Page 1

kitchen think

Instructions for Installation and Use

Model EG600P

T o the Installer

Before installation fill in the product details on the back cover this book.

The information can be found on the rating plate.

T o the User

You must read the instructions prior to installing and using the appliance and

then retain them for future reference.

Page 2

Safety precautions

T o maintain the efficiency and safety of this appliance, we recommend that you do the follo wing:

• only call the Service Centres authorised by the manufacturer

• always use original spare parts

1 This appliance is intended for non-professional use

within the home.

2 These instructions are only for those countries whose

symbols appear in the booklet and on the matriculation

plate of the appliance.

3 This owner’ s manual is f or a class 1 appliance (in-

stalled independently) or class 2 - sub-class 1 appliances (installed between two cabinets).

4 Before using your appliance, read the instructions in

this owner’ s manual carefully since you will find all the

instructions you require to ensure safe installation, use

and maintenance. Always keep this owner’ s manual close

to hand since you may need to refer to it in the future.

5 When you have removed the packing, check that the

appliance is not damaged. If in doubt, do not use the

appliance and contact professionally qualified personnel. Never leave the packing components (plastic bags,

foamed polystyrene, nails, etc.) within the reach of

children since they are a source of potential danger .

6 The appliance must be installed only by a qualified

person in compliance with the instructions provided.

The manufacturer declines all responsibility for improper

installation which may harm persons and animals and

damage property.

7 The electrical safety of this appliance can only be guar-

anteed if the cooker is correctly and efficiently earthed,

in compliance with regulations on electrical safety. Always ensure that the earthing is efficient; if you have

any doubts call in a qualified technician to check the

system. The manufacturer denies all responsibility for

damage resulting from a system which has not been

earthed.

8 Before plugging the appliance into the mains, check

that the specifications indicated on the date plate (on

the appliance and/or packaging) correspond to those

of the electrical and gas mains of your home.

9 Check that the electrical capacity of the system and

sockets will support the maximum power of the appliance, as indicated on the data plate. If in doubt, consult a professionally qualified technician.

10 An omnipolar switch with a contact opening of at least

3 mm or more, is required for the installation.

11 If the socket and appliance plug are not compatible,

have the socket replaced with a suitable model by a

qualified technician. The latter, in particular, will also

have to ensure that the cross section of the socket

cables are suitable for the power absorbed by the appliance. The use of adapters, multiple sockets and/or

extensions, is not recommended. If their use cannot

be avoided, remember to use only single or multiple

adapters and extensions which comply with current

safety regulations. In these cases, never exceed the

maximum current capacity indicated on the single

adapter or extension and the maximum power indicated

on the multiple adapter.

12 Do not leave the appliance plugged in if it is not in use.

Switch off the main switch and gas supply when you

are not using the cooker .

13 The openings and slots used for ventilation and disper-

sion of heat on the rear and below the control panel

must never be covered.

14 The user must not replace the supply cable of this ap-

pliance. Always call an after-sales servicing centre

authorised by the manufacturer in the case of cable

damage or replacement.

15 This appliance must be used for the purpose for which

it was expressly designed. Any other use (for example:

heating rooms) is considered to be improper and consequently dangerous. The manufacturer declines all

responsibility for damage resulting from improper and

irresponsible use.

16 A number of fundamental rules must be followed when

using electrical appliances. The following are of particular importance:

• do not touch the appliance when your hands or feet are

wet

• do not use the appliance barefooted

• do not use extensions, but if these are necessary caution must be exercised.

• never pull the power supply cable or the appliance to

unplug the appliance plug from the mains.

• never leave the appliance exposed to atmospheric

agents (rain, sun etc.)

• do not allow children or persons who are not familiar

with the appliance to use it, without supervision.

17 Always unplug the hob from the mains or switch off the

main switch before cleaning or carrying out maintenance

operations.

18 If you are no longer using an appliance of this type,

remember to make it unserviceable by unplugging the

appliance from the mains and cutting the supply cable.

Also make all potentially dangerous parts of the appliance, safe, above all for children who could play with

the appliance.

19 T o a void accidental spillage do not use cookw are with

uneven or def ormed bottoms on the burners. Turn the

handles of pots and pans inwards to avoid knocking

them over accidentally.

20 Some parts of the appliance remain heated for a long

time after use. Make sure not to touch them.

21 Never use flammable liquids such as alcohol or gaso-

line, etc. near the appliance when it is in use.

22 When using small electric appliances near the hob, keep

the power supply cable aw a y from the hot parts.

23 Make sure the knobs are in the “•”/”¡” position when the

appliance is not in use.

24 When the appliance is in use, the heating elements

and some parts of the oven door become extremely

hot. Make sure you don’t touch them and keep children

well away.

2 5 Gas appliances require regular air exchange to en-

sure trouble-free performance. When installing the

cooker, follow the instructions pr ovided in the paragraph on “ Positioning” the appliance.

26 Some of the models have a glass hob cover . This could

crack if overheated so make sure all the burners or

electric hot plates are off before closing it.

27 If the cooker is placed on a pedestal, take the neces-

sary precautions to prevent the same from sliding off

the pedestal itself.

2

Page 3

Instructions for installation

The following instructions should be read by a qualified

technician to ensure that the appliance is installed, regulated and technically serviced correctly in compliance with

current regulations.

Important: remember to unplug the appliance from the

mains before regulating the appliance or carrying out

any maintenance work.

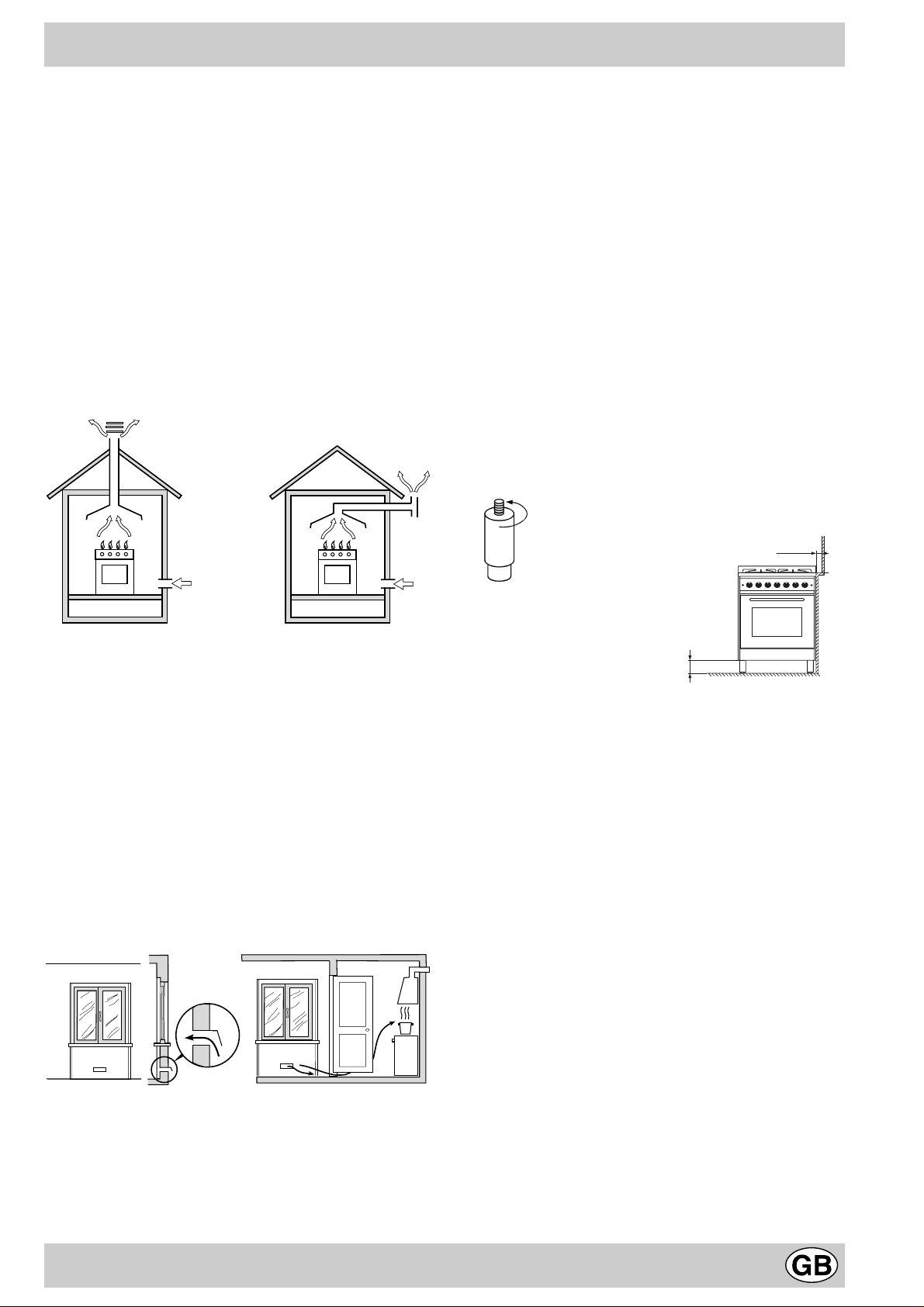

Positioning

Important: this appliance may be installed and used only

in permanently ventilated rooms in compliance with current Norms in force. The following requirements must be

observed.

a) The room must be equipped with an exhaust system

that vents the combustion fumes to the outside. It may

consist of a hood or an electric fan that automatically

starts each time the appliance is turned on.

c) Intensive and prolonged use of the appliance may re-

sult in the need for supplemental air circulation, e.g.

opening windows or increasing mechanical venting (if

present).

d) Liquid petroleum gas descends towards the floor as it

is heavier than air . Thus, rooms containing LPG cylinders must also be equipped with apertures to the outside for ventilation of gas in the event of leaks. LPG

cylinders must not, therefore, be installed or stored in

rooms or storage areas that are below ground level (cellars, etc.) whether they are partially or completely full.

