Hot Melt Technologies BENCHMARK 205-LV4 Service Manual

BENCHMARK 205-LV4

SERVICE MANUAL

Your System Configuration

Tank Size

8 lb (3.6 kg) 1 gal (4.4 L)

Voltage Requirements

120 VAC, Single Phase, 20 A

Motor Rating

120 VAC, 43 RPM

1723 W. Hamlin Rd | Rochester Hills, MI 48309

248.853.2011 | www.hotmelt-tech.com

Product Introduction

Intended Use

Benchmark® and ProFlex® adhesive melters and components are designed to melt

and pump thermoplastic hotmelt adhesives and sealants. Any other use is considered

to be unintended. Hot Melt Technologies (HMT) will not be liable for personal

injury or property damage resulting from unintended use. Intended use includes

the observance of HMT safety instructions. HMT recommends obtaining detailed

information on the hotmelt materials being used.

The product is only intended for use in industrial applications and may

only be used to melt and pump thermoplastic hotmelt adhesives

(e.g. EVA, PSA, APO, Polyamid).

The product may only be installed, assembled, commissioned, operated,

maintained, repaired, de-commissioned and disposed of by trained

personnel.

The product may only be operated with compatible original components

and original accessories from Hot Melt Technologies Inc.

The product is to be used exclusively for the purpose described herein

and within the limits defined in this document. The product must not

be modified with respect to its structure or its safety features without

the written consent of Hot Melt Technologies. No changes to the

software or hardware of HMT products are permitted. Only use

original spare parts, original accessories or standard parts that

have been approved by HMT.

The instructions are part of this product. No applications other than those described

in the instructions are permitted.

Improper Use

Examples of misuse of the product include:

Melting and pumping of unsuitable adhesives

(e.g. PUR-Polyurethane hot melt adhesives)

In defective condition

With electrical cabinet open

With the tank lid open

Melting and pumping materials which, when under vacuum or pressure,

can pose a health hazard or endanger safety in the workplace

(e.g. solvents, explosive or highly flammable materials)

Cleaning the product with highly flammable materials (e.g. solvents)

Use in environments that require cleaning of the product with jets or

sprays of water

Processing of food

Residual Risks

In the design of the Benchmark and ProFlex systems, every measure was taken

to protect personnel from potential danger. However, some residual risks can

not be avoided:

Risk of burns from hot material

Risk of burns when filling the tank, from the tank lid, and from the hose

and gun exposed metal surfaces.

Risk of burns when conducting maintenance and repair work for which

the melter or components must be heated up.

Material fumes may be hazardous. Always avoid direct inhalation.

©2015 Hot Melt Technologies, Inc

Benchmark 205-LV4

Table of Contents .......................................................................................................... 3

Safety & Set Up ...........................................................................................................4-5

Operating Instructions.................................................................................................6-8

Front Panel Controls ...............................................................................................6-7

Adjusting Hose & Gun Temperatures .......................................................................8

Components ..............................................................................................................9-11

Exploded View ...........................................................................................................9

Tank & Pump Assembly ...........................................................................................10

Front Panel ..............................................................................................................11

Electrical ..................................................................................................................12-13

Fuse & Relay Chart ................................................................................................... 12

Schematic ................................................................................................................. 13

Hose Information ...................................................................................................14-15

Benchmark Series ....................................................................................................14

Proper Hose Usage ..................................................................................................15

Handgun Information .............................................................................................16-17

ETC Handgun ........................................................................................................... 16

ETC Handgun Parts List ...........................................................................................17

Nozzle Information .................................................................................................18-19

400 Series Extrusion Nozzles ................................................................................... 18

500 Series Extrusion Nozzles ................................................................................... 19

Accessory Information .................................................................................................. 20

LV/HV Optional Items ..............................................................................................20

DFS Kits ......................................................................................................................... 21

Warranty Information ..................................................................................................22

Technical Services & Support ........................................................................................ 23

©2015 Hot Melt Technologies, Inc Page 3

Safety & Set Up

Benchmark 205-LV4

STOP

STOP

If incorrectly used, this machine can cause severe injury.

Those who use and maintain the machine should be trained

in its proper use, warned of its dangers, and should read the

entire manual before attempting to set up, operate, adjust or

service the machine.

WARNING

Do not allow the pump motor to stall. A prolonged stall may damage

the motor and other components.

Do not connect or disconnect electrical connectors, or remove

components, with the power on. This will prevent arcing of electrical

contacts and possible failure of components.

