Hotpoint FDM550P, FDM550P.R, FDM554P, FDM554P.R Service Information

Indesit Company UK Ltd

© 2010 Reg. Office: Peterborough PE2 9JB Registered in London: 106725

Service

Information

Hotpoint

Freestanding

DISHWASHER

Model Covered

Hotpoint

Italian manufacture

FDM550P 54445

FDM554P 63569

Polish manufacture

FDM550P.R 56396

FDM554P.R 64674

5407485 Issue 3 June 2010

2 of 35

Service Manual UK

Indesit Company

English

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable

product knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must be undertaken with the appliance disconnected (unplugged)

from the electrical supply.

4. Servicing must be preceded by Earth Continuity and Insulation Resistance checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on

metal and plastic parts.

6. After Servicing the appliance must be rechecked for Electrical Safety. In the case of appliances which

are connected to a water supply (i.e.: Washing Machines, Dishwashers & Food Centres etc.) checks

must be made for leaks from seals gaskets and pipe work and rectification carried out where

necessary.

7. It can be dangerous to attempt ‘DIY’ repairs / maintenance on complex equipment and the Company

recommends that any problem with the appliance is referred to its own Service Organisation.

8. Whilst the Company has endeavoured to ensure the accuracy of the data within this publication they

cannot hold themselves responsible for any inconvenience or loss occasioned by any error within.

INDEX

Safety Notes & General Servicing Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Console Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Programme Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Setting the Water Hardness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Component Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 13

Fault Codes & Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 19

Wiring Diagram - models fitted with DEA601 Power Module . . . . . . . . . . . . . . . . . . . . . . 20

Wiring Diagram - models fitted with DEA602 Power Module . . . . . . . . . . . . . . . . . . . . . . 21

Power Module photo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Module Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 - 24

Dismantling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 - 30

General Dishwashing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 - 34

Production Changes

DEA602 Power Module Introduced:

FDM550P.R - from Serial Number 91231.9999

FDM554P.R - from Serial Number 91023.9999

Standby Function Added:

All Models from March 2010

3 of 35

Indesit Company

Service Manual UK English

TECHNICAL SPECIFICATIONS

Models FDM550P - 54445 - White

FDM554P - 63569 - White

FDM550P.R - 56396 - White

FDM554P.R - 64674 - White

Energy Class A

Washing Class A

Drying Class A

Noise Level 51dB

Country of Origin FDM550P - FDM5504P:- Italy

FDM550P.R - FDM554P.R:- Poland

Dimensions Height 850 mm

Width 595 mm

Depth 570 mm

Weight 43 Kg

Capacity 12 place settings - FDM550P + FDM550P.R

14 place settings - FDM554P + FDM5540.R

Electrical Supply 230/240 Volts AC @ 50Hz

Energy Consumption Standard Cycle: 1.08kW/h

Water Consumption Standard Cycle: 15 litres

Drying Residual Heat Drying (Natural)

Controls Electronic DEA 601 with soldered EEPROM - see Production changes

or Electronic DEA 602 with soldered EEPROM - see Production changes

Tub Stainless Steel

Heater type Flow through type with built in safety cut out and fuse

Heater Wattage 1.8 kW @ 230V AC

Heater Resistance 29.20Ω

Circulation Motor Synchronous Motor

Motor RPM 2800

Motor Power Consumption 60 Watts

Detergent Dispenser Capacity 25g + 5g

Rinse Aid Dispenser Capacity 14 0ml

Fill Valve Resistance 3.72KΩ approx.

Water Pressure 0.56 bar (Max 10 bar)

Regeneration Valve 4.1KΩ approx.

Drain Pump Plaset Motor Synchronous

Motor Winding Resistance: 216Ω + or - 7%

Power Consumption: 26 Watts

Thermistor Sump Mounted

Wash Programmes 5 - Intensive, Normal, Prewash, Eco, Fast Wash

Wash Temperatures 45°C, 52°C, 48°C, 63°C

Salt Refill Indicator LED on console

Rinse Aid Indicator LED on console

4 of 35

Service Manual UK

Indesit Company

English

GENERAL INFORMATION

This model is a freestanding front loading dishwasher providing a choice of 5 wash programmes to

suit load requirements.

The Programme Selector, Option buttons and LED indicators are mounted on the front panel.

There are "Low" warning LED’s mounted on the Console for Salt and Rinse Aid.

Water hardness is adjusted by the user before the machine is first used.

