Page 1

CX65SP6 PT/HA

GB

English

Operating Instructions

COOKER AND OVEN

Contents

Operating Instructions,1

Control Panel,1

Overall view,2

Warning,3

Installation,5

Installation,

Start-up and use,10

Cooking modes,11

Precautions and tips,14

Care and maintenance,15

Assistance,15

1

2

PT

Português

Instruções para a utilização

FOGÃO E FORNO

Índice

Instruções para a utilização,1

Painel de comandos,1

Vista de conjunto,2

Attentacao,3

Instalaçao,16

Início e utilizaçao, 21

Utilizaçao do forno,22

Precauçoes e conselhos,25

Manutençao e cuidados,26

Assistencia técnica,26

7

6

4

3

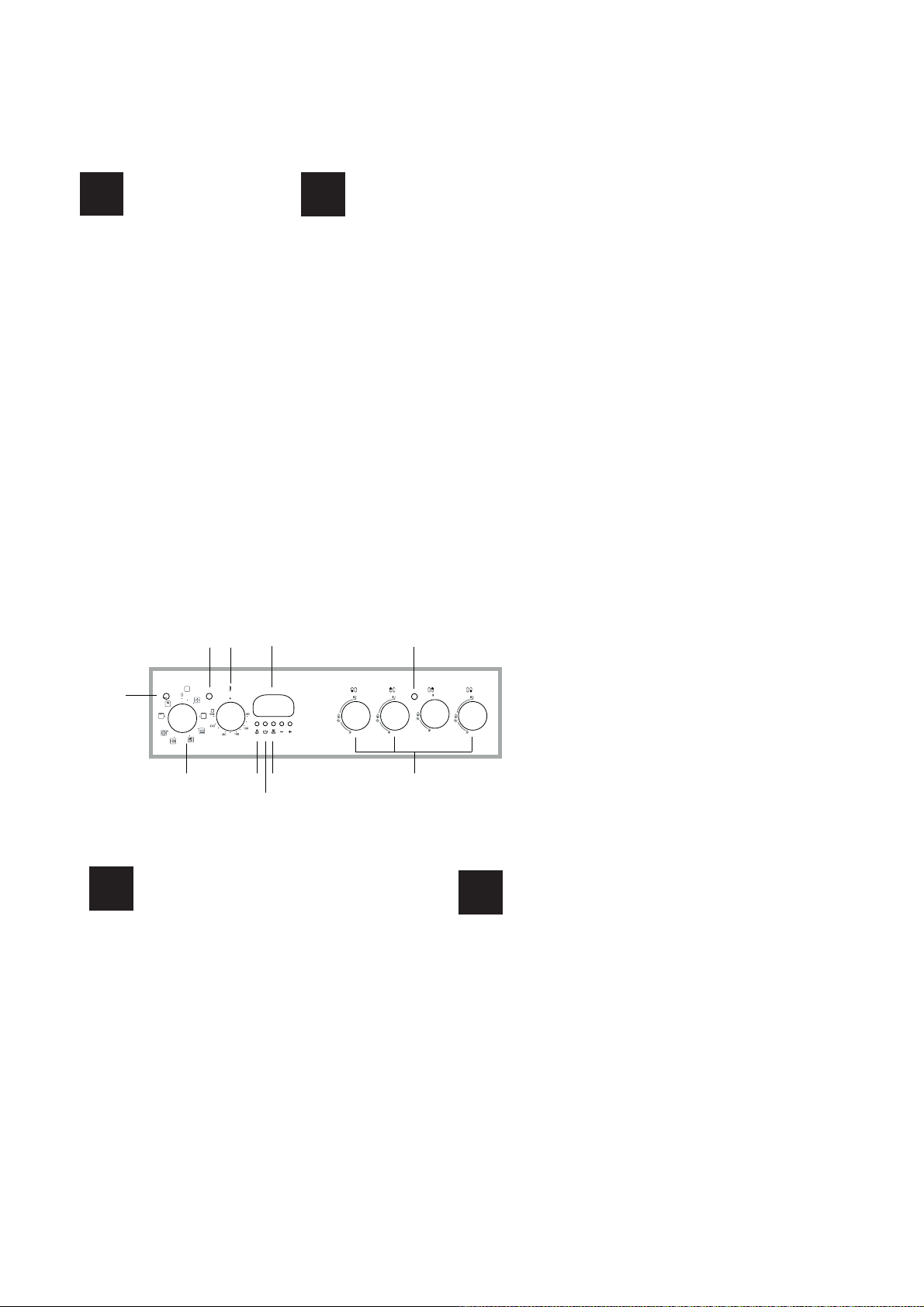

GB

1.THERMOSTAT knob

2.THERMOSTAT indicator light

3.SELECTOR knob

4.OVENIndicator light

5.Hob BURNER control knob

6. ELECTRIC HOTPLATE indicator light

7. Electronic cooking programmer

8.TIMER button

9.COOKING TIME button

10.COOKING END TIME button

Description of the appliance

Control panel

8910

5

Descrição do aparelho

PT

Painel de comandos

1.Selector para a temperatura de cozedura (termostato)

2.Indicador de funcionamento termostato

3.Botão selector das funções de cozedura

4.Indicador de funcionamento forno

5.Botão luz do forno e rotisserie

6.Indicador de funcionamento chapas

7.O programador de cozedura electrónico

8.Botão contador de minutos.

9.Botão duração da cozedura

10.Botão final da cozedura

1

Page 2

GB

2

3

4

5

8

1

6

6

9

10

11

12

13

7

14

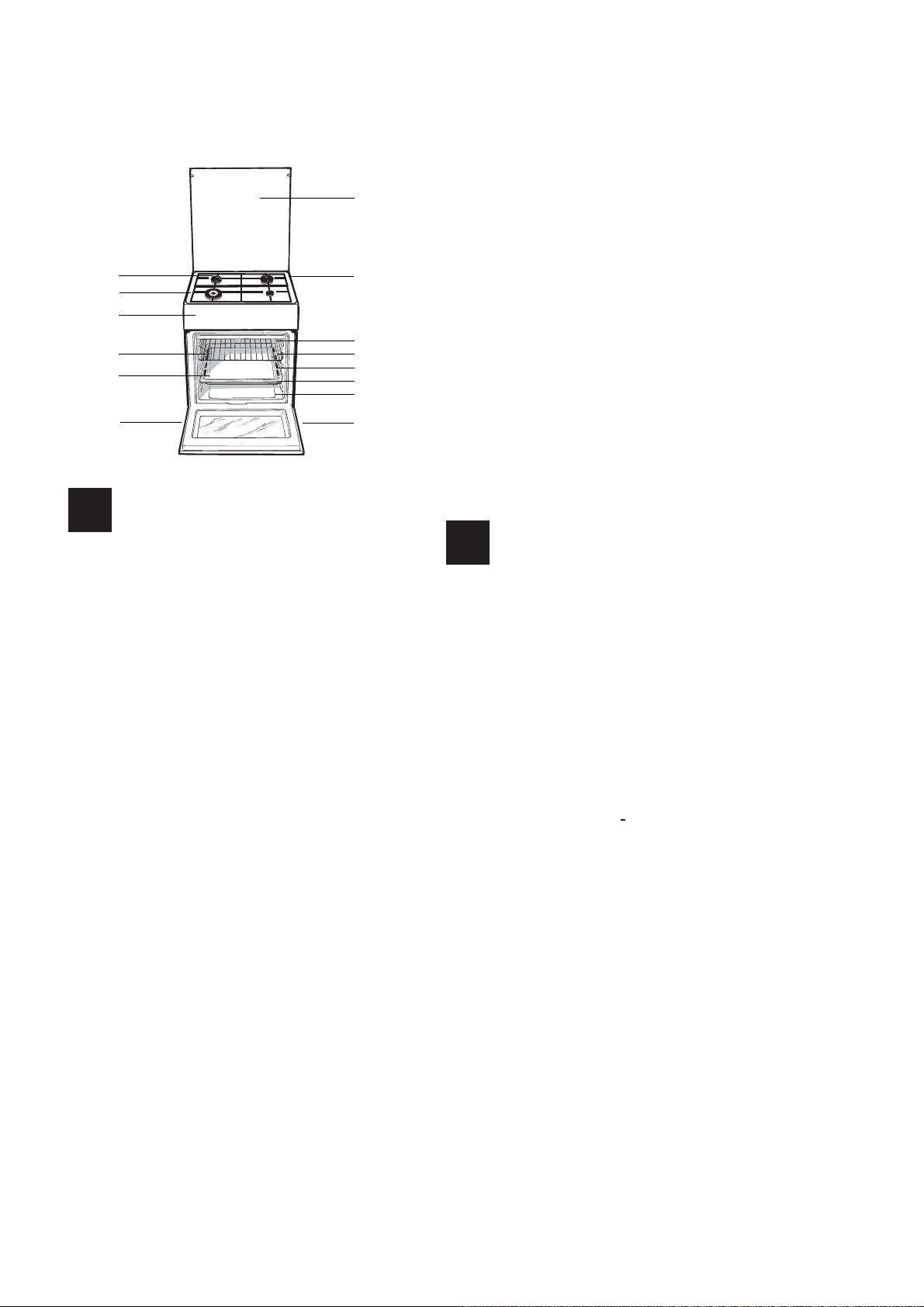

Description of the appliance

Overall view

1 Hob burner

2 Hob Grid

3.Control panel

4.Sliding grill rack

5.DRIPPING pan

6.Adjustable foot

7.Containment surface for spills

8.GUIDE RAILS for the sliding racks

9.position 5

10.position 4

11.position 3

12.position 2

13.position 1

14.Glass Cover*(Available only on certain models)

Descrição do aparelho

PT

Vista de conjunto

1 Queimador a gás

2 Grade do piano de trabalho

3 Painel de comandos

4 Prateleira GRADE

5 Prateleira BANDEJA PINGADEIRA

6 Pé de regulação

7 Plano de retenção dos eventuais vazamentos

8 GUIAS de deslizamento das prateleiras

9 Posição 5

10 Posição 4

11 Posição 3

12Posição 2

13 Posição 1

14 O sobretampo de vidro (Presente apenas em alguns modelos)

2

Page 3

GB

WARNINGWARNINGWARNING

WARNING: The appliance and its

accessible parts become hot during

use.

Care should be taken to avoid

touching heating elements.

Children less than 8 years of age shall

be kept away unless continuously

supervised.

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance in a

safe way and understand the hazards

involved. Children shall not play with

the appliance. Cleaning and user

maintenance shall not be made by

children without supervision.

WARNING: Unattended cooking on a

hob with fat or oil can be dangerous

and may result in fire.

Do not use harsh abrasive cleaners

or sharp metal scrapers to clean

the oven door glass since they can

scratch the surface, which may result

in shattering of the glass.

