Page 1

Hoshizaki

Hoshizaki America, Inc.

Professional Series

Refrigerated Kitchen Equipment

Model

SSE

“A Superior Degree

of Reliability”

www.hoshizaki.com

SERVICE MANUAL

Number: 73177

Issued: 4-14-2010

Revised: 9-17-2015

Page 2

IMPORTANT

Only qualied service technicians should install, service, and maintain the

unit. No service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual. Failure to service and maintain

the equipment in accordance with this manual may adversely affect safety,

performance, component life, and warranty coverage.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write, or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Phone: 1-800-233-1940 Technical Support

(770) 487-2331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number __________________________

• Serial Number __________________________

• Complete and detailed explanation of the problem.

2

Page 3

IMPORTANT

This manual should be read carefully before the unit is serviced or maintenance

operations are performed. Only qualied service technicians should install,

service, and maintain the unit. Read the warnings contained in this booklet

carefully as they give important information regarding safety. Please retain this

booklet for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 5

I. General Information ............................................................................................................ 6

A. Construction .................................................................................................................. 6

1. One Section ............................................................................................................. 6

2. Two Section ............................................................................................................. 7

3. Three Section .......................................................................................................... 8

B. Sequence of Operation ................................................................................................. 9

1. Sequence Cycles and Shutdown ............................................................................. 9

a) Startup .............................................................................................................. 9

b) Cool Down ......................................................................................................... 9

c) Cool Down Achieved ......................................................................................... 9

d) Cool Down Restart ............................................................................................ 9

e) Defrost ............................................................................................................... 9

2. Sequence Flow Chart ............................................................................................ 10

C. Display Board ...............................................................................................................11

D. Control Board .............................................................................................................. 12

1. Control Board Layout ............................................................................................. 13

2. Features ................................................................................................................. 14

a) LED Display ..................................................................................................... 14

b) Guarded Access Menu ..................................................................................... 14

c) Service Menu ................................................................................................... 14

d) Alarm Signals ................................................................................................... 14

e) Defrost ............................................................................................................. 14

f) Default Safety Program ..................................................................................... 14

g) High Voltage and Low Voltage Cut-outs ........................................................... 14

3. LED Lights and Alarm Safeties Chart .................................................................... 15

4. Controls and Adjustments ...................................................................................... 17

a) Default Dip Switch Settings .............................................................................. 17

b) Unit Operation (Freezer/Refrigerator) (S3 dip switch 1) ................................... 17

c) Cabinet Light/Heated Glass Door (S3 dip switch 2) ......................................... 18

d) Door Switch Type (S3 dip switch 3) .................................................................. 18

e) Reach-In/Pass Thru Defrost Initiation Temperature (S3 dip switch 4) .............. 18

f) Display Board Operation (S3 dip switch 5) ....................................................... 18

g) Dual Temp Unit (S3 dip switch 6) ..................................................................... 19

h) Freezer Evaporator Fan Operation (except RFH1) (S3 dip switch 7) ............... 19

i) RFH1 Condensate Pan Heater Operation (S3 dip switch 8) ............................. 19

3

Page 4

5. Guarded Access Menu .......................................................................................... 20

a) Temperature Setpoint ....................................................................................... 20

b) Defrost Frequency ............................................................................................ 20

c) Temperature Display Scale (°F or °C) .............................................................. 21

6. Service Menu ........................................................................................................ 22

E. Compressor Thermal Overload and Short Cycle Protection ........................................ 23

F. Perimeter Heater .......................................................................................................... 23

G. Thermistors ................................................................................................................. 23

III. Technical Data ................................................................................................................ 24

A. Wiring Diagrams .......................................................................................................... 24

1. RH_-SSE-XX (FG, HG, FS, or HS) Models ........................................................... 24

2. PTR_SSE-XXXX (FSFS, HSHS, FGFG, HGHG, HGHS) Models ......................... 25

IV. Service Diagnosis ........................................................................................................... 26

A. Diagnostic Procedure .................................................................................................. 26

B. Control Board Check ................................................................................................... 29

C. Thermistor Check ........................................................................................................ 30

D. Diagnostic Chart ......................................................................................................... 31

1. Unit Not Cooling ..................................................................................................... 31

2. Evaporator is Frozen Up ........................................................................................ 33

3. Defrost Fails to Terminate ...................................................................................... 33

4. Other ...................................................................................................................... 33

V. Removal and Replacement of Components .................................................................... 34

A. Service for Refrigerant Lines ....................................................................................... 34

1. Refrigerant Recovery ............................................................................................. 34

2. Brazing .................................................................................................................. 35

3. Evacuation and Recharge (R-134a) ...................................................................... 35

B. Removal and Replacement of Compressor ................................................................. 36

C. Removal and Replacement of Compressor Electronic Unit ........................................ 37

D. Removal and Replacement of Expansion Valve .......................................................... 38

E. Removal and Replacement of Evaporator ................................................................... 39

F. Removal and Replacement of Evaporator Fan Motor .................................................. 40

G. Removal and Replacement of Door Gasket ............................................................... 40

H. Removal and Replacement of Door Closure Spring ................................................... 41

I. Door Re-Hinging ........................................................................................................... 42

J. Removal and Replacement of Control Board ............................................................... 42

K. Removal and Replacement of Thermistors ................................................................. 43

VI. Cleaning Instructions ...................................................................................................... 44

4

Page 5

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, or damage to the unit.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

CAUTION Indicates a situation which could result in damage to the unit.

IMPORTANT Indicates important information about the use and care of the

unit.

WARNING

This unit should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore

dangerous. The manufacturer cannot be held responsible for eventual damage

caused by improper, incorrect, and unreasonable use.

To reduce the risk of death, electric shock, serious injury, or re, follow

basic precautions including the following:

• This unit requires an independent power supply. See the nameplate for proper

voltage and breaker/fuse size. Failure to use a proper breaker or fuse can

result in a tripped breaker, blown fuse, or damage to existing wiring. This

could lead to heat generation or re.

• THIS UNIT MUST BE GROUNDED: This unit is equipped with a 3-prong

grounding plug to reduce the risk of potential shock hazards. It must be

plugged into a properly grounded, independent 3-prong wall outlet. If the

outlet is a 2-prong outlet, it is your personal responsibility to have a qualied

electrician replace it with a properly grounded, independent 3-prong wall

outlet. Do not remove the ground prong from the power cord and do not use

an adapter plug.

• Do not use an extension cord.

• Make sure the control switch is in the "OFF" position before plugging in or

unplugging the unit to reduce the risk of electric shock.

• Do not use a unit with a damaged power cord. The power cord should not be

altered, jerked, bundled, weighed down, pinched, or tangled. Such actions

could result in electric shock or re. To unplug the unit, be sure to pull the

plug, not the cord, and do not jerk the cord.

• To reduce the risk of electric shock, do not touch the plug or control switch

with damp hands.

• This unit should be disassembled or repaired only by qualied service

personnel to reduce the risk of electric shock, injury, or re.

• Do not make any alterations to the unit. Alterations could result in electric

shock, injury, re, or damage to the unit.

5

Page 6

I. General Information

A. Construction

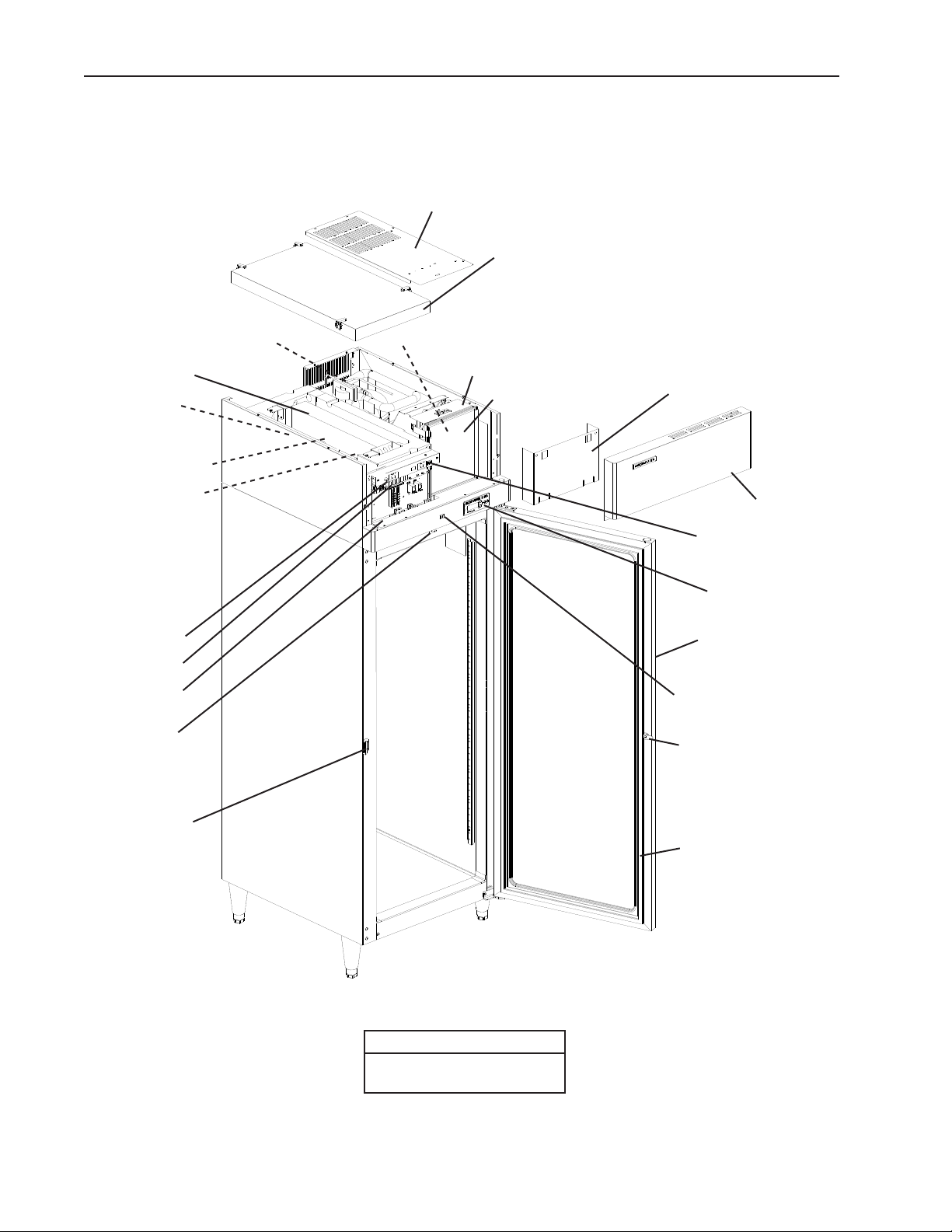

1. One Section

Compressor and

Compressor Electronic Unit

Top Cover

Evaporator Case Cover

Condenser Fan Motor

Evaporator

Evaporator

Fan Motor

Cabinet Thermistor

Defrost Thermistor

Power Switch

Control Board

Control Box

Door Switch

Condenser

Condenser Air Filter

Control Box Cover

Front Panel

Perimeter Heater

Switch

Display Board

Door

Light Switch

(glass door model)

