Operator’s Manual

Portable Generator

Model: HM2000

WARNING: Do not assemble, install or operate this equipment without reading ALL

of this manual and the safety precautions and warning illustrated in this manual.

KDAR Company

15009 Manchester Rd. #283

Ballwin, MO 63011

Tel: 314-692-8555

Fax: 314-692-8578

Web: www.hotmaxtorches.com

SAFETY PRECAUTIONS AND WARNINGS

PLEASE READ BEFORE USING EQUIPMENT

DANGER

DANGER indicates a potentially hazardous situation which, if not avoided, WILL, result in

death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate personal injury, or property damage.

WARNING—Failure to follow the instructions and warnings in this manual

may result in death, serious injury or

property damage.

1. Know your generator and how to use it

properly. When using the generator

consider the limitations and potential

hazards.

2. The generator must be placed on a firm

surface with sufficient support.

3. Do not overload the generator as this

will damage or shorten the life of the

unit. Refer to the name plate for load

ratings.

4. Do not tamper with the parts that

may increase or decrease the governed engine speed. Increased engine

speed increases the chance of personal

injury.

5. Always remove the spark plug or spark

plug cable before performing maintenance to avoid accidental starting.

6. Never operate a generator with missing or broken parts or without protective housing or covers.

7. Generators should never be operated

or stored in wet or damp conditions

or on highly conductive surfaces such

as metal decking and steel work.

8. Always keep the generator clean and

free of oil, mud and other foreign

matter.

9. Extension cord, power cords and

electrical equipment used with the

generator must be in good condition.

Never operate electrical equipment

with damaged or defective cords.

10. When operating a power tool or

equipment outdoors, use an outdoor

extension cord marked “W-A” or

“W.” These extension cords are rated

for outdoor use and reduce the risk of

electrical shock.

11. Do not touch engine muffler or other

engine or generator parts which get

hot during operation.

KDAR Company 1

SAFETY PRECAUTIONS AND WARNINGS

PLEASE READ BEFORE USING EQUIPMENT

12. Stay alert. Watch what you are doing and

use common sense when operating a generator. Do not use a generator while tired

or under the influence of drug, alcohol or

medication. A moment of inattention

while operating the generator may result

in serious personal injury or death.

13. Always store the generator in a well ventilated area with the fuel tank empty. Follow the instructions in this manual for

preparing to store a generator. Never

store fuel near the generator.

14. Never operate a generator if any of the

following conditions are present.

a. Uncontrolled change in engine speed.

b. Sparking.

c. Overheating of connected equipment.

d. Electrical output loss.

e. Damage to receptacles.

f. Engine misfire.

g. Excessive vibration.

h. Flame or smoke.

i. An enclosed compartment.

j. Rain or inclement weather. The units

should never be allowed to get wet.

15. Check the unit before each use for signs

of deterioration such as worn or porous

hose, loose or missing clamps, a damaged tank or cap. Replace all defective

parts before operating the generator.

16. The generator should be operated, serviced and/or refueled under the following

conditions only.

a. Start and run the generator out-

doors. Never run a generator in an

enclosed area even if the windows

and doors are opened. Avoid areas

where exhaust vapors can be

trapped. DANGER—CARBON

MONOXIDE HAZARD: The engine

exhaust contains carbon monoxide,

a poisonous, odorless, invisible gas

which, if breathed, may cause death

or personal injury.

b. Good ventilation for cooling. The

generator is air cooled and requires appropriate air flow. Temperatures should not exceed 104°

F ambient.

c.

Refuel the generator in a well ventilated area with sufficient light.

Allow the engine to cool for 3-4

minutes before refueling. Avoid

spills and never refuel while the

generator is running.

d. Never refuel the generator near

open flames, sparking electrical

equipment or pilot lights.

e. Never start or run the generator

without the muffler and air filter

installed and in good condition as

they work as flame arresters in

case of backfires.

f. Never smoke near the generator.

17. Properly ground the generator as instructed in this manual prior to use.

18. Do not wear lose clothing or jewelry

that could get caught in the starter or

other moving parts.

19. The generator must be at operating

speed prior to connecting electrical

loads.

20. Always disconnect electrical loads before shutting down the generator.

21. Never let the generator run out of fuel

while under electrical load as this may

cause an electrical surge that could damage equipment.

22. A power line conditioner should be used

when powering solid state equipment or

appliances such as a television.

