Page 1

Operator’s Manual

Model 125WFG

Wire Feed Welder

MIG Welders

WARNING: Do not assemble, install, or operate this equipment without reading ALL of this manual

and the safety precautions and warnings illustrated in this manual.

KDAR Company Tel: (314) 692-8555

1 Mulch Lane Fax: (314) 692-8578

St. Louis, MO 63044 Web Site: www.hotmaxtorches.com

Page 2

SAFETY PRECAUTIONS AND WARNINGS

PLEASE READ BEFORE USING EQUIPMENT

WARNING

ELECTRIC SHOCK CAN KILL.

The input circuits are live and hot when the power is on

Do not touch live electrical parts

Wear dry, hole free insulated work gloves and body protection when operating

Do not touch torch components if in contact with the work piece or ground

Always turn off power before cleaning, checking, or changing parts

Properly ground this piece of equipment per state and federal requirements

Inspect and replace any worn or damaged torch cables or leads

Keep all panels and covers securely in place

Keep away from the torch tip and weld arc when trigger is pressed

Ground the metal or work piece to the ground cable (Earth Clamp)

Never dip the tip into water to cool or attempt to use welder in or under water

This DC equipment holds a lot of power in the off position, before touching, make sure voltage is

near zero on input capacitors before touching any parts.

Keep children away from this equipment

Protect yourself and others from possible injury

Pacemaker wearers should consult with their doctor before operating

Read and follow all instructions in this manual before operating

All installation, operation, and maintenance procedures are to be

performed only by qualified individuals

ARC RAYS CAN BURN SKIN AND EYES

Arc rays when welding produce intense ultraviolet and infrared rays that can burn skin and eyes

Wear face protection, either helmet or shield, when operating. ANSI Z49.1 approved shade #9

recommended for all cutting currents less than 300 amperes. The lens should conform to ANSI

Z87.1 standards for testing.

Wear approved safety glasses with side shields under the face protection

Warn others not to stare at the arc as it can cause damage to the eyes. Provide barriers to protect

other workers in the area from the arc while operating

Wear flame resistant gloves, clothing, and shoes when operating

FUMES AND GASES CAN BE HAZARDOUS

Arc welding produces fumes and gases and breathing these gases is hazardous to your health

Keep your head out of the fumes and do not breath the fumes while welding

Work only in a confined area if it has sufficient ventilation, or while wearing an air supplied

respirator. Fumes from welding deplete the oxygen supply and can be harmful. Always be sure

there is ample breathing air

Read the MSDS sheets and the instructions from manufacturers for metals to be welded, coatings,

and cleaners

Do not use the welder near hydrocarbon vapors coming from degreasing, cleaning, or spraying

operations. The heat and rays can react with solvent vapors to create the gas phosgene, a very toxic

gas and other irritating gases

Do not weld coated metals, such as galvanized, lead, or cadmium plated steel. Before welding, all

plating must be removed. The area must be well ventilated or an air supplied hood must be used.

The coatings and chemicals when burned cause highly irritating and toxic fumes.

Do not weld containers with toxic, flammable, or reactive elements stored in them. They must be

emptied and properly prepared before welding.

KDAR Company 1

Page 3

WELDING SPARKS CAN CAUSE INJURY, FIRE, OR EXPLOSION

Remove all flammable materials from the welding area

Always have a charged fire extinguisher available in the welding area

When not welding make sure the welding tip is not grounded, this causes a heat build up and

possible fire

Avoid welding near hydraulic lines, fuel lines, electrical cords, air hoses, or welding guns and

cables

Sparks and hot metal fly out from the work area when welding, wear approved safety glasses with

side shields under approved helmets, wear proper body and hand protection, and wear flame

resistant ear plugs to keep sparks from entering the ears

CYLINDERS CAN EXPLODE IF DAMAGED

Gas cylinders contain gas under very high pressure. If damaged they can result in that cylinder

exploding. Gas cylinders are a major part of metalworking and must be treated with care.

