Hot Max 250WFG Operator's Manual

Operator’s Manual

Model 250WFG

MIG/TIG/ARC Welder

MIG/TIG/ARC

Welder

WARNING: Do not assemble, install, or operate this equipment without reading ALL of this manual

and the safety precautions and warnings illustrated in this manual.

KDAR Company Tel: (314) 692-8555

1 Mulch Lane Fax: (314) 692-8578

St. Louis, MO 63044 Web Site: www.hotmaxtorches.com

SAFETY PRECAUTIONS AND WARNINGS

PLEASE READ BEFORE USING EQUIPMENT

WARNING

ELECTRIC SHOCK CAN KILL.

The input circuits are live and hot when the power is on

Do not touch live electrical parts

Wear dry, hole free insulated work gloves and body protection when operating

Do not touch torch components if in contact with the work piece or ground

Always turn off power before cleaning, checking, or changing parts

Properly ground this piece of equipment per state and federal requirements

Inspect and replace any worn or damaged torch cables or leads

Keep all panels and covers securely in place

Keep away from the torch tip and weld arc when trigger is pressed

Ground the metal or work piece to the ground cable (Earth Clamp)

Never dip the tip into water to cool or attempt to use welder in or under water

This DC equipment holds a lot of power in the off position, before touching, make sure voltage is

near zero on input capacitors before touching any parts.

Keep children away from this equipment

Protect yourself and others from possible injury

Pacemaker wearers should consult with their doctor before operating

Read and follow all instructions in this manual before operating

All installation, operation, and maintenance procedures are to be

performed only by qualified individuals

ARC RAYS CAN BURN SKIN AND EYES

Arc rays when welding produce intense ultraviolet and infrared rays that can burn skin and eyes

Wear face protection, either helmet or shield, when operating. ANSI Z49.1 approved shade #9

recommended for all cutting currents less than 300 amperes. The lens should conform to ANSI

Z87.1 standards for testing.

Wear approved safety glasses with side shields under the face protection

Warn others not to stare at the arc as it can cause damage to the eyes. Provide barriers to protect

other workers in the area from the arc while operating

Wear flame resistant gloves, clothing, and shoes when operating

FUMES AND GASES CAN BE HAZARDOUS

Arc welding produces fumes and gases and breathing these gases is hazardous to your health

Keep your head out of the fumes and do not breath the fumes while welding

Work only in a confined area if it has sufficient ventilation, or while wearing an air supplied

respirator. Fumes from welding deplete the oxygen supply and can be harmful. Always be sure

there is ample breathing air

Read the MSDS sheets and the instructions from manufacturers for metals to be welded, coatings,

and cleaners

Do not use the welder near hydrocarbon vapors coming from degreasing, cleaning, or spraying

operations. The heat and rays can react with solvent vapors to create the gas phosgene, a very toxic

gas and other irritating gases

Do not weld coated metals, such as galvanized, lead, or cadmium plated steel. Before welding, all

plating must be removed. The area must be well ventilated or an air supplied hood must be used.

The coatings and chemicals when burned cause highly irritating and toxic fumes.

Do not weld containers with toxic, flammable, or reactive elements stored in them. They must be

emptied and properly prepared before welding.

KDAR Company 1

WELDING SPARKS CAN CAUSE INJURY, FIRE, OR EXPLOSION

Remove all flammable materials from the welding area

Always have a charged fire extinguisher available in the welding area

When not welding make sure the welding tip is not grounded, this causes a heat build up and

possible fire

Avoid welding near hydraulic lines, fuel lines, electrical cords, air hoses, or welding guns and

cables

Sparks and hot metal fly out from the work area when welding, wear approved safety glasses with

side shields under approved helmets, wear proper body and hand protection, and wear flame

resistant ear plugs to keep sparks from entering the ears

CYLINDERS CAN EXPLODE IF DAMAGED

Gas cylinders contain gas under very high pressure. If damaged they can result in that cylinder ex-

ploding. Gas cylinders are a major part of metalworking and must be treated with care.