Door Lock

Door Latch

Door Gasket

Model Shown: RH1-SSE-FG

Models

RH1-SSE-FG, RH1-SSE-HG

RH1-SSE-FS, RH1-SSE-HS

6

Page 7

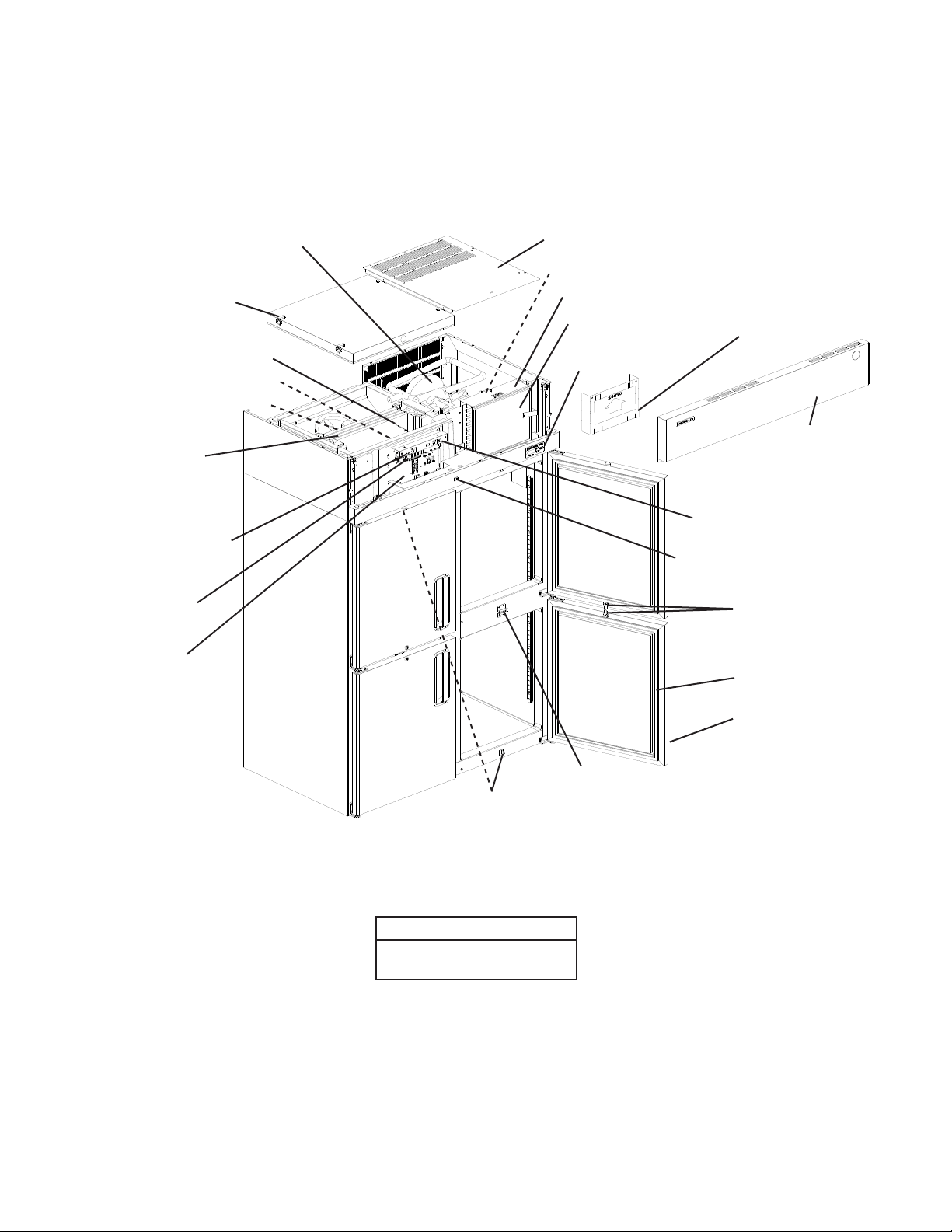

2. Two Section

Compressor and

Compressor Electronic Unit

Evaporator

Case Cover

Top Cover

Condenser Fan Motor

Condenser

Condenser Air Filter

Control Box Cover

Defrost Thermistor

Cabinet Thermistor

Evaporator Fan Motor

Evaporator

Power Switch

Control Board

Control Box

Display Board

Front Panel

Perimeter Heater

Switch

Light Switch

(glass door model)

Door Lock

Door Gasket

Door

Door Latch

Door Switch

Model Shown: RH2-SSE-HS

Models

RH2-SSE-FG, RH2-SSE-HG

RH2-SSE-FS, RH2-SSE-HS

7

Page 8

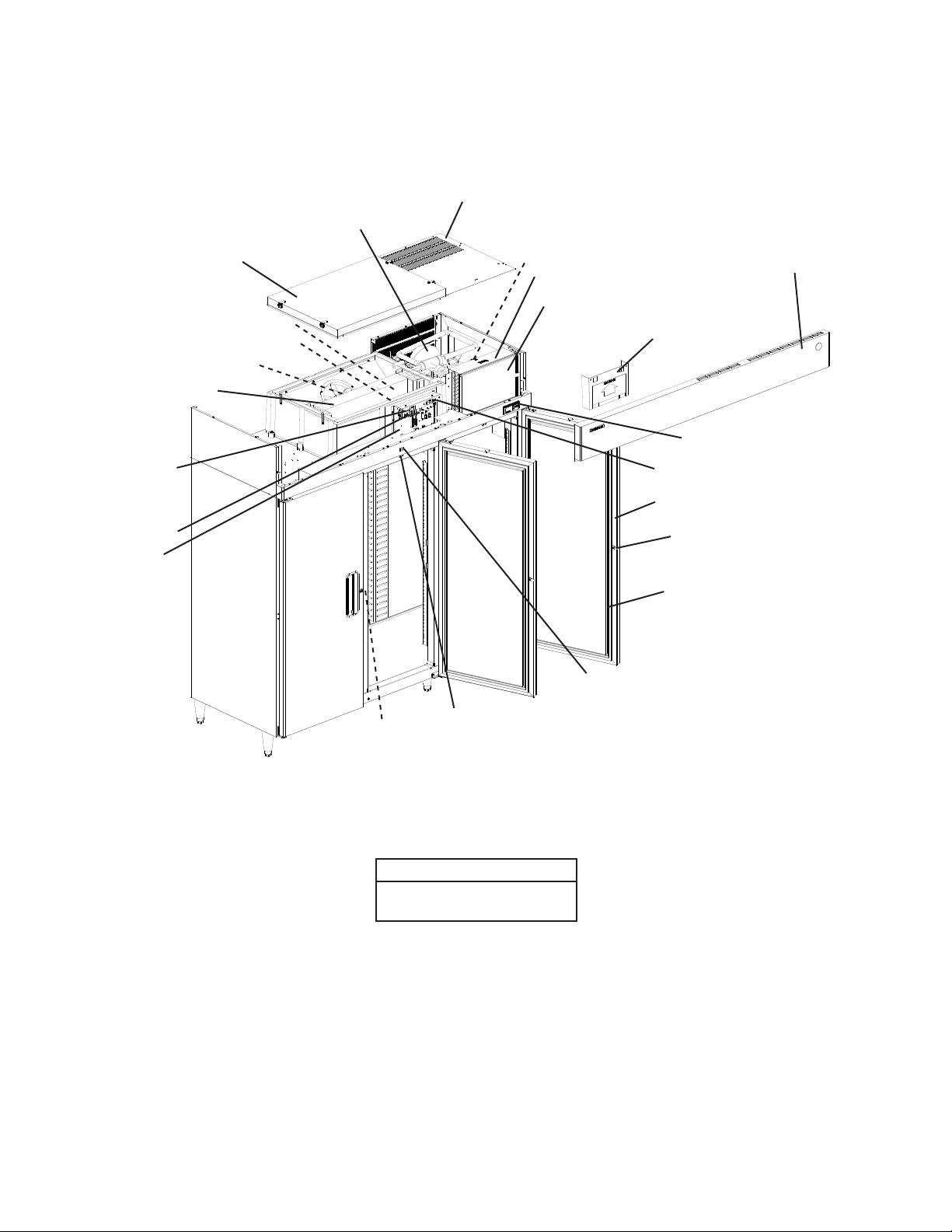

3. Three Section

Compressor and Compressor Electronic Unit

Top Cover

Evaporator Case Cover

Defrost Thermistor

Cabinet Thermistor

Evaporator Fan Motor

Evaporator

Power Switch

Control Board

Control Box

Door Latch

Condenser Fan Motor

Door Switch

Condenser

Condenser Air Filter

Control Box Cover

Light Switch

(glass door model)

Front Panel

Display Board

Perimeter Heater Switch

Door

Door Lock

Door Gasket

Model Shown: RH3-SSE-FS

Models

RH3-SSE-FG, RH3-SSE-HG

RH3-SSE-FS, RH3-SSE-HS

8

Page 9

B. Sequence of Operation

1. Sequence Cycles and Shutdown

The steps in the sequence are as outlined below.This unit utilizes a control board to

switch the components on and off as needed. When power is supplied and the power

switch is in the "ON" position, CB red "POWER OK" LED comes on and CB revision

(r###) appears on DB.

Note: 1. "POWER OK" LED remains on until the power switch is moved to the "OFF"

position, the power supply is turned off, or the unit is unplugged from the

electrical outlet.

2. There is a minimum 2.5-minute Comp on time and 2.5-minute Comp off time.

a) Startup

No Component LED on: EvapFM energizes. 2.5-minute Comp delay timer starts.

Cabinet temperature appears on DB.

b) Cool Down

LEDs 4 and 5 on: 2.5-minute Comp delay timer terminates, EvapFM continues,

Comp, ConFM, and PH energize.

c) Cool Down Achieved

No Component LED on: CB monitors cooling of the cabinet via CTh. CTh cools to

3°F (1.7°C) below setpoint. EvapFM continues, Comp, ConFM, and PH de-energize.

d) Cool Down Restart

LEDs 4 and 5 on: CTh warms to 3°F (1.7°C) above setpoint. EvapFM continues,

Comp, ConFM, and PH energize.

e) Defrost

LED 5 on:

(1a) Temperature-Initiated Defrost

DTh cools to 13°F (-10°C). Comp and PH, if energized, de-energize, EvapFM

continues. If energized, ConFM continues, otherwise, ConFM energizes. Cabinet

temperature is displayed on DB during defrost.

