Hotpoint 7HPH 640S, 7HPH 640 ST, 7HPHR 640ST, 7HPH 640, 7HPH 640 ST GH RU/HA User Manual

Operating Instructions

GB

GB

English,1

CISPH640 M /HA

CISPH640 M IX /HA

CISPH640 MS /HA

CISPH640 MS IX /HA

CISPH640 MST /HA

CISPH640 MST IX /HA

7HPH 640 RU/HA

7HPH 640 GH RU/HA

7HPH 640S RU/HA

7HPH 640 ST /HA

7HPH 640 ST GH RU/HA

7HPHR 640 ST /HA

RS

Русский,12

HOB

Contents

GB

Installation, 2-5

Positioning

Electrical connection

Gas connection

Data plate

Burner and nozzle specifications

Description of the appliance, 6

Overall view

Start-up and use, 7-8

Practical advice on using the burners

Practical advice on using the electric hotplates

Precautions and tips, 9

General safety

Disposal

Maintenance and care, 10

Switching the appliance off

Cleaning the appliance

Gas tap maintenance

Troubleshooting, 11

Installation

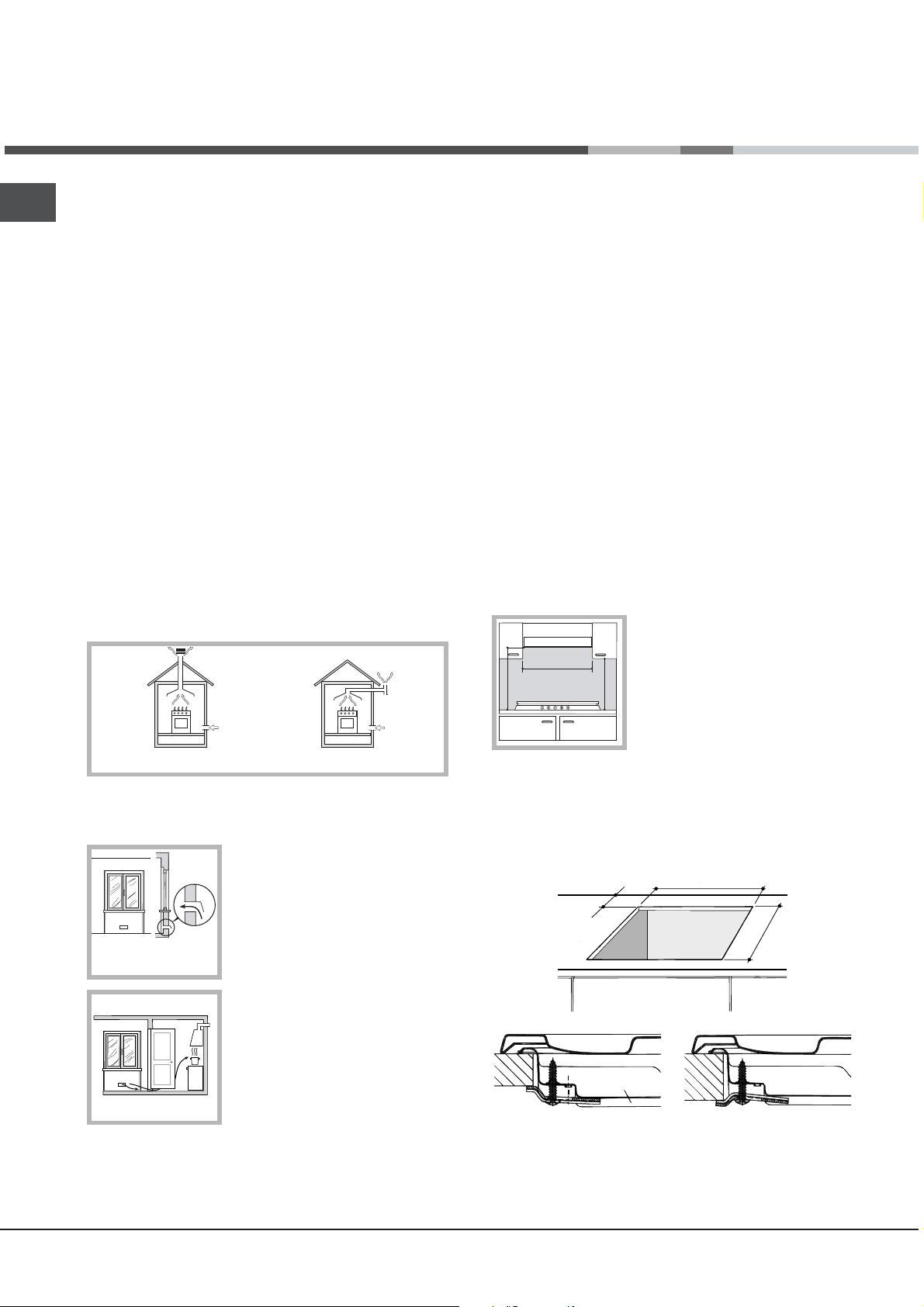

A

Examples of ventilation holes

for comburant air.

GB

Before operating your new appliance please read this

instruction booklet carefully. It contains important information

for safe use, installation and care of the appliance.

Please keep these operating instructions for future

reference. Pass them on to possible new owners of the

appliance.

Positioning

Keep packaging material out of the reach of children. It

can become a choking or suffocation hazard (see

Precautions and tips).

The appliance must be installed by a qualified professional

according to the instructions provided. Incorrect installation

may cause harm to people and animals or may damage

property.

This unit may be installed and used only in permanently

ventilated rooms in accordance with British Standard Codes

Of Practice: B.S. 6172 / B.S. 5440, Par. 2 and B.S. 6891

Current Editions. The following requirements must be

observed:

The room must be equipped with an air extraction system

that expels any combustion fumes. This may consist of a

hood or an electric fan that automatically starts each time

the appliance is switched on.

also be equipped with vents to allow gas to escape in the

event of a leak. As a result LPG cylinders, whether

partially or completely full, must not be installed or stored

in rooms or storage areas that are below ground level

(cellars, etc.). It is advisable to keep only the cylinder

being used in the room, positioned so that it is not

subject to heat produced by external sources (ovens,

fireplaces, stoves, etc. ) which could raise the

temperature of the cylinder above 50°C.

