Hoshizaki America JWE-2400CUA-L-25B Installation Manual

DISHWASHER

INSTRUCTION MANUAL

JWE-2400CUA-L-25B

JWE-2400CUA-R-25B

FOR END USER

L1J002111 (041811)

IMPORTANT

Only qualified service technicians should install, service and maintain the

product. No installation, service or maintenance should be undertaken until

the technician has thoroughly read this Instruction Manual. Likewise, the

owner/manager should not proceed to operate the product until the installer

has instructed them on its proper operation. Failure to install, operate, and

maintain the equipment in accordance with this manual may adversely affect

safety, performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualified service technicians in the

installation, maintenance, and service of the product.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

* Model Number

* Serial Number

* Complete and detailed explanation of the problem.

i

IMPORTANT

This manual should be read carefully before the product is installed and

operated. Only qualified service technicians should install, service, and

maintain the product. Read the warnings contained in this booklet carefully as

they give important information regarding safety. Please retain this booklet for

any further reference that may be necessary.

CONTENTS

1. CONSTRUCTION --------------------------------------------------------------------------------------1

[a] GENERAL --------------------------------------------------------------------------------------------1

[b] OPERATION PANEL -------------------------------------------------------------------------------3

[c] CONVEYOR SPEED SWITCH ------------------------------------------------------------------4

[d] ACCESSORIES -------------------------------------------------------------------------------------4

[e] PERIODICAL REPLACEMENT PARTS ------------------------------------------------------5

2. CHECKS BEFORE OPERATION -------------------------------------------------------------------5

[a] CHECKS AFTER INSTALLATION --------------------------------------------------------------5

[b] WATER REQUIREMENTS -----------------------------------------------------------------------5

[c] CHECKS BEFORE OPERATION---------------------------------------------------------------6

3. CHECKING THE DETERGENT TANK AND RINSE AID TANK -----------------------------7

4. CHECKING THE OPERATION BOX ---------------------------------------------------------------7

5. CHECKING THE TABLE LIMIT SWITCH ---------------------------------------------------------7

6. PREPARING THE WASH COMPARTMENT -----------------------------------------------------7

[a] AUTO FILL -------------------------------------------------------------------------------------------8

PAGE

7. LOADING -------------------------------------------------------------------------------------------------9

[a] PREWASH -------------------------------------------------------------------------------------------9

[b] LOADING DISHES ---------------------------------------------------------------------------------9

[c] LOADING RACKS -------------------------------------------------------------------------------- 10

8. WASH AND RINSE ----------------------------------------------------------------------------------- 10

[a] OPERATING TEMPERATURES -------------------------------------------------------------- 10

[b] RACK CONVEYOR SPEED AND WASH INITIATION ---------------------------------- 10

9. UNLOADING --------------------------------------------------------------------------------------------11

10. INSUFFICIENT WASHING RESULTS ---------------------------------------------------------- 12

11. SHUTDOWN ------------------------------------------------------------------------------------------- 13

ii

12. INTERRUPTION -------------------------------------------------------------------------------------- 14

13. EMERGENCY STOP -------------------------------------------------------------------------------- 14

14. DAILY MAINTENANCE ----------------------------------------------------------------------------- 15

15. WEEKLY MAINTENANCE -------------------------------------------------------------------------- 20

[a] HEATER -------------------------------------------------------------------------------------------- 20

[b] EXTERIOR ----------------------------------------------------------------------------------------- 20

16. MONTHLY INSPECTION --------------------------------------------------------------------------- 20

[a] WATER SUPPLY LINE -------------------------------------------------------------------------- 20

17. TROUBLESHOOTING ------------------------------------------------------------------------------ 21

[a] TROUBLES REQUIRING IMMEDIATE SERVICE CALL -------------------------------- 21

[b] TROUBLES REQUIRING CHECK BY USER ---------------------------------------------- 21

[c] TROUBLES WITHOUT ERROR CODE INDICATION ----------------------------------- 22

18. LONG STORAGE, RELOCATION, DISPOSAL, TRANSFER -----------------------------22

iii

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING

CAUTION

Indicates a situation which could result in damage to the unit.

