Hoshizaki America FH1-SSB-HD-H-0 Service Manual

NUMBER:

ISSUED:

REVISED:

73077

MARCH 8, 1999

MARCH 18, 2003

HOSHIZAKI

TempGuardTM REACH-IN

MODELS

RH1-SSB(-HD/-GD) FH1-SSB(-HD)

RH2-SSB(-HD/-GD) FH2-SSB(-HD)

RH3-SSB(-HD/-GD) FH3-SSB(-HD)

RIR2-SSB51-02

RFH2-SSB(-HD)

RFH3-SSB(-HD)

with

IMPORTANT

Only qualified service technicians should attempt to service or maintain this unit. No

service or maintenance should be undertaken until the technician has thoroughly read

this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: HOSHIZAKI Technical Support Department

Phone: 1-800-233-1940 Technical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: To expedite assistance, all correspondence/communication MUST include the following

information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

Please review this manual. It should be read carefully before the unit is serviced or maintenance operations are performed. Only qualified service technicians should service and

maintain the unit. This manual should be made available to the technician prior to service

or maintenance.

CONTENTS

PAGE

I. ELECTRONIC CONTROL OPERATION .................................................................. 4

1. NORMAL ELECTRONIC CONTROL PROCESS

OPERATION FOR REFRIGERATOR .............................................................. 4

2. TIME - TEMPERATURE CONTROL CHART FOR REFRIGERATOR ............... 5

3. NORMAL ELECTRONIC CONTROL PROCESS .................................................

FLOW OPERATION FOR FREEZER .............................................................. 6

4. TIME - TEMPERATURE CONTROL CHART FOR FREEZER........................... 7

5. DISPLAY BOARD .............................................................................................. 8

6. ALARM / ALERT SIGNALS ............................................................................. 10

7. DEFROST FOR REFRIGERATOR .................................................................. 16

8. DEFROST FOR FREEZER .............................................................................. 16

9. START-UP DELAY........................................................................................... 16

10. PERIMETER FRAME HEATER ...................................................................... 17

11. GLASS DOOR HEATER ................................................................................. 17

12. DIAGNOSTIC MENU ....................................................................................... 17

13. CONTROL BOARD ......................................................................................... 20

FLOW ......................................