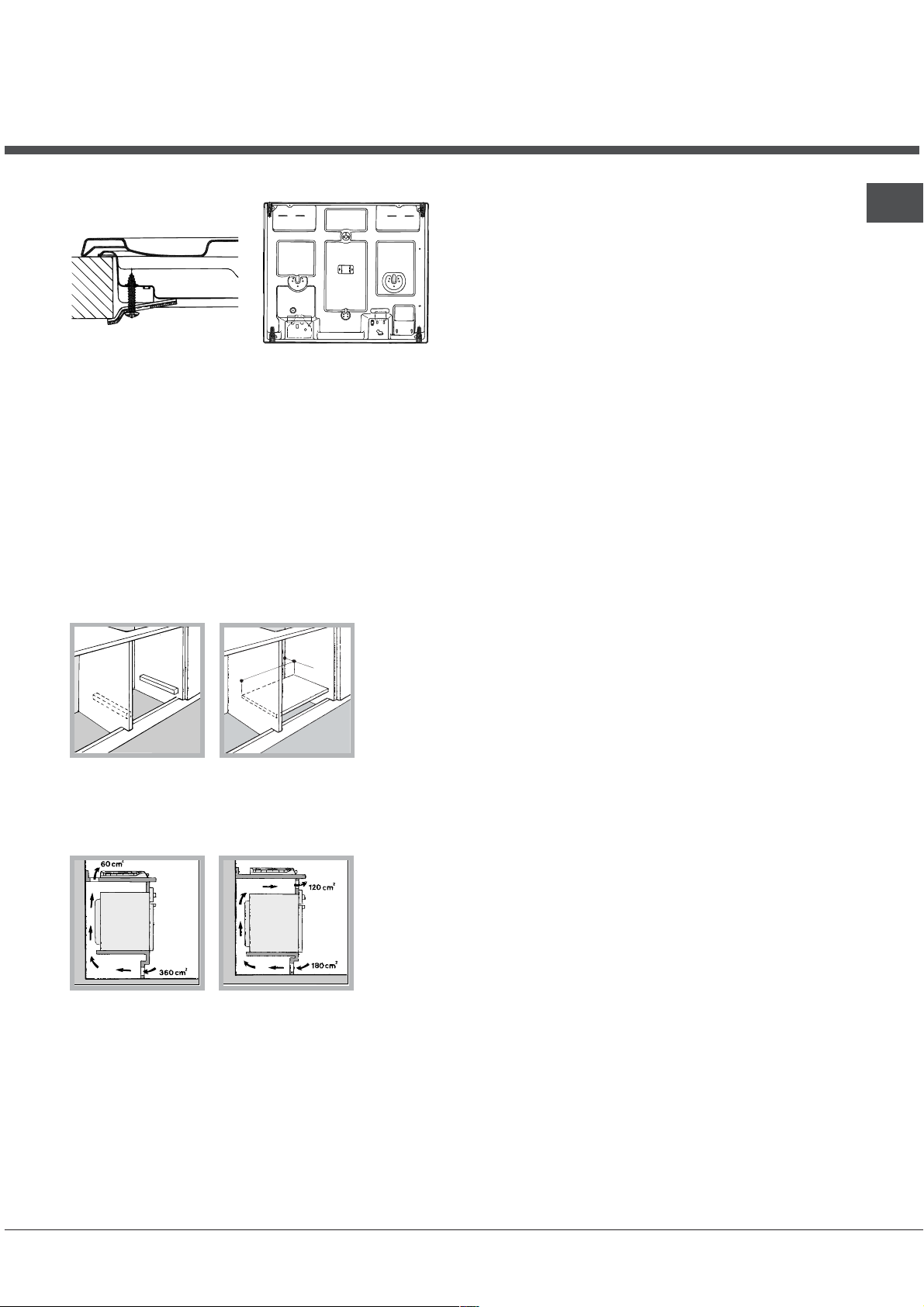

Fitting the appliance

Gas and mixed hobs are manufactured with type X degree

protection against overheating. The following precautions

must be taken when installing the hob:

Kitchen cabinets adjacent to the appliance and taller

than the top of the hob must be at least 600 mm from the

edge of the hob.

Hoods must be installed according to their relative

installation instruction manuals and at a minimum

distance of 650 mm from the hob.

Place the wall cabinets adjacent to the hood at a

minimum height of 420 mm from the hob (see figure).

If the hob is installed beneath a

wall cabinet, the latter must be

600mm min.

situated at a minimum of 700 mm

above the hob (see figure).

700mm min.

600mm min.

In a chimney stack or branched flue.

(exclusively for cooking appliances)

Directly to

the Outside

The room must also allow proper air circulation, as air is

needed for combustion to occur normally. The flow of air

must not be less than 2 m

3

/h per kW of installed power.

The air circulation system may

take air directly from the outside

by means of a pipe with an inner

cross section of at least 100 cm

the opening must not be

vulnerable to any type of

blockages.

Adjacent

Room

Room to be

Vented

The system can also provide the

air needed for combustion

indirectly, i.e. from adjacent rooms

fitted with air circulation tubes as

described above. However, these