IMPORTANT

This product should be destined only to the use for which it has been

expressly conceived. Any other use should be considered improper and

therefore dangerous. The manufacturer cannot be held responsible for injury

or damage resulting from improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or fi re, follow

basic precautions including the following:

• Electrical connection must be hard-wired and must meet national, state, and

local electrical code requirements. Failure to meet these code requirements

could result in death, electric shock, serious injury, fi re, or severe damage to

equipment.

• This unit requires independent power supplies for the dishwasher and for the

booster tank. See the nameplate for proper voltage and breaker/fuse sizes.

Failure to use proper breakers or fuses can result in tripped breakers, blown

fuses, or damage to existing wiring. This could lead to heat generation or

fi re.

• THIS UNIT MUST BE GROUNDED. Failure to properly ground this unit

could result in death or serious injury.

• This unit should be disassembled or repaired only by qualified service

personnel to reduce the risk of electric shock, injury, or fi re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, fi re, or damage to the unit.

Indicates a hazardous situation which could result in death or

serious injury.

Indicates important information about the use and care of the

unit.

WARNING

iv

1. CONSTRUCTION

[a] GENERAL

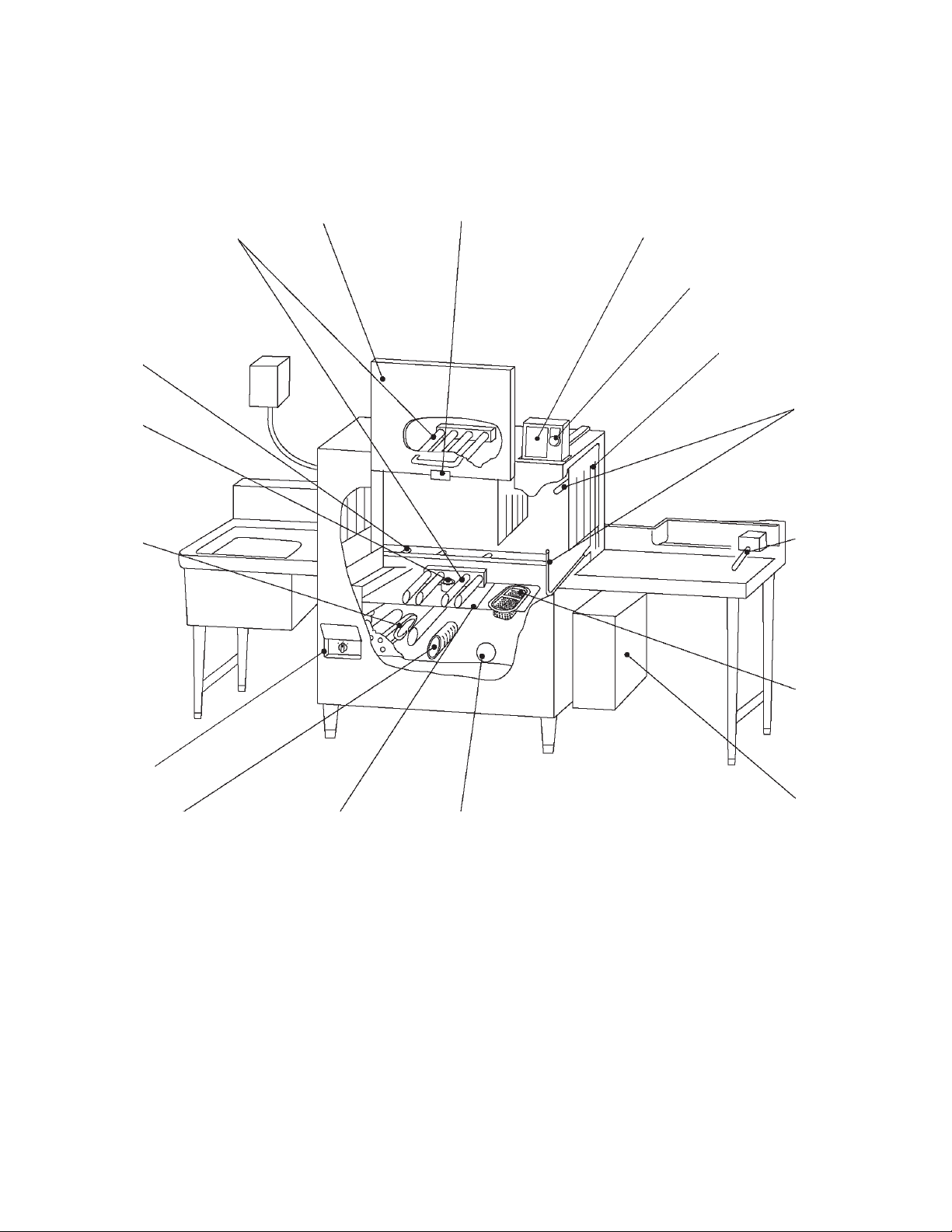

* The illustration shows the “-L” model (rack fl ows from left to right).

[17] [16]

[1] [15]

[14]

[13]

[2]

[12]

[3]

[4] [11]

[10]

[5]

[9]

[6] [7] [8]

[1] Upper Wash Spray Arm, Lower Wash Spray Arm

Sprays wash water onto dishes.

[2] Rack Rail, Conveyor

[3] Drain Pipe

Pull out to drain.

[4] Heater

Keeps wash water at proper temperature.

1

[5] Conveyor Speed Switch

See “[c] CONVEYOR SPEED SWITCH”.

[6] Pump Filter

Prevents scraps from being drawn into the pump.

[7] Separator

[8] Water Level Sensor

Detects wash water level.

[9] Booster Tank

[10] Tank Filter

Separates wash water and scraps.

[11] Table Limit Switch

Stops washing operation when a rack reaches the end of the clean dishtable.

[12] Upper Rinse Spray Arm, Lower Rinse Spray Arm

Sprays rinse water onto dishes to rinse off detergent.

[13] Curtain

Prevents splashing from the entrance and exit of the wash compartment.

[14] Emergency Stop Button

Stops the unit in case of emergency.

[15] Operation Panel

See “[b] OPERATION PANEL”.

[16] Hook

Holds the service panel in its open position.