Protect gas cylinders from excessive heat, mechanical shocks, slag, open flames, sparks, and arcs

Always keep cylinders in an upright position securely fastened to a fixed support

Valve protection caps should always be in place and hand tight except when the cylinder is in use

Keep all cylinders away from any welding or electrical circuits

Never allow the arc from a welder to contact a cylinder

Never cut any type of pressurized cylinder, an explosion could result

Always turn your face away from the valve when opening the cylinder

Read and follow all instructions on compressed gas cylinders, associated equipment, and CGA pub-

lication P-1 listed in the Safety Standards before using

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS

Electric current used in arc welding can create Electro-Magnetic Fields (EMF)

Magnetic fields can affect pacemakers and wearers should avoid proximity to EMF. Wearers need

to contact their doctors before operating this type of equipment

Exposure to EMF during operation of this equipment may have other health effects which are not

yet known

Route the work and torch cables together and not around your body

Do not place your body between the torch cable and the ground cable. They both need to be on the

same side of your body when operating

Do not work next to the welding machine

ELECTRICALLY POWERED EQUIPMENT

Disconnect power source or turn off circuit breaker at the power panel before working on any

equipment

Only install equipment using the US National Electrical Code, all local codes, and the manufactur-

er’s recommendations

HOT PARTS CAN CAUSE SERIOUS BURNS

Do not touch hot parts without wearing protection.

Allow the torch to cool sufficiently before working with parts that could potentially be hot.

KDAR Company 2

NOISE CAN DAMAGE HEARING

Prolonged noise exposure from welding equipment can cause damage if levels of noise exceed the

OSHA standards

Wear approved hearing protectors

Warn other workers nearby of the high noise level and hazard

CALIFORNIA PROPOSITION 65 WARNINGS

Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to cause

birth defects, and in some cases, cancer. (California Health and Safety Code Section 25249.5 et seq.)

PRINCIPAL SAFETY STANDARDS

AMERICAN WELDING SOCIETY

AWS C5.2, Recommended Practices for Plasma Arc Cutting

AWS F4.1, Recommended Safe Practices for the Preparation for Welding and Cutting

OSHA STANDARDS

OSHA 29 CFR 1910, Safety and Health Standards

NATIONAL FIRE PROTECTION ASSOCIATION

NFPA Standard 70, National Electric Code

NFPA Standard 51B, Cutting and Welding Processes

AMERICAN NATIONAL STANDARDS INSTITUTE

ANSI Standard Z87.1, Safe Practices for Occupation and Educational Eye and Face Protection