The internal surfaces of the

compartment (where present) may

become hot.

Never use steam cleaners or pressure

cleaners on the appliance.

Remove any liquid from

the lid before opening it.

Do not close the glass cover (if present)

when the gas burners or electric

hotplates are still hot.

WARNING: Ensure that the appliance is

switched off before replacing the lamp

to avoid the possibility of electric shock.

CAUTION: the use of inappropriate hob

guards can cause accidents.

! When you place the rack inside,

make sure that the stop is directed

upwards and in the back of the cavity.

NEVER try to extinguish a fire with

water, but switch off the appliance

and then cover flame e.g. with a lid or

a fire blanket.

3

Page 4

PT

ATENÇAOATENÇAOATENÇAO

ATENÇÃO: Este aparelho e as suas

partes acessíveis aquecem muito

durante a utilização.

É preciso ter atenção e evitar tocar

os elementos que aquecem.

Manter afastadas as crianças com

menos de 8 anos, caso não estejam

a ser vigiadas.

O presente aparelho pode ser utilizado por crianças com mais de 8 anos

e por pessoas com capacidades

físicas, sensoriais ou mentais reduzidas ou com pouca experiência e

conhecimentos, caso sejam adequadamente vigiadas ou caso tenham

recebido instruções em relação ao

uso do aparelho de forma segura

e tenham conhecimento dos perigos associados. As crianças não

devem brincar com o aparelho. As

operações de limpeza e manutenção

não devem ser efectuadas por crianças sem vigilância.

ATENÇÃO: Deixar um fogão com

gordura e óleo sem vigilância

pode ser perigoso e provocar um

incêndio.

NUNCA tente apagar as chamas

com água. É necessário desligar o

aparelho e cobrir as chamas com

uma tampa ou com uma manta

ignífuga.

Não utilizar produtos abrasivos nem

espátulas de metal cortantes para

limpar a porta em vidro do forno,

uma vez que pode riscar a superfície, provocando a ruptura do vidro.

As superfícies internas da gaveta (se

presentes) podem ficar muito quentes.

Nunca utilize equipamento de limpeza a vapor ou de alta pressão para

limpar o aparelho.

Elimine os líquidos presentes na tampa antes de abri-la. Não feche a tampa de vidro (se presente) se os queimadores ou a chapa eléctrica ainda

estiverem quentes.

ATENÇÃO: Assegure-se de que o

aparelho esteja desligado antes de

substituir a lâmpada, para evitar a

possibilidade de choques eléctricos.

ATENÇÃO: O uso de protecções do

plano inadequadas pode causar incidentes.

! Quando inserir a grelha, assegure-

-se de que o bloqueio esteja voltado

para cima e na parte posterior da

cavidade.

4

Page 5

Installation

! Before operating your new appliance please read

this instruction booklet carefully. It contains important

information concerning the safe installation and

operation of the appliance.

! Please keep these operating instructions for future

reference. Make sure that the instructions are kept with

the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualified

professional according to the instructions provided.

! Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

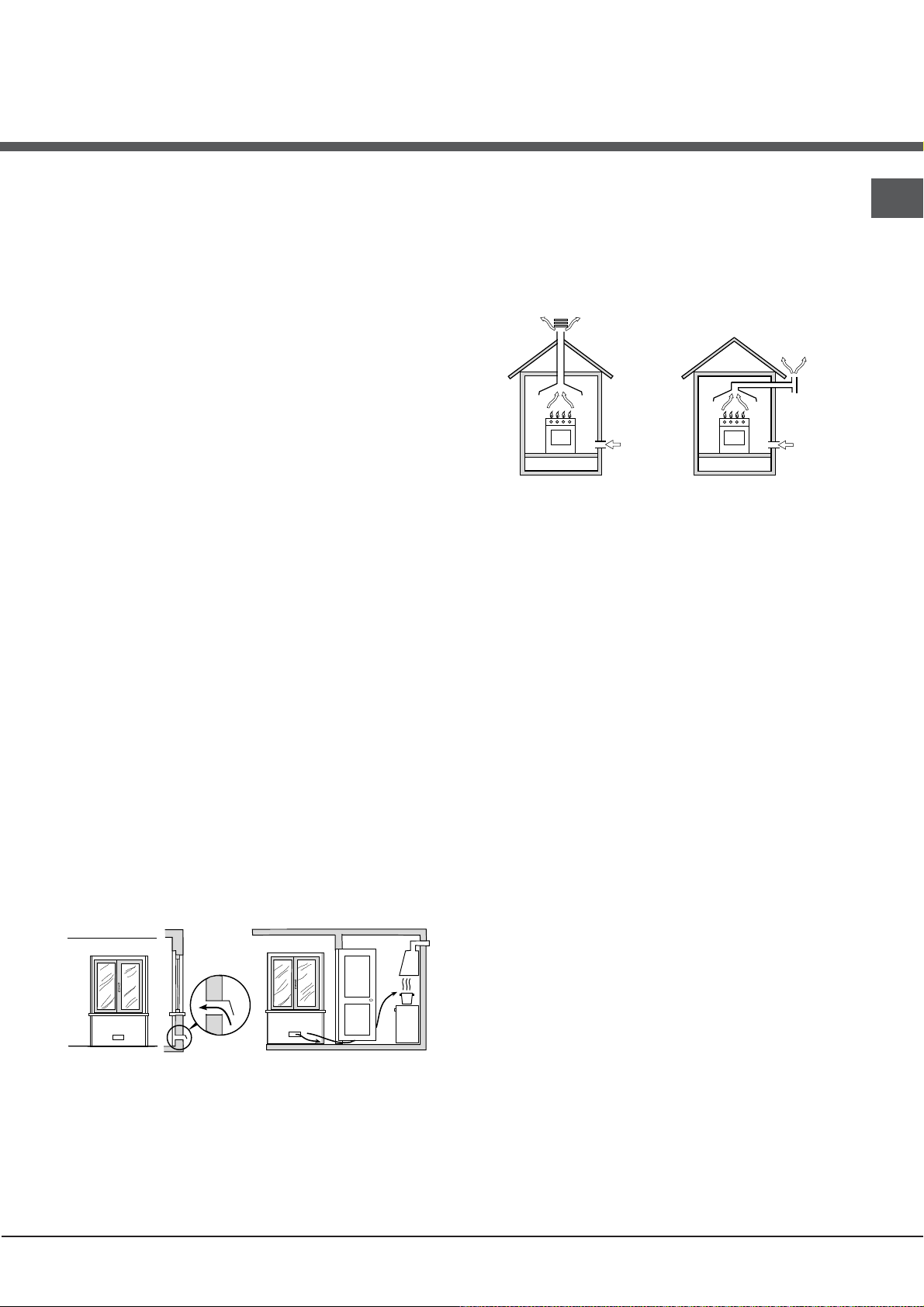

Room ventilation

The appliance may only be installed in permanentlyventilated rooms, in accordance with current national

legislation. The room in which the appliance is installed

must be ventilated adequately so as to provide as

much air as is needed by the normal gas combustion

process (the flow of air must not be lower than 2 m

per kW of installed power).

The air inlets, protected by grilles, should have a duct

with an inner cross section of at least 100 cm

should be positioned so that they are not liable to even

partial obstruction (see gure A).

These inlets should be enlarged by 100% - with a

minimum of 200 cm

hob is not equipped with a flame failure safety device.

When the flow of air is provided in an indirect manner

from adjacent rooms (see gure B), provided that these

are not communal parts of a building, areas with

increased fire hazards or bedrooms, the inlets should

be fitted with a ventilation duct leading outside as

described above.

Adjacent room Room requiring ventilation

A B

2

- whenever the surface of the

2

and

3

/h

Disposing of combustion fumes

The disposal of combustion fumes should be

guaranteed using a hood connected to a safe and

efficient natural suction chimney, or using an electric

fan that begins to operate automatically every time the

appliance is switched on (see gure).

Fumes channelled Fumes channelled through

straight outside a chimney or a branched

flue system (reserved for

cooking appliances)

! The liquefied petroleum gases are heavier than air

and collect by the floor, therefore all rooms containing

LPG cylinders must have openings leading outside so

that any leaked gas can escape easily.

LPG cylinders, therefore, whether partially or

completely full, must not be installed or stored in rooms

or storage areas that are below ground level (cellars,

etc.). Only the cylinder being used should be stored

in the room; this should also be kept well away from

sources of heat (ovens, chimneys, stoves) that may

cause the temperature of the cylinder to rise above

50°C.

Positioning and levelling

! It is possible to install the appliance alongside

cupboards whose height does not exceed that of the

hob surface.

! Make sure that the wall in contact with the back of

the appliance is made from a non-flammable, heatresistant material (T 90°C).

GB

A

Ventilation opening Increase in the gap

between

for comburent air the door and the

flooring

! After prolonged use of the appliance, it is advisable to

open a window or increase the speed of any fans used.

To install the appliance correctly:

• Place it in the kitchen, the dining room or the bed-sit

(not in the bathroom).

• If the top of the hob is higher than the cupboards,

the appliance must be installed at least 600 mm away

from them.

5

Page 6

GB

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min. mm.

420

Min. mm.

• If the cooker is

installed underneath a

wall cabinet, there must

be a minimum distance

of 420 mm between this

cabinet and the top of

the hob.

This distance should be

increased to 700 mm

if the wall cabinets are

flammable (see gure).

indicated on the data plate.

• The socket is compatible with the plug of the

appliance. If the socket is incompatible with the

plug, ask an authorised technician to replace it. Do

not use extension cords or multiple sockets.

! Once the appliance has been installed, the power

supply cable and the electrical socket must be easily

accessible.

! The cable must not be bent or compressed.

• Do not position blinds behind the cooker or less than

200 mm away from its sides.

• Any hoods must be installed according to the

instructions listed in the relevant operating manual.