It is a good idea to keep only the cylinder being used in

the room, positioned so that it is not subject to heat

produced by external sources (ovens, fireplaces, stoves,

etc. ) which could raise the temperature of the cylinder

to above 50°C.

Prior to installing the cooker, 95 ÷ 155 mm high supporting feet (provided) should be fitted into the holes to be

found in the bottom of the cooker (fig.F). These feet are

screw-adjustable and whenever necessary should be used

to make sure the cooker stands level.

min. 100mm

In a chimney stack or branched flue

(exclusively for cooking appliances)

b)

The room must also have a system to permit proper air circula-

Directly to the outside

tion, needed for combustion to occur normally . The flow of air

needed for combustion must not be less than 3 m3/h per kW of

installed power . The air circulation system may take air directly

from the outside by means of a pipe with an inner cross section of

at least 100 cm2; the opening must not be able to be accidentally

blocked. For those appliances not equipped with a safety device

for accidental flame loss, the ventilation apertures must be increased by 100%, with the minimum being 200cm2 (Fig. A). The

system can also provide the air needed for combustion by indirect means, i.e. from adjacent rooms fitted with air circulation

tubes as described above. Howev er, these rooms must not be

common rooms or bedrooms.

Detail A Room

A

Examples of ventilation holes

for comburant air

Fig. A

adjacent

Enlarging the ventilation slot

window and floor

Room to be

ventilated

between

Fig. B

fig.F

fig.E

95÷155mm

Installation of the cooker

The appliance can be installed next to furniture units which

are no taller than the top of the cooker hob. The wall in

direct contact with the back panel of the cooker must be

made of non-flammable materials. During operation the

back panel of the cooker could reach a temperature of

50°C above room temperature. For proper installation of

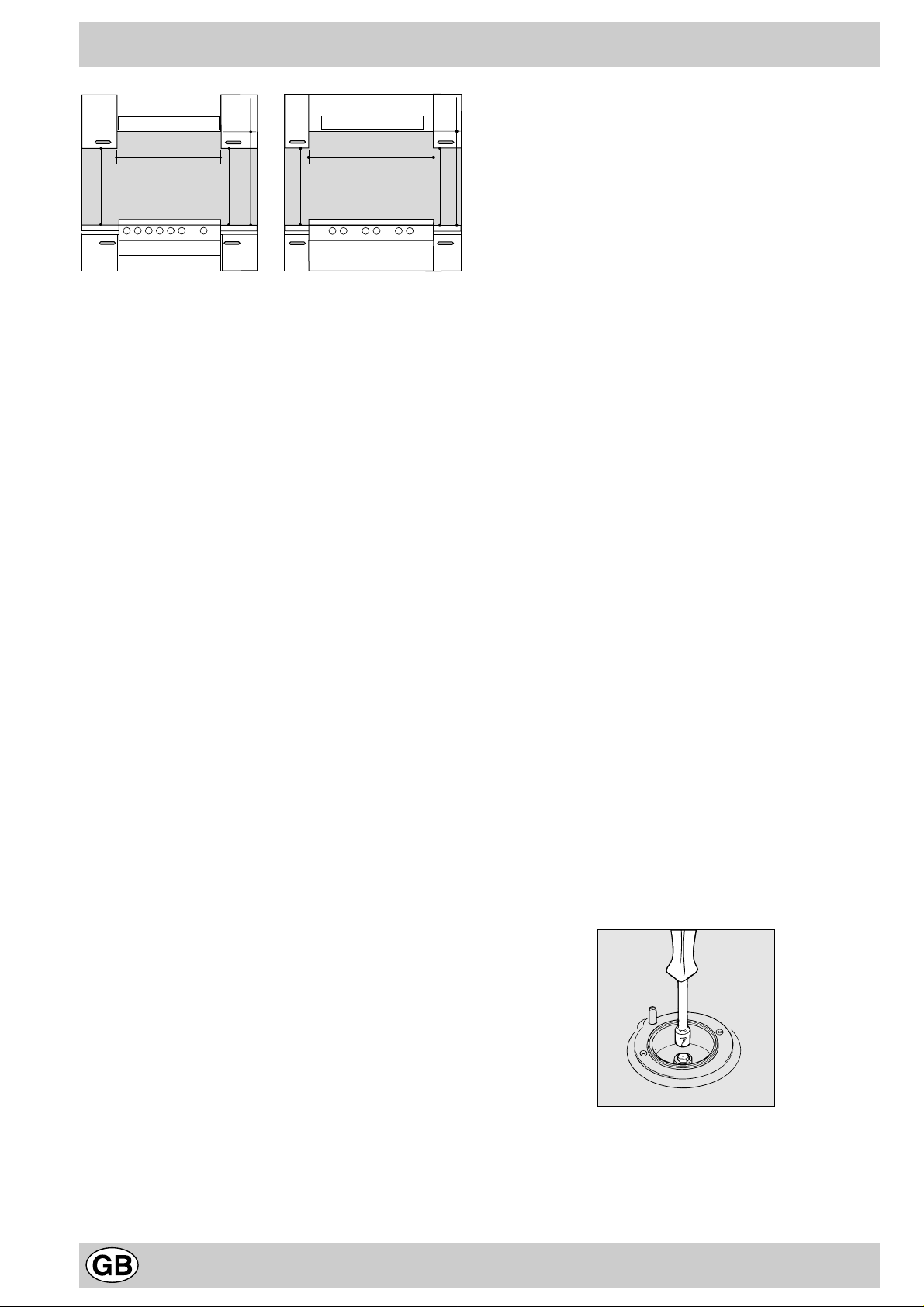

the cooker , the f ollowing precautions must be taken:

For trouble-free operation of appliances installed in housing units, the minimum distances shown in fig.E should

be observed. Adjacent surfaces and the wall at the rear

should also be able to withstand an overheating temperature of 65°C

a) The appliance can be placed in a kitchen, dining room

or bedsit, but not in a bathroom.

b) Any hoods must be installed according to the require-

ments in the installation manual for the hoods them-

selves.

c) If the cooker is installed beneath a wall cabinet, the

latter must be situated at a minimum of 420 mm above

the hob. The minimum distance between the worktop

and kitchen units made of combustible material is 700

mm (Fig. C and D).

d) The wall in direct contact with the back panel of the

cooker must be made of non-flammable materials.

3

Page 4

Instructions for installation

HOOD

Min. mm.

600

mm.

420

Min.

420

Min. mm.

mm. with hood

650

min.

mm. without hood

700

min.

mm.

420

Min.

Fig. C Fig. D

Gas connecting

The appliance should be connected to the gas mains or to

a gas cylinder in compliance with current Norms in force.

Before making the connection, check that the cooker is

regulated for the gas supply you are using. If not, follow

the instructions indicated in the paragraph “Adapting to

different types of gas.” On some models the gas supply

can be connected on the left or on the right, as necessary;

to change the connection, reverse the position of the hose

holder with that of the cap and replace the gasket (supplied with the appliance). When using liquid gas from a

cylinder, install a pressure regulator which complies with

current Norms in force.

Important: Check that the supply pressure complies with

the values indicated in table 1 “Burner and Nozzle Characteristics” since this will ensure safe operation, correct consumption and ensure a longer life to your appliance.

Connection with hose

Make the connection using a gas hose that complies with

requirements set forth by the current standards. The inner

diameters of the pipe are as follows:

- 8 mm for liquid gas;

-13mm for methane gas;

When installing the hose, remember to take the following

precautions:

• No part of the hose should touch parts whose tem-

perature exceeds 50°C;

• The length of the hose should be less than 1500 mm;

• The hose should not be subject to twisting or pulling,

and should not have bends or kinks.

• The hose should not touch objects with sharp edges,

moving parts, and it should not be crushed;

• The full length of the hose should be easy to inspect in

order to check its condition;

Check that the hose fits firmly into place at the two ends

and fix it with clamps complying with current standards. If

any of the above recommendations can not be followed,

flexible metal pipes should be used.

If the cooker is installed according to the conditions of

Class 2, subdivision 1, only a flexible metal pipe which is

in compliance with current safety standards should be used

to make the connection to the gas mains.

HOOD

Min. mm.

900

mm. with hood

420

650

Min. mm.

min.

Checking that the connection is tight

Important: When installation has been completed, check

the pipe fittings for leaks using a soapy solution. Never

use a flame.

Once the connection has been made, ensure that the flex-

mm. without hood

ible metal pipe does not touch any moving parts and is

700

not crushed.

min.

Connecting the supply cable to the mains

Install a standardised plug corresponding to the load indicated on the data plate. When connecting the cable directly to the mains, install an omnipolar circuit-breaker with

a minimum contact opening of 3 mm between the appliance and the mains. The omnipolar circuit break er should

be sized according to the load and should comply with

current regulations (the earth wire should not be interrupted

by the circuit breaker). The supply cable must be in such a

position that no part of it can reach a temperature of 50°C

above room temperature. Before connecting to the power

supply, make sure that:

• the limiter valve and the domestic system can withstand the load from the appliance (see rating plate);

• the mains are properly earthed in compliance with current directives and regulations;

• there is easy access to the socket and omnipolar circuit breaker, once the hob has been installed.

N.B.:never use reducers, adapters or shunts since they

can cause heating or burning.

