Hoshizaki American, Inc. HPR100A Service Manual

Hoshizaki America, Inc.

Hoshizaki

Commercial Kitchen Equipment

Model

Refrigerated Prep Table with Raised Rail

“A Superior Degree

of Reliability”

www.hoshizaki.com

SERVICE MANUAL

Number: 73168

Issued: 8-12-2009

IMPORTANT

Only qualied service technicians should install, service, and maintain the

unit. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain

the equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 3069

Attn: Hoshizaki Technical Support Department

Phone: 1-800-33-1940 Technical Support

(770) 487-331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number __________________________

• Serial Number __________________________

• Complete and detailed explanation of the problem.

IMPORTANT

This manual should be read carefully before the unit is serviced or

maintenance operations are performed. Only qualied service technicians

should install, service, and maintain the unit. Read the warnings contained

in this booklet carefully as they give important information regarding safety.

Please retain this booklet for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 6

I. Specications ..................................................................................................................... 7

A. Nameplate Ratings ....................................................................................................... 7

B. Dimensions ................................................................................................................... 7

II. General Information .......................................................................................................... 8

A. Construction .................................................................................................................. 8

B. Sequence of Operation ................................................................................................. 9

1. Startup .................................................................................................................... 9

. Cool Down .............................................................................................................. 9

3. Cool Down Achieved .............................................................................................. 9

4. Cool Down Restart ................................................................................................ 10

5. Cabinet Defrost ..................................................................................................... 10

6. Rail Defrost ............................................................................................................ 11

C. Sequence of Operation Charts ................................................................................... 1

1. Cabinet Cooling ..................................................................................................... 1

. Cabinet and Rail Cooling ....................................................................................... 13

D. Control Board ............................................................................................................. 15

1. Control Board Location .......................................................................................... 15

. Control Board Layout ............................................................................................ 16

3. Features ................................................................................................................ 17

4. Controls and Adjustments ..................................................................................... 18

a) Switch Settings ................................................................................................ 18

b) Temperature Display ....................................................................................... 18

c) Temperature Setpoint ...................................................................................... 19

d) Cabinet Defrost ................................................................................................ 19

e) Energy Saving Mode ....................................................................................... 19

f) Temperature Correction Factor ........................................................................ 0

5. Service Menu ........................................................................................................ 1

a) Service Menu Access ...................................................................................... 1

b) Service Menu Chart .........................................................................................

6. Alarm Signals ...................................................................................................... 3

7. Control Board Check Procedure ........................................................................... 3

8. Control Board Replacement .................................................................................. 3

E. Thermistor Check ....................................................................................................... 4

F. Perimeter Heater ......................................................................................................... 4

G. Compressor Protector ................................................................................................ 4

3

III. Service Diagnosis ........................................................................................................... 5

A. Alarm Signals .............................................................................................................. 5

1. High Temperature Alarm (E1) ............................................................................... 7

. Low Temperature Alarm (E) ................................................................................ 8

3. Cabinet Defrost Alarm (E3) ................................................................................... 9

4. High Condenser Temperature Alarm (clogged lter) (E7) ..................................... 30

5. Defrost Thermistor (cabinet) Malfunction Alarm (E8) ............................................ 31

6. Condenser Thermistor Malfunction Alarm (E9) ..................................................... 3

7. Control Board Alarms (EA and ED) ....................................................................... 33

B. Service Chart .............................................................................................................. 33

1. No Operation ......................................................................................................... 33

. Cabinet Cooling ..................................................................................................... 34

3. Rail Cooling ........................................................................................................... 36

4. Cabinet Defrost .................................................................................................... 37

5. Other ..................................................................................................................... 38

IV. Removal and Replacement of Components .................................................................. 39

A. Service for Refrigerant Lines ...................................................................................... 39

1. Refrigerant Recovery ............................................................................................ 39

. Brazing .................................................................................................................. 40

3. Evacuation and Recharge (R-404A) ..................................................................... 40

B. Removal and Replacement of Refrigeration System Cartridge .................................. 4

1. Refrigerant Recovery Procedure ........................................................................... 4

. Refrigeration System Pump-Down Procedure ..................................................... 44

C. Removal and Replacement of Compressor ................................................................ 47

D. Removal and Replacement of Cabinet Evaporator .................................................... 48

E. Removal and Replacement of Expansion Valve ......................................................... 49

F. Removal and Replacement of Liquid Line Valve ........................................................ 50

G. Removal and Replacement of Condenser.................................................................. 51

H. Removal and Replacement of Thermistors and Thermostat ...................................... 5

1. Cabinet Thermistor ................................................................................................ 5

. Defrost Thermistor ................................................................................................. 5

3. Defrost Thermostat ................................................................................................ 53

4. Rail Thermistor ...................................................................................................... 53

5. Condenser Thermistor (clogged lter) ................................................................... 54

I. Removal and Replacement of Defrost Heater.............................................................. 54

J. Removal and Replacement of Fan Motors .................................................................. 55

1. Cabinet Fan Motor ................................................................................................. 55

. Condenser Fan Motor ........................................................................................... 56

3. Rail Fan Motor ....................................................................................................... 56

K. Removal and Replacement of Door Gasket ............................................................... 57

L. Door Re-Hinging and Drawer Conversion ................................................................... 57

V. Cleaning and Maintenance Instructions .......................................................................... 58

A. Cleaning ...................................................................................................................... 58

1. Work Surface ......................................................................................................... 58

. Rail and Rail Cover ............................................................................................... 59

3. Exterior .................................................................................................................. 59

4. Cabinet Interior ...................................................................................................... 59

4

5. Door/Drawer Gaskets ............................................................................................ 59

6. Shelves (if applicable) ........................................................................................... 59

7. Drawers (if applicable) ........................................................................................... 59

B. Maintenance ............................................................................................................... 60

1. Rail Condensate Pan ............................................................................................ 60

. Air Filter ................................................................................................................. 60

3. Condenser ............................................................................................................. 60

4. Power Supply Connection ..................................................................................... 60

C. Shutdown and Long Storage ...................................................................................... 61

VI. Technical Information .................................................................................................... 6

A. Refrigeration Circuit .................................................................................................... 6

1. HPR46A(-D), HPR7A(-D), HPR100A(-D) ............................................................ 6

B. Wiring Diagrams ......................................................................................................... 63

1. HPR46A(-D) .......................................................................................................... 63

a. HPR7A(-D) Auxiliary Code U-5 and Earlier .......................................................

b. HPR7A(-D) Auxiliary Code U-6 and Later .........................................................

3. HPR100A(-D) ........................................................................................................ 66

64

65

5

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

CAUTION Indicates a situation which could result in damage to the unit.

IMPORTANT Indicates important information about the use and care of the

unit.

WARNING

This unit should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore

dangerous. The manufacturer cannot be held responsible for eventual damage

caused by improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or re, follow

basic precautions including the following:

• This unit requires an independent power supply. See the nameplate for

proper voltage and breaker/fuse size. Failure to use a proper breaker or fuse

can result in a tripped breaker, blown fuse, or damage to existing wiring. This

could lead to heat generation or re.

• THIS APPLIANCE MUST BE GROUNDED: This unit is equipped with a

3-prong grounding plug to reduce the risk of potential shock hazards. It must

be plugged into a properly grounded, independent 3-prong wall outlet. If the

outlet is a -prong outlet, it is your personal responsibility to have a qualied

electrician replace it with a properly grounded, independent 3-prong wall

outlet. Do not remove the ground prong from the power cord and do not use

an adapter plug.

• Do not use an extension cord.

• Make sure the power switch is in the "OFF" position before plugging in or

unplugging the unit to reduce the risk of electric shock.