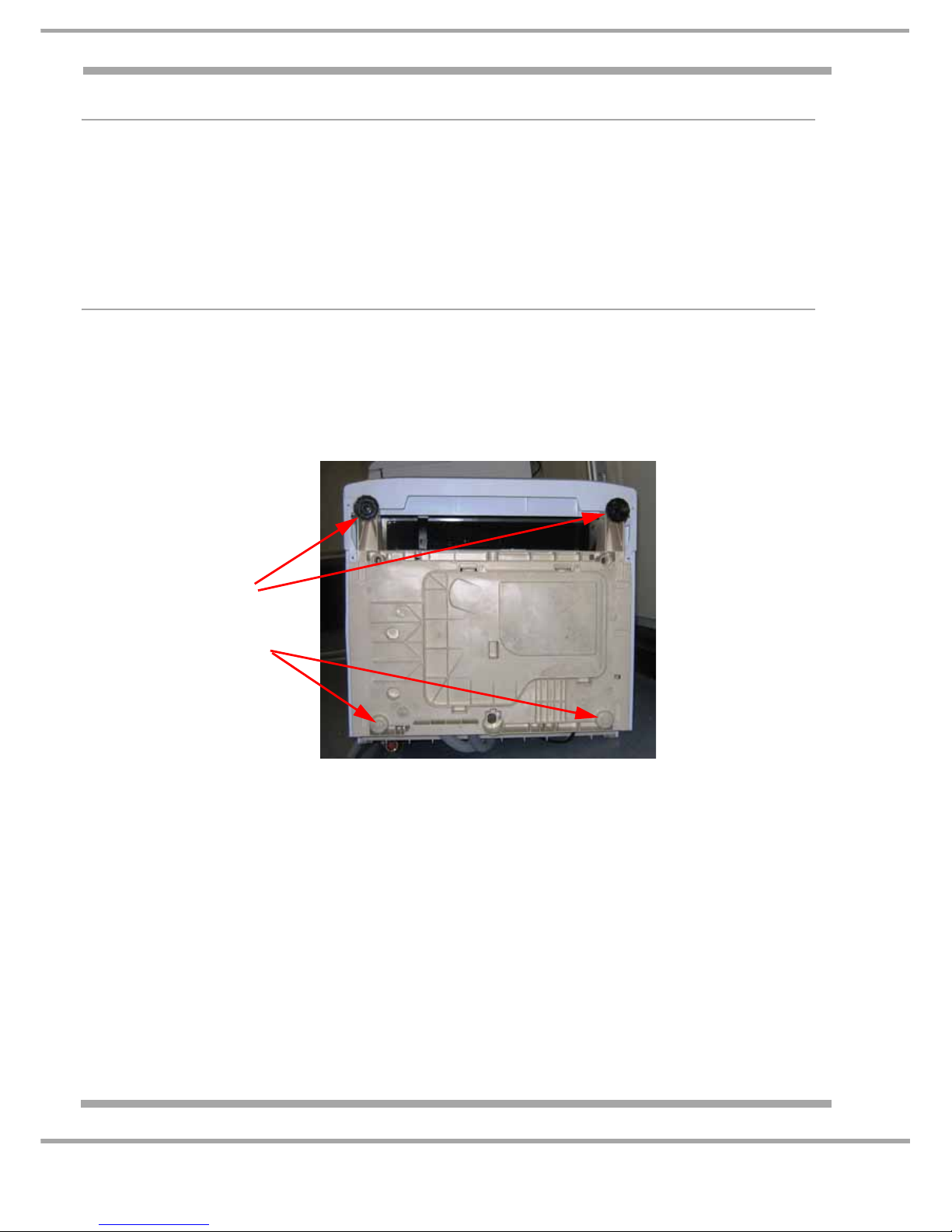

Levelling the Dishwasher

There are 2 adjustable feet at the front.

There are 2 solid moulded sliders at the rear.

The dishwasher must be level to prevent distortion of the cabinet and poor closing of the door.

Dishwasher seen from underneath.

