HOSOKAWA MICRON POWDER SYSTEMS

10 Chatham Road, Summit, NJ 07901 · Tel. (908) 273-6360 · Fax (908) 273-7432

Revision

Date

Description

Issue

October 23, 2018

Issue

Carefully read this manual

before operating or servicing this equipment

OPERATING & MAINTENANCE

MANUAL

Mikro Air Jet Sieve®

Document No.: M691477 – 181023.01

Record the MODEL and SERIAL NUMBER of your Air Jet Sieve and always refer to them when

ordering replacement parts or requesting service assistance.

Please refer to pages 46 through 56 for additional Service Information

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

IMPORTANT NOTICE:

(1) Before installing, operating or maintaining this instrument, carefully read this Manual and

follow the safety recommendations in Section 3.

(2) Reproduction of this manual in part or in whole is strictly prohibited without prior permission

from Hosokawa Micron Powder Systems.

(3) The contents of this manual are subject to change without notice.

(4) The contents of this manual have been carefully prepared. If you have any questions, find

errors or omissions, please contact Hosokawa Micron Powder Systems.

(5) Hosokawa Micron Powder Systems does not permit the improper use or handling of this

product by a third party. Only Hosokawa Micron Powder Systems service personnel are

authorized to repair or modify this product. Note that Hosokawa Micron Powder Systems

assumes no responsibility for damage or injury attributed to repairs, changes, etc. performed

by a third party.

(6) Hosokawa Micron Powder Systems assumes no responsibility for damages or injury

resulting from the attaching, using options or consumables other than Hosokawa Micron

Powder Systems genuine qualified parts.

(7) The software of this product is owned by Hosokawa Micron Powder Systems and copyright

protected. Copying the software and/or instruction manual in part or whole without

permission from Hosokawa Micron Powder Systems is prohibited.

(8) The MAJSx was designed for use with the Hosokawa Micron Test Sieve Screens. While other

manufactures screens can and do fit the instrument, Hosokawa Micron Powder Systems

cannot guarantee operational results and is not responsible should any damage occur.

(9) The warranty period of this machine is one (1) year from the date of shipment. Any

Dismantling, Tampering “Opening” or “Removal” of Fixed Components will VOID the

Warranty, unless specified herein.

Introduction

The Mikro Air Jet Sieve® is a highly accurate and reliable particle size analyzer designed for determining

the particle size distribution of dry powder ranging from 20 μm to 4,750 μm.

Record your Air Jet Sieve MODEL and SERIAL NUMBER.

Refer to them when ordering replacement parts or requesting service assistance.

Page 2 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

CRITICAL INFORMATION:

This Instruction Manual describes the proper and safe operation of the Hosokawa Micron Product.

It is important that this Instruction Manual be read and fully understood before equipment

installation, operation, maintenance and/or inspection of this instrument. Especially, complete

understanding of the warning labels, as contained in this manual for safe operation of this

instrument.

Prediction of all possible operation hazards as defined in the manual is impossible however; the

dangers can be minimized by following the instructions described in this manual. Operate this

device with great care and make every endeavor to avoid any accident or damage to the device.

Page 3 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Table of Contents

Section 1: Process Description .................................................................................................................... 5

Section 2: Principles of Operation .............................................................................................................. 6

Section 3: Safety ........................................................................................................................................... 8

Section 3-1: Precautions ......................................................................................................................... 8

Section 3-2: Electrical Shock ............................................................................................................... 10

Section 3-3: Personal Protective Equipment ...................................................................................... 10

Section 3-4: Material Safety Data Sheet (MSDS) .............................................................................. 10

Section 3-5: First Aid ........................................................................................................................... 10

Section 3-6: Administrator & Supervisor Operators Instructions .................................................. 10

Section 4: What is in the Box..................................................................................................................... 11

Section 4-1: Major Components ......................................................................................................... 11

Section 5: Unpacking and Installation ..................................................................................................... 12

Section 5: Unpacking and Installation (continued) ................................................................................. 13

Section 6: General Arrangement Drawing .............................................................................................. 14

Section 7: MAJSx2 Operation Component Layout ................................................................................. 15

Section 8: Preparing the MAJSx2 Air Jet Sieve ....................................................................................... 16

Section 8-1: Power/Communication Panel .................................................................................... 16

Section 8-2: Cable Connection ....................................................................................................... 16

Section 9: Basic Model Operating Procedure (Factory Default) ............................................................. 17

Section 9-1: Power-up the MAJSx2 ...................................................................................................... 17

Section 9-2: Set-Up for Basic Operation ............................................................................................ 18

Section 9-3: Basic Mode (Manual) Operating Procedure ................................................................. 20

Section 10: Advance Model Operating Procedure (Optional) ................................................................. 22

Section 10-1: Power-up the MAJSx2 in the Advance Operation Mode ............................................ 22

Section 10-2: SIEVE Page ..................................................................................................................... 24

Section 10-3: REPORT Page ................................................................................................................ 32

Section 10-4: SETTINGS Page ............................................................................................................. 35

Section 11: Optimizing Sieving Times ....................................................................................................... 44

Section 12: Maintenance ............................................................................................................................. 44

Section 12-1: Disassembly and Cleaning ............................................................................................. 44

Section 12-2: Cleaning of Test Sieve Screens ...................................................................................... 45

Section 12-3: Test Sieve Screen Selection Chart ................................................................................. 46

Section 12-4: Test Sieve Screen Statical Data Terminology Chart ................................................... 47

Section 12-5: Recommended Test Sieve Screen Recertification Schedule ...................................... 47

Section 12-6: Troubleshooting .............................................................................................................. 48

Section 12-7: Critical Instrument Verification ................................................................................... 49

12-7.1 Verification of Vacuum Gauge ............................................................................................. 49

12-7.2 Verification of Timer ............................................................................................................. 49

12-7.3 Calibration of Test Sieve Screens ......................................................................................... 49

Section 12-8: Recommended Operating Parameters ........................................................................ 50

12-8.1 Mikro Air Jet Sieve® (MAJSx2) ............................................................................................ 50

12-8.2 Vacuum Pressure ................................................................................................................... 50

12-8.3 Sample Weight and Sieving Time. ....................................................................................... 50

12-8.4 Sieving of Difficult Material ................................................................................................. 51

Section 12-9: Instructions for Connecting the Cyclone to the MASJx2 ........................................... 51

12-9.1 Adhere to the following Instruction steps: .......................................................................... 51

Section 12-10: Instructions for Cleaning the Vacuum ...................................................................... 52

Section 12-11: Recommended Vacuum Filter Replacement ............................................................ 52

Section 13: Aftermarket Services .............................................................................................................. 55

Section 13-1: Aftermarket Service Regional Parts Coordinators .................................................... 56

Page 4 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Section 1: Process Description

The Mikro Air Jet Sieve® – Model X2 (MAJSx2) is easy to operate and quickly determines particle size with

a short series of sieve test screens. The system utilizes the pneumatic sieving principle that enhances the

accuracy and reproducibility of particle size analysis. Use of this device has become a preferred method

for such tasks as quality assurance of incoming raw materials and confirmation of final product

specifications.

While under negative pressure sample particles are dispersed and de-agglomerated by means of a

positive airflow introduced upward through the rotating slit wand. Those particles small enough to pass

through a defined Test Sieve opening are carried in the airflow to the vacuum collector.

Precise particle size ranging from 20 to 4,750 μm can quickly be determined. This unique rotating wand

method also eliminates the need for tapping or brushing and increases reproducibility with controlled

measurements of pressure drop and duration. Overall the system is designed to operate cleaner, quieter

and requires less space than other types of similar analytical equipment.

The most important variables to insure a repeatable analysis using the Mikro Air Jet Sieve® are as follows:

The Sample Volume.

The Vacuum Pressure.

The Sieving Time.

The Test Sieve Screen Integrity.

Page 5 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

CRITICAL OPERATION INFORMATION:

The MAJSx2 was designed for use with the Hosokawa Micron Test Sieve Screens. While certain

manufactures screens can and do fit the instrument, Hosokawa Micron Powder Systems cannot

guarantee operational results and is not responsible should any damage occur.

Hosokawa Micron 200mm diameter Test Sieve Screens are supplied with a Blue Test Sieve Gasket and a

Black O-Ring. Remove and Discard the Blue Test Sieve Gasket. ONLY the Black O-Ring is to be used

on the Test Sieve Screen for proper vacuum seal.