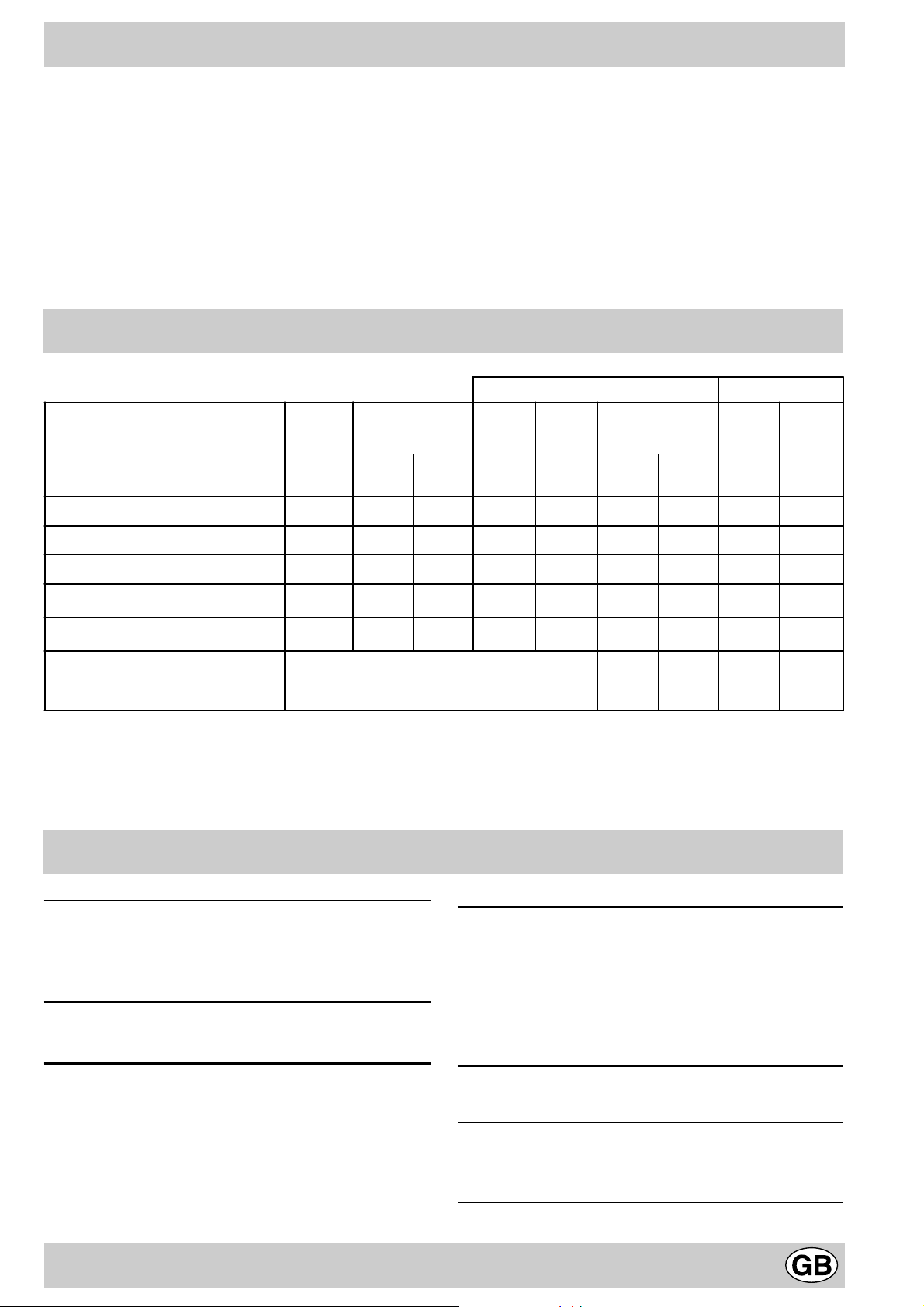

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of gas with

respect to the gas for which it was manufactured (indicated on the label attached to the back of the appliance

and to the packaging), follow these steps:

a) replace the hose holder mounted on the appliance with

that supplied in the bag of “cooker accessories”.

Warning: The hose holder f or liquid gas is marked 8, the

hose holder for methane gas is marked 13. Always fit a

new sealing gasket.

b) Replacing the burner nozzles on the hob:

• remove the grids and slide the burners from their

housings;

• unscrew the nozzles using a 7 mm socket spanner,

and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

Connecting a flexible jointless stainless steel pipe to

a threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas cylindrical

male attachment. Only use pipes and gaskets complying

with current standards. The full length of the pipe m ust not

exceed 2000 mm.

• Replace all the parts, following the steps described

above in the re verse order .

c) Minimum regulation of the hob burners:

•

turn the tap to minimum;

4

Page 5

Instructions for installation

• remove the knob and adjust the regulation screw , which

is positioned in or next to the tap pin, until the flame is

small but steady.

N.B.: In the case of liquid gas, the regulation screw

must be screwed in all the way.

• check that the flame does not go out when you turn the

tap quickly from high to low.

d) Regulating the primary air of the burners:

The primary air of the burners does not need to be regulated.

Warning

On completion of this operation, replace the old rating

sticker with one indicating the new type of gas used, which

can be found in the nozzle kit provided.

Note

Should the pressure of the gas used be different (or vary)

from the recommended pressure, it is necessary to fit a

suitable pressure regulator onto the inlet pipe in compliance with current National Regulations relative to “regulators for channelled gas”.

Burner and Nozzle specifications

Table 1 Liquid gas Natural ga s

BURNER

C.Rapid

B. Semi-rapid

Diameter

(mm)

100 3.00 0.7 40 86 218 214 116 286

75 1.90 0.4 30 70 138 136 106 181

Thermal p ower

kW (H.s.*)

Nomin. Reduc. G30 G31 G20

By-pass

1/100

(mm)

Injector

1/100

(mm)

Flow *

g/h

Injector

1/100

(mm)

Flow*

l/h

A. Auxiliary

D. Triple Ring (L iqui d Gas)

D. Triple Ring (Natural gas)

Supply pressure

* At 15°C and 1013 mbar-dry gas

Propane P.C.S. = 50.37 MJ/Kg

Butane P.C.S. = 49.47 MJ/Kg

Natural P.C.S. = 37.78 MJ/m3

Inner dimensions of the oven:

Inner Volume of the Oven:

551.000.4 30 50737179 95

130 3.25 1.5 63 91 236 232

130 3.40 1.5 133 324

Nominal

Minimu m

Maximu m

28-30

20

35

37

25

45

Technical Specifications

ENERGY LABEL

Width 43,5 cm

Depth 40 cm

Height 32 cm

56 litres

Directive 2002/40/EC on the label of electric ovens

Norm EN 50304

Energy consumption for Natural convection

heating mode: a Convection

Declared energy consumption for Forced convection Class

heating mode: u Baking

20

17

25

Inner Dimensions of the Food W armer:

Width 46 cm

Depth 42 cm

Height 8,5 cm

V oltage and Frequency of P ower Supply:

see data plate

Burners:

adaptable for use with all the types of gas indicated on

the data plate.

5

Page 6

Technical Specifications

Disposal of old electrical appliances

The European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment (WEEE), requires that old

household electrical appliances must not be disposed of

in the normal unsorted municipal waste stream. Old

appliances must be collected separately in order to optimise

the recovery and recycling of the materials they contain

and reduce the impact on human health and the

environment. The crossed out “wheeled bin” symbol on the

product reminds you of your obligation, that when you

dispose of the appliance it must be separately collected.

Consumers may take their old appliance to public waste

collection areas, other communal collection areas, or if

national legislation allows return it to a retailer when

purchasing a similar new product.

All major household appliance manufacturers are active in

the creation of systems to manage the collection and

disposal of old appliances.

This appliance conforms with the following European

Community directives:

- 73/23/EEC of 19/02/73 (Low V oltage) and subsequent

amendments;

- 89/336/EEC of 03/05/89 (Electromagnetic Compatibility) and subsequent amendments;

- 90/396/EEC of 29/06/90 and subsequent amendments;

- 93/68/EEC of 22/07/93 and subsequent amendments.

