Hotpoint FDYF11011K, FDYF11011G, FDYF11011P Service Information

Indesit Company UK Ltd

© 2015 Reg. Office: Peterborough PE2 9JB Registered in London: 106725

Service

Information

Hotpoint

Freestanding

DISHWASHER

with

Digit Display

using

DEA700 & DEA603

controls

Models Covered:

Comm

Model: Code

FDYF11011G 82748

FDYF11011K 82752

FDYF11011P 82746

5407865 Issue 1 Feb. 2015.

SM004058 ~ C00309783

2 of 39

Service Manual UK

Indesit Company

English

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable product

knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected (unplugged) from

the electrical supply.

4. Servicing must be preceded by Earth Continuity and Insulation Resistance checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on metal

and plastic parts.

6. After Servicing the appliance must be rechecked for Electrical Safety. In the case of appliances which

are connected to a water supply (i.e.: Washing Machines, Dishwashers & Food Centres etc.) checks

must be made for leaks from seals gaskets and pipe work and rectification carried out where necessary.

7. It can be dangerous to attempt ‘DIY’ repairs / maintenance on complex equipment and the Company

recommends that any problem with the appliance is referred to its own Service Organisation.

8. Whilst the Company has endeavoured to ensure the accuracy of the data within this publication they

cannot hold themselves responsible for any inconvenience or loss occasioned by any error within.

INDEX

Safety Notes & General Servicing Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fault Codes & Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 8

Wiring Diagram / Power Module photo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 10

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

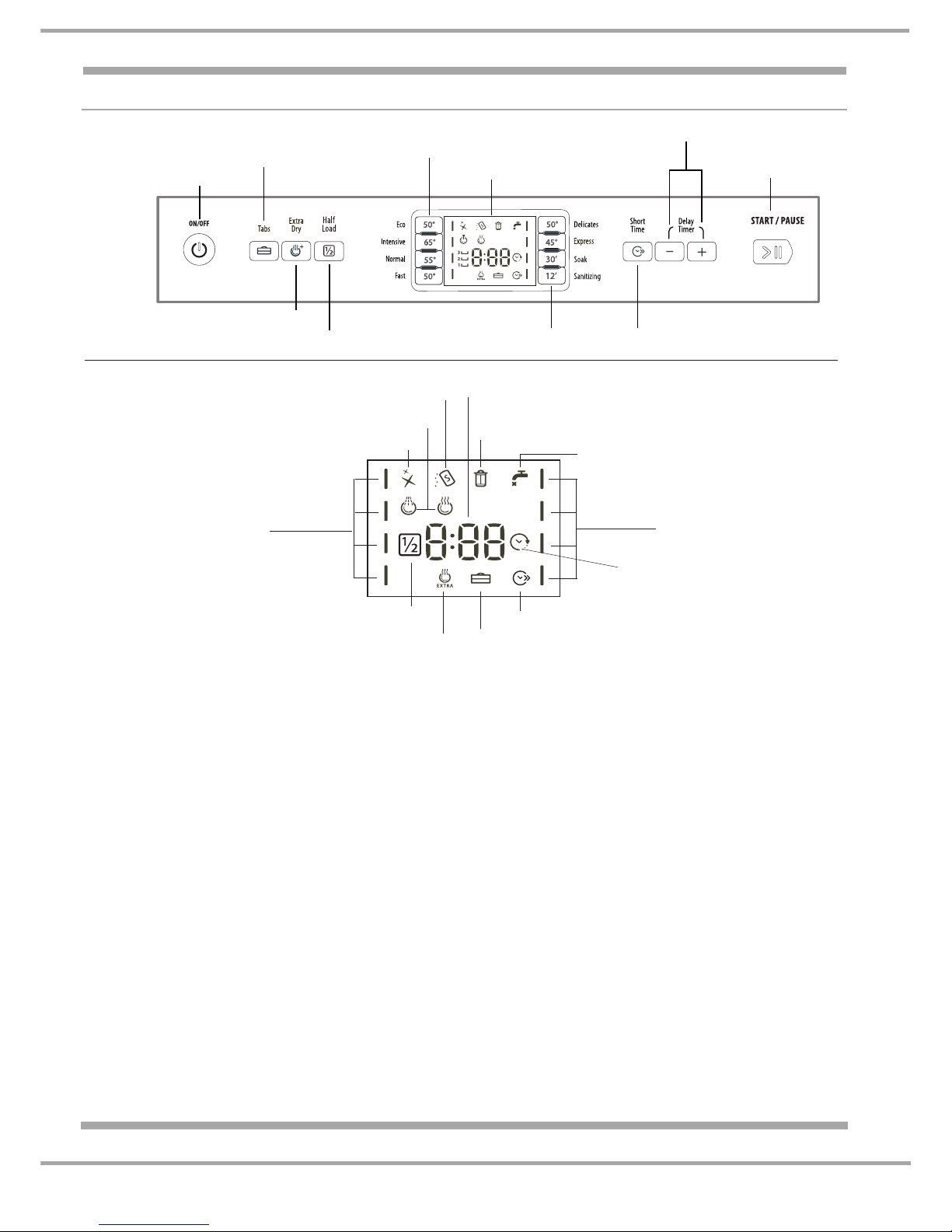

Console Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 - 14

Basic Use and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Programme Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Component Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 21

Auto Test Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 - 23

Dismantling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 - 30

Module Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 - 32

General Dishwashing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 - 36

Production Changes

First production models were fitted with DEA700 electronics

The DEA603 electronics module replaced DEA700 in production with the introduction of

Industrial code ending xxxxxxx 2500.