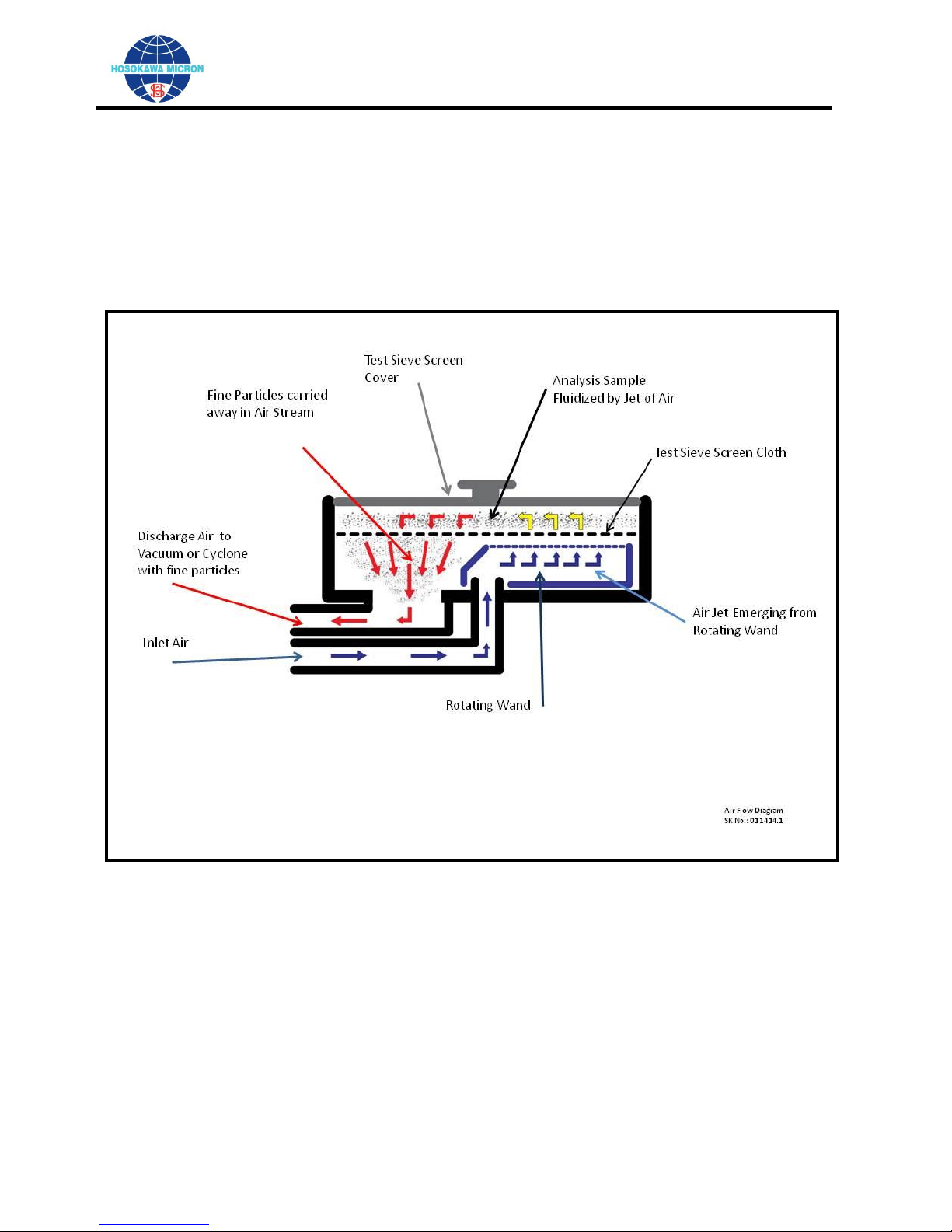

Section 2: Principles of Operation

The Mikro Air Jet Sieve® - Model x2 (MAJSx2) is a highly accurate and reliable particle size analyzer

designed to determine the particle size distribution of dry powders ranging from 20 to 4,750 micron. The

short sieving times at each sieve cut point are obtained by a reverse air current jetting out of a rotating air

wand beneath the Test Sieve Screens. This jetting air action disperses and distributes the analysis

material across the surface of the Test Sieve Screen. A Vacuum Fines Collector produces the required

airflow jetting action. The same airflow carries the fines fraction that passes through the Test Sieve

Screen, according to the principle of aerodynamic sifting. The fines fraction is then collected in either a

High Efficiency Cyclone or the Vacuum Fines Collector. A step-by-step description of this sieving action of

the Mikro Air Jet Sieve® as shown on Air Flow Diagram Sketch No.: 011414.1, on page 7 of 56 is as

follows:

Air enters through the Air Inlet opening located on the back of the MAJSx2.

Air continues through the duct to the hollow rotation wand.

Air exits the special shaped slot in the top of the rotating wand with sufficient velocity to pass through

the Test Sieve Screen.

The wand is propelled by the electric motor, thereby sweeping the complete diameter of the sieving

area.

The jet of air distributes, de-blinds, (dislodges) and possibly de-agglomerates the powder analysis

sample residing on the top surface of the Test Sieve Screen.

Those particles fine enough to pass through the Test Sieve Screen are carried away in the air stream

and collected in the vacuum and/or cyclone.

Air and fine particles enter the primary discharge duct and exit the MAJSx2.

The vacuum pressure is set by the operator on the “Testing” screen (while in the advance mode) or

“Sieving” screen (while in the basic mode) and is automatically adjusted internally by a rotating valve

located between the “Air Inlet” and “Vacuum” air ducts.

The recommended vacuum pressure range, displayed on the “Testing” screen (while in the advance

mode) or “Sieving” screen (while in the basic mode) of the MAJSx2 during operation, should read

between 8 and 16 inches water column. Refer to page 49 for vacuum gauge verification procedures.

Utilizing the standard MAJSx2 arrangement, the fine dust particles and air exit the main unit and travel

through the vacuum hose to the vacuum collection canister.

If an optional cyclone is attached the dust-laden air is redirected to the cyclone and based upon the

efficiency of the cyclone the coarse particles are collected in the cyclone container and the ultra-fines

are carried in the air stream to the vacuum collection canister.

Page 6 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Sketch No.: 011414.1

Page 7 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

SECTION 3 - 1:

Precautions

SECTION 3 - 2:

Electrical Shock

SECTION 3 - 3:

Personal Protective Equipment

SECTION 3 - 4:

MSDS (MATERIAL SAFETY DATA SHEET)

SECTION 3 - 5:

First Aid

SECTION 3 - 6:

Administrators and Supervisors of Operators’ Instructions

CAUTION:

Indicates that handling the machine improperly could result in severe personal injury, death or

serious property damage.

Locate the MAJSx2 in an area where the electrical components will not be exposed to water.

Locate the MAJSx2 in a place where it will not be adversely affected by high temperature, high

humidity or excessive dust. A safe operating temperature range is -10˚C ~ 60˚C (14˚F ~ 140˚F)

Relative humidity should not exceed 90% non-condensing.

Do not subject the MAJSx2 to strong shock or vibration. Doing so can and will result in failure of

the MAJSx2.

As specified by the Material Safety Data Sheet (MSDS) of the powder being analyzed, use

proper personal protection and/or a suitable respirator in accordance with plant policy, OSHA or

local regulations

Section 3: Safety

Section 3-1: Precautions

The precautions shown below are for safe operation of the MAJSx2.

In this instruction manual, in order to use the MAJSx2 safely, the following indications and symbols are

used to identify precautions.

Page 8 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

WARNING:

The instrument is to be properly grounded (earthed); not doing so may result in an electric

shock.

While the machine is energized and running, never open the Access Covers. Doing so may

cause injury.

Before performing maintenance, inspection, etc., turn OFF the power to the main body and

disconnect the power plug from the power receptacle. When touching parts in the machine,

wait for approximately 10 seconds or more after disconnecting the power plug. Not doing so

may cause an electric shock

Use ONLY the supplied power cable. If a power cable other than the one supplied is connected,

a fire, electric shock or serious failure may result.

Do not damage, place a heavy object on or forcedly pull the power cord. Doing so may result in

a fire and/or electric shock.

Do not use the machine in a place where combustible gas or ignitable products may be

present. Doing so may result in a fire.

Do not modify the machine.

This machine is not rated for use in a hazardous environment. Do not analyze flammable or

explosive materials.

When cleaning the pan area, refer to the maintenance service section of this manual for

additional information.

Use properly grounded power outlets for the MAJSx

2

, vacuum and all auxiliary equipment

attached to the sieving device

Page 9 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Do not open the Access Covers on the bottom of the

instrument when energized.

Touching the electronic components inside may result in an

electric shock or damage to the electronics.

To protect the instrument from the effects of static electricity confirm the following:

Confirm that the Main Access Cover is attached with all four mounting threaded rubber

pads and that all of the pads are securely tightened and are in good condition.

Confirm that the touch screen panel bottom plate is attached and secured with all five (5)

screws.

Use properly grounded power outlets for the MAJSx2, vacuum and all auxiliary equipment

attached to the sieving device.

Section 3-2: Electrical Shock

Section 3-3: Personal Protective Equipment

When operating this instrument, wear dustproof goggles, dustproof masks, gloves, etc. as

required.

Section 3-4: Material Safety Data Sheet (MSDS)

When using this machine, carefully read and follow the MSDS pre-cautions for the specific powder

sample being analyzed.

Section 3-5: First Aid

In the event the analyzed powder comes in contact with the operators’ eyes, skin or is inhaled,

administer First Aid in accordance with the prior reviewed powder MSDS.

Section 3-6: Administrator & Supervisor Operators Instructions

Before installing, operating or maintaining this equipment all individuals involved in the installation,

operation and maintenance must carefully read and understand the contents of this manual and

follow the Safety Recommendations.

Page 10 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

MAJSx2

Mikro Air Jet Sieve® with threaded Wand

Tapping Hammer

Sieve Brush

Polycarbonate Test Sieve Screen Cover

Power Cord - IEC 60320 C-13 plug

Vacuum Cord Adapter with IEC 60320 C-14 and

appropriate receptacle.

Operation Manual

Vacuum (Model No.: 390 – 30 - 118)

Main Vacuum (Application Specific)

One (1) Primary collection bag (390 & 30 only)

One (1) minimum two (2) meter length of hose

with connection cuffs

For 110 volt vacuums - Power Cord Adapter

For 220 volt vacuums - one (1) C-14 fitting is

mounted on vacuum power cable.