Always close and secure the control panel access cover to protect

internal electrical components.

Always operate the system with the tank full and lid on.

Prior to dismantling, assembly, or adjustment of certain service parts

(hose/gun fittings, pump assemblies, etc.), the part(s) being serviced

should be preheated to reduce the chance of stripping threads or

ruining components.

Working on or around hot melt adhesives and equipment can cause

severe burns.

Use eye protection, gloves and protective clothing while operating

and/or servicing hot melt equipment.

Before installing any hot melt equipment, determine proper electrical

requirements per all applicable codes.

At Hot Melt Technologies, we pay special attention to the needs of

operators and service personnel when designing equipment, but

molten hot melt adhesives are dangerous and can cause severe burns.

Extreme care must be exercised to insure personnel safety.

Fire, explosion, personal injury, property, and/or equipment damage

can result if the material(s) used in or around any hot melt adhesive

supply unit are toxic, heat, or re sensitive. Always read the

manufacturer’s recommended use guidelines.

All HMT units are equipped with over temperature protection as

a necessary safety device. Run-away heating can cause hot melt

materials to exceed their flashpoint.

Page 4 ©2015 Hot Melt Technologies, Inc

Safety & Set Up

Benchmark 205-LV4

Before Using Your Hot Melt System

It is your responsibility and obligation to make sure your system:

Has been properly installed off the floor and on a steady,

level work surface away from combustible materials.

Has been located in such a way that the controls are away

from the operator and that the control panel is securely

closed at all times.

Is the right capacity system for the intended use.

Is connected to the proper power supply. (See Below).

Is only used to do what a hot melt system is designed to do.

Is not used by anyone unable to operate it properly.

Is used in an area where the room temperature does not

fall below 65 °F.

Is used in an area which is free from blowing air caused by

cooling fans, open doors or windows.

Power

Supply

Cord

20 Amp Connection

3 Prong

Grounding

Plug

Grounding

Prong

NEMA 5-20 Type

20 Amp Wall

Receptacle

Prevent Serious Equipment Damage

Protect your hot melt equipment by installing a GFEP

(Ground Fault Equipment Protector) device in your

distribution panel.

HMT recommends that hot melt systems be protected

from unintended line-to-ground currents by installing

an appropriate ground fault equipment protection

(GFEP) device. Contact HMT Technical Service & Support

or a qualied electrical contractor for more information.

When installing a GFEP device always comply with local

electrical codes.

Basic Electrical Power Connections

For 120 VAC Operation

A fused 20 amp 120 VAC electrical supply is required.

Performance problems will occur with voltages less than 108

VAC or greater than 132 VAC.

Total amperage draw will depend on the final system

configuration; number of hoses & length, guns, accessories, etc.

Do not allow the system to share the same circuit with other

electrical items. A dedicated supply is recommended.

Do not use an extension cord.

If you change the configuration of your system in any way

that may affect the electrical requirements (ex. add a gun,

longer hose, automate, etc.) call HMT Technical Service &

Support at 248-853-2011 for assistance.