23. Never insert anything through the ventilation slots, this could cause damage to

the generator or personal injury.

24. Drain fuel before transporting the generator.

25. Generators are heavy, use proper lifting

techniques.

KDAR Company 2

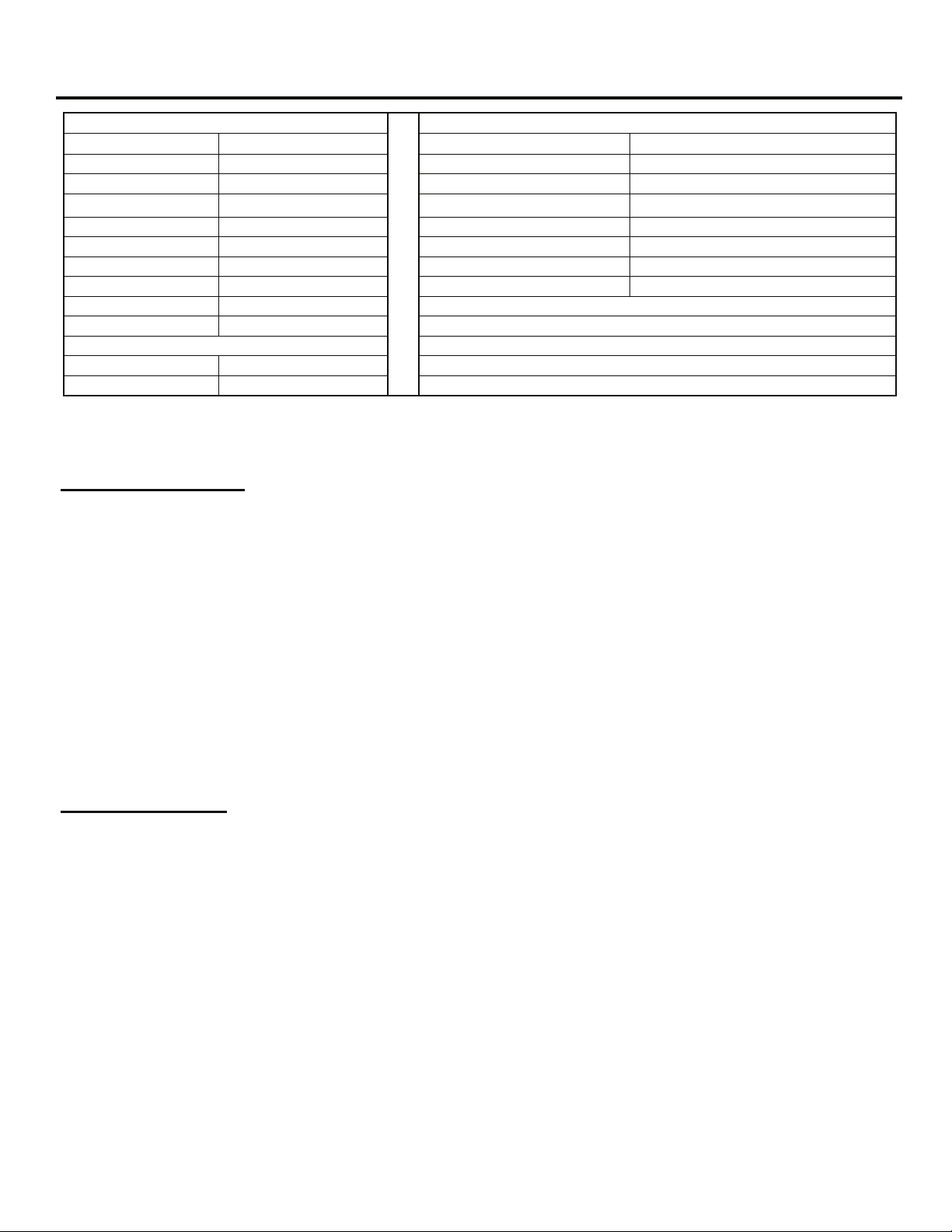

Specifications/Features & Benefits/Package Contents

Generator Ratings

Type Brush Single Phase

Voltage Regulate AVR

AC Rated Output 2.0kW/2000 Watts

AC Maximum Output 1.8kW/1800 Watts

AC Voltage 120V/240V

AC Frequency 60 Hz

120 VAC Amperage Rated 15/Max 17

240 VAC Amperage Rated 7.5/Max 8.3

DC Voltage 12V Battery Charger

DC Amperage 8.3 Amps

Dimensions & Weight

Dimensions (inches) 23.6 x 17.7 x 18.5

Weight 86.0 Lbs.