[17] Service Panel

2

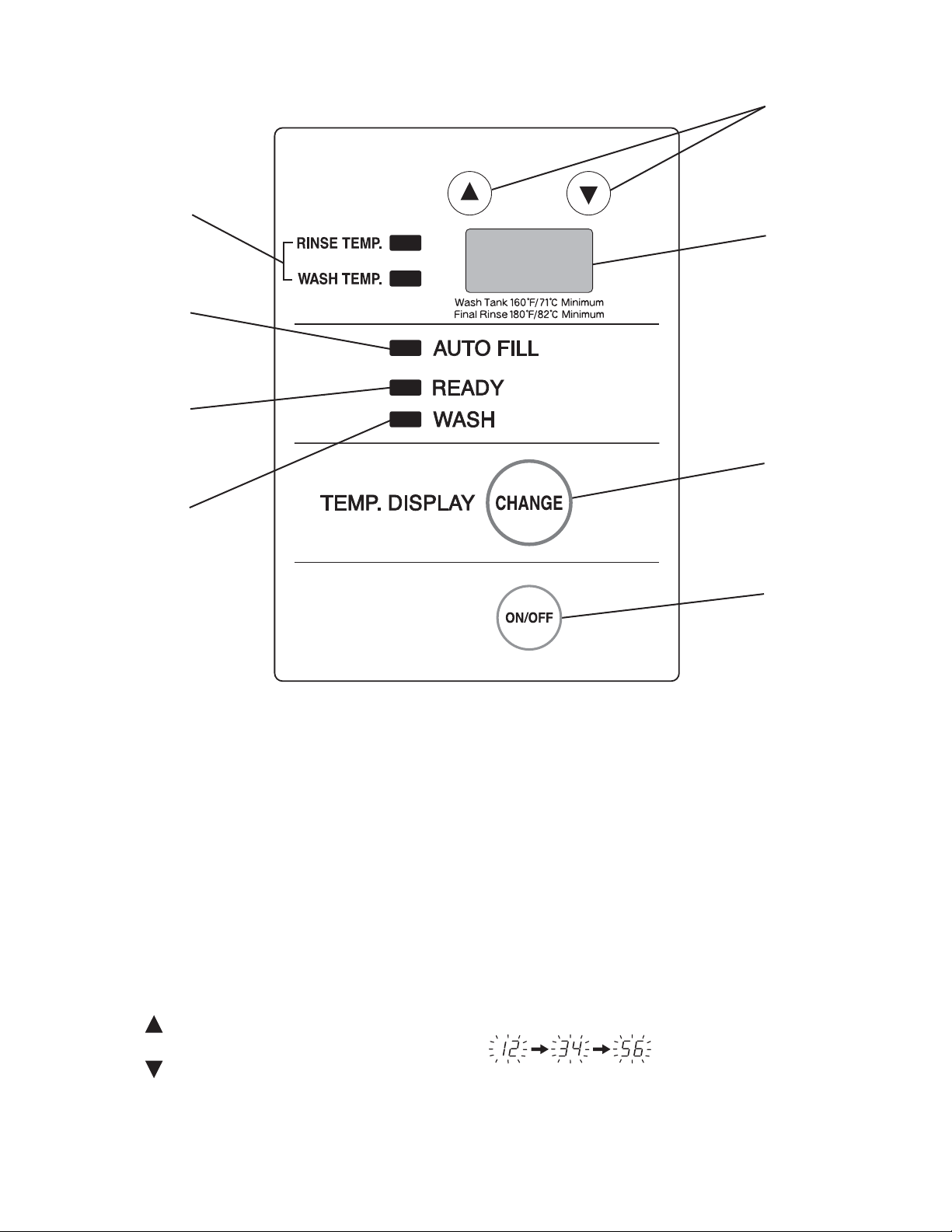

[b] OPERATION PANEL

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[1] Water Temperature Lamps

Light up to indicate the water temperature shown in the display.

[2] “AUTO FILL” Lamp

Flashes during the auto fi ll cycle, and goes off at the end of the cycle.

[3] “READY” Lamp

Lights up when the auto fi ll cycle completes and the dishwasher is ready to wash.

[4] “WASH” Lamp

Lights up during washing operation.

[5] Up Button, Down Button

Indicates the total hours of operation in six digits by two digits each time.

Example: 123,456 hours are indicated by

Press to stop the beep in case of error.

Serv

ice personnel also use these buttons to change the controller settings.

3

[6] Display

Indicates wash water temperature in wash cycle, rinse water temperature in rinse

cycle, and error codes in case of trouble. See “17. TROUBLESHOOTING”.

[7] “CHANGE” Button

Press to change the wash tank water temperature shown in the display to the booster

tank water temperature.

[8] “ON/OFF” Button

Turns on/off the power for operation.