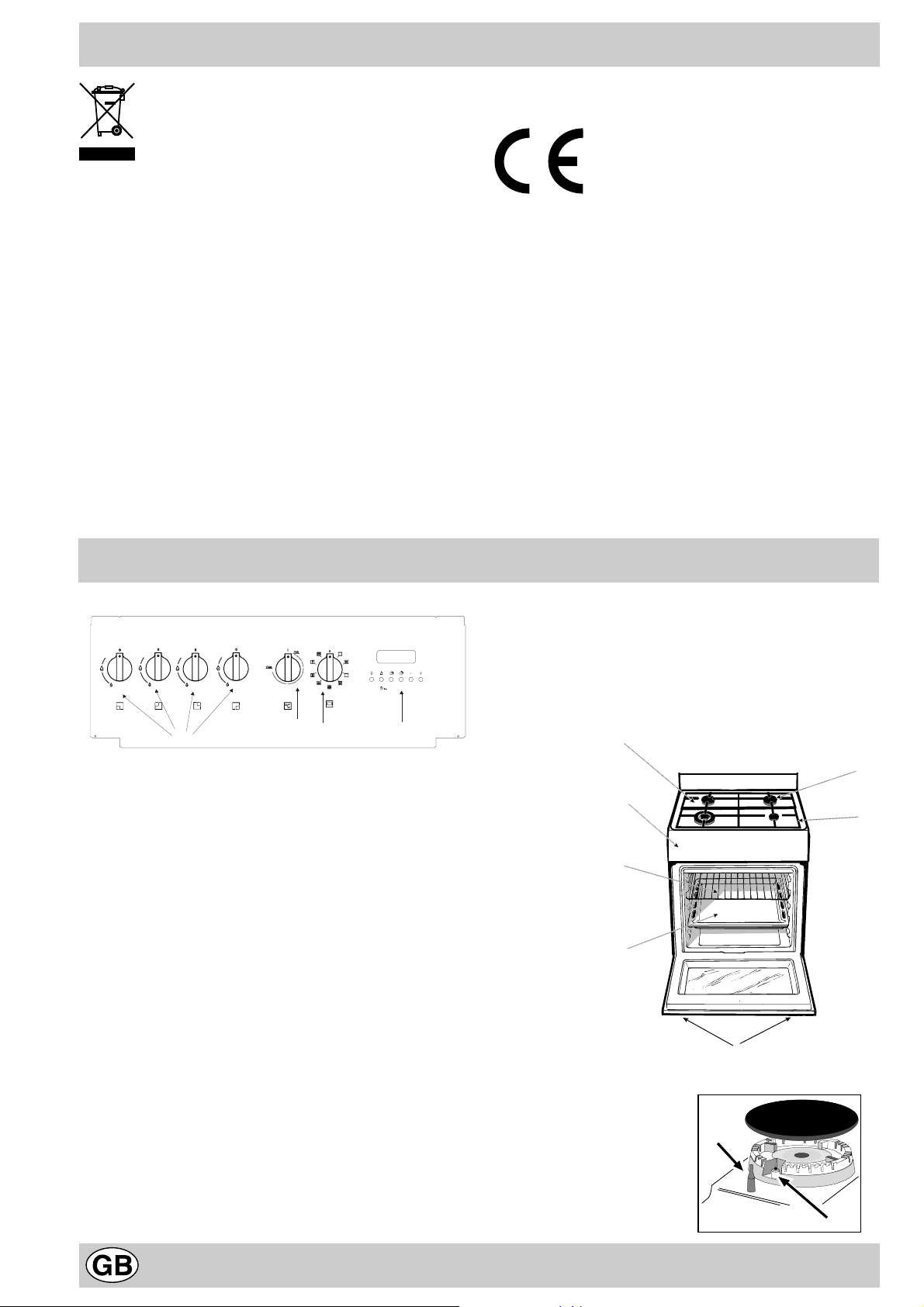

The cooker with Pirò oven

M

N

A Hob surface

B Gas Burner

C Electronic Lighting Device

D T op Grate

E Control panel

F Adjustable Feet or Legs

G Dripping Pan or Baking Sheet

H Flame Failure Device f or Cooktop Burners

K Oven Rack

L Cooking mode selection knob

M Cooking temperature selection knob

N Control Knobs for Gas Burners on Hob

O Electronic programmer - Allows you to programme

the desired cooking mode by selecting the cooking

time and the end cooking time. It can also be used

as a timer.

L

O

A

B

E

D

K

G

F

H

C

6

Page 7

8

7

1

2 3 4 5 6

The cooker with Pirò oven

1 Oven Light

2 Timer/clock adjustment

3 End cooking time

10

A

9

4 Cooking time

5 Decrease minutes

6 Increase minutes

7 Timer indicator enabled

8 Pre-heating (m flashing) or cooking (m on) under way

indicator

9 Duration/ end cooking time programme indicator

10 Door lock indicator

Instructions for use

The various features of cooker are controlled through the knobs

and buttons located on the control panel.

HOB

Control Knobs for the Gas Burners on the Hob (N)

The position of the gas burner controlled by each one of the

knobs is shown by a solid ring •. T o light one of the burners, hold

a lighted match or lighter near the burner and, at the same time,

press down and turn the corresponding knob counter clockwise

to the maximum setting . Each burner can be operated at its

maximum, minimum or intermediate power . Shown on the knob

are the different symbols for off • (the knob is on this setting

when the symbol corresponds with the reference mark on the

control panel), for maximum and minimum .

To obtain these settings, turn the knob counter clockwise with

respect to the off position. T o turn off the burner , turn the knob

clockwise until it stops (corresponding again with the • symbol).

Electronic Ignition for the Gas Cooktop

To light a specific burner push the corresponding knob all the

way in and turn it counter-clockwise to maximum keeping it

pressed down until the burner lights.

Warning: Should the burner flames accidentally go out, turn

off the control knob and wait at least 1 minute before trying

to re-light.

Models with Flame Failure Device

These models are identified by the presence of a flame detection device (see detail H).

Important: since the top burners are equipped with a safety

device, after lighting the burner keep the knob pressed in for

about 3 seconds to allow the gas to pass until the safety ther-

mocouple is heated.

Practical advice on using the burners

For the best performance of your burners, keep the following in

mind:

• use the appropriate cookware for each burner (see table) so

that the flames do not extend beyond the bottom of the

cookware;

• only flat bottom cookware should be used;

• at the boiling point, turn the knob to minimum;

• always use a lid with the cookware.

Burner ø Cookware Diameter (cm)

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

Triple Crown (TC) 24 - 26

N.B. On the models supplied with a reducer shelf, remember

that this should be used only for the auxiliary burner when you

use casserole dishes with a diameter under 12 cm.

OVEN:

The

7 Cuochi

convection ovens with those of the more modern fan assisted models in a single appliance.

It is an extremely versatile appliance that allows you to choose

easily and safely between 7 different cooking modes. The

various features offered by the oven are selected by means

of selector knob “L” situated on the control panel.

Warning: The first time you use your appliance, we recommend that you set the thermostat to the highest setting and

leave the oven on for about half an hour with nothing in it,

with the oven door shut. Then, open the o ven door and let the

room air. The odour that is often detected during this initial

use is due to the evaporation of substances used to protect

the oven during storage and until it is installed.

“Demo Mode” disabled

If the message “DEMO ON” appears on the display, place

the knob “L” in the 0 position and then press keys “1” to “6”

in sequence to bring the kitchen back into operating mode.

Setting the digital clock

The time can only be set on the clock when knob “L” is in

position 0.

After connecting to the electricity mains or after a power failure, update the time by holding down k e y “2” until the time

appears on the display again and then adjust using the keys

and/or t.

s

oven combines the advantages of traditional

7

Page 8

Instructions for use

Timer Feature

Please remember that the timer does not control the starting

or stopping of the oven, it merely sounds a buzzer when the

time is up and can be interrupted at any time just by pressing

a button.

To set the timer, press key “2” a nd adjust using key s

and/or t. The n icon will remind you the timer is on.

Once the countdown is over , a buzzer will sound, and will stop

doing so after 1 minute or if you press any b utton whatsoever .

N.B.: When the display is on “end”, the timer may not be

set.

The oven light

It can be turned on/off at any time with the oven turned

off, simply by pressing b utton “1” or by opening the door .

It always remains on during cooking.

Cooling ventilation

In order to reduce the temperature of the exterior of the

oven, some models are fitted with a cooling fan that generates a flow of air that can be heard exiting between the

oven door and the control panel.

Note: When cooking is done, the fan stays on until the

oven cools down sufficiently.

Note: In “F ast cooking” and in “Baking” mode , the fan comes

on automatically only when the oven is hot.

Warning: the appliance is fitted with a diagnosis system which

detects any malfunctions. The user is informed of the latter

by messages such as “Er xy” (xy=numerical code between 01 and 99). In these cases, you need to call for

technical assistance as the oven is faulty.

How T o Use Y our Oven

Note: When the oven door is locked (for example, right

after a F AST CLEAN programme has been completed), it

is not possible to start cooking due to the high temperature inside the oven. The display will indicate this status

by means of the word “HOT”. You will only be able to cook

again once the “key” symbol has gone off.

Turn knob “L ” to select the desired cooking mode.

The oven will immediately start the pre-heating phase,

during which the icon m will flash on the display , and the

cooking temperature associated with the mode selected

will be displayed: should this value not be the one you

desire, you can modify it simply by turning knob “M”.

Once pre-heating is complete, three consecutive beeps will

sound and the icon m will come on permanently. Now you

can place the food to be cooked inside the pre-heated oven.

Note: the F AST COOKING and GRILL modes do not include

a pre-heating phase.

Please remember that you can always do the following when

cooking is under way:

• change the cooking mode b y t urning knob “L”;

• change the temperature by turning knob “M”;

• programme the cooking time and end cooking time (see

paragraph entitled “Programming the cooking mode”).

• stop it at any time by setting knob “L” bac k to 0.

• to set the timer

Warning: Place the dripping pan provided on the bottom shelf

of the oven to prevent any sauce and/or grease from dripping

s

onto the bottom of the oven only when grilling food or when

using the rotisserie (only available on certain models). F or all

other types of cooking, never use the bottom rack and never

place anything on the bottom of the oven when it is in operation because this could damage the enamel coating. Always

place your cookware (dishes, aluminium foil, etc. etc.) on the

grid provided with the appliance inserted especially along the

oven guides.

Convection Mode

Position of thermostat knob “M”: Between 40°C and 250°C.

On this setting, the top and bottom heating elements come

on. This is the classic, traditional type of oven which has

been perfected, with exceptional heat distribution and reduced energy consumption. The convection oven is still

unequalled when it comes to cooking dishes made up of

several ingredients, e.g. cabbage with ribs, local stockfish

recipes, tender veal with rice, etc... Excellent results are

achieved when preparing beef- or veal-based dishes as

well: braised meats, stew, goulash, wild game, ham etc.,

which need to cook slowly and require basting or the addition of liquid. It nonetheless remains the best system for

cooking pastries as well as fruit and cooking casseroles

in the oven. When cooking in convection mode, use only

one rack, as the temperature would not be distributed evenly

on several racks. Using the different rack heights available, you can balance the amount of heat between the top

and the bottom of the oven. Select from among the various rack heights based on whether the dish needs more

or less heat from the top.

Multi-Cooking Mode b

Position of thermostat knob “M”: Between 40°C and 250°C.

The heating elements and the fan come on alternately . Since

the heat remains constant and uniform throughout the oven,

the air cooks and browns food uniformly over its entire surface. With this mode, you can also cook various dishes at

the same time, as long as their respective cooking temperatures are the same. A maximum of 2 racks can be used at

the same time, following the instructions in the section entitled: “Cooking On More Than One Rack”.

This cooking mode is particularly recommended for

dishes requiring a gratin finish or for those requiring

considerably prolonged cooking times, such as for

example: lasagne, pasta bakes, roast chicken and

potatoes, etc… Moreo ver, the excellent heat distribution

makes it possible to use lower temperatures when

cooking roasts. This results in less loss of juices, meat

which is more tender and a decrease in the loss of

weight of the roast. The Multi-cooking mode is especiall y

suited for cooking fish, which can be prepared with the

addition of a limited amount of condiments, thus

maintaining their flavour and appearance. Excellent

results can be attained when cooking vegetable-based

side dishes like courgettes, aubergines, peppers, etc.

Desserts: this mode is also perfect for baking leavened

cakes.

