Page 1

Instructions for Installation and Use

Electric Hood

Page 2

CE marking certifies that this appliance conforms to the

following EEC directives:-

- Low Voltage Equipment 72/23/EEC

- Electromagnetic Compatibility 89/336/EEC

Retention of this Instruction Book

This Instruction Book must be kept handy for reference as it contains important details on the safe and proper use

of the appliance.

If you sell or pass the appliance to someone else, or move house and leave it behind, make sure this Book is

also provided so the new owner can become familiar with the appliance and safety warnings.

If the Book is lost or damaged a copy may be obtained from:

Merloni Elettrodomestici UK Ltd., Morley Way , Peterborough, PE2 9JB

2

Page 3

Ø 150mm

B

E

E

P

M

Ø 150mm

87

min.

135

D

1 2

Q

L

3 4

Page 4

E

G

H

C

D

5

F

6 7

Page 5

5

2

Fig. 8

8

6

3

9

Fig. 9

4

7

1

8

4

Fig. 11

11

10 12

Fig. 10

Fig. 12

Page 6

GB

Consult the designs in the front pages referenced in the text by

alphabet letters. Closely follow the instructions set out in

this manual. All responsibility, for any eventual inconveniences,

damages or fires caused by not complying with the instructions

in this manual, is declined.

Installation

The cooker hood must be placed at a minimum distance of

50 cm from the cooking plane for electric cookers and 65cm

for gas or mixed cookers.

The hood is equipped with a top air outlet B (Fig. 2) for

discharge of fumes to the outside (Ducting version

exhaust pipe and pipe fixing clamps not provided).

Should it not be possible to discharge cooking fumes and vapour to

the outside, the hood can be used in the filter version, fitting an

activated carbon filter (in the case of the model with two suction

motors then two active carbon filters are required), a discharge tube,

for the expulsion of fumes, should be mounted on the connection ring

C (Fig. 7) situated on the top of the wall cabinet (discharge tube and

fixing brackets are not supplied).

The models with no suction motor only operate in ducting mode, and

must be connected to an external suction device (not supplied).

Preliminary information for installation of the hood:

Disconnect the hood during electrical connection, by turning the

home mains switch off.