Protect gas cylinders from excessive heat, mechanical shocks, slag, open flames, sparks, and arcs

Always keep cylinders in an upright position securely fastened to a fixed support

Valve protection caps should always be in place and hand tight except when the cylinder is in use

Keep all cylinders away from any welding or electrical circuits

Never allow the arc from a welder to contact a cylinder

Never cut any type of pressurized cylinder, an explosion could result

Always turn your face away from the valve when opening the cylinder

Read and follow all instructions on compressed gas cylinders, associated equipment, and CGA

publication P-1 listed in the Safety Standards before using

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS

Electric current used in arc welding can create Electro-Magnetic Fields (EMF)

Magnetic fields can affect pacemakers and wearers should avoid proximity to EMF. Wearers need

to contact their doctors before operating this type of equipment

Exposure to EMF during operation of this equipment may have other health effects which are not

yet known

Route the work and torch cables together and not around your body

Do not place your body between the torch cable and the ground cable. They both need to be on the

same side of your body when operating

Do not work next to the welding machine

ELECTRICALLY POWERED EQUIPMENT

Disconnect power source or turn off the breaker in the power panel before working on any

equipment

Only install equipment using the US National Electrical Code, all local codes, and the man-

ufacturer’s recommendations

HOT PARTS CAN CAUSE SERIOUS BURNS

Do not touch hot parts without wearing protection.

Allow the torch to cool sufficiently before working with parts that could potentially be hot.

KDAR Company 2

Page 4

NOISE CAN DAMAGE HEARING

Prolonged noise exposure from welding equipment can cause damage if levels of noise exceed the

OSHA standards

Wear approved hearing protectors

Warn other workers nearby of the high noise level and hazard

CALIFORNIA PROPOSITION 65 WARNINGS

Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to cause

birth defects, and in some cases, cancer. (California Health and Safety Code Section 25249.5 et seq.)

PRINCIPAL SAFETY STANDARDS

AMERICAN WELDING SOCIETY

AWS C5.2, Recommended Practices for Plasma Arc Cutting

AWS F4.1, Recommended Safe Practices for the Preparation for Welding and Cutting

OSHA STANDARDS

OSHA 29 CFR 1910, Safety and Health Standards

NATIONAL FIRE PROTECTION ASSOCIATION

NFPA Standard 70, National Electric Code

NFPA Standard 51B, Cutting and Welding Processes

AMERICAN NATIONAL STANDARDS INSTITUTE

ANSI Standard Z87.1, Safe Practices for Occupation and Educational Eye and Face Protection