Manufacturers Operation Manual

No.:390

No.:118

No.: 30

Compatible Electronic Balances

consisting of:

Balance Main Body

(DEFAULT Interface Settings)

Balance Pan

Balance Pan Support

Communication Cable

(Serial type in accordance with the

manufacturers specifications)

Power transformer

Manufacturers Operating / Instruction Manual

Mettler Toledo

model MS1602S

Rice Lake

model TP-3200

Shimadzu

model UX4200H

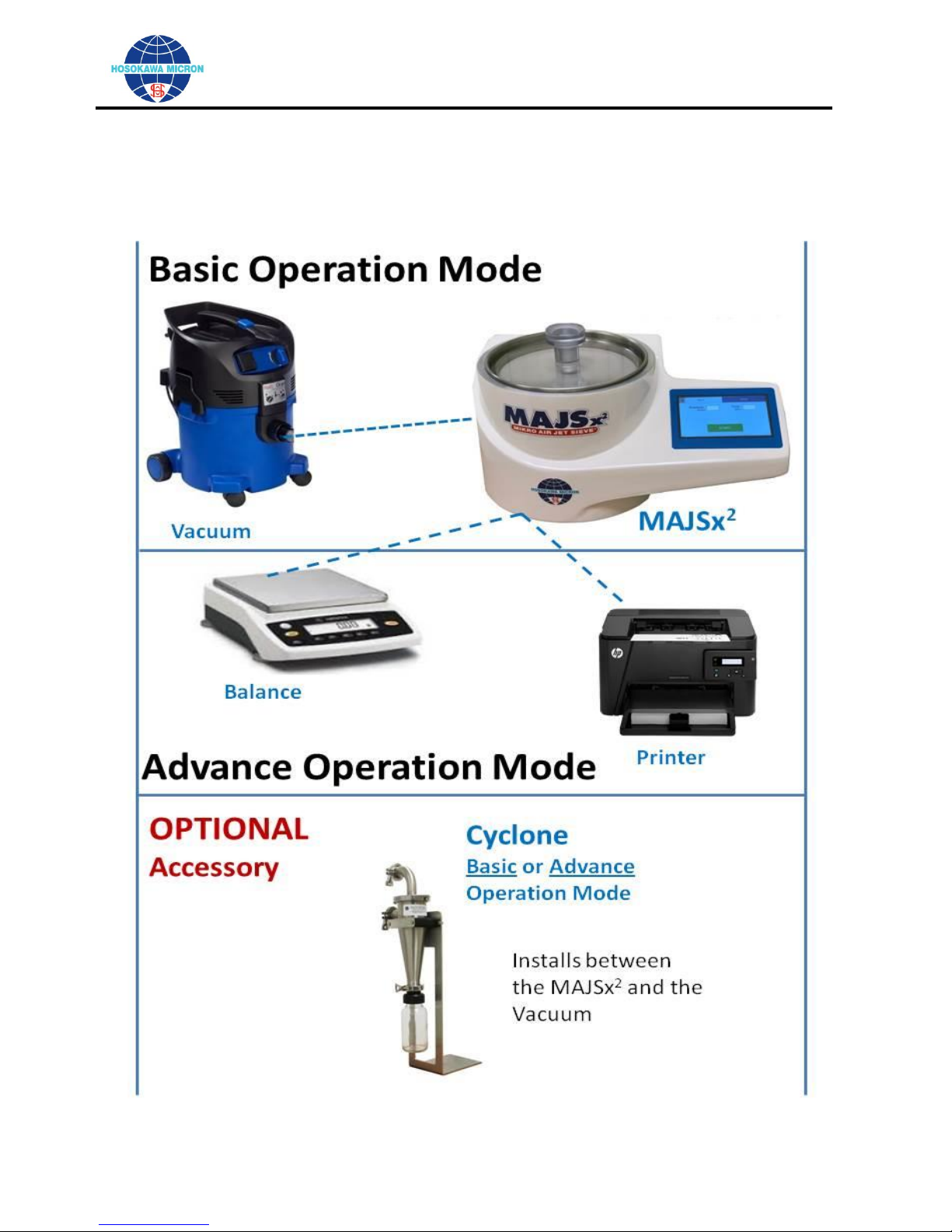

Section 4: What is in the Box

Section 4-1: Major Components

Page 11 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

The back of the MAJSx2 is to be positioned no less than a minimum of six

(6) inches from a wall or a solid obstruction to enable the operator easy

access to the “Power” switch and the Circuit protector.

Section 5: Unpacking and Installation

Unpack and remove the MAJSx2 from the shipping box. Confirm receipt of all required

components as detailed in the “What’s in the Box” section.

Place the accessories (sieve cover, tapping hammer, sieve brush, power cord and, depending

upon the model, the USB “Flash Drive” and CAT 5 cable) aside for the moment.

Locate the MAJSx2 on a level, firm horizontal laboratory bench/table capable of sustaining

vibration and positioned for easy operator access.

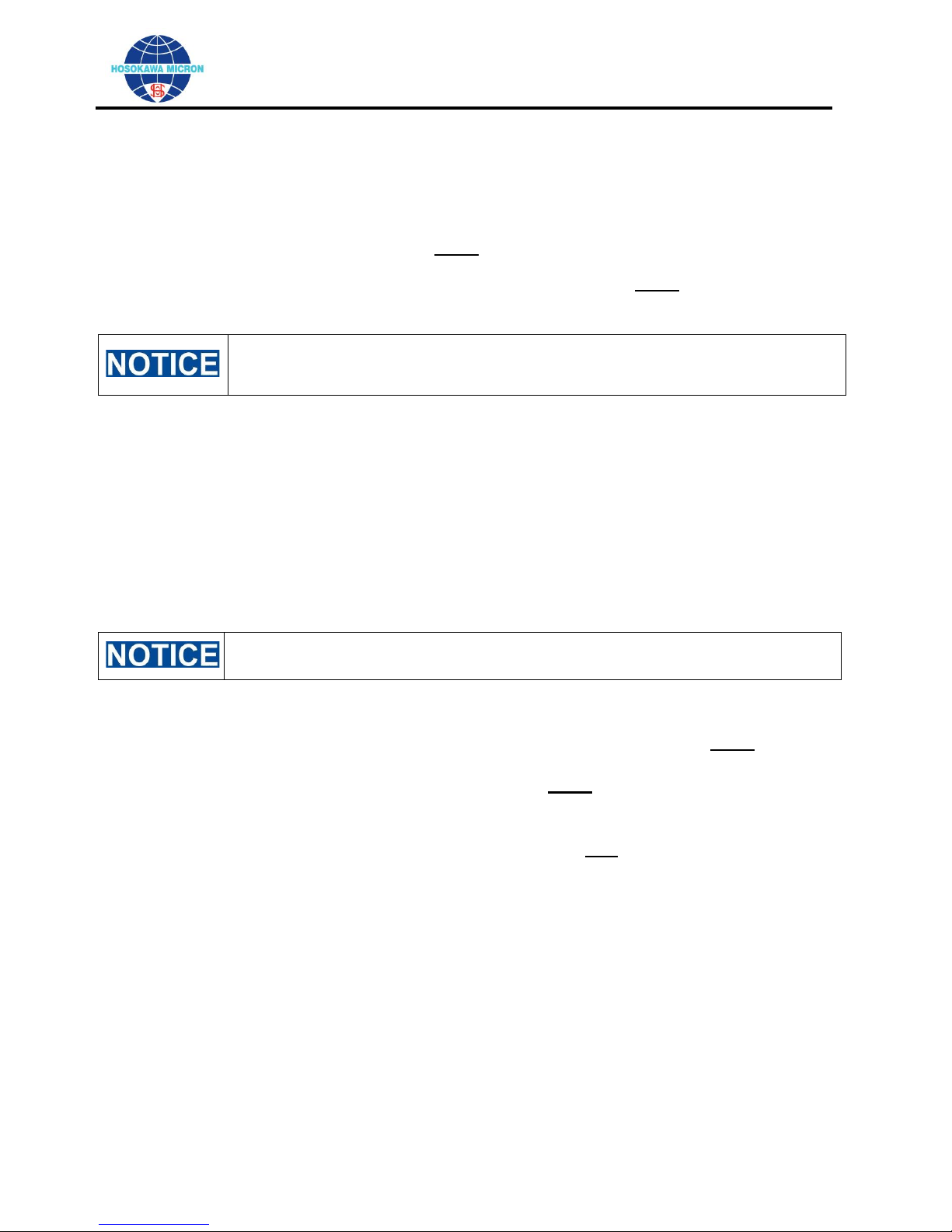

Refer to General Arrangement Drawing below for dimensions. The MAJSx2 weighs approximately

26 Lbs. (11.8 kg). All necessary CAUTIONS are to be used when lifting the instrument.

Prior to attaching the power cord to the MAJSx2, confirm that a 3-prong 90 to 240 volt, 50/60 hertz

grounded house outlet is within three (3) feet (36 inches) (1 meter) of the MAJSx2. The electrical

power outlet should have “Ground” (“Earth”) protection, and rated for a minimum of 15Amps@110

volt / 10Amps@230 volt, 60/50 Hertz.

Confirm that the power switch, located on the back of the MAJSx

the power cord into the receptacle located on the back (labeled “A/C IN”) of the MAJSx. Insert the

opposite end of the power cord into the house power receptacle.

MAJSx2 ADVANCED OPERATION: Insert the USB “Flash Drive” into one of the USB ports

located on the back (labeled “USB”) of the MAJSx2 for additional storage capacity. Note: The

MAJSx2 will recognizes each USB “Flash Drive” by clicking on the ICON located in the upper

left corner of the display.

Open/Unpack the vacuum and confirm receipt of all the required components (Vacuum Main Body,

One (1) Primary collection paper bag, and one (1) two (2) meter length (minimum) of hose with

connection cuffs, Power Cord, and Operation Manual). Additionally, confirm that the filters are

properly installed in accordance with the manufacturer’s instruction manual. Prior to closing the

vacuum, familiarization with the inside of the vacuum, especially the filter installation, is

recommended. Where ever possible, locate the vacuum, depending upon the vacuum physical

size, beneath or alongside of the lab bench/table. If mounted beneath the lab bench/table, to

eliminate the hose from being draped over the top of the bench/table, drill a 2.5 inch (63.5 mm)

diameter hole in the bench/table countertop. This size hole will provide ample clearance to pass

both the vacuum hose and vacuum power cord through the countertop making for a cleaner

installation.

After locating the vacuum under the bench/table or in another convenient location, plug the

vacuum power cord connector into the MAJSx2 female vacuum power receptacle, (rated for

15Amp@110 volt / 10A@230 volt) located on the back of the MAJSx2. NOTE: the vacuum

operating voltage MUST be the same as the voltage that is supplied to the MAJSx2. In order to

achieve reproducible analysis results using the MAJSx2, the vacuum MUST always be plugged

into the MAJSx2 power outlet IEC 60320 C-13 receptacle (or adapter), (rated for 15Amp@110 volt

/ 10Amp@230 volt) located on the back of the MAJSx2. The vacuum’s power switch MUST

always be in the “ON” position.