Adjustable Feet

Non-adjustable

sliders

Front

Rear

5 of 35

Indesit Company

Service Manual UK English

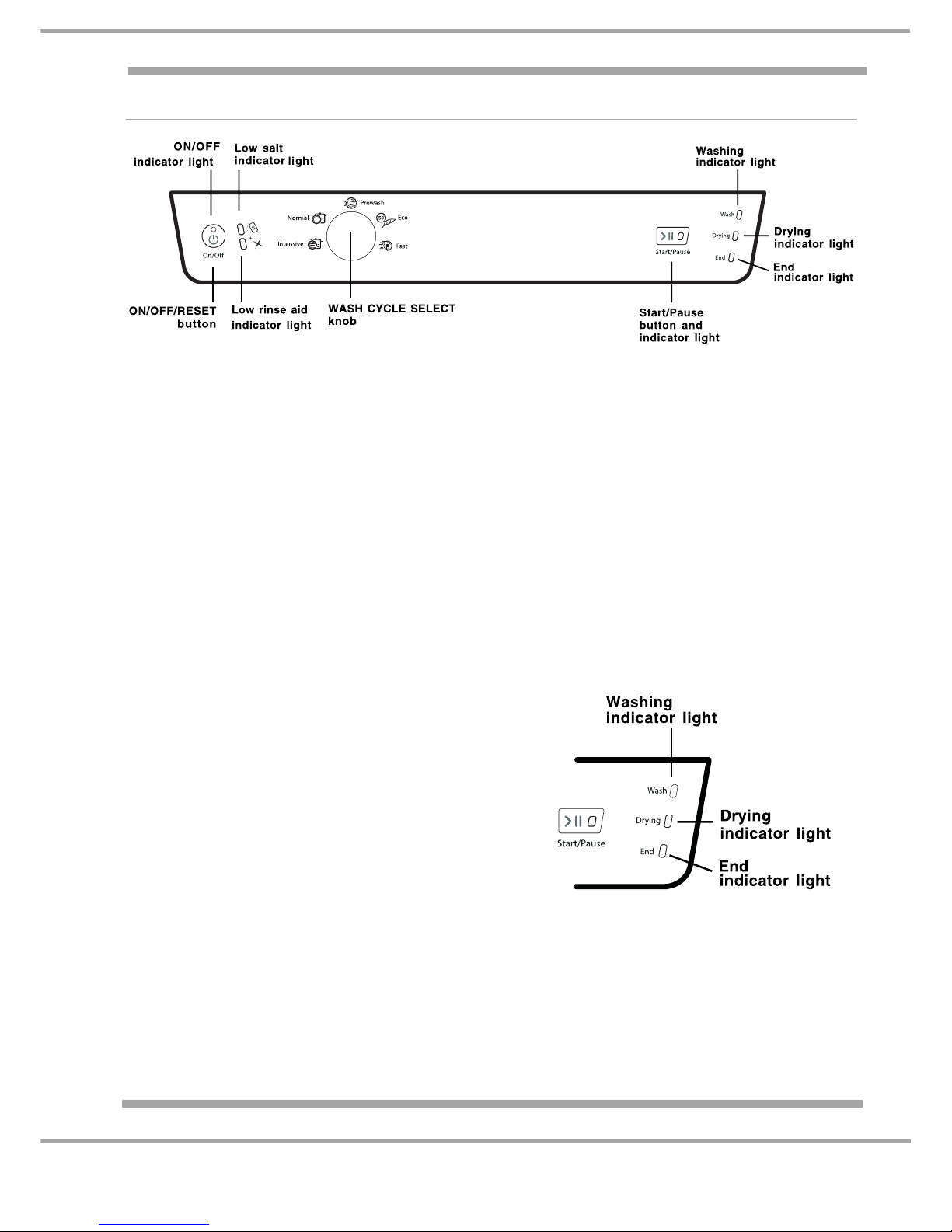

CONSOLE PANEL

ON-OFF/RESET BUTTON

Press this button to switch the appliance on.

To Re-set a programme that requires cancelling press and hold down the On-Off button.

ON-OFF INDICATOR LAMP

This Lamp shows that the Dishwasher is Switched on.

START/PAUSE BUTTON

Once the Programme and Options required have been selected. Pushing this button once will

start the selected Programme.

During a Programme if this button is pushed the Cycle will stop until the button is pushed

again, when the cycle will continue.

START/PAUSE INDICATOR LAMP

STAND-BY

When the cycle has completed the programme, 10 minutes after the door is opened the machine will

go into stand-by. The LEDs will turn off.

Push the On/Off button to remove the machine from stand-by mode.

Lamp States

1. Lamp FlashingWaiting for a Cycle to be selected

and Started

2. Lamp Green and On,Programme in progress

WASH CYCLE SELECTOR

Used to select the required Wash Programme

PROGRESS LAMPS

These lamps show the Delayed Time set, if this Option

has been selected and during a Cycle, Programme

progress.

