Hotpoint FEW10, FEW14, FEW12 User Manual

INSTRUCTIONS on INSTALLATION & USE for the FIRST EDITION RANGE

FEW14, FEW12, FEW10

Hotpoint recommends, for your own safety and to ensure you get the best possible results from your

Washing Machine, you read through this booklet and follow these steps thoroughly.

STEP 1

machine where possible on a solid floor,

STEP 3

Read through this section to familiarise

STEP 5

How to start your selected programme

Electrical Guide

Choose a location for your washing

with the electrical sockets and water

supply tap easily accessible.

Allow sufficient space: 600mm width,

600m depth and 900mm height.

DO NOT install in a bath or shower

room.

WARNING: This appliance must be earthed.

Dispenser Drawer

yourself with the different

compartments within the dispenser

drawer.

NOTE: Always follow manufacturer’s dosage

recommendations.

Using your Machine

and how to stop or change the

programme if so required.

STEP 2

STEP 4

STEP 6

Installation Guide

Dispose of packaging material in a safe

place and remove any labels.

Please read instructions thoroughly to

ensure you understand each stage

before you begin.

Remember you may be charged for a service call if a

problem with your washing machine is caused by

incorrect installation or misuse.

Programme Selector Dial

A wash chart is provided to help you to

select your required programme.

Examples given for the maximum washing load

weight for different fabric types.

Options Guide

All available optional wash features are

explained within this section - These

allow you to adjust your selected wash

programme to suit your needs.

NOTE: Progress indicator lights show what stage in

STEP 7

DO NOT overload the washing machine.

the programme cycle has been reached.

A Typical Wash Programme

A picture guide provides a clear

explanation how to set a wash

programme.

NOTE: Hotpoint recommend, on completion of

your programme, that you switch off both the

electricity and water supply to the appliance.

STEP 8

READ BEFORE

CONTACTING

SERVICE!

NOTE: In addition to the temperature of the

incoming water,the selec tion of optional wash

features will affect the programme times.

Troubleshooting

Please refer to the Troubleshooting

section if you have any problems when

using your washing machine.

There may be nothing wrong!

Read the rest of these instructions to get the best from your appliance, remember to fill in your guarantee registration.

Keep this Book in a safe place for quick reference.