ANSI Standard Z49.1, Safety in Welding and Cutting

KDAR Company 3

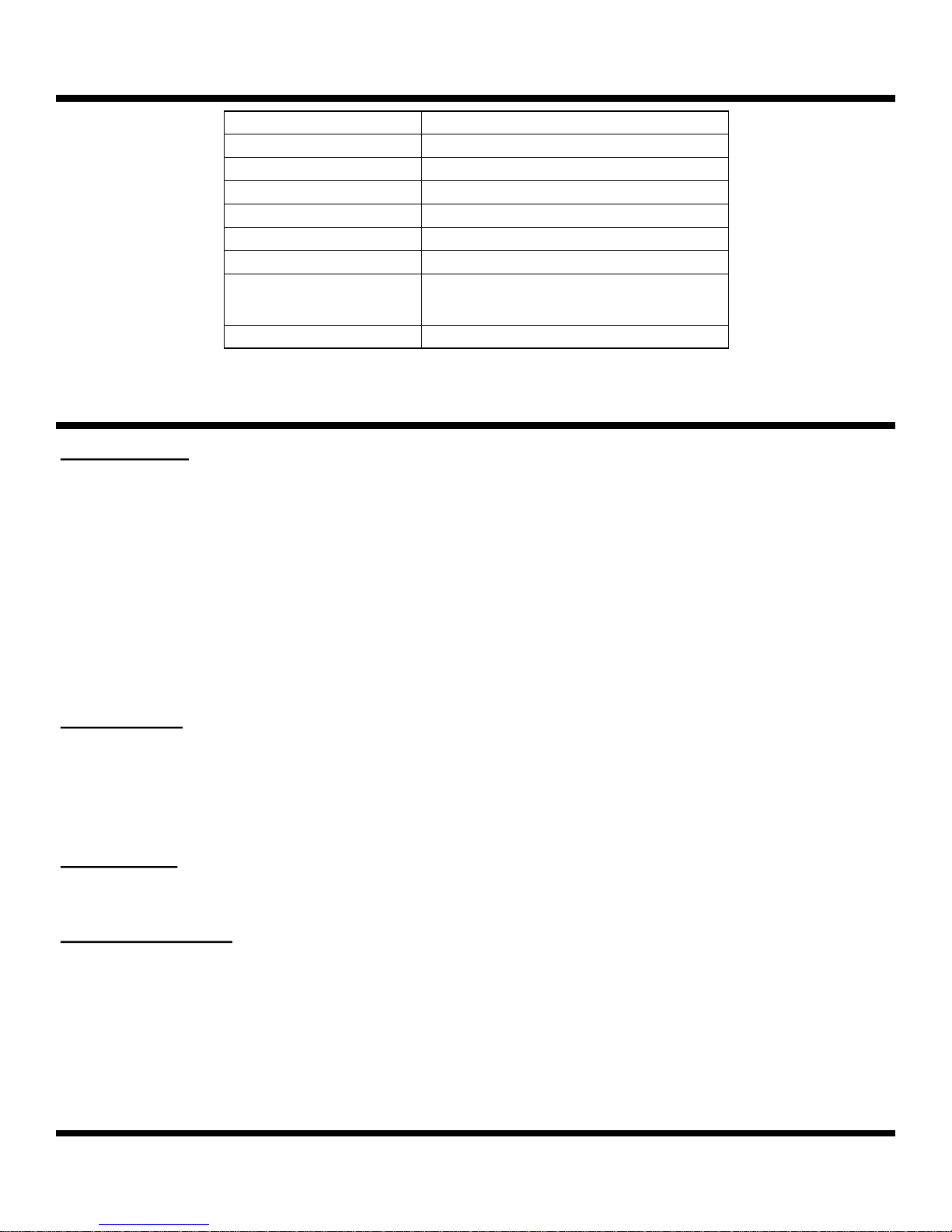

Specifications

Rated Input 50 Amps @ 220 Volts, 60 Hz, Single Phase

Rated Output - Arc 30- 230 Amps, 21.2 to 29.2 Volts DC

Rated Output - MIG 50 - 250 Amps, 16.5 to 26.5 Volts DC

Rated Output - TIG 20 - 230 Amps, 10.8 to 19.2 Volts DC

Duty Cycle - Arc 60% at 230 Amps, 100% at 178 Amps

Duty Cycle - MIG 60% at 250 Amps, 100% at 194 Amps

Duty Cycle - TIG 60% at 230 Amps, 100% at 178 Amps

Welding Wire Spool Sizes

8" x 2" (200mm x 50mm)

12" x 4" (300mm x 100mm)

Weight 150 Pounds

Table 1

Features & Benefits

MIG Welding

Infinite output voltage controls which can be adjusted as you weld.

Infinite wire speed control.

Heavy duty, professional quality Trafimet 250 Amp MIG gun with 10’ hose.

Factory pre-wired and ready for optional spool gun.

Separate MIG shielding gas connection for Argon/CO2.

Heavy duty double drive motor easily handles 11 and 33 pound wire spools.

Comes with two sets of drive wheels to handle .030” (.8 mm), .040” (1.0 mm) and .045” (1.2 mm) MIG

wire.

Quick feed button allows for faster loading of MIG wire into the gun.

Comes with three .040” (1.0 mm) contact tips.

TIG Welding

250 Amp rated TIG Torch with 12’ hose.

Heavy duty metal foot petal with 15’ control wiring.

Separate TIG shielding gas connection for Argon.

Three TIG gas nozzles, one collet body, three collets, one short cap and one long cap.

Arc Welding

300 Amp electrode holder with 10’ cable assembly.

Common Features

300 Amp ground clamp with 10’ cable assembly

Tank tray that holds up to 9.5” diameter tacks weighing less than 330 pounds.

Heavy duty 10” solid rubber rear wheels and 3” castors in front for mobility.

Argon/CO2 regulator with 5’ hose included for MIG and TIG applications.

36V heated regulator output (optional heated regulator available)

Circuit breaker for overload protection.

6’ grounded power cord (plug not included).