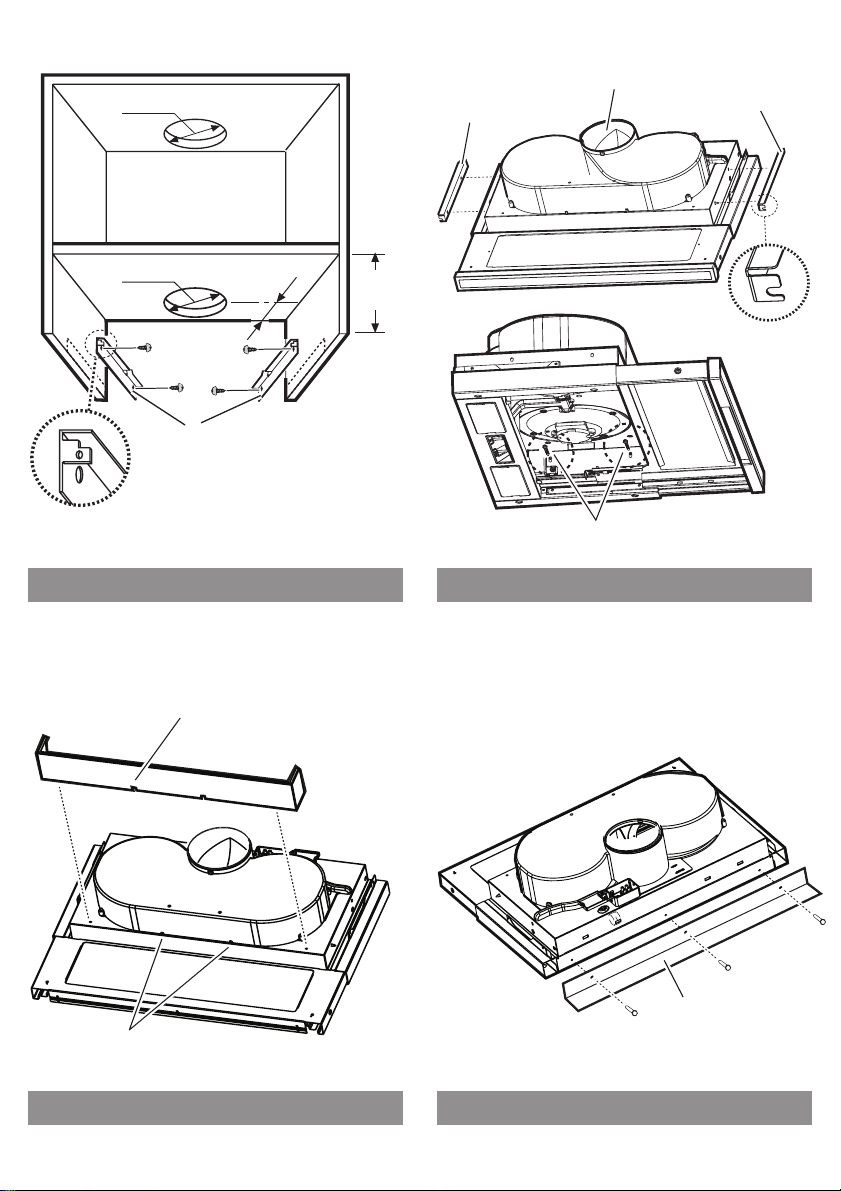

1. Fix the 2 brackets D (Fig. 1) to the side panel of the wall cabinet

2. Fix 2 brackets E (Fig. 2) to the sides of the cooker hood

3. Fix the aesthetic mask Q from the inside of the cooker

INSTRUCTION ON MOUNTING AND USE

(one per side) with 2 screws for each bracket (align the bracket

to lower border).

Position the bracket to touch the back border of the wall

cabinet, considering that the back border of the bracket

corresponds to the back side of the cooker hood;

If the cooker hood is provided with a spacer, in case of

use, move the bracket forward to the same thickness

as the spacer.

Drill a hole on the ceiling of the wall cabinet to pass the

discharge tube and the electrical cable (the quote

indicated in Fig. 1 does not include the eventual spacer).

(one per side).

a. remove the extractable part of the cooker hood;

b. Remove the grease filter(s) and, if envisaged, the

carbon filter(s).

ttention, to be carried out only the first time the carbon

filter is removed!

To avoid damage during transport, the handle of the

carbon filter is blocked with a screw.

Remove the screw before dismantling every carbon

filter; the screw is not to be reused.

c. fix the brackets with two screws P per bracket from

inside the cooker hood, affix them as more as possible

upwards (air exit side) and then serrate the screws.

hood using two screws, (if supplied - Fig. 3 the L tabs

present on the body of the cooker hood serve as further

fixing for the mask and should be visible once the mask

has been fitted) and then finally affix the spacer M with

three Clips from the external part of the cooker hood (if

supplied - Fig. 4).

4. Insert the cooker hood in the wall cabinet, ensuring to

position the cooker hood bracket E above the wall

cabinet bracket D (Fig. 5).

Thread the electric cable through the appropriate perforation.

5. Block the cooker hood with two screws on the frontal part

(Fig. 5 one per side).

6. Connect the cable to the electrical mains, only when the

installation is completed.