Moreover , this mode can also be used to thaw quickly white

or red meat and bread by setting the temperature to 80 °C. T o

thaw more delicate foods, set the thermostat to 60°C or use

only the cold air circulation feature by setting the thermostat

to 0°C.

8

Page 9

Instructions for use

Grill d

Position of thermostat knob “M”: 50%, 75%, 100%.

The top heating element and the turnspit (where present) come

on.

The extremely high and direct temperature of the grill makes

it possible to brown the surface of meats and roasts while

locking in the juices to keep them tender. The grill is also

highly recommended for dishes that require a high temperature

on the surface: such as beef steaks, veal, rib steak, filets,

hamburgers etc...

Always cook in this mode with the oven door closed

Some grilling examples are included in the “Practical Cooking Advice” paragraph.

Note: turn knob “M” and the display will indicate the 3 different energy percentages which represent the minimum

(50%), medium (75%) and maximum setting (100%) respectively.

Gratin e

Position of thermostat knob “M”: Between 40°C and 250°C.

The top heating element, the fan and the turnspit (where

present) come on.

This combination of features increases the effectiveness of

the unidirectional thermal radiation of the heating elements

through forced circulation of the air throughout the ov en. This

helps prevent food from burning on the surface, allowing the

heat to penetrate right into the food. Excellent results are

achieved with kebabs made with meats and vegetables, sausages, ribs, lamb chops, chicken in a spicy sauce, quail,

pork chops, etc.

All “gratin” cooking must be done with the oven door shut.,

by setting the maximum temperature to 200°C

The “gratin” mode is ideal for cooking grouper steaks, tuna,

swordfish, stuffed cuttlefish etc.

“Fast cooking” Mode v

Position of thermostat knob “ M”: Between 40°C and 250°C.

The heating elements and the fan come on, guaranteeing

constant heat distributed uniformly throughout the oven.

This mode is especially recommended for cooking pre-packed

food quickly (as pre-heating is not necessary), such as for

example: frozen or pre-cooked food) as well as for a few

“home-made” dishes.

The best results when cooking using the “F ast cooking” mode

are obtained if you use one cooking rack only (the second

from the bottom), please see the table entitled “Practical

Cooking Advice”.

“Defrosting” Mode U

Position of thermostat knob “M”: any

The fan located on the bottom of the oven makes the air

circulate at room temperature around the food. This is recommended for the defrosting of all types of food, but in

particular for delicate types of food which do not require

heat, such as for example: ice cream cakes, cream desserts, fruit sweets. By using the fan, the defrosting time is

approximately halved. In the case of meat, fish and bread,

it is possible to accelerate the process using the “multicooking” mode and setting the temperature to 80° - 100°C.

Automatic cleaning with the fast clean function

This function is designed to clean your oven thoroughly.

For details on the fast clean function, please refer to the

paragraph entitled “Automatic cleaning with the fast clean

function”.

V

Restoring after a blackout

Pizza Mode w

Position of thermostat knob “ M”: Between 40°C and 250°C.

The bottom and circular heating elements, as well as the fan,

will come on. This combination rapidly heats the ov en due to

the large amounts of power used by the appliance (2800 W),

which results in the production of considerable heat coming

prevalently from the bottom.

The pizza mode is ideal for foods requiring high temperatures to cook, like pizzas and large roasts. pizzas and large

roasts. Only use one dripping pan or rack at a time. Howe ver,

if more than one is used, these must be switched halfway

through the cooking process.

Baking Mode u

Position of thermostat knob “ M”: Between 40°C and 250°C.

The rear heating element and the fan come on, guaranteeing

delicate heat distributed uniformly throughout the oven.

This mode is ideal for baking and cooking delicate foods especially cakes that need to rise - and for the preparation of

certain tartlets on 3 shelves at the same time. Here are a few

examples: cream puffs, sweet and savoury biscuits, savoury

puffs, Swiss rolls and small portions of vegetables au gratin,

etc…..

If the temperature inside the oven has not dropped below

a value that is too low , the appliance comes with a system

that allows you to resume cooking/pyrolysis from the point

in which it was interrupted at the time of the black-out.

Remember that this function will be disabled if the knobs

“L” and “M” are turned during the power f ailure. Once the

cooking/pyrolysis has been completed, remember to update the time if you want to .

NOTE

Please bear in mind that, for safety reasons, cooking/pyrolysis programmes waiting to start are not restored when

the power comes back on.

9

Page 10

Programming the cooking mode

The cooking time and/or end cooking time can be programmed after the desired cooking mode has been selected.

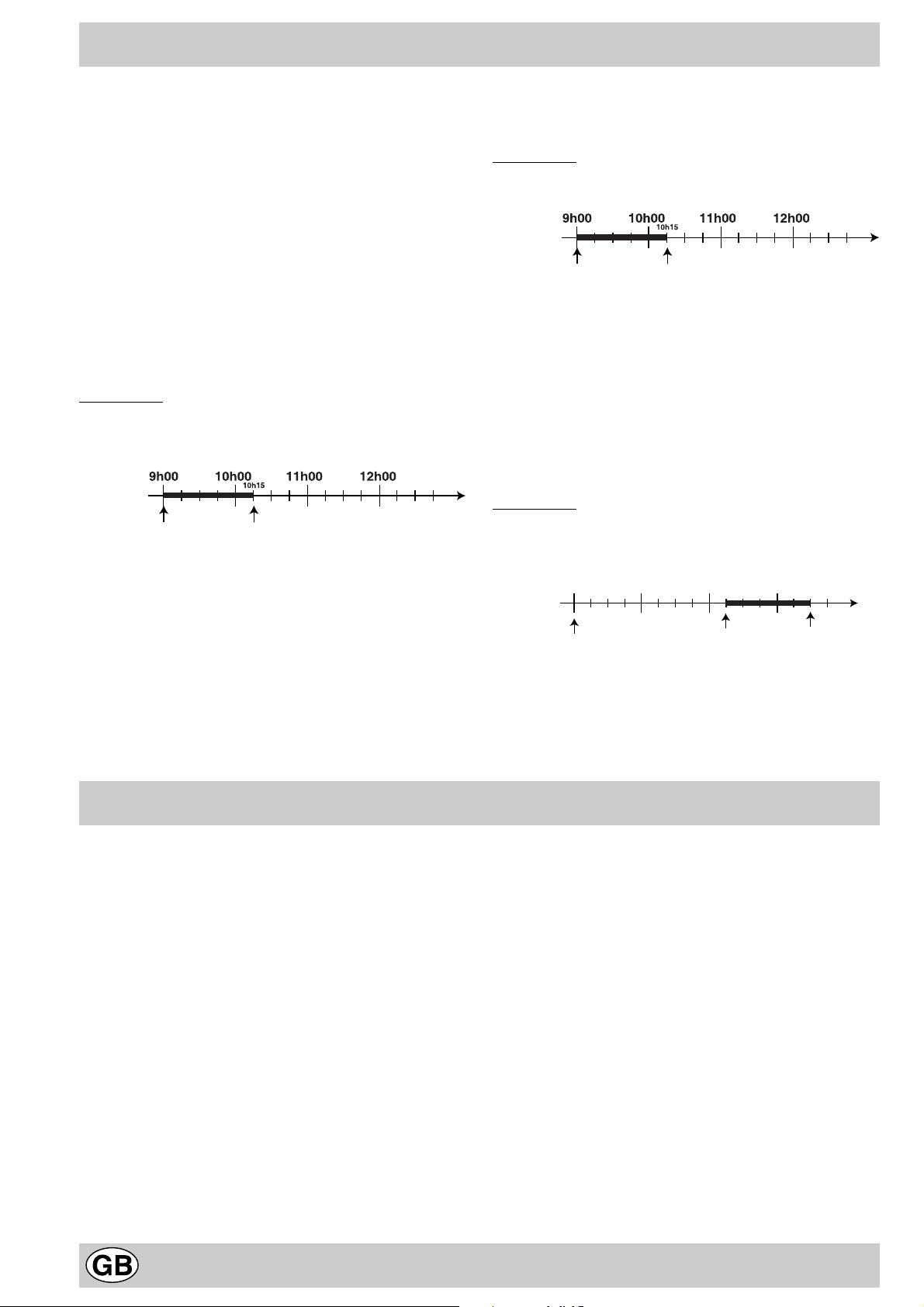

Programming the cooking time

Press button “4” and then adjust the cooking time by pressing keys s and t. Press the “4” button to store the

setting. The temperature selected (which can be adjusted

using knob “M” ) and the amount of time left until cooking

is complete will be displayed alternately

Once this time is up, the word «end» will be displayed and

a sequence of acoustic signals will be emitted to indicate

that cooking is complete.

• Press any button to silence the acoustic signal.

• Turn knob “L” back to position 0 to remove the word

«end» from the display.

For example

It is 9:00 a.m. and a cooking time of 1 hour and 15 minutes

is programmed. Cooking will stop automatically at 10:15

a.m..

Cooking time

= 1h15

Manual

start

Automatic stop

Time

Programming the end cooking time

Press button “3” and then adjust by pressing keys

s

and t. Press the “3” button to store the setting. The

display will remind you alternately of the temperature se-

lected and the amount of time left until cooking is complete.

When the end cooking time selected previously is up, the

word «end» will be displayed and a sequence of acoustic

signals will be emitted to indicate that cooking is complete..

• Press any button to silence the acoustic signal.

• Turn knob “L” back to position 0 to remove the word

«end» from the display.

For example

It is 9:00 a.m. and the end cooking time is set at 10:15

a.m.. Cooking will last 1 hour and 15 minutes.

Cooking time

= 1h15

Manual

start

Automatic stop

Time

Delayed cooking programming

Press button “4” and then adjust the cooking time by pressing keys s and t. Press the “4” to store the setting.

The temperature and the time set previously will be displayed alternately .

Press button “3” and then adjust end cooking time by press-

ing keys s and t. Press the”3" button to store the

setting and the display will remind you of the end cooking

time and of the temperature set alternately .