• Do not use a unit with a damaged power cord. The power cord should not be

altered, jerked, bundled, weighed down, pinched, or tangled. Such actions

could result in electric shock or re. To unplug the unit, be sure to pull the

plug, not the cord, and do not jerk the cord.

• To reduce the risk of electric shock, do not touch the plug or power switch

with damp hands.

• This unit should be disassembled or repaired only by qualied service

personnel to reduce the risk of electric shock, injury, or re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, re, or damage to the unit.

6

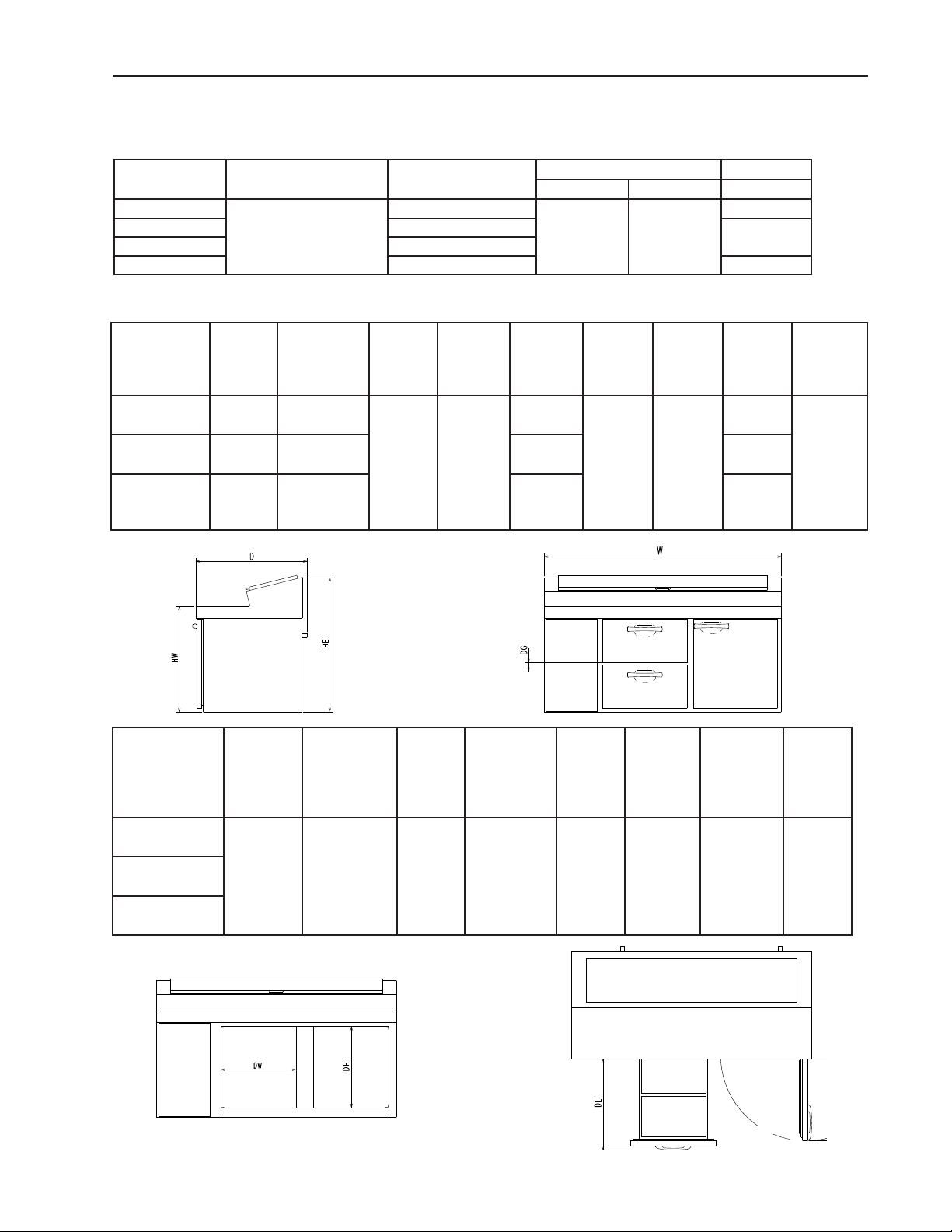

I. Specications

A. Nameplate Ratings

Design Pressure (PSIG) Refrigerant

Model AC Supply Voltage Amperes

HPR46A(-D)

HPR7A

HPR7A-D

HPR100A(-D) TBD TBD

115/60/1

See Unit Nameplate

7.6

13.6

HI LO 404A

8.5 oz.

450 50

36.1 oz.

B. Dimensions

Model

HPR46A(-D)

(1 Section)

HPR7A(-D)

( Section)

HPR100A(-D)

(3 Section)

Model

HPR46A(-D)

(1 Section)

HPR7A(-D)

( Section)

HPR100A(-D)

(3 Section)

Rail

Interior

Volume

Cu. Ft.

8.5 1

18.8 18 188.8

9.1 6 533.8

Door

Opening

Height

mm (in.)

616.

(4.6)

Capacity

QTY of 1/6

Sized Pans

Opening

Width

(DH)

mm (in.)

(.45)

Door

(DW)

570.3

Exterior

Height

(HE)

mm (in.)

1040

(40.95)

Door

Swing

(DS)

mm (in.)

608.3

(3.95)

Worktop

Height

(HW)

mm (in.)

816

(3.13)

Drawer

Extension

mm (in.)

649.1

(5.56)

Exterior

Width

mm (in.)

1168.4

(99.76)

(DE)

(W)

(46)

(7)

Exterior

Depth

mm (in.)

858.5

(33.79)

Drawer

Gap

(DG)

mm (in.)

19

(0.75)

(D)

Interior

Height

mm (in.)

640.5

(5.)

Door

Open

Position

105°

Interior

Width

mm (in.)

604.1

(3.78)

1309.1

(51.54)

014.1

(79.30)

Rail Cover

Open

Positions

45°

and

65°

Interior

Depth

mm (in.)

641.8

(5.7)

Caster

Height

mm (in.)

101.6

(4)