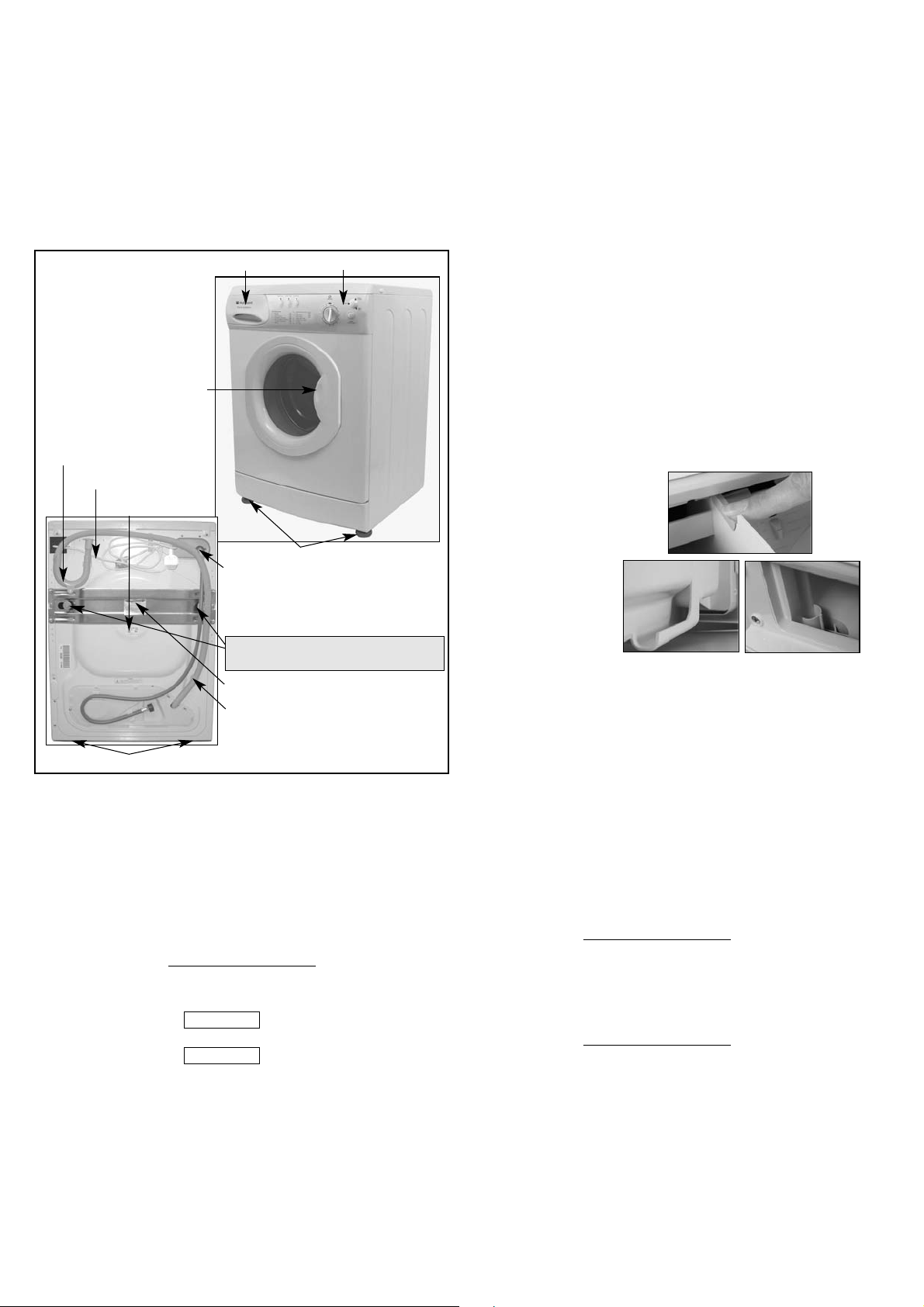

Getting to Know your Appliance

Plumbing Indicator Line label

Cold Water inlet point and attached

Fill Hose (Blue connector)

Control Panel

Interlocking door

and release lever

Rating Plate

Mains Cable

Drainage Hose

Hooked End Support

Dispenser Drawer

Front Adjustable Feet

Back Feet

Cleaning the Exterior:

Use a damp cloth or silicon polish to clean the exterior surfaces of the

appliance.

Cleaning the Door Bowl:

Clean the internal surface of the door bowl regularly with a soft cloth.

A build up of soap powder and water hardness residue may result in

water leaking from the door.

Cleaning the Dispenser Drawer & Compartments:

It is advisable to clean the dispenser drawer regularly:

1

Pull the drawer out until it reaches its stop.

2

Press the drawer release latch

down to remove the dispenser

drawer.

4

Relocate the dispenser drawer and push it

firmly back into place.

3

A

B

Clean and dry the

dispenser drawer,

syphons, grate and

fabric conditioner exit

channel (A).

Also, regularly clean the

outlet pipe area (B).

● Do not try to clean any

part of the dispenser

drawer while the machine

is working.

WARNINGS:

● Do not clean any part of the

machine with abrasive cleaners,

scouring agents, acids,any

bleaches or metal polish, as

they may cause damage.

Key Contacts

After Sales Service

Over 1100 trained specialists, directly employed by us,ensure that you can have complete confidence in both the appliances and

services we offer.

Extended Warranties

UK: 08709 088 088

Monday to Sunday, 8am to 8pm

www

.hotpointservice.co.uk

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

UK: 08709 077 077

Monday to Friday, 8.30am to 5pm

Saturday,8.30am to 12 noon

www

.hotpointservice.co.uk

Republic of Ireland: (01) 842 6836

Repair Service and Information Desk

UK: 08709 066 066

Monday to Friday, 8am to 7.30pm

Saturday,8.30am to 5.30pm

Sunday,9.30am to 3.30pm

www

.hotpointservice.co.uk

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

The Model number (which can be found on

the control panel)

The Serial number (which can be found on the

inner door trim)

Two Transit Fixings (! BOTH must be

removed before you use your machine).