3 of 39

Indesit Company

Service Manual UK English

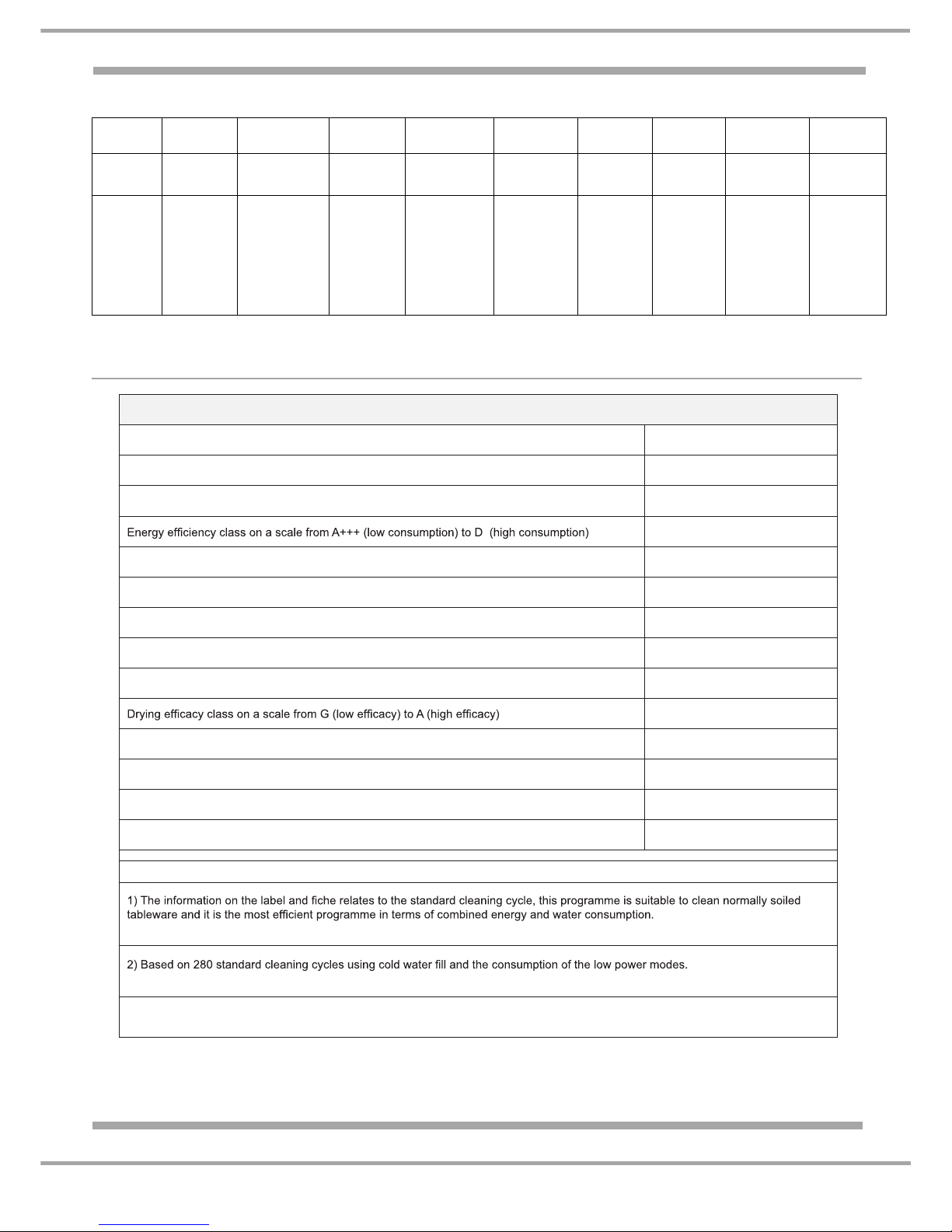

Model Matrix - FDYF11011P

Product Fiche - FDYF11011

FD Y F 1 1 01 1 P

Build Product Size Interface Basket

Water

Load

Motor

Type

Energy

Cutlery

Tray

Colour

F=Free-

standing

D=Dish-

washer

E=Experi-

ence

Y=Style

F=Futura

A=Aquarius

U=Ultima

F=Digit

B=Basic

Led

L= Led+

D=LCD

3=Flexiload

med.

1=Flexiload

Basic

4=Flexiload

High

5=Flexiload

Star

3=9 litres

1=12 Litres

2=10 Litres

4=7 Litres

0=Sync

Motor

1= Flex-

ipower

2=A++

1=A+

3=A+++

0=Stand-

ard

1=Cutlery

Tray

2=N/A

3=Active

O2

P=Polar

G=Graph-

ite

K=Black

V=Cream

SB=Gun

metal

Product Fiche

Brand

HOTPOINT

Model

FDYF 11011

Rated capacity in standard place settings (1)

13

A+

Energy consumption per year in kWh (2)

295.0

Energy consumption of the standard cleaning cycle in kWh

1.04

Power consumption of the off-mode in W

0.5

Power consumption of the left-on mode in W

5.0

Water consumption per year in litres (3)

3080.0

A

Programme time for standard cleaning cycle in minutes

190’

The duration of the left-on mode in minutes

10

Noise in dB(A) Re 1pW

49

Built-in model

No

NOTES

The standard cleaning cycle

corresponds to the Eco cycle.