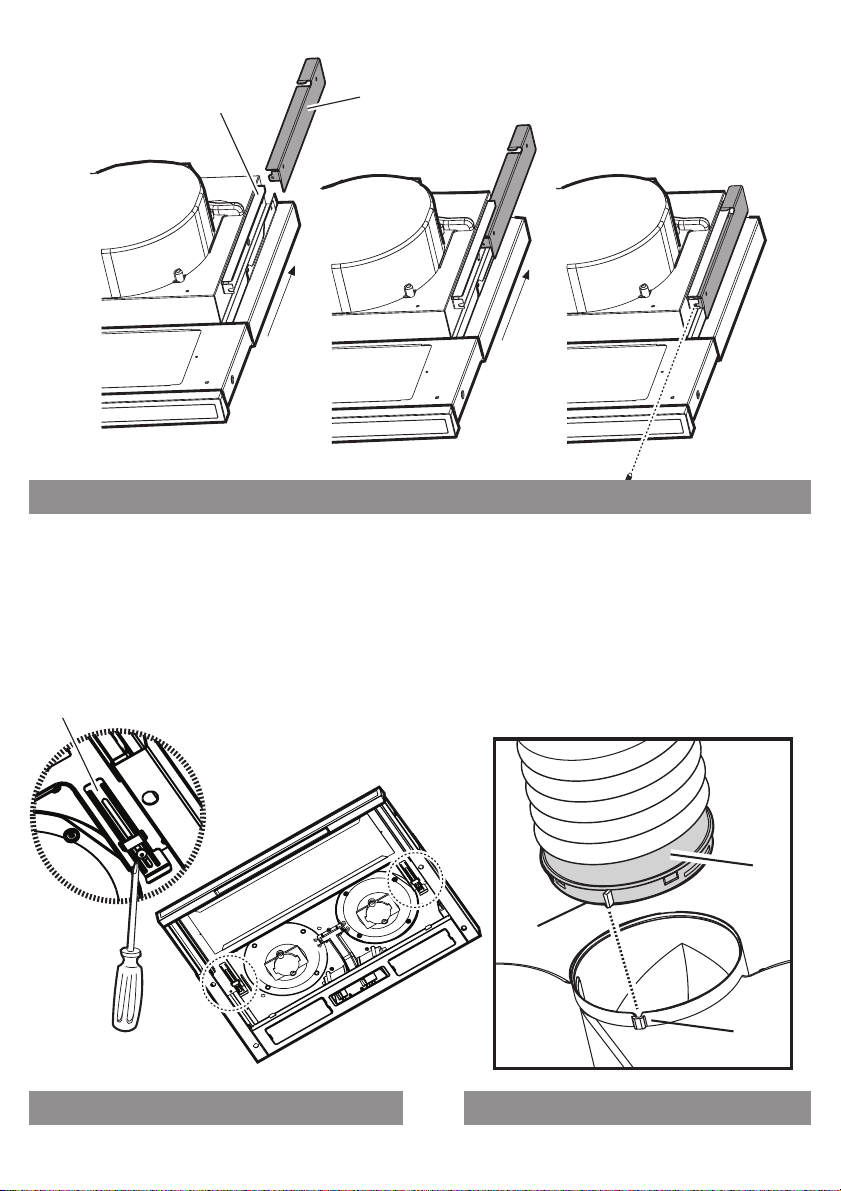

7. If the cooker hood should not touch perfectly with the

lower border of the wall cabinet then regulate by

loosening the screws P of the brackets E mounted on

the cooker hood (Fig. 2), it will be possible to regulate

the perfect matching of the cooker hood and wall cabinet,

once regulated tighten the screws.

8. Regulate the gliding of the extractable drawer in relation

to the depth of the wall cabinet by acting on the two skirting

boards F (Fig. 6).

In this way it will be possible to place the front in line with

the wall cabinet (Fig. 6).

a. Loosen the screws on the skirting board F;

b. Move the ledges backwards or forwards depending on

requirement.

c. Lock in the screws on the ledges.

9. Install a discharge tube on the connection ring C supplied,

preferably with a diameter equivalent to the connection

ring (Fig. 7). the discharge tube should be sufficiently

long to reach outside (Suction version) or the ceiling of

the wall cabinet (Filter version).

10.Fix the connection ring C (snap into place), at the upper

exit of the cooker hood.

To ease the installation, the ring is equipped with an index G that

should correspond to the appropriate guide H placed on the

upper air exit.

11.Complete the installation of the discharge tube.

12. Reinstall, if envisaged, the carbon and the grease filter(s)

and connect the hood to the power network and check

its perfect functioning.

Electrical connection

The electrical tension must correspond to the tension noted on the

label placed inside the cooker hood. Connect the electrical plug,

where provided, to the an easily accessible outlet in conformity with

local standards in force.

Where an electrical plug is not provided (for direct connection to

electrical network) place a standards approved bipolar switch with

an aperture distance of not less than 3mm (accessible) from the

contacts.

Page 7

GB

Description of the hood - Fig. 1

1 Control panel

2 Grease filter (1 or 2 depending on the model in possession)

3 Grease filter release handle

4 Lighting

5 Vapour screen (extractable), according to the model available,

6 Aesthetic mask (Available on the basis of the model in

7 Spacer (Available on the basis of the model in possession).

8 Wall cabinet (not supplied, the cabinet illustration is included to

Operation

Description of control panel and hood operation

INSTRUCTION ON MOUNTING AND USE

which may be in metal, glass or provided with grease filter.

possession).

explain the type of installation).

ab

a. on/off light switch

b. on/off aspiration switch and power selection

Use the high suction speed in cases of concentrated kitchen

vapours. It is recommended that the cooker hood suction is switched

on for 5 minutes prior to cooking and to leave in operation during

cooking and for another 15 minutes approximately after terminating

cooking.

Cleaning

The cooker hood should be cleaned regularly internally and externally.

For cleaning use a cloth moistened with denatured alcohol or neutral

liquid detergents. Avoid abrasive detergents.

Failure to carry out the basic standards of the cleaning of the cooker

hood and replacement of the filters may cause fire risks.

Cleaning the glass vapour screen (available only in some models)

The glass be dismounted and cleaned using a normal glass detergent.

Instructions for removing the glass (Fig. 12):

1. Remove the grease filter.

2. Lightly push the glass downwards and allow it slide forwards.

3. Remove the glass allowing it to rotate slightly.

After cleaning, follow the instructions in reverse to remount the glass.

Maintenance

Prior to any maintenance operation ensure that the cooker hood is

disconnected from the power supply.

Grease filter

This must be cleaned once a month using non aggressive detergents,

either by hand or in the dish-washer, which must be set to a low

temperature and a short cycle.