For example

It is 9:00 a.m. and a cooking time of 1 hour and 15 minutes

and 12:20 as the end cooking time are programmed. Cooking

will start automatically at 11:15 a.m..

Cooking time

= 1h15 and

end cooking

time set at

12.30 p.m.

9h00 10h00 11h00 12h00

11h15

Automatic

start

12h30

Programmed end

The icon A will remind you that you have programmed the

cooking time and/or the end cooking time.

T o cancel a programmed time

To cancel any programming you hav e made, set knob “L”

to position “0”.

Automatic cleaning with the fast clean function

When the fast clean function has been enabled, the

temperature inside the oven reaches 500°C, which is

necessary to burn all food residue that has built up inside it.

If you look through the oven glass, you may notice some

particles that light up as they are destroyed by pyrolysis

upon contact with the heating elements: this is simply

spontaneous combustion: it is perfectly normal and hazard-

free.

A few useful tips before automatic cleaning begins

1- Try to remove large scr aps of food and caked-on dirt with

a damp sponge. Avoid using detergents or an y other special

products recommended for oven cleaning.

2- Remove all the accessories from the oven, as these are

not designed to withstand such high temperatures. In addition,

some accessories could affect the efficiency of the automatic

cleaning cycle by obstructing the circulation of heat along all

the interior walls of the oven. The accessories can easily be

washed like everyday crockery (even in your dishwasher).

3- Do not place tea towels over the oven handle.

Warning: during the automatic cleaning cycle, the surfaces

may become very hot. Keep children away from these.

How to enable the fast clean function

– Shut the oven door .

– Set the selector knob to V

– To programme the fast clean cycle time and/or cycle

end time, follow the instructions provided in the paragraph entitled “Fast clean programming”. Please note

that you can choose a cycle time of between 60 and

120 minutes, depending on the degree of soil in your

oven.

Safety devices

Given the high temperatures reached inside it, the oven is

fitted with several safety devices:

• the door is locked automatically as soon as the temperature exceeds a certain value, to avoid all risk of

burns;

• the heating elements are no longer electrically pow-

ered, as a precautionary measure, should a fault occur.

10

Page 11

Automatic cleaning with the fast clean function

• Once the oven door has been locked, you cannot make

any changes to the cycle time and cycle end settings.

• If the temperature in appliance’ s electrical component

area has reached a safe value, it is not possible to

start the “Fast clean” cycle. The word “HOT” will appear

on the display. Wait for the cooling fan to switch off

before restarting the “F ast clean” progr amme.

What happens at the end of an automatic cleaning

cycle?

At the end of the automatic cleaning cycle, the word “end”

is displayed and an acoustic signal is sounded, which can

be silenced just by pressing any one of the buttons . Turn

knob “L” to the “0” setting and the word “end” will disappear .

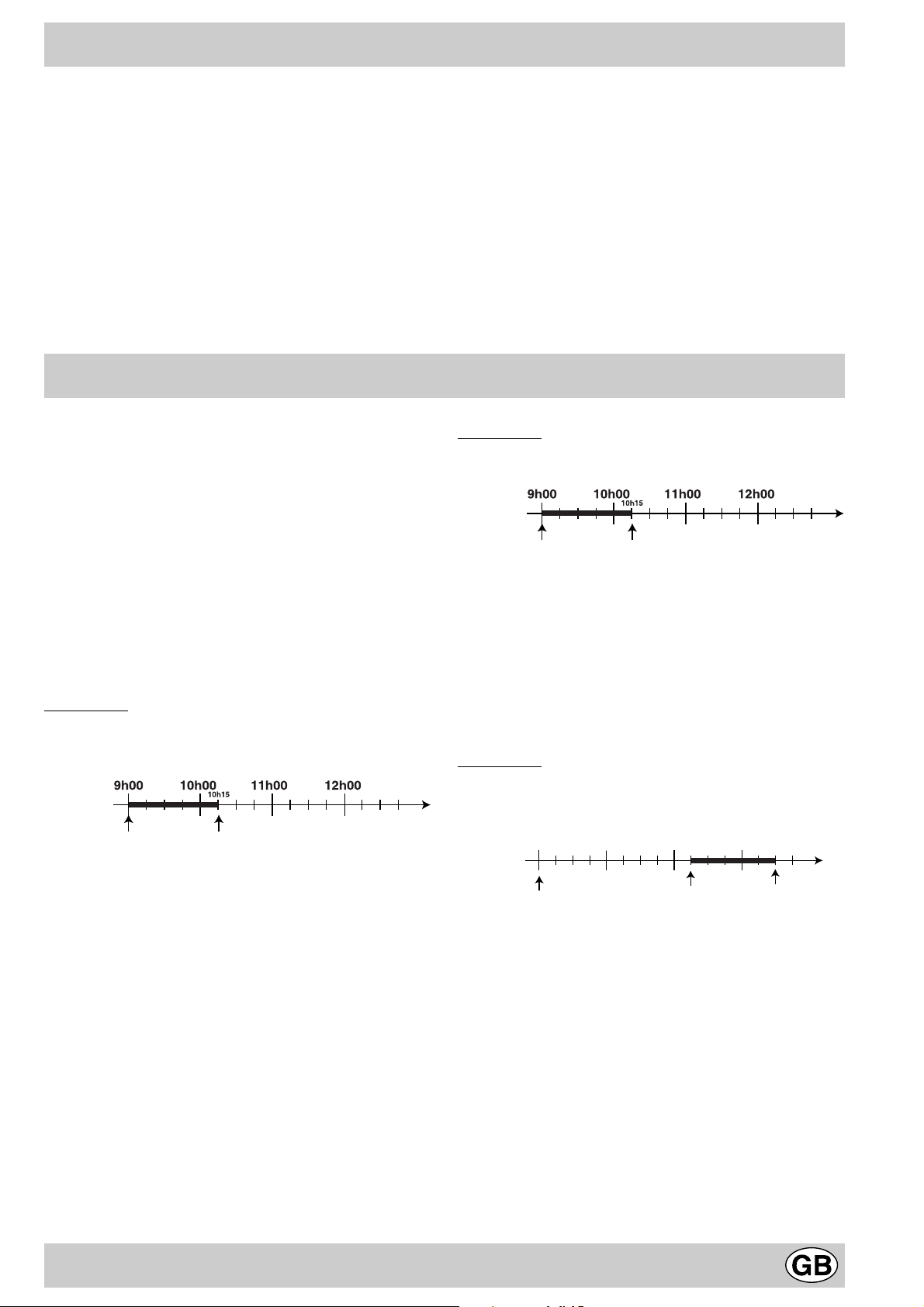

Fast clean programming

The fast clean cycle time and/or cycle end time can be

programmed after selecting the fast clean mode, and within

the 10 first minutes of operation..

Programming the fast clean cycle time

Press button “4” and then adjust the cooking time by pressing keys s and t. Press the “4” button to store the

setting. The time left until the end of the fast clean cycle

will be displayed.

Once this time is up, the word «end» will be displayed and

a sequence of acoustic signals will be sounded to indicate

that the cleaning cycle is complete.

• Press any button to silence the acoustic signal.

• Turn knob “L” back to position 0 to remove the word

«end» from the display.

For example

It is 9:00 a.m. and a fast clean cycle time of 1 hour and 15

minutes is programmed. The fast clean cycle will end

automatically at 10:15 a.m..

Cooking time

= 1h15

Manual

start

Automatic stop

Programming the fast clean cycle end time

Press button “3” and then adjust by pressing keys

and t. Press the “3” button to store the setting. The time

left until the end of the fast clean cycle will be displayed.

When the previously selected fast clean cycle time is up,

the word «end» will be displayed and a sequence of acoustic

signals will be sounded to indicate that the fast-clean mode

is complete.

• Press any button to silence the acoustic signal.

• Turn knob “L” back to position 0 to remove the word

«end» from the display.

Time

s

To open the oven door, y ou will hav e to wait until the temperature inside it has dropped to a suitable value.

You will notice some white dust deposits on the bottom and

sides of your oven; remove them with a damp sponge once

the oven has cooled down completely.

You may on the other hand pref er to tak e advantage of the

heat accumulated to start cooking immediately; in this case

the dust can stay where it is: it is completely harmless and

will not affect your food in any way.

Warning: to maximise the efficiency and life of the

appliance, we recommend that automatic clean is carried

out with the hob off.

For example

It is 9:00 a.m. and the fast clean cycle end time is set at

10:15 a.m.. Fast clean will last 1 hour and 15 minutes.

Cooking time

= 1h15

Manual

start

Automatic stop

Time

Delayed fast clean cycle programming

Press button “4” and then adjust the cooking time by pressing keys s and t. Press the”4" button to store the

setting and display it.

Press button “3” and then adjust end cooking time by press-

ing keys s and t. Press the”3" button to store the

setting and the display will remind you of the end cooking

time and of the temperature set alternately .

For example

It is 9:00 a.m. and a fast clean cycle time of 1 hour and 15

minutes and 12:20 as the cycle end time are programmed.

The fast clean cycle will start automatically at 11:15 a.m..

Cooking time

= 1h15 and

end cooking

time set at

12.30 p.m.

9h00 10h00 11h00 12h00

11h15

Automatic

start

12h30

Programmed end

The icon A will remind you that you have programmed the

fast clean cycle time and/or the cycle end time.

T o cancel a programmed time

To cancel any programming you hav e made, set knob “L”

to position “0”.

11

Page 12

Do not worry if

1 the cooling fan is operating at low speed at the start of

the fast clean cycle;

2 the electrical system limiter blows when F ast Clean is

in use: this is due to a mains overload (too many electric household appliances used at the same time);

3 the oven door is locked during the Fast Clean pro-

gramme: this is an appliance safety device; the door

will only open when the oven has cooled completely;

4 small stains are left on the interior surface of the oven

after the Fast Clean cycle: we recommend y ou remove

the toughest grease spots and large scraps of food

before the self-cleaning cycle and that you set the cy-

Practical Cooking Advice

The oven offers a wide range of alternatives which allow

you to cook any type of food in the best possible way.