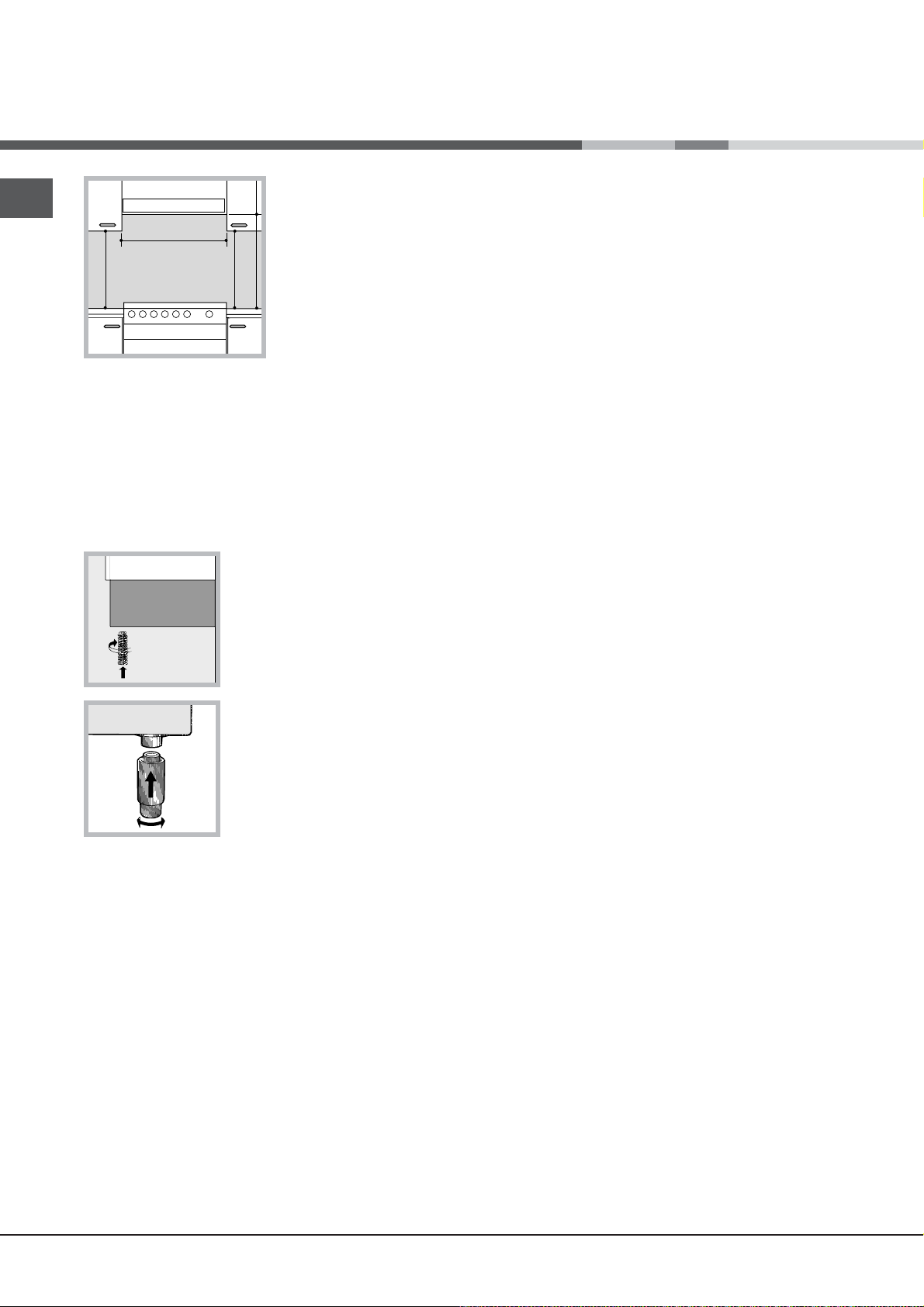

Levelling

If it is necessary to level the appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (see gure).

The legs* fit into the slots on the

underside of the base of the

cooker.

Electrical connection

Install a standardised plug corresponding to the load

indicated on the appliance data plate (see Technical

data table).

The appliance must be directly connected to the mains

using an omnipolar circuit-breaker with a minimum contact

opening of 3 mm installed between the appliance and

the mains. The circuit-breaker must be suitable for the

charge indicated and must comply with current electrical

regulations (the earthing wire must not be interrupted by

the circuit-breaker). The supply cable must be positioned

so that it does not come into contact with temperatures

higher than 50°C at any point.

Before connecting the appliance to the power supply,

make sure that:

• The appliance is earthed and the plug is compliant with

the law.

• The socket can withstand the maximum power of the

appliance, which is indicated by the data plate.

• The voltage is in the range between the values

6

! The cable must be checked regularly and replaced

by authorised technicians only.

! The manufacturer declines any liability should

these safety measures not be observed.

Gas connection

Connection to the gas network or to the gas cylinder

may be carried out using a flexible rubber or steel hose,

in accordance with current national legislation and after

making sure that the appliance is suited to the type of gas

with which it will be supplied (see the rating sticker on

the cover: if this is not the case see below). When using

liquid gas from a cylinder, install a pressure regulator

which complies with current national regulations. To

make connection easier, the gas supply may be turned

sideways*: reverse the position of the hose holder with

that of the cap and replace the gasket that is supplied

with the appliance.

! Check that the pressure of the gas supply is

consistent with the values indicated in the Table

of burner and nozzle specifications (see below).

This will ensure the safe operation and durability of

your appliance while maintaining efficient energy

consumption.

Gas connection using a flexible rubber hose

Make sure that the hose complies with current national

legislation. The internal diameter of the hose must

measure: 8 mm for liquid gas supply; 13 mm for

methane gas supply.

Once the connection has been performed, make sure

that the hose:

• Does not come into contact with any parts that reach

temperatures of over 50°C.

• Is not subject to any pulling or twisting forces and

that it is not kinked or bent.

• Does not come into contact with blades, sharp

corners or moving parts and that it is not

compressed.

• Is easy to inspect along its whole length so that its

Page 7

condition may be checked.

• Is shorter than 1500 mm.

• Fits firmly into place at both ends, where it will

be fixed using clamps that comply with current

regulations.

3. Replace all the components

by following the above

instructions in reverse.

Adjusting the hob burners’

minimum setting:

GB

! If one or more of these conditions is not fulfilled

or if the cooker must be installed according to the

conditions listed for class 2 - subclass 1 appliances

(installed between two cupboards), the flexible steel

hose must be used instead (see below).

Connecting a flexible jointless stainless steel pipe

to a threaded attachment

Make sure that the hose and gaskets comply with

current national legislation.

To begin using the hose, remove the hose holder on

the appliance (the gas supply inlet on the appliance is

a cylindrical threaded 1/2 gas male attachment).

! Perform the connection in such a way that the hose

length does not exceed a maximum of 2 metres,

making sure that the hose is not compressed and does

not come into contact with moving parts.

Checking the tightness of the connection

When the installation process is complete, check the

hose fittings for leaks using a soapy solution. Never

use a flame.

1. Turn the tap to the minimum

2. Remove the knob and adjust

the regulatory screw, which is positioned inside or next

to the tap pin, until the flame is small but steady.

! If the appliance is connected to a liquid gas supply,

the regulatory screw must be fastened as tightly as

possible:

the

burner

While

3.

alight, quickly change the position of the knob from

minimum to maximum and vice versa several times,

checking that the flame is not extinguished.

! The hob burners do not require primary air

adjustment.

! After adjusting the appliance so it may be used with

a different type of gas, replace the old rating label with

a new one that corresponds to the new type of gas

(these labels are available from Authorised Technical

Assistance Centres).

is

position.

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

Adapting the hob

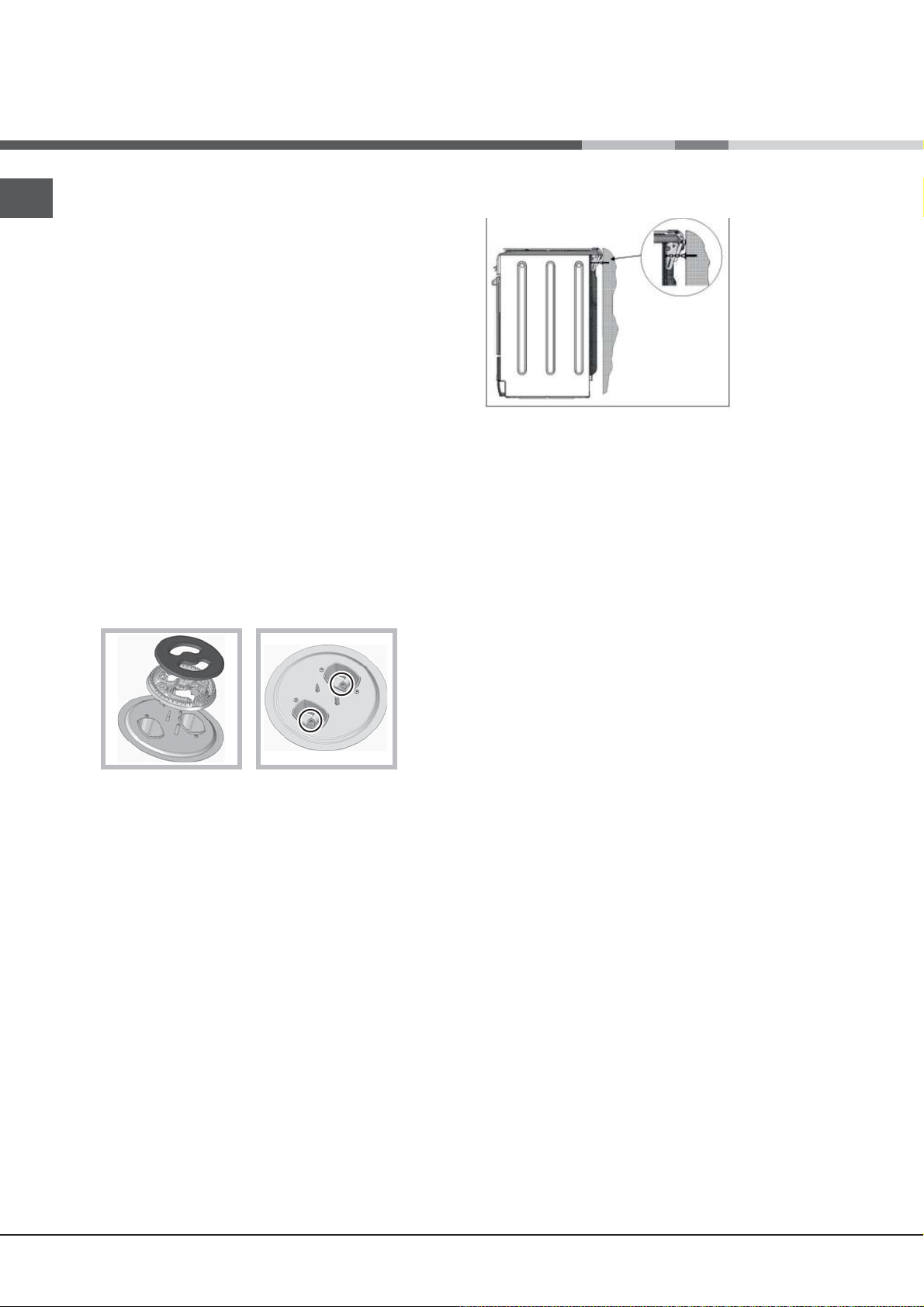

Replacing the nozzles for the hob burners:

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner

(see gure), and replace them with nozzles suited to

the new type of gas (see Burner and nozzle speci cations

table).

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating to

“regulators for channelled gas”.