(1b) Optional Time-Initiated Defrost

The optional time-initiated defrost is factory set to 0 times per day. Before

changing this setting, contact Hoshizaki Technical Support at 1-800-233-1940 for

recommendations.

When set to greater than 0, defrost initiates when the defrost timer terminates. For

further details, see "II.D.5.b) Defrost Frequency."

(2) Defrost Termination

DTh warms to 40°F (4.4°C). EvapFM and ConFM continue. 2.5 minute delay

before Comp and PH energize.

Legend: CB–control board; ConFM–condenser fan motor; Comp–compressor;

CTh–cabinet thermistor; DB–display board; DTh–defrost thermistor;

EvapFM–evaporator fan motor; PH–perimeter heater

9

Page 10

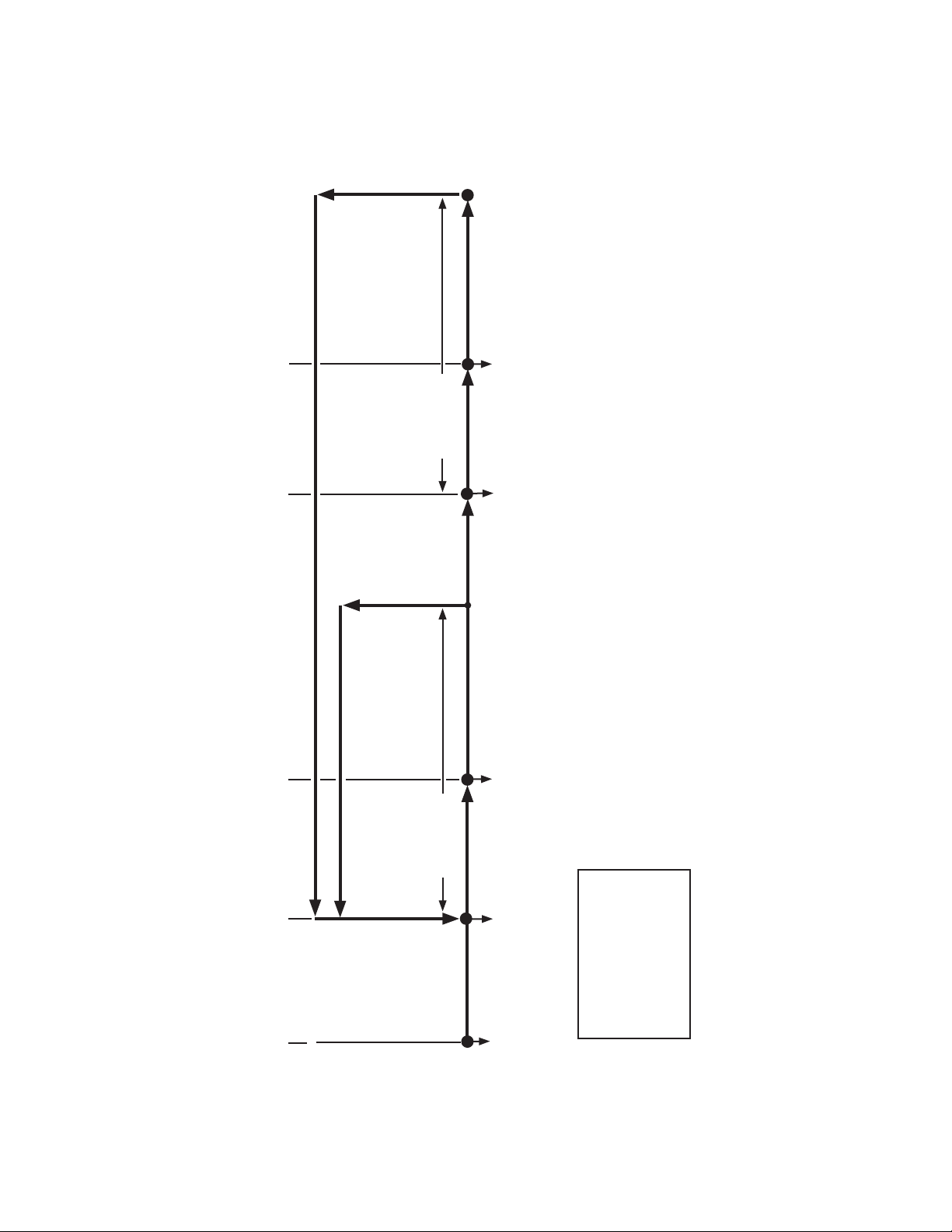

2. Sequence Flow Chart

5. Defrost Termination

4. Defrost

DTh warms to

40°F (4.4°C)

DTh cools to

13°F (-10°C) or

optional defrost

timer terminates

EvapFM continues

ConFM continues

DTh in control

EvapFM continues

ConFM continues

Comp de-energized

PH de-energized

CTh warms to

3°F (1.7°C)

above setpoint

Refrigerator Sequence Flow Chart

3. Cool Down Achieved

CTh cools to

3°F (1.7°C)

below setpoint

EvapFM continues

Comp de-energized

ConFM de-energized

PH de-energized

Note: Minimum 2.5-minute Comp on time and 2.5-minute Comp off time.

CTh in control

2. Cool Down

EvapFM continues

Comp energized

ConFM energized

PH energized

Legend:

EvapFM-cabinet fan motor

CTh-cabinet thermistor

Comp-compressor

ConFM-condenser fan motor

DTh-defrost thermistor

1. Startup

2.5-minute Comp

delay timer starts

EvapFM energized

PH-perimeter heater

10

Page 11

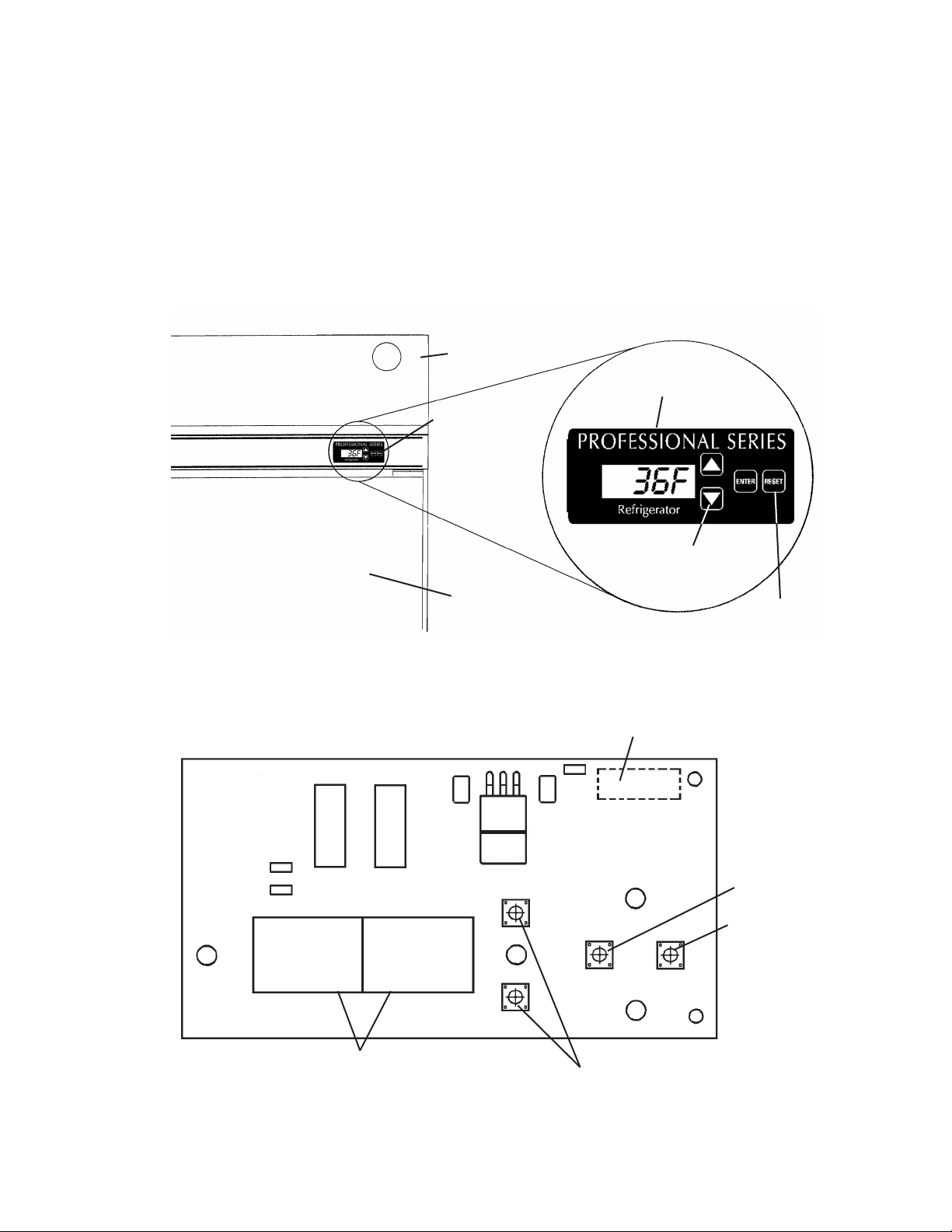

C. Display Board

When the power switch is moved to the "ON" position, the control board revision

appears on the display board. "r###" indicates the control board revision level (e.g.,

r23C). Afterward, the current cabinet temperature is displayed. The display board also

allows for access to the guarded access menu and service menu. From the guarded

access menu, the cabinet setpoint, defrost frequency, and temperature display scale can

be adjusted. For further details, see "II.D.5. Guarded Access Menu." From the service

menu, information regarding unit functions can be obtained. For further details, see

"II.D.6. Service Menu."

Display Board

Front Panel

Display Board

Door

Fig. 1

Display

Board

Up and Down

Buttons

"RESET" Button:

Temporarily

silences audible

alarms

Ribbon Cable Connector

LED Display

Fig. 2

11

P/N 2A0883-01

Up and Down Buttons

"ENTER" Button

"RESET" Button

Page 12

D. Control Board

• A Hoshizaki exclusive control board is employed in all Hoshizaki Professional Series

Reach-Ins.

• All models are pretested and factory set.

CAUTION

1. The control board is fragile, handle very carefully.

2. The control board contains integrated circuits, which are susceptible to failure

due to static discharge. It is especially important to touch the metal part of

the unit before handling or replacing the control board.

3. Do not touch the electronic devices on the control board or the back of the

control board.