Actual energy

consumption depends on how the appliance is used.

3) Based on 280 standard cleaning cycles. Actual water consumption depends on how the appliance is used.

4 of 39

Service Manual UK

Indesit Company

English

TECHNICAL SPECIFICATIONS

Models FDYF11011G 82748 Graphite

FDYF11011K 82752 Black

FDYF11011P 82746 White

First Production 2013

Energy Class A+

Washing Class A

Drying Class A

Noise Level 49 dB

Country of Origin Poland

Dimensions Height - 850 mm

Width - 600 mm

Depth - 600mm

Capacity 13 place settings

Electrical Supply 220/240 Volts AC @ 50Hz

Cable Length: 1.28 Metres

Energy Consumption Off Mode: 0.5 Watts

(2011 Regulations) Left On Mode: 5 Watts

Standard Cycle: 1.04 kW/h

Water Consumption Standard Cycle: 11 litres

Drying Natural Drying

Controls Electronic DEA 700 or DEA603 (Industrial Code ending ’2500’ )

Tub Stainless Steel

Heater type Flow through type with built in safety cut out and fuse

Heater Wattage 1.8 kW @ 230V AC

Heater Resistance 29.20Ω

Circulation Motor Synchronous

Detergent Dispenser Capacity 25g + 5g ** only available as part of the door panel

Rinse Aid Dispenser Capacity 140ml

Fill Valve Resistance 3.72 KΩ approx.

Water Pressure 0.56 bar (Max 10 bar)

Regeneration Valve 4.1 KΩ approx.

Drain Pump Synchronous motor

Power Consumption: 26 Watts

Thermistor Sump Mounted

Wash Programmes 8 - Eco, Auto Intensive, Auto Normal, Auto Fast, Duo Wash,

Delicates, Express 30’, Soak.

Wash Temperatures Between 50

°C and 70°C

Salt Refill Indicator Symbol on display

Rinse Aid Indicator Symbol on display

Supply Water Pressure 0.5 to 10 Bar (7.25 psi - 145 psi)

5 of 39

Indesit Company

Service Manual UK English

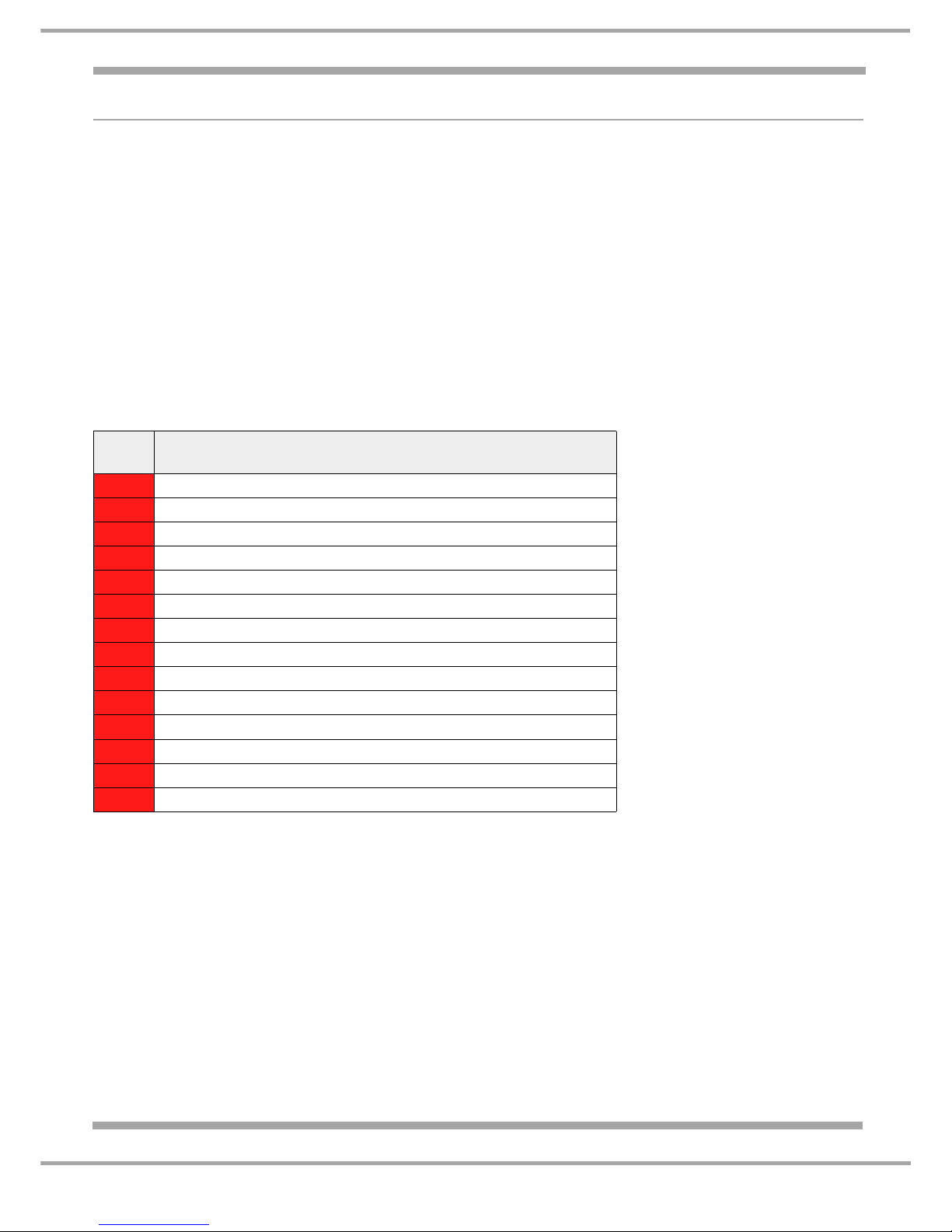

FAULT CODES - Basic

If there is a fault (active):

The service technician will find the machine immobilized, with the Fault Code shown in the display and

other LEDs on the Control Panel blinking (usually On/Off, Salt and Rinse Aid).