R

L

T

D

H

U

E

O

F

V

STEP 1 STEP 2

n

f

e

s

h

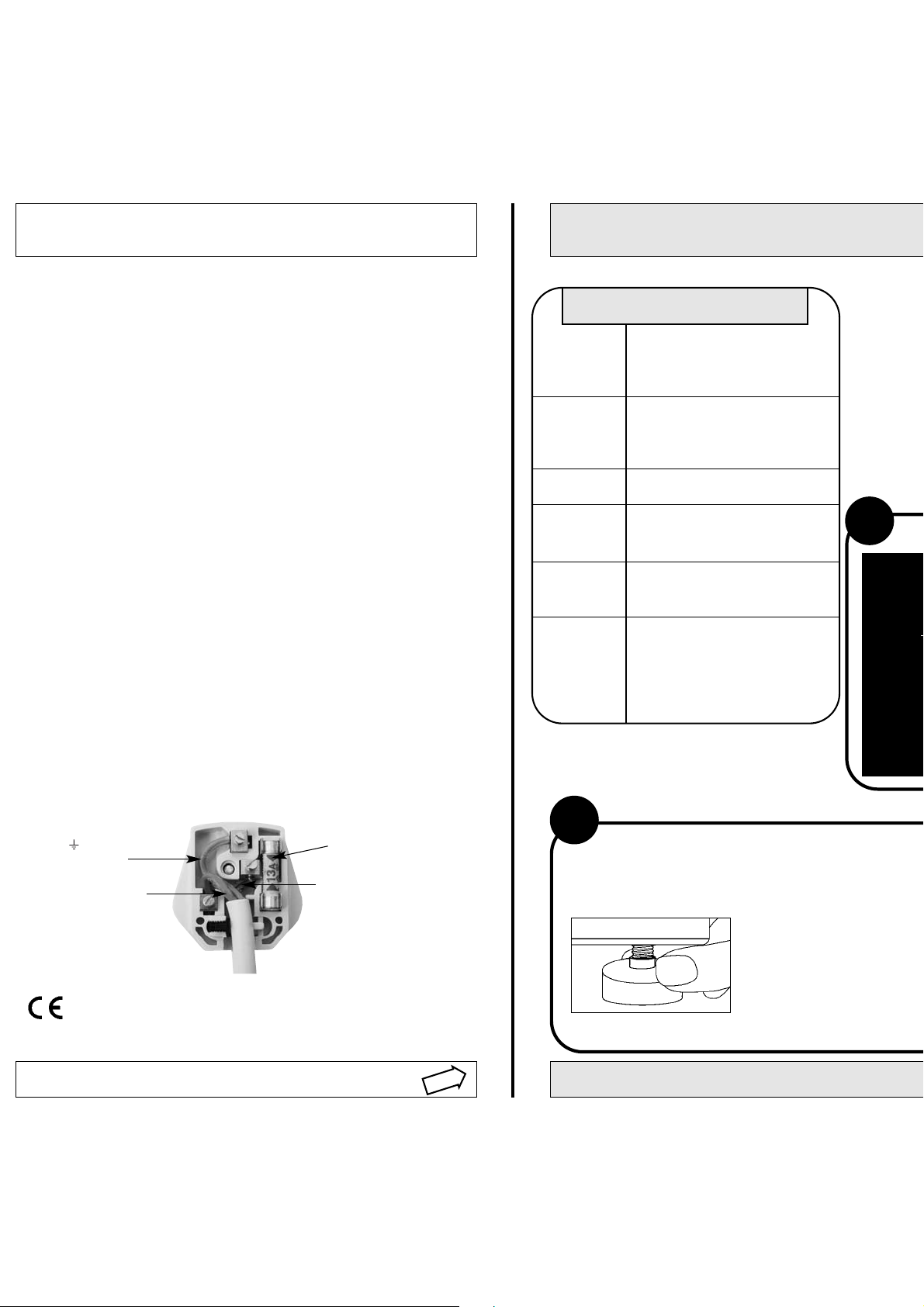

Electricity Supply

WARNING:

The appliance must be earthed.

Fuses

Your appliance comes fitted with a plug and a 13 amp (13A) fuse. If

you need to replace the fuse,use only those rated at 13 amp (13A)

and ASTA approved to BS1362. To change the fuse lift the holder to

vertical position and lift the fuse out. To replace the fuse, insert the

fuse and push fuse holder down into the locked position. Correct

replacement is identified by colour coding or the marking on base of

plug.

WARNING: Do not use the plug unless the fuse holder is in the locked

position and the top cover firmly replaced.