Enlarging the ventilation slot

between window and floor.

rooms must not be communal

rooms, bedrooms or rooms that

may present a fire hazard.

Liquid petroleum gas sinks to the floor as it is heavier

than air. Therefore, rooms containing LPG cylinders must

The installation cavity should have the dimensions

indicated in the figure.

Fastening hooks are provided, allowing you to fasten the

hob to tops that are between 20 and 40 mm thick. To

ensure the hob is securely fastened to the top, we

recommend you use all the hooks provided.

555 mm

2

;

55 mm

475 mm

Hook fastening diagram

Hooking position Hooking position

for top H=20 mm for top H=30 mm

2

Front

Hooking position Back

for top H=40 mm

Use the hooks contained in the accessory pack

Where the hob is not installed over a built-in oven, a

wooden panel must be installed as insulation. This must

be placed at a minimum distance of 20 mm from the

lower part of the hob.

Ventilation

To ensure adequate ventilation, the back panel of the

cabinet must be removed. It is advisable to install the oven

so that it rests on two strips of wood, or on a completely flat

surface with an opening of at least 45 x 560 mm (see

diagrams).

45 mm

.

m

m

0

6

5

.

When installing the cooktop above a built-in oven

without forced ventilation, ensure that there are air

inlets and outlets for ventilating the interior of the

cabinet adequately.