Refer to the Fault Code chart below for guidance.

If Warning or Last Fault is indicated:

Starting the autotest, the last Fault or the current Warning will be displayed for 20 seconds.

Once this time has elapsed, the autotest sequence starts automatically.

If the autotest reaches the end, the Last Fault will be reset.

Should the Autotest procedure be interrupted for whatever reason, data in the Last Fault memory will be

saved. N.B.: The "Last Fault detected electronically" will always be displayed.

Basic Fault Code Chart

For more detailed information refer to next page.

Fault Possible Cause

F01

ANTI-FLOODING OVERFLOW

F02

WATER FILL SOLENOID VALVE FAILURE

F03

DRAIN TIMEOUT

F04

THERMISTOR (NTC) not compliant

F05

Not applicable to this model

F06

WATER FILL TIMEOUT

F07

WATER TURBINE damaged

F08

TEMPERATURE TIMEOUT (1 hour)

F09

Software recognition error.

F10

HEATING ELEMENT CIRCUIT not compliant

F11

Not applicable to this model

F12

COMMUNICATION error between main board and display

F13

MAIN BOARD not Working

F15

VIRTUAL SENSOR - Inconsistent readings

6 of 39

Service Manual UK

Indesit Company

English

FAULT CODES - Detailed

- Pressure switch faulty;

- Pressure switch tube damaged;

- Water in air trap;

- Air trap damaged.

- Tap closed or partially closed;

- Filler hose pinched;

- Filler hose ſlter clogged/bent;

- Water pressure low or ƀow meter doesn’t work;

- Water solenoid valve faulty or disconnected.

- Turbine faulty or disconnected;

- Connector terminals not making contact;

- Turbine wiring faulty;

- Turbine faulty, disconnected or wet;

- WATER has been introduced manually;

- Filler hose ſlter obstructed;

- Pressure switch faulty.

- NTC sensor bracket detached from bowl;

- Fault in electrical circuit of heating element;

- Heating element ITR incorrectly calibrated/faulty;

- Excessive suds;

- Heating element false contact

- NTC sensor incorrectly calibrated

- Lime scale on heating element.Water hardness

setting not compliant. User not putting in salt

- NTC sensor separated from socket (replaces

ſrst check)

- Heating element defective.

- Main board not programmed;

- Incorrect setting ſle.

- Heating element cables disconnected;

- Main board relay defective

- Heating element defective;

- Main board relay defective.

- Fault in Main board/user interface wiring;

- Disconnect from electrical power supply.Wait 2

minutes.Reconnect appliance to power supply

and test again;

- User interface defective.

- Replace main board.

- Replace wash pump.

Pressure switch has not indicated

completion of fill, even though

turbine has filled appliance with

water correctly.

Maximum interval of time for completion of ſll has been exceeded.

Turbine has given no signal indicating entry of water, even though ſll

has effectively been completed.

Maximum interval of time for establishing temperature has been

exceeded (1 hour).

Software recognition error Processor not programmed.

HEATING ELEMENT CIRCUIT not

Note:

This code may display

during an Auto Test

If the dishwasher is working normally,

ignore this Fault Code during an Auto Test.

compliant (circuit open).

No communication/connection

between main board and user

interface.

Main board NOT WORKING

Reading between Wash pump and

Drain pump not consistent.

PRESSURE SWITCH

non compliant

WATER FILL

TIMEOUT

WATER TURBINE

damaged

TEMPERATURE

TIMEOUT (1 hour)

Software recogni-

tion error. Main

board not pro-

grammed

HEATING ELE-

MENT CIRCUIT not

compliant

Not Applicable

to this model

COMMUNICATION

error between main

board and display

Main board NOT

WORKING

VIRTUAL SENSOR

F05

F06

F07

F08

F09

F10

F11

F12

F13

F15

- Water leak;

- Float switch or wiring defective;

- New main board: Eeprom was programmed

off-site; to reset thealarm, switch off and switch

on again using the ON/OFF button.

- Fill solenoid valve failure;

- Main boardſll solenoid valve triacshort-circuiting;

- Make certain drain hose is not on the ƀoor.

- Drain pump blocked by foreign matter;

- Drain pump faulty/disconnected;

- Drain hose blocked;

- Drain trap blocked;

- Air bubble in hose;

- Check drain pump wiring and connectors at

component end and main board end;

- Check integrity of drain pump impeller;

- Replace drain pump.

- NTC sensor cables disconnected or damaged;

- Cablesor connectors disconnectedor short-circuiting;

- NTC sensor wet, short-circuit;

- NTC sensor damaged, open circuit.

Bowl ƀoat microswitch electrical

circuit OPEN! (must be closed)

Fill valve admits water even when

deactivated.

Maximum drain time elapsed.