7

Page 8

GB

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of their

housing. The burner consists of two separate parts (see

pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The two

nozzles have the same hole diameter.

3. Replace all the components by completing the above

operations in reverse order.

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the adjustment screw, which

is positioned in or next to the tap pin, until the flame is

small but steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

Safety Chain

! In order

to prevent

accidental

tipping of the

appliance, for

example by

a child climbing onto the

oven door, the

supplied safety

chain MUST be

installed!

The cooker is fitted with a safety chain to be fixed by

means of a screw (not supplied with the cooker) to

the wall behind the appliance, at the same height as

the chain is attached to the appliance.

Choose the screw and the screw anchor according

to the type of material of the wall behind the appliance. If the head of the screw has a diameter smaller

than 9mm, a washer should be used. Concrete wall

requires the screw of at least 8mm of diameter, and

60mm of length.

Ensure that the chain is fixed to the rear wall of the

cooker and to the wall, as shown in figure, so that

after installation it is tensioned and parallel to the

ground level.

4. Some appliances have a safety device

(thermocouple) fitted. If the device fails to work

when the burners are set to the low flame setting,

increase this low flame setting using the adjusting

screw.

5. Once the adjustment has been made, replace the

seals on the by-passes using sealing wax

! If the appliance is connected to liquid gas, the

regulation screw must be fastened as tightly as

possible.

! Once this procedure is finished, replace the old

rating sticker with one indicating the new type of gas

used. Stickers are available from any of our Service

Centres.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in

order to comply with current national regulations).

8

Page 9

Table of burner and nozzle specifications

S

R

TC A

Table 1 Liquid gas Natural gas

Burner Diameter

(mm)

Triple.ring (TC) 130 3.25 1.50 63 2,x65 236 232 2x99 309

Rapid (Large)

(R)

Semi-rapid

(Medium) (S)

Auxiliary

(Small) (A)

Supply

pressure

* At 15°C and 1013 mbar - dry gas

** Propane P.C.S. = 50.37 MJ/kg

*** Butane P.C.S. = 49.47 MJ/kg

Natural P.C.S. = 37.78 MJ/m³

100 3.00 0.70 41 86 218 214 116 286

75 1.90 0.40 30 70 138 136 106 181

55 1.00 0.40 30 50 73 71 79 95

Maximised (mbar)

CX65SP6 PT/HA

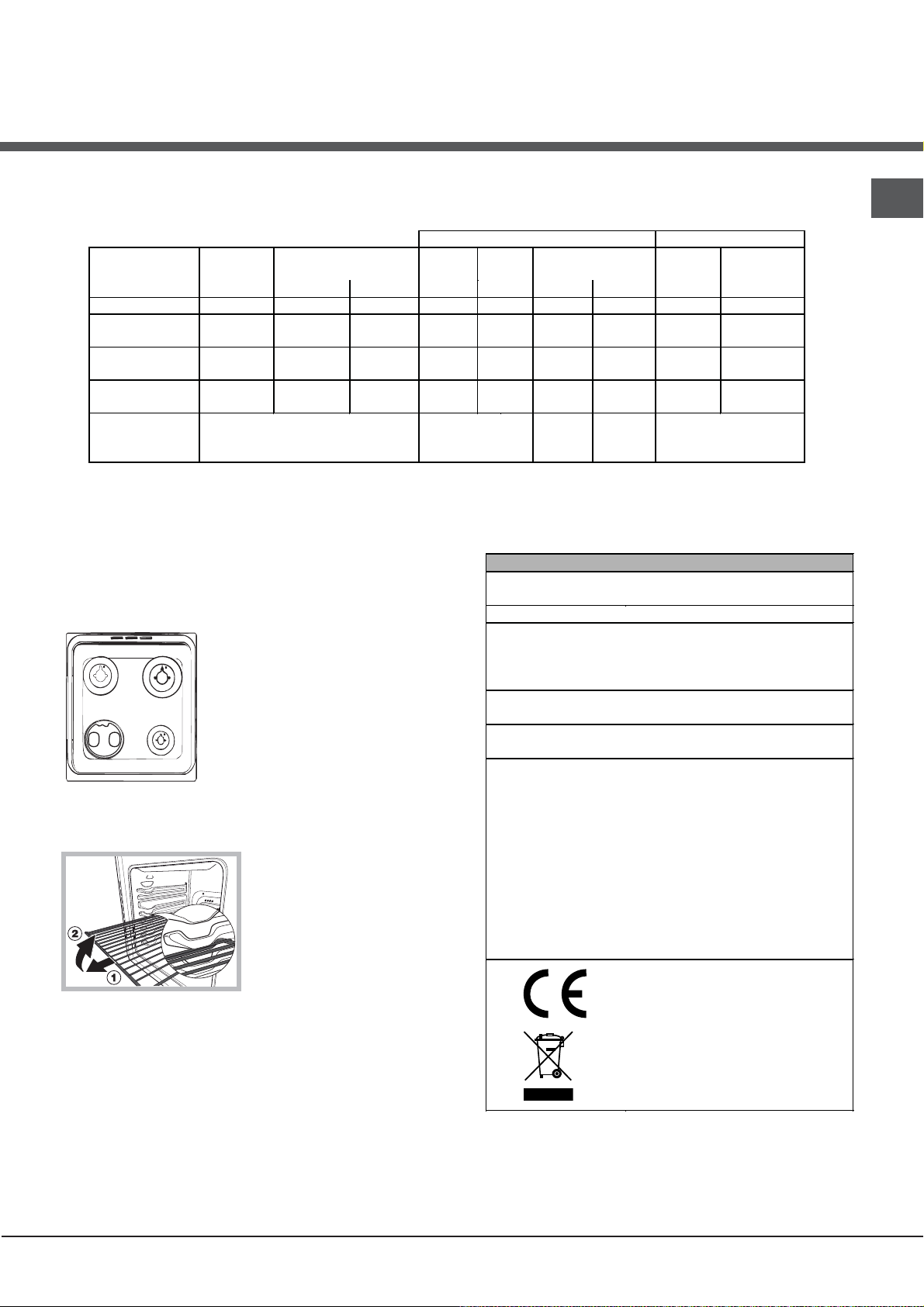

WARNING! The oven is

provided with a stop system to extract the racks

and prevent them from

coming out of the oven.(1)

As shown in the drawing,

to extract them completely, simply lift the racks,

holding them on the front

part, and pull (2).

Thermal power

kW (p.c.s.*)

Nominal Reduced *** **

Nomina l (mbar)

Minimal (mbar)

Bypass

1/100

(mm)

Nozzle

1/100

(mm)

TECHNICAL DATA

Oven dimensions

(HxWxD)

Volume

Useful

measurements

relating to the oven

compartment

Burners

Voltage and

frequency

ENERGY LABEL

Data plate, is located inside the flap or, after the oven

compartment has been opened, on the left-hand wall

inside the oven.

Capacity*

g/h

28-30

20

35

Nozzle

1/100

(mm)

37

25

45

32x43.5x40 cm

56 l

width 42 cm

depth 44 cm

height 8.5 cm

may be adapted for use with any

type of gas shown on the data plate

see data plate

Directive 2002/40/EC on the label

of electric ovens.

Regulation EN 50304

Energy consumption for Natural

convection – heating mode:

X

Traditional mode;

Declared energy consumption for

Forced convection Class –

heating mode:

EC Directives: 2006/95/EC dated

12/12/06 (Low Voltage) and

subsequent amendments 2004/108/EC dated 15/12/04

(Electromagnetic Compatibility)

and subsequent amendments 2004/142/EC dated 30/11/09

(Gas) 1275/2008 (Stand-by/ Off

mode)

Capacity*

20

17

25

u

Baking.

GB

l/h

9

Page 10

Start-up and use

GB

Using the hob

Lighting the burners

For each BURNER knob there is a complete ring showing

the strength of the flame for the relevant burner.

To light one of the burners on the hob:

1. Bring a flame or gas lighter close to the burner.

2. Press the BURNER knob and turn it in an

anticlockwise direction so that it is pointing to the

maximum flame setting E.

3. Adjust the intensity of the flame to the desired level by

turning the BURNER knob in an anticlockwise direction.

This may be the minimum setting C, the maximum setting

E or any position in between the two.

If the appliance is fitted with an

electronic lighting device* (see

gure), press the BURNER knob

and turn it in an anticlockwise

direction, towards the minimum

flame setting, until the burner

is lit. The burner may be

extinguished when the knob is

released. If this occurs, repeat

the operation, holding the knob down for a longer period

of time.

! If the flame is accidentally extinguished, switch off the

burner and wait for at least 1 minute before attempting

to relight it.

If the appliance is equipped with a flame failure

safety device*, press and hold the BURNER knob for

approximately 2-3 seconds to keep the flame alight

and to activate the device.

To switch the burner off, turn the knob until it reaches

the stop position •.

Practical advice on using the burners

For the burners to work in the most efficient way

possible and to save on the amount of gas consumed,

it is recommended that only pans that have a lid and

a flat base are used. They should also be suited to the

size of the burner:

! For models equipped with a reducer grid, the latter

must be used only for the auxiliary burner, when pans

with a diameter of less than 12 cm are used.

Using the oven

! The first time you use your appliance, heat the empty

oven with its door closed at its maximum temperature

for at least half an hour. Ensure that the room is well

ventilated before switching the oven off and opening

the oven door. The appliance may emit a slightly

unpleasant odour caused by protective substances

used during the manufacturing process burning away.

! Never put objects directly on the bottom of the oven;

this will avoid the enamel coating being damaged.

! Before operating the product, remove all plastic film

from the sides of the appliance.

1. Select the desired cooking mode by turning the

SELECTOR knob.

2. Select the recommended temperature for the

cooking mode or the desired temperature by turning

the THERMOSTAT knob.

A list detailing cooking modes and suggested cooking

temperatures can be found in the relevant table (see

Oven cooking advice table).

During cooking it is always possible to:

• Change the cooking mode by turning the

SELECTOR knob.

• Change the temperature by turning the

THERMOSTAT knob.

• Stop cooking by turning the SELECTOR knob to the

“0” position.

! Always place cookware on the rack(s) provided.

THERMOSTAT indicator light

When this is illuminated, the oven is generating heat.

It switches off when the inside of the oven reaches

the selected temperature. At this point the light

illuminates and switches off alternately, indicating

that the thermostat is working and is maintaining the

temperature at a constant level.

To identify the type of burner, please refer to the

diagrams contained in the “Burner and nozzle

specifications”.

10

OPERATION indicator light

When this is illuminated, the oven is generating heat.

