Page 1

Hoshizaki America, Inc.

Hoshizaki

Stackable Square Cuber

Model

IM-500SAA

“A Superior Degree

of Reliability”

www.hoshizaki.com

SERVICE MANUAL

Number: M029-897

Issued: 2-8-2013

Revised: 5-19-2014

Page 2

WARNING

Only qualied service technicians should install and service the appliance. To

obtain the name and phone number of your local Hoshizaki Certied Service

Representative, visit www.hoshizaki.com. No service should be undertaken until

the technician has thoroughly read this Service Manual. Failure to service and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage and may result in costly water

damage. Proper installation is the responsibility of the installer. Product failure or

property damage due to improper installation is not covered under warranty.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service of the appliance.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, send an e-mail message, or write to the Hoshizaki Technical

Support Department for assistance.

Phone: 1-800-233-1940; (770) 487-2331

Fax: 1-800-843-1056; (770) 487-3360

E-mail: techsupport@hoshizaki.com

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

2

Page 3

IMPORTANT

This manual should be read carefully before the appliance is serviced. Read

the warnings and guidelines contained in this manual carefully as they provide

essential information for the continued safe use, service, and maintenance of the

appliance. Retain this manual for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 4

I. Construction and Water/Refrigeration Circuit Diagram ....................................................... 6

A. Construction .................................................................................................................. 6

B. Water/Refrigeration Circuit Diagram .............................................................................. 7

II. Sequence of Operation and Service Diagnosis ................................................................. 8

A. Sequence of Operation Flow Chart ............................................................................... 8

B. Sequence of Operation ................................................................................................. 9

1. Startup Cycle ............................................................................................................ 9

2. Harvest Cycle .......................................................................................................... 9

3. Freeze Cycle ............................................................................................................ 9

4. Shutdown ............................................................................................................... 10

C. Service Diagnosis Table ...............................................................................................11

D. Bin Control Check and Cleaning ................................................................................. 14

1. Bin Control Check .................................................................................................. 14

2. Bin Control Cleaning .............................................................................................. 15

E. Evaporator Thermistor Check ...................................................................................... 16

III. Controls and Adjustments ............................................................................................... 17

A. Control Switch ............................................................................................................. 17

B. Control Board .............................................................................................................. 17

1. Control Board Layout ............................................................................................. 18

C. Control Buttons ............................................................................................................ 19

D. Control Board Settings ................................................................................................ 20

E. Control Board Information Display .............................................................................. 23

F. Control Board Model Code Setting .............................................................................. 25

1. Control Board Replacement ................................................................................... 25

2. Checking or Changing the Control Board Model Code .......................................... 25

G. Error Codes ................................................................................................................ 27

H. Quick Adjustments ...................................................................................................... 28

1. Dimple Diameter .................................................................................................... 28

2. Ice Clarity .............................................................................................................. 29

IV. Refrigeration Circuit and Component Service Information.............................................. 30

A. Refrigeration Circuit Service Information .................................................................... 30

B. Component Service Information .................................................................................. 32

V. Maintenance .................................................................................................................... 34

VI. Preparing the Icemaker for Periods of Non-Use ............................................................. 35

VII. Disposal ......................................................................................................................... 36

VIII. Technical Information .................................................................................................... 37

A. Specication Data ....................................................................................................... 37

B. Performance Data ....................................................................................................... 38

C. Wiring Diagram ........................................................................................................... 39

3

Page 4

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, damage to the appliance, or damage to property.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

NOTICE Indicates a situation which could result in damage to the

appliance or property.

IMPORTANT Indicates important information about the use and care of the

appliance.

WARNING

The appliance should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for injury or damage resulting from

improper, incorrect, and unreasonable use. Failure to service and maintain the

appliance in accordance with this manual will adversely affect safety, performance,

component life, and warranty coverage and may result in costly water damage.

To reduce the risk of death, electric shock, serious injury, or re, follow basic

precautions including the following:

• Only qualied service technicians should install and service this appliance.

• The appliance must be installed in accordance with applicable national, state, and

local codes and regulations. Failure to meet these code requirements could result in

death, electric shock, serious injury, re, or damage to the appliance.

• Electrical connection must be hard-wired and must meet national, state, and local

electrical code requirements. Failure to meet these code requirements could result

in death, electric shock, serious injury, re, or damage.

• The icemaker requires an independent power supply of proper capacity. See the

nameplate for electrical specications. Failure to use an independent power supply

of proper capacity can result in a tripped breaker, blown fuse, damage to existing

wiring, or component failure. This could lead to heat generation or re.

• THE ICEMAKER MUST BE GROUNDED. Failure to properly ground the icemaker

could result in death or serious injury.

• To reduce the risk of electric shock, do not touch the control switch with damp

hands.

• Move the control switch to the "OFF" position and turn off the power supply before

servicing. Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

• Do not make any alterations to the appliance. Alterations could result in electric

shock, serious injury, re, or damage.

4

Page 5

WARNING, continued

• The appliance is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

• Children should be properly supervised around the appliance.

• Do not climb, stand, or hang on the appliance or allow children or animals to do so.