Engine Type & Displacement OHV Single Cylinder 163cc

Maximum Output HP/RPM 5.5/3600

Oil Capacity .63 Qt. (.6 Liter)

Low Oil Shut Down Standard

Fuel Type Gasoline

Fuel Capacity 4.0 Gallons

Run Time @ 1/2 Load 13 Hours

Operating Noise Level 67 dB(A) @ 24 Ft.

Outlets

1 x Dual AC 120/240V 12.5 Amp Twist Lock, 4 Prong (L14-30)

1 x 12V DC 8.3 Amp Connector

2 x 120V 20 Amp Grounded

Engine

Table 1

Features & Benefits

1. Peak Output—2000 Watts

2. Rated Output—1800 Watts

3. Single Phase 60 Hz

4. On/Off Switch

5. Voltmeter

6. Low Oil Shut Off

7. Separate Ground Connector

8. Generator/Motor on Rubber Mounts

9. 12 Volt DC Circuit, 8.3 Amps, Battery Charger

10. All Outlets Circuit Protected

11. 2 x 120V AC, 20 Amp Grounded (5-20R)

12. Dual 120/240V AC, 12.5A Twist Lock (L14-30)

13. 5.5 HP Engine rated at 3600 RPM, 163cc

14. Spark Arrestor Muffler

15. TCI Ignition

16. Gas Tank, 4.0 Gal, with Input Fuel Filter

17. Fuel Shut Off with Internal Fuel Filter

18. Noise Level of 67 dB(A) @ 24 Ft.

19. Run Time of 11 Hours at 50% Load

Package Contents

1. Generator

2. Operator’s Manual

3. Warranty Card

4. Spark Plug Wrench

KDAR Company 3

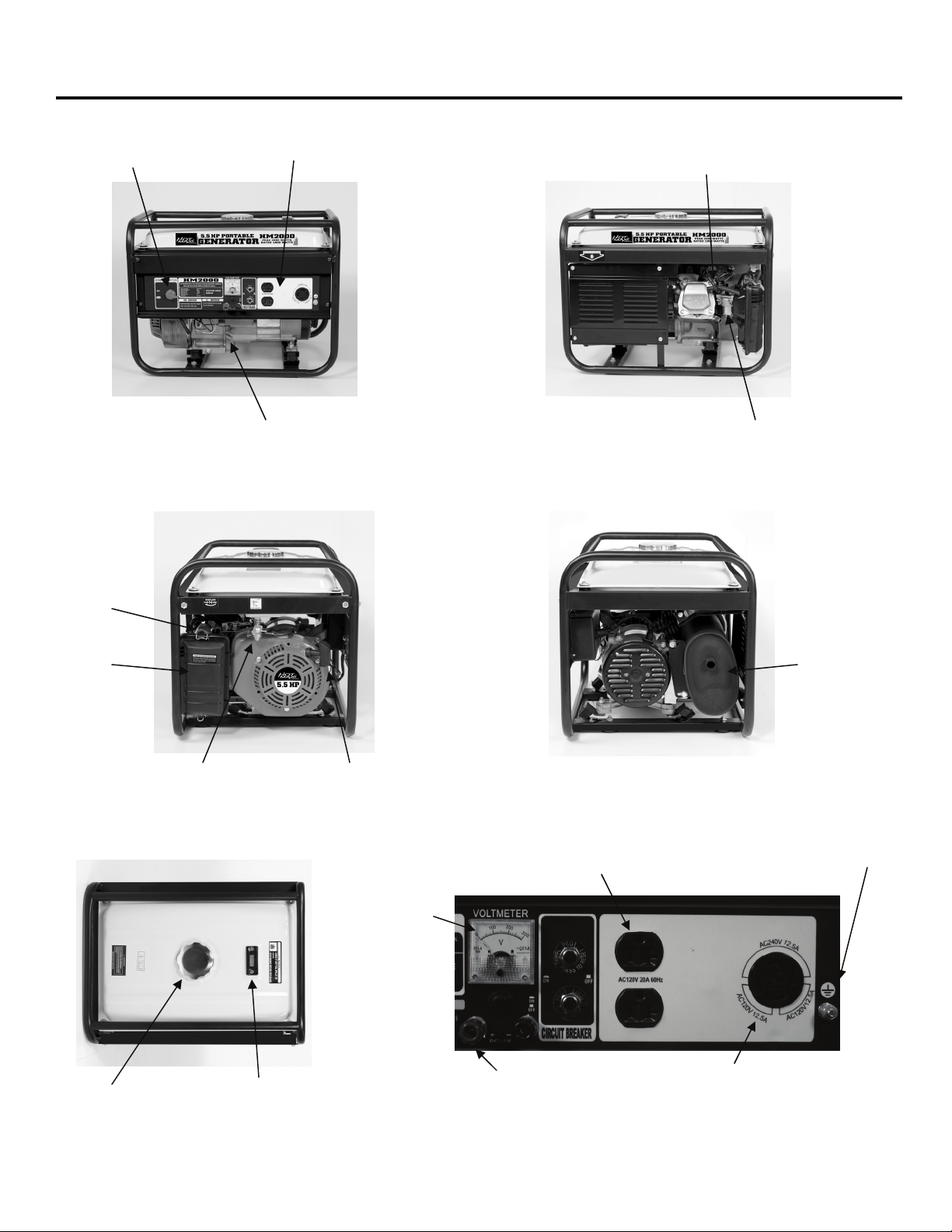

Set Up

ON/OFF

Switch

Control

Panel

Oil

Filler

Cap

Spark

Plug

Carburetor

Choke

Air

Filter

Fuel

Valve

Manual

Recoil

Starter

Voltage

Meter

120V AC 20 Amp

Outlet

Muffler

Ground

Terminal

Gas Cap

Fuel Level

Gauge

DC Connection

Battery Charge Only

KDAR Company

120/240V AC

12.5 Amp L14-30 Outlet

4

Set Up

Engine Preparation

Engine Oil

NOTE: Engine oil is a major factor affecting

the performance and service life of this generator. Non-detergent and 2-stroke engine oils

WILL damage the engine and are not recommended.

1. Use 4 stroke oil, or an equivalent high detergent, premium quality motor oil certified to

meet or exceed U.S. automobile manufacturer’s requirements for Service Classification

SG, SF/CC, CD. This designation will be on

the motor oil container.

2. SAE 10W-30 is recommended for general, alltemperature use. See chart for appropriate

weights for your area.

3. Locate the oil filler cap and remove.

Oil Filler

Cap

Fueling the Engine

WA RNI NG

• Gasoline is extremely flammable and is