4. Do not change wiring and connections. Never misconnect terminals.

5. Always replace the whole control board assembly if it goes bad.

6. Do not short out power supply to test for voltage.

7. Keep the thermistor leads, clogged lter thermostat leads, door switch leads,

pressure switch leads, and ribbon cable at least 1-1/2" away from high

voltage leads (100VAC or more) to protect against electrical noise.

12

Page 13

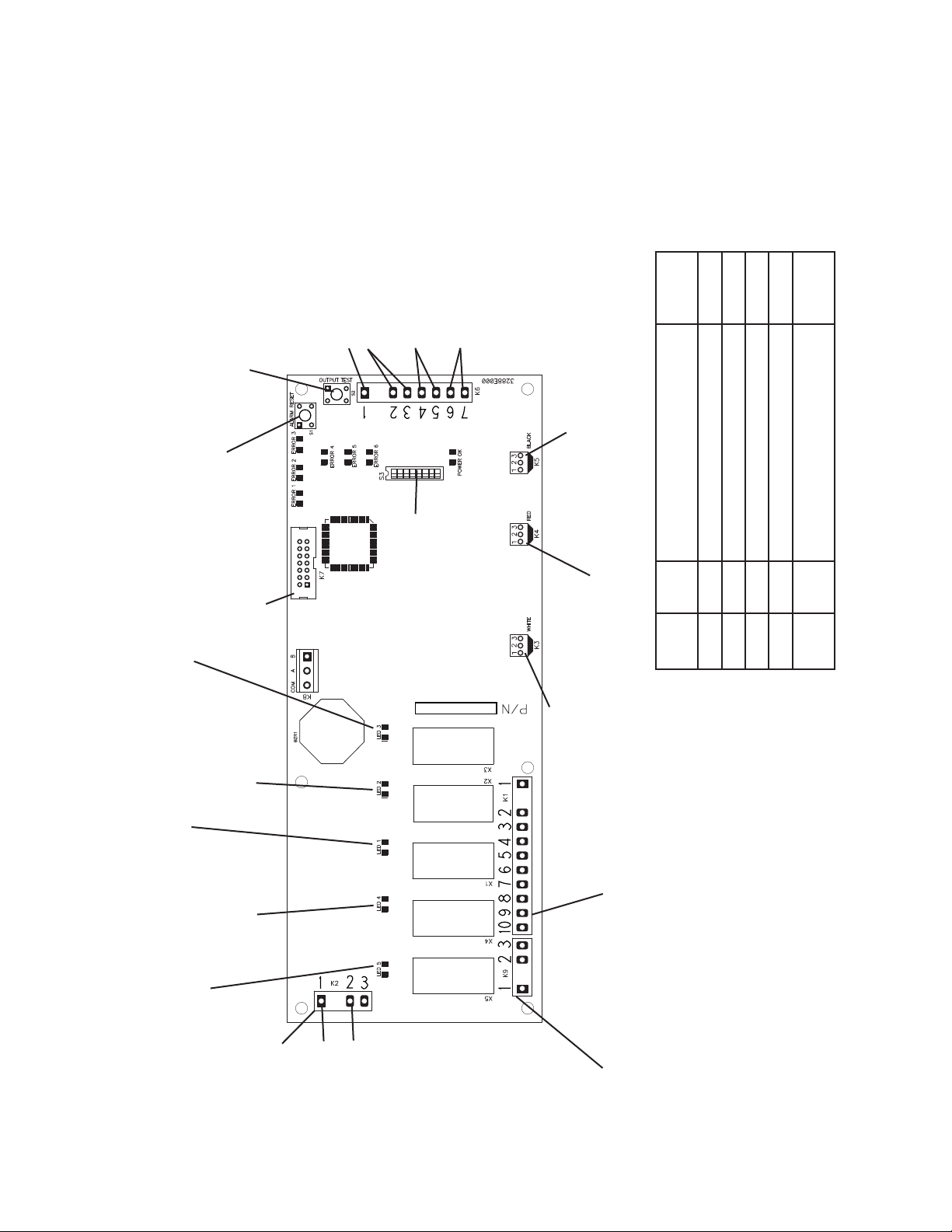

1. Control Board Layout

ETAD

SNOISIVER FO DROCER

50/02/21

A

gwD yssA weN

NOITPIRCSED

OCD/OCE

VER

"R-A" Control Board

• LED 3 (X3 Relay)

Evaporator Fan Motor

(Off when Evaporator Fan Relay Energizes)

• S1 "ALARM RESET" Button

• K7 Connector

• S2 "OUTPUT TEST" Button

LED

ON

ON/OFF

• K6 Connector (5VDC)

#1 Open

#2 and #3 Clogged Filter Thermostat

(pink) (Normally Open)

#4 and #5 Cabinet Light

(light blue) (Normally Closed)

#6 and #7 High Pressure Switch

(violet) (Normally Closed)

• K5 Connector (5VDC)

Open

Condensate Pan Heater (RFH1)

S3 Dip Switch

• K4 Connector (5VDC)

Display Cable

Cabinet Thermistor (gray (GY))

X3X2

Relay LED Component Energized

X1 1 Defrost Heater (Freezer) ON

X2 2 Cabinet Light ON

X3 3 Evaporator Fan Motor OFF

X4 4 Compressor Relay ON

X5 5 Condenser Fan Motor

• LED 1 (X1 Relay)

Defrost Heater

• LED 5 (X5 Relay)

(Freezer)

Condenser Fan Motor

Condensate Pan Heater (RFH1)

• LED 2 (X2 Relay)

Cabinet Light

• LED 4 (X4 Relay)

Compressor Relay

• K2 Connector

(10VAC)

• K3 Connector (5VDC)

Defrost Thermistor (orange (O))

X1

X4

• K1 Connector (115VAC)

#1 Power Switch Input

(black)

#2 Open

#3 Evaporator Fan Motor

(dark blue)

#4 Open

#5 Cabinet Light

(light blue)

#6 Open

#7 Open

#8 Open

#9 Power Switch Input

(black)

#10 Compressor Relay

(gray)

X5

• K9 Connector (115VAC)

#3 Condenser Fan Motor

(black)

#2 Condenser Fan Motor

#2 Transformer

(red)

(red)

#1 Transformer

(brown)

13

Page 14

2. Features

a) LED Display

The display board identies system details and diagnostic information. A ribbon cable

connects the display board to the control board for system communication. Be sure to

keep the ribbon cable at least 1-1/2" away from high voltage leads (100VAC or more)

to protect against electrical noise.

b) Guarded Access Menu

Three settings can be viewed and changed from the guarded access menu:

Temperature Setpoint, Defrost Frequency, and Temperature Display Scale (°F or °C).

For details, see "II.D.5. Guarded Access Menu."

c) Service Menu

The service menu allows for the viewing and setting of system operating details and

parameters. For details, see "II.D.6. Service Menu."

d) Alarm Signals

Alarm signals are designed to protect the unit and food product. These alarms give

information or warnings in the event the unit is operating out of acceptable parameters.

For details, see "II.D.3. LED Lights and Alarm Safeties Chart."

e) Defrost

Main defrost control: Temperature-initiated, temperature-terminated defrost. Optional

defrost control: Time-initiated, temperature-terminated defrost.

For details, see "II.D.5.b) Defrost Frequency."

f) Default Safety Program

Cabinet Thermistor: In the event the cabinet thermistor reading is out of range, the

compressor operates on a xed time basis of 5-minutes on and 5-minutes off.

Defrost Thermistor: In the event the defrost (evaporator) thermistor reading is out

of range, defrost initiation occurs every 6 hours and terminates at 40°F cabinet

thermistor temperature.

Cabinet and Defrost Thermistor: In the event both thermistor readings are out of

range, the compressor operates on a xed time basis of 5-minutes on and 5-minutes

off and a defrost cycle initiates every 6 hours and terminates after 45 minutes. For

further details, see "IV.C. Thermistor Check."

g) High Voltage and Low Voltage Cut-outs

The maximum and minimum allowable supply voltages of this unit are limited by the

high and low voltage cut-outs.

If high voltage (140VAC±5% or more) is present, the unit automatically stops and the

control board signals with "E6" display and 8-beep alarm every 3 seconds.

If low voltage (92VAC±5% or less) is present, the unit automatically stops and the

control board signals with "E7" display and 9-beep alarm every 3 seconds.

When the proper supply voltage is resumed, the unit automatically starts running

again.

14

Page 15

3. LED Lights and Alarm Safeties Chart

With proper power supply, the "POWER OK" LED energizes and remains on. LEDs

1 through 5 energize as the unit cycles through the sequence of operation. If an error

occurs, the alarm code and cabinet temperature are displayed in 2-second intervals and

an alarm sounds. To temporarily reset alarm, press the display board "RESET" button. To

reset and clear the control board memory of an alarm, press the control board "ALARM

RESET" button. See the table below for a description of alarms and reset options.

Sequence Steps LEDs Energized Components Notes

Start - EvapFM LED 3 off when EvapFM energized.

Cool Down 4 and 5 EvapFM, Comp, and ConFM At startup 2.5 minute Comp delay.

Cool Down Achieved - EvapFM 2.5 minute minimum off time.

Defrost 5 EvapFM, ConFM Door Open 2 Cabinet Light (solid door) -

Alarm Signals

Alarm

Code

E1 3

E2 4

E3 5 N/A [Freezer Only] Defrost longer than 1 hour. N/A

E4 6

E6 8

E7 9

E8 Constant

No. of Beeps

(every 10 sec.) Problem Reset Options

High Temperature Alarm

Cabinet temperature has remained above

setpoint by 10°F (5.6°C) for more than 2 hours.

Low Temperature Alarm

Cabinet temperature has remained below

setpoint by 8°F (4.4°C) for more than 1 hour.

High Pressure Alarm

Compressor discharge pressure is outside

normal operating range. Pressure switch has

been triggered 3 or more times in 1 hour.

If switch trips 5 times in 1 hour, compressor

stops and will not restart.

High Voltage (140VAC±5% or less) "POWER OK" LED turns off if voltage

Low Voltage (90VAC±5% or less)

Cabinet Thermistor

During alarm, unit operates in cabinet

thermistor fail mode.

Cabinet Thermistor Fail Mode: Unit on

5 minutes, off 5 minutes. This continues until

thermistor is replaced.

Press the display board "RESET"

button. If temperature has returned to

setpoint range, alarm stops and "E1"

clears.

If temperature is not back in range,

pressing the display board "RESET"

button temporarily silences the alarm

for 5 minutes. "E1" continues to ash.

Press the display board "RESET"

button. If temperature has returned to

setpoint range, alarm stops and "E2"

clears.