Using the supplied vacuum hose, connect the vacuum hose to the MAJSx2 vacuum port located on

the back of the MAJSx2, labeled “Vacuum Inlet”.

Page 12 of 56

2

, is in the “OFF” position. Insert

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

The MAJSx2 Advanced Model can be set-up to Print either directly to an

attached printer or to a Corporate Local Area Network (LAN) printer.

Installation / Powering the MAJSx2

Section 5: Unpacking and Installation (continued)

ELECTRONIC BALANCE FOR MAJSx2 ADVANCED OPERATION: Open/unpack the electronic

balance and confirm receipt of all the required components (balance main body, balance pan,

balance pan supporter, interface communication cable, power transformer, and instruction

manual). Depending upon the Electronic Balance Manufacturer, connect the supplied RS232

serial cable. The Electronic Balance MUST always be powered “ON” and connected to the

MAJSx

MAJSx2, the balance factory DEFAULT RS232 interface settings MUST be used.

Compatible balances are: Mettler Toledo model MS – Shimadzu model UX and Rice Lake

model TP

PRINTER FOR MAJSx2 ADVANCED PRINTING OPERATION: Confirm receipt of all required

components. The Printer components include the printer main body, toner cartridge; installation/

warranty guide, operations manual, and power cord, a USB Cable or a CAT 5 Network (LAN)

cable will be required for connection to the MAJSx2. When using a direct connected printer, locate

the printer, depending upon its physical size, as close as possible to the MAJSx2. After positioning

the printer, plug the printer power cord into an independent wall socket. Next make certain to

connect the printer USB cable to one of the USB ports located on the back of the MAJSx2. After

connecting the components, follow the manufacturer’s instructions to complete the installation.

When connecting the MAJSx

recommended to contact the local IT Department for installation clearances and

recommendations.

2

, prior to powering “ON” the MAJSx

2

ADVANCED model to a “CORPORATE LAN NETWORK” it is

2

. In order for the balance to communicate with the

Store the installation, operation and warranty manuals/guides in a safe location for future

reference.

In order to achieve reproducible analysis results using the MAJSx2, the vacuum MUST always be

plugged into the Vacuum Power outlet located on the back of the MAJSx2.

The vacuum power switch, located on the vacuum body MUST always be in the “ON” position.

The vacuum power outlet located on the back of the MAJSx2 is rated for a maximum of 15

Amp@230V, 50/60Hz, single phase.

When operating the MAJSx2 in Basic Mode, the instrument is NOT capable of communicating with

a balance and/or a printer.

When operating the MAJSx2 in the Advance mode, it is suggested that the Electronic Balance be

powered “ON” and connected to the MAJSx2, prior to powering “switching” ON” the MAJSx

2

.

When operating the MAJSx2 in the Advance mode, the MAJSx2 will display an ICON when a USB

“Flash Drive” and a Balance are connected and communication has been established.

The USB “Flash Drive” is used as an alternate storage location.

Connect the electrical power cord of the MAJSx2 and, if operating in the Advance mode, the

optional balance and printer to a suitable sized wall outlet, proper voltage 90 - 240V, 50/60Hz,

single phase.

Page 13 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Section 6: General Arrangement Drawing

(Front View)

(Top View)

Page 14 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

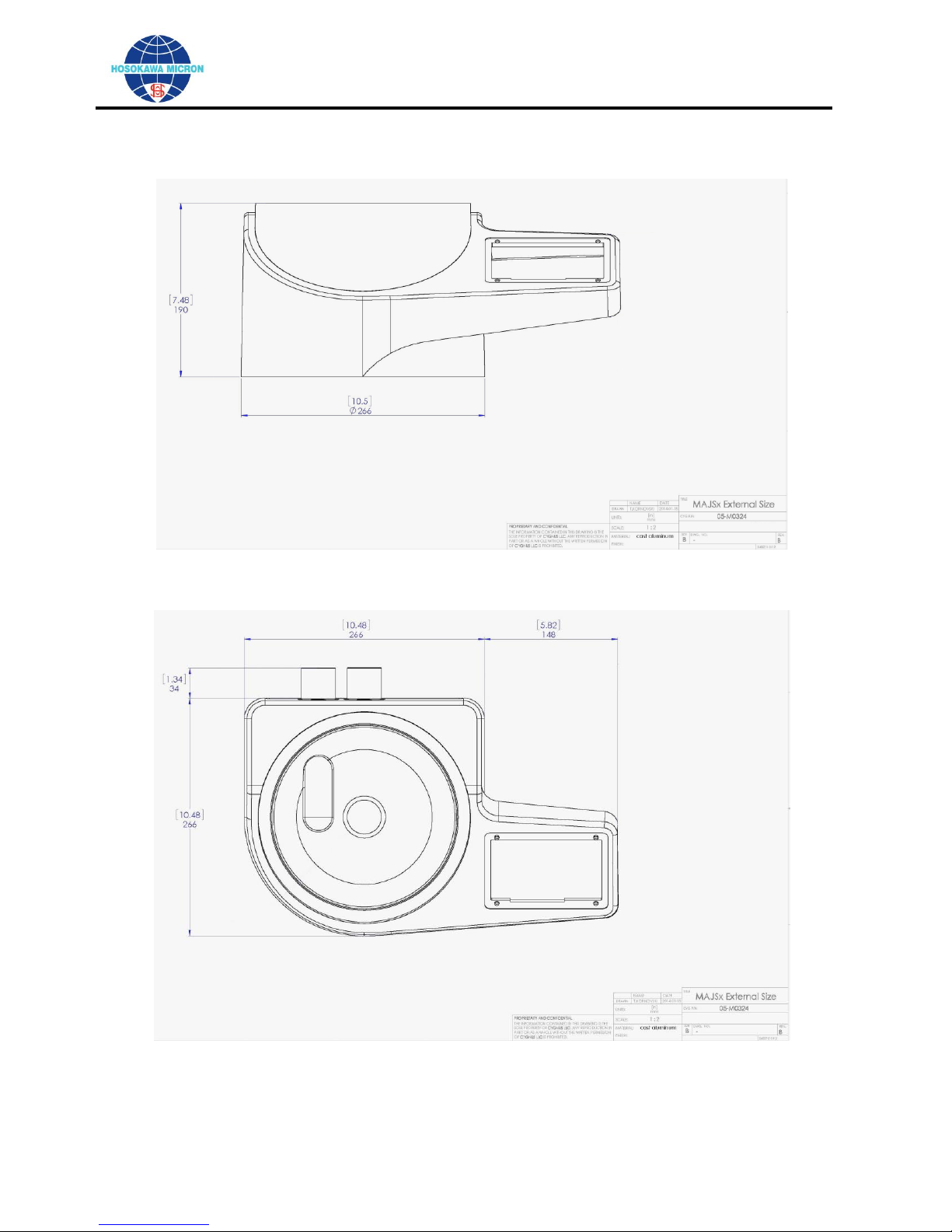

Section 7: MAJSx2 Operation Component Layout

Page 15 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Section 8: Preparing the MAJSx2 Air Jet Sieve

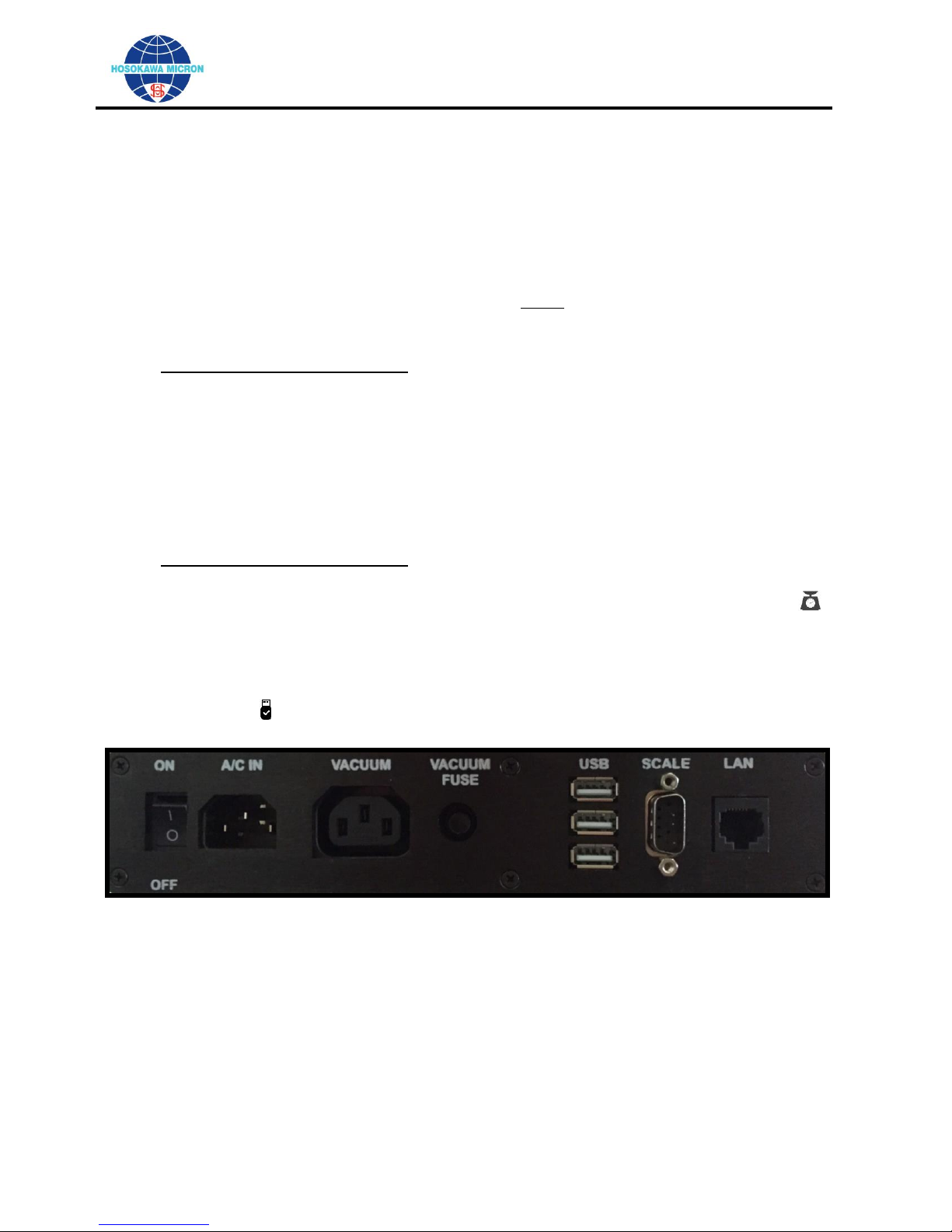

Section 8-1: Power/Communication Panel

(See Figure 1 - Left to Right)

Power “On/Off” switch

Main power “A/C IN” supply 90-240 volt, single phase, 50/60 hertz, current draw without the

vacuum attached is 0.5 amperes at 110 volt 60 Hertz, Single Phase.

