Page 1

Operator’s Manual

Mobile Max Portable Torch Kit

Model MM-1

WARNING: Do not assemble, install or operate this equipment without reading ALL of

this manual and the safety precautions and warnings illustrated in this manual.

KDAR Company

1 Mulch Lane

St. Louis, MO 63044

Tel: (314) 692-8555

Fax: (314) 692-8578

Web Site: www.hotmaxtorches.com

Page 2

SAFETY PRECAUTIONS AND WARNINGS

PLEASE READ BEFORE USING EQUIPMENT

WARNING

ARC RAYS CAN BURN SKIN AND EYES

Gas welding and cutting produce intense ultraviolet and infrared rays that can burn skin and eyes

Wear face protection, either helmet or shield when operating with ANSI Z49.1 approved shade

Wear approved safety glasses with side shields under the face protection

Warn others not to stare at the light as it can cause damage to the eyes. Provide barriers to protect

Wear flame resistant gloves, clothing, and shoes when operating

FUMES AND GASES CAN BE HAZARDOUS

Gas cutting produces fumes and gases and breathing these gases is hazardous to your health

Keep your head out of the fumes and do not breath the fumes while cutting/welding

Work only in a confined area if it has sufficient ventilation, or while wearing an air supplied res-

Read the MSDS sheets and the instructions from manufacturers for metals to be welded, coat-

Do not use the welder near hydrocarbon vapors coming from degreasing, cleaning, or spraying

Do not weld/cut coated metals, such as galvanized, lead, or cadmium plated steel. Before weld-

Do not weld/cut containers with toxic, flammable, or reactive elements stored in them. They

Keep children away from this equipment

Protect your self and others from possible injury

Pacemaker wearers should consult with their doctor before operating

Read and follow all instructions in this manual before operating

All installation, operation, and maintenance procedures are to be per-

formed only by qualified individuals

#9 recommended for all activities. The lens should conform to ANSI Z87.1 standards for testing.

other workers in the area from the light while operating

pirator. Fumes from welding deplete the oxygen supply and can be harmful. Always be sure

there is ample breathing air

ings, and cleaners

operations. The heat and rays can react with solvent vapors to create the gas phosgene, a very

toxic gas and other irritating gases

ing, all plating must be removed. The area must be well ventilated or an air supplied hood must

be used. The coatings and chemicals when burned cause highly irritating and toxic fumes.

must be emptied and properly prepared before welding.

WELDING SPARKS CAN CAUSE INJURY, FIRE, OR EXPLOSION

Remove all flammable materials from the welding area.

Always have a charged fire extinguisher available in the welding area.

When not welding make sure the welding gas cylinder valves are closed.

Avoid welding near hydraulic lines, fuel lines, electrical cords, air hoses, or welding gas lines.

Sparks and hot metal fly out from the work area when welding, wear approved safety glasses with

side shields under approved helmets, wear proper body and hand protection, and wear flame resistant ear plugs to keep sparks from entering the ears

KDAR Company

1

Page 3

CYLINDERS CAN EXPLODE IF DAMAGED

Gas cylinders contain gas under very high pressure. If damaged they can result in that cylinder ex-

ploding. Gas cylinders are a major part of metalworking and must be treated with care.

Protect gas cylinders from excessive heat, mechanical shocks, slag, open flames, sparks, and arcs

Always keep cylinders in an upright position securely fastened to a fixed support

Valve protection caps should always be in place and hand tight except when the cylinder is in use

Keep all cylinders away from any welding or electrical circuits

Never allow the flame from a torch to contact a cylinder

Never cut any type of pressurized cylinder, an explosion could result

Always turn your face away from the valve when opening the cylinder

Read and follow all instructions on compressed gas cylinders, associated equipment, and CGA pub-

lication P-1 listed in the Safety Standards before using

HOT PARTS CAN CAUSE SERIOUS BURNS

Do not touch hat parts without wearing protection.

Allow the torch to cool sufficiently before working with parts that could potentially be hot.

NOISE CAN DAMAGE HEARING

Prolonged noise exposure from welding equipment can cause damage if levels of noise exceed the

OSHA standards

Wear approved hearing protectors

Warn other workers nearby of the high noise level and hazard

CALIFORNIA PROPOSITION 65 WARNINGS

Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to cause

birth defects, and in some cases, cancer. (California Health and Safety Code Section 25249.5 et seq.)