If the temperature is not back in range,

pressing the display board "RESET"

button temporarily silences the alarm

for 5 minutes. "E2" continues to ash.

After 5 high pressure switch trips, the

alarm can be silenced for 1 hour by

pressing the display board "RESET"

button.

Service Tech: Reset by pressing the

control board "ALARM RESET" button.

protection operates. The voltage

safeties automatically reset when

voltage is corrected.

Press the display board "RESET"

button to temporarily silence the alarm

for 5 minutes.

After replacing thermistor, alarm

resets.

During alarm, press the display board

"RESET" button to silence alarm for

5 minutes.

15

Page 16

Alarm Signals (continued)

Alarm

Code

E9 Constant

E10 10

CF 1

door 2 Door open: Display alternates between cabinet

No. of Beeps

(every 10 sec.) Problem Reset Options

Defrost Thermistor

During alarm, unit operates in the defrost

thermistor fail mode.

Defrost Thermistor Fail Mode: Defrost occurs

once every 6 hours and terminates after

45minutes.

N/A [Dual Temp Models Only] Communication

error between control boards.

Clogged Filter Alarm (condenser thermostat)

Condenser lter needs cleaning.

WARNING: If this alarm occurs frequently,

discharge temperature is consistently too

high. Failure to take action could result in

damage to the compressor.

temperature and "door."

Door open longer than 3 minutes: alternating

display continues and alarm sounds.

After replacing thermistor, alarm

resets.

During alarm, press the display board

"RESET" button to silence alarm for

5 minutes.

N/A

Clean lter. Allow time for thermostat

to react, then press the display board

"RESET" button.

During alarm, press the display board

"RESET" button to silence alarm for

2hours.

Close door. During alarm, press

the display board "RESET" button

to temporarily silence alarm for

3minutes.

Note: Setting service menu item #3 to "ON" resets all alarms regardless of whether

or not the problems are resolved. This is a complete clearing of all alarms. See

"II.D.6. Service Menu" for details.

16

Page 17

4. Controls and Adjustments

CAUTION

Dip switches are factory set. Failure to maintain factory settings may adversely

affect performance and warranty coverage. For more information, contact

Hoshizaki Technical Support at 1-800-233-1940.

a) Default Dip Switch Settings

The S3 dip switch settings are factory-set to the following positions:

S3 Dip Switch

Dip Switch No. 1 2 3 4 5 6 7 8

All SSE Models ON OFF OFF OFF OFF OFF OFF OFF

S3 Dip Switch

RFH1 Condensate Pan Heater Operation (8)

Freezer Evaporator Fan

Operation (except RFH1) (7)

Dual Temp Unit (6)

Display Board Operation (5)

Reach-In/Pass Thru Defrost

Initiation Temperature (4)

Door Switch Type (Rocker/Plunger) (3)

Cabinet Light/Heated Glass Door (2)

Unit Operation (Freezer/Refrigerator) (1)

b) Unit Operation (Freezer/Refrigerator) (S3 dip switch 1)

This setting determines whether the control board operates in refrigerator mode or

freezer mode. It also determines the temperature setpoint range at which the unit

operates.

Factory set, no adjustment required.

S3 Dip Switch Setting

No. 1

OFF Freezer -10°F (-23°C) to 25°F (-3.9°C) -3°F (-19.4°C)

ON Refrigerator 36°F (2.2°C) to 50°F (10°C) 36°F (2.2°C)

Unit Operation Temperature Setpoint Range Factory Default

17

Page 18

c) Cabinet Light/Heated Glass Door (S3 dip switch 2)

When the cabinet light option is selected (S3 dip switch 2 "OFF"), the control board

energizes the K1 connector pin #5 light blue (LBU) wire and turns on the cabinet light

(solid door models) each time the door and door switch open.

When the heated glass door option is selected (S3 dip switch 2 "ON"), the control board

energizes the K1 connector pin #5 when the compressor is off, and de-energizes when

the compressor turns on. Professional Series SSE glass doors are not heated.

Factory set, no adjustment required. Do not adjust to "ON" position on SSE models.

S3 Dip Switch Setting

No. 2

OFF Cabinet Light (Solid Door)

ON Heated Glass Door (No Longer Applicable)

Cabinet Light/Heated Glass Door

d) Door Switch Type (S3 dip switch 3)

Hoshizaki has utilized both normally open and normally closed door switch contact

styles. S3 dip switch 3 is used to select the type of switch used on a particular model.

Factory set, no adjustment required.

S3 Dip Switch Setting

No. 3

OFF Rocker Door Switch (square): Open Contacts when Doors are Open

ON Plunger Door Switch (round): Closed Contacts when Doors are Open

Door Switch Type (Rocker or Plunger)

e) Reach-In/Pass Thru Defrost Initiation Temperature (S3 dip switch 4)

Refrigerators only. Pass Thru refrigerator models require a defrost initiation temperature

that is different from the reach-in refrigerator models.

Factory set, no adjustment required.

S3 Dip Switch Setting

No. 4

OFF All Refrigerators Except Pass Thru 13°F (-10.5°C)

ON Pass Thru 8°F (-13.3°C)

Model

Defrost Initiation

Temperature

f) Display Board Operation (S3 dip switch 5)

The display board may be disabled by moving S3 dip switch 5 to the "ON" position. When

the display board is disabled, the control board operates in default mode.

Default Mode: Compressor on 5-minutes then off 5-minutes. See "II.D.2.f) Default Safety

Program."

Factory set, no adjustment required.

S3 Dip Switch Setting

No. 5

OFF Enabled

ON Disabled

Display Board Status

18

Page 19

g) Dual Temp Unit (S3 dip switch 6)

Dual Temp units require S3 dip switch 6 be placed in the "ON" position for proper

operation. CAUTION! Do not adjust S3 dip switch 6 out of the factory default

position on this model. This dip switch must be left in the factory default position

or this unit will not operate correctly. Factory set, no adjustment required.

S3 Dip Switch Setting

No. 6

OFF All Models Except Dual Temp

ON Dual Temp Models

Dual Temp Selector Switch

h) Freezer Evaporator Fan Operation (except RFH1) (S3 dip switch 7)

Active when S3 dip switch 1 and S3 dip switch 8 are in the "OFF" position (freezer

application). When S3 dip switch 7 is in the "ON" positon, evaporator fan operates

continuously (except during defrost) and the temperature at which the evaporator fan

resumes after defrost changes from 0°F (-17.7°C) to 70°F (21°C). When set to the

"OFF" position, the evaporator fan cycles on and off with the compressor. After defrost,

evaporator fan resumes when evaporator temperature reaches 0°F (-17.7°C).

Factory set, no adjustment required.

Note: S3 dip switch 7 is ignored when S3 dip switch 1 or S3 dip switch 8 is in the "ON"

position.

S3 Dip Switch Setting

No. 7

OFF

ON

Evap. Fan Cycles On and Off with the Compressor

After Defrost, Evap. Fan Restarts when Defrost Thermistor Reaches 0°F (-17.7°C)

After Defrost, Evap. Fan Restarts when Defrost Thermistor Reaches 70°F (21°C)

Freezer Evaporator Fan Operation

Continuous Evap. Fan (except during defrost)

i) RFH1 Condensate Pan Heater Operation (S3 dip switch 8)

Active when S3dip switch 1 is in the "OFF" position (freezer application) and S3 dip

switch6is in the "ON" position (Dual Tempapplication). When S3 dip switch 8 is in the

"OFF" position, the condensate pan heater is not active and the evaporator fan cycles

according to S3 dip switch 7 setting. When S3 dip switch 8 is in the "ON" position, the

control board energizes the condensate pan heater through the control board X5relay

(on when compressor is off) and the evaporator fan runs continuously (except in defrost).

CAUTION! Do not adjust S3 dip switch 8 out of the factory default position on this

model. This dip switch must be left in the factory default position or this unit will

not operate correctly. Factory set, no adjustment required.

Note: S3 dip switch 8 is ignored when S3 dip switch 1 is in the "ON" position or S3dip

switch 6 is in the "OFF" position.

S3 Dip Switch Setting

No. 8

OFF

ON

After Defrost, Evap. Fan Restarts when Defrost Thermistor Reaches 0°F (-17.7°C)

RFH1 Condensate Pan Heater Operation

X5 Relay Controls Condenser Fan Motor

Evap. Fan Defaults to S3 Dip Switch 7 Setting

X5 Relay Controls Condensate Pan Heater

Continuous Evap. Fan (except during defrost)

19

Page 20

5. Guarded Access Menu

Three settings can be viewed and adjusted from this menu: temperature setpoint, defrost

frequency, and temperature display scale. To enter the guarded access menu, press

and hold the up and down buttons simultaneously for 3 seconds. The current setpoint

temperature is displayed.

a) Temperature Setpoint

The temperature setpoint is the value for the average cabinet temperature. The

temperature differential for the compressor to turn on and off is ±3°F of the setpoint. For

example, setpoint = 36°F (2.2°C), compressor on at 39°F (3.9°C), compressor off at

33°F(0.6°C). If necessary, adjust the setpoint temperature as follows:

1) Press and hold the up and down buttons simultaneously for 3 seconds. The current

setpoint temperature is displayed.

2) To change the setpoint, press the up or down button until the desired value appears.

The cabinet temperature is adjustable between 36°F and 50°F (2.2°C and 10°C).

Factory default is 36°F (2.2°C).

3) Press the "ENTER" button to set the value and view the next setting. If no change in

value is desired, press the "ENTER" button repeatedly until you return to the normal

display. If you do not cycle through the menu and no button is pressed in 15 seconds,

the display returns to normal and the temperature setpoint remains unchanged.

b) Defrost Frequency

This unit uses an off-cycle defrost initiated by temperature or time. During defrost the

cabinet temperature is displayed and the condenser fan motor and evaporator fan motor

are energized.

• Defrost Initiation Temperature: 13°F (-10°C). (8°F (-13.3°C) for pass thru units).

• Defrost Termination Temperature: 40°F (4.4°C).

• Defrost Initiated Time: Adjustable between 0 and 12 defrosts per 24 hrs. The factory

default setting is 0. Before changing this setting, contact Hoshizaki Technical Support

at 1-800-233-1940 for recommendations. When changed, the defrost setting will take

effect after the next defrost based on the previous setting. If it is desired that this

change in interval timing take effect immediately, turn the unit off and back on. The next

time-initiated defrost initiates "x" hours after power is turned back on. For example, if

the setting is dF 6, x=4 the next defrost takes place 4 hours from the time that power is

turned back on.

• 1-Hour Defrost Backup Timer: When defrost is initiated (temperature or time), a 1-hour

back-up defrost timer starts. The 1-hour back-up defrost timer terminates the defrost

cycle in cases where the defrost thermistor fails to terminate the defrost cycle within

1hour.