With time you will learn to make the best use of this versatile cooking appliance and the following directions are

only a guideline which may be varied according to your

own personal experience.

Cooking on More Than One Rack

If you have to cook food using several racks, use either

the “pastry” mode u or the “Multi-cooking mode” mode

b, as these are the only modes that allow you to do so.

When cooking delicate food on more than one rack, use

the “pastry” mode uwhich allows you to cook on 3 racks

at the same time (the 1st, 3rd and 5th). Some examples

are included in the “Practical Cooking Advice” table.

When cooking other food on several racks, use the “Multi-

cooking”mode b, keeping the following suggestions in

mind:

• The oven is fitted with 5 racks. During fan assisted

cooking, use two of the three central racks; the lowest

and highest racks receive the hot air directly and therefore delicate foodstuffs could be burnt on these racks.

• As a general rule, use the 2nd and 4th rack from the

bottom, placing the foodstuffs that require greater heat

on the 2nd rack from the bottom. For example, when

cooking meat roasts together with other food, place

the roast on the 2nd rack from the bottom and the more

delicate food on the 4th rack from the bottom.

• When cooking food that requires differing times and

temperatures, set a temperature that is somewhere

between the two temperatures required, place the more

delicate food on the 4th rack from the bottom and take

the food requiring less time out of the oven first.

• Use the dripping pan on the lower rack and the grid on

the upper;

Using the “Fast Cooking” Mode

Functional, fast and practical for those of you who use

pre-packed products (such as for example: frozen or precooked food) along with other food items . You will find useful suggestions in the “Practical Cooking Advice” table.

cle time in accordance with the degree of soil in your

oven;

5 you see ventilated air exiting the oven for a while when

cooking is complete: it is due to the normal cooling

phase of the oven interior;

6 when using the “grill” mode, the top heating element

isn’t always on (red in colour): its operation is controlled by a thermostat;

7 a blast of hot steam exits the oven when you open the

door during cooking;

8 drops of water or steam form inside the oven if you

leave food inside the oven after cooking is complete;

Using the Grill

The “7 Cuochi” oven offers you several different grilling

modes..

Use the “grill” mode d, with the oven door closed, plac-

ing the food under the centre of the grill (situated on the

3rd or 4th rack from the bottom).

T o catch any f at and/or grease that may drip from the rac k,

place the dripping pan provided on the first rack from the

bottom.

When using this mode, we recommend you set the energy

level to the highest setting, even though lower levels can

be set, simply by adjusting the thermostat knob to the

desired level.

The e“Gratin”, only with the oven door shut, , is ex-

tremely useful for grilling foods rapidly, as the distribution

of heat makes it possible not only to brown the surface,

but also to cook the bottom part.

Moreover, it can also be used for browning foods at the

end of the cooking process, such as adding that gratin

finish to pasta bakes, for example.

When using this mode, place the grid on the 2nd or 3rd

oven rack from the bottom (see cooking table) then, to

prevent fat and grease from dripping onto the bottom of

the oven and thus smoke from forming, place a drippingpan on the 1st rack from the bottom.

Important: always use the “Gratin” with the oven door

shut. This will allow you both to obtain excellent results

and to save on energy (approximately 10%).

When using this mode, we advise you to set the thermostat to 200°C, as it is the most efficient way to use the

grill, which is based on the use of infrared rays. Ho we v er ,

this does not mean you cannot use lower temperatures,

simply by adjusting the thermostat knob to the desired

temperature.

Therefore the best results when using the grill modes

are obtained by placing the grid on the lower racks

(see cooking table) then, to prevent fat and grease from

dripping onto the bottom of the oven and smoke from

forming, place a dripping-pan on the 1st oven rack from

the bottom.

12

Page 13

Practical Cooking Advice

Baking Cakes

When baking cakes, always place them in a preheated

oven. Do not open the oven door during baking to prevent

the cake from dropping. In general:

Pastry is too dry

Increase the temperature by 10°C and reduce the

cooking time.

Pastry dropped

Use less liquid or low er the temperature by 10°C.

Pastry is too da rk on top

Place it on a lower rack, lower the temperature, and

increase the cooking time.

Cooked well on the inside but sticky on the outside

Use less liquid, lower the temperature, and increase the

cooking time.

The pastry sticks to the pan

Grease the pan well and sprinkle i t with a dus ting of

flour or use greaseproof paper.

I used more than one level (in the function

"ventilated oven") and they are not all at the sam e

cooking point

Use a lower temperature setting. It is not necessary to

remove the food from all the racks at the same time.

Cooking Pizza

For best results when cooking pizza, use the w “pizza

mode”:

• Preheat the oven for at least 10 minutes

• Use a light aluminium pizza pan, placing it on the rack

supplied with the oven. If the dripping pan is used, this

will extend the cooking time, making it difficult to get a

crispy crust;

• Do not open the oven door frequently while the pizza is

cooking;

• If the pizza has a lot of toppings (three or four), we

recommend you add the mozzarella cheese on top

halfway through the cooking process.

• If cooking on more than one rack (up to 2), we advise

you to use the Multi-cooking Mode b, as the Pizza

Mode w would heat the bottom rack more than the

others.

Cooking Fish and Meat

When cooking white meat, fowl and fish, use temperature

settings from 180 °C to 200 °C.

For red meat that should be well done on the outside while

tender and juicy in the inside, it is a good idea to start with

a high temperature setting (200°C-220°C) for a short time,

then turn the oven down afterwards.

In general, the larger the roast, the lower the temperature

setting. Place the meat on the centre of the grid and place

the dripping pan beneath it to catch the fat.

Make sure that the grid is inserted so that it is in the centre of the oven. If you would like to increase the amount of

heat from below, use the low rack heights. For savoury

roasts (especially duck and wild game), dress the meat

with lard or bacon on the top.

13

Page 14

Practical Cooking Advice

Setting made Type of food Weight

(in kg)

1 Traditional

a

2 Baking

u

3 Fast cooking

v

4 Multicooking

b

5 Pizza

w

Duck

Roast veal or beef

Pork roast

Biscuits (short pastry)

Tarts

Tarts

Fruit cakes

Plum cake

Sponge cake

Stuffed pancakes

Small cakes (on 2 racks)

Cheese puffs (on 2 racks)

Cream puffs (on 3 racks)

Biscuits (on 3 racks)

Meringues (on 3 racks)

Frozen food

Pizza

Courgette and prawn pie

Country style spinach pie

Turnovers

Lasagne

Golden Rolls

Chicken morsels

Pre-cooked food

Golden chicken wings

Fresh Food

Biscuits (short pastry)

Plum cake

Cheese puffs

Pizza (on 2 racks)

Lasagne

Lamb

Roast chicken + potatoes

Mackerel

Plum cake

Cream puffs (on 2 racks)

Biscuits (on 2 racks)

Sponge cake (on 1 rack)

Sponge cake (on 2 racks)

Savoury p ies

Pizza

Roast veal or beef

Chicken

(on 2 racks)

0.5

0.7

0.5

1.2

0.6

0.4

0.7

0.7

0.5

0.3

0.4

0.5

0.3

0.5

0.4

0.4

0.4 2 - 200 20-25

0.3

0.6

0.2

1+1

0.5

0.5

0.5

1.0

1.5

0.5

Position of the

rack from the

oven bottom

1

1

1

-

1

1

1

1

1

1

1

1

1

3

3

3

3

3

3

2/3

3

3

2-4

2-4

2-4

1-3-5

1-3-5

1-3-5

2

2

2

2

2

2

2

2

2

2

2-4

3

2

2-4

2

2

2-4

2-4

2

2-4

3

3

2

2/3

Preheating

time (min.)

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

-

-

-

-

-

-

-

-

-

-

15

10

10

15

10

10

10

10

10

10

15

15

10

10

Thermostat

setting

200

200

200

180

180

180

180

180

160

200

190

210

180

180

90

Max

200

220

200

200

180

220

200

180

210

230

180

180

200

180

170

190

180

170

170

200

220

220

180

Cooking

time

(min.)

65-75

70-75

70-80

15-20

30-35

20-30

40-45

40-50

25-30

30-35

20-25

15-20

20-25

20-25

180

12

20

30-35

25

35

25-30

15-20

15-18

45

10-12

15-20

30-35

40-45

60-70

30-35

40-50

20-25

10-15

15-20

20-25

25-30

15-20

25-30

60-70

6 Grill

d

7 Gratin

e

cooking times are approximate and may vary accordin g to personal taste. When cooking using the grill o r

N.B.:

gratin, the dripping pan must always be placed on the 1st oven rack from the bottom.

Soles and cuttlefish

Squid and prawn kebabs

Cod filet

Grilled vegetables

Veal steak

Cutlets

Hamburgers

Mackerels

Toasted sandwiches

Grilled chicken

Cuttlefish

1

1

1

1

1

1

1

1

n.° 4

1.5

1.5

4

4

4

3/4

4

4

4

4

4

3

3

10

10

-

-

-

-

-

-

-

-

-

5

5

5

5

5

5

5

5

5

200

200

14

8-10

6-8

10

10-15

15-20

15-20

7-10

15-20

2-3

55-60

30-35

Page 15

Routine Maintenance and Cleaning

coperchio

guarnizione

lampadina

cavità

Before each operation, disconnect the cooker from the

electrical supply . T o ensure that the appliance stands the

test of time, it must be thoroughly cleaned frequently , k eeping in mind that:

••

• do not use steam equipment to clean the appliance

••

• the enamelled parts and the self-cleaning panels, where

present, are washed with warm water without using any

abrasive powders or corrosive substances which could

ruin them;

• the inside of the oven should be cleaned fairly often

while it is still warm, using warm water and detergent

followed by careful rinsing and drying;

• the flame spreaders should be washed frequently with

hot water and detergent, taking care to eliminate any

scale;

• In cookers equipped with automatic lighting, the termi-

nal part of the electronic instant lighting devices should

be cleaned frequently (C) and the gas outlet holes on

the flame spreaders should be checked to make sure

they are free of any obstructions;

• stainless steel may become marked if it comes into

contact with very hard water or harsh detergents (containing phosphorous) for long periods of time. After

cleaning, rinse and dry thoroughly. It is also recommended that any remaining drops of water be dried;

• On models with glass covers, the covers should be

cleaned with hot water; the use of rough cloths or

abrasives is to be avoided

N.B.: A void closing the cover while the gas b urners

are still warm. Remove any liquid from the lid before opening it.