II. SERVICE DIAGNOSIS ........................................................................................... 22

III. REMOVAL AND REPLACEMENT OF COMPONENTS ....................................... 26

1. SERVICE FOR REFRIGERANT LINES ........................................................... 26

2. BRAZING ......................................................................................................... 27

3. REMOVAL AND REPLACEMENT OF COMPRESSOR ................................... 28

4. REMOVAL AND REPLACEMENT OF DRIER ................................................. 29

5. REMOVAL AND REPLACEMENT OF EXPANSION VALVE ........................... 30

6. REMOVAL AND REPLACEMENT OF EVAPORATOR .................................... 31

7. REMOVAL AND REPLACEMENT OF DOOR GASKET .................................. 31

8. REMOVAL AND REPLACEMENT OF DOOR CLOSURE SPRING .................. 32

9. REMOVAL AND REPLACEMENT OF CONTROL BOARD .............................. 33

10. DOOR RE-HINGING ......................................................................................... 34

IV. CLEANING INSTRUCTIONS ............................................................................... 35

V. WIRING DIAGRAMS ............................................................................................ 36

3

I. ELECTRONIC CONTROL OPERATION

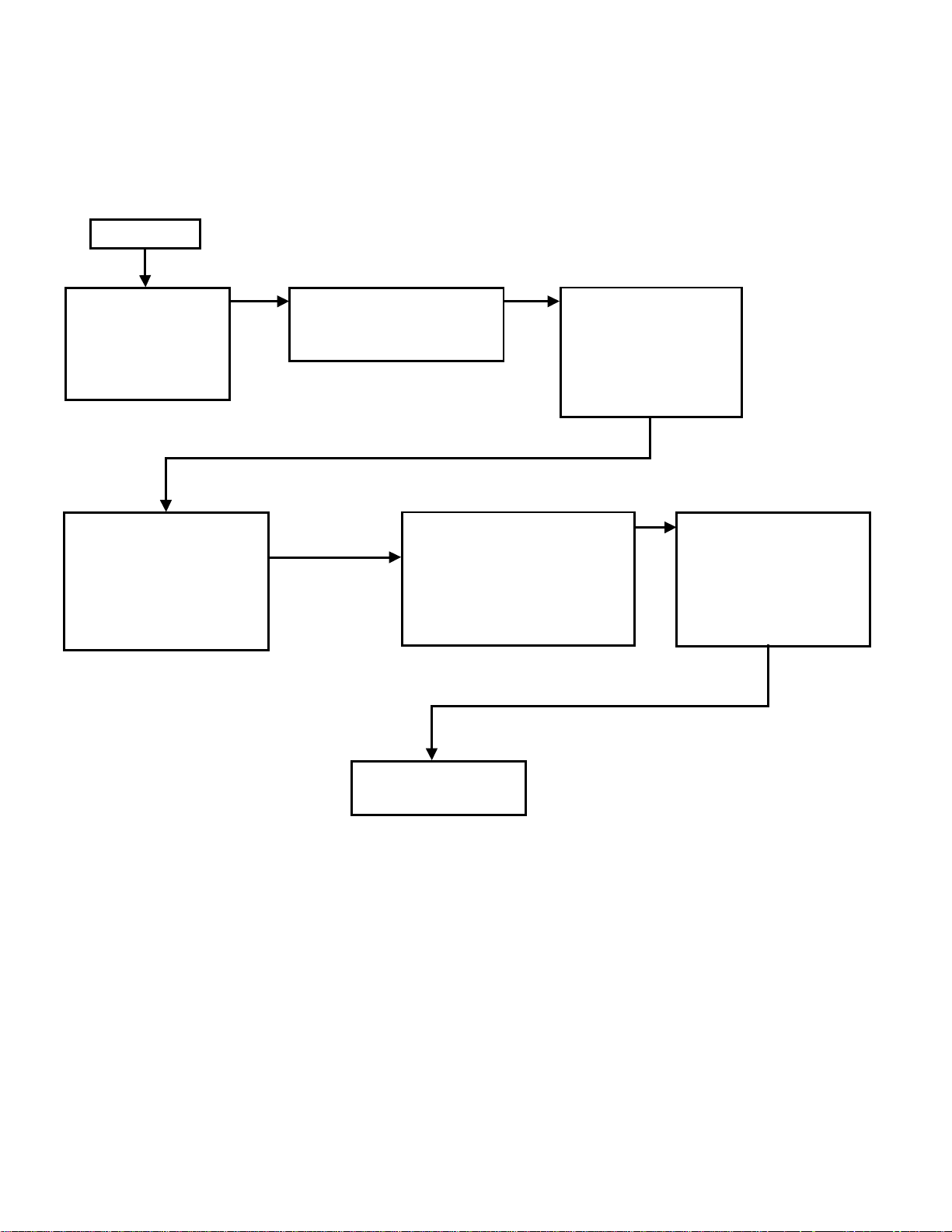

1. NORMAL ELECTRONIC CONTROL PROCESS FLOW OPERATION FOR REFRIGERATOR

POWER ON

Board Self Check

Display Read R##

(## is chip revision)

1) Frame heaters on

2) Evaporator fan on

Cycle On (Cut-on

Temperature reached)

[Minimum 2.5 minutes]

1. Compressor on

2. Condenser Fan on

(Normal Cycling)

2.5 minute delay

1. Compressor start-up

2. Condenser Fan start-up

If evaporator temperature

Continues as

normal cycling

reaches 13°F, unit initiates

defrost.

Compressor off

(Note: Condenser Fan and

Evaporator Fan are on.)

Cycle Off (Cut-out

Temperature reached)

[Minimum 2.5 minutes]

1) Compressor off

2) Condenser Fan off

(Normal Cycling)

Evaporator temperature

reaches 40°F, defrost

terminated

Compressor on

Condenser Fan on

Continues as

Normal Cycling

Note:

1) Cut-on / Cut-off / and Cabinet Temperature are read by the same sensor, called “cabinet

thermistor.

2) Defrost Thermistor reads Evaporator temperature.

