For the latest prices, please check AutomationDirect.com.

Ethernet Communication Modules

Simple connections

Ethernet

Communications

Module

H4-ECOM100 $510.00

Overview

Ethernet Communications Modules offer

features such as:

• High-speed peer-to-peer networking

of PLCs

• Fast updates with DirectSOFT Programming

Software

• High-performance access for Human

Machine Interface (HMI), ERP, MES or

other Windows-based software

• Industry standard ModbusTCP/IP

Client/Server Protocol

• Free SDK for custom drivers

• Easy setup

The Ethernet Communication Module

(ECOM) supports high-speed peer-topeer networking of PLCs. No longer are

you forced to designate a single PLC to be

the network master. Any PLC can initiate

communications with any other PLC. Link

your PLCs with PCs using industry standard Modbus TCP/IP protocol connected

through standard cables, hubs, and

repeaters. Or, use KEPSeverEX* I/O Server

to link to your favorite HMI/SCADA,

data historian, MES or ERP software

to DirectLOGIC PLCs. Our DataWorx

data collection software includes ECOM

drivers as well. DirectSOFT Programming

Software can be used to monitor or

update the program in any DirectLOGIC

PLC on the network.

* KEPSEvErEX may bE PurchaSEd from

KEPwarE and will SuPPort any EXiSting

aPPlicationS. (httPS://www.KEPwarE.com/

En-uS/ProductS/KEPSErvErEX)

Use Category 5 UTP cables or 62.5/125

ST-style fiber optic cables depending

on the requirements of your application. Inexpensive UTP cables can be

run up to 100 meters between nodes,

and fiber optic cables can be run up to

2,000 meters. Fiber optic cables virtually

eliminate electrical noise problems. Use

repeaters to extend distances and expand

the number of nodes.

Specifications H4-ECOM100

Communications

Data Transfer Rate

Link Distance

Ethernet Port

Ethernet Protocols

Power Consumption

10/100Base-T Ethernet

100Mbps max.

100 meters (328 ft)

RJ45

TCP/IP, IPX, MODBUS TCP/IP,

DHCP, HTML configuration

300mA @ 5VDC

H4-ECOM100

H4-ECOM100 supports the

Industry Standard Modbus TCP/IP

Client/Server Protocol

The

H4-ECOM100 IBox

communications

instructions

Over 40 communications IBox instructions are available when using the

H4-ECOM100 with D4-454 CPUs and

DirectSOFT6 programming software.

These easy-to-use instructions allow you

to:

• Enable/disable module DHCP

• Read/write module IP, Gateway and

Subnet Mask addresses

• Read/write module ID, Name and

Description

• Send E-mail messages

• Read/Write PLC memory to networked

Hx-ECOM100 modules

See the following page for example

communications IBox instructions.

tDL4-22

DL405 PLCs

1-800-633-0405

For the latest prices, please check AutomationDirect.com.