Oven light

This is switched on by turning the SELECTOR knob to

any position other than “0”. It remains lit as long as the

8

oven is operating. By selecting

light is switched on without any of the heating elements

being activated.

with the knob, the

Page 11

Cooking modes

! A temperature value can be set for all cooking modes

between 60°C and Max, except for the following modes

• GRILL (recommended: set only to MAX power level)

• GRATIN (recommended: do not exceed 200°C).

X

TRADITIONAL OVEN mode

d

The central part of the top heating element is switched

on. The high and direct temperature of the grill is

recommended for food that requires a high surface

temperature (veal and beef steaks, fillet steak and

entrecôte). This cooking mode uses a limited amount of

energy and is ideal for grilling small dishes. Place the

food in the centre of the rack, as it will not be cooked

properly if it is placed in the corners.

GRILL mode

GB

Both the top and bottom heating elements will come

on. When using this traditional cooking mode, it is best

to use one cooking rack only. If more than one rack is

used, the heat will be distributed in an uneven manner.

u

BAKING mode

The rear heating element and the fan are switched

on, thus guaranteeing the distribution of heat in a

delicate and uniform manner throughout the entire

oven. This mode is ideal for baking and cooking

temperature sensitive foods (such as cakes that need

to rise) and for the preparation of pastries on 3 shelves

simultaneously.

W

The heating elements and the fan come on,

guaranteeing the distribution of heat consistently and

uniformly throughout the oven.

Preheating is not necessary for this cooking mode. This

mode is particularly suitable for cooking pre-packed

food quickly (frozen or pre-cooked). The best results

are achieved using one cooking rack only.

Y

FAST COOKING mode

MULTI-COOKING mode

GRATIN

e

The top heating element and the rotisserie (where

present) are activated and the fan begins to

operate. This combination of features increases the

effectiveness of the unidirectional thermal radiation

provided by the heating elements through forced

circulation of the air throughout the oven. This helps

prevent food from burning on the surface and allows

the heat to penetrate right into the food.

! The GRILL and GRATIN cooking modes must be

performed with the oven door shut.

Timer*

To activate the Timer proceed as follows:

1. Turn the TIMER knob in a clockwise direction 4 for

almost one complete revolution to set the buzzer.

2. Turn the TIMER knob in an anticlockwise direction 5

to set the desired length of time.

mode

Practical cooking advice

! Do not place racks in position 1 or 5 during fanassisted cooking. Excessive direct heat can burn

temperature sensitive foods.

All the heating elements (top, bottom and circular)

switch on and the fan begins to operate. Since the heat

remains constant throughout the oven, the air cooks

and browns food in a uniform manner. A maximum of

two racks may be used at the same time.

Z

The circular heating elements and the elements at

the bottom of the oven are switched on and the fan is

activated. This combination heats the oven rapidly by

producing a considerable amount of heat, particularly

from the element at the bottom. If you use more than

one rack at a time, switch the position of the dishes

halfway through the cooking process.

PIZZA mode

MULTILEVEL

• Use positions 2 and 4, placing the food that requires

more heat on the rack in position 2.

• Place the dripping pan on the bottom and the rack

on top.

GRILL

• When using the GRILL cooking mode, place the rack

in position 5 and the dripping pan in position 1 to

collect cooking residues (fat and/or grease). When

using the GRATIN cooking mode, place the rack in

position 2 or 3 and the dripping pan in position 1 to

collect cooking residues.

• We recommend that the power level is set to

maximum. The top heating element is regulated by a

thermostat and may not always operate constantly.

11

Page 12

GB

PIZZA MODE

• Use a light aluminium pizza pan. Place it on the rack

provided.

For a crispy crust, do not use the dripping pan as

Oven cooking advice table

it prevents the crust from forming by extending the

total cooking time.

• If the pizza has a lot of toppings, we recommend

adding the mozzarella cheese on top of the pizza

halfway through the cooking process.

Cooking

modes

Traditional

Oven

Baking

Mode

Fast

cooking

Multi-

cooking

Pizza Mode

Barbecue

Gratin

Foods Weight

(in kg)

Rack Position Pre-heating

time

(minutes)

Duck

Roast veal or beef

Pork roast

Biscuits (short pastry)

Tarts

Tarts

Fruit cakes

Plum cake

Sponge cake

Stuffed pancakes (on 2 racks)

Small cakes (on 2 racks)

Cheese puffs (on 2 racks)

Cream puffs (on 3 racks)

Biscuits (on 3 racks)

Meringues (on 3 racks)

Frozen food

Pizza

Courgette and prawn pie

Country style spinach pie

Turnovers

Lasagne

Golden Rolls

Chicken morsels

Pre-cooked food

Golden chicken wings

Fresh Food

Biscuits (short pastry)

Plum cake

Cheese puffs

Pizza (on 2 racks)

Lasagne

Lamb

Roast chicken + potatoes

Mackerel

Plum cake

Cream puffs (on 2 racks)

Biscuits (on 2 racks)

Sponge cake (on 1 rack)

Sponge cake (on 2 racks)

Savoury pies

Pizza

Roast veal or beef

Chicken

Soles and cuttlefish

Squid and prawn kebabs

Cuttlefish

Cod filet

Grilled vegetables

Veal steak

Sausages

Hamburgers

Mackerels

Toasted sandwiches (or toast)

Grilled chicken

Cuttlefish

1

1

1

-

1

0.5

1

0.7

0.5

1.2

0.6

0.4

0.7

0.7

0.5

0.3

0.4

0.5

0.3

0.5

0.4

0.4

0.4

0.3

0.6

0.2

1

1

1

1+1

1

1

0.5

0.5

0.5

1

1.5

0.5

1

1

0.7

0.6

0.6

0.8

0.4

0.8

0.6

0.6

1

4 and 6

1.5

1.5

3

3

3

3

3

3

2 or 3

3

3

2 and 4

2 and 4

2 and 4

1 and 3 and 5

1 and 3 and 5

1 and 3 and 5

2

2

2

2

2

2

2

2

2

2

2

2 and 4

3

2

2 and 4

2

2

2 and 4

2 and 4

2

2 and 4

3

3

2

2 or 3

4

4

4

4

3 or 4

4

4

4

4

4

2

2

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

-

-

-

-

-

-

-

-

-

-

15

10

10

15

10

10

10

10

10

10

15

15

10

10

-

-

-

-

-

-

-

-

-

10

10

Recommended

temperature

200

200

200

180

180

180

180

180

160

200

190

210

180

180

90

250

200

220

200

200

180

220

200

200

180

210

230

180

180

200

180

170

190

180

170

170

200

220

220

180

Max

Max

Max

Max

Max

Max

Max

Max

Max

Max

200

200

Cooking

time

(minutes)

65-75

70-75

70-80

15-20

30-35

20-30

40-45

40-50

25-30

30-35

20-25

15-20

20-25

20-25

180

12

20

30-35

25

35

25-30

15-20

20-25

15-18

45

10-12

15-20

30-35

40-45

60-70

30-35

40-50

20-25

10-15

15-20

20-25

25-30

15-20

25-30

60-70

10-12

8-10

10-15

10-15

15-20

15-20

15-20

10-12

15-20

3-5

55-60

30-35

12

Page 13

Planning cooking with the electronic

programmer

Setting the clock

After the appliance has been connected to the

power supply, or after a blackout, the display will

automatically reset to 0:00 and begin to blink. To set

the time:

and the

1. Press the COOKING TIME button

COOKING END TIME simultaneously.

2. Within 4 seconds of having pressed these buttons,

set the exact time by pressing the

button advances the hours and the button

The

decreases the hours.

Once the time has been set, the programmer

automatically switches to manual mode.

Setting the timer

The timer enables a countdown to be set, when the

time has elapsed a buzzer sounds.

To set the timer proceed as follows:

1. press the TIMER button

. The display shows:

and buttons.

.

2. Press the and buttons to set the desired time.

3. When the buttons are released the timer begins

counting down and the current time appears on the

display.

4. After the time has elapsed a buzzer will sound, and

this can be switched off by pressing any button (except

and buttons). The symbol will switch off.

the

! The timer does not switch the oven on or off.

Adjusting the volume of the buzzer

After selecting and confirming the clock settings, use

button to adjust the volume of the alarm buzzer.

the

Setting the cooking time with a delayed start

First decide which cooking mode you wish to use and

set a suitable temperature using the SELECTOR and

THERMOSTAT knobs on the oven.

At this point it is possible to set the cooking time:

1. Press the COOKING TIME button

2. Within 4 seconds of having pressed this button, set

the desired amount of time by pressing the

buttons. If, for example, you wish to set a cooking time

of 30 minutes, the display will show:

.

and

3. 4 seconds after the buttons are released, the current

time (for example 10.00) reappears on the display with

the symbol

Next the desired cooking end time must be set:

4. Press the END COOKING TIME button

5. Within 4 seconds of having pressed this button,

adjust the cooking end time by pressing the

buttons. If, for example, you want cooking to end at

13.00, the display shows:

and the letter A (AUTO).

.

and

6. 4 seconds after the buttons are released, the current

time (for example 10.00) reappears on the display with

the letter A (AUTO).

At this point, the oven is programmed to switch on

automatically at 12:30 and switch off after 30 minutes,

at 13.00.

Setting the cooking time with an immediate start

Follow the above procedure for setting the cooking

time (points 1-3).

! When the letter A appears, this indicates that both

the cooking time and the end cooking time have been

programmed in AUTO mode. To restore the oven to

manual operation, after each AUTO cooking mode

and END COOKING

press the COOKING TIME

buttons simultaneously.

TIME

! The symbol will remain lit, along with the oven, for

the entire duration of the cooking programme.

The set cooking duration can be displayed at any time

by pressing the COOKING TIME button

the cooking end time may be displayed by pressing

the END COOKING TIME button

time has elapsed a buzzer sounds. To stop it, press

any button apart from the

. When the cooking

and buttons.

, and

GB

13

Page 14

Precautions and tips

! This appliance has been designed and manufactured

in compliance with international safety standards.

The following warnings are provided for safety reasons

and must be read carefully.

General safety

• The appliance was designed for domestic use inside

the home and is not intended for commercial or

industrial use.

• The appliance must not be installed outdoors, even in

covered areas. It is extremely dangerous to leave the

appliance exposed to rain and storms.

• Do not touch the appliance with bare feet or with wet

or damp hands and feet.

• The appliance must be used by adults only for

the preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous.

The manufacturer may not be held liable for any

damage resulting from improper, incorrect and

unreasonable use of the appliance.

• The instruction booklet accompanies a class 1

(insulated) or class 2 - subclass 1 (recessed

between 2 cupboards) appliance.

• Do not touch the heating elements or certain

parts of the oven door when the appliance is in

use; these parts become extremely hot. Keep

children well away from the appliance.

• Make sure that the power supply cables of other

electrical appliances do not come into contact with

the hot parts of the oven.

• The openings used for the ventilation and dispersion

of heat must never be covered.