ANSI Standard Z49.1, Safety in Welding and Cutting

KDAR Company 3

Page 5

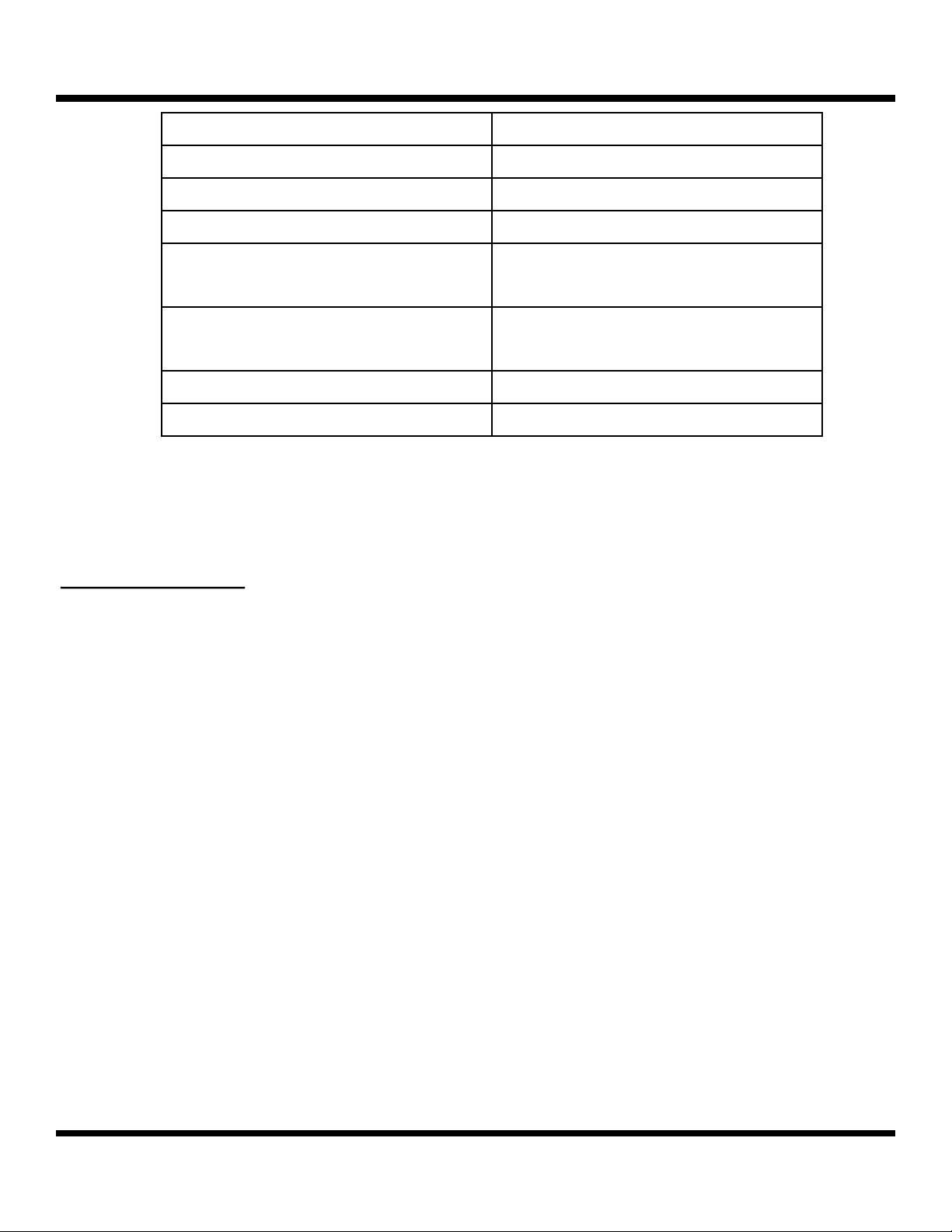

Specifications

Rated input 115VAC, 60 hertz, 18 amps

Maximum output open-circuit voltage 28 volts DC

Rated output 80 AMPS@18volts 20%duty cycle

Wire feed rate 59 to 393 in/min (1.5-10.0m/min)

Specifications of applicable welding

wire

Welding Wire Spool 8”x2” (200mmx50mm)

Weight 54 lb (24.5 kg)

Dimensions (Length*Width*Height) 16”x9.6”x14.5” (408x244x367)

Features & Benefits

Light weight, small size all steel case.

Easy to use.

MIG/MAG ready, regulator and 5’ hose in-

cluded.

Optional spool gun available.

Infinite output voltage level.

Infinite wire feed speed control.

Wire at gun is “cold” when not welding.

Power on indicator light and overload indicator

light equipped.

Fan cooled.

20% duty cycle minimum.

Welds 22 gauge to 5/16” with flux cored wire.

Built in wire feeder with easy to use tension

adjustment lever.

Dual size groove drive roller to fit sizes .23”

to .35” wire (.6 to .9 mm).

.025”-.030” (0.6-0.8mm) solid steel

.030”-.035” (0.8-0.9mm) Flux-Cored

4”x2” (100mmx50mm)

Table 1

Easy polarity change for switching to and from

gas.

Flux covered (FCAW) set up from the factory,

ready to weld.

Welds steel, aluminum, and stainless (special

gas required for aluminum and stainless).

2 year limited warranty on the machine.

90 day limited warranty on gun and hose.

Comes with the following components.

2 replacement tips

Hex wrench to change wire feed roller.

Gas nozzle for MIG welding.

10# spool adaptor.

Gas regulator

5’ gas hose

2# Reel of .030” Flux Core Wire

KDAR Company 4

Page 6

Safety Considerations

Warning

Electric Shock Can Kill

Only qualified personnel should attempt to install this equipment.