4

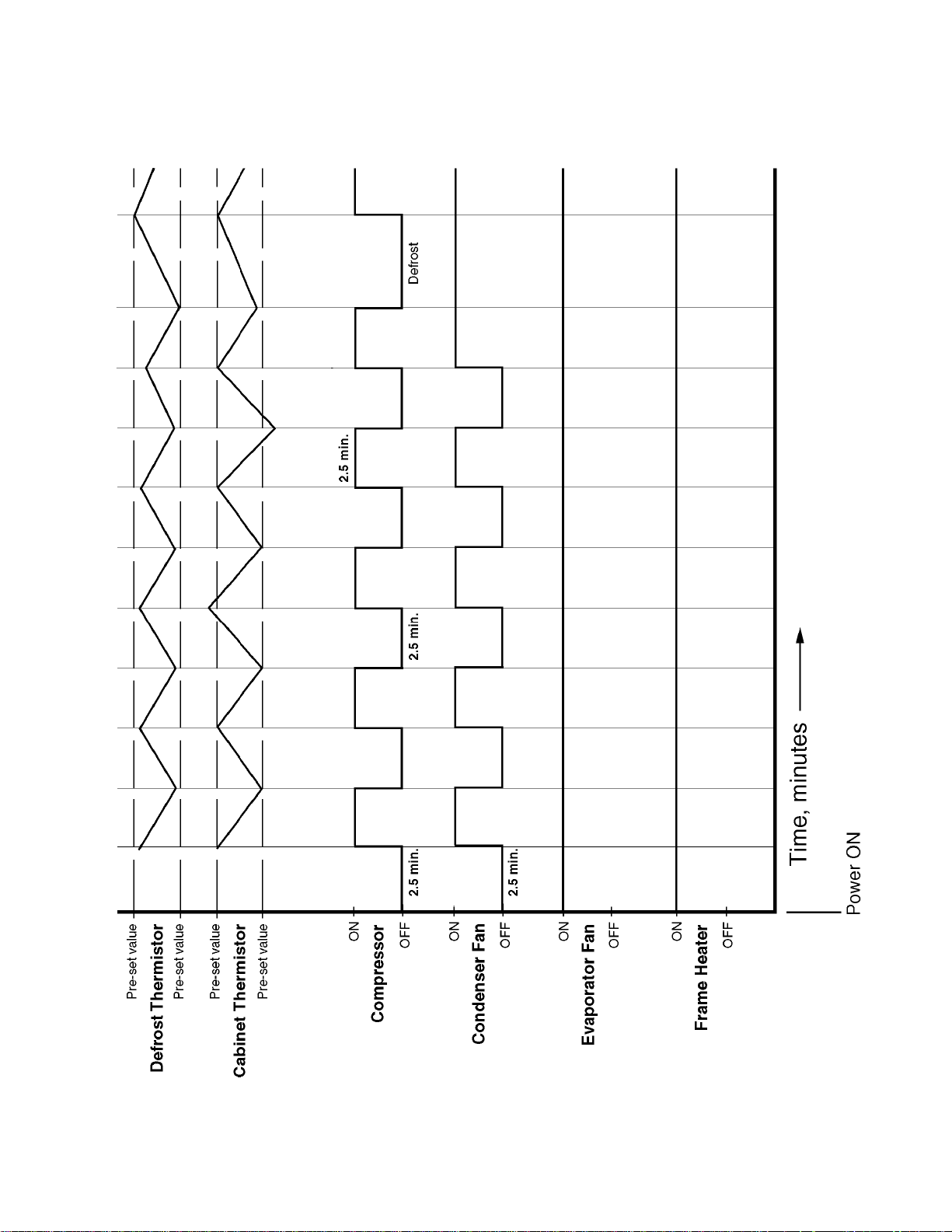

2. TIME - TEMPERATURE CONTROL CHART FOR REFRIGERATOR

5

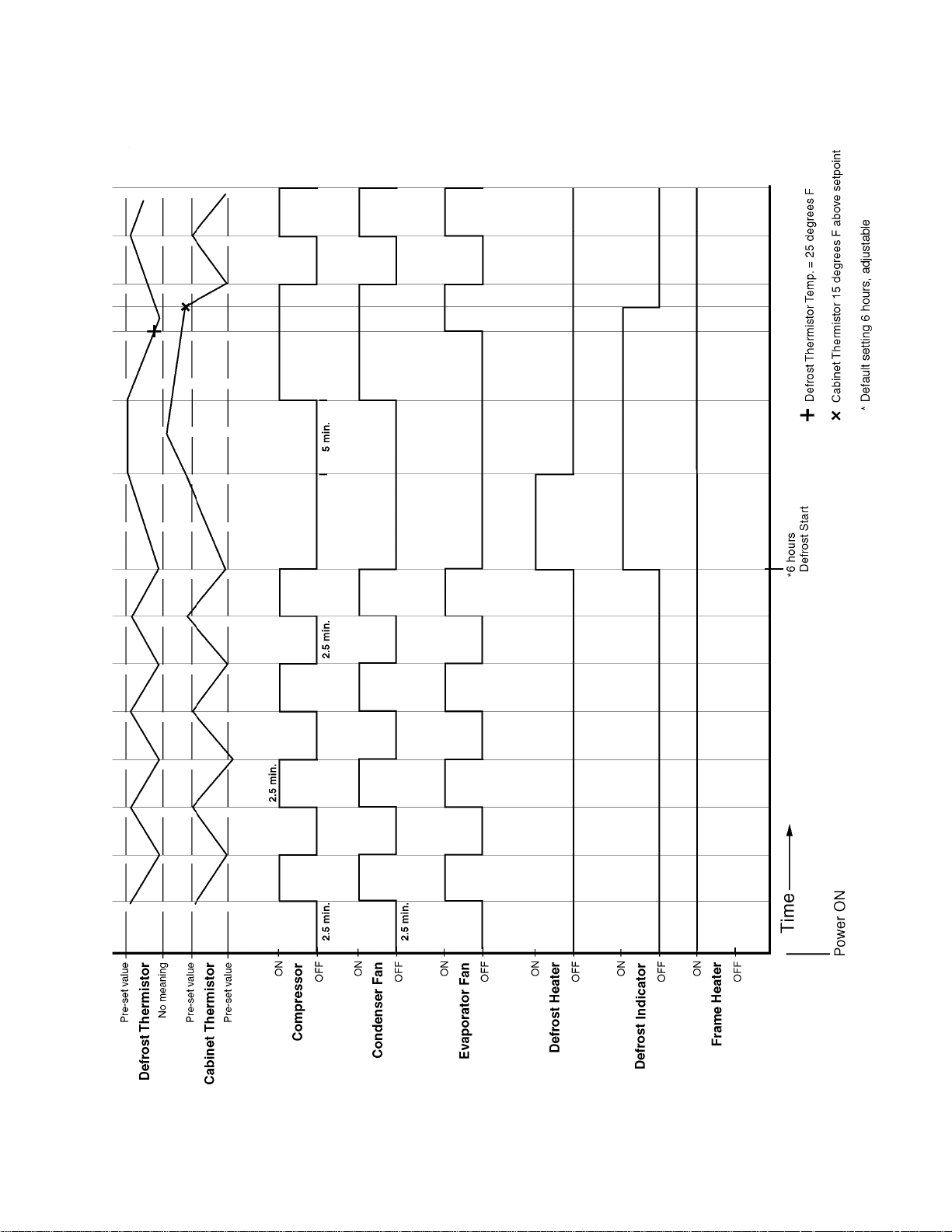

3. NORMAL ELECTRONIC CONTROL PROCESS FLOW OPERATION FOR FREEZER

POWER ON

Board Self Check

Display Read R##

(## is chip revision)

Frame heaters on

Cycle On (Cut-on

Temperature reached)

[Minimum 2.5 minutes]

1. Compressor start-up

2. Condenser Fan start-up

3. Evaporator Fan start-up

Continue as

Normal Cycling

2.5 minute delay

1. Compressor start-up

2. Condenser Fan start-up

3. Evaporator Fan start-up

Defrost Start

Preprogrammed time interval

1. Compressor off

2. Evaporator Fan off

3. Condenser Fan off

4. Defrost Heater on

5. “dEF” displayed

Cycle Off (Cut-out

Temperature reached)

[Minimum 2.5 minutes]

1. Compressor off

2. Condenser Fan off

3. Evaporator Fan off

Defrost end

defrost thermistor

reached 100°F

Defrost Heater off

Five minutes after

Defrost Heater off

1. Compressor on

2. Condenser Fan on

Note:

1) Cut-on / Cut-off / Cabinet Temperature are read by the same sensor, called “cabinet

thermistor.