• Always use oven gloves when placing cookware in

the oven or when removing it.

• Do not use flammable liquids (alcohol, petrol, etc...)

near the appliance while it is in use.

• Do not place flammable material in the lower storage

compartment or in the oven itself. if the appliance is

switched on accidentally, they could catch fire.

• The internal surfaces of the compartment (where

present) may become hot.

•

• Always make sure the knobs are in the

when the appliance is not in use.

• When unplugging the appliance, always pull the

plug from the mains socket; do not pull on the cable.

• Never perform any cleaning or maintenance work

without having disconnected the appliance from the

electricity mains.

• If the appliance breaks down, under no

circumstances should you attempt to perform

the repairs yourself. Repairs carried out by

inexperienced persons may cause injury or further

malfunctioning of the appliance. Contact Assistance.

position

• Do not rest heavy objects on the open oven door.

• The appliance should not be operated by people

(including children) with reduced physical, sensory

or mental capacities, by inexperienced individuals

or by anyone who is not familiar with the product.

These individuals should, at the very least, be

supervised by someone who assumes responsibility

for their safety or receive preliminary instructions

relating to the operation of the appliance.

• Do not let children play with the appliance.

•

If the cooker is placed on a pedestal, take the necessary precautions to prevent the cooker from sliding

off the pedestal itself.

Disposal

• When disposing of packaging material: observe

local legislation so that the packaging may be

reused.

• The European Directive 2002/96/EC relating

to Waste Electrical and Electronic Equipment

(WEEE) states that household appliances should

not be disposed of using the normal solid urban

waste cycle. Exhausted appliances should be

collected separately in order to optimise the cost

of re-using and recycling the materials inside the

machine, while preventing potential damage to the

atmosphere and to public health. The crossed-out

dustbin is marked on all products to remind the

owner of their obligations regarding separated

waste collection.

For further information relating to the correct

disposal of exhausted household appliances,

owners may contact the public service provided or

their local dealer.

Respecting and conserving the

environment

• You can help to reduce the peak load of the

electricity supply network companies by using the

oven in the hours between late afternoon and the

early hours of the morning.

• Always keep the oven door closed when using

the GRILL and GRATIN modes: This will achieve

improved results while saving energy (approximately

10%).

• Check the door seals regularly and wipe them clean

to ensure they are free of debris so that they adhere

properly to the door, thus avoiding heat dispersion.

GB

14

Page 15

Care and maintenance

GB

Switching the appliance off

Disconnect your appliance from the electricity supply

before carrying out any work on it.

Cleaning the appliance

! Never use steam cleaners or pressure cleaners on

the appliance.

• The stainless steel or enamel-coated external parts

and the rubber seals may be cleaned using a

sponge that has been soaked in lukewarm water

and neutral soap. Use specialised products for the

removal of stubborn stains. After cleaning, rinse well

and dry thoroughly. Do not use abrasive powders or

corrosive substances.

• The hob grids, burner caps, flame spreader rings

and burners may be removed to make cleaning

easier; wash them in hot water and non-abrasive

detergent, making sure all burnt-on residue is

removed before drying them thoroughly.

Inspecting the oven seals

Check the door seals around the oven regularly. If

the seals are damaged, please contact your nearest

Authorised After-sales Service Centre. We recommend

that the oven is not used until the seals have been

replaced.

Replacing the oven light bulb

1. After disconnecting the

oven from the electricity mains,

remove the glass lid covering the

lamp socket (see gure).

2. Remove the light bulb and

replace it with a similar one:

voltage 230 V, wattage 25 W,

cap E 14.

3. Replace the lid and reconnect the oven to the

electricity supply.

! Do not use the oven lamp as/for ambient lighting.

• Clean the terminal part of the flame failure safety

devices* frequently.

• The inside of the oven should ideally be cleaned

after each use, while it is still lukewarm. Use hot

water and detergent, then rinse well and dry with a

soft cloth. Do not use abrasive products.

• Clean the glass part of the oven door using a

sponge and a non-abrasive cleaning product, then

dry thoroughly with a soft cloth. Do not use rough

abrasive material or sharp metal scrapers as these

could scratch the surface and cause the glass to

crack.

• The accessories can be washed like everyday

crockery, and are even dishwasher safe.

• Do not close the cover when the burners are alight

or when they are still hot.

WARNING! The glass lid can break

in if it is heated up. Turn off all the

burners and the electric plates before closing the lid.

Gas tap maintenance

Over time, the taps may become jammed or difficult to

turn. If this occurs, the tap must be replaced.

! This procedure must be performed by a qualified

technician authorised by the manufacturer.

Assistance

! Never use the services of an unauthorised technician.

Please have the following information to hand:

• The type of problem encountered.

• The appliance model (Mod.).

• The serial number (S/N).

The latter two pieces of information can be found on the

data plate located on the appliance.

15

Page 16

Instalação

! É importante guardar este folheto para poder

consultá-lo a qualquer momento. No caso de venda,

cessão ou mudança, assegure-se que o mesmo

permaneça com o aparelho.

! Leia com atenção as instruções: nas quais há

informações importantes sobre a instalação, a

utilização e a segurança.

! A instalação do aparelho deve ser realizada segundo

estas instruções e por pessoal profissional qualificado.

! Qualquer intervenção de regulação ou manutenção,

deve ser efectuada com o fogão desligado da rede

eléctrica.

Ventilação dos locais

O aparelho poderá ser instalado somente em locais

permanentemente ventilados, nos termos previstos

pelos regulamentos nacionais em vigor. No local no

qual o aparelho é instalado deve poder chegar tanto ar

quanto pedido pela regular combustão do gás (o fluxo

de ar não deve ser inferior a 2 m

instalada).

As tomadas de admissão do ar, protegidas por

grades, devem ter uma conduta de ao menos 100

2

de secção útil e devem ser colocadas em modo

cm

que não possam ser obstruídas, mesmo parcialmente

(ver gura A).

Estas tomadas de ar devem ser aumentadas de 100%

- com um mínimo de 200 cm

plano de trabalho do fogão não tenha o dispositivo

de segurança para a falta de chama e quando o fluxo

de ar ocorre em modo indirecto a partir de locais

adjacentes (ver gura B) - desde que não constituam

partes comuns do imóvel, ambientes com perigo de

incêndio ou quartos de dormir - que possuam um

conduto de ventilação comunicador com a parte

externa, como descrito acima.

Sala ao lado Sala a ser ventilada

A B

3

/h por kW de potência

2

– no caso em que o

Descarga dos fumos de combustão

A descarga dos fumos de combustão deve ser

garantida por meio de um exaustor ligado a uma

chaminé com tiragem natural de segura eficiência,

ou por meio de uma ventoinha eléctrica que entre

automaticamente em função cada vez que se ligar o

aparelho (ver guras).

Descarga directamente Descarga através de uma

para o exterior chaminé ou uma conduta

para fumo ramificada

(reservada para os

aparelhos de

cozedura).

! Os gases liquefeitos de petróleo, mais pesados

que o ar, ficam em baixo, portanto os locais onde

estão contidos os recipientes de GLP devem prever

aberturas para o exterior para o escoamento das

eventuais fugas de gás.

Os cilindros de GLP, mesmo vazios ou parcialmente

cheios, não devem ser instalados nem guardados

em lugares ou vãos a nível mais baixo do que o solo

(caves etc.). Manter no local somente o cilindro que

estiver sendo utilizado, longe de fontes de calor

(fornos, chaminés, esquentadores) que possam levá-lo

a uma temperatura superior a 50ºC.

PT

Posicionamento e nivelamento

! É possível instalar o aparelho ao lado de móveis que

não superem a altura do plano de trabalho.

! Assegurar-se de que a parede em contacto com a

parte traseira do aparelho seja de um material não

inflamável e resistente ao calor (T 90°C).

A

Abertura para ventilação Aumento do vão entre

do ar comburente a porta e o chão

! Após um uso prolongado do aparelho é aconselhável

abrir uma janela ou aumentar a velocidade dos

eventuais ventiladores.

Para uma instalação correcta:

• colocar o aparelho na cozinha, na sala de jantar ou

numa sala única (não na casa de banho);

• se o plano da cozinha for mais alto que o dos

móveis, estes deverão ser colocados a pelo menos

600 mm do aparelho;

16

Page 17

PT

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min. mm.

420

Min. mm.

• se o fogão for

instalado embaixo de

uma prateleira, esta

deverá estar pelo menos

a 420 mm. (milímetros) do

plano de trabalho.

Tal distância deve ser de

700 mm se as prateleiras

forem de material

inflamável (ver gura);

• não colocar cortinas atrás do fogão ou a menos de

200 mm dos seus lados;

• se houver exaustor, o mesmo deverá ser instalado

seguindo as indicações contidas no relativo livrete

de instruções.

• a tensão de alimentação seja entre os valores da

placa de identificação;

• a tomada seja compatível com a ficha do aparelho.

Em caso contrário, substitua a tomada ou a ficha;

não empregue extensões nem tomadas múltiplas.

! Depois de ter instalado o aparelho, o acesso ao cabo

eléctrico e à tomada da corrente deve ser fácil.

! O cabo não deve ser dobrado nem comprimido.

! O cabo deve ser verificado periodicamente e

substituído somente por técnicos autorizados.

! A empresa exime-se de qualquer responsabilidade

se estas regras não forem obedecidas.

Ligação ao gás

Nivelamento

Se for necessário nivelar o

aparelho, parafusar os pés

de regulação fornecidos em

dotação nos específicos

lugares colocados nos cantos

na base do fogão (ver gura).

As pernas* devem ser

encaixadas na base do fogão.

Ligação eléctrica

Monte no cabo uma ficha em conformidade com

as normas para a carga indicada na placa de

identificação (veja a tabela dos Dados técnicos).

No caso de uma ligação directa à rede, será

necessário interpor, entre o aparelho e a rede, um

interruptor omnipolar com abertura mínima entre os

contactos de 3 mm. na dimensão certa para a carga

e em conformidade com as normas nacionais em

vigor (a ligação à terra não deve ser interrompida pelo

interruptor). O cabo de alimentação deve ser colocado

de maneira que em nenhum ponto ultrapasse de 50°C

a temperatura do ambiente.

Antes de efectuar a ligação, certifique-se que:

• a tomada tenha uma ligação à terra e seja em

conformidade com a legislação;

• a tomada tenha a capacidade de suportar a carga

máxima de potência da máquina, indicada na placa

de identificação;

17

A ligação do aparelho à rede do gás ou à botija do

gás pode ser efectuada com um tubo flexível de

borracha ou de aço, conforme prescrito pelas normas

nacionais em vigor e somente após ter controlado que

o mesmo esteja regulado para o tipo de gás com o

qual será alimentado (veja a etiqueta de calibragem

sobre a tampa: em caso contrárioveja abaixo). Em

caso de alimentação com gás líquido de botija, utilizar

reguladores de pressão em conformidade com as

normas nacionais em vigor. Para facilitar a ligação, a

alimentação do gás é orientável lateralmente *: inverter

o porta-borracha para a ligação com a tampa de fecho

e substituir a guarnição de vedação fornecida em

dotação.