Ethernet Communication Modules

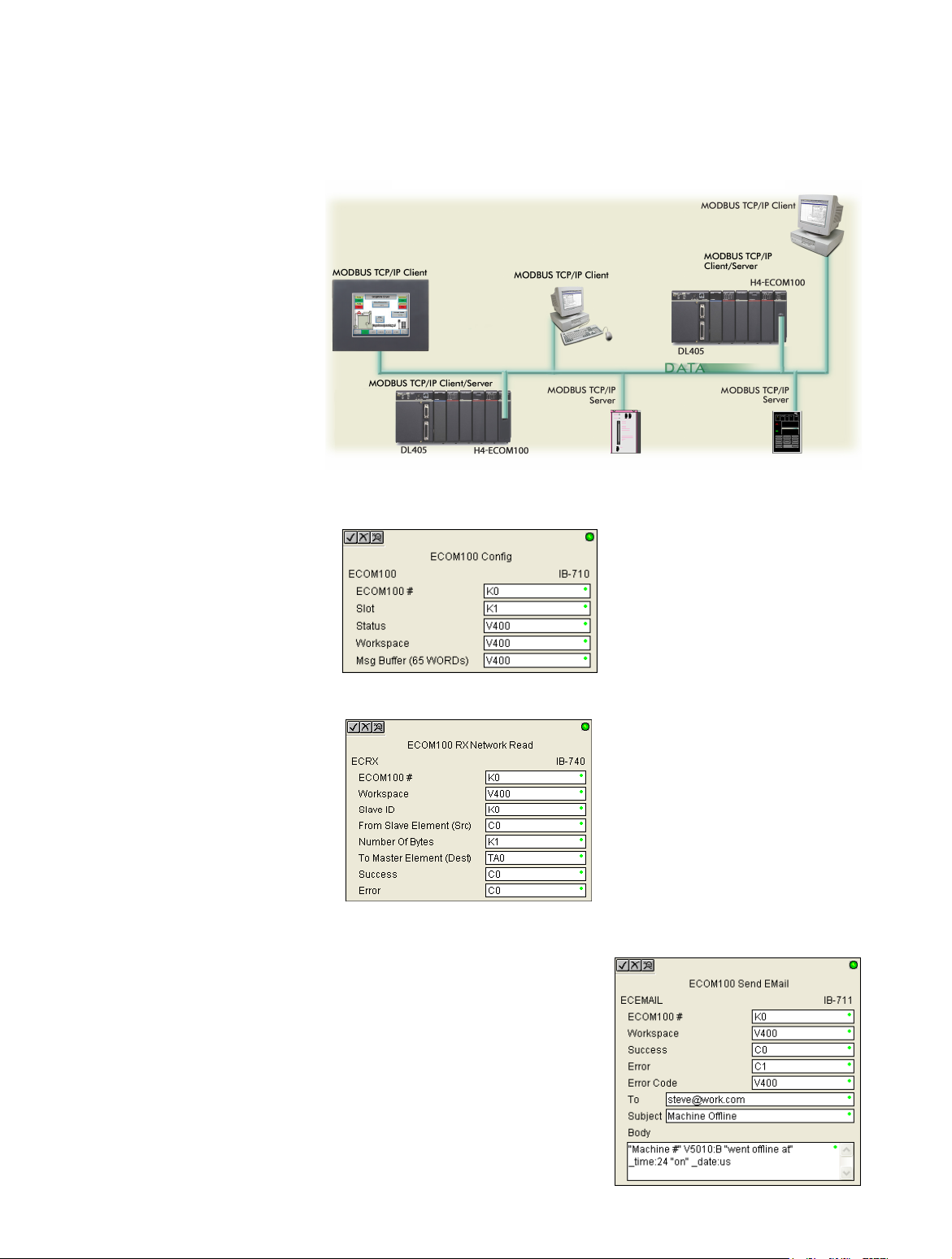

Modbus TCP/IP support

The H4-ECOM100 supports the industry

standard Modbus TCP/IP Client/Server

protocol in addition to the standard IP

and IPX protocols. This allows the DL405

PLC with an H4-ECOM100 module to

serve as a client (master) or as a server

(slave) on a Modbus TCP/IP Ethernet

network. The H4-ECOM100 can actively

issue Modbus commands to other nodes

or devices on the Modbus TCP/IP network

or simply respond to connected Modbus

TCP/IP clients.

PLC-to-PLC

communications

PLC-to-PLC or PLC to a Modbus TCP/IP

device communications can be accomplished using standard Read from Network

(RX) and Write to Network (WX) instructions (D4-454, all H4 series ECOMs and

all DirectSOFT versions). If you’re using our

DirectSOFT6 programming software with a

D4-454 PLC and an H4-ECOM100, you

can use fill-in-the-blank IBox instructions

to simplify your communications programming. The H4-ECOM100 supports the

ECOM Configuration IBox for use with

the ECRX and ECWX IBox instructions to

read/write to other ECOMs. H4 series

ECOM modules support the NETCFG

Configuration IBox for use with the NETRX

and NETWX IBox instructions to read/write

to other ECOM modules. The communications IBox instructions execute with built-in

interlocking to greatly simplify communications programming.

Modbus TCP/IP communications architecture

ECOM100 Configuration IBox

ECOM100 Read Network IBox

NetEdit3 software

NetEdit3 Software is installed with

DirectSOFT and it can be downloaded on the AutomationDirect.com

website. Use NetEdit3 to configure

the ECOM modules for your network.