6 of 35

Service Manual UK

Indesit Company

English

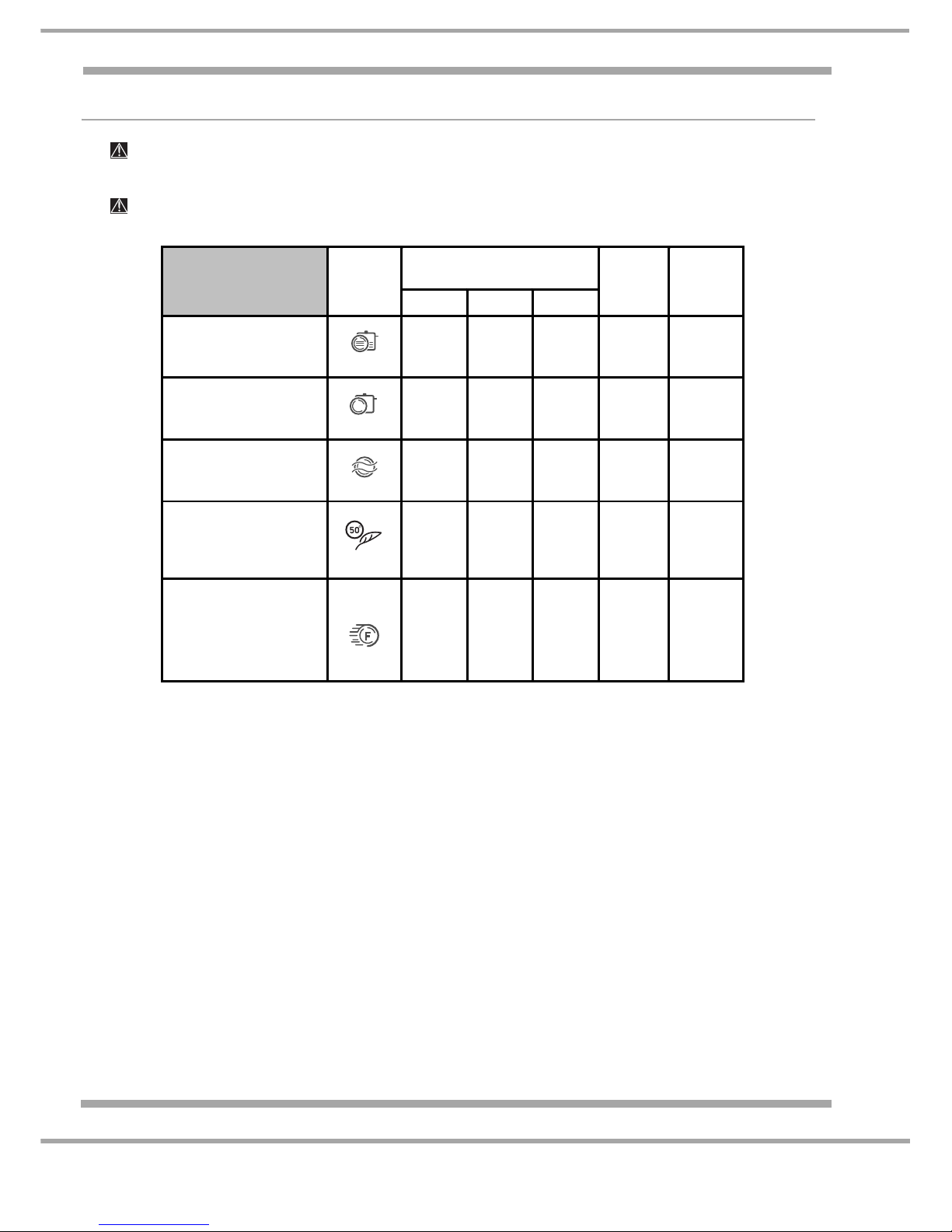

PROGRAMME GUIDE

Notes:

1. Optimum performance levels when using Quick cycle can be achieved by observing the

maximum amounts of crockery specified.

2. * The Eco wash cycle adheres to the regulation EN-50242.

Although it has a longer duration than other wash cycles it uses less energy and is less harmful

to the environment.

3. To make it easier to measure out the detergent, it is worth remembering that:

1 tablespoon = 15 grams of powder = approximately 15 ml of liquid

1 teaspoon = 5 grams of powder = approximately 5 ml of liquid

The number and type of wash cycles and options may vary depending on the dishwasher model.

Detergent

(A) = compartment A

(B) = compartment B

Wash cycle selection

instructions

Wash cycle

Powder Liquid Tablets

Wash

cycles

which

include

drying

Wash cycle

duration

(tolerance

±10%)

Hrs. Min.

Heavily soiled dishes and

pans (not to be used for

delicate items).

Intensive

35 g (A) 35 ml (A) 1 (A)

Yes 2:15’

Normally soiled pans and

dishes. Standard daily wash

cycle.

Normal

29 g (A)

6 g (B)

29 ml (A)

6 ml (B)

1 (A) Yes 1:45’

Pre-wash for dishes while

awaiting completion of the

load with the dishes from the

next meal.

Prewash

No No No No 0:08’

Environmentally-friendly wash

cycle with low energy

consumption levels, suitable

for pans and dishes.

Eco

*

29 g (A)

6 g (B)

29 ml (A)

6 ml (B)

1 (A) Yes 2:35’

Economic and fast wash to

be used for lightly soiled

dishes. (Run cycle

immediately after use) (2

plates + 2 glasses + 4 pieces

of cutlery + 1 saucepan + 1

small frying pan).

Fast wash

25 g (A) 25 ml (A) 1 (A) No 0:35’

If the crockery is only lightly soiled or if it has been rinsed with water before being placed in the

dishwasher, reduce the amount of detergent used accordingly.