Turn off the input power at the power panel or disconnect switch and discharge

capacitors before working inside the equipment.

Take care not to touch electrically hot parts

Make sure the unit is switched off before plugging it into a the power outlet.

Package Contents

Installation/Setup

KDAR Company 5

Page 7

Installation/Setup

Selecting A Location

The 125WFG Welder should be placed where clean cool air can easily flow through the vents in the front of

the unit. Dirt and dust can be drawn into the unit resulting in excessive operating temperatures and shutdowns,

therefore, dirt and dust around the unit should be kept to a minimum.

The 125WFG Welder should be placed on a stable, level surface suitable to hold the unit’s weight.

Components and Controls

1. Output voltage adjust knob

2. Power switch

3. Wire feed rate adjust knob

4. Thermal overload indicator

5. Ground clamp connection port

6. Gun trigger lead connectors

7. Door latch

8. Ground (work) clamp and cable

9. Welding gun and cable assembly

10. Overload reset button - the protector will

cut off the circuit if the welding machine

is in excess of the maximum load, after

which the switch must be manually reset.

11. Power Cord

12. Shielding gas inlet fitting

13. Spool gun selection switch

14. Positive (+) and Negative (-) output

terminals

15. Wing nut to secure welding gun

16. Wire feed gearbox

17. Wire spool spindle/shaft

6 KDAR Company

Page 8

Installation/Setup

Warning

Always unplug the welder before connecting or disconnecting the Ground Clamp cable

and/or the Gun Cable.

Ground Clamp & Lead Connection

1. Ground Cable Attachment: Th e Hot Max MI G

Welders use a convenient 1/4 turn connection for

attaching the ground cable to the unit. Insert the

male end of the ground cable into the female connection port (1) and turn 1/4 turn clockwise.

2. For FCAW (Flux Cored Arc Welding) Only:

The WFG series of welders are delivered set up for

FCAW welding with negative electrode polarity.

The cable coming out of the wing nut (6) on the

connector block is attached to the negative (-) output terminal and the ground lead is connected to

the positive (+) terminal.

3. GMAW (Gas Metal Arc Welding) Only: To set

up for GMAW welding with positive electrode polarity, connect the cable coming from the wing nut

(6) on the connector block to the positive (+) output terminal and the ground lead to the negative (-)

output terminal. Make sure all connections are

tight.

4. Gun Selection: Select standar d gun or optional

spool gun using the gun selector switch (4).

Figure C-1

Gun Installation

1. Insert the male connector on the gun cable into the

gun cable connection port (3). With the connector

all the way in the connector block tighten the wing

nut (6) to secure the gun.

2. Connect the gun lead terminal to the gun lead connector (2).

KDAR Company 7

Page 9

Installation/Setup

Gas Connection

Warning

Cylinder can explode if damaged. Keep cylinder chained upright to a secure support.

Keep cylinder away from areas where it could be damaged.

Never lift or move the welder with the cylinder attached.

Do not let the welding electrode touch the cylinder.

Keep the cylinder away from welding or other live circuits.

Shielding Gas may be harmful to health or cause death.

Turn off gas supply when not in use.

Refer to American National Standard Z-49.1, “Safety in Welding and Cutting” from the Amer-

ican Welding Society for more information.

Gas Hook Up

When using the GMAW process, a cylinder of shielding gas must be used. Shielding gas cylinders and gas can

be obtained at a local gas supply company or some farm supply stores. The recommended gases for the Hot

Max 125MIG welder is either Welding grade CO2 or a Argon/CO2 blend with 75-80% Argon and 20-25%

CO2 (see Suggested Settings chart on the welder compartment door).

1. Insure the cylinder is properly secured to a wall or other stationary support to prevent it from falling over

during setup or operation. Be sure the cylinder is insulated from the work circuit and ground.

2. Once the cylinder is properly secured,

remove the cylinder cap. Standing to one

side slowly open the cylinder valve for an

instant to blow away any debris that may

have accumulated in the valve outlet.

3. Attach the flow regulator to the cylinder

valve and tighten with a wrench.

