB1370MJS

26.75

15.75

Refer to Parts List

7

Cut-Out

+10°C (+/-3°C)

VVPL00003242_0007

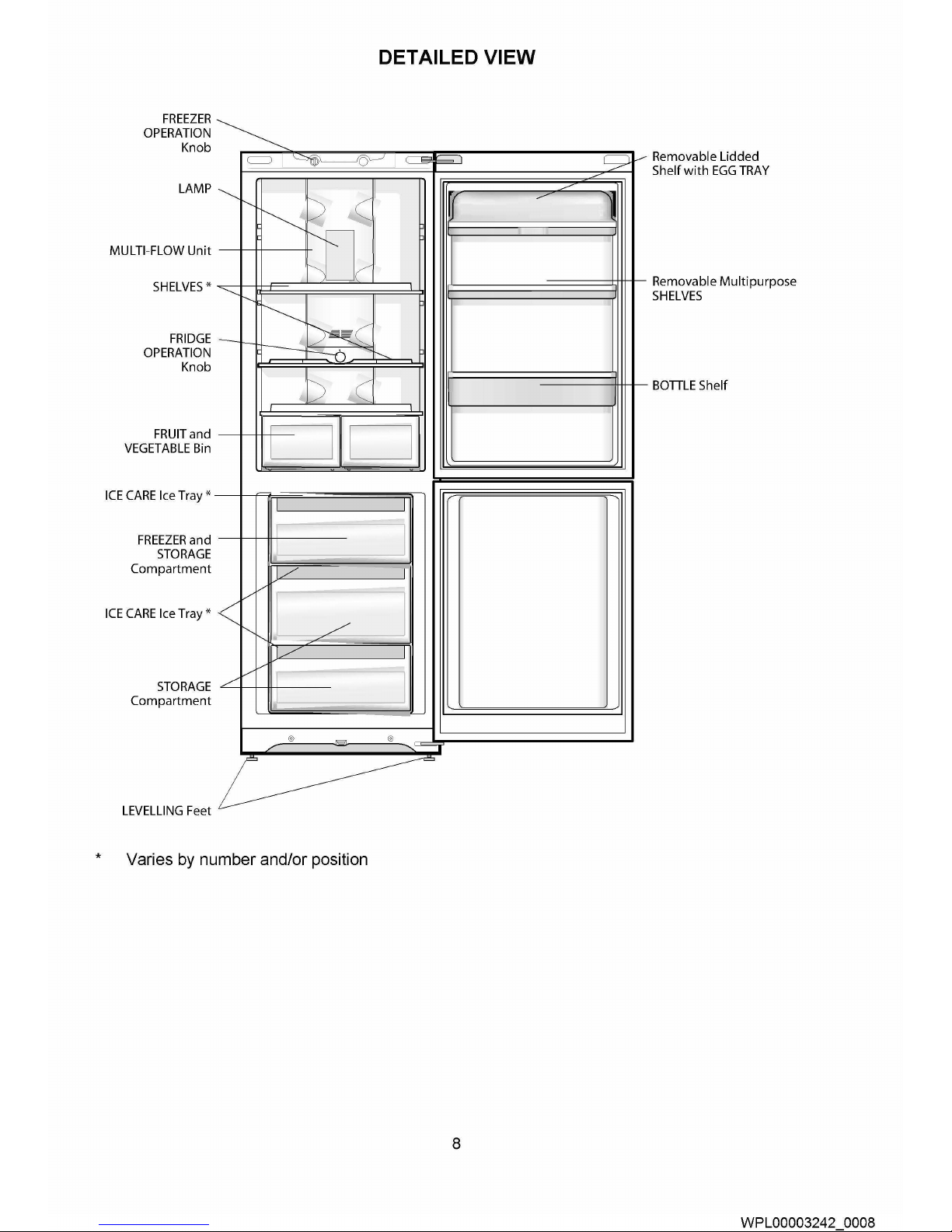

*

FREEZER

OPERATION

Knob

LAMP

MULTI-FLOW Unit

SHELVES*

FRIDGE

OPERATION

Knob

FRUIT

and

VEGETABLE

Bin

ICE

CARE

Ice

Tray*

FREEZER

and

STORAGE

Compartment

ICE

CARE

Ice

Tray*

STORAGE

Compartment

LEVELLING

Feet

DETAILED VIEW

~

~

I

'-~'

~

I

1

~

"-

~

s;

rr

~

"'-;::-

~

/

~

"-

~

-

~

c-----_

.f.

~

(

.

~

'----

')

J)

4d

1

I

ICJ

I

T

I

I

~

J

I/

1-

/

v

r/

<

J

"'-

~

T

,.,.-/

I

/

/

/

I

-~J

J

©

~

©

/'

,

~

..

~

Varies by number and/or position

8

9

----

~

__.,-

l

v

Removable Lidded

Shelf with

EGG

TRAY

Removable Multi purpose

SHELVES

BODLE Shelf

VVPL00003242_0008

Loading...

Loading...