7 of 35

Indesit Company

Service Manual UK English

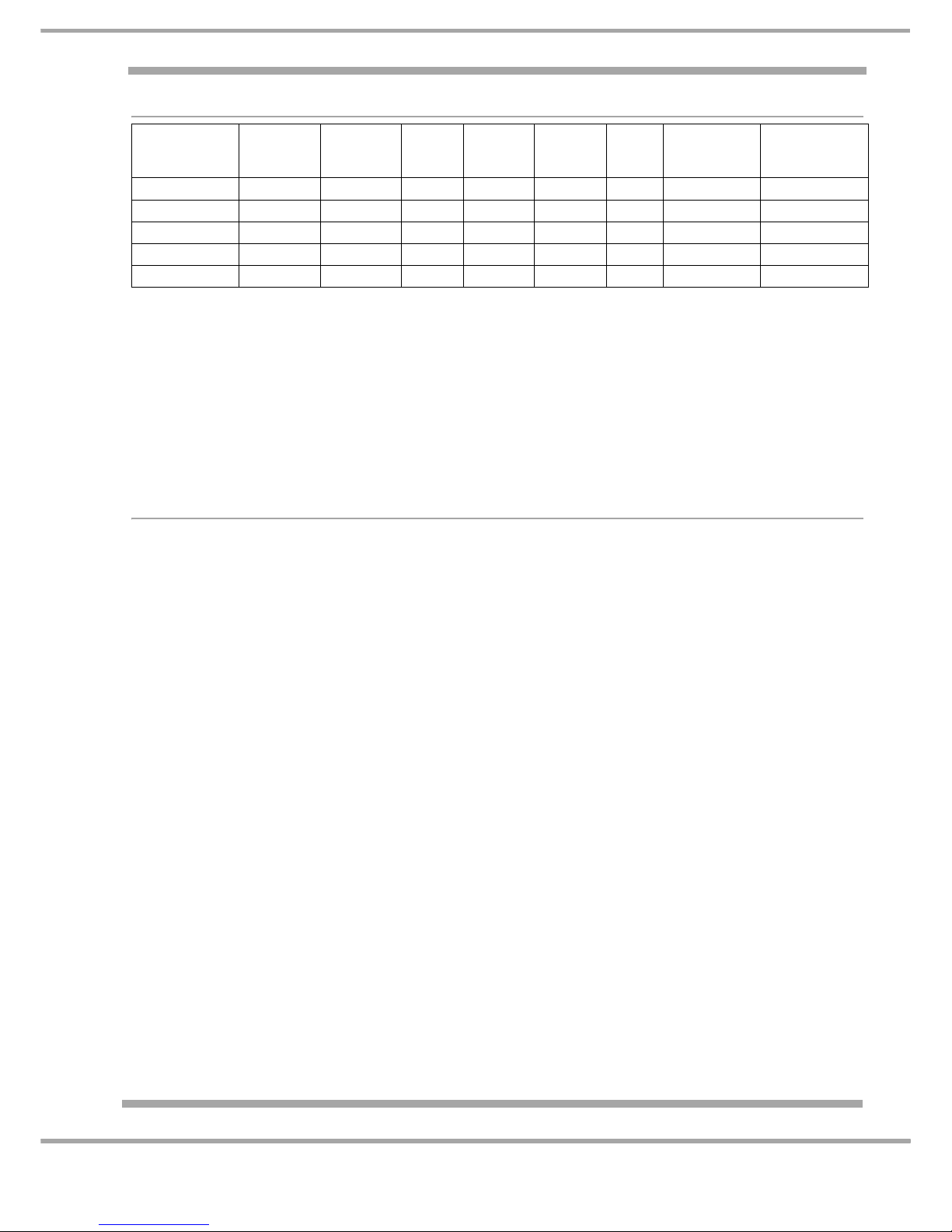

Programme Cycle Sequences

Notes:

1. *The Eco wash cycle adheres to the regulation EN-50242.

Although it has a longer duration than other wash cycles it uses less energy and is less harmful

to the environment.

2. To make it easier to measure out the detergent, it is worth remembering that:

1 tablespoon = 15 grams of powder = approximately 15 ml of liquid.

1 teaspoon = 5 grams of powder = approximately 5 ml of liquid.

BASIC MACHINE USE

Note: Water Hardness MUST be set BEFORE first use or after module replacement.

Refer to following page

Setting a Programme

1. Turn the Machine On (On-Off Button). Start Pause Button Flashes

2. Turn the Wash Cycle Select Knob to the desired Programme.

3. Press the Start Button. The lamp will stop flashing and stay per manently On.

Cancelling a Programme in progress

Press and Hold the ON/OFF BUTTON. All Leds will turn off

End of Programme

The END programme progress lamp will illuminate.

Salt and Rinse Aid Lamps Flashing together

If the salt and rinse aid warning lights flash as well as 1 or more programme progress / delay

and Start lights the machine has a fault. See page 18.