explosive under certain conditions.

• Fuel and refuel in a well ventilated

area with the engine stopped.

• Do not smoke or allow flames or

sparks in the area where the engine is

being refueled or where gasoline is

stored.

• Do not over fill the tank (there should

be no fuel in the filler neck).

• After refueling, make sure the tank

cap is closed properly and securely.

• Be careful not to spill fuel when fueling

or refueling. Spilled fuel or fuel vapor

may ignite.

• If fuel is spilled make sure the area is

dry and free of fumes before starting

the engine.

• Avoid fuel contact with the skin or

breathing vapors for a prolonged period.

• KEEP FUEL OUT OF THE REACH

OF CHILDREN.

1. Unleaded gasoline with a octane rating of 86 or

higher is recommended because it produces

fewer engine and spark plug deposits and extends the exhaust system life.

2. Remove tank cap and fill tank.

3. Do not fill tank above the shoulder of the fuel

strainer.

4. Fill with .63 quarts (.6 Liters) of motor oil.

5. Confirm proper fill by replacing the dip stick and

checking the oil level.

Strainer

Shoulder

KDAR Company 5

4. Never use stale or contaminated gasoline or

oil/gasoline mixture. KDAR recommends a

fuel stabilizer.

5. Avoid getting dirt or water in the fuel tank.

Grounding the Generator

KDAR recommends generators be properly connected to an appropriate earth ground to help prevent electric shock. The ground terminal found on

the control panel is connected to the frame of the

generator for this purpose. Connecting a length of

heavy gauge (6 AWG minimum) copper wire between the generator and a copper rod driven into

the ground should provide an acceptable ground

connection. Please contact a local qualified electrician to insure local codes are being followed.

Set Up

Spark Arresting Muffler

All Hot Max generators are equipped with spark

arresting mufflers allowing for use around agricultural crops, forests, brush, grass and other similar

items. Spark arresting mufflers are required in the

State of California and on some U.S. Forest Service Land and may also be legally required under

other statutes and ordinances. The California statues requiring a spark arresting muffler are Sections

13005(b), 4442 and 4443.