KDAR Company 4

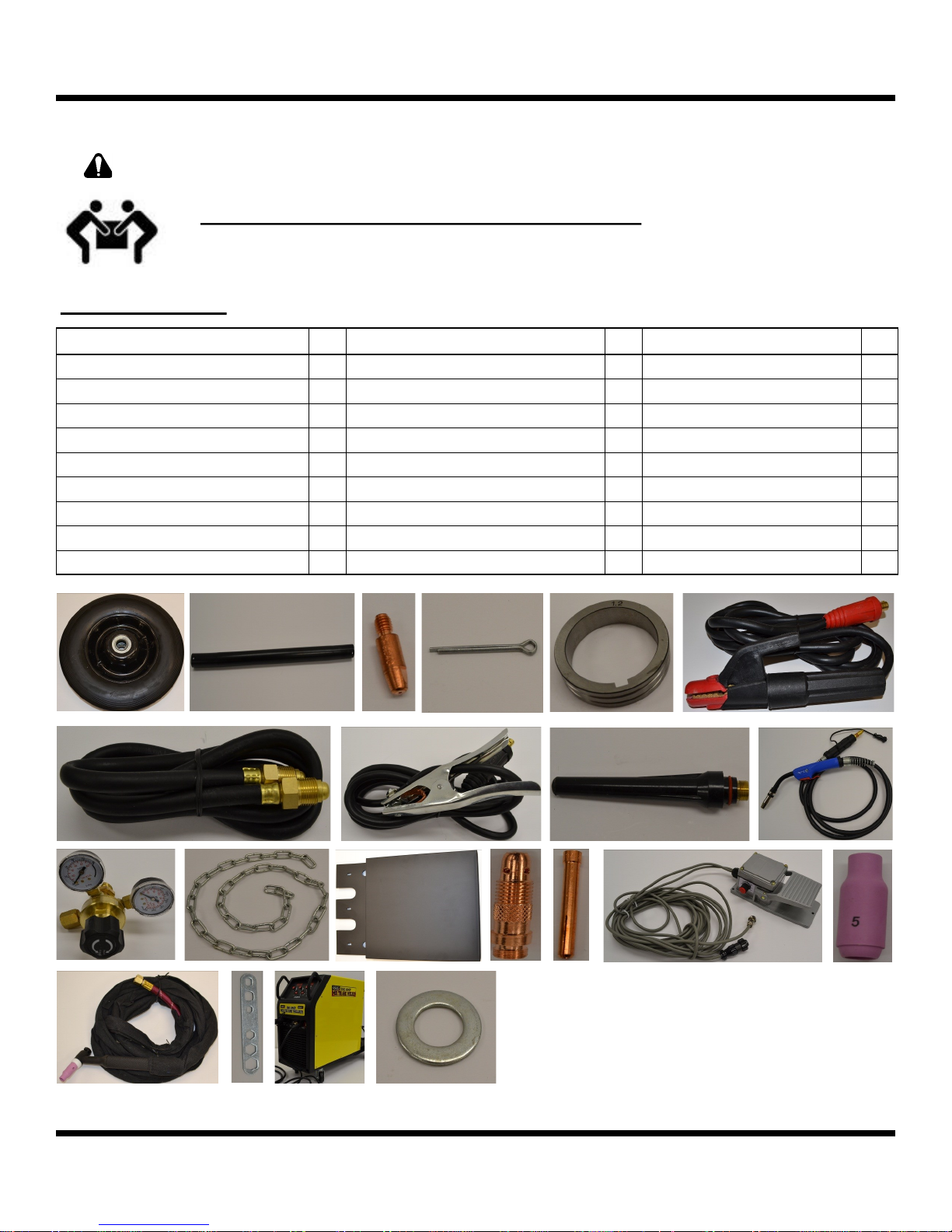

Installation/Setup

Safety Considerations

Warning

Improper Lifting Techniques Can Cause Injury

This unit requires two people when being lifted.

Always use proper lifting techniques.

Package Contents

Item Qty Item Qty Item Qty

6mm x 12mm Bolts 6 Front Caster Wheels (attached) 2 Tank Deck 1

6mm Lock Washers 6 Gas Hose 5' 1 TIG Collet Body 1

10" Solid Wheels 2 Ground Clamp w/10" Cable 1 TIG Collets 3

Axle 1 Long Black Cap 1 TIG Foot Peddle w/15' Lead 1

Caster Retention Nuts (attached) 8 MIG Gun w/10' Hose 1 TIG Gas Nozzle 3

Contact Tips 3 Regulator 1 TIG Gun w/12' Hose 1

Cotter Pins 2 Shielding Gas Nozzle (attached) 1 Universal Wrench 1

Drive Wheels 4 Tank Chain 2 Welder 1

Electrode Holder w/10' Cable 1 Tank Cradle (attached) 2 Wheel Washers 4

Pictures not to scale.

KDAR Company 5

Loading...

Loading...