Electrical connection

Hobs equipped with a three-pole power supply cable are

designed to operate with alternating current at the voltage

and frequency indicated on the data plate (this is located on

the lower part of the appliance). The earth wire in the cable

has a green and yellow cover. If the appliance is to be

installed above a built-in electric oven, the electrical

connection of the hob and the oven must be carried out

separately, both for electrical safety purposes and to make

extracting the oven easier.

Connecting the supply cable to the mains

Install a standardised plug corresponding to the load

indicated on the data plate.

The appliance must be directly connected to the mains using

an omnipolar circuit-breaker with a minimum contact opening

of 3 mm installed between the appliance and the mains. The

circuit-breaker must be suitable for the charge indicated and

must comply with current electrical regulations (the earthing

wire must not be interrupted by the circuit-breaker). The

supply cable must not come into contact with surfaces with

temperatures higher than 50°C.

The installer must ensure that the correct electrical

connection has been made and that it is compliant with

safety regulations.

Before connecting to the power supply, make sure that:

The appliance is earthed and the plug is compliant with

the law.

The socket can withstand the maximum power of the

appliance, which is indicated on the data plate.

The voltage is in the range between the values indicated

on the data plate.

The socket is compatible with the plug of the appliance. If

the socket is incompatible with the plug, ask an

authorised technician to replace it. Do not use extension

cords or multiple sockets.

Once the appliance has been installed, the power supply

cable and the electrical socket must be easily accessible.

The cable must not be bent or compressed.

The cable must be checked regularly and replaced by

authorised technicians only (see Assistance).

The manufacturer declines any liability should these safety

measures not be observed.

Gas connection

The appliance should be connected to the main gas supply

or to a gas cylinder in compliance with current national

regulations. Before carrying out the connection, make sure

the cooker is compatible with the gas supply you wish to

use. If this is not the case, follow the instructions indicated in

the paragraph Adapting to different types of gas.

When using liquid gas from a cylinder, install a pressure

regulator which complies with current national regulations.

Check that the pressure of the gas supply is consistent

with the values indicated in Table 1 (Burner and nozzle

specifications). This will ensure the safe operation and

longevity of your appliance while maintaining efficient

energy consumption.

Connection with a rigid pipe (copper or steel)

Connection to the gas system must be carried out in such

a way as not to place any strain of any kind on the

appliance.

There is an adjustable L-shaped pipe fitting on the

GB

3

GB

appliance supply ramp and this is fitted with a seal in

order to prevent leaks. The seal must always be replaced

after rotating the pipe fitting (seal provided with

appliance). The gas supply pipe fitting is a threaded 1/2

gas cylindrical male attachment.

Connecting a flexible jointless stainless steel pipe to a

threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas cylindrical

male attachment.

These pipes must be installed so that they are never longer

than 2000 mm when fully extended. Once connection has

been carried out, make sure that the flexible metal pipe

does not touch any moving parts and is not compressed.

Only use pipes and seals that comply with current national

regulations.

Checking the tightness of the connection

When the installation process is complete, check the pipe

fittings for leaks using a soapy solution. Never use a flame.

Adapting to different types

of gas

To adapt the hob to a different type of gas other than default

type (indicated on the rating plate at the base of the hob or

on the packaging), the burner nozzles should be replaced

as follows:

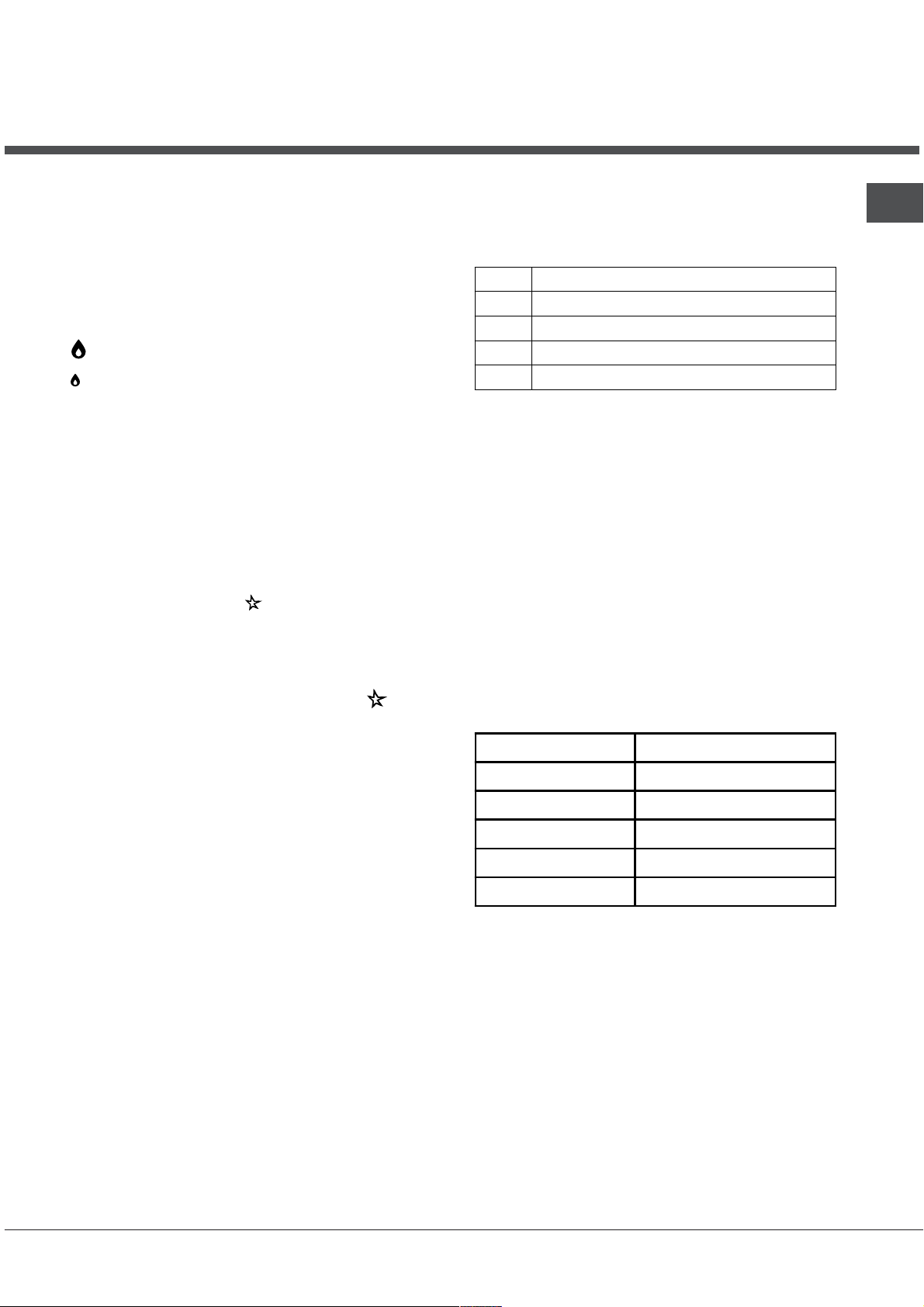

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner, and

replace them with nozzles for the new type of gas (see

table 1 Burner and nozzle characteristics).

3. Reassemble the parts following the above procedure in

the reverse order.

4. Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Sticker are available from any of our Service Centres.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position of

the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax or a similar

substance.

If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

Should the gas pressure used be different (or vary slightly)

from the recommended pressure, a suitable pressure

regulator must be fitted to the inlet pipe (in order to comply

with current national regulations).

Adjusting the burners primary air :

Does not require adjusting.

Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the adjustment screw,

which is positioned in or next to the tap pin, until the

flame is small but steady.

4

DATA PLATE

Electrical

connections

see data plate

This appliance conforms to the

following European Economic

Community directives:

- 2006/95/EEC dated 12/12/06

(Low Voltage) and subsequent

amendments

- 2004/108/EEC dated 15/12/04

(Electromagnetic Compatibility)

and subsequent amendments

- 93/68/EEC dated 22/07/93 and

subsequent amendments.

- 90/396/EEC dated 29/06/90

(Gas) and subsequent

amendments.

- 2002/96/EC and subsequent

amendments.