THERMISTOR (NTC) circuit not

compliant (break in continuity or

short-circuit)

FAULT

CODE

F01

ANTI-FLOODING

OVERFLOW

WATER FILL

SOLENOID VALVE

FAILURE

DRAIN TIMEOUT

THERMISTOR (NTC)

not compliant

NAME

POSSIBLE CAUSE

CHECKS

F02

F03

F04

7 of 39

Indesit Company

Service Manual UK English

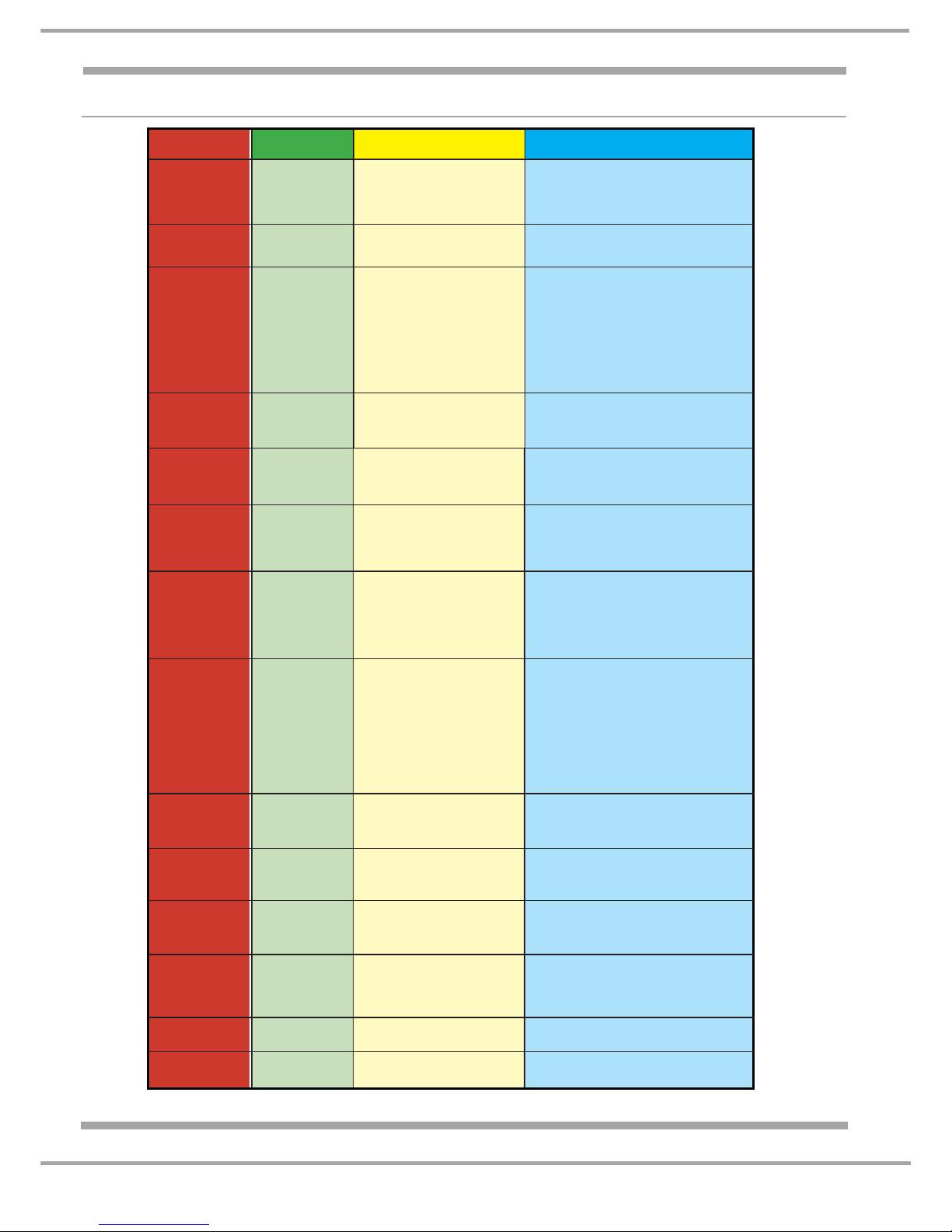

Thermistor - Resistance Chart

Fault Notes

• Filling

After the initial drain period, it is norma l at the start of a cycle for the machine to pause for a perio d

before filling.

• Heating Element

An open circuit heating element can display either the heating time out fault code or the open

circuit heater fault code (F8 & F10), depending on the cycle in progress or the phase of the cycle

when the heater fails.

If a dishwasher has an open circuit heating element, the machine may run for up to 75 minutes

before a fault code will display.

It is recommended before a module is replaced or when the fault is not obvious, the heating

element is tested for continuity and resistance to Earth at its terminals, with the heater

disconnected.

continued...

Temperature

in degrees C

Resistance

in K Ohms

Temperature

in degrees C

Resistance

in K Ohms

- 40 24751.661 50 146.215

- 35 17127.169 55 117.828

- 30 12014.762 60 95.420

- 25 8524.305 65 77.718

- 20 6113.811 70 63.584

- 15 4435.437 75 52.260

- 10 3249.216 80 43.166

- 5 2403.515 85 35.808

0 1794.358 90 29.828

+ 5 1351.294 95 24.961

10 1025.870 100 20.955

15 785.018 105 17.668

20 605.252 110 14.951

25 470.000 115 12.695

30 367.480 120 10.824

35 289.186 125 9.259

40 229.014

45 182.485

8 of 39

Service Manual UK

Indesit Company

English

• Programme Times

The times in the handbook and displayed at the start of the cycle, are average times and will be

affected by the following points:

• Inlet water temperature below 19°C

• Tab option enabled

• Water hardness setting set to positions 4 or 5

• Condition of the heating element (limescale built up)

• Excessive foam caused by using tablets with a small or light load.