7

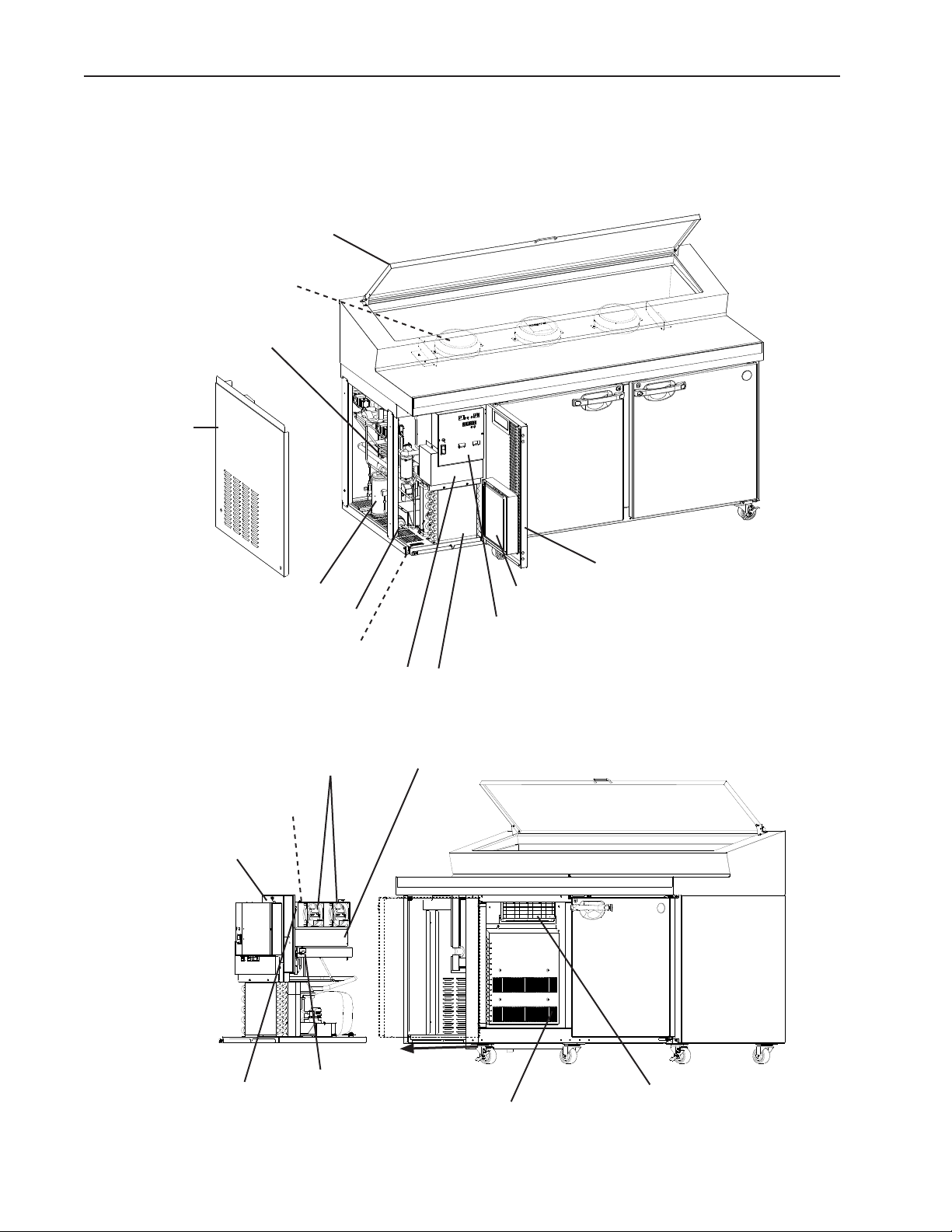

II. General Information

A. Construction

This Hoshizaki unit features a cartridge-type refrigeration system that can be removed

(excluding the rail evaporator).

Rail Cover

Rail Fan Motors and

Fan Shrouds

Compressor

Side Panel

Receiver Tank

Condenser Fan Motor

Cabinet Evaporator

Fan Motors

Cabinet Defrost Thermistor

Refrigeration

Cartridge

Drier

Wire Cover

Front Panel

Air Filter

Control Box

Condenser

Cabinet Evaporator

Assembly

Defrost Thermostat

Cabinet Thermistor

Cabinet Air Duct

Cabinet Interior Side

Panel

8

B. Sequence of Operation

The steps in the sequence are as outlined below.

1. Startup

When the power switch is in the "ON" position, the cabinet temperature is displayed

and cabinet cooling begins. When the power switch is in the "ON" position and the rail

cooling switch is moved to the "NORMAL" or "LOW" position, the rail temperature is

displayed and rail cooling begins. The "NORMAL" rail switch position is designed for use

when the rail cover is open. The "LOW" rail switch position is designed for use when the

rail cover is closed. For further details, see "II.D.4.a) Switch Settings."

a) Power Switch "ON," Rail Cooling Switch "OFF"

Cabinet temperature at or above setpoint: CabFM, CLLV, and PH energize. The

minute Comp delay timer and 6 hour DT start.

b) Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW"

Cabinet temperature and rail temperature at or above setpoint: CabFM, CLLV, PH,

RailFM, and RLLV energize. The minute Comp delay timer and 6 hour DT start.

2. Cool Down

a) Power Switch "ON," Rail Cooling Switch "OFF"

CabFM, CLLV, and PH continue. The minute Comp delay timer expires and Comp

and ConFM energize.

b) Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW"

CabFM, CLLV, PH, RailFM, and RLLV continue. The minute Comp delay timer

expires and Comp and ConFM energize.

3. Cool Down Achieved

To prevent Comp hard starts, CLLV (rail cooling switch "OFF") or RLLV (rail cooling

switch "NORMAL" or "LOW") remains energized when Comp is off.

a) Power Switch "ON," Rail Cooling Switch "OFF"

CTh reaches 3.6°F (°C) below setpoint. CabFM and PH continue, Comp and ConFM

de-energize. CLLV de-energizes for seconds (CLLV then remains energized during

Comp off time).

b) Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW"

CTh, RTh, or both have reached 3.6°F (°C) below setpoint.

(1) Cabinet still cooling, RTh reaches 3.6°F (2°C) below setpoint

CabFM, Comp, CondFM, CLLV, and PH continue. RailFM continues when rail

cooling switch is in the "NORMAL" position and per F9 setting when in the "LOW"

position. For details, see "II.D.4.a) Switch Settings." RLLV de-energizes.

(2) CTh reaches 3.6°F (2°C) below setpoint, rail still cooling

CabFM, Comp, CondFM, PH, RailFM, and RLLV continue. CLLV de-energizes.

9

(3) Both CTh and RTh reach 3.6°F (2°C) below setpoint

CabFM and PH continue. RailFM continues when rail cooling switch is in the

"NORMAL" position and per F9 setting when in the "LOW" position. For details,

see "II.D.4.a) Switch Settings." Comp, ConFM, and CLLV de-energize. RLLV

de-energizes for seconds. RLLV energizes, then remains energized during

Comp off time.

4. Cool Down Restart

a) Power Switch "ON," Rail Cooling Switch "OFF"

CTh warms to setpoint, the CabFM, CLLV, and PH continue. minute Comp delay

timer starts. After the minute delay timer expires, Comp and ConFM energize.

Cycle continues until power is turned off, the 6 hour DT expires and CB initiates

a cabinet defrost, or the "MANUAL DEFROST" button is pressed for 5 seconds

(evaporator temperature must be below 49°F (9.4°C)).

b) Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW"

CTh, RTh, or both have warmed to setpoint.

(1) CTh at or above setpoint, RTh warms to setpoint

CabFM, Comp, ConFM, CLLV, PH, continue. RailFM continues when rail switch is

in the "NORMAL" position and resumes continuous operation when in the "LOW"

position. RLLV energizes.

(2) CTh warms to setpoint, RTh at or above setpoint

CabFM, Comp, ConFM, PH, RailFM, and RLLV continue. CLLV energizes.

(3) CTh or RTh warms to setpoint

CabFM, PH, RailFM (RailFM continues when rail switch is in the "NORMAL"

position and resumes continuous operation when in the "LOW" position), and

RLLV continue. The minute Comp delay timer starts. If CTh has warmed to

setpoint and RTh has not, CLLV energizes and RLLV de-energizes. If RTh

has warmed to setpoint and CTh has not, RLLV continues and CLLV remains

de-energized. After the minute Comp delay timer expires, Comp and ConFM

energize.

5. Cabinet Defrost

The rst cabinet defrost occurs 6 hours after the unit is turned on. Cabinet defrost is

initiated when the 6 hour DT expires or the "MANUAL DEFROST" button is pressed

for 5 seconds. Cabinet defrost termination occurs when the evaporator temperature

reaches 49°F (9.4°C). Note that the defrost is a heated defrost, and therefore will have a

tendency to raise the cabinet temperature. Cabinet temperature is not displayed during

defrost; "dF" is displayed in its place. After defrost, there is a 5 minute delay before the

compressor will start.

Note: To prevent Comp hard starts, CLLV (rail cooling switch "OFF") or RLLV (rail

cooling switch "NORMAL" or "LOW") remains energized when Comp is off.