KDAR Company 6

Operation

Pre-Start Preparation

NOTE: The following procedures are to be

completed each time the generator is started.

1. Before starting the generator, check to make

sure there are no loose or missing parts.

WA RNI NG

The generator must not be operated if all factory installed heat shields are not in place. Failure to comply may result in the fuel tank over

heating which could cause personal injury from

fire.

Starting the Engine

1. Check the oil and fuel levels.

2. Disconnect all electrical loads from the generator.

3. Open the fuel shut off valve.

6. Pull starter rope with a fast steady pull.

Starter

Rope

Handle

7. As engine warms up return choke back to open

position

CAUTION

Allow the generator to run for 5 minutes each

time it is restarted before applying load. This

will let the engine and generator stabilize.

4. Slide choke to the left (if starting a cold engine).

5. Turn RUN/STOP switch to the RUN position

RUN

DANGER

• Provide adequate ventilation for

toxic exhaust gases and cooling air

flow.

• Do not start or run the generator in

and enclosed area, even if windows

or doors are open.

• Engines give off carbon monoxide, a

odorless colorless, poison gas.

• Breathing carbon monoxide can

cause nausea, fainting or death.

Applying Load

• This generator has been pre-tested and adjusted

at the factory to handle its rated load.

• Apply load only after the generator is running

and has warmed up for 5 minutes.

• Voltage is regulated by the speed of the engine

which is adjusted at the factory for correct output. Readjusting will void the warranty.

KDAR Company 7

Operation

CAUTION

• Do not exceed the maximum wattage

rating for the generator when using

one or more receptacles.

• Do not exceed the amperage rating of

any one receptacle.

• Do not apply heavy electrical load for

the first 2– 3 hours of operation

(break-in period).

Total Wattage Determination

To insure the generator is not overloaded and damaged as a result, it is essential to know the total

watts of the connected load. The following steps

will help determine the intended load.

1. Determine what item or items you intend to

connect to the generator.

2. Check the wattage requirements for each item,

referring to the item’s nameplate. If watts are

not referenced on the nameplate they can be

calculated by multiplying amps and voltage

(amps x voltage = watts).

3. Add the wattage requirements for each item to

get the total wattage required.

4. Appliances and tools with motors will require

additional wattage at start up, usually 2 1/2 to 4

times their running wattage.

5. The generators rated running watts should

meet or exceed the watts required for the

equipment you intend to run.

6. Always connect the heaviest load to the generator first, then add additional items one at a

time in order of descending wattage requirements.

For more information on calculating wattage requirements see the panel on the top of the carton

this unit was shipped in or the charts in the back of

CAUTION

• Check the voltage and frequency require-

ments of all electronic equipment prior to

hooking it up to a generator.

• Equipment could be damaged if it is not de-

signed to operate within +/- 10% voltage

variation and +/- 3 hz frequency variation

from the generator nameplate rating.

• To help prevent damage, always have addi-

tional load plugged into the generator if

solid state equipment is used.

• A power line conditioner is recommended

for some solid state appliances.

A power line conditioner is recommended when

running the following solid state items.

• Television

• Appliances with digital displays

• Telephone equipment

• Garage door openers

• Stereos

• Personal computers

• Copy machines

• Printers

• Fax machines

WA RNI NG

Special isolation equipment is required for temporary or permanent connections to a residential electrical system. Therefore, to avoid electrocution or property damage, ONLY a trained

electrician should connect a generator to a residential electrical system.

Shutting Off the Generator

1. Disconnect the entire load.

2. Allow engine to run for 2-3 minutes without

load.

3. Flip ON/OFF switch to the “OFF” position.

4. Make sure the generator has completely

stopped.

5. Close the fuel shut off valve if the generator is

to be stored or transported.

KDAR Company 8

Maintenance Schedule

Maintenance

Item What To Do

Engine Oil

Air Cleaner

Clean or Replace

Sedimant Cap Clean

Spark Plug Check, adjust gap and clean

Spark Arrester Clean

Fuel Tank and Strainer Clean

Fuel Filter (Attached to fuel

valve)

Fuel Line Clean - Replace if necessary

Exhaust System

Fittings & Fasteners Check, replace if necessary

Check Oil Level

Change

Check

Clean - Replace if necessary

Check for leakage. Tighten

or replace gasket, if necessary

First

Each

Use

Month or

20 Hours

X

X X

X

X

X

X

X

X

X

X

X

X

Every 3

Months or

50 Hours

Every 6

Months or

100 Hours

Every Year

or 300

Hours

Engine Oil Change

1. Change oil while engine is warm to assure

complete and rapid draining.