NOTE: - The display is not a coun t down timer. It is normal occasionally for the same time to show

for an extended period.

• Machine Starts up for a few minutes when not in use

The machine inlet valve is 'letting by' and water is leaking into the machine when not in use.

Providing the machine is plugged in and the door close d (it does not have to be switched on), once

the water in the machine is enough to operate the pressure switch to full level, the machine drain

pump will energise until the pressure switch resets to empty (plus 30 seconds).

Note: - Fault code F2 displays if the water letting by is fast enough to be recognised by the water

turbine.

Indesit Company

9 of 39

Service Manual UK English

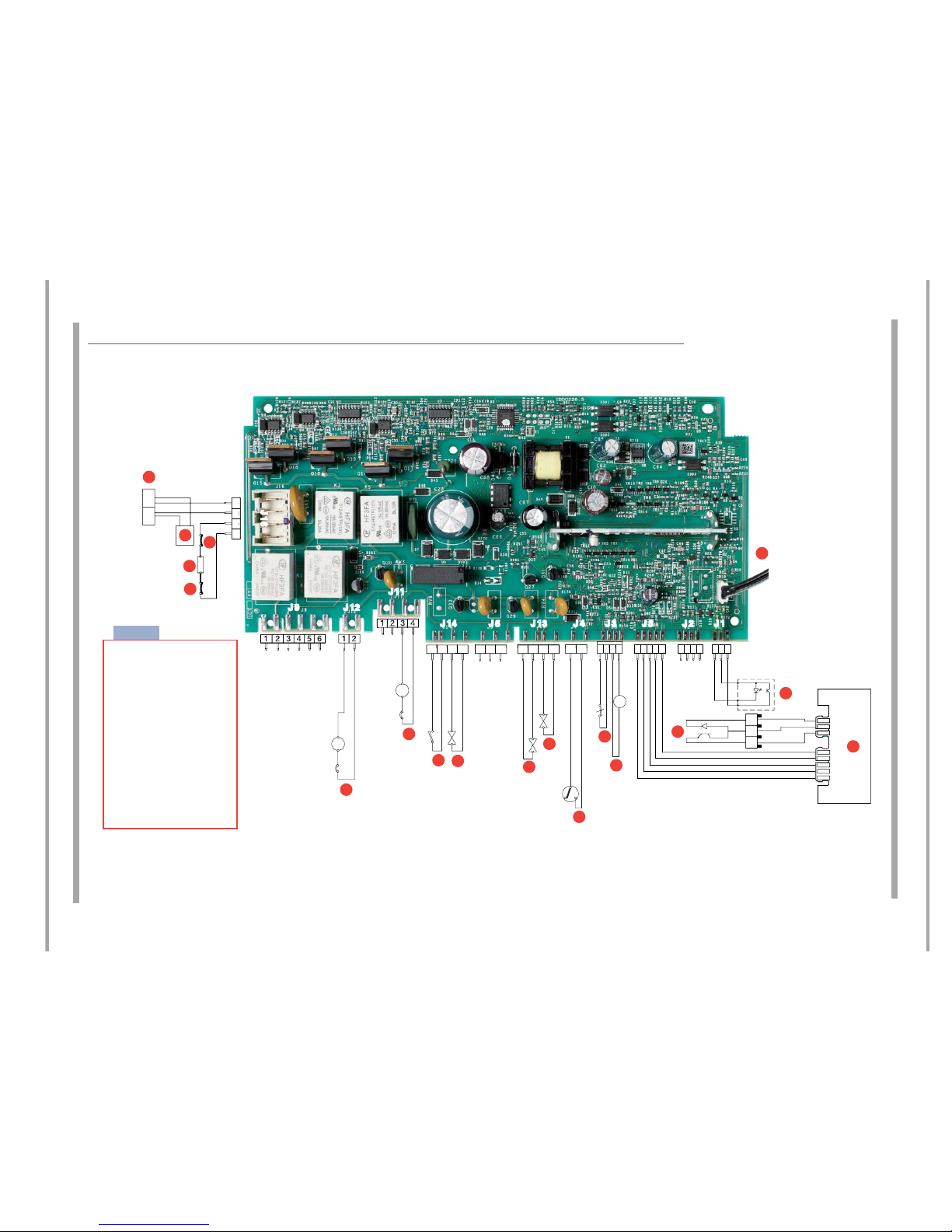

WIRING DIAGRAM DEA700 Module

1234

65432121

4321

54321

12

3

J 9

J 11

J 12

J 5 J 13 J 8J 14 J 4 J2J 3 J 1

J

16

P

N

O

M

S

C

A

H

G

L

I

R

Q

Key:

D

E

NL

B

F

A Mains power

B Noise lter

C Heating element

D Thermoprotector (95°C)

E Thermal fuse (206°C)