10

a) Cabinet Defrost: Power Switch "ON," Rail Cooling Switch "OFF"

CLLV continues, CabFM, Comp, ConFM, and PH de-energize. DH energizes and

warms DTh to 49°F (9.4°C) (or the 100-minute defrost termination timer expires

or DTst warms to 10°F±5°F (49°C±3°C)). When DTh reaches 49°F (9.4°C),

DH de-energizes, CLLV continues and a 5 minute Comp delay timer starts. When the

5-minute Comp delay timer expires, CabFM and PH energize for 10 seconds. Comp

and ConFM then energize and a 5-minute CabFM and PH delay timer starts. After the

5-minute CabFM and PH delay timer expires, CabFM and PH energize.

b) Cabinet Defrost: Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW"

(1) Cabinet cool down achieved, rail still cooling

Comp, CondFM, RailFM, and RLLV continue. CabFM and PH de-energize, and

CLLV remains de-energized. DH energizes and warms DTh to 49°F (9.4°C) (or

the 100-minute defrost termination timer expires or the DTst warms to 10°F±5°F

(49°C±3°C)). When DTh reaches 49°F (9.4°C), DH de-energizes, Comp, ConFM,

RailFM, and RLLV continue. CabFM and PH energize for 10 seconds. CLLV then

energizes and a 5-minute CabFM and PH delay timer starts. After the 5-minute

CabFM and PH delay timer expires, CabFM and PH energize.

(2) Cabinet still cooling, rail cool down achieved

RailFM continues (RailFM continues when rail switch is in the "NORMAL"

position and per F9 setting when in the "LOW" position), RLLV and DH energize,

CabFM, Comp, ConFM, and PH de-energize. CLLV de-energizes for seconds,

then energizes again. DH warms DTh to 49°F (9.4°C) (or the 100-minute

defrost termination timer expires or the DTst warms to 10°F±5°F (49°C±3°C)).

When DTh reaches 49°F (9.4°C), DH de-energizes, RailFM continues, RLLV

de-energizes, CLLV energizes, and a 5-minute Comp delay timer starts. When the

5-minute Comp delay timer expires, CLLV and RailFM continue. CabFM and PH

energize for 10 seconds. Comp and ConFM then energize and a 5-minute CabFM

and PH delay timer starts. After the 5-minute CabFM and PH delay timer expires,

CabFM and PH energize.

6. Rail Defrost

For rail defrost (manual defrost), remove product from the rail area and store in a

properly refrigerated area, then move the rail cooling switch to the "OFF" position.

Legend: CabFM–cabinet fan motor; CB–control board; Comp–compressor;

ConFM–condenser fan motor; CLLV–cabinet liquid line valve; CTh–cabinet

thermistor; DH–defrost heater; DT–defrost timer; DTh–defrost thermistor;