4. Attach one end of the gas hose to the output fitting of the regulator and tighten

securely with a wrench.

5. Test to insure the flow regulator is closed

by opening cylinder valve slightly. If the

regulator is not closed turn the black

knob counter clockwise until the flow of

gas has stopped.

6. Connect the other end of the hose to the

gas inlet fitting on the 125WFG welder

making sure that the hose is not kinked or

twisted.

KDAR Company 8

Page 10

Installation/Setup

Gas Hook Up (cont.)

7. Reopen the regulator valve until the flow indicator shows

15 L/min (initial flow setting). The setting may need to be

adjusted by the operator to compensate for welding conditions.

8. Always close the cylinder valve and open the regulator

valve when not in use.

Input Connections

The 125WFG welder has power input cables located on the rear of the unit.

KDAR Company 9

Page 11

Safety Considerations

Warning

Electric Shock Can Kill

Do not touch live electrical parts of the electrode with skin or wet clothing.

Insulate yourself from work and ground.

Always wear insulated gloves and keep them dry.

Fumes & Gases Can Be Hazardous

Plasma cutter should only be used in a well ventilated area or with an exhaust

system.

Keep your head away from the fumes.

Operation

Arc Rays Can Burn Skin and Eyes

Always were eye, ear and body protection.

Cutting Sparks Can Cause Injury, Fire , or Explosion

Do not use near flammable material.

Do not cut or gouge on containers that have held combustibles.

KDAR Company 10

Page 12

Operation

Controls

1. Output Voltage Control—The Hot Max infinite

setting output voltage control knob adjusts to any

setting from 25 to 125 amps. Additionally, the

voltage can be adjusted while welding.

2. Power On/Off Switch—A light within the switch

will be illuminated and the cooling fan will run

when the power is on.

3. Speed Control—Controls the wire feed speed.

The control can be preset on the dial to the setting

specified on the application chart located inside the

wire feed section door.

4. Overload Indicator—This LED comes on to indicate the duty cycle had been exceeded. Output will

be shut off until the unit has cooled to an acceptable operating temperature. The fan will continue to

run.

9. Gun Trigger—Pressing the trigger activates the

welding output, wire feed and gas operation. Re-

leasing the trigger stops the welding output, wire

feed and gas operation. Releasing the trigger also

starts the burn back function to prevent the welding wire from sticking to the working weld.

10. Overload Breaker—This breaker protects the unit

from damage due to exceeding the maximum output. The breaker pops out when tripped and must

be pushed in to be reset.

KDAR Company 11

Page 13

Operation

Use the welding wire board

with 4 "(100 mm) in diameter

Figure D-2

4

7

6

5

Use the welding wire board

with 8 "(200 mm) in diameter

Figure D-1

2

1

3

Loading Wire

Note: Always tur n power off when wor king inside

the welder enclosure.

8” Diameter Spool

1. Remove the wing nut (5), and plastic tension spacer (6).

2. Place the spool adaptor (2) over the shaft as

shown.

3. Replace spacer and wing nut. Make sure the wing

nut is positioned so that it does not interfere with

the locking tab.

4. Place spool on the spool adaptor making sure the

hole in the spool engages the stud (3) on the spool

adaptor and the spool slides completely over the

locking tab.

4” Diameter Spool

1. Remove wing nut (5) and the plastic tension spacer

(6).

2. Place the spool (label out) on the shaft with the

wire feeding from under the spool.

3. Replace the spacer, washer and wing nut

Adjusting Friction Break

While turning the spool with one hand begin tightening the wing nut with the other. Once you start to feel

tension; then turn the wing nut an additional 1/4 to 1/2

turn.

The intent is for the friction break to produce just

enough friction to prevent the spool from continuing

to turn after the drive motor has stopped.

KDAR Company 12

Page 14

Operation

Wire Feeding

1. Release the spring loaded tension arm (1) by flipping it to the right and down.

2. Lift the idle arm (2).

3. Make sure the grove size on the drive roll (5) is in

the feeding position that matches the wire size being used. Refer to the Suggested Settings for

Welding chart at the back of this manual or on the

inside of the welder compartment door.