! Para garantir um funcionamento seguro, uma

utilização de energia apropriada e maior duração

da aparelhagem, assegurar-se que a pressão de

alimentação respeite os valores indicados na tabela

“Características dos queimadores e dos bicos” (ver

abaixo).

Ligação do gás com tubo flexível de borracha

Verificar que o tubo seja em conformidade com as

normas nacionais em vigor. O diâmetro interno do tubo

deve ser de: 8 mm para a alimentação com gás líquido;

13 mm para a alimentação com gás metano.

Quando a ligação estiver terminada, assegure-se de

que o tubo:

• não esteja em contacto em ponto algum com partes

que alcancem temperaturas superiores a 50ºC;

• não esteja sujeito a qualquer esforço de tracção e

de torção não apresente dobras nem apertos;

• não encoste em corpos cortantes, arestas agudas

nem em peças móveis e não esteja esmagado;

• seja fácil de inspeccionar ao longo de todo o próprio

Page 18

percurso, a fim de poder-se controlar o estado de

conservação do mesmo;

• tenha um comprimento menor do que 1500 mm;

• esteja bem apoiado nas duas pontas, onde deve

ser fixado mediante braçadeiras de bloqueio nos

termos dos regulamentos nacionais em vigor.

Ponto de

ligação

Fita isoladora

Conjunto

do tubo

Ponto de

ligação

Conjunto

do tubo

SUPERFÍCIE QUENTE

Fita

isoladora

! Se uma ou mais destas condições não puder ser

respeitada ou se o fogão for instalado conforme

as condições da classe 2 – subclasse 1 (aparelho

encaixando entre dois móveis), deverá ser utilizado o

tubo flexível de aço (ver abaixo).

Ligação com tubo flexível de aço inoxidável com

parede contínua com rosca

Verificar que o tubo e as guarnições sejam em

conformidade com as normas nacionais em vigor.

Para poder instalar o tubo, elimine o porta-borracha

presente no aparelho (a junta de entrada de gás no

aparelho tem rosca de 1/2 gás macho cilíndrica).

! Efectuar a ligação em modo que o comprimento da

tubagem não supere os 2 metros de extensão máxima

e assegurar-se de que o tubo não entre em contacto

com partes móveis e não seja esmagado.

Controle da vedação

Ao terminar a instalação controlar a vedação de todas

as juntas utilizando uma solução de sabão e nunca

uma chama.

3. coloque outra vez todas as

peças no lugar, realizando as operações na ordem

contrária à acima apresentada.

Regulação do mínimo dos queimadores do plano:

1. coloque a torneira na posição de mínimo;

2. retire o selector e ajuste o parafuso de regulação

situado no interior ou ao lado da haste da torneira até

obter uma pequena chama regular.

! No caso dos gases líquidos, o parafuso de regulação

deve ser atarraxado até o fundo;

verifique em seguida se ao girar rapidamente a

3.

torneira da posição de máximo até a de mínimo, o

queimador não se apague;

! Os queimadores do plano não precisam de nenhuma

regulação do ar primário.

! Após a regulação com um gás diferente daquele com

o qual foi aferido o aparelho, troque a velha etiqueta

de calibragem por outra que corresponda ao novo tipo

de gás, que pode ser encontrada junto aos nossos

Centros de Assistência Técnica Autorizados.

! Se a pressão do gás utilizado for diferente (ou

variável) daquela prevista, é necessário instalar

na tubagem de entrada um regulador de pressão

conforme as Normas Nacionais em vigor sobre os

“reguladores para gás canalizados”.

PT

Adaptação aos diferentes tipos de gás

É possível adaptar o aparelho a um tipo de gás

diferente daquele para o qual foi preparado (indicado

na etiqueta de calibragem na tampa).

Adaptação ao plano de cozedura

Substituição dos bicos dos queimadores do plano:

1. retire as grades e desenfie os queimadores das

suas sedes;

2. desparafusar os bicos

utilizando uma chave a tubo de

7 mm (ver gura), e substituí-los

com aqueles apropriados para

o novo tipo de gás (ver tabela

“Características dos queimadores

e dos bicos”);

Substituição dos bicos do queimador de tripla coroa

1. retire as grelhas e extraia os queimadores das suas sedes.

O queimador é composto por duas partes separadas (ver

figuras);

2. desenrosque os bicos, utilizando uma chave de tubo de 7

mm. Troque os bicos por outros adequados ao novo tipo

de gás (ver a tabela 1). Os dois bicos têm furos idênticos.

3. volte a colocar todas as peças no lugar, realizando as

operações na ordem contrária à acima apresentada.

18

Page 19

PT

• Regulação do ar primário dos queimadores

Os queimadores não necessitam de qualquer regulação de

ar primário.

• Regulação dos mínimos

1. Coloque a torneira na posição de mínimo;

2. Retire o selector e ajuste o parafuso de regulação situado

no interior ou ao lado da haste da torneira até obter uma

pequena chama regular.

3. Verifique se ao girar rapidamente o botão

da posição de máximo até a de mínimo, os

queimadores não se apagam.

4. Nos aparelhos equipados com dispositivo

de segurança (termopar), em caso de não

funcionamento do dispositivo com os queimadores

no mínimo, aumente a capacidade dos próprios

mínimos mediante o parafuso de regulação.

5. Depois de realizar a regulação, restabeleça os

lacres situados nos ‘by-pass’ com cera lacre ou

materiais equivalentes.

! No caso dos gases líquidos, o parafuso de regulação

deve ser atarraxado até o fundo.

! Ao terminar a operação substitua a velha etiqueta

de calibragem com a que corresponde ao novo

gás utilizado que se acha nos nossos Centros de

Assistência Técnica.

! Se a pressão do gás utilizado for diferente (ou

variável) daquela prevista, é necessário instalar

na tubagem de entrada um regulador de pressão

(conforme as Normas Nacionais em vigor).

anilha. As paredes de betão requerem um parafuso

com pelo menos 8 mm de diâmetro e 60 mm de

comprimento.

Assegure-se de que a correia seja fixada à parede

traseira do fogão e à parede, tal como mostrado

na figura, para que esteja bem esticada após a

instalação e paralela ao nível do chão.

A correia de segurança

! Para evitar a

queda acidental do aparelho,

por exemplo, por uma

criança subir

para a porta

do forno, DEVE

ser instalada

a correia de

segurança

fornecida! O

fogão é instalado com uma correia de segurança fixada com um parafuso (não fornecido com o fogão)

à parede atrás do aparelho, à mesma altura que a

correia é fixada ao aparelho. Seleccione o parafuso

e bucha de acordo com o tipo de material da parede atrás do aparelho. Se a cabeça do aparelho tiver

um diâmetro inferior a 9 mm, deve ser usada uma

19

Page 20

Tabela das características dos queimadores e bicos

S

R

TC A

Tabela 1 Gás Líquido Gás Natural

Queimador Diâmetro

(mm.)

Tripla Coroa

(TC)

Rápido

(Grande)(R)

Semi Rápido

(Médio)(S)

Auxiliar

(Pequeno)(A)

Pressões de

fornecimento

* A 15°C 1013 mbars-gás seco

** Propano P.C.S. = 50,37 MJ/Kg

*** Butano P.C.S. = 49,47 MJ/Kg

Natural P.C.S. = 37,78 MJ/m3

130 3.25 1.50 63 2x65 236 232 2x99 309

100 3.00 0.70 41 86 218 214 116 286

75 1.90 0.40 30 70 138 136 106 181

55 1.00 0.40 30 50 73 71 79 95

Potência térmica

kW (p.c.s.*)

Nominal Reduzida *** **

Nominal (mbar)

Mínima (mbar)

Máxima (mbar)

CX65SP6 PT/HA

ATENÇÃO! O forno está

equipado com um sistema

de bloqueio das grelhas

que permite retirá-las sem

que estas ressaiam do

forno(1).

Para retirar completamente as grelhas, tal como

indicado no desenho, basta levantá-las, segurando-as pela parte da frente, e

puxá-las (2).

By-pass

1/100

(mm)

bico

1/100

(mm)

DADOS TÉCNICOS

Medidas Forno

HxLxP

Volume

Medidas úteis da

gaveta estufa

Queimadores

Tensão e

frequência de

fornecimento

ETIQUETA DE

ENERGIA

O placa de identifi caçăo e’ situada no interior da parte

escamoteável ou, uma vez aberto o compartimento

aquecedor de alimentos, na parede interna esquerda.

vazão*

28-30

20

35

g/h

37

25

45

bico

1/100

(mm)

20

17

25

32x43,5x40 cm

Litros 56

largura 42 cm, profundidade 44

cm, altura 8,5 cm

adaptáveis a todos os tipos de

gás indicados na placa das

características

veja a placa das características

Directiva 2002/40/CE acerca dos

fornos eléctricos. Norma EN 50304

Consumo de energia com

convecção Natural – função de

aquecimento:

Consumo de energia da

declaração de Classe com

convecção Forçada - função de

aquecimento:

Directivas Comunitárias:

2006/95/EC de 12/12/06 (Baixa

Tensão) e posteriores

modificações – -2004/108/EC de

15/12/04 (Compatibilidade

Electromagnética) e posteriores

modificações - 2009/142/EC de

30/11/09 (Gás) e posteriores

modificações - 2002/96/EC.

1275/2008 (Stand-by/ Off mode)

vazão*

l/h

X

Tradicional;

u

Pastelaria.

PT

20

Page 21

Início e utilização

PT

Utilização do plano de cozedura

Acendimento dos queimadores

Em correspondência com cada selector de

QUEIMADOR está indicado um círculo cheio para o

queimador associado.

Para acender um queimador do plano de cozedura:

1. aproximar uma chama ou um acendedor ao

queimador;

2. pressionar e contemporaneamente girar no sentido

contrário ao dos ponteiros do relógio o selector

QUEIMADOR no símbolo da chama máxima E;

3. regular a potência da chama desejada, girando no

sentido contrário ao dos ponteiros do relógio o selector

QUEIMADOR: no mínimo C, no máximo E ou numa

posição intermediária.

Se o aparelho for equipado com

dispositivo de acendimento

electrónico* (ver gura) será

suficiente pressionar e

contemporaneamente girar

no sentido contrário ao dos

ponteiros do relógio o selector

QUEIMADOR no símbolo de

chama mínima, até o acendimento. Pode ocorrer que

o queimador se apague no momento em que se solta

o selector. Neste caso, repetira operação mantendo

pressionado o selector por mais tempo.