2. Generator should be on a level surface.

3. Remove oil filler cap.

4. Place pan under generator to catch oil.

5. Remove oil drain plug.

6. Allow oil to drain completely.

7. Replace drain plug.

8. Refill with recommended oil (page 5).

9. Check oil level.

Oil Filler

Cap

Oil Drain

Plug

Air Cleaner Service

1. Unsnap the air cleaner cover clips.

2. Remove the air filter element.

3. Wash the element in a solution of household

detergent and warm water and rinse thoroughly

(a nonflammable or high flash point solvent

can also be used).

4. Allow to dry completely.

5. Pour a small amount of clean

engine oil on the element and

squeeze out the excess.

6. Reinstall air filter element and

replace cover.

Spark Arrestor Cleaning

1. Engine must be cool and muffler safe to touch

to remove the Spark Arrestor from the muffler.

2. To remove the Spark Arrestor, loosen screw on

clamp and remove the Arrestor. (Make sure to

handle carefully and gently)

3. Brush lightly the element in a solution of

household detergent and warm water and rinse

thoroughly (a nonflammable or high flash

point solvent can also be used).

4. Re-install Arrestor and tighten Clamp.

KDAR Company 9

Fuel Filter Cleaning

1. Drain fuel from tank.

2. Disconnect fuel line from fuel valve.

3. Remove fuel valve from tank.

4. Remove fuel filter from the top of the fuel

valve by unthreading (should be able to be removed with fingers).

5. Clean fuel filter with a nonflammable or high

flashpoint solvent.

6. Reattach fuel filter to fuel valve and reattach

fuel valve to tank and fuel line.

Fuel Valve Cleaning

1. Remove the sediment cup and O-ring at the

bottom of the fuel valve with a small wrench.

2. Clean and wash out the sediment cup with a

nonflammable or high flashpoint solvent.

3. Replace the sediment cup and O-ring.

1. Remove the spark plug cap.

2. Clean any dirt from around the spark plug

base.

3. Use the wrench supplied with the generator to

remove the spark plug.

4. Visually inspect the spark plug and discard if

the insulator is cracked or chipped.

3. Clean with a wire brush if the spark plug is to

be reused.

4. Measure the plug gap with a feeler gauge.

5. Correct as necessary by carefully bending the

side electrode.

The gap should be: 0.70—0.80mm (0.028-

0.031 in.)

Sediment

Cup

Fuel Strainer Cleaning

1. Remove the plastic fuel strainer from under the

fuel tank cap.

2. Clean and wash out the strainer with a nonflammable or high flashpoint solvent.

3. Replace strainer.

Spark Plug Service

Recommended Spark Plug:

BP6ES (NGK)

W20EPR-U (Nippondensu)

To insure proper engine operation, the spark plug

must be properly gapped and free of deposits.

WA RN I N G

If the engine has been running, the muffler will be very hot. Care must be taken

not to touch the muffler when removing

the spark plug.

8. Check to make sure the spark plug washer is in

good condition.

9. Thread the spark plug in by hand to prevent

cross-threading.

10. After the spark plug is seated, tighten with the

spark plug wrench to compress the washer.

If installing a new spark plug, tighten 1/2 turn

after the spark plug seats to compress the

washer. If reinstalling a used spark plug,

tighten 1/8-1/4 turn after the spark plug seats to

compress the washer.

CAUTION

The spark plug must be securely tightened. An

improperly tightened spark plug can become

very hot and could damage the engine.

Never use spark plugs which have an improper

heat range. Use only the recommended spark

plugs or equivalent.

KDAR Company 10

Transporting/Storage

Preparing for Transportation

1. Turn the engine switch and fuel valve to the

off or stop position.

2. Let the engine cool before transporting.

3. Keep the generator level to prevent fuel spillage.

4. Take care not to drop or strike the generator

when transporting.

5. Do not place heavy objects on the generator.

Preparation for Storage

1. Be sure the storage area is free of excessive

humidity and dust.

2. Preparation will depend on the length of time

the generator will be stored as outlined below.