Serious injury could occur or the appliance could be damaged.

• Do not use combustible spray or place volatile or ammable substances near the

appliance. They might catch re.

• Keep the area around the appliance clean. Dirt, dust, or insects in the appliance

could cause harm to individuals or damage to the appliance.

NOTICE

• Follow the instructions in this manual carefully to reduce the risk of costly water

damage.

• In areas where water damage is a concern, install in a contained area with a oor

drain.

• Install the appliance in a location that stays above freezing. Normal operating

ambient temperature must be within 45°F to 100°F (7°C to 38°C).

• Do not leave the appliance on during extended periods of non-use, extended

absences, or in sub-freezing temperatures. To properly prepare the appliance for

these occasions, follow the instructions in "VI. Preparing the Icemaker for Periods of

Non-Use."

• Do not place objects on top of the appliance.

• The dispenser unit/ice storage bin is for ice use only. Do not store anything else in

the dispenser unit/ice storage bin.

5

Page 6

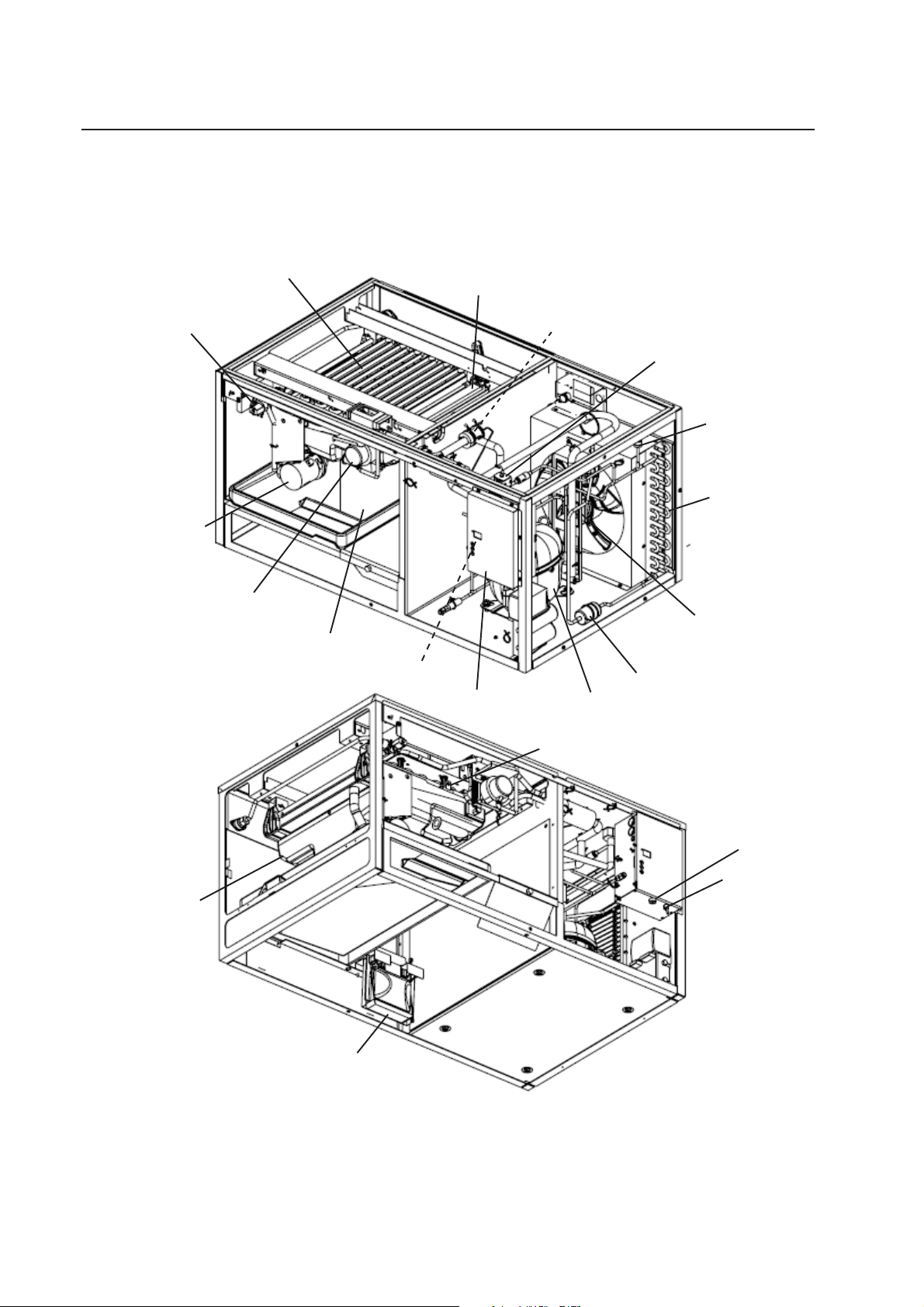

I. Construction and Water/Refrigeration Circuit Diagram

A. Construction

1. Air-Cooled Model (SAA)

Inlet Water Valve

Pump Motor

Actuator Motor

Evaporator

Drain Pan

Control Board Thermistor

Water Plate

Control Box

Thermostatic Expansion Valve

Hot Gas Valve

High-Pressure

Switch

Condenser

Fan Motor

Drier

Compressor

Water Tank

Evaporator Thermistor

Fuse Holder

Control

Switch

Bin Control

Model Shown: IM-500SAA

6

Page 7

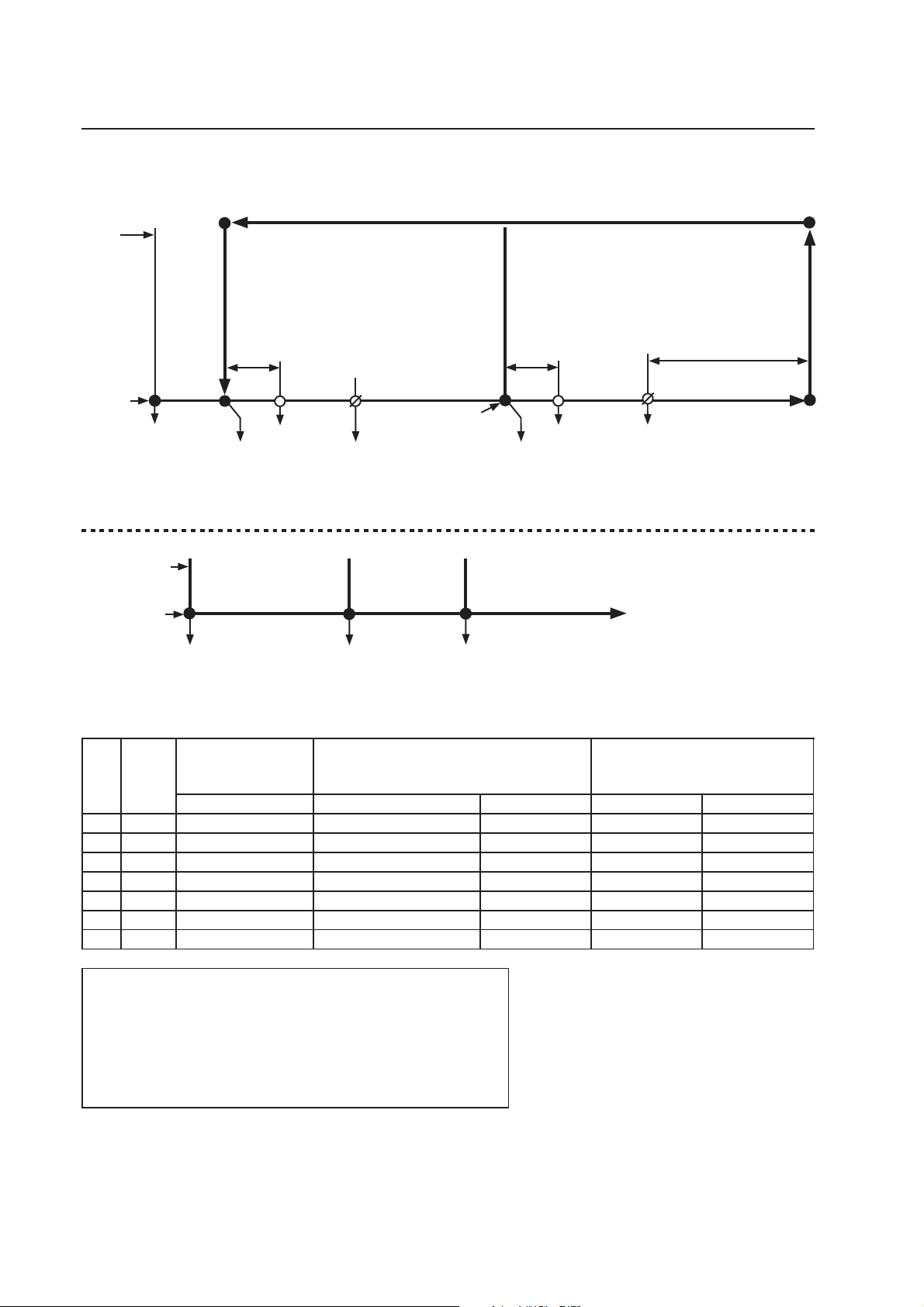

B. Water/Refrigeration Circuit Diagram

1. Air-Cooled Model (SAA)

Inlet

Water

Valve

Thermostatic Expansion Valve

Evaporator

Evaporator Thermistor

Hot Gas

Valve

Strainer

Water

Pump

Condenser

Fan Motor

Compressor

Water Tank

Heat Exchanger

Drier

Water Circuit

Refrigerant Circuit

7

Page 8

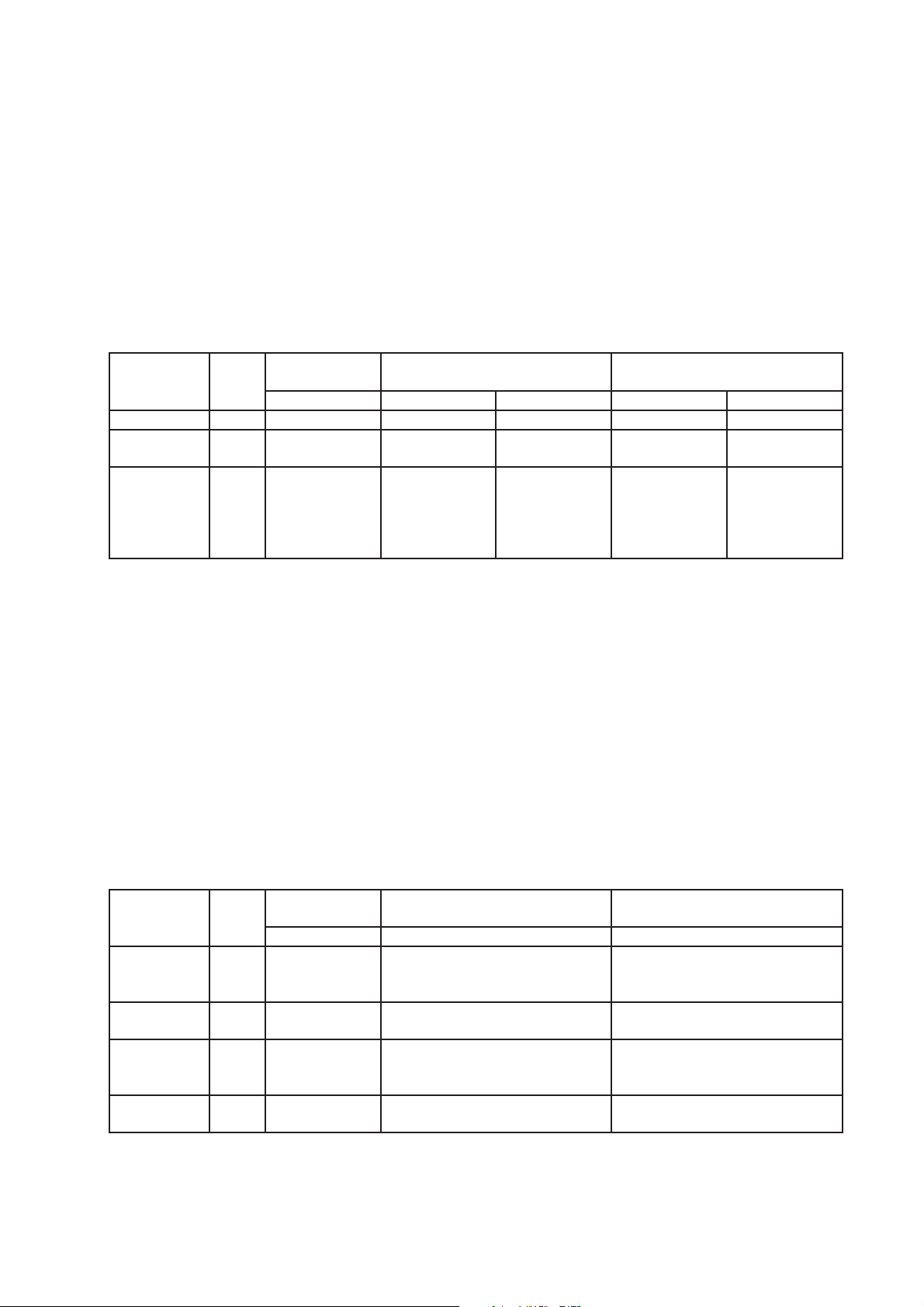

II. Sequence of Operation and Service Diagnosis

A. Sequence of Operation Flow Chart

"IM" Control Board

Cycle

Steps

Startup