F Synchronous drain pump

G Synchronous washing motor

H Door microswitch

I Dispenser solenoid valve

L Load solenoid valve

M Regeneration solenoid valve

N Pressure switch

O Overow switch

P Meter turbine

Q Rinse aid reader

R User interface

S Salt reader

T Temperature sensor

T

4321

432121

4321

321

54321 321 32

1

DEA700

Module

Indesit Company

10 of 39

Service Manual UK English

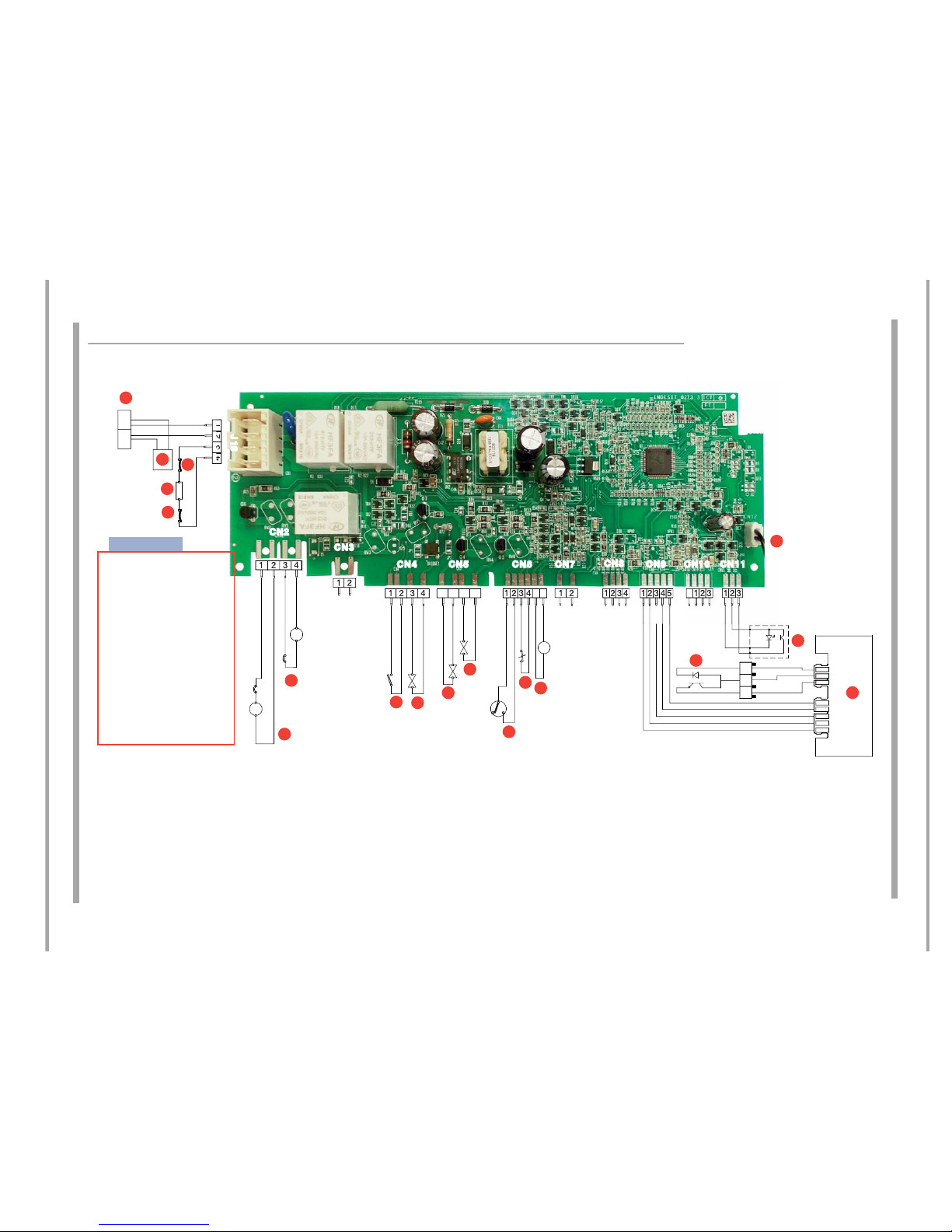

WIRING DIAGRAM DEA603 Module

1234

4321

21

4321 543213 4 2121 3214321 32

1

54

3

2

112

3

4321 5 6

P

N

O

M

CN2

S

CN3

CN5 CN9

CN4

CN7 CN10 CN11

J 16

C

A

H

G

L

I

R

Q

D

E

NL

B

F

CN6

CN8

Key:

A Mains power

B Noise lter

C Heating element

D Thermoprotector (95°C)

E Thermal fuse (206°C)

F Synchronous drain pump

G Synchronous washing motor

H Door microswitch

I Dispenser solenoid valve

L Load solenoid valve

M Regeneration solenoid valve

N Pressure switch

O Overow switch

P Meter turbine

Q Rinse aid reader

R User interface

S Salt reader

T Temperature sensor

T

DEA603

Module

11 of 39

Indesit Company

Service Manual UK English

GENERAL INFORMATION

These models are freestanding front loading Dishwashers providing a choice of 8 Wash Cycles.

They have A+ Energy performance.

Programmes and all Options are set using the display, which is mounted on the console.

Extra Dry, Tabs, Half Load, Shortime and Delay Options are also available on selected programmes.

Smaller loads can be washed using either the top or bottom ba sket.

There are "Low" warning indicators on the console display for Salt and Rinse Aid.

The user adjusts Water Hardness before the machine is first used.

Rinse Aid is electronically controlled and has to be adjusted from the Console.