Cycle

Pre-wash 1Pre-wash

2

Wash Rinse 1 Rinse 2

Warm

Rinse

Drying

WITH

water

Drying

WITHOUT

water

INTENSIVE 45°C n/a 63°C Cold Cold 70°C 15 mins 20 mins

NORMAL Cold n/a 52°C Cold n/a 70°C 18 mins 8 mins

PREWASH Cold n/a n/a n/a n/a n/a n/a n/a

ECO* Cold Cold 48°C n/a n/a 70°C 10 mins 40 mins

FAST WASH n/a n/a 50°C Cold n/a n/a n/a n/a

8 of 35

Service Manual UK

Indesit Company

English

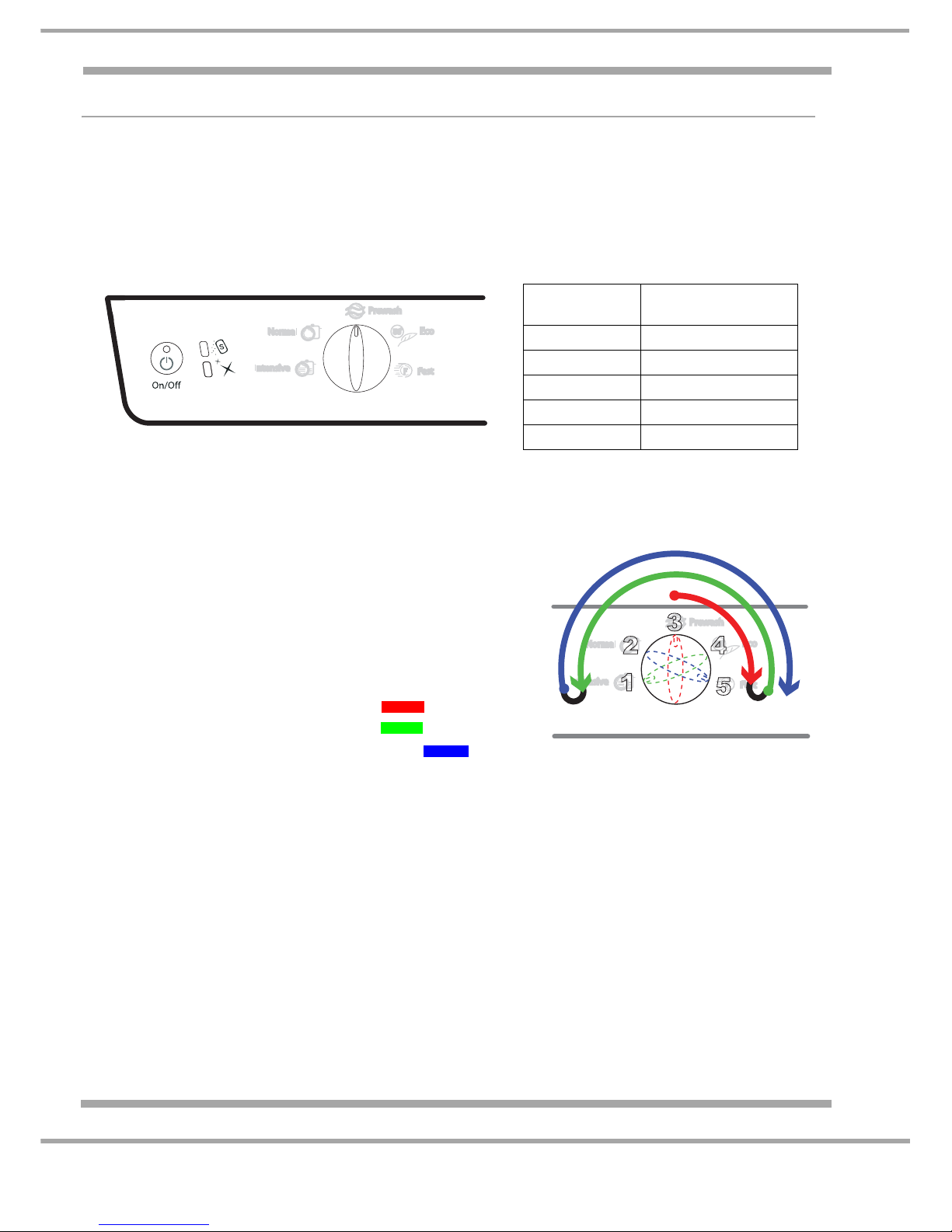

SETTING THE WATER HARDNESS

These models have 5 Water Hardness Settings to allow for the water supply where the machine is

located.

The Water Hardness Setting must be set:

- before the machine is used for the first time (the factory default setting is 3)

- if a new Module has been fitted or if the machine is moved to a different water area.

Use the Water Hardness Setting Table above to determine WATER HARDNESS then follow the

following procedure to set the machine to the required Water Hardness.

Note: If the correct Water Hardness Setting is not set, reliability and performance could be

affected.

1. Connect the machine to the mains power supply and

make sure that the power is On.

2. Ensure that the dishwasher is switched Off

(connected to the mains but switched Off at the

console).

3. Close the dishwasher Door and Set the Selector knob

to position 3 (see Fig.1 above).

4. Open the dishwasher Door. (this starts the sequence)

5. Perform the following sequence - see Fig 2

a. Rotate the Selector to position 5

b. Rotate the Selector to position 1

c. Rotate the Selector to position 5 again

d. Switch the machine ON at the console.

e. The Program Progress Lamps should now be Flashing.

f. Rotate the Selector (within 10 seconds) to the required hardness setting (refer to chart

above.) If setting 5 is required, leave the selector at position 5 until the lights stop flashing.

When the lights stop flashing, the setting will be taken from where the selector was positioned.

Note. It is important all steps are carried out with pausing, otherwise the machine will reset to

previous or default setting when the lights stop flashing.