If necessary, adjust the time-initiated defrost frequency as follows:

1) Press and hold the up and down buttons simultaneously for 3 seconds. Press the

"ENTER" button until "dF" is displayed.

2) To change the defrost frequency, press the up or down button until the desired value

appears. The defrost frequency is adjustable between 0 and 12 defrosts per 24 hrs.

20

Page 21

3) To save the value, press the "ENTER" button repeatedly until you have cycled through

the menu and the unit returns to normal display mode. If you do not cycle through the

menu and no button is pressed within 15 seconds, the display returns to normal and the

defrost frequency remains unchanged.

c) Temperature Display Scale (°F or °C)

To change the display scale, follow the steps below.

1) Press and hold the up and down buttons simultaneously for 3 seconds. Press the

"ENTER" button until "F" or "C" temperature display scale is displayed.

2) To change the temperature display, press the up or down buttons until the desired scale

is displayed. The factory default is "F".

3) Press the "ENTER" button to save the value and return to normal display mode. If

you do not press the "ENTER" button and no button is pressed within 15 seconds,

the display returns to normal display and the temperature display scale remains

unchanged.

21

Page 22

6. Service Menu

From the service menu information regarding the functioning of the unit can be obtained.

To access the service menu, press and hold the up and down buttons and the "ENTER"

button simultaneously for 3 seconds. Scroll through the service menu list using the

"ENTER" button. Change options using the up/down arrows. To exit, press the "ENTER"

button until normal display mode returns. To exit the service menu at any point, press

and hold the "ENTER" button for 3 seconds or the service menu display remains on the

display board for 10 minutes after the last keystroke, then automatically reverts to normal

operation (cabinet temperature display). All information given in degrees automatically

displays in the current selected scale (°F or °C).

Display Denition

1OFF Displays current cabinet temperature.

1 ON Displays current evaporator temperature. Display will automatically revert to cabinet sensor after ve minutes.

2OFF Manual forced defrost option not activated.

2 ON

3OFF Unconditional alarm reset option not activated.

3 ON

4 16

5 50

6 45

7 45 Length of last defrost cycle (Freezer Only).

8 67

9-10

R_ _ 0

Manual forced defrost option activated. Changing from 2OFF to 2 ON initates a forced defrost upon returning

to the normal display mode.

Unconditional alarm reset option activated. Changing from 3OFF to 3 ON resets all alarm display codes

simultaneously. This is a complete clearing of alarms.

Right two digits represent compressor run time in last 24 hours to the nearest hour. Example: 16 hours total

run time in the last 24 hours.

Right two digits represent compressor on time percentage for the last 5 run cycles. A run cycle begins when

the compressor switches from off to on and ends the next time it switches from off to on. (See diagram below).

Example: 50% run time over the last 5 run cycles.

Value is calculated as follows: Percent On Time = On Time Last 5 Cycles/Total Time Last 5 Cycles. Value is

saved every 5 cycles.

Note: "On Time Last 5 Cycles" does not include an on time that was terminated by a defrost cycle or the rst

on time after a defrost, and "Total Time Last 5 Cycles" does not include an on or off time that was terminated

by a defrost cycle, the time spent in defrost, or the rst on time after a defrost.

Right two digits represent compressor run time for the last run cycle. Example: 45 minutes of compressor run

time in last run cycle.

Right two digits represent highest cabinet temperature recorded during the last high temperature alarm.

Example: Temperature reached 67 degrees during last high temperature alarm. Display will show "8--" if there

has not been a high temperature alarm. Value is saved every 8.5 minutes when in alarm.

Right three places represent lowest cabinet temperature recorded during the last low temperature alarm.

Example: Temperature reached -10 degrees during the last low temperature alarm. Display will show "9--" if

there has not been a low temperature alarm. Value is saved every 8.5 minutes when in alarm.

The diagram below is an example of a run cycle used to calculate run time:

22

Page 23

E. Compressor Thermal Overload and Short Cycle Protection

1. Compressor Thermal Overload: When a temperature or amperage value is above the

limit specied by the compressor manufacturer, a thermal overload activates, turning off

the compressor. The compressor restarts when the thermal overload resets.

• Compressor thermal overload resets automatically.

• If the condenser fan is operating and the compressor is off, it is most likely that the

thermal overload opened.

2. Short Cycle Protection: There is a 2.5-minute compressor delay at start up and a

2.5-minute mandatory on time.

Any time the compressor turns off, it will remain off for a minimum of 2.5 minutes.

Any time the compressor starts, it will remain on for a minimum of 2.5 minutes.

Note: Time may vary with high pressure switch or thermal overload activation.

F. Perimeter Heater

This unit is equipped with a perimeter heater. The perimeter heater is controlled by

the perimeter heater switch located on the control box. To help prevent the formation

of condensation on the front frame, turn the perimeter heater on (perimeter heater

switch red marking visible). When on, the perimeter heater cycles on and off with the

compressor. If operating the unit under conditions where condensation does not form,

this heater may be turned off (perimeter heater switch red marking hidden).

G. Thermistors

The cabinet thermistor is used for cabinet temperature control and the defrost thermistor

is used for initiation and defrost termination. Thermistor resistance varies depending on

temperature. The control board monitors the resistance to control system operation. No

adjustment is required. For further details, see "IV.C. Thermistor Check."

23

Page 24

III. Technical Data

A. Wiring Diagrams

1. RH_-SSE-XX (FG, HG, FS, or HS) Models

Transformer Ouput

10V at 115VAC Input

24

Page 25

2. PTR_SSE-XXXX (FSFS, HSHS, FGFG, HGHG, HGHS) Models

25

Transformer Ouput

10V at 115VAC Input

Page 26

IV. Service Diagnosis

WARNING

1. This unit should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

2. Risk of electric shock. Use extreme caution and exercise safe electrical

practices.

3. Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

4. Make sure all food zones are clean after the unit is serviced. For cleaning

procedures, see "VI. Cleaning Instructions."

A. Diagnostic Procedure

The diagnostic procedure is basically a sequence check which can be used at unit

startup or for system diagnosis. This procedure allows you to diagnose electrical system

and component failures. Before conducting the diagnostic procedure, check for proper

voltage per unit nameplate. The maximum allowable voltage variation is ±10 percent

of the nameplate rating. Check the control board S3 dip switch settings to assure that

they are in the factory default position. Check CB using the steps in "IV.B. Control Board

Check." For factory default settings, see "II.D.4.a) Default Dip Switch Settings." The

service menu may used to view history information. To access the service menu, press

and hold the up and down buttons and "ENTER" button simultaneously for 3 seconds.

Scroll through the service menu list using the "ENTER" button. For further details, see

"II.D.6. Service Menu." As you go through the diagnostic procedure, check to assure the

components energize and de-energize correctly. If not, those components or controls are

suspect. Always choose a white (W) neutral wire to establish a good neutral connection

when checking high voltages.

IMPORTANT

The maximum allowable voltage variation is ±10 percent of the nameplate

rating. 115VAC is used as reference voltage when checking voltage to

components. Voltage may vary depending on power supply.

1) Raise the front panel and move the power switch to the "OFF" position.

2) Unplug the unit from the electrical outlet.

3) Remove the control box cover.

4) Plug the unit back into the electrical outlet.

5) Move the power switch to the "ON" position.

6) The red "POWER OK" LED on CB comes on and stays on while the unit is in operation.

26

Page 27

7) Startup–no component LEDs are on (LED 3 off for EvapFM operation): There is a

5-second delay while CB identies program revision. Revision (r###) is shown on DB.

After 5-second delay, DB shows current cabinet temperature and EvapFM energizes.

2.5 minute Comp delay timer starts. Diagnosis: Check that red "POWER OK" LED is

on. If not, verify incoming voltage supply. Check transformer input and output voltage

(115VAC input and 10VAC output voltage) and transformer continuity. If 115VAC input

and 10VAC output voltage is present, and the red "POWER OK" LED is off, CB is bad

and must be replaced. Check that EvapFM is running. If not, check EvapFM blade for

binding. Next, check for 115VAC at K1 connector pin #3 dark blue (DBU) to any white

(W) neutral wire. If 115VAC is not present, CB is bad and must be replaced. If 115VAC is

present, check EvapFM continuity.

8) Cool-Down–LED 4 (Comp) and LED 5 (ConFM) are on: EvapFM continues and

2.5 minute Comp delay timer terminates. Comp, ConFM, and PH energize (if PH switch

is in the on position (red marking visible)).

Comp Circuit Diagnosis: If Comp does not start, check for 115VAC at K1 connector

pin #10 gray (GY) wire to any white (W) neutral wire. If 115VAC is not present, CB is

bad and must be replaced. If 115VAC is present, check for 115VAC at Comp relay coil

gray (GY) wire to any white (W) neutral wire. If 115VAC is present, and Comp is not on,

check for 115VAC at Comp relay orange (O) wire to Comp relay red (R) wire. If 115VAC

is present, Comp relay is bad and must be replaced. If 115VAC is not present, check

for 115VAC at Comp relay red (R) wire to any white (W) neutral wire. If 115VAC is not

present, electronic unit is bad and must be replaced. If 115VAC is present, and Comp

is not on, remove the electronic unit to access Comp terminals. Next, check for 80VAC

from each Comp terminal to ground. If 80VAC is not present, electronic unit is bad and

must be replaced. If 80VAC is present, check Comp continuity.

ConFM Diagnosis: If ConFM does not start, check that the fan blade is not binding.

Next, check for 115VAC at red K9 connector pin #2 brown (BR) to any white (W) neutral

wire. If 115VAC is not present, CB is bad and must be replaced. If 115VAC is present,

check ConFM continuity.

If Comp and CondFM are on and the cabinet temperature is not dropping, check for

a restriction in the refrigeration circuit, correct TXV operation, and correct refrigerant

charge.

PH Diagnosis: Comp must be energized when troubleshooting PH. Conrm PH switch

is on (red marking visible). Next, check for voltage at PH switch. 115VAC should be

present from both black (BK) wires to any white (W) neutral wire. If 115VAC is present

on one and not the other, the PH switch is open. Conrm 115VAC at the PH relay coil.

Next, check for 115VAC from both black (BK) wires at the PH relay to any white (W)

neutral wire. If 115VAC is present on one and not the other, the PH relay contacts are

open. Check PH amp draw, if no amp draw is present, check the continuity of the PH.

27

Page 28

9) Defrost–LED 5 (ConFM) is on:

Temperature-Initiated Defrost: Dth cools to 13°F (-10°C), CB initiates defrost. EvapFM

and ConFM continue. Comp de-energizes. If ConFM is off, ConFM energizes once

defrost starts.