2) Defrost Thermistor reads Evaporator temperature.

Evaporator temperature

reaches below 25°F

1. Evaporator Fan on

Cabinet temperature reads

a value below 15°F above

the setpoint.

“dEF” no longer displayed,

cabinet temp. displayed.

6

4. TIME - TEMPERATURE CONTROL CHART FOR FREEZER

7

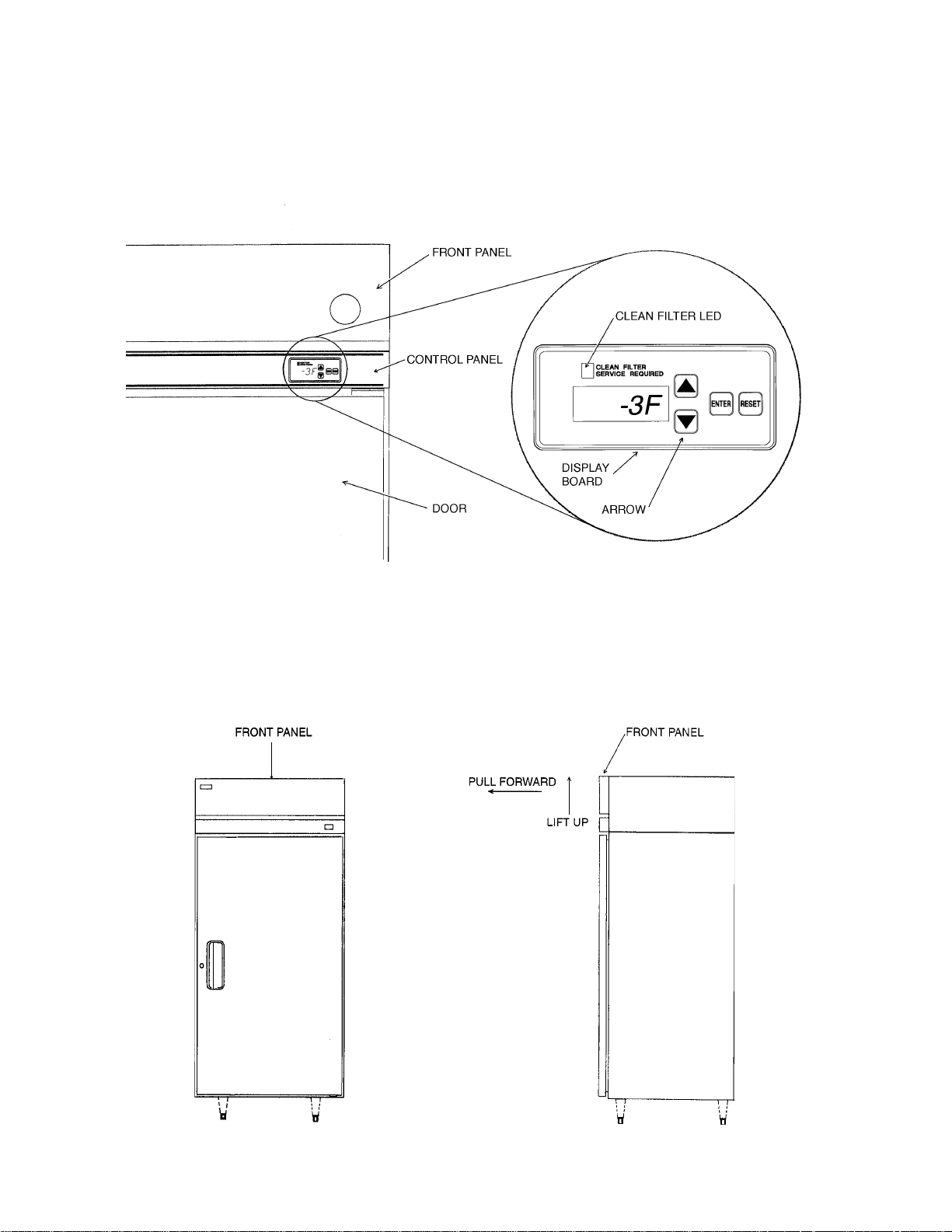

5. DISPLAY BOARD

The Display Board is located on the right hand side of the painted Control Panel between the top of

the Door and the Front Panel. From this area information regarding the functioning of the unit can be

obtained. From the Display Board various electronic controls and functions can also be adjusted.

Removing the Front Panel by lifting the panel up approximately one-half inch, then pulling it forward,

permits access to the Error Code Label, the Control Box and the Control Panel.

8

When unit is turned on, first display is “R##”, where “##” indicates chip revision level.