Flexible addressing allows you to use

your choice of protocols and identifying methods. Assign each module

a number or a name or both. You

don’t have to use an IP address,

but you can if it’s necessary for your

network. NetEdit3 uses two protocols for PC-to-PLC communications:

IPX and TCP/IP. The NetEdit3 screen

displays all identifiers and troubleshooting information for each module

on the network. You can use NetEdit3

to adjust parameters for PLC-to-PLC

communications by clicking on

Advanced Settings. The network

identifiers can also be changed from

DirectSOFT Programming Software.

Choose your slot

The ECOM modules plug into any I/O slot

of any local DL405 I/O base. The module

maintains identification data, descriptive

information, and communication parameters for PLC-to-PLC communications in

flash memory. Disconnect power before

installing or removing any PLC module.

H4-ECOM100 has

e-mail capability!

The H4-ECOM100 Send EMail

(ECEMAIL) IBox instruction will allow the

module to behave as an e-mail client

and send an SMTP request to your SMTP

Server to send a specified e-mail message

to the e-mail addresses in the IBox’s To:

field. The Body: field allows you to embed

real-time data in your e-mail message.

The D4-454 CPUs and DirectSOFT6.1 or

later are required to use the IBox instructions.

www.automationdirect.com/dl405

ECOM100 Send EMail IBox

DL405 PLCs

tDL4-23

Check the Power Budget

For the latest prices, please check AutomationDirect.com.

Verify your power budget

requirements

Your I/O configuration choice can be

affected by the power requirements of the

I/O modules you choose. When determining the types and quantity of I/O

modules you will be using, it is important

to remember there is a limited amount of

power available from the power supply.

The chart on the opposite page indicates

the power supplied and used by each

DL405 device. The adjacent chart shows

an example of how to calculate the power

used by your particular system. These

two charts should make it easy for you to

determine if the devices you have chosen

fit within the power budget of your system

configuration.

If the I/O you have chosen exceeds the

maximum power available from the power

supply, you can resolve the problem by

shifting some of the modules to an expansion base or remote I/O base (if you are

using remote I/O).

Warning: It is extremely important to calculate the

power budget correctly. If you exceed the power

budget, the system may operate in an unpredictable

manner which may result in a risk of personal injury

or equipment damage.

Use ZIPLinks to reduce

power requirements

If your application requires a lot of relay

outputs, consider using the ZIPLink AC

or DC relay output modules. These

modules can switch high current (10A)

loads without putting a load on your base

power budget. Refer to Wiring System for

DL405 PLCs later in this section for more

information.

This logo is placed next to I/O modules

that are supported by the ZIPLink connection systems.

See the I/O module specifications at the

end of this section.

Calculating your power

usage

The following example shows how to

calculate the power budget for the DL405

system. The example is constructed around

a single 8-slot base using the devices

shown. It is recommended you construct a

similar table for each base in your system

A

Base Number

0

Device Type 5 VDC (mA)

External 24 VDC

Power (mA)

B CURRENT SUPPLIED

CPU/Expansion Unit

/Remote Slave

D4-454 CPU 3700 400

C CURRENT REQUIRED

SLOT 0

SLOT 1

SLOT 2

SLOT 3

SLOT 4

SLOT 5

SLOT 6

SLOT 7

D4-16ND2 +150 +0

D4-16ND2 +150 +0

F4-04DA +120 +100

D4-08NA +100 +0

D4-08NA +100 +0

D4-16TD2 +100 +0

D4-16TD2 +100 +0

D4-16TR +1000 +0

D OTHER

BASE

Handheld Programmer

E Maximum Current Required

F Remaining Current Available

1. Using a chart similar to the one above, fill in column 2.

2. Using the tables on the opposite page, enter the current supplied and used by each device (columns 3 and 4). Pay special attention to

the current supplied by the CPU, Expansion Unit, and Remote Slave since they differ. Devices which fall into the “Other” category (Row D)

are devices such as the Base and the Handheld programmer, which also have power requirements, but do not plug directly into the base.

3. Add the current used by the system devices (columns 3 and 4) starting with Slot 0 and put the total in the row labeled “maximum current required” (Row E).