4. Detach the end of the wire from the spool and clip

a small amount of wire to get a good straight start.

Note: In or der to p r event the spool from un-

winding; it is important to keep tension on the wire

until after the idle arm and tension arm are back in

place.

5. Thread the wire through the inlet tube (4), over the

drive roll (5) and into the outlet guide tube (6).

6. Close the idle arm (2).

7. Move the spring loaded tension arm (1) into position.

8. If required, rotate the wire spool counter clockwise

to take up any slack in the wire.

9. If feeding problem occur because the wire is excessively flattened, turn the wing nut on the spring

loaded tension arm (1) counter clockwise to reduce

the pressure. If the drive roll (5) is slipping while

feeding the wire; turn the wing nut clockwise to

create more tension on the wire.

10. Remove nozzle (7) and contact tip (8) from

end of gun.

11. Turn on the Hot Max 125WFG.

12. With the gun cable assembly straight; press the

trigger switch. The welding wire will feed

through the cable and gun. Release the trigger

when the wire has fed approximately 2 inches

past the end of the gun.

13. Turn off the Hot Max 125WFG.

14. Replace the contact tip (8) and nozzle (7)

15. Cut wire off approximately 3/8” from the end

of the contact tip. The Hot Max 125WFG is

ready for welding.

Warning

When feeding the wire, the drive roll, the connector

block and gun contact tip are electrically charged

relative to work and ground and remain charged

for several seconds after the gun trigger is released.

KDAR Company 13

8 7

Figure 13

Page 15

Operation

Welding

1. See Suggested Settings at the back of this manual

or on the inside of the wire feed compartment door

for welding wire and shielding gas recommendations.

2 See Suggested Settings for information on setting

the controls on the Hot Max 125WFG for specific

welding wire and metal thickness.

3. Set the voltage and wire speed.

4. Insure the unit is set up for the correct polarity for

the welding wire and process being used. The Hot

Max 125WFG is shipped set up for FCAW (Flux

Cored Arc Welding)

5. Insure the proper nozzle and tip are installed on the

gun for the welding wire and process being used.

6. If required, turn on gas supply.

7. Connect the ground clamp to the metal being

welded. The clamp must make a good connection.

8. Position the gun of the joint to be welded. The

wire can touch the metal lightly.

9. Lower the welding helmet, pull the trigger on the

gun and start welding. The contact tip should be

about 3/8” from the work surface.

10. Release the trigger to stop welding and pull the

gun away from the work after the arc has stopped.

11. If there is no more welding to be done, close the

valve on the gas cylinder (if gas was used) and pull

the trigger on the gun to release the gas pressure

and then turn off the Hot Max 125WFG.

Changing the Welder for Feeding

Different Wire Sizes

The Hot Max 125WFG is shipped ready to

run .030” gasless flux cored wire. To run other sizes of wire the contact tip must be changed and the

drive feed roll may need to be changed.

Changing the Contact Tip

1. To change the contact tip (1) you must first

remove the nozzle (2). This is done by un-

screwing it counter clockwise.

2. Unscrew the contact tip counter clockwise.

3. Screw in selected contact tip clockwise. Hand

tighten only.

4. Replace nozzle by screwing on clockwise.

2 1

Figure 14

KDAR Company 14

Page 16

Operation

Shielding

Proce ss Welding Wire Gas 16 ga 14 ga 12 ga 10 ga

MIG DC+

.035 Dia 4043

Aluminum Wire

100% Argon B-5.5 C-7 C-9 C-9

MIG DC+

.035 Dia 5356

Aluminum Wire

100% Argon B-5.5 C-8 C-9 C-10

MIG DC+

.030 Dia 308L

Stainless Steel

Wire

98% Argon/

2% Oxygen

A-3 C-7 C-7 C-7

Voltage/Wire Spee d

Changing Drive Roll

The drive roll has two groves; the smaller grove is

for .023” - .025” welding wire and the larger grove is

for .030” - .035” welding wire. The welder is shipped

set up for the larger welding wire sizes.