If you fail to complete the sequence within the required time, switch the dishwasher OFF at the

power source and start again from step 1.

Once set, the setting will be remembered even if the power is turned off.

1

2

3

4

5

Fig.1

Water hardness setting table:

Hardness

(Clarke)

Set Hardness

0 - 7 1

7.7 - 14 2

14.7 - 21 3

21.7 - 42 4

42.7 - 63 5

1

2

3

4

5

Fig.2

9 of 35

Indesit Company

Service Manual UK English

COMPONENT DESCRIPTION

DEA Power Module

Mounted behind the plinth, this is an e lectronic device th at monitors and c ontrols all dev ices within

the appliance. If replacing this modul e, refer to the Mod ule Programming se ction on in this manual.

DEA601 Module

Fitted from first production to:

FDM554P.R before Serial number 91023.9999, FDM550P.R before Serial number 91231.9999).

DEA602 Module

Used in production - FDM554P.R from Seri al number 91024.0000, FDM550P.R from Serial number

00101.0000).

The pressure and door switches and associated wiring are Low voltage (12 Volts and 10mA) with

RAST 2.5 connector.

Pressure Switch

The pressure switch controls the overall volume of water inside the tub and signals if the heater can

be turned on. Different types of switch may be fitted depending on which type of Power modue is

fitted.

DEA601 Pressure Switch

Pressure Switch fitted to models with DEA601 module

(FDM554P.R before Serial number 91023.9999, FDM550P.R

before Serial number 91231.9999)

The pressure switch indicates the empty state only (full level not

reached). Full level is signalled when the pressure switch is not

signalling empty.

DEA602 Pressure Switch

Pressure switch fitted to models with DEA602 module

(FDM554P.R from Serial number 91024.0000, FDM550P.R from

Serial number 00101.0000)

The pressure switch and associated wiring is Low Voltage

(12 volts and 10 mA) with RAST 2.5 connector.

The pressure switch indicates the full stat e only (appli ance fill ed

with water).

Empty level is signalled when the pressure switch is not

signalling full.

Fill Valve

The appliance has an electromagneti cally operated solenoid valve, which is connected to the water

supply.

DEA601 Pressure Switch

DEA602 Pressure Switch

10 of 35

Service Manual UK

Indesit Company

English

Water Turbine

This is situated at the bottom of the Air Break. Consisting of a fixed reed switch and a magnet fitted

to an impeller. Unlike previous control systems, water fill is no longer dependant on the operation of

the pressure switch. The turbine generates a series of impulses as the water rotates the impeller

vanes.

The control module translates these impulses into litres of fill water (217 impulses is equal to 1 litre

of water). The turbine also regulates the maximum amount of water that can enter the tub, therefore

acting as an overflow device.

Anti Flood Device

Consisting of a polystyrene float and microswitch. An excess of water in the base panel operates the

float switch sending a signal to the control module operating the drain pump and displaying a fault

code on the console.

Filling Sequence

1. Static Fill of 2.5 litres measured by the Fill Turbine.

2. The module checks the state of the Pressure Switch

- if Pressure Switch reaches Full Position - Move to step 3.

- if Pressure Switch at Empty Position - then Pressure Switch Fault Code displays.

3. Dynamic Fill up to 4 litres measured by Fill Turbine.

4. The module checks state of the Pressure Switch.

- if Pressure Switch Full Position reached - Programme Continues to Wash.

- if Pressure Switch at Empty Position, fills with a maximum of 5.5 litres of wate r measured

by Fill Turbine.

If the Pressure Switch is still in the Empty Position, the machine will drain and continues

with the cycle. No Fault Code is displayed.

The Water Level in normal conditions is almost up to the top of the filter.

Key: Static Fill = Fill with Wash Pump Off

Dynamic Fill = Fill with Wash Pump On

Detergent & Rinse Aid Dispenser

Detergent and rinse aid is automatically released during the programme.

The release mechanism is activated by means of a solenoid. This in turn operates a plunger and

lever assembly, thus releasing detergent or rinse aid as required.

The dispenser incorporates a single solenoid.

Providing the dispenser lid is closed before use:> The 1st time solenoid is energised the detergent lid opens (powder or tablet);

> The 2nd time solenoid is energised rinse aid is dispensed.

Note:

Rinse Aid is injected into the machine when the dispenser solenoid is energised and the

detergent lid open.

Drain Pump

This is a separate unit fixed to the sump moulding. It is operated by means of a synchronous motor

and is controlled by the control module.