4. Subtract the row labeled “Maximum current required” (Row E), from the row labeled “Current Supplied” (Row B). Place the difference in

the row labeled “Remaining Current Available” (Row F).

5. If “Maximum Current Required” is greater than “Current Supplied” in either column 3 or 4, the power budget will be exceeded. It will be

unsafe to use this configuration and you will need to restructure your I/O configuration. Note the auxiliary 24VDC power supply does not

need to supply all the external power. If you need more than the 400mA supplied, you can add an external 24VDC power supply. This will

help keep you within your power budget for external power.

D4-08B-1 +80 +0

D4-HPP-1 +320 +0

2820 100

3700-2820=880 400-100=300

.

DL405 CPU power supply specifications and power requirements

Specification AC Powered Units 24 VDC Powered Units

D4-454,

Part Numbers

Voltage Withstand (dielectric)

Insulation Resistance

Input Voltage Range

Maximum Inrush Current

Maximum Power

tDL4-16

D4-EX (expansion base unit),

D4-RS (remote slave unit)

1 minute @ 1,500 VAC between primary, secondary, field ground, and run relay

85-132 VAC (110V range)

170-264 VAC (220V range)

20A 20A

50VA 38W

DL405 PLCs

D4-454DC-1, D4-EXDC (expansion base unit)

> 10Mq at 500VDC

20-28 VDC (24VDC)

with less than 10% ripple

1-800-633-0405

Power Requirements

Power Supplied

CPUs/Remote Units/

Expansion Units

D4-454 CPU

D4-454DC-1

Power-consuming

Device

I/O Bases Analog Modules (continued)

D4-04B-1

D4-06B-1

D4-08B-1

DC Input Modules

D4-16ND2

D4-16ND2F

D4-32ND3-1

D4-64ND2

5 VDC Current

Supplied in mA

3100

3100

5V Current

Consumed

80

80

80

150

150

150

300 max.

24V Aux Power

Supplied in mA

400

NONE

Power Consumed

External 24VDC

Current Required

NONE

NONE

NONE

NONE

NONE

NONE

NONE

CPUs/Remote Units/

Expansion Units

D4-EX

D4-EXDC

D4-RS

H4-EBC

Power-consuming

Device

F4-16AD-1

F4-16AD-2

F4-04DA-1

F4-04DA-2

F4-04DAS-1

F4-08DA-1

F4-08DA-2

F4-16DA-1

F4-16DA-2

F4-08RTD

F4-08THM-n

F4-08THM

Remote I/O

For the latest prices, please check AutomationDirect.com.

5V Current Supplied

in mA

4000

4000

3700

3470

5V Current

Consumed

75

75

70

90

60

90

80

90

80

80

120

110

24V Aux Power

Supplied in mA

400

NONE

400

400

External 24VDC

Current Required

100

100

75+20 per circuit

90

60 per circuit

100+20 per circuit

150

100+20 per circuit

25 max.

NONE

50

60

AC Input Modules

H4-ERM100

D4-08NA

D4-16NA

100

150

NONE

NONE

H4-ERM-F

D4-RM

AC/DC Input Modules

D4-16NE3 150 NONE

DC Output Modules

D4-16TD1

D4-16TD2

D4-32TD1

D4-32TD2

D4-64TD1

200

400

250

350

800

125

NONE

140

120 (4A max

including loads)

NONE

Communications and Networking

H4-ECOM100

D4-DCM

F4-MAS-MB

CoProcessors

F4-CP128-1 305 NONE

AC Output Modules

D4-08TA

D4-16TA

Relay Output Modules

D4-08TR

F4-08TRS-1

F4-08TRS-2

D4-16TR

250

450

550

575

575

1000

NONE

NONE

NONE

NONE

NONE

NONE

Specialty Modules

H4-CTRIO

D4-16SIM

F4-4LTC

Analog Modules Programming

F4-04AD

F4-04ADS

F4-08AD

150

370

75

100

120

90

D4-HPP-1 (Handheld Prog.) 320 NONE

Operator Interface

DV-1000 150 NONE

C-more Micro-Graphic 210 NONE

320(300)

450

300

300

500

235

400

150

280

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

75

www.automationdirect.com/dl405

DL405 PLCs

tDL4-17

Loading...

Loading...