Changing the Mains Lead

If you have damaged the existing lead and need a new one,contact

Hotpoint Service UK on: 08709 066 066 or

www.theservicecentre.co.uk (or in the Republic of Ireland on: 1850

302 200). A charge will be made.

We strongly advise that fitting a new lead is carried out by a qualified

electrician.

Seek professional advice if you need to use an extension lead.

Changing the Plug

If you need to change your plug, if it does not fit your socket: isolate

the machine from the mains supply.Cut off the supplied plug and

safely dispose of the discarded plug. DO NOT plug into any other

socket.

NOTE: If you change the plug, the colour of wires in the mains lead

may not match the colour of the markings which show the different

terminals in the plug.You must wire it as shown below:

Green and yellow (Earth)

wire to terminal marked ‘E’,

symbol , or coloured

green and yellow.

Blue (Neutral) wire to

terminal marked ‘N’ or

coloured black.

CE marking certifies that this appliance conforms to the following

EEC directives:

Low Voltage Equipment - 72/23/EEC & 93/68/EEC

Electromagnetic Compatibility - 89/336/EEC, 92/31/EEC & 93/68/EEC

13A ASTA approved fuse to

BS1362.

Brown (Live) wire to terminal

marked ‘L’ or coloured red.

TECHNICAL DETAILS

FEW14

Models

Dimensions

Capacity

Electric

Connections

Spin Speed

Control

programmes

according to

IEC456

directive

FEW12

FEW10

59.5cm wide

85cm high

60cm deep

from 1 to 5.5kg

voltage 220/240 Volts 50Hz

maximum absorbed power:

1700W-2100W

up to 1400rpm - FEW14

up to 1200rpm - FEW12

up to 1000rpm - FEW10

programme D

temperature 60˚C

run with a 5.5kg load

4

LEVEL?...

YOUR MACHINE WILL BE NOISY IF THE TWO FRONT

ADJUSTED SO THE MACHINE STANDS FIRM AND LE

When adjusting the feet, use a spirit level to check the machi

side to side and from front to back.

- Move your machine into its

(take care not to trap or kink

- Turn one or both front feet a

hand, until the feet cannot b

- The spring on each foot will

loose.

If it is placed on a fitted carpet, adjust the feet to ensure t

ventilation beneath the washing machine.