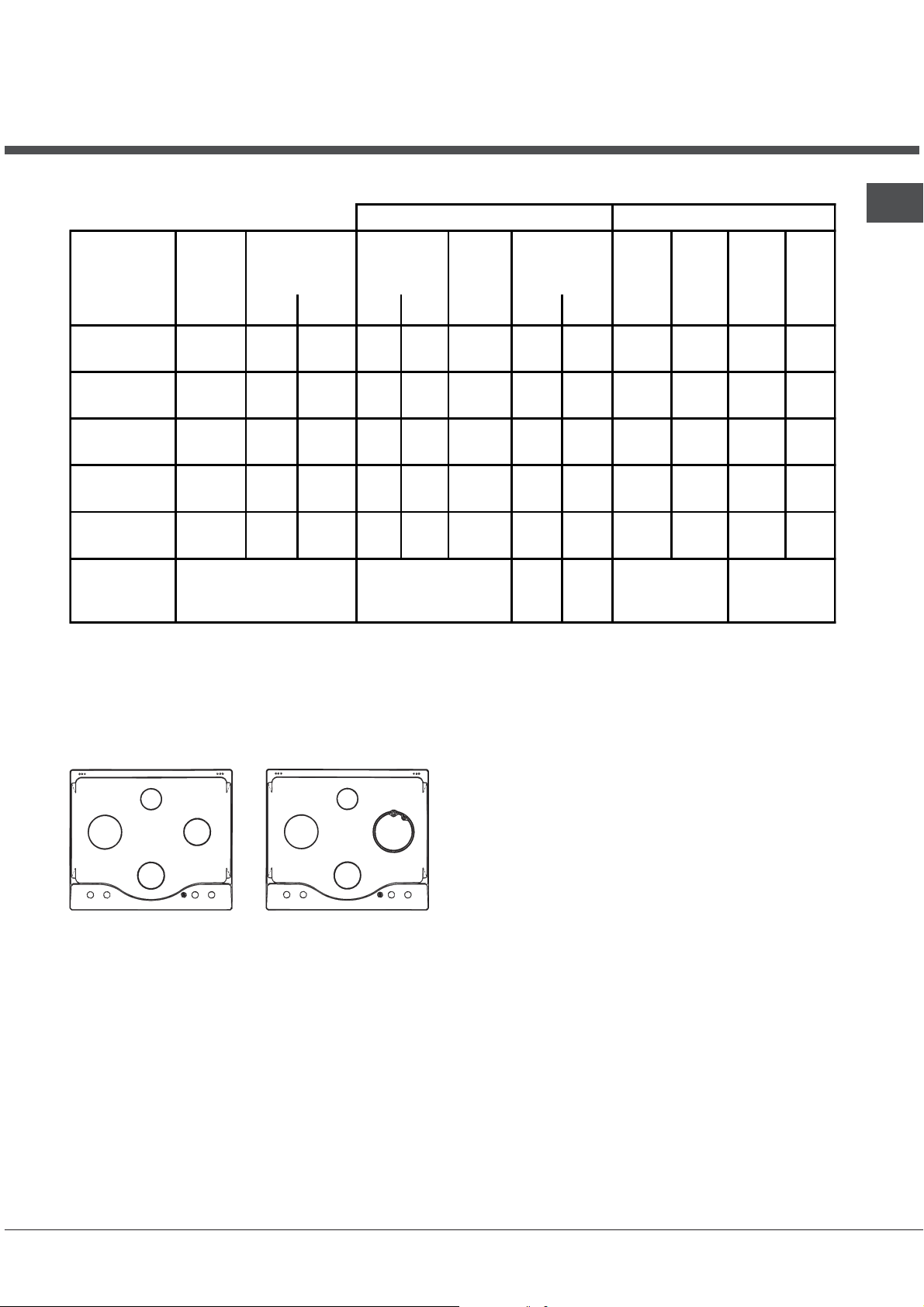

Burner and nozzle specifications

Table 1 Liquid Gas Natural Gas

GB

Burner Diameter

(mm)

Thermal Power

kW (p.c.s.*)

Nom. Red. (1) (mm) *** ** (mm) (mm)

Fast

(Large) (R)

Reduced Fast

(RR)

Semi Fast

(Medium) (S)

Auxiliary

(Small) (A)

Triple Crown

(TC)