Vacuum power “VACUUM” supply port, the vacuum MUST always be connected to the software

controlled “VACUUM” port of the MAJSx.

Vacuum receptacle fuse “VACUUM FUSE”

MAJSx Advanced Operation Only

o Three (3) USB ports permitting the connection of USB devices.

o One (1) RS232 DB9M serial port “SCALE” for the connection of a balance

o Local Area Network “LAN” port (CAT 5).

Section 8-2: Cable Connection

Insert the power cord in the “A/C IN” receptacle located on the back of the MAJSx

Insert/Connect the Vacuum power cord (or the vacuum power adapter cord) to the “VACUUM”

receptacle.

MAJSx Advanced Operation Only

o Connect a compatible “Balance” communication cable to the RS232 “SCALE” port

o Confirm that the Balance is recognized by the software and that the “Balance” ICON is

visibly dark black in the upper right corner of the screen. (see Figure 14).

o Connect the Network cable to the “LAN" port.

o Insert a USB “Flash Drive” into one of the USB ports on the back of the MAJSx2.

o Confirm that the USB “Flash Drive” is recognized by the software, and that the “USB”

ICON is visibly dark black in the upper left corner of the screen. (see Figure 4).

Figure 1

Page 16 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Section 9: Basic Model Operating Procedure (Factory Default)

(For the Advanced Model (MAJSx

2

-a) proceed to page 23)

Section 9-1: Power-up the MAJSx

2

Basic Operation Mode

For the system to perform properly, connect the vacuum hose and the vacuum power cable to the

appropriate ports before energizing the MAJSx2-b.

Confirm that the vacuum is plugged into the MAJSx2 “VACUUM” receptacle (outlet) and that

the suction hose is connected to the “VACUUM” port (see Figure 1), both located on the

back of the MAJSx2-b.

Figure 2 Figure 2a

Confirm that the vacuum power switch is in the “ON” position.

Next, energize the MAJSx2-b, by pressing the “On/Off” rocker switch to the “ON” position located

on the back of the MAJSx2-b as displayed in Figures 1.

The touch screen of the MAJSx2-b will briefly display the Hosokawa Logo during the software

startup. (see Figure 3)

Figure 3

Page 17 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

After the software has completely opened, the “SIEVE” window will be displayed (see Figure 4).

Figure 4

Section 9-2: Set-Up for Basic Operation

The SIEVE window displays the START button along with the Sieving Parameters, including the

“Pressure” and “Time” default values. (see Figure 4).

To enter or change the “Pressure”, press the corresponding cell, whether blank or pre-populated.

By doing so the keyboard will be activated and displayed. After typing the desired information,

press the Next button to save the entered value and to open/display the “Time” keyboard. After

typing the desired information, press the Next button to close the keyboard and save the entered

or changed values. (see Figures 5a & 5b).

Figure 5a Figure 5b

Pressing the ADMININSTRATOR folder will open the window that will display the “IP Address”

and “MAC ADDRESS” numbers, “Language”, “Pressure Unit”, “Check USB Update” and “MAJSx

Advanced Mode” and “FACTORY SETTINGS” selection buttons. (see Figure 6)

Figure 6

The specific “IP Address” is displayed when the MAJSx2-b is connected to a network. (see

Figure 6)

The unique MAC Address assigned to this MAJSx2-b will be displayed after “MAC:” (See

Figure 6)

Page 18 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

The “Language” selection button is a pull-down menu enabling the Operator to select the

language that is to be displayed throughout the MAJSx2 software (English, Spanish, Hindi,

Dutch, French, German, Italian, Japanese, Portuguese, Russian, Korean and Chinese). (See

Figure 7)

“Pressure Unit” button is a pull-down menu enabling the operator to select the desired

pressure measurement unit (inch H2O, Pascal, mm Hg, inch Hg, or PSI).(see Figure 8)

“Check USB Update” compares the installed software version to that contained on an

installed flash drive where the operator can upload software updates/patches. (see Figure 9).

“MAJSx Advanced Mode” button, provided the operator has the individualized specific

“Password” to convert the MAJSx2-b, “Basic” mode of operation to the MAJSx2-a “Advanced”

mode of operation. Contact Hosokawa Micron Powder Systems for more Information (See

Figure 10).

Figure 7 Figure 8

Figure 9

FACTORY SETTINGS In order to access the Factory Settings while in Basic Mode a

Password is required Contact Hosokawa Micron Powder Systems (see Figure 10)

Figure 10

Page 19 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

The MAJSx2 is designed for use with the Hosokawa Micron Test Sieve Screens.

While other manufactures Test Sieve Screens can and do fit the MAJSx2, HMPS cannot

guarantee operational results, or be held responsible should any damage occur.

When using the HMPS 200mm Test Sieve Screens, both a Black O-ring and a Blue Test Sieve

Gasket are supplied.

The Black O-ring is recommended to insure a proper vacuum seal.

The Blue Test Sieve Gasket is NOT required and should be removed and discarded.

Section 9-3: Basic Mode (Manual) Operating Procedure

Connect the Vacuum to the MAJSx2-b.

Insert the Vacuum power cord into the “VACUUM” power outlet located on the back of the

MAJSx2-b. Once plugged into the MAJSx2-b, confirm that the vacuum power switch is set to the

“ON” position. (see Figure 1)

Connect the Vacuum hose cuff to the vacuum port on the back of the MAJSx2-b labeled

“VACUUM”. (see Figure 1)

Press the On/Off rocker switch, located on the back of the MAJSx2-b, to the “ON” position. (See

Figure 1)

The MAJSx2-b software will perform the start-up sequence. Upon completion the SIEVE page will

be displayed. (see Figure 4)

Figure 4

Prior to pressing the START button, set the “Pressure” and “Time” values to the desired level that

will be used during sieving operation.

To enter or change the “Pressure”, press the corresponding cell, whether blank or pre-populated.

By doing so the keyboard will open enabling the desired numeric value to be entered

(recommended vacuum pressure 8 to 16 inch water column.

After entering the desired value, press the NEXT button to save the entered value and to open the

“Time” keyboard. After typing the desired sieving Time, press the NEXT button to close the

keyboard and save the entered/changed values. (see Figure 5a & 5b)

To heighten repeatability, independently record the Test Sieve Screen Number (Mesh) or Micron

Size, Pressure and Time used for each analysis.

Page 20 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Place the empty Test Sieve Screen on an independent balance and record the weight. Tare the

balance with the Test Sieve Screen remaining on the balance. Once tarred, place the sample

(suggested 10 to 100 grams) to be analyzed on the Test Sieve Screen and record the sample

weight.

Place the Test Sieve Screen with the sample on the MAJSx2-b and position the Test Sieve Cover

on the Test Sieve Screen.

With the Test Sieve Screen including the sample in place, using the previously entered sieving

parameters, press the START button to begin the analysis.

Once the START button is pressed, the MAJSx2-b sieving process will begin. The vacuum will

power and the slit wand will begin to rotate (clockwise) once the vacuum pressure reaches

approximately 7 inches of water column (or equivalent).

Should the desired Sieving Pressure not be reached, an error message will appear stating

“Pressure not Matched!” (see Figure 11)

Press the OK Button.

After pressing the OK button the software will return to the main “SIEVE” page. (see Figure 4)

Prior to restarting the process confirm that the Test Sieve Screen with the O-ring and the

Polycarbonate Test Sieve Screen Cover are properly seated in the MAJSx2-b housing, the vacuum

hose is properly connected, and the vacuum power switch is in the “ON” position.

In the event the condition continues, inspect the vacuum filters, as they may require cleaning.

After performing these checks press START. (see Figure 4).

Should the desired vacuum pressure continue not to be reached, refer to the guidelines in the

troubleshooting section of this manual.

Once the wand begins to rotate, the sieving time will begin to decrease. Both the Pressure and

the Time Left will be displayed on the screen, until the Time reaches 0 (see Figure 12)

Figure 11

Figure 12 Figure 13

Page 21 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

When using the MAJSx2 in the Basic Operation Mode, the MAJSx2-b is

NOT capable communicating with a balance or Printer.

If for any reason the process needs to be stopped, during the analysis (for example: to brush the

Test Sieve Cover free of statically charged sample) press the PAUSE button. (see Figure 12).

To re-start the analysis, press the RESUME button. If for whatever reason the analysis needs to

be aborted, press the ABORT button. (see Figure 13)

After the preset Time has reached 0, the wand will stop rotating, power to the vacuum will stop,

turning the vacuum off, and the MAJSx2-b screen will display the main SIEVE screen. (see Figure

4).

In order to determine the volume of the retained sample and complete the analysis, Tare the

independent balance, place the Test Sieve Screen with the retained sample on the balance.

Independently record the combined weight of the Retained Sample and the Test Sieve Screen.