PRINCIPAL SAFETY STANDARDS

AMERICAN WELDING SOCIETY

AWS C5.2, Recommended Practices for Plasma Arc Cutting

AWS F4.1, Recommended Safe Practices for the Preparation for Welding and Cutting

OSHA STANDARDS

OSHA 29 CFR 1910, Safety and Health Standards

NATIONAL FIRE PROTECTION ASSOCIATION

NFPA Standard 70, National Electric Code

NFPA Standard 51B, Cutting and Welding Processes

AMERICAN NATIONAL STANDARDS INSTITUTE

ANSI Standard Z87.1, Safe practices for Occupation and Educational Eye and Face Protection

ANSI Standard Z49.1, Safety in Welding and Cutting

KDAR Company 2

Page 4

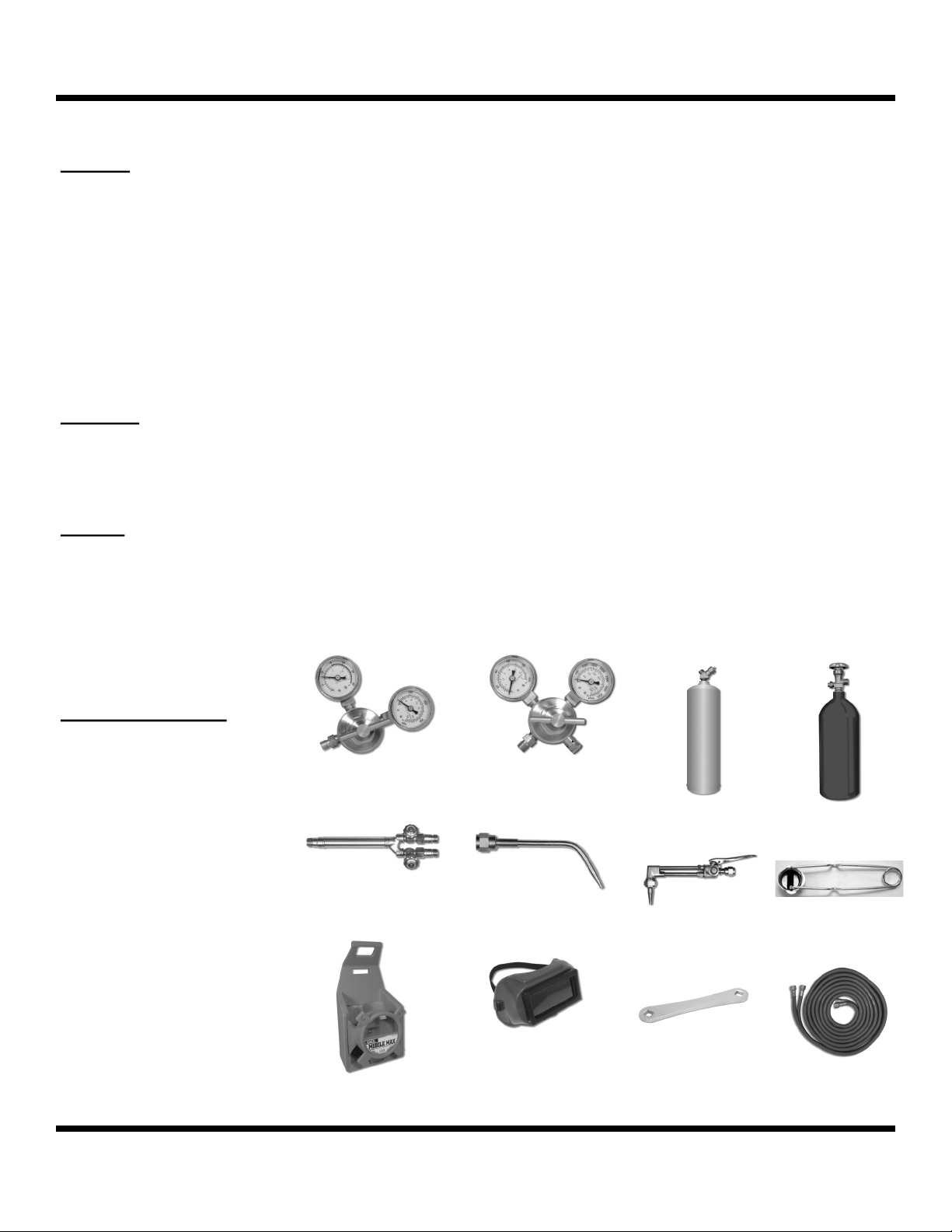

Installation & Setup

Features, Benefits & Functions

Features

Brass & Stainless Construction

Welds up to 1/4 Inch*

Cuts up to 4 Inches*

Welding Tip, #1 Size

Cutting Tip, 1-3-101 Victor Style

Twin Welding Hose, 10’ x 3/16”