HGV energized

Shutdown and Restart Sequence Flow Chart

Shutdown

and Restart

BC Operation

1. 30-Sec.

Startup

Cycle

1. Bin Full

2. Harvest Cycle

• HGV: If CBT≤81°F (27°C) (CB Setting

74), HGV repeatedly energizes 40sec./

de-energizes 40 sec.

• FM: If CBT≥118°F (48°C) (CB Setting 34),

FM operates continuously in harvest cycle

• Max. harvest time: 30 min.

WV Delay PM Delay

*1

WV energized *2

HGV continues

AMD energized

Comp energized

ET≥41°F (5°C)

(CB Setting 1)

Water Tank Closed

(Actuator Motor PS)

Comp continues

AMU energized

FM energized

WV energized *3

HGV de-energized

2. Icemaker Off

3. Freeze Cycle

• Max. freeze time: 45 min. (CB Setting 6)

*4

PM energized

Comp continues

FM continues

WV energized *4+*5

3. Ice Level Lowered

ET≤-1.3°F (-18.5°C)

(CB Setting 2)

Time varies based on

control board calculation

If CBT>81°F (27°C) (CB

Setting 74) and CBT≤111°F

(44°C) (CB Setting 70), HGV

energizes 5sec./de-energizes

25 sec./energizes 5 sec. (CB

Setting 71, 72)

Icemaker restarts at

1.30-Sec. Startup Cycle.