To change the drive roll position:

1. Connect the unit to the appropriate power source.

2. Open the wire drive compartment door, release the

spring loaded tension arm (1) by flipping it to the

right and down and lift the idle arm (2).

3. Turn the power on.

4. Turn the feed control speed to the minimum setting and momentarily pull the trigger to turn the

drive roll (4). Stop when the set screw (3) is facing

up.

Warning

When feeding the wire, the drive roll, the connector

block and gun contact tip are electrically charged

relative to work and ground and remain charged

for several seconds after the gun trigger is released.

5. Turn the power off.

6. Loosen the drive roll set screw (3) with the hex

wrench provided with the Hot Max 125WFG.

7. Remove the drive roll (4) turn it around and put it

back on the shaft.

8. Cut and straighten about 5” of the desired wire and

feed it through the wire inlet tube and into the outlet tube. Line up the drive roll grove with the

welding wire and tighten with the hex wrench.

Make sure the set screw is on the flat part of the

shaft.

Aluminum & Stainless Steel Wire

The Hot Max 125WFG is capable of welding with

both .035” aluminum and .030” stainless steel

welding wire. See the table below for welder settings for these wires.

Table 2

KDAR Company 15

Page 17

Maintenance

Warning

Electrical Shock Can Kill

Disconnect from the input power source prior to working inside the Hot Max

125WFG.

Allow only qualified personnel to do maintenance and trouble shooting.

General Maintenance

Power Supply Compartment

The Hot Max 125WFG does not have any serviceable

parts inside the power supply compartment. Do not

attempt to service parts in the power supply compartment. Contact KDAR Company for instructions if

you have problems that can not be corrected by following the trouble shooting instructions.

If you are working in dusty areas, dirt may get into

the air vents and cause the welder to run hot and trip

the thermal overload protection. If this happens, blow

the dirt out with low pressure air regularly.

Wire Feed Compartment

1. Occasionally dirt will accumulate in the wire feed

compartment. When this happens, simply vacuum

the dirt out of the compartment.

2. Each time the wire spool is changed, inspect the

inside diameter of the wire feed inlet tube. If necessary, clean the inside of the tube.

3. The motor and gearbox needs no lubrication or

maintenance.

Wire Spool Shaft

Requires no maintenance. Do Not Lubricate.

Gun Cable

1. To clean the cable liner, remove the gun cable

assembly from the welder and lay it out

straight on the floor.

2. Take the contact tip off of the gun. Blow low

pressure air through the liner from the gun end

of the liner.

3. Flex the cable over its entire length and blow

air through again. Repeat flexing the cable and

blowing air through until no dirt comes out.

Contact Tip & Nozzle

1. When dirt builds up in the contact tip hole,

wire feeding can be restricted. To clean the tip,

run the appropriate sized tip cleaner through

the tip repeatedly. This should remove any dirt

that has built up on the walls of the contact tip.

KDAR Company tip cleaner number 22034 is

available for selected distributors or hotmax-

torches.com.

2. Remove splatter from the inside gas nozzle and

the tip frequently.

KDAR Company 16

Page 18

Troubleshooting

Warning

Most components of the 125WFG welder are not serviceable by the operator and should only be serviced by a qualified repair technician. Unauthorized repairs to these units may result in danger to the

operator and will void the factory warranty. For your safety, please follow all safety precautions found

throughout this manual.

Problem

Nothing happens when the trigger is pulled; no wire

feed, weld output or gas flow. Fan is not operating.

When trigger is pulled there is no wire feed, weld

output or gas flow but the fan operates.

Little or no gas flow is evident when the trigger is

pulled. Wire feed, weld output and fan operate as

normal.

No wire feed when the trigger is pulled but the fan

runs, gas flows and there is weld output.

Possible Cause

1. Check to insure the power switch is turned on.

2. Insure correct voltage is applied to the welder.

3. Check to insure the circuit breaker is not

tripped.

1. The welder may have overheated and tripped

the thermostat. Let the welder cool down and

weld at a lower amperage setting.

2. Check for obstructions in the air flow and to

insure the gun cable assembly connections are

correct.