Using the previously saved information (the Total Weight of the Test Sieve Screen and the

Sample) the operator can determine the weight of the retained sample.

In order to determine the percentage of the sample that has passed through the Test Sieve Screen

use the following formula.

Initial sample weight (A) minus the Retained sample weight (B) divided by the Initial sample weight

(A) x 100. (A – B ÷ A x 100)

Section 10: Advance Model Operating Procedure (Optional)

Section 10-1: Power-up the MAJSx2 in the Advance Operation Mode

For the system to perform properly, connect the vacuum hose and the vacuum power cable to the

appropriate ports before energizing the MAJSx2-a.

Confirm that the vacuum power cord is plugged into the MAJSx2 “VACUUM” receptacle

(outlet) and that the cuffed vacuum hose is connected to the “VACUUM” port (see Figure 2),

both located on the back of the MAJSx2-a.

Figure 2

Page 22 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Confirm that the vacuum power switch is in the “ON” position.

Confirm that a compatible balance is connected to the MAJSx2-a by means of the RS232 serial

cable connection port located on the back of the MAJSx2-a (see Figure 1).

Confirm that the software recognized the compatible Balance. The “Balance” ICON in the

upper right corner will become dark black. (see Figure 14 ). In addition clicking on the ICON will

display the name of the connected balance.

Connect the Network cable to the “LAN" port (see Figure 1)

Insert the USB “Flash Drive” into one of the USB ports of the MAJSx2-a.

Confirm that the USB “Flash Drive” is recognized by the software. The “USB” ICON will become

dark black in the upper left corner of the screen. (See Figure 4). In order to remove the USB

safely click on the ICON, highlight the USB to be removed and follow the on screen instructions for

the proper removal.

Confirm that a Printer is connected to the MAJSx2-a by either USB, WIFI or CAT 5 network LAN

Energize the MAJSx2-a, by pressing the “On/Off” rocker switch to the “ON” position located on the

back of the MAJSx2-a (see Figures 1 & 2).

The touch screen of the MAJSx2-a will briefly display the Hosokawa MAJSx2 Logo during the

software startup. (see Figure 3)

Figure 3

After the software has completely opened, the Username Sign-In window will appear (see Figure

14).

Figure 14

Open the Username Keyboard by pressing the white cell to the right of the title Username:

Should this be the first time the software is started a default Username and Password will be

supplied by the Administrator. Only Administrators are permitted to customize the User list and

Set-Up the software for operation.

After entering the Default Username press the → to open the Password entry cell.

Enter the Default password then press the → to return to the main Sign-In page.

Page 23 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

In the event either the Username or the Password were incorrectly entered either or both

cells will be bordered in red and an error message will appear permitting the operator to reenter the information. (see Figures 15 & 16)

Figure 15 Figure 16

Provided the Username and the Password are entered properly, the software will advance

opening the Sieve page.

Section 10-2: SIEVE Page

Figure 17

On the Sieve page the details of the analysis to be performed will either be displayed or must

be entered by the operator.

In order to enter information the operator must first press the Select Recipe button to define

the type Recipe that will be performed.

Figure 18

Please note that depending on the Users Role (Administrator)(Power User)(Test User), the

User will have the ability to make either limited, unlimited, or limited to only running recipes.

Page 24 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

On this window the user can choose from the following to perform a recipe;

o No.: 1 “Temporary Recipe” (this is a onetime recipe and the set-up is NOT saved).

o No.: 2 “Add Recipe” (this is used to develop a recipe that will be used frequently, and

the operating parameters can NOT be changed)

o No.: 3 and higher are “Prior Saved” recipes. These recipes have been saved to

insure set-up and operation repeatability. These recipes can ONLY be edited by

either the “Power User” or the “Administrator”.

By pressing the “Pencil” ICON the saved parameters for that Recipe will be opened

allowing the Test User to make changes only to the Company – Sample – Lot No. - Percent

Mode and Sample type fields.

By pressing the “Trash Can” ICON the User can “Trash” (Delete) that specific Recipe from

the list.

If for any reason either the Pencil or Trash Can ICON’s are “Grayed-Out” on a

specific Recipe, that particular Recipe cannot either modified or trashed, by the User.

Figure 19

After selecting the Recipe to be performed the software will return to the “ Sieve” page where

the “User”, if permitted can enter the specific details for the analysis (Company – Sample – Lot

No.: Additionally the “Percent Mode” (Passing or Retained) and “Sample Type” “New” or

“Reuse” can be selected for the analysis. (see Figure 19)

If “New” is selected the software will instruct the “User” to introduce a “New” sample volume for

each Test Sieve Screen used for the analysis. If Sample Type “Reuse” is selected the

software will be modified such that a single volume of sample is to be used, and the volume of

sample staying on the Test Sieve Screen will be used as the sample for the next Test Sieve

Screen (this process is to be used for the entire number of Test Sieve Screens selected for the

Analysis).

In the event the “User makes an error during the information entry process, the User can re-

open the cell with the error by tapping on the errored cell (this will open the keyboard allowing

for the correction to be performed), or the User can press the Clear button, this will clear

(erase) all but the “User” field, allowing the User to re-enter all the information, after pressing

the Select Recipe button.

In the event the “User” has finished his session the LOGOUT button should be pressed, this

will open a window requesting confirmation of the LOGOUT action.

Page 25 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Should the answer be “Yes” the Sign In page will reappear. Should the answer be “NO” the

Window closes and the software returns to the Sieve page.

After re-entering the Analysis parameters on the Sieve page the NEXT button is to be

pressed.

This will open the Test Sieve Selection window (containing both ASTM/Mesh and ISO sizes).

To simplify the selection of Test Sieve Screen(s) there is a search window located above the

list. Enter the numeric value (either Micron or Mesh) of the desired Test Sieve Screen then

press NEXT (on the keyboard page). After pressing the NEXT button on the keyboard page

the Test Sieve Screen list will display all the Test Sieve Screens containing that value.(see

Figure 22)

Please note the Test Sieve Screen sizes can be selected in random order.

Figure 20

Figure 21 Figure 22

Once a Screen is selected the screen will be shown in the cell to the right of the selection

chart.

In the event a Screen is incorrectly selected simply tap on the incorrect screen to remove it

from the selected list.

NOTE: Test Sieve Screens can be selected at random (see Figure 22a)

Figure 22a

Page 26 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

After selecting the Test Sieve Screen sizes that will be used for the analysis recipe press the

NEXT button to advance the software. (see Figure 22a)

Figure 23

Please note that the Screen Micron order will be automatically aligned so that the process

always starts with the Finest (Smallest) micron opening (see Figure 23).

In order to Begin The Process the desired Vacuum Pressure, Sieving Time, and Boost Time

must be entered for EACH Test Sieve Screen.

o Vacuum Pressure Units is the pressure (Administrator settable Pressure Units) that

will be used for that particular Test Sieve Screen.

o Sieving Time (seconds) is the total desired Sieving Time (default slit wand rotation is

18 rpm) of operation (this is the time the slit wand and the vacuum will be powered),

that will be used for that particular Test Sieve Screen.

o Boost Time (seconds) is the time the slit wand will rotate at “Boost” Speed (24 rpm).

o The Boost Time is used to disperse difficult to sieve or highly cohesive samples.

o The Boost Time is an integral part of the “Sieving Time” and is active at the beginning

of the “Sieving Time” cycle. If the Boost option is not required enter 0 in the cell,

pressing the Begin The Process will not function without a numeric value in the cell..

After Pressure, Sieving and Boost Time cells have been entered press the Begin The

Process button to advance the software and start the menu driven analysis.

The software will instruct the User to place the finest (smallest) opening Test Sieve Screen on

the Scale to determine the Tare weight.

After pressing Accept the Tare weight will be displayed and the software will advance

requesting that the Sample be placed on the Screen for weighing. (see Figure 24)

After pressing Accept the software will instruct the User to place the Screen on the Sieve

(MAJSx2-a) body. (see Figure 25a)

If the User determines that an error took place with either of the weight measurements the

Undo button can be pressed to repeat the measurement.

Figure 24 Figure 25

Page 27 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 25a

Please Note, the User can press the Abort button at any time to terminate the analysis. (see

Figure 25a)

If the User wants to proceed with the analysis the START button is to be pressed.

Once the START is pressed the Vacuum will start and after the vacuum pressure exceeds

approximately 7 Inch water column (or equivalent) the slit wand will start rotating.

If a BOOST Time was entered the BOOST Cycle will time down first followed by the remaining

Sieving Time.

The Pressure Units and reducing Time Left will be displayed.

If for any reason the process needs to be paused press the Pause button, this will stop the

rotation of the Slit Wand and turn off the Vacuum. (see Figure 26)

Figure 26 Figure 27

After the User has performed whatever task that was required or cleared the issue the User

can either press the Abort or Resume to either stop the analysis or to complete the time

cycle. (see Figure 27)

In the event the Abort button is pressed the software will return to the Sieve page. (see

Figure 19)

Figure 28

Page 28 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

After the weight has been accepted by pressing the Accept button, the retained sample

weight will be displayed and the User will be instructed to “Remove the screen and then press

OK” this will advance the software to continue with the analysis similar to the method that was

used for the first Sieve screen by displaying the following screen: (see Figure 29)

Figure 29

The User is to follow the on-screen instruction until all of the Sieve screens have been used to

determine the overall analysis.

If on the “Sieve” page, REUSE was selected as the Sample Type the software will (lightly)

display the retained sample weight (in the “Place Sample on the Screen (Weight)” box. The

box will be shaded NOT permitting the User to make changes to the weight.

If NEW was selected for the Sample Type the User will be instructed to place a NEW sample

on the Screen, in order to determine the weight of the “NEW” sample.

Pressing the START button will, as with the prior Sieve screen start the Vacuum and after

the vacuum pressure exceeds approximately 7 Inch water column (or equivalent) the slit wand

will start rotating.

The Pressure Units and reducing Time Left will be displayed.