Note

CB

Setting

BC open 10 sec. or more

(BC actuator paddle

engaged). Shutdown

occurs at end of harvest

cycle.

Initial Harvest and

Initial Freeze after

Power On

All components

de-energized.

BC closed 80 sec. or more

(BC actuator paddle

disengaged).

Initial Harvest and Initial Freeze after

Bin Control Initiated Restart

Normal Harvest and Freeze

All WT WT>48°F (9°C) WT≤48°F (9°C) WT>48°F (9°C) WT≤48°F (9°C)

*1 NA 20 sec. 0 sec. 0 sec. 20 sec. 20 sec.

*2 10, 11 95 sec. 10 sec. (CB Setting NA) 95 sec. 30 sec. 95 sec.

*3 NA 10 sec. 0 sec. 10 sec. 0 sec. 10 sec.

PD*4 12 30 sec. × 2 30 sec. × 2 30 sec. × 2 30 sec. 30 sec.

PD*5 15 22 sec. × 2 22 sec. × 2 22 sec. × 2 22 sec. 22 sec.

FD*4 12 60 sec. 60 sec. 60 sec. 60 sec. 60 sec.

FD*5 15 44 sec. 44 sec. 44 sec. 44 sec. 44 sec.

Legend:

AMD–actuator motor down

AMU–actuator motor up

BC–bin control

CBT–control board thermistor

Comp–compressor

ET–evaporator thermistor

FD–full drain (CB Setting 14)

FM–fan motor

HGV–hot gas valve

PD–partial drain (CB Setting 14)

PM–pump motor

PS–position sensor

WT–water temperature

WV–inlet water valve

8

Page 9

B. Sequence of Operation

1. Startup Cycle

When power supply is turned on, "on" appears on CB display and HGV energizes.

30sec. later, harvest cycle starts.

• If the "RESET" button is pressed during 30-sec. startup cycle time, startup cycle ends

immediately and harvest cycle starts.

2. Harvest Cycle

HGV continues. Comp and AMD energize. WV energizes as listed in table below.

Initial Harvest

CB

Note

WV Delay NA 20 sec. 0 sec. 0 sec. 20 sec. 20 sec.

WV Time after

WV Delay

WV Time

when

ET≥41°F

(5°C)

(CB Setting 1)

Setting

10, 11 95 sec. 10 sec.

NA 10 sec. 0 sec. 10 sec. 0 sec. 10 sec.

after Power On

All WT WT>48°F (9°C) WT≤48°F (9°C) WT>48°F (9°C) WT≤48°F (9°C)

Initial Harvest after Bin Control

Initiated Restart

95 sec. 30 sec. 95 sec.

(CB Setting NA)

Normal Harvest

Note: ET temperature is recorded 30 seconds after PM energizes in the preceding

freeze cycle. Water temperature correction value (CB Setting 13) is added to ET

temperature and this is used as WT value.

If CBT≤81°F (27°C) (CB Setting 74) at beginning of harvest cycle, HGV repeatedly

energizes 40sec./de-energizes 40 sec. If CBT≥118°F (48°C) (CB Setting 34) at

beginning of harvest cycle, FM operates continuously in harvest cycle.

When ET reaches harvest cycle termination temperature (CB Setting 1) of 41°F (5°C) ,

HGV de-energizes, FM and AMU energize. Comp continues. WV energizes as listed in

table above. Harvest cycle is complete when actuator motor PS indicates water tank is

fully closed.

3. Freeze Cycle

Comp and FM continue. WV energizes for total time of WV Time 1 and WV Time 2 listed

in table below. PM energizes after PM delay listed in table below.

Note

PD

WV Time 1

and PM Delay

PD

WV Time 2

FD

WV Time 1

and PM Delay

FD

WV Time 2

CB

Setting

12 30 sec. × 2 30 sec. × 2 30 sec.

15 22 sec. × 2 22 sec. × 2 22 sec.

12 60 sec. 60 sec. 60 sec.

15 44 sec. 44 sec. 44 sec.

Initial Freeze

after Power On

All WT All WT All WT

Initial Freeze after Bin Control

Initiated Restart

Normal Freeze

9

Page 10

ET temperature is recorded 30 seconds after PM energizes. Water temperature

correction value (CB Setting 13) is added to ET temperature and this is used as WT

value in following harvest cycle.

If CBT>81°F (27°C) (CB Setting 74) and CBT≤111°F (44°C) (CB Setting 70), when

ET≤-1.3°F (-18.5°C) (CB Setting 2), HGV energizes 5 sec., de-energizes 25 sec.,

energizes 5 sec. (CB Settings 71 and 72) to reduce bonding of the water tank to the

evaporator.

CB monitors time after ET temperature≤32°F (0°C). CB terminates freeze cycle when the

following equation is satised:

temp. (absolute value) × time (min.) = (absolute value of CB Setting 2) × (CB Setting 3)

Using default settings, freeze cycle is terminated when:

temp. (absolute value) × time (min.) = 185

This formula helps maintain consistent dimple size regardless of differences in seasonal

ambient and water temperatures.

4. Shutdown

When BC is engaged (open) for more than 10 seconds, the icemaker shuts down after

harvest cycle.