3. Gun trigger may not operate properly.

1. Check to insure the gas supply is adequate.

2. Check the regulator and gas hoses to insure

there are no problems.

3. Check to insure there are no obstructions or

leaky seals in the gun cable assembly connection.

1. Check to see if the wire drive motor is turning.

If it is, make sure the drive roll is the correct

size and is installed properly.

2. Check to insure the cable liner and/or tip is not

clogged and is sized correctly.

3. Check to insure the Spool Gun Selection switch

is set to the correct position.

KDAR Company 17

Page 19

Troubleshooting

Problem

Arc is unstable—Poor starting

Possible Cause

1. Check to insure proper input voltage to the welder.

2. Check electrode polarity to make sure it is correct for the process being used.

3. Check tip for proper size and damage; replace if

necessary.

4. Insure proper gas flow for the process.

5. Make sure the connections for the ground cable

are correct.

6. Make sure the drive roll is installed and aligned

properly.

7. Make sure the wire size is correct and there is no

damage to the gun cable assembly.

Note: For problems that can not be corrected by following the troubleshooting proce-

dures listed above; please contact KDAR Company. NEVER attempt to work on any part

of the welder not listed above. Unauthorized repairs to the unit may result in danger to

the operator and will void the factory warranty.

KDAR Company 18

Page 20

Warranty

KDAR Company, and its affiliates, warrants that

all welders covered under this warranty is free

from defects in material and workmanship for one

year from the date of purchase. KDAR also warrants that all guns, hoses and ground clamp assemblies are free from defects in material and

workmanship for 90 days from the date of purchase. This warranty is extended to the original

purchaser who uses the product in a consumer

application (personal, residential or household

usage). All welders covered under this limited

warranty which are used in commercial applica-

tions (i.e. income producing) are warranted to be

free from defects in material and workmanship

for 90 days from the date of original purchase.

The products covered under this warranty are the

125WFG, 135WFG and 175WFG welders.

KDAR Company, and its affiliates, will repair or

replace, at KDAR’s sole discretion, parts found to

be defective in material or workmanship within

the warranty period. Warranty service will be

scheduled according to the normal work flow and

business hours of the service center doing the

work as well as the availability of replacement

parts. All decisions from KDAR Company regarding this limited warranty shall be final.

Original Purchaser’s Responsibility:

1. Retain the original cash register receipt as

proof of purchase.

2. Follow manual instructions regarding the care

and operation of your welder.

3. If warranty work is required, DO NOT RE-

TURN THIS WELDER TO THE RETAILER. Contact KDAR Company for instr uc-

tions. Visit www.hotmaxtorches.com or call

KDAR Company M-F 8AM-5PM CST to locate the nearest Authorized Service Center.

Not Covered:

1. Transportation charges for sending or delivering the welder to the Authorized Service Center or returning the repaired or replacement

welder back to the customer. These charges are

the responsibility of the customer.

2. Damages caused by ordinary wear, abuse, rain,

freeze damage, negligence, accident or failure

to operate or maintain the welder in accordance

with the instructions in the operator’s manual

supplied with the welder.

3. Damage caused by unauthorized repair or al-

terations.

Exclusions and Limitations:

KDAR Company makes no other warranty of

any kind, express or implied. Implied warranties, including warranties of merchantability

and of fitness for a particular purpose, are

hereby disclaimed. The warranty service described above is the exclusive remedy under

this warranty; liability for incidental and conse-

quential damages is excluded to the extent per-

mitted by law.

This warranty gives you specific legal rights, and

you may have other rights which vary from state to

state. Some states do not allow a disclaimer of implied warranties, or the exclusion of incidental and

consequential damages, so the above disclaimers

and exclusions may not apply to you.

For warranty service or to obtain service parts

or accessories:

Call: (314) 692-8555 M-F 8-5 PM, CST

Visit: www.hotmaxtorches.com

Write: KDAR Company

1 Mulch Lane

St. Louis, MO 63044

KDAR Company

1 Mulch Lane

St. Louis, MO 63044

Phone: (314) 692-8555 Fax: (314) 692-8578

Rev. 4 - Nov 2013

Loading...

Loading...