! Se a chama do queimador se apagar acidentalmente,

desligue o queimador e aguarde ao menos 1 minuto

antes de tentar novamente o acendimento.

Se o aparelho for equipado com um dispositivo

de segurança* para a falta de chama, mantenha

pressionado o selector do QUEIMADOR por

aproximadamente 2-3 segundos para manter acesa a

chama e activar o dispositivo.

Para apagar o queimador, girar o selector até que se

apague •.

Conselhos práticos para utilização dos queimadores

Para um melhor rendimento dos queimadores e um

consumo mínimo de gás é necessário usar recipientes

de fundo chato, dotados de tampa e proporcionados

ao queimador:

Queimador ř Diâmetro Recipientes (cm)

Rápido (R) 24 - 26

Semi Rápido (S) 16 - 20

Auxiliar (A) 10 - 14

Coroa Tripla (TC) 24 - 26

Para identificar o tipo de queimador, veja os desenhos

presentes no parágrafo “Características dos

queimadores e bicos”.

! Nos modelos equipados de grade de redução, a

mesma deverá ser utilizada somente para o queimador

auxiliar, quando forem utilizados recipientes de

diâmetro menor de 12 cm.

Utilização do forno

! Quando o acender pela primeira vez, aconselhamos

de fazer funcionar o forno vazio pelo menos durante

uma hora, com o termóstato posto à temperatura

máxima e a porta fechada. Em seguida, pode apagar,

abrir a porta do forno e ventilar a sala. O odor que

se sente deve-se à evaporação das substâncias

empregadas para proteger o forno.

! Nunca encoste objectos no fundo do forno, para

evitar riscos de danos ao esmalte.

! Antes do uso, remova taxativamente as películas de

plástico posicionadas aos lados do aparelho.

1. Para seleccionar o programa de cozedura que

desejar, rode o selector dos PROGRAMAS.

2. Escolha a temperatura recomendada para o

programa ou aquela desejada girando o selector do

TERMÓSTATO.

Uma lista com as cozeduras e as respectivas

temperaturas aconselhadas pode ser consultada na

específica tabela (veja a Tabela de cozedura no forno).

Durante a cozedura é sempre possível:

• modificar o programa de cozedura mediante o

selector dos PROGRAMAS;

• modificar a temperatura mediante o selector do

TERMÓSTATO;

• interromper a cozedura se recolocar o selector dos

PROGRAMAS na posição “0”.

! Coloque sempre os recipientes de cozedura sobre a

grade fornecida.

Indicador do TERMÓSTATO

Se estiver ligado significa que o forno está a produzir

calor. Desliga-se quando no interior do forno for

alcançada a temperatura seleccionada. A esta

altura, o indicador começa a piscar indicando que

o termóstato está a funcionar e mantém constante a

temperatura.

Indicador luminoso FUNCIONAMENTO FORNO

Se estiver ligado significa que o forno está a funcionar.

Luz do forno

Acende-se girando o selector dos PROGRAMAS em

qualquer posição diferente do “0” e fica acesa até

quando o forno estiver a funcionar. Seleccionando

com o selector, a luz acende-se sem activar algum

elemento aquecedor.

8

21

Page 22

Programas de cozedura

! Para todos os programas pode ser definida uma

temperatura

entre 60°C e MÁX., excepto:

• GRILL (é aconselhável configurar somente em

MÁX.);

• GRATIN (é aconselhável não ultrapassar a

temperatura de 200°C).

X

Activam-se os dois elementos aquecedores inferior

e superior. Com esta cozedura tradicional é melhor

utilizar um único tabuleiro: com mais de um tabuleiro

haverá má distribuição da temperatura.

u

Liga-se o elemento aquecedor traseiro e entra em

funcionamento a ventoinha para garantir um calor

suave e uniforme no interior do forno. Esta função

é indicada para a cozedura de comidas delicadas,

(especialmente doces que necessitarem de levitação)

e algumas preparações “mignon” em 3 prateleiras

simultaneamente.

W

Activam-se os elementos aquecedores e entra em

funcionamento a ventoinha para proporcionar um calor

constante e uniforme.

Este programa não necessita de aquecimento

prévio. Este programa é especificamente indicado

para cozeduras rápidas de alimentos previamente

preparados (congelados ou previamente cozidos).

Os melhores resultados são obtidos se utilizar apenas

uma prateleira.

Y

Activam-se todos os elementos aquecedores

(superior, inferior e circular) e entra em funcionamento

a ventoinha. Como o calor é constante e uniforme em

todo o forno, o ar coze e cora os alimentos de maneira

uniforme. É possível utilizar até duas prateleiras no

máximo contemporaneamente.

Programa de FORNO TRADIÇÃO

Programa FORNO PARA PASTÉIS

Programa de FAST COOKING

Programa de COZEDURA MÚLTIPLA

vez, será necessário trocar a posição das mesmas na

metade da cozedura.

d Programa de GRILL

Activa-se a parte central do elemento aquecedor

superior. Uma temperatura alta e directa do grill é

aconselhada para os alimentos que necessitarem de

uma alta temperatura superficial (bifes de vitela ou vaca,

filés, entrecôte). É um programa de baixos consumos,

ideal para grelhar pratos de pequenas dimensões.

Colocar os alimentos no meio da grelha, pois os

alimentos colocados nos cantos ficam crus.

e Programa

Activa-se o elemento aquecedor superior e começam

a funcionar a ventoinha e o espeto rotatório (se

houver). Une a irradiação térmica unidireccional com

a circulação forçada do ar no interior do forno. Deste

modo impede-se a queimadura da superfície dos

alimentos ao aumentar-se o poder de penetração do

calor.

! As cozeduras GRILL e GRATIN devem ser efectuadas

com a porta fechada.

Timer*

Para accionar o Timer (contador de minutos) proceder

da seguinte maneira:

1. para dar corda na campainha é necessário rodar

o selector do TIMER 4 uma volta quase inteira na

direcção dos ponteiros do relógio;

2. rodar no sentido contrário ao dos ponteiros do

relógio 5 o selector TIMER configurando o tempo

desejado;

Conselhos práticos para cozedura

! Nas cozeduras ventiladas não utilize as posições

das prateleiras 1 e 5: estes recebem directamente

ar quente que poderia provocar queimaduras em

alimentos delicados.

COZEDURA MÚLTIPLA

• Utilize as posições 2 e 4 dos tabuleiros, coloque na 2

os alimentos que necessitarem de mais calor.

• Coloque a bandeja pingadeira embaixo e a grade

em cima.

GRATIN

PT

Z

Activam-se os elementos aquecedores inferior e

circular e entra em funcionamento a ventoinha. Esta

combinação possibilita um aquecimento rápido do

forno, com um grande fluxo de calor principalmente

por baixo. Se utilizar mais de uma prateleira de cada

Programa do

FORNO PARA PIZZA

GRILL

• Nas cozeduras de GRILL coloque a grelha na

posição 5 e a bandeja pingadeira na posição 1

para recolher os resíduos de cozedura (molhos e/ou

gordura). Nas cozeduras GRATIN coloque a grelha

na posição 2 ou 3 e a bandeja pingadeira na posição

1 para recolher os resíduos de cozedura.

22

Page 23

PT

• É aconselhável configurar o nível de energia no

máximo. Não se alarme se a resistência superior

não permanecer constantemente acesa: o seu

funcionamento é controlado por um termóstato.

FORNO para PIZZA

• Utilize uma forma de alumínio leve, apoie-a na

Tabela de cozedura no forno

grelha do forno.

Se utilizar a bandeja pingadeira aumentará os

tempos de cozedura

e dificilmente será obtida uma pizza crocante.

• No caso de pizzas com muita cobertura é

aconselhável colocar o queijo mozzarella na metade

da cozedura.

Programas Alimentos Peso

Pato

Forno

Tradicional

Forno para

Pastéis

Cozinha Rápida

Cozedura

Múltipla

Forno para

Pizza

Grill

Gratin

Carne de vitela ou vaca assada

Carne de porco assada

Biscoitos (de massa tenra)

Tortas doces

Tortas doces

Torta de fruta

Plum cake

Pão-de-ló

Crêpes recheadas (em 2 prateleiras)

Queques pequenos (em 2 prateleiras)

Salgadinhos folhados como queijo

(em 2 prateleiras)

Bignés (em 3 prateleiras)

Biscoitos (em 3 prateleiras)

Merengues (em 3 prateleiras)

CongeladosCongelados

Pizza

Misto abóbora e camarão panado

Torta rústica de espinafre

Panzerotte

Lasanha

Pãezinhos doirados

Bolinhos de frango

PréPré-cozidoscozidos

Asas de frango doiradas

Comidas Frescas

Comidas Frescas

Biscoitos (de massa tenra)

Plum cake

Salgadinhos folhados de queijo

Pizza (em 2 prateleiras)

Lasanha

Cordeiro

Frango assado com batatas

Cavala

Plum cake

Bignés (em 2 prateleiras)

Biscoitos (em 2 prateleiras)

Pão-de-ló (em 1 prateleira)

Pão-de-ló (em 2 prateleiras)

Tortas salgadas

Pizza

Carne de vitela ou vaca assada

Frango

Linguado e chocas

Espetinhos de calamares e camarão

Chocas

Filé de bacalhau

Verduras na grelha

Bife de vitela

Chouriças

Hambúrgueres

Cavala

Tostas (ou pão torrado)

Frango na grelha

Chocas

(Kg)

4 ou 6

1

1

1

-

1

0.5

1

0.7

0.5

1.2

0.6

0.4

0.7

0.7

0.5

0.3

0.4

0.5

0.3

0.5

0.4

0.4

0.4

0.3

0.6

0.2

1

1

1

1+1

1

1

0.5

0.5

0.5

1

1.5

0.5

1

1

0.7

0.6

0.6

0.8

0.4

0.8

0.6

0.6

1

1.5

1.5

Posição das

prateleiras

3

3

3

3

3

3

2 ou 3

3

3

2 ou 4

2 ou 4

2 ou 4

1 e 3 e 5

1 e 3 e 5

1 e 3 e 5

2

2

2

2

2

2

2

2

2

2

2

2 ou 4

3

2

2 ou 4

2

2

2 ou 4

2 ou 4

2

2 ou 4

3

3

2

2 ou 3

4

4

4

4

3 ou 4

4

4

4

4

4

2

2

Pré

aquecimento

(minutos)

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

-

-

-

-

-

-

-

-

-

-

15

10

10

15

10

10

10

10

10

10

15

15

10

10

-

-

-

-

-

-

-

-

-

10

10

Temperatura

aconselhada

200

200

200

180

180

180

180

180

160

200

190

210

180

180

90

250

200

220

200

200

180

220

200

200

180

210

230