When BC is disengaged (closed) for more than 80 seconds, icemaker restarts at startup

cycle.

If BC is engaged (open) while the water tank is opening after the power supply is turned

on (or after the "RESET" button is pressed), shutdown does not start: Shutdown occurs

10seconds after actuator motor's internal position sensor indicates water tank is fully

open.

Legend: AMD–actuator motor down; AMU–actuator motor up; BC–bin control; CB–control

board; CBT–control board thermistor; Comp–compressor; ET–evaporator

thermistor; FD–full drain (CB Setting 14); FM–fan motor; HGV–hot gas valve;

PM–pump motor; PD–partial drain (CB Setting 14); PS–position sensor; WT–water

temperature; WV–inlet water valve

10

Page 11

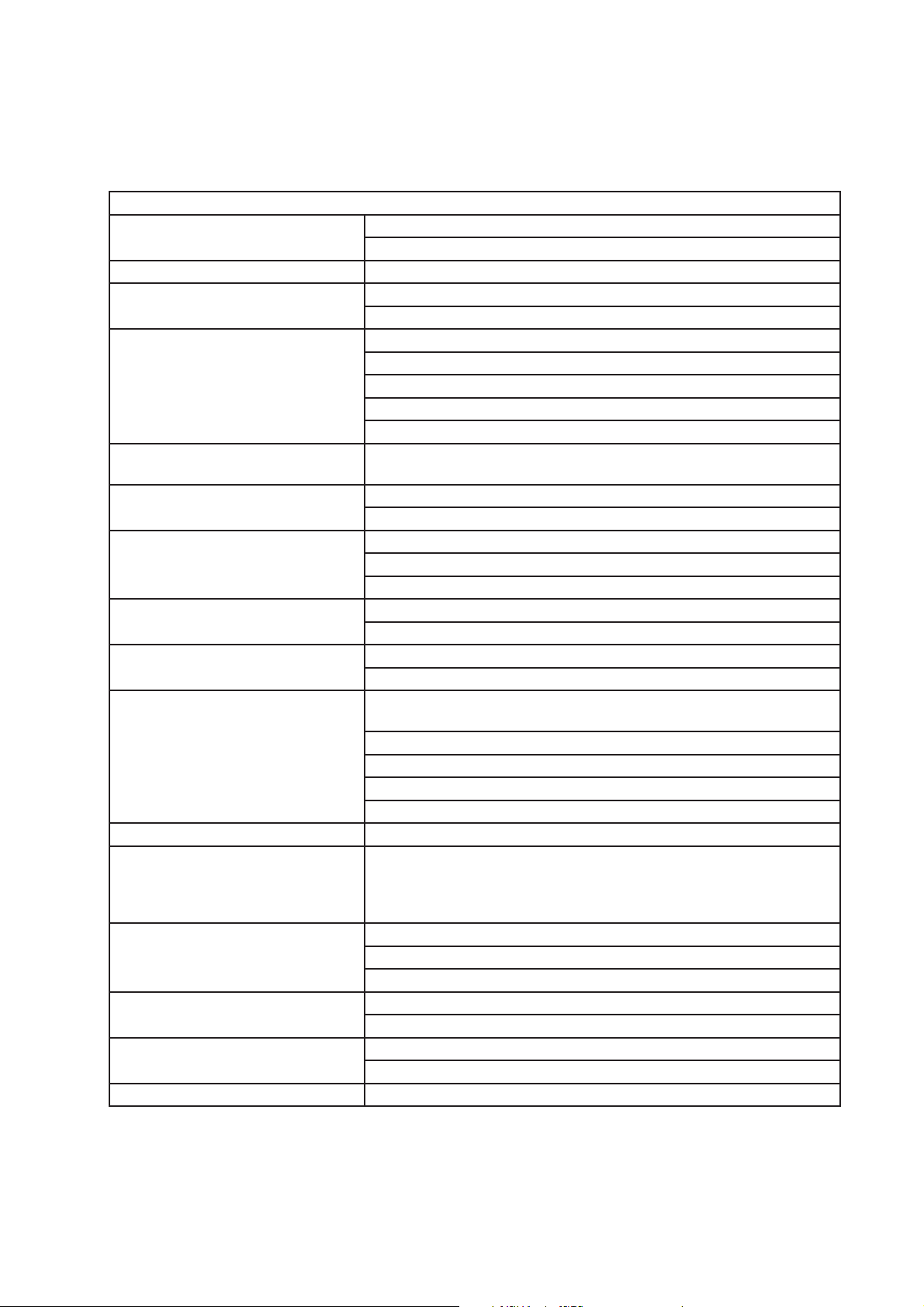

C. Service Diagnosis Table

First see "III.G. Error Codes." If there are no recorded errors, refer to the table below.

No Ice Production - Possible Cause

1. Power Supply a) Off, blown fuse, or tripped breaker.

b) Not within specications.

2. Fuse (Control Box) a) Blown.

3. Control Switch a) In "OFF" or "WASH" position.

b) Bad contacts.