Oxygen Regulator

*Larger Tip are Required to do this, Purchase Separately

Functions

Steel Cutting up to 4”*

Welding up to 1/4”*

Acetylene Regulator

Goggles & Striker

Torch Handle & Cutting Head

Heavy Duty Molded Tote Carrier

Refillable 20 Cubic Foot Oxygen Tank—CGA540

Refillable 10 Cubic Foot Acetylene Tank—CGA200

Built in Storage Unit with Clear Door

Solders up to 3/4” Copper & Brass

Silver Solders

Benefits

Everything in one Heavy Duty Molded

Case

Mobile and Easy to Carry on Job Site

Package Contents

1. Acetylene Regulator

2. Oxygen Regulator

3. Acetylene Tank

4. Oxygen Tank

5. Torch Handle

6. Welding Tip

7. Cutting Head w/Tip

8. Striker

9. Heavy Duty Tote

10. Goggles

11. Acetylene Tank Key

12. Hose

Acetylene

Regulator

Torch Handle

Attaches to Dual Purpose Cart (100MC), Sold Sepa-

rately

Cuts, Welds and Solders in One Kit

Oxygen

Regulator

Acetylene

Tank

Oxygen

Tank

Welding Tip

Cutting Head

Striker

Heavy Duty Tote

KDAR Company 3

Goggles

Acetylene Tank

Key

Hose

Page 5

Installation & Setup

Oxygen & Acetylene Filling

The Mobile Max is shipped with the tanks empty. Therefore, you will have to take the tanks to a local welding

gas supply distributor to have them filled prior to welding. Different welding gas suppliers handle tank filling

differently; some will fill the tanks while you wait while others require a tank exchange. You will need to select the type of supplier you prefer.

Attaching Regulators and Hoses

1. Secure the Mobile Max to an immovable object

such as a pole or a cart specifically designed to

hold the torch kit.

Note: Although the Mobile Max is intended to

be portable; it is important that the unit be secured

so it will not tip over during setup and operation.

2. Briefly open the oxygen tank valve (1) to remove

any debris that may have accumulated.

3. Wipe the oxygen regulator fitting (2) with a clean

dry cloth and tread the fitting onto the tank valve

and tighten with a wrench. Thread in the regulator

valve lever (3).

4. Using the acetylene tank valve key; briefly open

the acetylene tank valve (4) to remove any debris

that may have accumulated.

5. Wipe the acetylene regulator fitting (5) with a

clean dry cloth and thread the fitting onto the tank

valve and tighten with a wrench. Thread in the regulator valve lever (3).

6. Using compressed air; blow out the hoses prior to

using them for the first time.

7. Attach the hoses to the regulators; green to the ox-

ygen and red to the acetylene and tighten with a

wrench.

8. Attach the other end of the hose to the appropriate

fittings on the torch handle and tighten with a

wrench.

Note: The acetylene hose has left hand (r ever se)

treads and is marked with notches in the fitting (6).

1

Oxygen Tank

Valve

3

Acetylene

Regulator

Acetylene Tank

Valve Key

6

2

Oxygen

Regulator

5

Acetylene Tank

Valve

Hose Fittings

3

4

KDAR Company 4

Page 6

Installation & Setup

It is important that all fittings have been tightened

with a wrench by this point.

Insure the tank valves, regulators valves and torch

handle valves are turned to the off position.

Opening Valves

1. Attach the welding tip and tighten with a wrench.

2. Slowly open (clockwise) the oxygen cylinder

valve to allow oxygen to flow to the regulator.

Once the regulator begins to register pressure,

open the valve an additional 1 to 1 1/2 turns.

Note: This must be done slowly, as a sur ge of

pressure could damage the regulator diaphragm.

3. Slowly open the acetylene tank valve with the

tank key. This valve turns left (counter clockwise)

to open. Open slowly and not more then 1 turn.

4. Check for leaks. Leaks can not be seen, therefore,

use soapy water on all connection points to insure

there are no leaks.

Setting Working Pressures—Welding

WARNING

While setting working pressure gases will

be released from the torch. It is important

that no open flame or other heat source is

present during this operation.

1. Attach the welding tip to the end of the torch handle opposite the hose attachment and tighten with

a wrench.