DTst–defrost thermostat; PH–perimeter heater; RailFM–rail fan motor; RLLV–rail

liquid line valve; RTh–rail thermistor

11

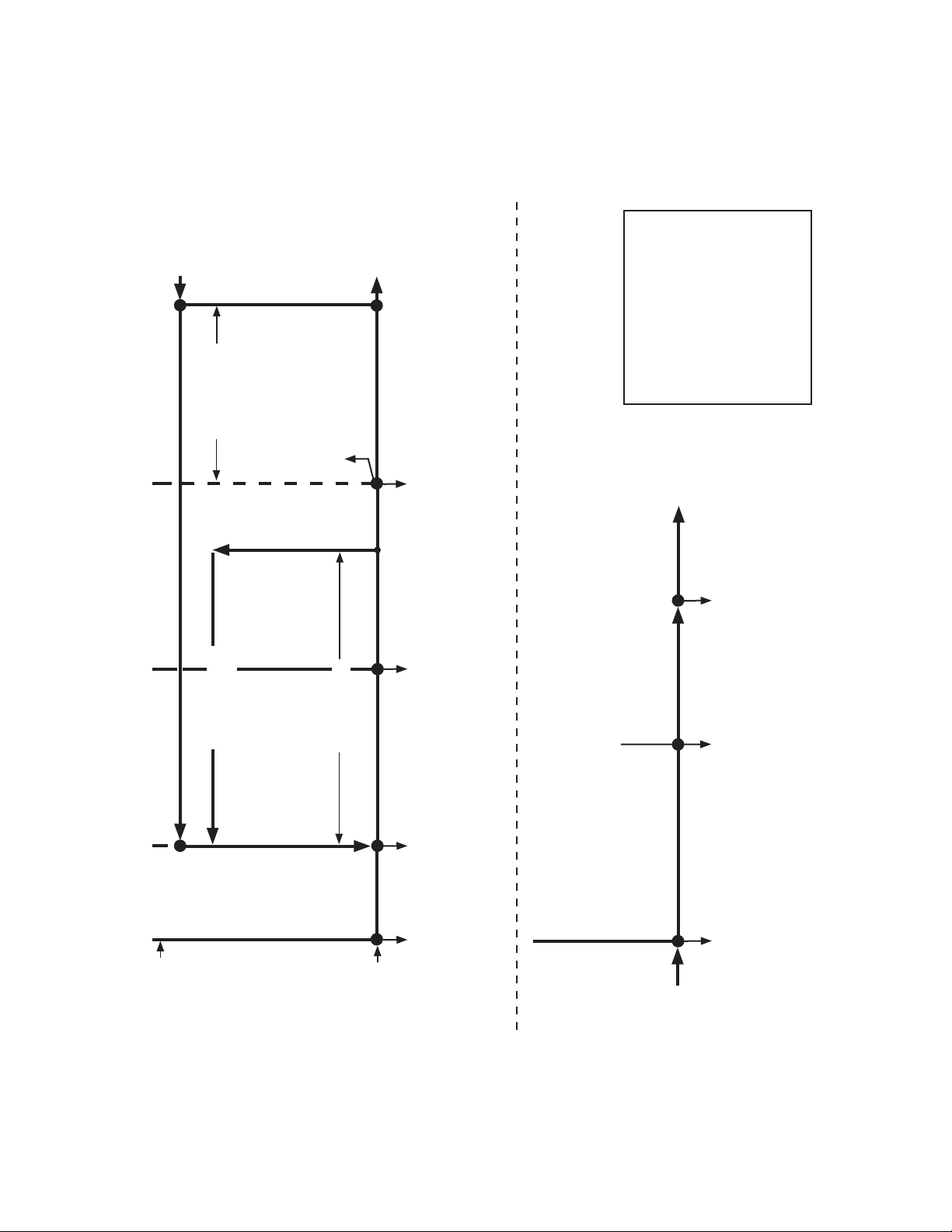

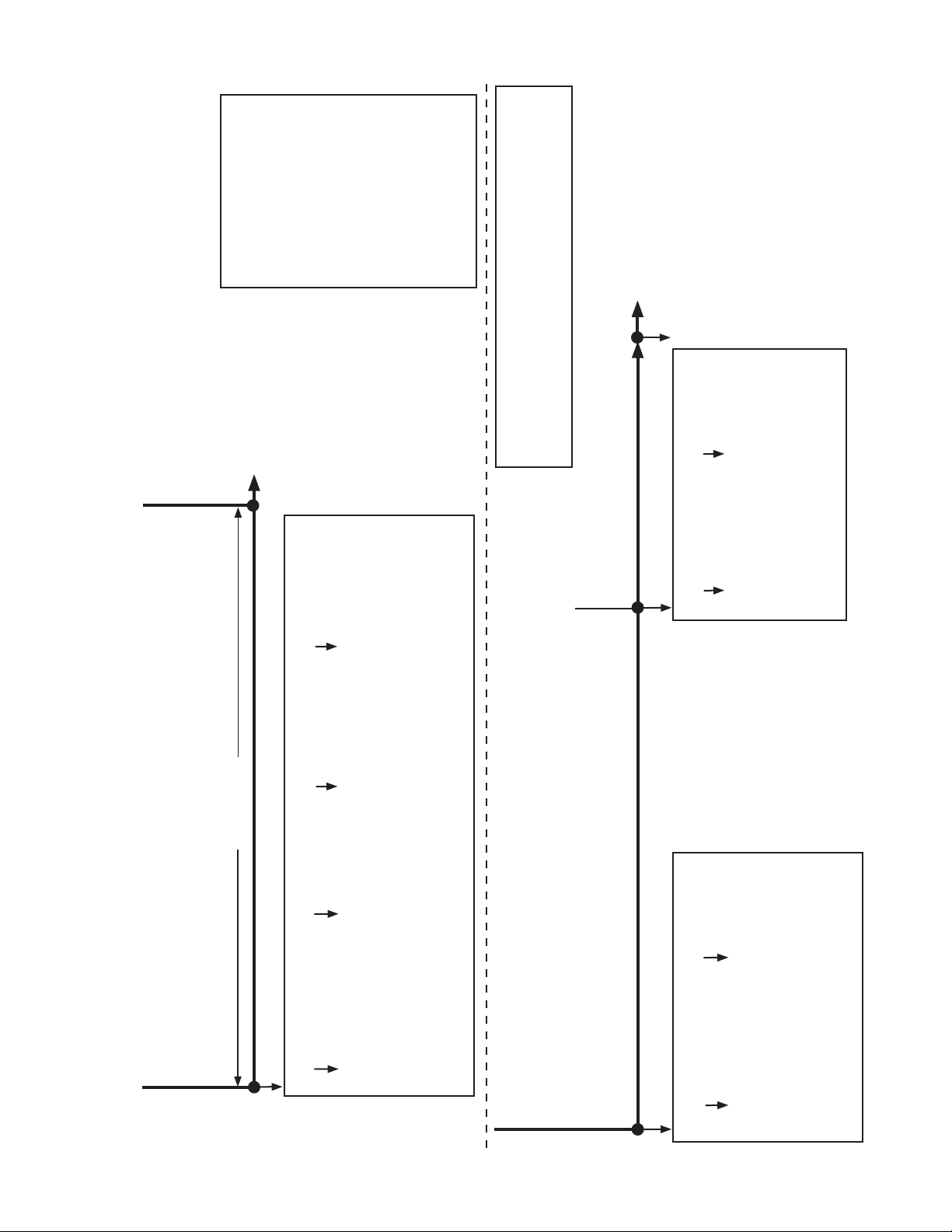

C. Sequence of Operation Charts

1. Cabinet Cooling

From 5 below

DTh in control

4. Cabinet Defrost

CTh reaches

To 5 below

resets

• 6 hour DT expires, then

3.6°F (°C)

termination timer starts

• 100-minute defrost

setpoint

CTh warms to

or more

below setpoint

CLLV energized

CabFM energized

DH energized

CabFM de-energized

Comp de-energized

ConFM de-energized

CLLV energized

PH energized

Comp de-energized

ConFM de-energized

PH de-energized

Legend:

CabFM-cabinet fan motor

Comp-compressor

ConFM-condenser fan motor

CLLV-cabinet liquid line valve

To above

CTh-cabinet thermistor

DH-defrost heater

DT-defrost timer

DTh-defrost thermistor

DTst-defrost thermostat

PH-perimeter heater

CabFM energized

CLLV energized

Comp energized

ConFM energized

PH energized

delay timer starts

-minute Comp

CTh in control

Power Switch "ON," Rail Cooling Switch "OFF"

CabFM energized

CLLV energized

Comp energized

ConFM energized

PH energized

Comp delay

timer starts

1. Startup 2. Cool Down 3. Cool Down Achieved

• -minute

Cycle Steps

• 6-hour DT

starts

CabFM energized

CLLV energized

PH energized

Initial startup

begins here

1

5-minute CabFM and

PH delay timer

Stage 2:

CabFM and PH

energize for 10 sec.

CLLV energized

Comp energized

ConFM energized

5. Cabinet Cool Down Defrost Recovery

(defrost terminated)

DTh reaches 49°F (9.4°C) or

Stage 1:

delay timer

DTst temperature reaches 10°F±5°F (49°C±3°C)

5-minute Comp

From 4

above

CLLV energized

DH de-energized

CabFM de-energized

Comp de-energized

ConFM de-energized

100-minute defrost termination timer expires or

PH de-energized

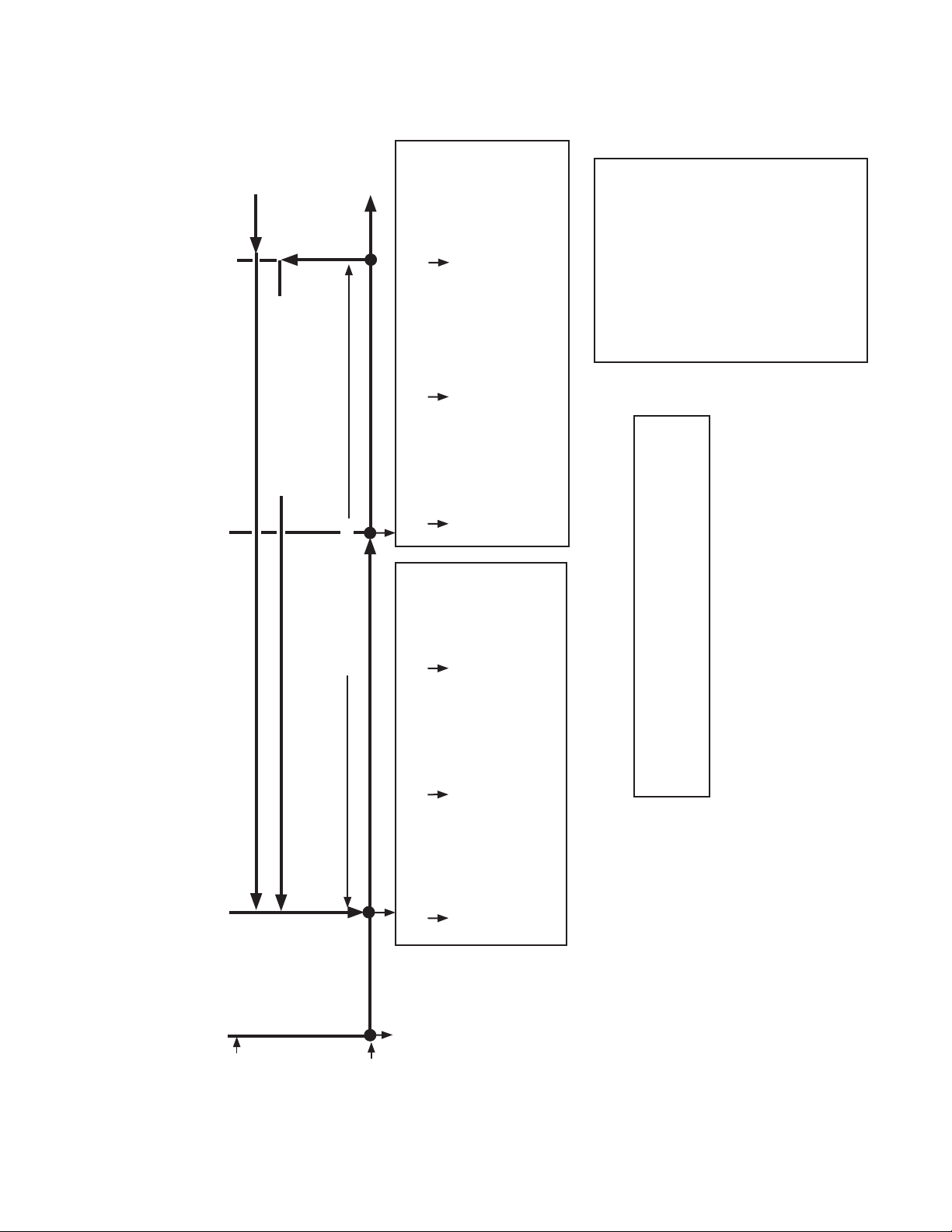

2. Cabinet and Rail Cooling

From 6

next page

4. Cabinet Defrost

Minimum minute Comp delay

if C and R were off

CTh and/or RTh reaches 3.6°F

(°C) or more below setpoint

3. Cool Down Achieved

To 4

next page

setpoint

warms to

CTh or RTh

C on

C off

C and R off

CabFM energized

PH energized

R off

CabFM energized

CLLV energized

R on

Comp energized

CabFM energized

RailFM energized

RLLV energized

CLLV de-energized

Comp de-energized

Comp energized

ConFM energized

PH energized

RailFM energized

ConFM energized

PH energized

RailFM energized

RLLV energized

ConFM de-energized

Legend:

C-cabinet cooling

RLLV de-energized

CLLV de-energized

CabFM-cabinet fan motor

Comp-compressor

ConFM-condenser fan motor

CLLV-cabinet liquid line valve

CTh-cabinet thermistor

DT-detrost timer

DH-defrost heater

DTh-defrost thermistor

DTst-defrost thermostat

PH-perimeter heater

R-rail cooling

RailFM-rail fan motor

RLLV-rail liquid line valve

RTh-rail thermistor

CTh and RTh in control

C on

R off

CabFM energized

CLLV energized

Comp energized

ConFM energized

PH energized

RailFM energized

RLLV de-energized

• C on-CTh at or above setpoint

• C off-CTh has reached 3.6°F (°C) or more below setpoint

• R on-RTh at or above setpoint

• R off-RTh has reached 3.6°F (°C) or more below setpoint

Comp energized

ConFM energized

PH energized

RailFM energized

RLLV energized

R on

CabFM energized

C off

Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW" Position

When in the "NORMAL" position, RailFM operates continuously.

When in the "LOW" position, RailFM operates continuously when rail is cooling down and intermittently

(per F9 setting) when rail cool down is achieved. See "II.D.4.a) Switch Settings" and "II.D.5. Service Menu."

CLLV de-energized

2. Cool Down

C on

R on

CabFM energized

CLLV energized

Comp energized

ConFM energized

PH energized

RailFM energized

RLLV energized

1. Start

delay timer starts

• 6-hour DT starts

• -minute Comp

CabFM energized

CLLV energized

PH energized

RailFM energized

RLLV energized

Cycle Steps

Initial startup

begins here

13

2. Cabinet and Rail Cooling (continued)

Legend:

C-cabinet cooling

CabFM-cabinet fan motor

Comp-compressor

ConFM-condenser fan motor

CLLV-cabinet liquid line valve

CTh-cabinet thermistor

DH-defrost heater

DT-defrost timer

DTh-defrost thermistor

DTst-defrost thermostat

PH-perimeter heater

To 5 below

R-rail cooling

RailFM-rail fan motor

RLLV-rail liquid line valve

To previous page

CabFM energized

• C on-CTh at or above setpoint

• C off-CTh has reached 3.6°F (°C) or more below setpoint

• R on-RTh at or above setpoint

• R off-RTh has reached 3.6°F (°C) or more below setpoint

C on

PH energized

R off

CabFM and PH

energize for 10 sec.

CLLV energized

RailFM energized

Comp energized

ConFM energized

RLLV de-energized

Stage 2: 5-minute CabFM and

DH energized

RailFM energized

RLLV energized

CabFM de-energized

CLLV de-energized

Comp de-energized

ConFM de-energized

C off

R off

DH energized

RailFM energized

RLLV energized

CabFM de-energized

C on

R off

DTh in control

When in the "NORMAL" position, RailFM operates continuously.

When in the "LOW" position, RailFM operates continuously when rail is cooling down and intermittently

(per F9 setting) when rail cool down is achieved. See "II.D.4.a) Switch Settings" and "II.D.5. Service Menu."

C off

R on

Comp energized

ConFM energized

CLLV de-energized

DH energized

RailFM energized

RLLV energized

PH de-energized

Comp de-energized

ConFM de-energized

PH de-energized

CabFM de-energized

CLLV de-energized

PH de-energized

PH delay timer starts

C on

R on

CabFM and PH

energize for 10 sec.

CLLV energized

Comp energized

Power Switch "ON," Rail Cooling Switch "NORMAL" or "LOW" Position (continued)

C on

R off

CLLV energized

RailFM energized

CabFM de-energized

ConFM energized

RailFM energized

RLLV energized

Comp de-energized

ConFM de-energized

DH de-energized

PH de-energized

RLLV de-energized

• 6-hour DT expires, then resets

• 100-minute defrost termination timer starts

4. Cabinet Defrost

C on

R on

Comp energized

ConFM energized

DH energized

RailFM energized

RLLV energized

CabFM de-energized

CLLV de-energized

PH de-energized

5. Cabinet Cool Down Defrost Recovery

14

DTh reaches 49°F (9.4°C) or

100-minute defrost termination timer expires or

DTst temperature reaches 10°F± 5°F (49°C±3°C)

Stage 1:

When Comp is off: 5-minute Comp delay timer starts

(defrost terminated)

When Comp is on: 5-minute recovery delay timer starts, Comp continues (rail on)

C on

R on

Comp energized

ConFM energized

RailFM energized

RLLV energized

CabFM de-energized

CLLV de-energized

DH de-energized

PH de-energized

D. Control Board

• A Hoshizaki exclusive solid-state control board is employed in all Hoshizaki

HPR46A(-D), HPR7A(-D), and HPR100A(-D) units.

• All models are pretested and factory set.

CAUTION

1. The control board is fragile; handle very carefully.

. The control board contains integrated circuits, which are susceptible to

failure due to static discharge. It is especially important to touch the metal

part of the unit when handling or replacing the control board.

3. Do not touch the electronic devices on the control board or the back of the

control board.

4. Do not attempt to repair the control board.

5. Do not short out power supply to test for voltage.

6. Keep the thermistor leads and pressure switch leads at least 1.5" (38 mm)

away from high voltage leads (100Vac or more) to protect against electrical

noise.

1. Control Board Location

The control panel is located behind the front panel. Follow the instructions and warnings

for safe and efcient operation of the unit.