©2015 Hot Melt Technologies, Inc Page 5

Operating Instructions

Benchmark 205-LV4

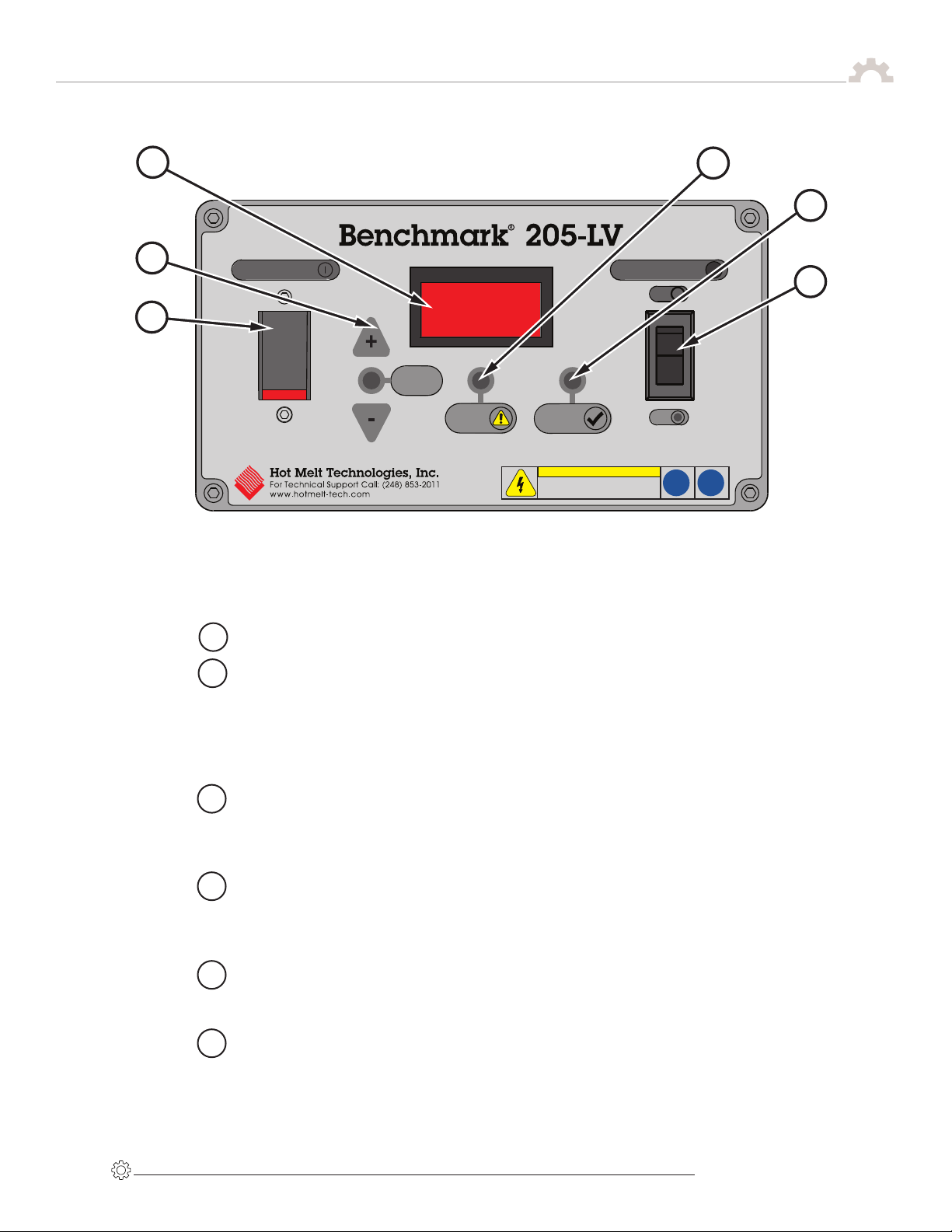

3

2

1

Main Power

Temperature Display

000

Set

Mode

Over

Temp

Pump

Ready

Front Panel Controls

4

5

Pump Control

On

Off

6

1

Main Power Switch: Turns the system “ON” or“OFF.”

To adjust the Tank Temperature Set Point: Press and hold the

2

“+” or “-” button for two (2) seconds to enter Set Mode. The Set Mode

LED will illuminate when Set Mode is active. While in Set Mode, use

the “+” or “-” button to change the tank temperature set point.

The tank temperature can be adjusted between 225°F and 400°F

(107°C and 204°C).

Temperature Display: Displays the tank temperature in °F or °C. If the

3

“+” or “-” button is pressed the tank temperature set point is displayed.

When released the Temperature Display will show the actual

tank temperature.

4

Over Temp: Over Temp occurs when the tank temperature reaches 425°F

(218°C). The Over Temp LED will ash red, for safety the system will shut

down, and “OFF” will be shown on the Temperature Display. Contact

Technical Service and Support for repair options.

5

Pump Ready: When the Pump Ready LED is illuminated, the pump

can be triggered on. The Pump Ready LED illuminates when the tank

temperature is within 25°F (14°C) of the tank temperature set point.

6

Pump Control “ON/OFF” Switch: Allows the pump motor to run

when triggered.

Page 6 ©2015 Hot Melt Technologies, Inc

Operating Instructions

Front Panel Controls

Benchmark 205-LV4

OFF

OFF

SET LOCK

SET LOCK

DEG C

DEG C

ON

ON

8

245-101

7

7

Celsius: If the “Deg °C” switch is in the ON position, the temperature

display will show the tank temperature in °C.

Set Lock: If the “Set Lock” switch is in the ON position, Set Mode

8

cannot be activated and the tank temperature set point cannot be

changed. The Set Mode LED will not illuminate when the "set lock"

switch is ON.

©2015 Hot Melt Technologies, Inc Page 7

Loading...

Loading...