Supply

pressures

100 3.00 0.7 41 39 86 218 214 116 286 143 286

100 2.60 0.70 41 39 80 189 186 110 248 135 248

75 1.65 0.4 30 28 64 120 118 96 157 105 157

55 1.00 0.4 30 28 50 73 71 71 95 80 95

130 3.25 1.3 60 57 91 236 232 133 309 150 303

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

* At 15°C and 1013 mbar-dry gas

** Propane P.C.S. = 50.37 MJ/kg.

*** Butane P.C.S. = 49.47 MJ/kg.

Natural P.C.S. = 37.78 MJ/m

3

By-pass

1/100

(mm)

Nozzle

1/100

28-30

20

35

Flow*

g/h

37

25

45

Nozzle

1/100

20

17

25

Flow*

l/h

Nozzle

1/100

Flow*

l/h

13

6,5

18

(1) Only for appliances with the security device.

A

R

S

S

RR

A

TC

S

CISPH 640.../HA CISPH 640MST.../HA

7HPH 640... /HA 7HPH 640ST... /HA

7HPH 640S... /HA 7HPHR 640ST... /HA

5

Description of the

appliance

GB

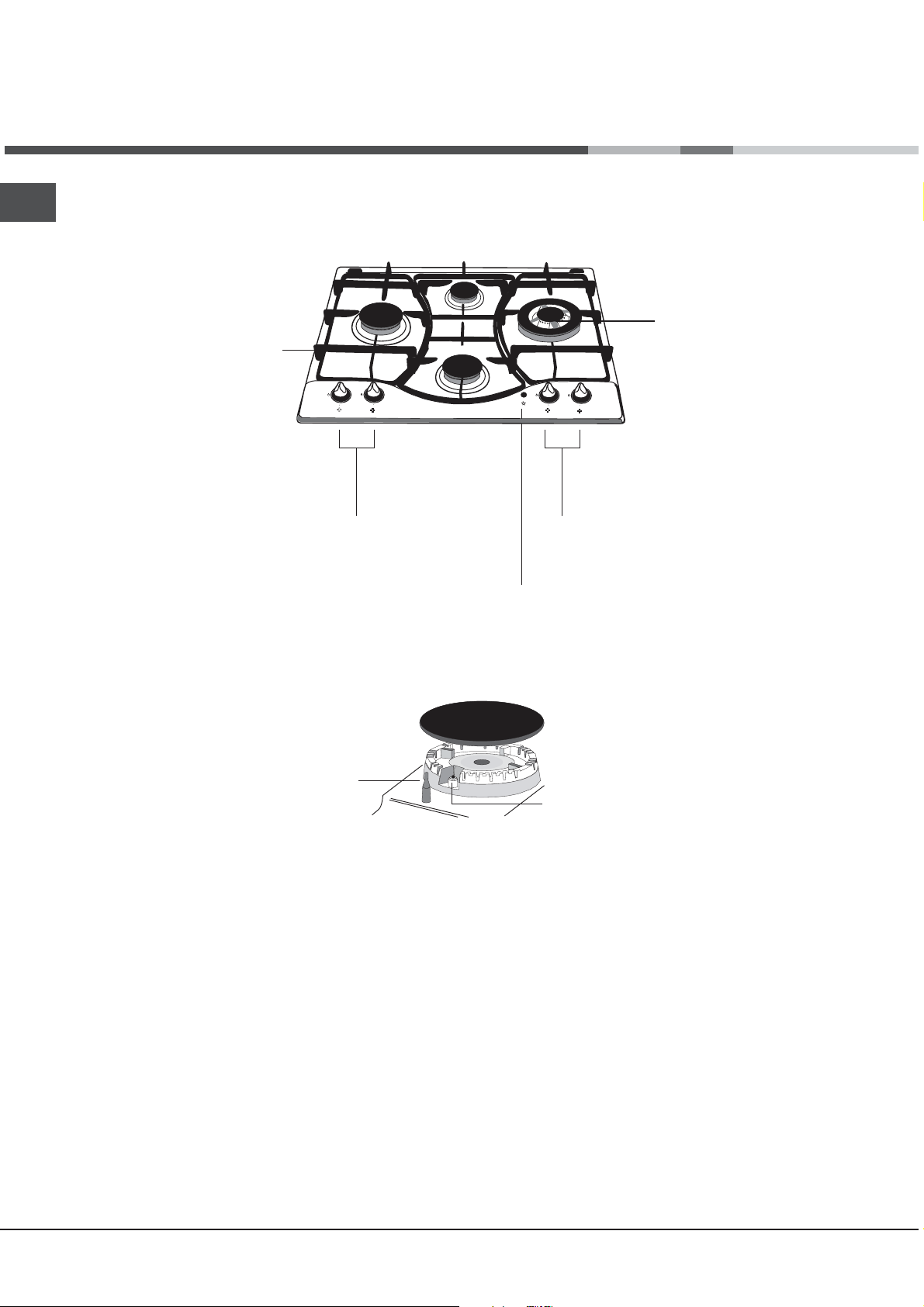

Overall view

Support Grid for

COOKWARE

Control Knobs for

GAS BURNERS

GAS BURNERS

Control Knobs for

GAS BURNERS

Ignition Button for

GAS BURNERS *

SAFETY

DEVICES *

GAS BURNERS differ in size and power. Use the

diameter of the cookware to choose the most

appropriate burner to cook with.

Control Knobs for GAS BURNERS adjust the

power or the size of the flame.

Only available on certain models.

*

Ignition for

GAS BURNERS *

GAS BURNER ignition* enables a specific burner

to be lit automatically.

SAFETY DEVICE* stops the gas flow if the flame

is accidentally extinguished.

6

Start-up and use

The position of the corresponding gas burner or

electric hotplate* is shown on every knob.

Gas burners

Each burner can be adjusted to one of the following

settings using the corresponding control knob:

Off

Maximum

Minimum

To light one of the burners, hold a lit match or

lighter near the burner and, at the same time, press

down and turn the corresponding knob anticlockwise to the maximum setting.

Since the burner is fitted with a safety device, the

knob should be pressed for approximately 2-3

seconds to allow the automatic device keeping the

flame alight to heat up.

When using models with an ignition button, light the

desired burner by first pressing the gas burners

button (identifiable by the

down the corresponding knob as far as possible and

turning it anticlockwise towards the maximum setting.