15

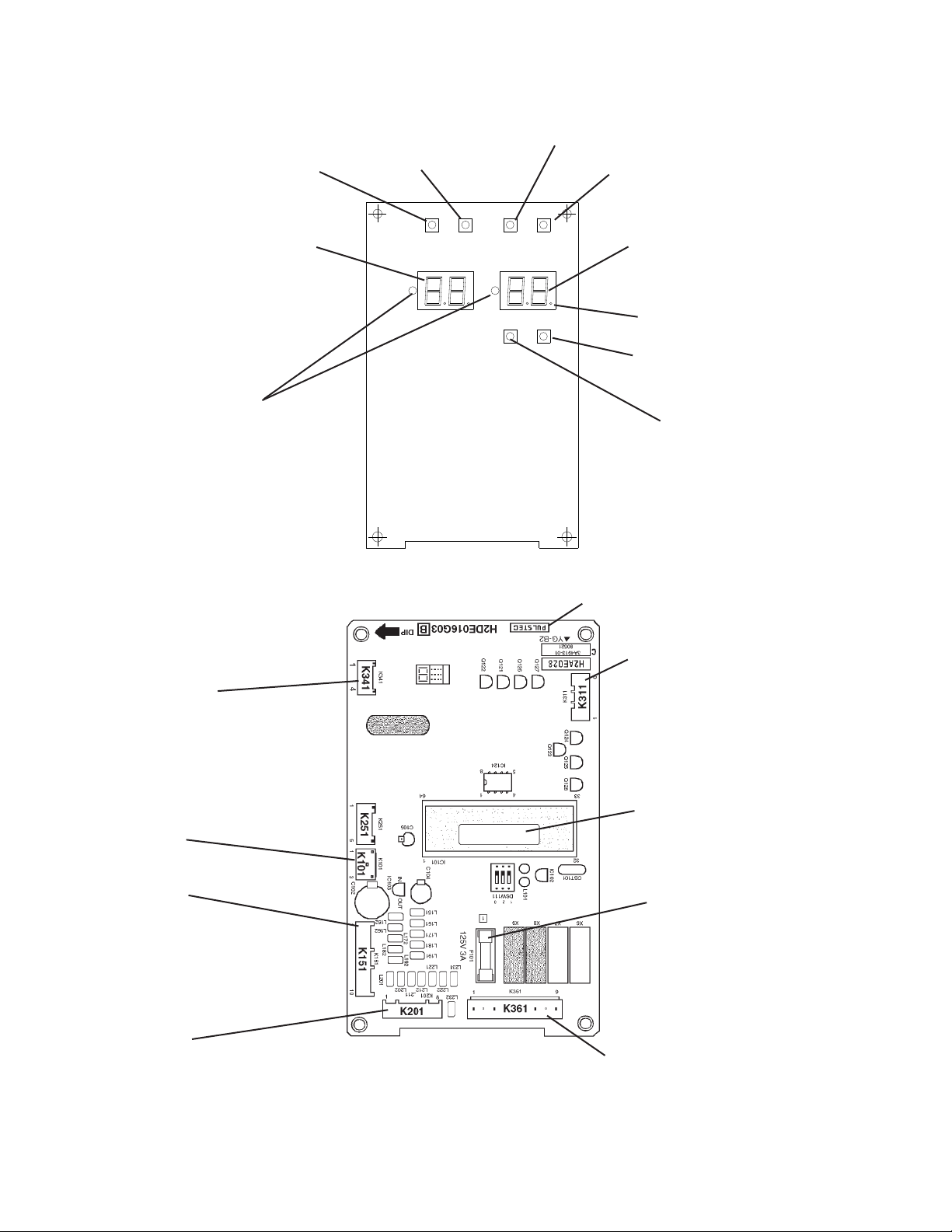

2. Control Board Layout

Display/Change

Rail Setpoint

Rail Temperature,

Alarm Display, and

Service Menu

LED on for

Negative Values

Display/Change

Cabinet Setpoint

Front

"UP" Button

"DOWN" Button

Cabinet Temperature,

Alarm Display, and

Service Menu

Energy Saving Mode LED

(Not used this model)

"SERVICE USE ONLY" Button

"MANUAL DEFROST" button

K341 Connector

# 1, Rail Fan Relay (Orange)

K101 Connector

# 1, 3 Transformer 10V

Control Voltage (Dark Blue)

K151 Connector

# 1, Condenser Thermistor

(Gray) (Clogged Filter

Thermistor)

# 3, 4 Defrost Thermistor (Orange)

(Cabinet) (DTh)

# 5, 6 Cabinet Thermistor (Black) (CTh)

# 7, 8 Service Jumper (White)

K01 Connector

# 1, Rail Switch (Yellow)

# 3, 4 Defrost Thermistor

(Orange. Not used, but must be in

place)

# 5, 6 Rail Thermistor (Black) (RTh)

# 7, 8 Rail Switch (Pink)

Rear

Board Part Number

K311 Connector

# 1, Comp Control

Relay (Brown)

# 3, 4 Cabinet Evaporator

Fan Relay (Red)

# 5, 6 Defrost Heater

Relay (Orange)

Chip Revision

Fuse 3A 15V

K361 Connector

# 1, 3 Rail Liquid Line

Solenoid Valve (RLLV)

# 1, 5 Cabinet Liquid Line

Solenoid Valve (CLLV)

16

3. Features

a) LED Display and Service Lock-Out

This control board uses twin LED displays to show system details and diagnostic

information. For control board voltage protection, a 3A 15V fuse is incorporated

into the control board circuitry. A service jumper is also provided to protect against

unwanted changes to the unit's settings. This service lock-out jumper is located on the

K151 connector terminals 7 and 8. See "II.D.4. Controls and Adjustments."

b) Compressor Short Cycle Protection

The start circuit of the compressor is timed such that at power-up and during any

compressor off time, there will be at least a minute delay before the compressor will

start. This protects the compressor against short cycling and potential compressor

damage or failure. To bypass the minute compressor delay timer (for unit

diagnostics), press and hold the rail "SET" button and move the power switch to the

"ON" position.

c) Alarm Signal

Alarm signals (E1 to E9, EA and ED) are designed to protect the unit and food

product. These alarms give information or warnings in the event the unit is operating

out of acceptable parameters. See "III.A. Alarm Signals."

d) Service Menu

A service menu (F0 to F9) allows for viewing and setting of system operating details

and parameters. See "II.D.5. Service Menu."

e) Automatic and Manual Defrost Capabilities

This unit features automatic and manual cabinet defrost capabilities. See "II.D.4.d)

Cabinet Defrost."

17

4. Controls and Adjustments

The cabinet and rail temperatures are updated every 30 seconds. The control board is

supplied with a service jumper on the K151 connector. Only the temperature setpoint

and the temperature scale ("F5") may be adjusted with this connector in place. To view

or adjust other selections, see "II.D.5. Service Menu."

a) Switch Settings

Power Switch "OFF": Unit off (both cabinet and rail).

Power Switch "ON": Cabinet temperature is displayed and cabinet cooling begins.

Cabinet fans and perimeter heaters are on and run continuously (except during defrost).

Rail Cooling Switch "OFF": Rail cooling off, cabinet cooling continues.

Rail Cooling Switch "NORMAL: Designed for use when the rail cover is open. Rail

temperature display on and rail cooling begins. The rail fans operate continuously.

Rail Cooling Switch "LOW": Designed for use when the rail cover is closed. Rail

temperature display is on and rail cooling begins. The rail fans operate intermittently

when "F9" is at the factory default setting. For access and adjustments to the "F9"

setting, see "II.D.5. Service Menu."

Note: A Hoshizaki OEM rail cooling switch must be used if replacing the rail cooling

switch. For details see "IV.M. Rail Cooling Switch."

b) Temperature Display

The temperature display can be changed between Fahrenheit and Celsius. To change

the temperature display, press and hold the cabinet "SET" button and the "SERVICE

USE ONLY" button for 5 seconds. "F0" appears in the display screen. Press the up

arrow button until "F5" appears in the display screen. "F5" is the only service menu

selection accessible with the service jumper in place.

Press the cabinet "SET" button to view the temperature display setting. Press the up or

down arrow button to switch between F° and C°. Press the cabinet "SET" button to save

the new setting. Press the cabinet "SET" button and the "SERVICE USE ONLY" button

for 5 seconds to return to normal temperature display.

"SET" buttons used to view current temperature settings.

Cabinet "SET" button used with "SERVICE USE ONLY"

button to enter and exit the service menu.

"MANUAL DEFROST"

button used to initiate

a manual defrost.

"UP" and "DOWN" arrow buttons

used to change temperature

settings, scroll through the service

menu, and to change menu settings.

"SERVICE USE ONLY"

button used with cabinet

"SET" button to enter and

exit the service menu.

18

c) Temperature Setpoint

The temperature setpoint is the temperature setting at which the compressor turns on.

The factory default temperature setpoints are 37° (3°C) for the cabinet and 33°F (1°C)

for the rail (see the chart below).

The temperature differential for the compressor to turn off is 3.6°F (°C) below the

temperature setpoint. The temperatures are updated every 30 seconds. If necessary,

adjust the temperature setpoint as outlined below.