1) TEMPERATURE DISPLAY

• The cabinet temperature is displayed (factory set is °F, but can be changed to read °C).

• The cabinet temperature is updated every 20 seconds.

• During refrigerator defrost, the cabinet temperature is displayed.

• During freezer defrost, the cabinet temperature is not displayed, “dEF” is displayed in its

place.

2) GUARDED ACCESS MENU

Three settings can be viewed and changed from this menu:

1. The Temperature Setpoint. This setpoint is the value for the average cabinet

temperature.

2. Defrost Frequency.

Refrigerator: Automatic defrost. “df X” has no effect.

Freezer: Ex. “dF 4” = 4 defrost cycles per day.

3. Units of Display. F = Fahrenheit, C = Celsius

To enter this menu, press and hold the up/down arrows together for 3 seconds. The

Temperature Setpoint will be displayed first. To change a value, push the up/down arrows until

the desired value is displayed. Then push “ENTER” to set the value and view the next setting.

If no change in the value is desired, press “ENTER”, and the next setting will be displayed.

At the end of the sequence, press “ENTER” and the unit will return to normal display mode.

Note: End sequence and press “Enter” for changes to take effect. If sequence is

not ended by pressing “ENTER,” display will return to normal temperature

display and no changes will take effect.

9

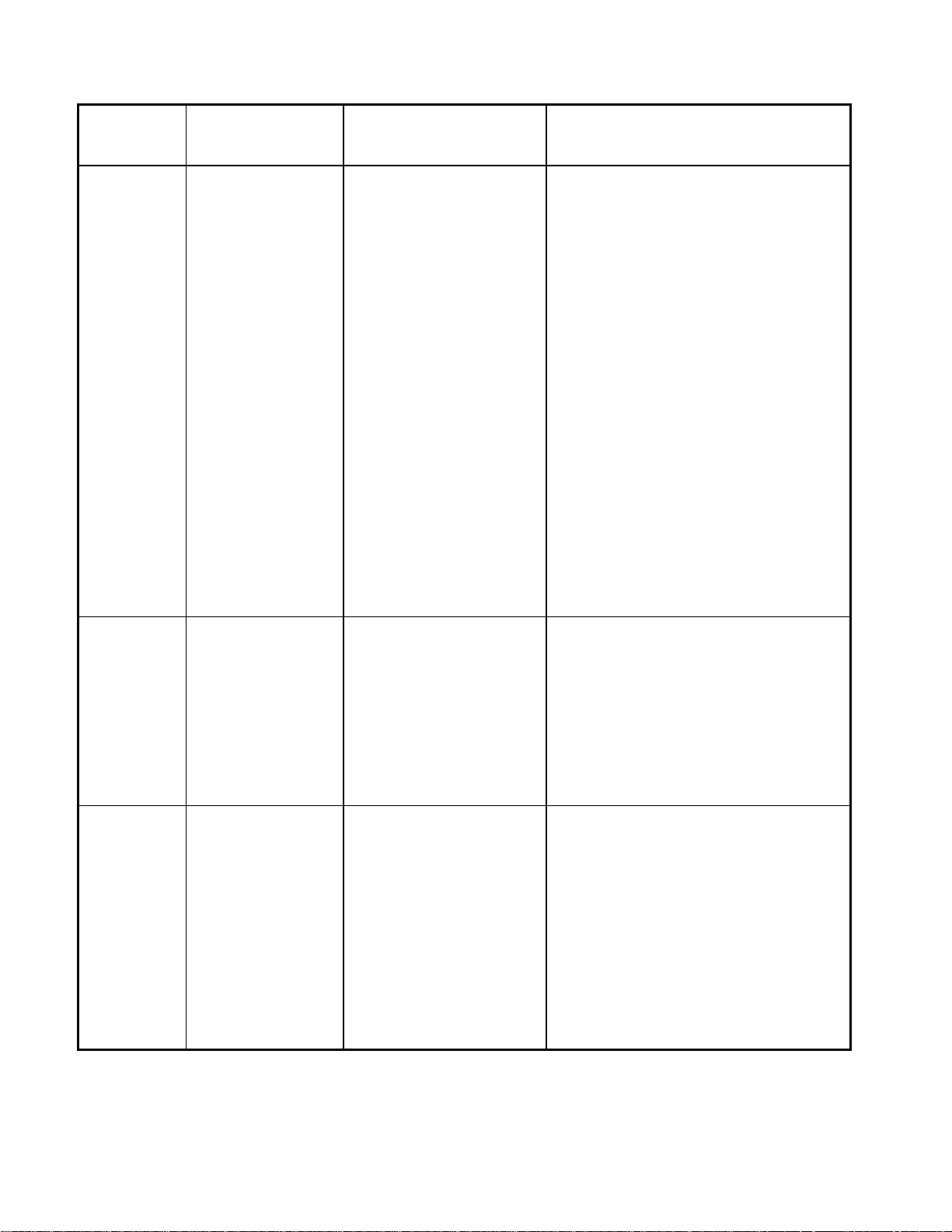

6. ALARM / ALERT SIGNALS (*EXCLUDING GLASS DOOR MODELS)

ALARM

3 beeps

every ten

seconds

ERROR

MESSAGE

“E1” every 2

seconds,

alternating

with cabinet

temp. readout

PROBLEM

[FREEZERS WITH BOARD

REVISION LEVEL 10 OR

BELOW AND ALL

REFRIGERATORS]

Cabinet temp. has

exceeded set temp. by

10°F for more than 2

hours.