Time-Initiated Defrost: If the factory time-initiated setting is moved from 0 defrost per

24 hours, the unit enters the defrost cycle once the time of the new setting expires.

EvapFM and ConFM continue. Comp de-energizes. If ConFM is off, ConFM energizes

once defrost starts.

Defrost Termination: Dth warms to 40°F (4.4°C). EvapFM and ConFM continue.

2.5 minutes later Comp and PH (if PH switch is on (red marking visible)) energize.

Diagnosis: Has Dth cooled to 13°F (-10°C)? Conrm Dth status, see "IV.C. Thermistor

Check." Conrm that Comp stops. If not, check for 115VAC at K1 connector pin #10

gray (GY) wire to any white (W) neutral wire. If 115VAC is present, CB is bad and must

be replaced. If Comp is on and 115VAC is not present, check Comp relay for closed

contacts. Conrm EvapFM and ConFM continue to run. If not, check for 115VAC at

K1 connector pin #3 dark blue (DBU) wire to any white (W) neutral wire for EvapFM

and 115VAC at red K9 connector pin #2 brown (BR) to any white (W) neutral wire

for ConFM. If 115VAC is not present, CB is bad and must be replaced. If 115VAC is

present, check that EvapFM or ConFM is not binding. Then, check EvapFM and ConFM

windings for continuity.

Conrm defrost termination. Conrm evaporator has warmed to defrost termination

temperature of 40°F (4.4°C). Check Dth status, see "IV.C. Thermistor Check."

2.5 minutes later LED 4 comes on and Comp energizes. EvapFM and ConFM continue.

Legend: CB–control board; ConFM–condenser fan motor; Comp–compressor;

CTh–cabinet thermistor; DB–display board; DTh–defrost thermistor;

EvapFM–evaporator fan motor; PH–perimeter heater

28

Page 29

B. Control Board Check

Before replacing a control board that does not show a visible defect and that you

suspect is bad, always conduct the following check procedure. This procedure will help

you verify your diagnosis. Always choose a white (W) neutral wire to establish a good

neutral connection when checking high voltages.

Alarm Reset: If the control board is in alarm (beeping), press the "ALARM RESET"

button on the control board with power on. For alarm information, see

"II.D.3. LED Lights and Alarm Safeties Chart."

1) Check S3 dip switch settings to assure that they are in the factory default position. For

factory default settings, see "II.D.4.a) Default Dip Switch Settings."

2) Move the power switch to the "ON" position. If the "POWER OK" LED is on, the control

board voltage is good. If the "POWER OK" LED is off, check the control transformer

secondary circuit. Transformer output is 10VAC at 115VAC primary input. If the

secondary circuit has proper voltage (10VAC) and the "POWER OK" LED is off, the

control board is bad and must be replaced. See "V.J. Removal and Replacement of

Control Board."

If the secondary circuit does not have proper voltage, check the control transformer

primary circuit. Check the power switch to a white (W) neutral wire.

3) The "OUTPUT TEST" button provides a relay sequence test. Move the power switch to

the "ON" position. Next, press the "OUTPUT TEST" button. The control board cycles

through all relays in sequence. The correct LED lighting sequence is 3, 2, 1, 4, 5. Note

that the order of the LEDs from the outer edge of the board is 5, 4, 1, 2, 3. Components

(e.g., compressor) cycle during the test. Following the output test, the unit resumes

operation. If the LEDs do not light as described above, the control board is bad and

must be replaced. See "V.J. Removal and Replacement of Control Board."

4) Conrm K6 connector output voltage (5VDC). Check at the following K6 connector

locations: Pin #2 to pin #3 pink (P) wires (Clogged Filter Thermostat), pin #4 to pin

#5 light blue (LBU) wires (Door Switch), and pin #6 to pin #7 violet (V) wires (High

Pressure Switch).

5) Conrm proper output voltage (3.8VDC) at RED K4 connector (cabinet thermistor)

pin #1 to pin #2 gray (GY) wires and WHITE K3 connector (defrost thermistor) pin #1 to

pin #2 orange (O) wires.

6) As the unit cycles through the sequence of operation, check for 115VAC from

K1 connector pins to corresponding components and relays as needed.

29

Page 30

C. Thermistor Check

In the event the cabinet thermistor reading is out of range, the compressor operates on

a xed time basis of 5-minutes on and 5-minutes off.

In the event the defrost (evaporator) thermistor reading is out of range, defrost initiation

occurs every 6 hours and terminates based on cabinet thermistor temperature.

In the event of both thermistor readings are out of range, the compressor operates on a

xed time basis of 5-minutes on and 5-minutes off and the defrost cycle initiates every

6hours and terminates after 45 minutes.

To check thermistor resistance, follow the steps below.

1) Raise the front panel. Move the power switch to the "OFF" position, then unplug the unit.

2) Remove the control box cover.

3) Remove the cabinet and defrost thermistors. See "V.K. Removal and Replacement of

Thermistor."

4) Disconnect the cabinet thermistor (gray (GY) wires) from the RED K3 connector or the

defrost thermistor (orange (O) wires) from the WHITE K3 connector.

5) Immerse the thermistor sensor portion in a glass containing ice and water for 2 or

3 minutes.

6) Check the resistance between the wires at the thermistor connector (cabinet thermistor

gray (G) wires or defrost thermistor orange (O) wires). Normal reading is within 4.7 to

6.2 kΩ. If outside the normal reading, replace the thermistor.

7) Replace the thermistors in their correct position. See "V.K. Removal Replacement of

Thermistor."

8) Reconnect the red and white thermistor connectors to the control board RED K4 and

WHITE K3 thermistor connectors.

9) Replace the control box cover in its correct position.

10) Plug the unit back in. Move the power switch to the "ON" position.

11) Close the front panel.

30

Page 31

D. Diagnostic Chart

1. Unit Not Cooling

Problem Possible Cause Remedy

[1] Unit does not

start.

[2] Evaporator fan

does not start.

[3] Cool down

does not start.

(compressor)

a) Power Supply

b) Cord and Plug 1. Defective. 1. Replace.

c) Power Switch

(Control Box)

d) Control Transformer 1. Open coil winding. 1. Check continuity and replace.

e) Wiring 1. Loose connection or open. 1. Tighten, check for continuity and

f) Control Board 1. In alarm. 1. See "II.D.3. LED Lights and Alarm

g) High Pressure Switch

(3 pressure trips in

1 hour, 6 beep alarm)

h) Cabinet Thermistor 1. Defective. 1. Replace.

i) Clogged Filter Thermostat 1. Clogged lter or condenser. 1. Clean lter or condenser coil.

a) Evaporator Fan Motor 1. Defective. 1. Replace.

b) Control Board 1. Defective. 1. See "IV.B. Control Board Check."

a) Setpoint 1. Incorrect. 1. Correct setpoint.

b) Cabinet Thermistor 1. Defective. 1. Check thermistor reading and

c) Control Board 1. In alarm. 1. See "II.D.3. LED Lights and Alarm

d) High Pressure Switch

(5 pressure trips in

1 hour, 6 beep alarm)

e) Compressor Relay 1. Bad contacts. 1. Replace.

f) Electronic Unit 1. Defective. 1. See "IV.A. Diagnostic Procedure."

1. Unplugged, off, blown fuse,

or tripped or defective circuit

breaker.

2. Loose connection. 2. Tighten.

3. Not within specications. 3. Refer to nameplate and correct.

1. "OFF" Position. 1. Move to "ON" position.

2. Bad contacts. 2. Check for continuity and replace.

2. Faulty. 2. Check continuity and replace.

2. Defective. 2. Replace.

1. Bad contacts. 1. Check continuity and replace.

2. Dirty air lter or condenser. 2. Clean

3. Ambient temperature too

warm.

4. Refrigerant overcharge. 4. Recharge.

5. Condenser fan not operating. 5. Replace.

6. Refrigerant lines or

components restricted.

2. Defective. 2. Replace.

2. Defective. 2. See "IV.B. Control Board Check."

1. Bad contacts. 1. Check continuity and replace.

2. Dirty air lter or condenser. 2. Clean.

3. Ambient temperature too

warm.

4. Refrigerant overcharge. 4. Recharge.

5. Condenser fan not operating. 5. Replace.

6. Refrigerant lines or

components restricted.

2. Open coil windings. 2. Replace.

1. Turn on, reset, or replace.

repair.

Safeties Chart."

3. Reduce temperature.

6. Recover, repair, replace drier,

evacuate, and recharge.

Factory defaults:

Refrigerator 36°F (2°C).

position. Replace.

Safeties Chart."

3. Reduce temperature.

6. Recover, repair, replace drier,

evacuate, and recharge.

31

Page 32

[3] Cool down

does not start.

(compressor)

(continued)

[4] Cool down starts,

temperature does

not drop.

g) Overload 1. Open. 1. Let compressor cool and overload

reset. If overload does not reset,

replace compressor. If overload

resets, check compressor

amperage and operating voltage.

2. Clogged lter or condenser

coil.

3. Condenser fan not operating. 3. Replace.

4. Defective. 4. Replace.

5. Open coil windings. 5. Replace.

h) Compressor 1. Defective. 1. Replace.

a) Location of Unit 1. Restricted air ow to

condenser or ambient

temperature too high.

b) Cabinet Temperature too

High

c) Setpoint 1. Incorrect. 1. Correct setpoint.

d) Door 1. Left open, opened too often. 1. Close, check for door open

e) Cabinet Thermistor 1. Defective. 1. Check thermistor reading and

f) Clogged Filter Thermostat 1. Clogged lter or condenser

g) Evaporator 1. Clogged or frozen. 1. Clean. Defrost and check defrost

h) Evaporator Fan Motor 1. Defective. 1. Replace.

i) Defrost 1. Not enough defrosts

j) Control Board 1. Defective. 1. See "IV.B. Control Board Check."

k) Refrigerant/Refrigerant

Lines

l) Expansion Valve (TXV)

(not adjustable)

m) Electronic Unit Voltage 1. Defective. 1. Replace.

n) Compressor 1. Defective. 1. Replace.

1. Warm food recently placed in

cabinet area.

2. Air ow blocked. 2. Remove blockage or redistribute

2. Not sealing. 2. Check for proper sealing.

coil.

2. Defective. 2. Replace.

occurring per day.

2. Defrost Thermistor. 2. Check position and ohm reading.

3. Control Board. 3. Replace.

1. Gas leaks. 1. Check for leaks with a leak

2. Refrigerant lines restricted. 2. Recover, repair, replace drier,

1. Defective. 1. Replace.

2. Clean.

1. Increase ventilation or lower

ambient temperature.

1. Pre-cool food product or allow

time for unit to return to normal

setpoint temperature.

food products.