Once the time reaches 0 the Slit wand will stop rotating and the Vacuum will turn-off.

The software will advance instructing the User to “Place the screen with the retained sample”

on the scale to determine the retained weight.

The “Sample on Scale (Weight)” will be displayed. If the User determines that an error has

occurred in the weighing process the User can press the Undo Button to repeat the weighing

process.

If the sample weight is deemed to be correct the User is instructed to “Remove the screen and

then press OK”

After the OK button is pressed the software advances to display the TEST REPORTS page.

In the event the weight of the retained sample is greater than the starting weight, an error

message will be displayed. (see Figure 30)

Figure 30

After pressing the OK button the software returns to the Sieve (Select Recipe) page.

Page 29 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 31

On the TESTS REPORTS page (see Figure 31) the User can select the “Results Type”

o Lin-Lin (Linear – Linear graph format)

o Rosin-Rammler (NOTE; The Rosin Rammler Result Type can be selected from the

“Pull-Down”. In order for the Rosin-Rammler calculation function to become active a

minimum of two (2) Test Sieve Screens must be used during the analysis recipe).

o Once the Rosin-Rammler “Result Type” is selected the software opens a window

enabling the User to change the three (3) “% Pass” values that will be used to

calculate the micron size for the corresponding percentage, after pressing the

Calculate button. (see Figures 32 & 33)

Figure 32 Figure 33

Also displayed on the TEST REPORTS page: (see Figure 31)

o Test Results in the “Percent Mode”

(Pass or Retain – whichever was selected after Selecting the Recipe Type)

o Size in microns (for each Test Sieve used in the analysis Recipe)

o Sample Weight (for each Test Sieve used in the analysis Recipe)

Initial (Before sieving)

Final (After Sieving)

o Cum. % (Sample Cumulative Percentage)

The page also has buttons that will permit the User to add ”Notes:” and if necessary perform

mathematical calculations (Calculator)

Additional User tools on this page are:

o GRAPH Pressing this button will graph the results for each Test Sieve Screen used

during the analysis. (see Figure 34)

Page 30 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 34

o PRINT Pressing this button will open the Printer selection sub window where the

User can select a printer to send the data for printing. (see Figure 35)

Figure 35

o SAVE Pressing this button will open the Select Device which will list the available

storage devices connected to the MAJSx2. The User must select (highlight) the

device where the analysis results are to be saved which will activate the NEXT button

then press the NEXT button to complete the Saving Function.

Figure 36

After Selecting a Device and pressing the NEXT button, a window will be displayed requesting

that User “Enter a File Name” before saving the Report. CAUTION in the event the Save

Button is pressed before the File Name is entered the Report will NOT be saved. (see figure

36)

Upon completion of the analysis recipe press the FINISH button to return to the Sieve page to

either Repeat Test or Select Recipe to select a different recipe.

In the event the LOGOUT button is pressed at any time a confirmation window will open,

Pressing NO will return to the location in the recipe that was open at the time the LOGOUT

button was pressed. If YES is pressed the software will return to the Username / Password

Sign-In page. (see Figures 37 & 38)

Page 31 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 37 Figure 38

Section 10-3: REPORT Page

Figure 38

This page Permits the User to sort the saved Analysis Recipes for comparative evaluation.

(see Figure 38)

The primary sort Pulldown window allows the User to select from one of the following fields as

the primary sort field.

o SAMPLE – (Sort Default Topic)

o LOT NO.

o DATE

o OPERATOR

After selecting a Primary Sort category the sort can be further narrowed by entering specific

term values in the blank cell to the right of the primary sort field.

The sort can be further narrowed by selecting a combination of the following secondary sort

fields.

o Percent Mode

Pass

Retain

o Sample Type:

Reuse

New

During the field selection process the saved Analysis automatically sorts to display only the

Analysis Results that meet the sort criteria. (see Figures 39 & 40)

Page 32 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 39 Figure 40

If at any time a selection error has been made the RESET button can be pressed clearing the

sorted items allowing the User to correct the sort criteria.

After the sort is processed those saved analysis will be displayed with a + on the right side

of the row. This is an indication that the analysis is available for comparison.

After selecting from the list the + switches to a - this is the button to be used to remove

the analysis from the comparison group.

NOTE a maximum of five (5) analysis can be selected, should more than five (5) be selected

the following ERROR message will be displayed. (see Figure 41)

Figure 41

After pressing the Exit button the display returns to the Sort selection chart permitting the

User to remove the excess comparison analysis from the list, by pressing the - button.

After the Analysis reports have been reduced to not more than five (5) the User must press the

NEXT button to advance to the step in the software where the User can perform additional

activities.

Figure 42

Page 33 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

On this page the User can either select, (see Figure 42)

Exit PRINT SAVE OVERLAY

o Pressing the Exit button will reopen the REPORT page.

o Pressing the PRINT button will open the FIND PRINTER window to select a

printer to send the data for printing. Additionally the User can select OVERLAY

which will send the OVERLAY graph to the selected printer for printing of the

selected Analysis.

o Pressing the SAVE Button will open the SELECT Device for saving the Sorted

Analysis. In the event the Data has no positive values an error message will be

displayed. Press the OK button to close the window.

o Pressing the OVERLAY Button will display the selected analyses on a single

graph. A legend of the selected analysis will be displayed by the test number # on

the upper right side of the graph. The User must press the X located in the upper

right corner to close the display. (see Figure 44)

Figure 43

Figure 44

Page 34 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Section 10-4: SETTINGS Page

The SETTINGS page is the location where the Administrator sets the main operating

parameters of the Mikro Air Jet Sieve (see Figure 45)

Displayed on this page are the following:

o IP Address: Internet Protocol (this is a unique identifier for electronic connected to the

internet) When connected to an Internet Accessible Network the specific address will

be displayed.

o MAC Address: Media Access Control (MAC) (this is a unique address that identifies

the network card, which is used to access the network. Each device has a unique

MAC assigned by its manufacturer.

o Pressure Units: This is a pull down controlled by the Administrator that will display

pressure values, according to the local standards and can be set for:

Inch Water (In H2O) (Recommended Range 7 to 16 In H2O)

Pascal (Pa) (Recommended Range 1741.88 to 3981.44 Pa)

Millimeter Mercury (mmHg) (Recommended Range 13.07 to 29.86 mmHg)

Inch Mercury (In Hg) (Recommended Range 0.51 to 1.18 IN Hg)

Pounds per Square Inch (psi) (Recommended Range 0.25 to 0.58 psi)

(See Figure 45)

o Weight: The DEFAULT for this category is Grams and is not capable of being changed

The following Features are controlled by the Administrator and are either ON or OFF:

LOGIN – Checking this box will enable the requirement for each user to Login

in order to use the MAJSx2.

RECIPES - Checking this box will enable the user to construct a recipe to be

used as a standard protocol.

WIFI (Wireless Fidelity) - Checking this box will enable the connection to a

WIFI within range, By checking the box the CONNECT TO WIFI window will

open displaying the WIFI networks (see Figure 46)

Figure 45

Figure 46 Figure 46a

Page 35 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Select the desired network, click in the PASSWORD: cell to open the keyboard for entry of the

selected network password. Once entered press the → button to close the keyboard enabling

the User to press the CONNECT button. After connecting to the desired Network the

”Successfully Connected to Network” window will be displayed (see Figure 46a. Press the

OK button to close the window and return to the SETTINGS page.

EXIT – Pressing this button will close the SETTINGS Page and the

software will reopen the SIEVE Page.

MORE – Pressing this button will open the SETTINGS page

permitting the Administrator to set DEFAULT settings:

(see Figure 47)

Figure 47

Time Zone – Pressing this Button opens a sub window where the Time Zone can be searched

for Setting of the Clock (and Date). Enter the first few letters of the location where the MAJSx2

is located and press the → on the keyboard to initiate the search. The window will display

those locations that contain the characters that were entered. Select the desired location and

press the APPLY button to lock the location. To Set the Clock Press the Set Clock button.

The SET TIMESTAMP window opens displaying the Set Date: cell and the Set Time: –

Hours – Minutes - Seconds cells. To set the date click on the date cell which will open a

calendar that can be scrolled until the desired date is located and set by pressing on the date.

To set the time there are individual up/down scroll buttons that permit the setting of the hours

(24 hour clock), minutes and seconds. After setting the date and time press the APPLY button

to lock the values and to return to the SETTINGS page. Note the CANCEL button can be

pressed at any time to return to the SEARCH TIME ZONE page.

Timestamp – Pressing the MM-DD-YYYY-hh-mm-am/pm button sets the format that will be

used throughout the software for the Date and Time. After setting the date and time press the

APPLY button to lock the values and to return to the SETTINGS page. Note the CANCEL

button can be pressed at any time to return to the SETTINGS page.

Language – Pressing this button opens the SEARCH LANGUAGE sub window where the

SYSTEM (display) Language can be set. Enter the first few letters of the desired language

that is to be displayed on the touch screen of the MAJSx2. After the desired language has

been identified and marked, press the → on the keyboard to initiate the search. The window

will display those languages that contain the characters that were entered. Select the desired

language and press the APPLY button to lock the language and to return to the SETTINGS

page. Note the CANCEL button can be pressed at any time to return to the SETTINGS page.

Basic Mode – Pressing this button will open the Change to Basic Mode window. On this

page pressing the APPLY button will change the Operation Mode from Advanced to Basic

opening the Basic Mode operation window. Note the CANCEL button can be pressed at any

time to return to the SETTINGS page.