[FREEZERS WITH BOARD

REVISION LEVEL 11 AND

ABOVE]

Cabinet temp. has

exceeded set temp. by

25°F for more than 4

hours.

(FOR BOARD REVISION

LEVEL SEE “[1] NORMAL

ELECTRONIC CONTROL

PROCESS FLOW

OPERATION”)

RESET OPTIONS

Press “RESET.” If temp. has

returned to setpoint range, alarm

will stop and “E1” will clear.

If temp. is not back in range, “RESET” will silence the alarm for 5

minutes. “E1” will continue to flash.

4 beeps

every 10

seconds

[FREEZER

ONLY]

5 beeps

every 10

seconds

“E2” every 2

seconds,

alternating

with cabinet

temp. readout

“E3” every 2

seconds,

alternating

with “dEF” or

cabinet temp.

Cabinet temp. has

remained below setpoint

by 8°F for more than 1

hour.

Defrost has taken

longer than 1 hour.

Control Board has

terminated defrost.

Press “RESET.” If temp. has

returned to setpoint range, alarm

will stop and “E2” will clear.

If temp. is not back in range, “RESET” will silence the alarm for 5

minutes. “E2” will continue to flash.

Press “RESET.” Alarm will stop

and “E3” will clear.

If 4 consecutive defrosts take

more than 1 hour, a qualified

service technician must be

called.

For the Service Tech to reset this

alarm, press “RESET” on the

Control Board itself.

10

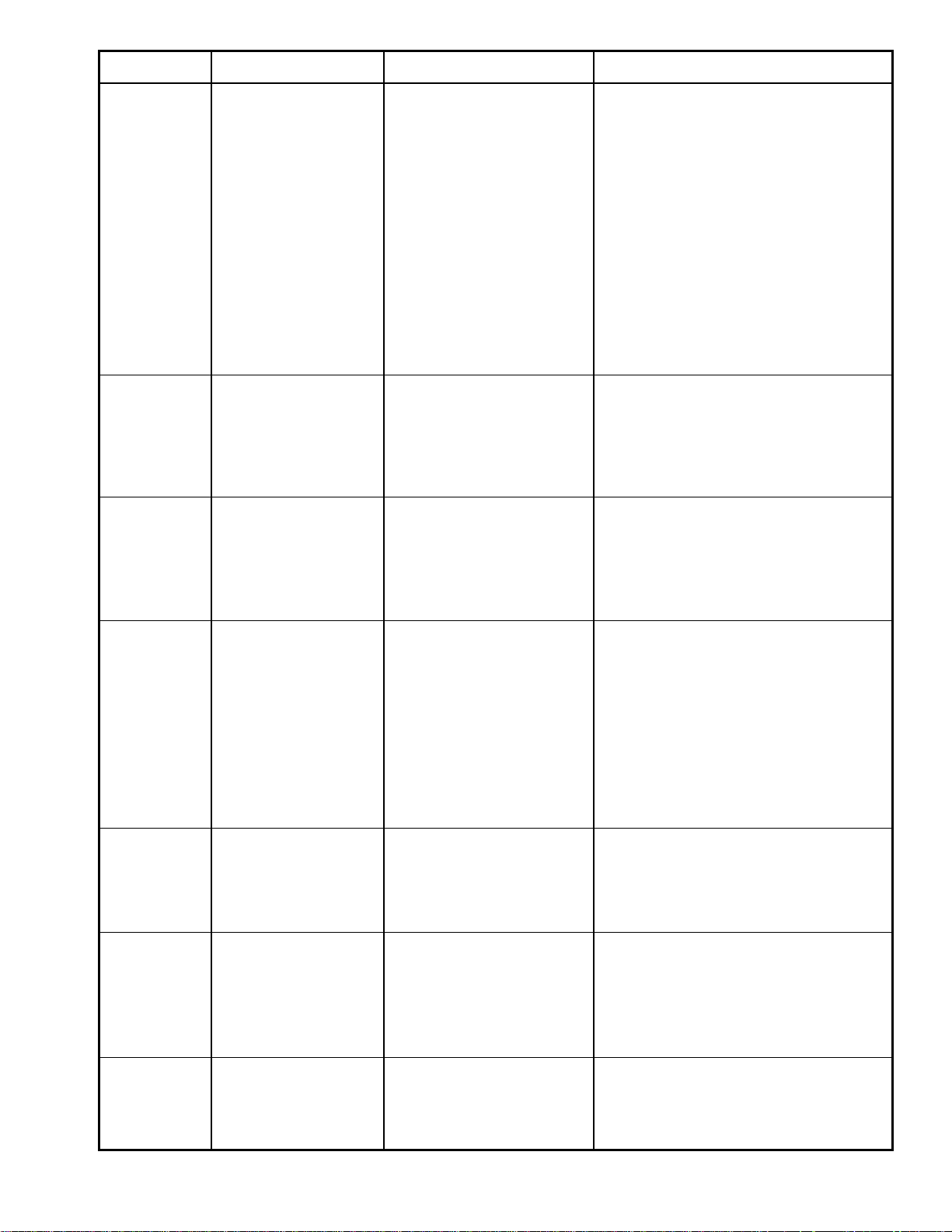

ALARM

ERROR MESSAGE

PROBLEM

RESET OPTIONS

6 beeps

every 10

seconds

8 beeps

every 10

seconds

9 beeps

every 10

seconds

“E4” every 2 seconds, alternating with

cabinet temp.