Note: The wor king pr essur e for the welding tip

supplied with the Mobile Max (#1) is a minimum of 3

and maximum of 5 PISG for oxygen and minimum of

3 and maximum of 5 PSIG for acetylene. If other tips

are used consult the tip charts on page 9.

2. Open the acetylene control knob (1) on the torch

handle by turning it clockwise. Turn the control

lever on the acetylene regulator until the desired

working pressure is reached. Once the working

pressure is reached turn off the control knob on

the torch handle. The regulator gauge reading

may increase slightly.

3. Open the oxygen control knob (2) on the torch

handle by turning it clockwise. Turn the control

lever on the oxygen regulator until the desired

working pressure is reached. Once the working

pressure is reached turn off the control knob on

the torch handle. The regulator gauge reading

may increase slightly.

Note: The Mobile Max is equipped with single

stage regulators and as such the working pressure

may need to be adjusted as the gas pressure in the

tanks decreases.

2

1

WARNING

Prior to lighting the torch make sure the

hoses are behind the operator and that

there is no chance of them being hit by a

hot spark or slag.

KDAR Company 5

Page 7

Operation

WARNING

At this point the operator should be wearing appropriate protective clothing such as

gloves and goggles.

Lighting the Torch

1. Open the acetylene control knob on the torch handle just enough to let some gas flow.

2. Holding the striker close to the welding tip

squeeze it a few times to create the sparks required to light the acetylene.

Note: A oxyacetylene torch should NEVER be lit

with oxygen present in the mixture.

Adjusting the Flame

1. If the acetylene is set too high the flame will be a

few inches away from the tip. Reduce the amount

of acetylene by turning the acetylene control knob

counter clockwise.

2. When the flame is about 8—10 inches long and

only has a small amount of black smoke; begin to

introduce oxygen by turning the oxygen control

knob clockwise.

3. As oxygen is added the flame will turn from a

yellow-orange to a whitish color and flame will

have three distinct cones (Figure 1). This is called

a carburizing flame and is not hot enough for

welding.

4. As oxygen is added to the mix the acetylene

feather will shrink and disappear into the cone

(Figure 2). This a neutral flame and is ideal for

welding.

5. If additional oxygen is added the cone will become shorter and fuzzy (Figure 3). This is a oxidizing flame and will cause breakdowns in the

material being welded and the weld itself.

Once a neutral flame has been achieved the torch

is ready for welding.

Heat Envelope

Acetylene

Feather

Beginning

Figure 1

Figure 2

Short Heat Envelope

Figure 3

of Cone

Heat Envelope

Sharp,

Bright Cone

Short, Fuzzy

Cone

KDAR Company 6

Page 8

Operation

Shutting Down

1. Using the acetylene control knob turn off the

flow of acetylene to the welding tip. This will

allow oxygen to continue to flow and will insure

any debris that may be in the orifice is blow out.

2. Turn off the oxygen using the oxygen control

knob on the torch handle.

3. If shutting down for only a short period of time,

close the tank valve on both the acetylene and

oxygen and leave the hoses filled with gas.

4. If shutting down for a longer per of time, close

the tank valve on both the acetylene and oxygen.

5. Bleed the acetylene line by opening the acetylene control knob on the torch handle. Watch the

regulator gauge, it should move to reading zero.

6. Close the acetylene control knob on the torch

handle.

7. Bleed the oxygen line by opening the oxygen

control knob on the torch handle. Watch the regulator gauge, it should move to reading zero.

8. Finally release the pressure on the regulator diaphragm by opening the regulator valve until little

or no pressure is felt. This will significantly improve the life of the regulator.

Setting Working Pressures—Cutting

WARNING

While setting working pressure gases will

be released from the torch. It is important

that no open flame or other heat source is

present during this operation.

Note: At this point the tanks should be tur ned off

and both the acetylene and oxygen lines cleared of

gas.

1. Remove the welding tip from the torch handle

and attach the cutting head. Tighten with a

wrench.

2. Insure that the both the acetylene and oxygen

control knobs on the torch handle are closed

(clockwise).

3. Insure the oxygen control knob (1) on the cutting

head is closed (clockwise).

1

4. Select the appropriate cutting tip for the material

being cut and attach it to the cutting head (the

Mobile Max is shipped with a #1 tip assembled

to the cutting head). Tighten with a wrench.

Note: The char t on page can be used as a

guide for selecting the correct tip for the job.

5. Close (counter clockwise) both the acetylene and

oxygen regulator valves.