Page 36 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Backup / Retrieve – Pressing this button will open the Backup/Retrieve window

(see Figure 48)

Figure 48

o Pressing BACKUP opens the Select the USB Device window where the user can

highlight the desired location for the backup to be placed. After highlighting the USB

Device the Next button becomes active. Pressing the Next button will open the New

File Window where the User is to enter the NEW Name of the Backup File. Click in

the blank cell to open the keyboard to enter the New Name. Once entered press the

GO button to save the file and receive confirmation that the Backup was Successful

and Identify the media where the file was saved. Press the DONE button to close the

confirmation window and return to the Backup / Retrieve window. Pressing Retrieve

Opens the Select USB Device window. Once the device is highlighted the Next

button becomes active. Enter the name of the Backup file that is stored on the

highlighted USB and press the GO button to retrieve the file and open the “Retrieve

Successful” window. Press the DONE button to close the confirmation window and

return to the Backup / Retrieve window. Note the CANCEL button can be pressed at

any time to return to the BACKUP / RETRIEVE page. Press the Back button to go

back one page to the SETTINGS page.

o In the event a USB Flash drive is not inserted in the MAJSx2 an error message

indicating No USB Device Found! will appear, press the EXIT button to close the

window.

Printers - Pressing this button will open the FIND PRINTER window, (see Figure 49)

Figure 49

Page 37 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

o Should a list of prior installed printers exist the User can select a printer from the

list or search the list by clicking on the magnifying glass to the right of the

search cell. This will open the software keyboard or if an external keyboard is

attached the operator can enter the first few letters of the desired printer that will

be used to search the field list. Press the arrow → button to start the search. The

list will be reduced to display only those printers containing the search characters.

Figure 50

o After the desired printer has been selected (highlighted) (see Figure 50). The

SET PRINTER button must be pressed to establish the selected printer as the

default printer where the data will be sent for printing.

o In the event there are no printers in the FIND PRINTER list, a NEW printer must

be added. Pressing the NEW button will open the ADD PRINTER window which

will automatically search via WIFI for those printers within range. (see Figure 51)

Figure 51

o After selecting the desired printer in the SELECT PPD DRIVER (Postscript Printer

Description) listing the most appropriate driver will be displayed at the top of the

listing.

o The User must select the driver to be added to the software. Pressing the ADD

button will open the ADD DETAILS window requiring the User to enter the

PRINTER NAME and PRINTER LOCATION.

Page 38 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

o The User must then press the ADD button to add the driver into the computer

permitting the printing to the specified printer. After pressing the ADD button the

software reopens the FIND PRINTER Page (see Figure 50).

Update Version - Pressing this button will open the Software Verification Window

which will display the Current Version and search for an Update. If the USB does not

contain an update a window stating “No Update Found!” will be displayed. (see Figure

52)

Figure 52

o Press the Back button to return the software to the SETTINGS page.

(see Figure 52)

Users - Pressing this button will open the Add / Modify User window. (see Figure 53)

Figure 53

Pressing the Add User button will open the New User Registration window

Page 39 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 53 Figure 54

The Administrator is the only User that can Add New Users and Modify existing Users.

The Admistrator will add the Username – Password – Confirm Cells with Temporary

access information. Clicking on any of the cells will open the Software keyboard for

information entry. Clicking on the Language Cell (English (Default) will open the SEARCH

LANGUAGE window enabling the Administrator to set the User Language, that will be

used specifically by the New User. (see Figure 53)

The User Role must also be established by the Administrator

o Adminsitrator – Has FULL rights to Add Users, Modify Users and to Create

Recipes.

o Power User – Has Rights to Create and Modify Recipes.

o Test User – Is limited to performing pre-set Recipes.

After the SUBMIT button has been pressed the User Added Successfully! Window will

be displyed.

Figure 55

o Press OK to close the window and return to the Add / Modify User window.

o Pressing the Modify User button opens the Modify User window (see Figure

54).

o After checking the EDIT box follow the same instructions that were given

for the New User Registration. Press OK to close the window and return to

the Add / Modify User window.

After Entering a New User or Modifying a User the next time that specific User “Signs –

In” the User will be given the opportunity to confirm or change the Password using the

following window. (see Figure 56)

Page 40 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Figure 56

In the event the cells are left blank or incorrect entries are made the window will remain

displayed after the OK button is pressed.

In the event the New User attempting to “sign-in” does not have the proper authority the

New User Password Entry window will remain open. In order to close the window the

User must press the CANCEL button.

Logs - Pressing this button will open the TRANSACTIONS / TESTS Log window.

(see Figure 57)

Figure 57

Pressing the TRANSACTIONS button will open the TRANSACTION Date Range Window.

Clicking on either blank cell will open a calendar for the Administrator to select the FROM

and the TO date range to be sorted.

After selecting the range press the OK button to sort the transactions for that period.

The Total Number of Transactions will be displayed beneath the date range. After the

sorting has completed the SAVE and PRINT buttons become active.

Pressing the SAVE button opens the “Select USB Device” window. After highlighting the

USB Device where the data is to be saved, the User can either press the NEXT button

which opens the Enter File Name window, or the CSV button or the PDF format button.

If the SAVE button is pressed and there is No Storage device attached “No USB Device

Found” Error message will be displayed. Press the EXIT button to clear the message.

The User also has the option to exit from the saving action by pressing the EXIT button.

Page 41 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

Provided a USB Device is attached a window opens enabling the User to enter the name

of the file that will be used to save the Transaction Data on the USB Device. Press the

OK button to complete the Data Saving action.

Pressing PRINT opens the “FIND PRINTER” window for the User to select the Printer

where the Transaction log will be printed. Press the PRINT button to print the Transaction

Log, or press the EXIT button to save the information. (see Figure 58a – 58b)

Figure 58a Figure 58b

Pressing the TEST LOG button will open the TESTS LOG Date Range Window.

Clicking on either blank cell will open a calendar for the Administrator to select the FROM

and the TO date range to be sorted. After selecting the range press the OK button to sort

the transactions for that period.

The Total Number of Tests will be displayed beneath the date range.

After the sorting has completed the SAVE and PRINT buttons become active.

Pressing the SAVE button opens the “Select USB Device” window. After highlighting

the USB Device where the data is to be saved, the User can either press the NEXT

button which opens the “Enter File Name” window, where after entering the file name

used to save the data, or the CSV button or the PDF format button.

The User also has the option to exit from the saving action by pressing the EXIT button.

This opens a window enabling the User to enter the name of the file that will be used to

save the Test Data on the USB Device. Press OK to complete the Data Saving

action.(see Figure 59)

Pressing PRINT opens the “FIND PRINTER” window for the User to select the Printer

where the Test log will be printed. Press the PRINT button to print the Test Log, or the

EXIT button to save the information. (see Figure 59)

Figure 59

After Saving / Printing either the “TRANSACTIONS” or “TESTS” LOGS press the BACK

Button to return to the SETTINGS Page.

Page 42 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

FACTORY SETTINGS - Pressing this button will open the FACTORY SETTINGS page.

(see Figure 60)

Figure 60

Displayed on the FACTORY SETTINGS page are the:

o Date and Time (24 hour clock)

o Factory Speed = 97

o RESET FACTORY DEFAULT

Pressing this button will reset the Factory Default speed to 97

o JOG WAND

This Button Permits the Administrator to manually Jog the Wand Motor

o Normal Wand Speed Display Window

This window permits the Administrator to set the Wand Speed at a value

between 0 - 255

o Current Speed = XX

Based on the installed motor the Speed closest to the Factory Setting is

Displayed here.

o GET NEW VALVE SPEED

Pressing this Button, the Administrator can determine the actual motor speed

based on the specific installed motor.

o JOG WAND BOOST

Pressing this button will simulate the Boost Speed of the Wand between 0 –

255 this should be no greater than 55%

o “Boost Wand Speed” Display Window

This is where the Administrator can make minor adjustments in the BOOST

speed, between 0 - 255

o EXIT

Pressing the button Exits the window and returns to the SETTINGS Window

o SET CLOCK

This button opens the “SET TIMESTAMP” where the Administrator can make

adjustments in the Date and Clock setting.

o SUBMIT

Pressing this button Saves the Administrator settings.

Page 43 of 56

OPERATING AND MAINTENANCE MANUAL

Mikro Air Jet Sieve®

HMPS accepts no responsibility for damage to the instrument resulting

from the cleaning process and/or misuse of cleaning solutions.

Section 11: Optimizing Sieving Times

The Mikro Air Jet Sieve® process can be optimized to save time when performing an analysis.

To achieve the optimum time, select the finest Test Sieve Screen used during the analysis.

Place the same amount of sample, typically used, on the Test Sieve Screen and identify

the total weight.

Manually record this weight.

Program (10) ten seconds into the “Sieving Time” (MAJSx2-a) or the “Time Remaining”

(MAJSx2-b) and run the unit until it shuts off.

Brush any dust that accumulated on the Test Sieve Cover back into the Test Sieve Screen

and weigh the Test Sieve Screen with the retained sample.

Manually record this weight and continue to repeat the ten-second increments, recording

the weights, until you find you have three runs without any weight change.

Once the fine particles have been removed and the weight no longer reduces, the

optimum time has been achieved.

The optimum time can then be set at twenty seconds shorter than the total length of your

test protocol.

This optimum time can also be used on both fine as well as coarse opening Test Sieves

Screens.

Section 12: Maintenance

Section 12-1: Disassembly and Cleaning

The information contained here-in is intended to be a guide ONLY. Frequency and extent

of cleaning depends on the user’s corporate policy, regularity of use, material and

environment.

Remove as much dry powder using a vacuum prior to starting the cleaning process.

Use the MAJSx2 “ON/OFF” power switch to the “Off” position, then un-plug the Jet Sieve

from the power source and remove the power cable from the body.

Using a sponge, cloth, etc., lightly wash the pan area of the MAJSx2. Care should be used

NOT to oversaturate the area such that liquid collects in the pan or discharge duct. An

excessive amount of liquid will damage internal electronic and mechanical components. If

a scouring pad or hard bristle brush, or similar are used, surface damage to the MAJSx2

pan or discharge area will occur. As a result CAUTION must be used during cleaning.

Recommended Air Jet Sieve Housing cleaning can be performed by using either a dry

vacuum and or with a damp towel. In the event the damp towel method is used use a mild

non-corrosive/non-abrasive solution. Additionally when selecting a solution care should be