Important: periodically check the wear of the gas hose

and substitute it if there are any defects; we recommended

changing it every year .

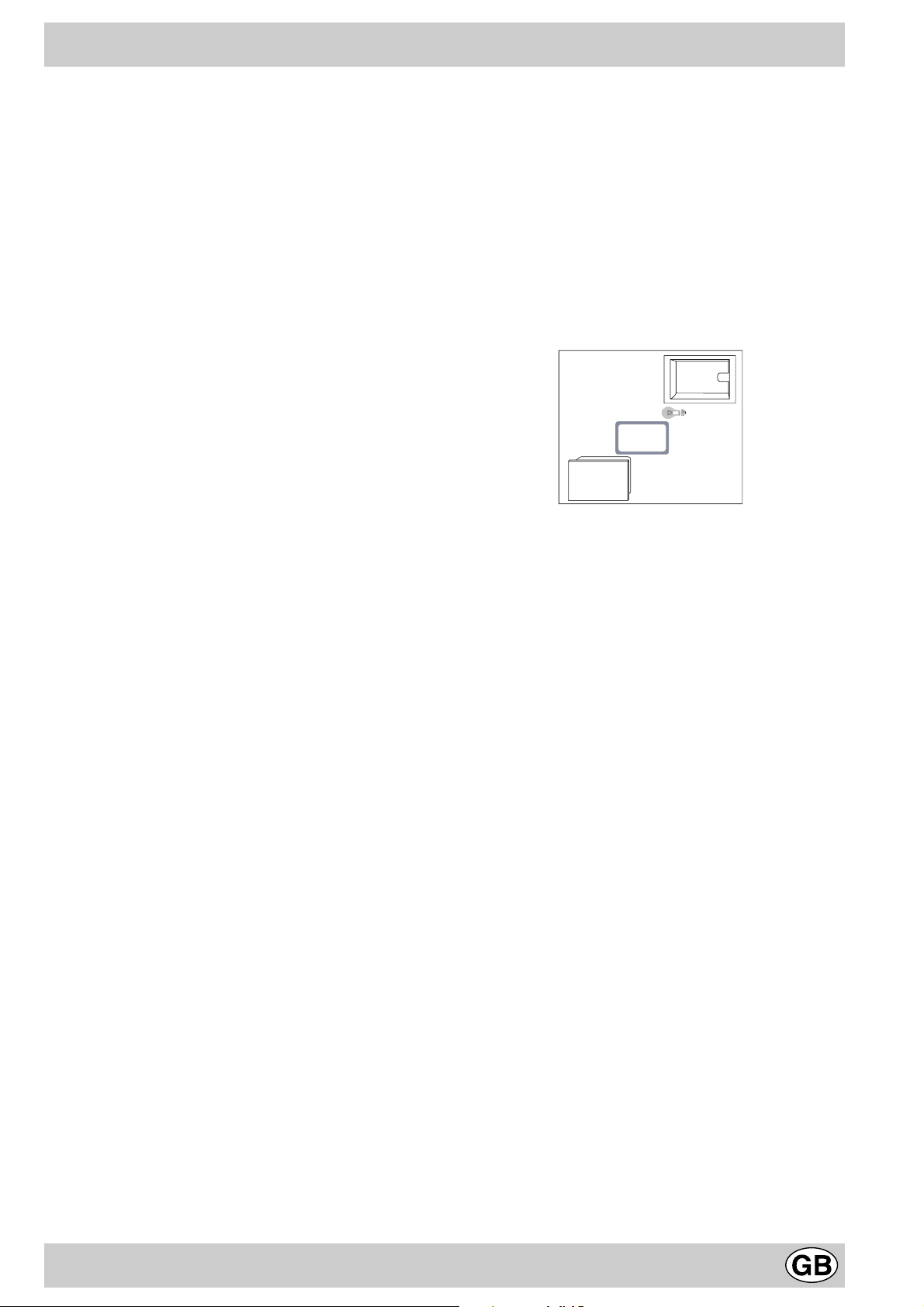

Replacing the oven light bulb

• Before any operation, disconnect the hob from the electrical supply by pulling out the plug or using the switch

that connects the oven to the electricity mains.

• Using a narrow , thin object (screwdriver , spoon handle,

etc.), remove the glass lid.

• Remove the lamp and replace it with one that has the

same properties:

- V oltage: 230/240 V

- power 15W

- E 14 cap

• Replace the glass cover taking care to position the seal

correctly .

Gas tap maintenance

The taps may jam in time or they may become difficult to

turn. If so, the tap itself must be replaced.

N.B.: This procedure must be performed by a technician authorised by the manufacturer .

15

Page 16

NOTES

16

Page 17

Page 18

After Sales Service

No one is better placed to care for your Hotpoint appliance during the course of its working life than us -

the manufacturer.

Essential Contact Information

Hotpoint Service

We are the largest service team in Europe offering you access to 400 skilled telephone advisors and

1100 fully qualified engineers on call to ensure you receive fast, reliable, local service.

UK: 08709 066 066

Republic of Ireland: 0818 313 413

www .hotpointservice.co.uk

Please note: Our advisors will require the following information:

Model number:

Serial number:

Parts and Accessories

We supply a full range of genuine replacement parts as well as accessory products that protect and

hygienically clean your appliance to keep it looking good and functioning efficiently throughout its life.

UK: 08709 077 077

Republic of Ireland: 0818 313 413

www .hotpointservice.co.uk

Appliance Registration

We want to giv e you additional benefits of Hotpoint ownership. To activate your free 5 year parts guarantee

you must register your appliance with us.

UK: 0870 6092094

Republic of Ireland: 01 230 0800

www .hotpointservice.co.uk

Indesit Company UK Ltd. Morley Way, Peterborough, PE2 9JB

Indesit Company Unit 49 Airways Industrial Estate,Dublin 17

Recycling & Disposal Information

As part of Hotpoint's continued commitment to helping the environment, Hotpoint reserves the right to use quality , recycled

components to keep down customer costs and minimise material wastage.

Please dispose of packaging and old appliances carefully. To minimise the risk of injury to children, remove the door, plug

and cut the mains cable off flush with the appliance. Dispose of these parts separately to ensure that the appliance can

no longer be plugged into a mains socket, and the door cannot be locked shut.

17

Page 19

Guarantee

12 Months Parts and Labour Guarantee

Your appliance has the benefit of our manufacturer’s guarantee, which covers the cost of breakdown

repairs for twelve months from the date of purchase.

This gives you the reassurance that if, within that time, your appliance is proven to be defective because

of either workmanship or materials, we will, at our discretion, either repair or replace the appliance at no

cost to you.

This guarantee is subject to the following conditions:

-

The appliance has been installed and operated correctly and in accordance with our

operating and maintenance instructions.

-

The appliance is used only on the electricity or gas supply printed on the rating plate.

-

The appliance has been used for normal domestic purposes only.

-

The appliance has not been altered, serviced, maintained, dismantled, or otherwise

interfered with by any person not authorised by us.

-

Any repair work must be undertaken by us or our appointed agent.

-

Any parts removed during repair work or any appliance that is replaced become our property.

-

The appliance is used in the United Kingdom or Republic of Ireland.

The guarantee does not cover:

-

Damage resulting from transportation, improper use, neglect or interference or as a result

of improper installation.

-

Replacement of any consumable item or accessory . These include but are not limited to: plugs,

cables, batteries, light bulbs, fluorescent tubes and starters, covers and filters.

-

Replacement of any removable parts made of glass or plastic.

THIS GUARANTEE WILL NOT APPLY IF THE APPLIANCE HAS BEEN USED IN COMMERCIAL OR

NON-DOMESTIC PREMISES.

5 Year Parts Guarantee

Hotpoint also offers you a free 5 year parts guarantee. This additional guarantee is conditional on you

registering your appliance with us and the parts being fitted by one of our authorised engineers. There will

be a charge for our engineer's time. To activate the extra parts warranty on your appliance, simply call our

registration line on 0870 6092094 (ROI 01 230 0800).

Extended Guarantees

We offer a selection of repair protection plans that enable you to fully cover yourself against the expense

of repair bills for the life of your policy. To find the ideal plan for you please call our advice line on 08709

088 088 (ROI 01 230 0233).

Free Helpdesk Service

We have a dedicated team who can provide free advice and assistance with your appliance if you

experience any technical difficulties within the first 90 days of ownership. Simply call our Hotpoint Service

Hotline on 08709 066 066 (ROI 0818 313 413) for telephone assistance, or, where necessary, to arrange

for an engineer to call. If we cannot resolve the technical problem we will replace your machine or, if you

prefer, give you your money back.

18

Page 20

Key Contacts

After Sales Service

Over 1200 trained specialists, directly employed by us, ensure that you can have complete confidence in

both the appliances and services we offer.

Repair Service and Information Desk

UK: 08709 066 066

(Open 8 to 8 Mon - Fri, 8 to 6 Sat, 10 to 4 Sun & Bank Holidays)

www.theservicecentre.co.uk

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

Model number:

Serial number:

Extended Warranties

UK: 08709 088 088

(Open 8 to 8 Mon - Sun)

www.theservicecentre.co.uk

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

UK: 08709 077 077

(Open 8-30 to 5-30 Mon - Fri & 9 to 12 Sat)

www .theservicecentre.co.uk

Republic of Ireland: (01) 842 6836

General Domestic Appliances Limited, Morley Way, Peterborough, PE2 9JB.

CODE: 195053510.00

07-05 Part no. FP190 - 01

19

Loading...

Loading...