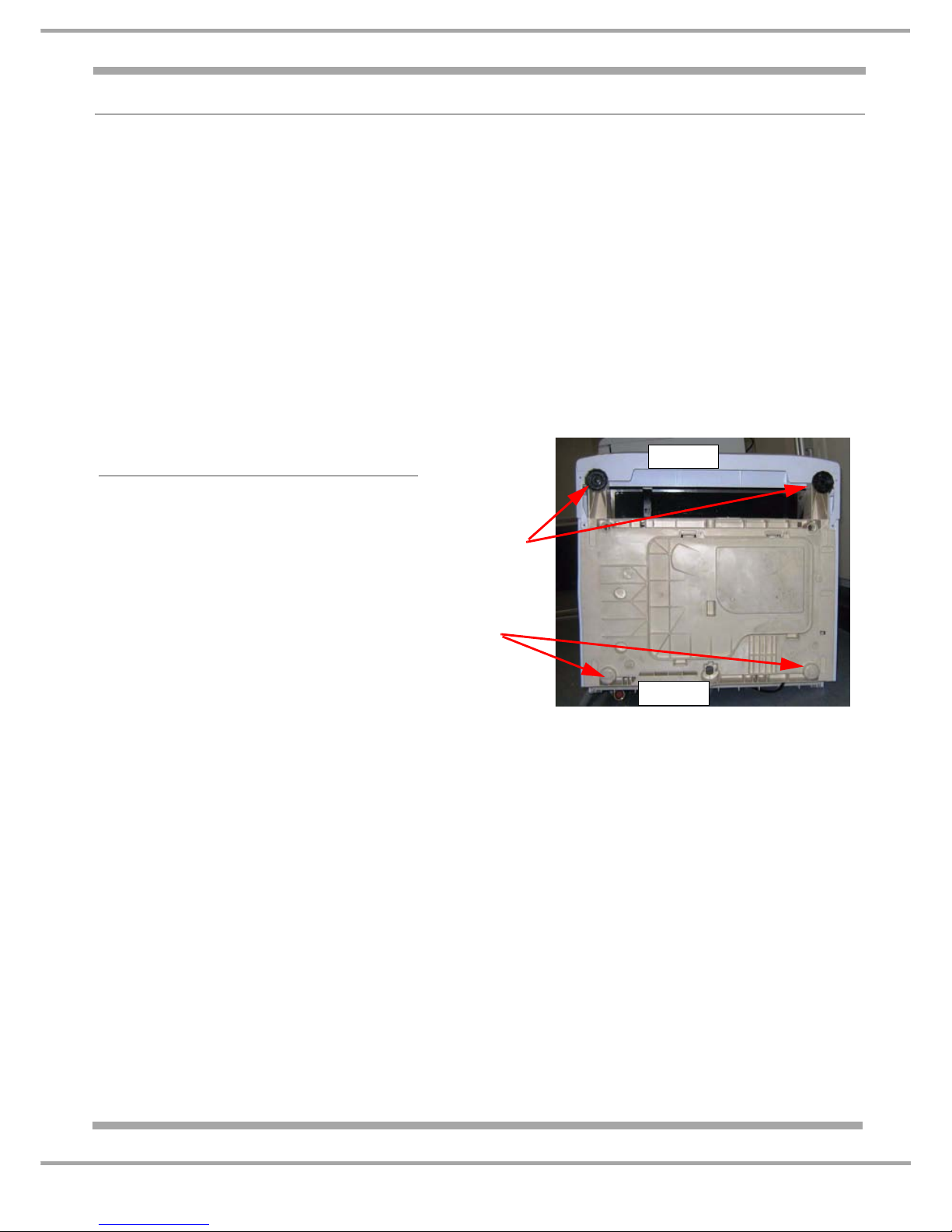

Levelling the Dishwasher

There are 2 adjustable feet at the front.

There are 2 solid moulded sliders at the

rear.

The dishwasher must be level to prevent

distortion of the cabinet and poor closing of

the door.

Refer to the photo (right) of the dishwasher

seen from underneath.

Adjustable

Non-adjustable

sliders

Front

Rear

Feet

12 of 39

Service Manual UK

Indesit Company

English

CONSOLE P ANEL

The following information is displayed during a cycle.

> Estimated Programme duration time

This will countdown as the cycle progresses, and the time to finish will automatically update as the

programme progresses.

The first programme displayed will always be the most commonly used programme.

This is not a countdown timer, but an estimate time to the end of the cycle.

> If an Option as been selected a bar will illuminate above the Option button.

Fault Codes will display in the event of a machine failure - for example: F 6

Other information messages will scroll across the Display.

ON-OFF/RESET BUTTON

Press this button to switch the appliance on.

To Re-set a programme that requires cancelling press and hold down the On-Off button.

ON-OFF INDICATOR LAMP

This Lamp shows that the Dishwasher is Switched on.

Display

Wash cycle

Wash cycle

Half Load indicator light

Low Rinse Aid indicator light

Low Salt indicator light

Blocked Filter indicator light

Extra Drying indicator light Multi-Functional Tablets indicator light (Tabs)

Washing and Drying indicator lights

Tap Shut-Off indicator light

Delayed Start

indicator light

Remaining Time indicator

Short Time option indicator light

Control Panel

Start/Pause button

and indicator lights

On-Off/Reset button

and indicator light

Extra Drying option button

Half Load option button

Delayed Start buttons

Multi-functional Tablets

option button (Tabs)

Display

Wash-Cycle Selection buttons

Short Time option button

Wash-Cycle Selection buttons

*** Only in completely built-in models * Only available in selected models.

The number and type of wash cycles and options may vary depending on the dishwasher model.

Loading...

Loading...