When washed in a dish-washer, the grease filter may discolour

slightly, but this does not affect its filtering capacity.

To remove the grease filter, pull the spring release handle (f) towards

the opposite side of the cooker hood and extract the filter - (Fig. 9).

Charcoal filter (filter version only)

It absorbs unpleasant odours caused by cooking.

Two carbon filters are required for cooker hoods with two motors and

one filter for cooker hoods with one motor.

The carbon filter should be replaced every 4 months in cases of

normal use, or more frequently for intensive use of the cooker hood.

The carbon filter may NOT be washed or regenerated.

Place the carbon filter in order to cover the protection grill for the

motor fan wheel, then turn the central handle of the filter

clockwise (Fig. 10).

To dismount the central handle of the filter turn the handle anticlockwise.

Attention, to be carried out only the first time the

carbon filter is removed!

To avoid damage during transport, the handle of the carbon

filter is blocked with a screw.

Remove the screw before dismantling every carbon filter;

the screw is not to be reused.

Replacing lamps - Fig. 4

Firstly check that the lamps are well cooled prior to replacing

them.

Access the lamp housing area:

remove the lamp holder using a small screwdriver or similar

tool as a lever.

Replace the damaged light bulb.

Use only 40W max (E14) olive shape light bulbs.

Then close the lamp housing (snap lock).

If the lights do not work, make sure that the lamps are fitted

properly into their housings before you call for technical

assistance.

Caution

This appliance is designed to be operated by adults. Children should

not be allowed to tamper with the controls or play with the appliance.

Do not use the cooker hood where the grill is not correctly fixed! The

suctioned air must not be conveyed in the same channel used for

fumes discharged by appliances powered by other than electricity.

The environment must always be adequately aerated when the

cooker hood and other appliances powered by other than electricity

are used at the same time. Flambé cooking with a cooker hood is

prohibited. The use of a free flame is damaging to the filters and may

cause fire accidents, therefore free flame cooking must be avoided.

Frying of foods must be kept under close control in order to avoid

overheated oil catching fire. Carry out fumes discharging in

accordance with the regulations in force by local laws for safety and

technical restrictions.

Page 8

Page 9

Page 10

Page 11

After Sales Service

"No company is better positioned to offer an after sales service on a

Hotpoint appliance than us - the manufacturer"

As part of our commitment to you, all Hotpoint appliances have the added benefit of a fully inclusive

parts and labour guarantee for the first 12 months. In addition to this you also have the advantage of

engineer. When the 12 months parts and labour guarantee expires we offer the following after sales

Note: Our operators will require the Model number and the Serial number of your appliance

Available 364 days a year with a fast, effective and value for money service. We have the largest

white goods repair service in the UK with over 1000 of our own fully trained engineers. All repairs

If you require any information or have any questions about your appliance, our operators are on hand

Whether you have just one or a number of Hotpoint appliances in your kitchen, we offer two service

●

Repair Protection Plan - FREE service repairs for a single Hotpoint appliance during the

●

Kitchen Cover - FREE service repairs for all your Hotpoint appliances less than

free replacement parts for the first 5 years when fitted by a Hotpoint

service options:

Repair Service and Information Help Desk

UK: 08709 066066

www.hotpointservice.co.uk

Republic of Ireland: 1850 302 200

include a parts and labour guarantee for 12 months from the date of the repair.

with help and advice.

All this ensures that you will receive the best available after sales service possible.

Extended Warranties

UK: 08709 088 088

www.hotpointservice.co.uk

Republic of Ireland: 1850 502 200

cover plans to give you total peace of mind.

period of cover.

8 years old.

Genuine Parts and Accessories

UK: 08709 077 077

www.hotpointservice.co.uk

A wide range of genuine parts and accessories are available from our hotline or through our website.

Genuine parts and accessories, extended warranties and service repairs are all

Republic of Ireland: (01) 842 6836

available on our web-site at:

GB91 0

Page 12

Key Contacts

After Sales Service

Over 1200 trained specialists, directly employed by us, ensure that you can have complete

confidence in both the appliances and services we offer.

Repair Service and Information Desk

(Open 8 to 8 Mon - Fri, 8 to 6 Sat, 10 to 4 Sun & Bank Holidays)

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

(Open 8-30 to 5-30 Mon - Fri & 9 to 12 Sat)

RepublicofIreland:(01)8426836

UK: 08709 066 066

www.hotpointservice.co.uk

Model number:

Serial number:

Extended Warranties

UK: 08709 088 088

(Open 8 to 8 Mon - Sun)

www.hotpointservice.co.uk

UK: 08709 077 077

www.hotpointservice.co.uk

Indesit Company, Morley Way , Peterborough, PE2 9JB

LI2JEA Ed. 01/05

Loading...

Loading...