Some models are equipped with an ignition switch

incorporated into the control knob. If this is the case,

the ignitor is present, but not the switch (the

symbol is located near each knob).

To light a burner, simply press the corresponding

knob all the way in and then turn it in the counterclockwise direction to the "High" setting, keeping it

pressed in until the burner lights.

If a flame is accidentally extinguished, turn off the

control knob and wait for at least 1 minute before

trying to relight it.

symbol), then pressing

Electric hotplates*

GB

The corresponding knob may be turned clockwise or

anti-clockwise and set to six different positions:

Setting Normal or Fast Plate

0 Off

1 Low

2 - 5 Medium

6 High

When the selector knob is in any position other than

the off position, the on light comes on.

Practical advice on using the burners

To ensure the burners operate efficiently:

Use appropriate cookware for each burner (see

table) so that the flames do not extend beyond the

bottom of the cookware.

Always use cookware with a flat base and a cover.

When the contents of the pan reach boiling point,

turn the knob to minimum.

Burner ø Cookware Diameter (cm)

Fast (R) 24 – 26

Reduced Fast (RR) 22 – 24

Semi Fast (S) 16 – 20

Auxiliary (A) 10 – 14

To switch off the burner, turn the knob in a

clockwise direction until it stops (when reaches the

position).

Triple Crown (TC) 24 – 26

Only available on certain models.

*

7

GB

Practical advice on using the electric

hotplates

To avoid heat loss and damage to the hotplates, use

pans with a flat base, whose diameter is no less than

that of the hotplate itself.

Setting Normal or Fast Plate

0

Off

1

Cooking vegetables, fish

Cooking potatoes (using steam) soups,

2

chickpeas, beans.

Continuing the cooking of large quantities of

3

food, minestrone

4

For roasting (average)

5

For roasting (above average)

For browning and reaching a boil in a short

6

time.

Before using the hotplates for the first time, you

should heat them at maximum temperature for

approximately 4 minutes, without placing any pans on

them. During this initial stage, their protective coating

hardens and reaches its maximum resistance.

Only available on certain models.

*

8

Loading...

Loading...