3

NOTE: A

MOVE T

ALONG

WHIC

YOU

HOOK

LEVEL T

(*see Ge

D

Installation

F

O

(

O

W

OX

1

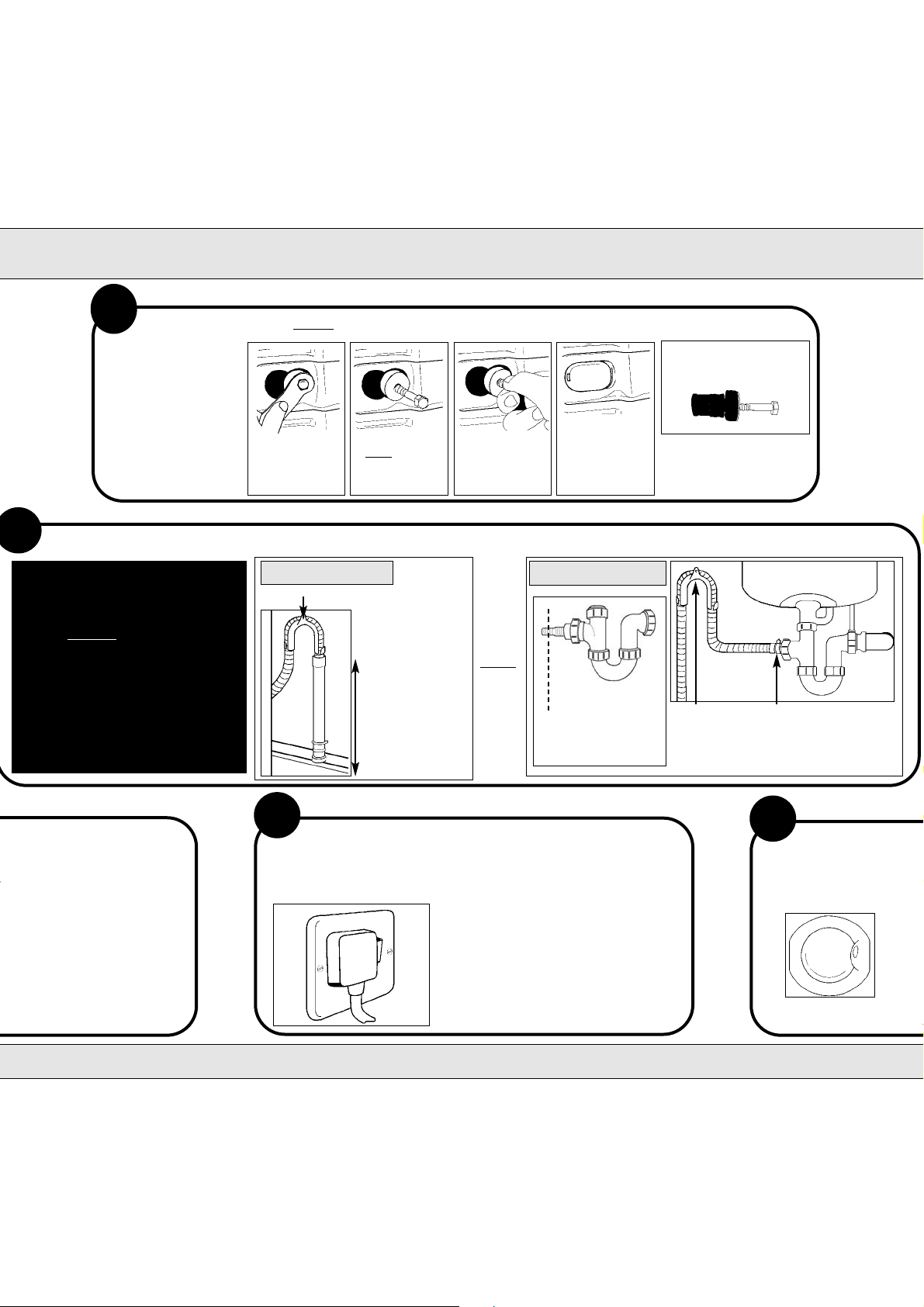

REMOVE TWO TRANSIT FIXINGS... Follow these instructions to remove the TWO transit fixings.

IMPORTANT:

Situated, one either

side of the rear panel,

BOTH transit bolts

(complete with

spacers) MUST be

removed before use...

Failure to do so may

cause damage to

your machine!

3

DRAINAGE SYSTEM...we recommend one of the following:

NOTE: ALTHOUGH YOU MAY NEED TO

MOVE THE HOOKED END SUPPORT

ALONG THE GREY DRAINAGE HOSE,

T REMOVE IT.

DO NO

WHICHEVER DRAINAGE METHOD

YOU USE,MAKE SURE THAT THE

HOOKED END SUPPORT IS FIXED

LEVEL TO,OR ABOVE THE ‘PLUMBING

INDICATOR LINE’*

(*see Getting to Know your Appliance)

Unscrew the

bolt using a

13mm spanner.

STANDPIPE METHOD

Hooked End Support

threads can be

Insert drainage hose

approximately 100mm

into the standpipe.

.............................

Standpipe height:

minimum 500mm

from the floor.

OP when 3

ST

seen.

Hold, slide

sideways and

pull to remove.

OR

For safety,insert

one of the

plastic covers

(supplied with

your machine)

over the hole.

UNDER SINK METHOD

cut off the blocked

end of the under sink

drainage unit.

It is important the transit

bolt and spacer come out

intact (see pic).

! Repeat steps to remove

the second transit bolt.

800mm

from floor

Fix the hooked

end support at

a minimum

800mm from

the floor.

Attach the GREY

drainage hose to the

under sink drainage

unit securely,using a

hose clip.

O FRONT FEET ARE NOT

AND LEVEL.

k the machine stands level...from

ine into its final location

trap or kink the hoses.

front feet anti-clockwise by

et cannot be turned any more.

ch foot will stop them coming

to ensure that there is adequate

5

CONNECT TO THE POWER SUPPLY...

PLUG YOUR MACHINE INTO AN ELECTRICAL SOCKET WHICH IS

EASILY ACCESSIBLE. SWITCH ON.

NOTE: Hotpoint recommend

extension leads are not used.

Move your machine into position,

take care not to trap or kink the

hoses.

6

READY...

TO CHECK ALL PARTS O

CLEAN THE INSIDE OF Y

RUN PROGRAMME ‘C’

WITH

✗

THIS WILL TAKE APPR

Loading...

Loading...