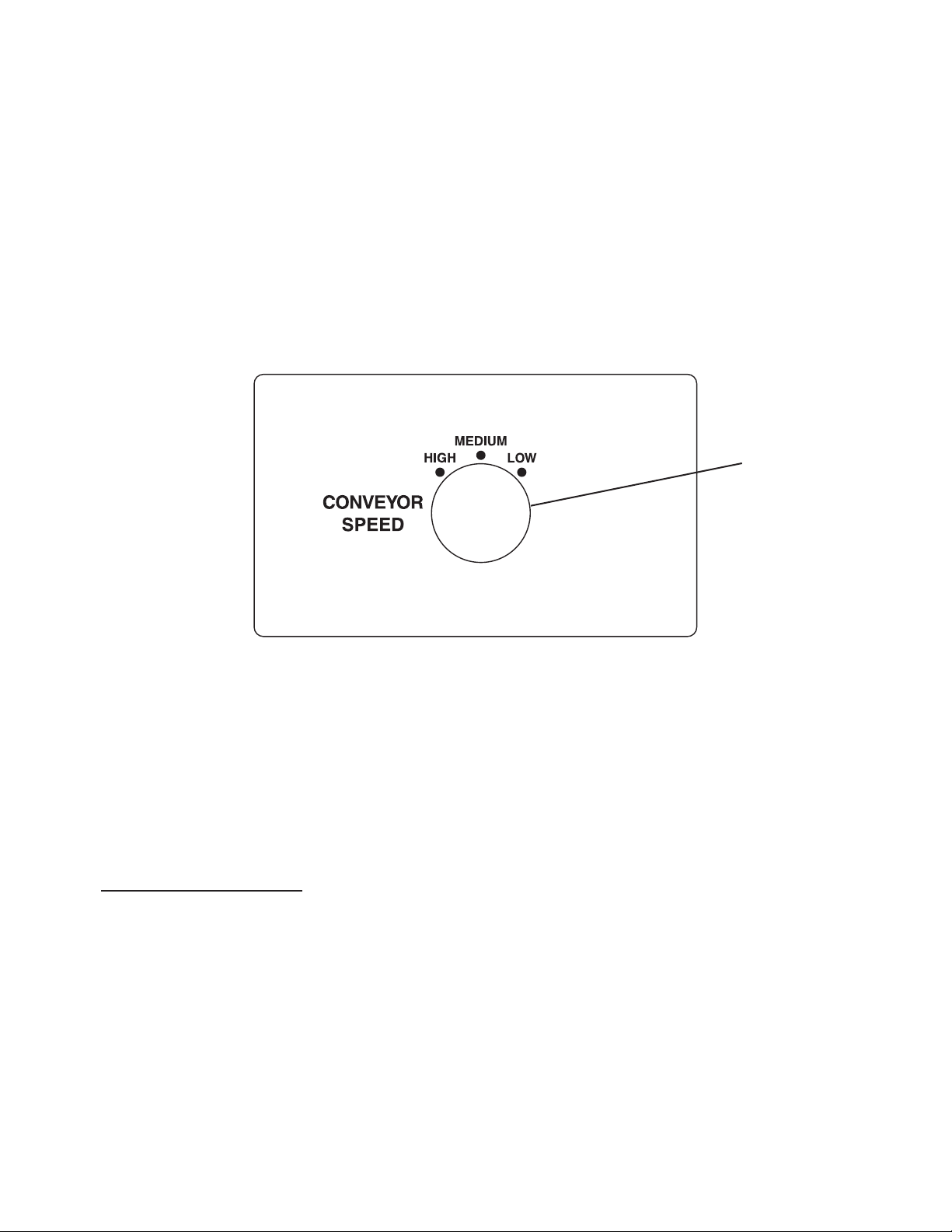

[c] CONVEYOR SPEED SWITCH

[1]

[1] Conveyor Speed Switch

Changes the rack conveyor speed in three levels (high, medium, low).

[d] ACCESSORIES

Instruction manual x 1 Installation manual x 1

Universal rack x 1 Operation sheet x 1

Required for installation:

Operation box assembly x 1 Hook - drain x 1

Guard (L), (R) x 1 each Cable cover (S) x 1

Hook - drain securing bolt w/washer

(stainless steel M6 x 12) x 1

Upper wash spray arm x 1

Cable tie x 2

Curtain (S) x 2 Curtain (L) x 1

Shaft - curtain x 3 (2 types) Table limit switch x 1

Strainer x 1 Gasket x 1

4

Loading...

Loading...