4. High-Pressure Switch a) Dirty condenser or air lter.

b) Fan motor not operating.

c) Refrigerant overcharged.

d) Bad contacts.

e) Refrigerant lines or components restricted.

5. Control Transformer

(115VAC/10.5VAC)

6. Control Board a) Error. See "III.G. Error Codes."

7. Bin Control

See "II.D. Bin Control Check and

Cleaning"

8. Water Supply a) Water supply off or improper water pressure.

9. Inlet Water Valve a) Screen or orice restricted.

10. Compressor a) Compressor relay/magnetic contactor contacts bad or coil winding

11. Hot Gas Valve a) Defective.

12. Evaporator (Cube Control)

Thermistor

See "II.E. Evaporator Thermistor

Check"

13. Pump Motor a) Mechanical seal worn out.

14. Thermostatic Expansion Valve a) Bulb loose.

15. Fan Motor a) Defective.

16. Water System a) Water leaks.

a) Coil winding open or shorted.

b) Defective.

a) Tripped with bin lled with ice.

b) Actuator does not move freely.

c) Defective.

b) External water lters restricted.

b) Coil winding open.

open.

b) Start capacitor or run capacitor defective (single phase).

c) Internal protector open.

d) Start relay contacts bad or coil winding open (single phase).

e) Defective.

a) Loose, disconnected, or defective.

b) Defective.

c) Defective capacitor.

b) Defective.

b) Defective capacitor.

11

Page 12

Low Ice Production - Possible Cause

Long Harvest Cycle

1. Evaporator a) Scaled up.

2. Refrigerant Charge a) Low.

3. Control Board a) Thermistor connection loose (K3).

b) Defective.

4. Evaporator (Cube Control)

Thermistor

See "II.E. Evaporator Thermistor

Check"

5. Hot Gas Valve a) Erratic or closed.

6. Compressor a) Inefficient or off.

7. Thermostatic Expansion Valve a) Defective.

1. Evaporator a) Scaled up, dirty.

2. Hot Gas Valve a) Defective.

3. Condenser a) Restricted.

4. Control Board a) Defective.

5. Refrigerant Charge a) Low.

6. Thermostatic Expansion Valve a) Bulb loose.

7. Compressor a) Inefficient or off.

a) Loose, disconnected, or defective.

Long Freeze Cycle

b) Defective.

Slab Does Not Break Into Separate Cubes - Possible Cause

1. Spring a) Over-extended.

2. Water Plate a) Obstacle caught between evaporator and water plate.

Cubes Drop Separately - Possible Cause

1. Refrigerant Charge a) Low - Long harvest cycle.

2. Cam Arm a) Worn out.

Imperfect Ice Production - Possible Cause

1. Water Supply a) Improper water pressure.

b) External water lters restricted.

c) Water leaks from water tank or water plate due to broken tank or

plate or icemaker out of level.

2. Inlet Water Valve a) Water leaks from valve body or water supply pipe joint.

3. Water Plate a) Spray holes restricted.

4. Pump Motor a) Defective.

Large-Hole Cubes - Possible Cause (Also see III.H.1. Dimple Diameter")

1. Refrigerant Charge a) Low.

2. Condenser a) Dirty condenser or air lter.

3. Fan Motor a) Defective.

12

Page 13

Large-Hole Cubes - Possible Cause (Also see III.H.1. Dimple Diameter")

4. Icemaker Location a) Insufficient clearance.

b) Ambient temperature too high.

5. Water Supply a) Water leaks.

b) Improper water pressure.

Cloudy Cubes - Possible Cause

1. Water Quality a) High hardness. See "III.H.2. Ice Clarity."

2. Slush Ice a) Use Anti-Slush Control (Control Board Settings 50 and 51).

13

Page 14

D. Bin Control Check and Cleaning

1. Bin Control Check

This appliance uses a lever-actuated proximity switch to control the ice level in the

storage bin. No adjustment is required.

To check, follow the steps below.

1) Turn off the power supply.

2) Remove the front panel, then move the control switch to the "OFF" position.

3) Remove the control box cover. Clear any ice away from BC.

4) Check BC wire harness connections.

5) Disconnect BC wire harness connector from CB CN11 connector.

6) Check for continuity across the wires of BC wire harness connector. When the actuator

paddle is not engaged, BC switch is closed. If open, check that the wire harness

connector is properly connected and that the actuator paddle is not sticking. Clean if

necessary. See "II.D.2. Bin Control Cleaning." If BC switch still reads open, replace BC.

7) Press and hold the actuator paddle; check for continuity across the wires of BC wire

harness connector. When the actuator paddle is engaged, BC switch is open. If closed,

check that the actuator paddle is not restricted. Clean if necessary. See "II.D.2. Bin

Control Cleaning." If BC switch still reads closed, replace BC.

8) Reconnect BC wire harness connector to CB CN11 connector, then move the control

switch to the "ICE" position. Turn on the power supply.

9) Allow the icemaker to cycle on. Press and hold the actuator paddle for at least

10seconds. The icemaker should shut down. If it does not, replace CB.