6. Slowly open (counter clockwise) the oxygen cylinder valve to allow oxygen to flow to the regulator. Once the regulator begins to register pressure, open the valve an additional 1 to 1 1/2

turns.

Note: This must be done slowly, as a sur ge of

pressure could damage the regulator diaphragm.

7. Open the oxygen regulator until the regulator

reaches the desired working pressure.

Note: Wor king pr essur e char ts ar e found on

page 9.

KDAR Company 7

Page 9

Operation

8. Check all connections for leaks. Leaks can not

be seen, therefore, use soapy water on all connection points to insure there are no leaks.

9. Open the oxygen control knob on the torch handle two full turns. No oxygen should flow at this

time because the oxygen flow is controlled by

the valve on the cutting head.

10. Insure oxygen flows by turning the control knob

on the cutting head a quarter of turn. Quickly

close the valve after confirming oxygen flow.

11. Press the oxygen cutting lever (1) briefly to confirm a steam of oxygen flows from the center

hole in the cutting tip.

1

12. Slowly open the acetylene tank valve with the

tank key. This valve turns left (counter clockwise) to open. Open slowly and not more then 1

turn.

13. Open the acetylene regulator until the regulator

reaches the desired working pressure.

Note: Wor king pr essur e char ts ar e found on

page 9.

14. Briefly open the acetylene control knob on the

torch handle to confirm acetylene is flowing.

15. Check all connections for leaks using soapy water..

Lighting the Torch

WARNING

Prior to lighting the torch make sure the

hoses are behind the operator and that

there is no chance of them being hit by a

hot spark or slag.

At this point the operator should be wearing appropriate protective clothing such as

gloves and goggles.

1. Open the acetylene control knob on the torch

handle just enough to let some gas flow about a

quarter turn.

2. Holding the striker close to the cutting tip

squeeze it a few times to create the sparks required to light the acetylene.

Note: A oxyacetylene torch should NEVER be lit

with oxygen present in the mixture.

Adjusting the Flame

1. Open the oxygen valve on the cutting head.

2. Develop a neutral flame at the preheat holes

(Figure 4) by that results in a cone about 1/8th

inch long. This is accomplished by alternately

increasing the flow of acetylene and then oxygen.

Cutting Hole

Figure 4

Preheat Holes

KDAR Company 8

Page 10

Operation

3. Press the oxygen cutting lever briefly to insure

oxygen is flowing through the cutting hole.

4. Further adjustment may now be needed to insure

a neutral flame in the preheat holes. Generally a

reduction in oxygen.

5. The torch is ready for cutting.

Shutting Down

1. Using the acetylene control knob on the torch

handle turn off the flow of acetylene to the welding tip. This will allow oxygen to continue to

flow and will insure any debris that may be in

the preheat holes is blow out.

2. Press the oxygen cutting lever to insure debris is

cleared from the cutting hole.

3. Turn off the oxygen using the oxygen control

knob on cutting head.

3. If shutting down for only a short period of time,

close the tank valve on both the acetylene and

oxygen tank and leave the hoses filled with gas.

4. If shutting down for a longer per of time, close

the tank valve on both the acetylene and oxygen

tanks.

5. Bleed the acetylene line by opening the acetylene control knob on the torch handle. Watch the

regulator gauge, it should move to reading zero.

6. Close the acetylene control knob on the torch

handle.

7. Bleed the oxygen line by opening the oxygen

control knob on the cutting head. Watch the regulator gauge, it should move to reading zero.

8. Finally release the pressure on the regulator diaphragm by opening the regulator valve until little

or no pressure is felt. This will significantly improve the life of the regulator.

Welding Nozzle Chart

Oxygen Pressure

Metal

Thickness

Up to 1/32" 000 3 5 3 5

1/16"-3/64" 00 3 5 3 5

1/32"-5/64" 0 3 5 3 5

3/64"-3/32" 1 3 5 3 5

1/16"-1/8" 2 3 5 3 5

1/8"-3/16" 3 4 7 3 6

3/16"-1/4" 4 5 10 4 7

Tip

Size Min. Max. Min. Max.

P.S.I.G.

Acetylene Pressure

P.S.I.G.

Cutting Tip Chart

Oxygen Pressure

Metal

Thickness

1/8" 000 20 25 3 5

1/4" 00 20 25 3 5

3/8" 0 25 30 3 5

1/2" 0 30 35 3 5

3/4" 1 30 35 3 5

1" 2 35 40 3 6

2" 3 40 45 4 8

3" 4 40 50 5 11

4" 5 45 55 6 13

Tip

Size Min. Max. Min. Max.