Less than 1 Month

• No preparation necessary.

1 to 2 Months

• Fill with fresh gasoline.

• Add fuel stabilizer to the gasoline.

2 Months to 1 Year

• Fill with fresh gasoline.

• Add fuel stabilizer to the gasoline.

• Drain the carburetor float bowl.

• Drain the fuel sediment cup.

1 Year or More

• Fill with fresh gasoline.

• Add fuel stabilizer to the gasoline.

• Drain the carburetor float bowl.

• Drain the fuel sediment cup.

• Remove the spark plug and put one ta-

blespoon of clean engine oil into the

cylinder. Turn engine slowly with the

pull rope to distribute the oil and reinstall the spark plug.

• Change the engine oil.

• After removal from storage, drain the

stored gasoline into a suitable container

and fill with fresh gasoline before starting.

Drain Carburetor

WA RN I N G

• Gasoline is extremely flammable and

is explosive under certain conditions.

• Do not smoke or allow flames or

sparks in the area when the carburetor is being drained.

• Be careful not to spill fuel when

draining the carburetor. Spilled fuel

or fuel vapor may ignite.

• Avoid fuel contact with the skin or

breathing vapors for a prolonged period.

• KEEP FUEL OUT OF THE REACH

OF CHILDREN.

1. Loosen the carburetor drain screw.

2. Drain carburetor into a suitable container.

3. Replace drain screw.

Carburetor

Drain Screw

Internal Oiling

1. Remove the spark plug.

2. Pour 1 tablespoon of clean engine oil into the

cylinder.

3. Crank the engine several times by pulling on

the starter rope.

4. Reinstall the spark plug.

5. Slowly pull the starter rope until resistance is

felt. At this point the piston is coming up on its

compression stroke and both the intake and

exhaust valves are closed. Storing the engine in

this position will help protect it from internal

corrosion.

KDAR Company 11

Engine Will Not Start

Troubleshooting

Is there fuel in the tank? Refill the tank.

YES

Is there oil in the engine? Add the recommended oil.

YES

Is there a spark from the

spark plug?

YES

NO

To Check:

1. Remove the spark plug cap and

clean any dirt from around the

spark plug.

2. Remove the spark plug and install the spark plug in the plug

cap.

3. Set the plug side electrode on the

cylinder head.

4. Crank engine, sparks should

jump across the gap.

NO

NO

Replace the

spark plug.

Still no Spark

Take the generator to an

authorized KDAR generator service center.

WA RN I N G

• Be sure there is no spilled fuel

in the area.

• Gasoline is extremely flamma-

ble and is explosive under certain conditions.

Is the fuel reaching the

carburetor?

YES

If the engine still does

not start, take the generator to a authorized

KDAR service center.

NO

To Check:

1. Turn off the engine switch and

loosen the carburetor drain

screw.

2. Fuel should flow from the drain

when the fuel valve is turned on.

NOTE: The nearest KDAR authorized service center can be found by visiting

www.hotmaxtorches.com.

Clean the fuel sediment cup

and fuel filter.

KDAR Company 12

Troubleshooting

No Electricity at the AC Receptacles

Is the AC circuit breaker

on?

YES

Check the electrical appliance or equipment for defects.

DEFECTS

Replace the electrical appliance or equipment or

take the appliance or

equipment to an electrical

repair shop.

NO

NO DEFECTS

Turn the AC circuit breaker

on.

Take the generator to a

KDAR authorized service

center.

NOTE: The nearest KDAR authorized service center can be found by visiting

www.hotmaxtorches.com.

KDAR Company 13

Determining Your Power Needs

There are two parts to determining your power

requirements. 1) The running watts required,

calculated by adding the running watts of each

of the appliances to be run and 2) Peak watts

required, calculated by adding the total running

watts needed to the highest level of surge watts

required (additional start watts).

Example

Running

Appliance

Refrigerator/Freezer

Television

Well Pump 1/2 HP

Lights (4 x 60 Watts)

Space Heater

Total Running Watts

Highest Surge Watts

Watts

700 2200

500 0

1000 3000

240 0

1800 0

4240

3000

* Additional watts required to start the appliance

In this example you will need a generator that produces a minimum output of 4240 running watts and has a

peak output of 7240 watts.