11 of 35

Indesit Company

Service Manual UK English

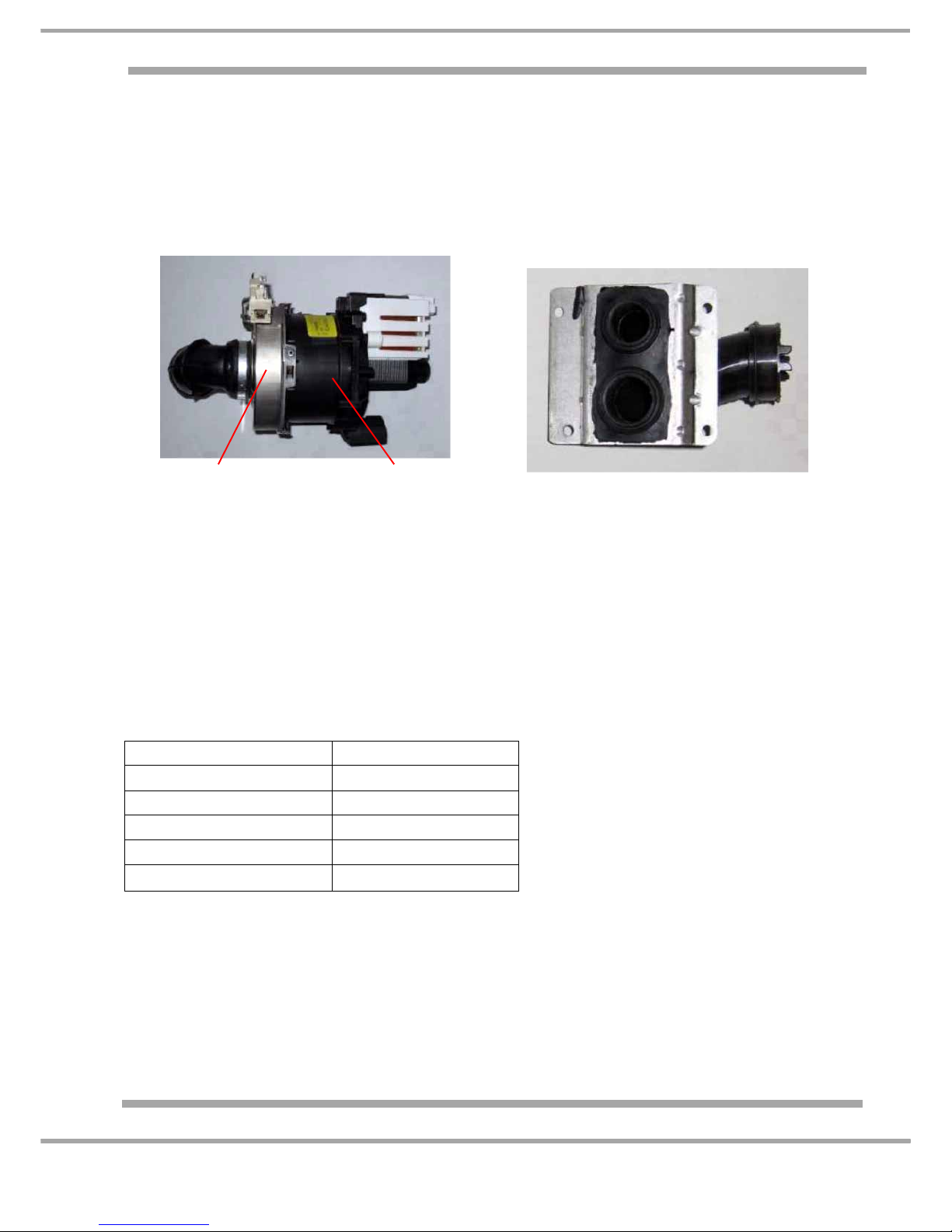

Heater

The heater is encased in a metal housing with integral safety cut-out and fuse. It connects to the

Circulating Wash pump housing via a bayonet fitting. Refer to the Circulating Wash Pump description.

Circulating Wash Pump

The motor used is a synchronous motor. The pump housing is connected to the water dispenser,

which feeds the lower and upper spray arms.

Thermistor

Situated on the sump. A temperature rise in the water is converted to a changing resistance value.

A rise in temperature will give a lower resistance across the terminals of the thermistor; the control

module monitors this value and when it is the same as that as defined in the programme selected,

the module will advance the programme out of the heating stage.

Regeneration Procedure

Unlike previous models Regeneration is not carried out during every wash. The Control Module

counts the number of Litres used since the last Regeneration.

The volume of water (in Litres) used between Regeneration is dependant upon the Water Hardness

Setting stored in the Control Module. (Refer to "Setting the Water Hardness"). See Chart below.

Regeneration Sequence

1. Regeneration valve activated, after 2 seconds, the fill inlet solenoid is opened to allow water

flow, water flows from the inlet through the salt and the mixture of water and salt reaches the

resins.

2. Solenoid valve closes (the inlet valve and after 2 seconds the regeneration valve)

3. Pause for 10 minutes

4. Fill with 190cc of water. (same procedure as step 1.)

5. 5 minutes pause

Circulation Wash Pump Assembly

Water Dispenser

Water Hardness Setting Regenerates Every...

No water is stored for Regeneration and

regeneration will always take place at

the end of last rinse, after the number of

litres has been achieved.

1 150 litres

2 100 litres

3 65 litres

4 30 litres

5 15 litres

Heater Assembly Pump Motor

Loading...

Loading...