“E6” every 2 seconds,

alternating with

cabinet temp.

“E7” every 2 seconds, alternating with

cabinet temp.

Compressor discharge pressure is

outside normal operating range. Pressure

switch has been

triggered 3 or more

times in 1 hour.

Line voltage is too

high.

Line voltage is too

low.

Press “RESET.” If pressure switch

resets automatically, alarm will

stop and “E4” will clear when

pressure switch closes.

If switch trips 5 times in 1 hour

compressor will be stopped, and

not re-start. A service technician

must be called.

For the Service Tech to reset this

alarm, press “RESET” on the

Control Board itself.

Alarm automatically resets when

acceptable voltage is detected.

Press “RESET” to silence alarm for

5 minutes.

Alarm automatically resets when

acceptable voltage is detected.

Press “RESET” to silence alarm for

5 minutes.

1 beep

every 10

seconds

Continuous

buzzer

Continuous

buzzer

*2 beeps

every ten

seconds

“CF” every 2 seconds, alternating with

cabinet temp.;

“CLEAN FILTER”

LED lights.

“E8” every 2 seconds

“E9” every 2 seconds, alternating with

the cabinet temp.

*“door” every 2

seconds, alternating

with the cabinet temp.

Condenser filter

needs cleaning.

Cabinet temp. sensor

has failed.

Defrost temp. sensor

has failed.

*Display: Door open

Display and sound:

Door open longer than

3 minutes.

Clean filter. Allow time for sensor

to react, then press “RESET.”

During alarm, press “RESET” to

silence alarm for 2 hours.

If this alarm occurs frequently,

discharge temperature is consistently too high.

Replace sensor. Alarm will reset.

During alarm press “RESET” to

silence buzzer for 5 minutes.

Replace sensor. Alarm will reset.

During alarm press “RESET” to

silence buzzer for 5 minutes.

*Close door. During alarm, press

“RESET” to silence buzzer for 3

minutes.

11

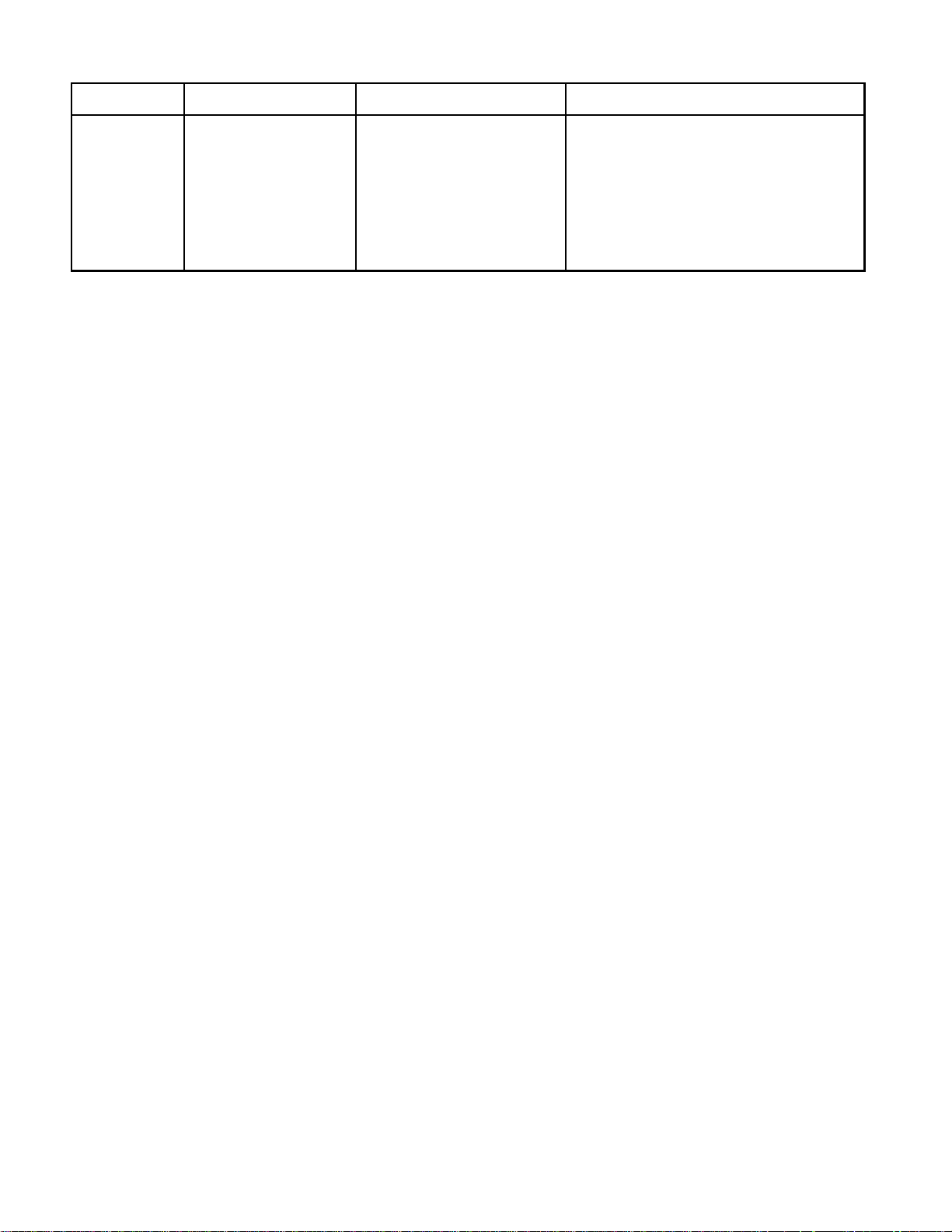

ALARM

ERROR MESSAGE

PROBLEM

RESET OPTIONS

*10 beeps

every 10

seconds

*“E10” every 2 seconds, alternating with

cabinet temp.