P.S.I.G.

Acetylene Pressure

P.S.I.G.

Heating Nozzle Chart

Acetylene

Pressure

Range

Tip

P.S.I.G. P.S.I.G.

Size

4 6-10 8-12 6 20 7 22

6 8-12 10-15 14 40 15 44

8 10-15 20-30 30 80 33 88

10 12-15 30-40 40 100 44 110

Oxygen

Pressure

Range

Acetylene Cubic

Feet/Hour

Min. Max. Min. Max.

Oxygen Cubic

Feet/Hour

KDAR Company 9

Page 11

Maintenance and Additional Products

General Maintenance

1. Prior to EVERY use, inspect hoses for damage.

Note: Never tr y to r epair damaged gas hoses.

Damaged hoses should be replaced.

2. Prior to EVERY use, check all connections for

leaks.

3. Clean splatter and slag off of the outside of

welding and cutting tips as required.

4. Regularly clean tip holes with a welding tip

cleaner (Hot Max # 22034).

Note: Never use oil, grease, pipe dope, or Teflon

tape on any part of the Mobile Max equipment.

Hot Max Victor ® Style

3 Piece Torch Kits

Model VH-1 - Medium Duty

Model VHD-1 - Heavy Duty

Additional Hot Max Products

Model 100MC

Red Cart for MM-1 Mobile Max

Model VTK-MD

Medium Duty Victor ® Style

Torch Kit

Model VTK-HD-A

Heavy Duty Victor ® Style

Deluxe Gas Torch Kit

KDAR Company 10

Page 12

Warranty

KDAR Company, and its affiliates, warrants that

all MM-1 Mobile Max torch kits covered under

this warranty is free from defects in material and

workmanship for one year from the date of purchase. KDAR also warrants that the hoses are free

from defects in material and workmanship for 90

days from the date of purchase. This warranty is

extended to the original purchaser who uses the

product in a consumer application (personal, residential or household usage). All torch kits covered under this limited warranty which are used in

commercial applications (i.e. income producing)

are warranted to be free from defects in material

and workmanship for 90 days from the date of

original purchase. The product covered under this

warranty is the MM-1 Mobile Max torch kit.

KDAR Company, and its affiliates, will repair or

replace, at KDAR’s sole discretion, parts found to

be defective in material or workmanship within

the warranty period. Warranty service will be

scheduled according to the normal work flow and

business hours of the service center doing the

work as well as the availability of replacement

parts. All decisions from KDAR Company re-

garding this limited warranty shall be final.

Original Purchaser’s Responsibility:

1. Retain the original cash register receipt as

proof of purchase.

2. Follow manual instructions regarding the care

and operation of your torch kit.

3. If warranty work is required, DO NOT RE-

TURN THIS TORCH KIT TO THE RETAILER. Contact KDAR Company for in-

structions. Visit www.hotmaxtorches.com or

call KDAR Company M-F 8AM-5PM CST to

locate the nearest Authorized Service Center.

Not Covered:

1. Transportation charges for sending or delivering the torch kit to the Authorized Service

Center or returning the repaired or replacement

torch kit back to the customer. These charges

are the responsibility of the customer.

2. Damages caused by ordinary wear, abuse, rain,

freeze damage, negligence, accident or failure

to operate or maintain the torch kit in accordance with the instructions in the operator’s

manual supplied with the equipment.

3. Damage caused by unauthorized repair or al-

terations.

Exclusions and Limitations:

KDAR Company makes no other warranty of

any kind, express or implied. Implied warranties, including warranties of merchantability

and of fitness for a particular purpose, are

hereby disclaimed. The warranty service described above is the exclusive remedy under

this warranty; liability for incidental and conse-

quential damages is excluded to the extent per-

mitted by law.

This warranty gives you specific legal rights, and

you may have other rights which vary from state to

state. Some states do not allow a disclaimer of implied warranties, or the exclusion of incidental and

consequential damages, so the above disclaimers

and exclusions may not apply to you.

For warranty service or to obtain service parts

or accessories:

Call: (314) 692-8555 M-F 8-5 PM, CST

Visit: www.hotmaxtorches.com

Write: KDAR Company

1 Mulch Lane

St. Louis, MO 63044

KDAR Company

1 Mulch Lane

St. Louis, MO 63044

Phone: (314) 692-8555 Fax: (314) 692-8578

Loading...

Loading...