Note: The cabinet and rail temperature setpoints must be changed individually.

1) Press the appropriate "SET" button to display the current temperature setpoint.

) Press and hold the appropriate "SET" button while pressing the up or down arrow

button. See the chart below for temperature setpoint ranges.

3) Release the "SET" button. As long as the unit is not turned off, the new setpoint will be

saved automatically after 10 seconds.

Section Temperature Setpoint Range

Cabinet

Rail

1 to 53°F

(-6 to +1°C)

-13 to +53°F

(-5 to +1°C)

Default

37°F

(3°C)

33°F

(1°C)

d) Cabinet Defrost

The automatic cabinet defrost is factory set for once every 6 hours. See "II.D.5. Service

Menu." The cabinet defrost thermistor will signal the control board to start a defrost once

the 6 hour defrost timer has expired and the cabinet evaporator temperature is below

49°F (9.4°C). Defrost is heated, and therefore will have a tendency to raise the cabinet

temperature.

For a manual cabinet defrost press the "MANUAL DEFROST" button on the control

board for 5 seconds to initiate a defrost. This will restart the 6-hour defrost timer.

Cabinet temperature is not displayed during defrost; "dF" is displayed in its place. The

control board will terminate the cabinet defrost and begin defrost recovery when a signal

from the cabinet defrost thermistor is greater than 49°F (9.4°C). After defrost, there is a

5-minute delay before the compressor will start.

This unit has an additional defrost thermistor located behind the wire cover that connects

to the K01 connector, terminals 3 and 4. This thermistor is not used for defrost

purposes on this model, but must be in place for proper operation of the control board.

e) Energy Saving Mode

"Energy Saving Mode" is not used on this unit. The "Energy Saving Mode" LED is

located to the bottom right of the cabinet display and should be off. See "II.D.. Control

Board Layout." If the "Energy Saving Mode" LED is on, press the "SERVICE USE

ONLY" button for 5 seconds to exit and disable the "Energy Saving Mode."

19

f) Temperature Correction Factor

In cases where there is a discrepancy between the actual cabinet or rail temperature

and the displayed temperature, a temperature correction factor is used to correct the

displayed temperature.

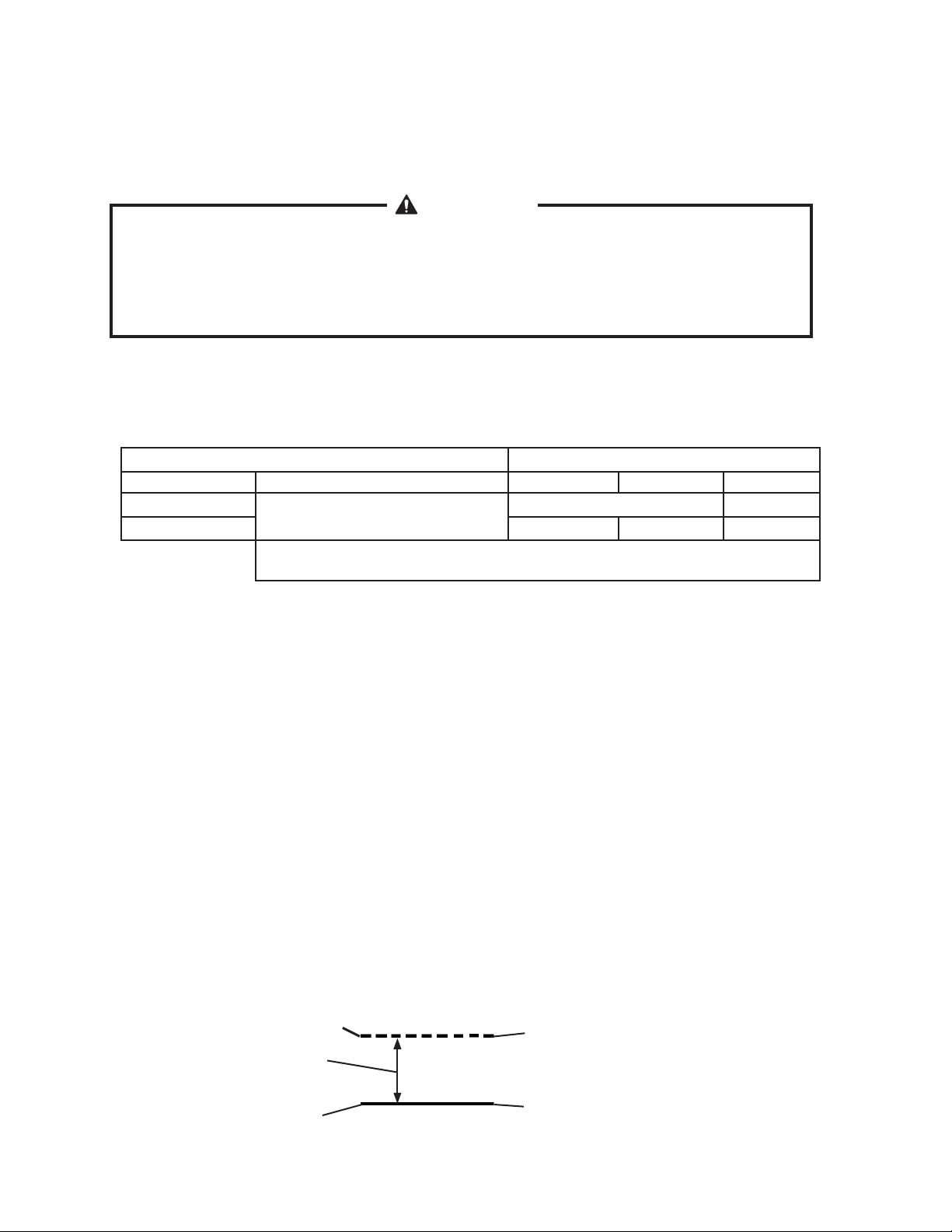

WARNING

This unit has been factory tested with the default settings listed. Avoid using

this function except to conrm that the setting is correct. If set incorrectly, the

display could show an acceptable temperature even though the temperature

is out of the proper range. This value should only be changed after consulting

with the Hoshizaki Technical Support Department at 1-800-33-1940.

To view the current values, move the power switch to the "ON" position while pressing

the up arrow button. The current cabinet temperature correction factor will be shown. If

"18" is displayed, the value is 1.8°F (1°C). Press the cabinet "SET" button to display the

rail temperature correction factor.

Cabinet

Rail

Temperature Correction Factor

Area Setting Range 1-Section 2-Section 3-Section

-9 to 9°F in 0.9°F increments

(-5 to 5°C in 0.5°C increments)

Negative values are indicated by an LED to the left of the value (Decimals are

not shown on display)

1.8°F (1°C) (0°F (0°C)

0°F (0°C)

Default

TBD

TBD

If it is determined through discussion with Hoshizaki Technical Support that the setting

needs to be changed, follow the steps below.

1) Display the cabinet or rail temperature correction factor as outlined above.

) Press the up or down button to increase or decrease the cabinet value.

3) Press the cabinet "SET" button to save the new cabinet value.

4) Press the cabinet "SET" button again to view the rail value.

5) Press the up or down button to increase or decrease the rail value.

6) Press the cabinet "SET" button to save the new rail value.

7) Turn the power off and then back on. The unit will start running with the new value(s).

[Example]

When the actual cabinet temperature is 5.4°F (3°C) higher than the displayed temperature,

change the temperature correction factor to 5.4°F (3°C), so that the displayed temperature

matches the cabinet temperature.

47.8°F (8.7°C)

5.4°F (3°C)

Difference

°F (6°C)

4.4

Actual Area Temperature

Displayed Temperature

0

Loading...

Loading...