*Freezer and Refrigerator boards not

communicating

properly to control

compressor delay

(RFH only).

*EXCLUDING GLASS DOOR MODELS

*When communication is restored,

alarm will reset.

*During alarm, press “RESET” to

silence buzzer for 18 hours.

12

a) HIGH TEMPERATURE ALARM FUNCTION

FOR FREEZERS WITH BOARD REVISION LEVEL 10 OR BELOW* AND FOR ALL REFRIGERATORS,

when c

OR FOR FREEZERS WITH BOARD REVISION LEVEL 11 AND ABOVE**, when cabinet temp. has

abinet temp. has exceeded set temp. by 10°F or more for more than 2 hours;

exceeded set temp. by 25°F or more for more than 4 hours,

an alarm buzzer sounds 3 beeps every 10 seconds, and an error message “E1” flashes

every 2 seconds, alternating with the cabinet temperature readout.

Reset Options:

If temperature has returned to setpoint range, pressing “RESET” on the Display Board will stop

the buzzer and clear the “E1” message.

If temperature is not back in range, pressing “RESET” on the display board will silence the

buzzer for 5 minutes. The “E1” message will continue to flash.

Note: Setting DIAGNOSTIC MENU item 3 to ON resets all alarms regardles of whether or not

setpoints are reached. This is a complete clearing of all alarms. See DIAGNOSTIC

MENU for details.

*FOR BOARD REVISION LEVEL SEE “[1] NORMAL ELECTRONIC CONTROL PROCESS FLOW

OPERATION”.

**UNLESS OTHERWISE NOTED.

b) LOW TEMPERATURE ALARM FUNCTION

When the cabinet temperature has been below the setpoint by 8°F for more than 1 hour, the

buzzer will sound 4 beeps every 10 seconds, and “E2” will flash every 2 seconds, alternating

with the cabinet temperature readout.

Reset Options:

If temperature has returned to setpoint range, pressing “RESET” on the Display Board will stop

the buzzer and clear the “E2” message.

If temperature is not back in range, pressing “RESET” on the Display Board will silence the

buzzer for 5 minutes. The “E2” message will continue to flash.

Note: Setting DIAGNOSTIC MENU item 3 to ON resets all alarms regardles of whether or not

setpoints are reached. This is a complete clearing of all alarms. See DIAGNOSTIC

MENU for details.

c) DEFROST ERROR ALERT FUNCTION [FREEZER ONLY]

If, for any reason, the defrost takes longer than 1 hour, the alarm buzzer will sound 5 beeps

every 10 seconds, and “E3” will flash every 2 seconds, alternating with either “dEF” or the

cabinet temperature. If this alarm activates, the Control Board will automatically terminate the

defrost.

Reset options:

Pressing “RESET” on the Display Board will reset the buzzer and clear the “E3” from the

display.

13

IMPORTANT

If 4 consecutive defrosts take more than 1 hour, pressing “RESET” on the Display Board will

only silence the buzzer until the next defrost that lasts more than 1 hour.

For the Service Tech to reset this alarm, press “RESET” on the Control Board itself.

d) HIGH PRESSURE ALERT FUNCTION

In order to protect the compressor if the discharge pressure reaches a preset value (outside the

normal operating range), a switch will temporarily stop the compressor. At another preset

pressure, the compressor will attempt to restart. If the switch is triggered 3 times in 1 hour, the

buzzer will sound 6 beeps every 10 seconds, and “E4” will flash every 2 seconds, alternating

with the cabinet temperature. The same sequence will occur if the switch trips the fourth time in

1 hour.

Reset Options:

During the third and fourth trip alarm, the buzzer can be silenced by pressing” RESET” on the

Display Board.

The buzzer and display will automatically reset when the pressure switch closes after the 3rd

and 4th reset.

After the 5th pressure trip, the buzzer can be silenced for 1 hour by pressing “RESET” on the

Display Board.

IMPORTANT

If the switch trips 5 times in 1 hour, the compressor will be stopped, and a service technician

must be called.

For the Service Tech to reset this alarm, press “RESET” on the Control Board itself.

e) HIGH VOLTAGE ALERT FUNCTION

When the unit detects the line voltage is above a preset value for 10 seconds, to protect the

compressor, the compressor will shut down. The buzzer will sound 8 beeps every 10 seconds.

“E6” will flash every 2 seconds, alternating with the cabinet temperature.

Reset Options:

This alarm automatically resets when an acceptable voltage is detected.

The buzzer can be silenced for 5 minutes while in alarm by pressing “RESET” on the Display

Board.

f) LOW VOLTAGE ALERT FUNCTION

When the unit detects the line voltage is below a preset value for 10 seconds, to protect the

compressor, the compressor will shut down. The buzzer will sound 9 beeps every 10 seconds.

“E7” will flash every 2 seconds, alternating with cabinet temperature.

14

Loading...

Loading...