Worksheet

Running

Appliance

A. Total Running Watts

B. Highest Surge Watts

Watts

Running Watts Requirement:

Peak Watts Required (A+B):

Surge*

Watts

Surge*

Watts

Power Needs

Watts Estimate Chart

Appliance

Household

AC, Central 10,000 BTU

AC, Window 10,000 BTU

AM/FM Radio

CD/DVD Player

Cloths Drier - Gas

Coffee Maker

Curling Iron

Deep Freezer

Dishwasher - Hot Dry

Electric Stove - 8" Element

Electric Water Heater

Fan

Furnace Fan Blower - 1/2 HP

Furnace Fan Blower - 1/3 HP

Hair Dryer

Hot Plate/Griddle

Iron

Light Bulb - 60 Watt

Light Bulb - 75 Watt

Microwave Oven - 1000 Watts

Microwave Oven - 625 Watts

Refrigerator/Freezer

Security System

Space Heater

Stereo Receiver

Sump Pump 1/2 HP

Television - 27"

Toaster

Toaster Oven

VCR

Video Game System

Washing Machine

Well Pump 1/2 HP

Tools

Air Compressor 1 HP

Air Compressor 1/4 HP

Circular Saw

Electric Drill 1/2" - 5.4 Amp

Electric Drill 3/8" - 4 Amp

Halogen Work Light - 1000

Watt

Reciprocating Saw

Office Equipment

Computer w/Monitor

Copy Machine

Fax Machine

Laser Printer

Running

Watts

1500 4500

1200 3600

100 0

100 0

700 1800

1000 0

1500 0

500 1500

1500 1500

2100 0

4000 0

200 0

800 2250

700 1400

1000 0

1500 0

1400 0

60 0

75 0

1000 0

625 0

700 2200

500 0

1800 0

450 0

800 1300

500 0

850 0

1200 0

100 0

40 0

1150 2250

1000 3000

1600 4500

975 1600

1400 2300

600 900

440 600

1000 0

Surge*

Watts

960 0

800 0

1600 0

65 0

950 0

KDAR Company 14

Limited Warranty

KDAR Company, and its affiliates, warrants that

the generators covered under this warranty are free

from defects in material and workmanship for One

year from the date of purchase. This warranty is

extended to the original purchaser who uses the

product in a consumer application (personal, residential or household usage). All generators covered under this limited warranty which are used in

commercial applications (i.e. income producing)

are warranted to be free from defects in material

and workmanship for 90 days from the date of

original purchase.

KDAR Company, and its affiliates, will repair or

replace, at KDAR’s sole discretion, parts found to

be defective in material or workmanship within the

warranty period. Warranty service will be scheduled according to the normal work flow and business hours of the service center doing the work as

well as the availability of replacement parts. All

decisions from KDAR Company regarding this

limited warranty shall be final.

Original Purchaser’s Responsibility:

1. Retain the original cash register receipt as

proof of purchase.

2. Follow manual instructions regarding the care

and operation of your generator.

3. If warranty work is required, DO NOT RE-

TURN THIS GENERATOR TO THE RETAILER. Take the generator to the nearest

KDAR Authorized Service Center for evaluation. Visit www.hotmaxtorches.com or call

KDAR Company M-F 8AM-5PM CST to locate the nearest Authorized Service Center.

Not Covered:

1. Transportation charges for sending or delivering the generator to the Authorized Service

Center or returning the repaired or replacement

generator back to the customer. These charges

are the responsibility of the customer.

2. Damages caused by ordinary wear, abuse, rain,

freeze damage, negligence, accident or failure

to operate or maintain the generator in accordance with the instructions in the operator’s

manual supplied with the generator.

3. Damage caused by unauthorized repair or alterations.

Exclusions and Limitations:

KDAR Company makes no other warranty of

any kind, express or implied. Implied warranties, including warranties of merchantability

and of fitness for a particular purpose, are

hereby disclaimed. The warranty service described above is the exclusive remedy under

this warranty; liability for incidental and consequential damages is excluded to the extent permitted by law.

This warranty gives you specific legal rights, and

you may have other rights which vary from state to

state. Some states do not allow a disclaimer of implied warranties, or the exclusion of incidental and

consequential damages, so the above disclaimers

and exclusions may not apply to you.

For warranty service or to obtain service parts

or accessories:

Call: 314-692-8555 M-F 8-5 PM, CST

Or:

Write: KDAR Company

15009 Manchester Rd #283

Ballwin, MO 63011

KDAR Company 15

Loading...

Loading...