Factory defaults:

Refrigerator 36°F (2°C).

at time of warm cabinet

temperature.

position. Replace.

1. Clean lter or condenser coil.

cycle.

1. See "II.D.5.b) Defrost

Frequency."

Reposition in evaporator. See

"IV.C. Thermistor Check."

detector. Repair leaks.

Replace drier, evacuate and

recharge. See "V.A. Service for

Refrigerant Lines."

evacuate, and recharge.

32

Page 33

[5] Cabinet

Temperature

Too Low

a) Setpoint 1. Incorrect. 1. Correct setpoint.

b) Cabinet Thermistor 1. Defective. 1. Check and replace.

c) Evaporator Fan Motor 1. Defective. 1. Replace.

d) Control Board 1. Defective. 1. See "IV.B. Control Board Check."

2. Evaporator is Frozen Up

[1] Evaporator does

not defrost

completely.

[2] Compressor on

during defrost.

a) Defrost Frequency 1. Not enough defrosts

b) Defrost Thermistor 1. Out of position or defective. 1. Reposition or replace.

c) Control Board 1. Defective. 1. Replace.

a) Compressor Relay 1. Bad Contacts. 1. Replace.

b) Control Board 1. Defective. 1. See "IV.B. Control Board Check."

3. Defrost Fails to Terminate

[1] Defrost cycle

too long.

[2] Compressor

operates during

defrost.

a) Defrost Thermistor 1. Out of position or defective. 1. Reposition or replace.

b) Defrost Frequency 1. Not enough defrosts

c) Control Board 1. Defective. 1. See "IV.B. Control Board Check."

a) Compressor Relay 1. Bad Contacts. 1. Replace relay.

b) Control Board 1. Defective. 1. Replace.

Factory defaults:

Refrigerator 36°F (2°C).

1. See "II.D.5. b) Defrost Frequency."

occurring per day.

Operation in humid

conditions.

1. See "II.D.5.b) Defrost Frequency."

occurring per day. Operation

in humid conditions.

4. Other

[1] Abnormal Noise. a) Fasteners 1. Loose fasteners allow

vibration of part.

b) Compressor 1. Problem with mount or

electronic unit.

2. Floodback to compressor. 2. Check for signs of oodback

3. Defective. 3. Replace.

[2] Condensate

water overow.

c) Fan (evaporator or

condenser)

d) Relay 1. Chattering. 1. Replace.

a) Cabinet Contents 1. Loading of large volumes

b) Location of Unit 1. Unit located near high

c) Seals 1. Poor sealing around

d) Environment 1. Extreme environment and

1. Fan blade loose. 1. Adjust and tighten.

2. Defective motor. 2. Replace.

of warm, moist, uncovered

product.

humidity source such as

fryer, steamer, etc.

evaporator, door gaskets.

door-opening conditions.

1. Tighten fasteners.

1. Properly mount compressor.

Replace any missing grommets.

to compressor. Evacuate and

recharge if necessary.

1. Allow product to cool before

placing in cabinet. Cover

product with plastic wrap.

1. Relocate.

1. Adjust or replace.

1. Adjust conditions.

33

Page 34

V. Removal and Replacement of Components

WARNING

1. This unit should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

2. Move the power switch to the "OFF" position and unplug the unit from the

electrical outlet before servicing.

A. Service for Refrigerant Lines

WARNING

1. Repairs requiring the refrigeration circuit to be opened must be performed by

properly trained and EPA-certied service personnel.

2. Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

3. Use an electronic leak detector or soap bubbles to check for leaks. Add a

trace of refrigerant to the system (if using an electronic leak detector), and

then raise the pressure using nitrogen gas (140 PSIG). DO NOT use R-134a

as a mixture with pressurized air for leak testing.

CAUTION

1. Do not leave the system open for longer than 15 minutes when replacing or

servicing parts. The Polyol Ester (POE) oils used in R-134a units can absorb

moisture quickly. Therefore it is important to prevent moisture from entering

the system when replacing or servicing parts.

2. Always install a new drier every time the sealed refrigeration system is

opened.

3. Do not replace the drier until after all other repair or replacement has been

made. Install the new drier with the arrow on the drier in the direction of the

refrigerant ow.

4. When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

1. Refrigerant Recovery

The unit is provided with refrigerant access valves. Using proper refrigerant practices

recover the refrigerant from the access valves and store it in an approved container. Do

not discharge the refrigerant into the atmosphere.

34

Page 35

2. Brazing

WARNING

1. R-134a itself is not ammable at atmospheric pressure and temperatures up

to 176°F (80°C).

2. R-134a itself is not explosive or poisonous. However, when exposed to high

temperatures (open ames), R-134a can be decomposed to form hydrouoric

acid and carbonyl uoride both of which are hazardous.

3. Do not use silver alloy or copper alloy containing arsenic.

4. Use an electronic leak detector or soap bubbles to check for leaks. Add a

trace of refrigerant to the system (if using an electronic leak detector), and

then raise the pressure using nitrogen gas (140PSIG). DO NOT use R-134a

as a mixture with pressurized air for leak testing.

1) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.

CAUTION

1. Always install a new drier every time the sealed refrigeration system is

opened.

2. Do not replace the drier until after all other repair or replacement has been

made. Install the new drier with the arrow on the drier in the direction of the

refrigerant ow.

3. When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

2) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). DO NOT use R-134a as a mixture with

pressurized air for leak testing.

Note: Because the pipes in the evaporator case are specially coated to resist corrosion,

it is important to make connections outside the evaporator case when possible. If

it is necessary to braze inside the evaporator case, use sandpaper to remove the

coating from the brazing connections before unbrazing the components.

3. Evacuation and Recharge (R-134a)

1) Attach a vacuum pump to the system. Be sure the charging hoses are connected to both

high and low-side access valves.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump. Never allow the oil in the vacuum pump to ow backwards.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period depends

on pump capacity.

35

Page 36

4) Close the low-side valve and high-side valve on the service manifold.

5) Disconnect the gauge manifold hose from the vacuum pump and attach it to a

refrigerant service cylinder. Remember to loosen the connection and purge the air from

the hose. See the nameplate for the required refrigerant charge. Hoshizaki recommends

only virgin refrigerant or reclaimed refrigerant which meets ARI Standard 700 (latest

edition) be used.

6) A liquid charge is recommended for charging an R-134a system. Invert the service

cylinder and place it on scales. Open the high-side valve on the gauge manifold valve.

7) Allow the system to charge with liquid until the proper charge weight is met.

8) If necessary, add any remaining charge to the system through the low-side. Use a

throttling valve or liquid dispensing device to add the remaining liquid charge through

the low-side access port with the unit running.

9) Close gauge manifold valves and disconnect the hoses and service manifold.

10) Cap the access valves to prevent a possible leak.

B. Removal and Replacement of Compressor

CAUTION

1. Always install a new drier every time the sealed refrigeration system is

opened.

2. Do not replace the drier until after all other repair or replacement has been

made. Install the new drier with the arrow on the drier in the direction of the

refrigerant ow.

3. When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

Note: Due to the ability of the POE oil in the compressor to absorb moisture quickly,

the compressor must not be opened more than 15 minutes for replacement or

service. Do not mix lubricants of different compressors even if both are charged

with R-134a, except when they use the same lubricant.

1) Raise the front panel. Then, move the power switch to the "OFF" position and unplug

the unit.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container. See "V.A. Service for

Refrigerant Lines."

4) Loosen the 2 screws securing the compressor electronic unit to the compressor. See

Fig. 3. Remove the electronic unit from the compressor.

5) Remove the discharge and suction pipes.

6) Remove the hold-down bolts, washers, and rubber grommets.

7) Remove the compressor.

8) Place the new compressor in position and secure it using the grommets, washers and

bolts.

36

Page 37

9) Remove the drier, then place the new drier in position.

11) Remove plugs from the suction, discharge, and process pipes.

12) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.

See "V.A.2. Brazing."

13) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). DO NOT use R-134a as a mixture with

pressurized air for leak testing.

14) Evacuate the system, and charge it with refrigerant. See "V.A.3. Evacuation and

Recharge (R-134a)." See the nameplate for the required refrigerant charge.

15) Connect and secure the compressor electronic unit to the new compressor.

16) Replace the panels in their correct positions.

17) Plug the unit back in. Move the power switch to the "ON" position.

18) Close the front panel.

C. Removal and Replacement of Compressor Electronic Unit

CAUTION! Do not attempt to repair the compressor electronic unit.

1) Raise the front panel, then move the power switch to the "OFF" position and unplug the

unit.

2) Remove the rear panel.

3) Loosen the 2 screws securing the compressor electronic unit to the compressor. See

Fig. 3. Remove the electronic unit from the compressor.

4) Remove the wire cover from the compressor electronic unit, then disconnect the wires

from the compressor electronic unit.

5) Remove the wire cover from the new compressor electronic unit and connect the wires.

Replace and secure the wire cover.

6) Secure the new electronic unit to the compressor.

7) Replace the rear panel in its correct position.

8) Plug the unit back in. Move the power switch to the "ON" position.

9) Close the front panel.

Variable Speed Compressor

Electronic Unit

Mounting Screws

Fig. 3

37

Compressor Electronic Unit

Page 38

D. Removal and Replacement of Expansion Valve

Moisture in the refrigeration circuit may exceed drier capacity and freeze up at the

expansion valve.

CAUTION

1. Always install a new drier every time the sealed refrigeration system is

opened.

2. Do not replace the drier until after all other repair or replacement has been

made. Install the new drier with the arrow on the drier in the direction of the

refrigerant ow.

3. When brazing, protect the valve body and drier by using wet cloths to prevent

the valve body and drier from overheating. Do not allow the valve body or

drier to exceed 250°F (121°C).

1) Raise the front panel, then move the power switch to the "OFF" position and unplug the

unit.

2) Remove the evaporator case cover and panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the insulation and the expansion valve bulb on the suction line.

5) Remove the expansion valve cover and disconnect the expansion valve. Place the new

expansion valve in position.

6) Remove the drier, then place the new drier in position.

7) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.

See "V.A.2. Brazing."

8) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). DO NOT use R-134a as a mixture with

pressurized air for leak testing.

9) Evacuate the system, and charge it with refrigerant. See "V.A.3. Evacuation and

Recharge (R-134a)." See the nameplate for the required refrigerant charge.

10) Attach the expansion valve bulb to the suction line in the same location as the previous

bulb. The bulb should be between the 10 and 2 o'clock position on the tube. Be sure to

secure the bulb with the clamp and holder and to insulate it.

11) Place the expansion valve cover in position.

12) Replace the evaporator case cover and panels in their correct positions.

13) Plug the unit back in. Move the power switch to the "ON" position.

14) Close the front panel.

38

Page 39