Note: If BC is engaged (open) while the water tank is opening after the power supply

is turned on (or after the "RESET" button is pressed), shutdown does not start:

Shutdown occurs 10seconds after actuator motor's internal position sensor

indicates water tank is fully open.

Legend: BC–bin control; CB–control board

Bin Control Bracket

Thumbscrew

Bin Control Cable Connector

Fig. 1

Bin Control

Switch Mount

Actuator Paddle

14

Magnet

Page 15

2. Bin Control Cleaning

Scale may build up on BC. Scale can cause the actuator paddle and magnet to stick. In

this case, BC should be cleaned.

WARNING

CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the icemaker is serviced. Make sure that none have fallen

into the dispense unit/ice storage bin.

1) Turn off the power supply.

2) Remove the front panel, then move the control switch to the "OFF" position.

3) Clear any ice away from BC.

4) Carefully remove the BC cable from the cable ties in the evaporator case, then remove

the BC from the bin control bracket and move to the front of the icemaker for cleaning.

5) Remove the actuator paddle from the switch mount. See Fig. 1.

6) Wipe down BC with a mixture of 1 part of Hoshizaki "Scale Away" and 25 parts of warm

water. Rinse the parts thoroughly with clean water.

7) Reassemble BC and replace it in its correct position.

Note: If the magnet was removed for cleaning, be sure to replace it in its correct

position.

8) Replace the BC cable into the cable ties in the evaporator case, then move the control

switch to the "ICE" position.

9) Conrm CB wire harness connections are secure, then replace the control box cover in

its correct position.

10) Turn on the power supply to start the automatic icemaking process.

11) Replace the front panel in its correct position.

Legend: BC–bin control; CB–control board

15

Page 16

E. Evaporator Thermistor Check

To check thermistor resistance, follow the steps below.

1) Turn off the power supply.

2) Remove the front panel. Move the control switch to the "OFF" position.

3) Remove the control box cover.

4) Remove the thermistor from the evaporator.

5) Immerse the thermistor sensor portion in a glass containing ice and water for 2 or 3 min.

6) Disconnect the thermistor connector from CB CN13 connector and check the resistance

between thermistor leads. Normal range is 4.7 to 6.2 kΩ. If outside the normal range,

replace the thermistor. See "IV.B. Component Service Information." If within the normal

range, continue to the next step.

7) Replace the thermistor in its correct position. See "IV.B. Component Service

Information."

8) Reconnect the thermistor connector to CB CN13 connector.

9) Replace the control box cover in its correct position.

10) Move the control switch to the "ICE" position.

11) Replace the front panel in its correct position.

12) Turn on the power supply.

Legend: CB–control board; Comp–compressor

16

Page 17

III. Controls and Adjustments

A. Control Switch

The control switch has three positions: OFF for power off, ICE for icemaking, and WASH

to energize the water pump when cleaning and sanitizing.

B. Control Board

• A Hoshizaki exclusive control board is employed in IM series appliances.

• All models are pretested and factory adjusted.

NOTICE

• Fragile, handle very carefully.

• The control board contains integrated circuits, which are susceptible to failure

due to static discharge. It is especially important to touch the metal part of the

icemaker when handling or replacing the control board.

• Do not touch the electronic devices on the control board or the back of the control

board.

• Do not change wiring and connections.

• Do not short out power supply to test for voltage.

• Always replace the whole control board assembly if it goes bad.

17

Page 18

1. Control Board Layout

• CN9 Connector

Display Output

• RESET Button

• SERVICE 1 Button

• SERVICE 2 Button

• CN16 Connector

Actuator Motor Position Sensor (Hall IC) Input

• CN11 Connector

Bin Control Input

• CN13 Connector

Evaporator (Cube Control) Thermistor Input

• CN10 Connector

Compressor Start DC Relay Drive Output

• CN4 Connector

Data Input/Output

• CN1 Connector

Control Transformer (10.5VAC) Input

• CN2 Connector

115VAC Input

• F1 Fuse

6.3A, 250VAC

• CN3 Connector

• CN5 Connector

Actuator Motor Output

115VAC Output: Pump Motor; Hot Gas Valve;

Fan Motor; Inlet Water Valve; Compressor Relay

"IM" Control Board

Part Number P01873-01 Version 1.3A or Later

18

Page 19

C. Control Buttons

The control board features RESET, SERVICE 1, and SERVICE 2 Buttons

1. RESET Button

• Press briey to go to initial harvest cycle.

• Press and hold for 3 seconds to enter control board setting mode. For details about

control board settings, see "III.D. Control Board Setting Mode and Control Board

Settings."

2. SERVICE 1 and SERVICE 2 Buttons

• Press the "SERVICE 1" or "SERVICE 2" button briey to display the current freeze

cycle termination temperature (Control Board Setting 2). This setting controls dimple

diameter. For details about adjusting the dimple diameter, see "III.H.1. Dimple

Diameter." NOTICE! Do not decrease dimple size below 3/16" (5 mm).

• Press and hold the "SERVICE 1" button for 3 seconds to enter information display and

model code setting mode. For details about information display and model code setting,

see "III.F. Model Code Setting Mode."

19

Page 20

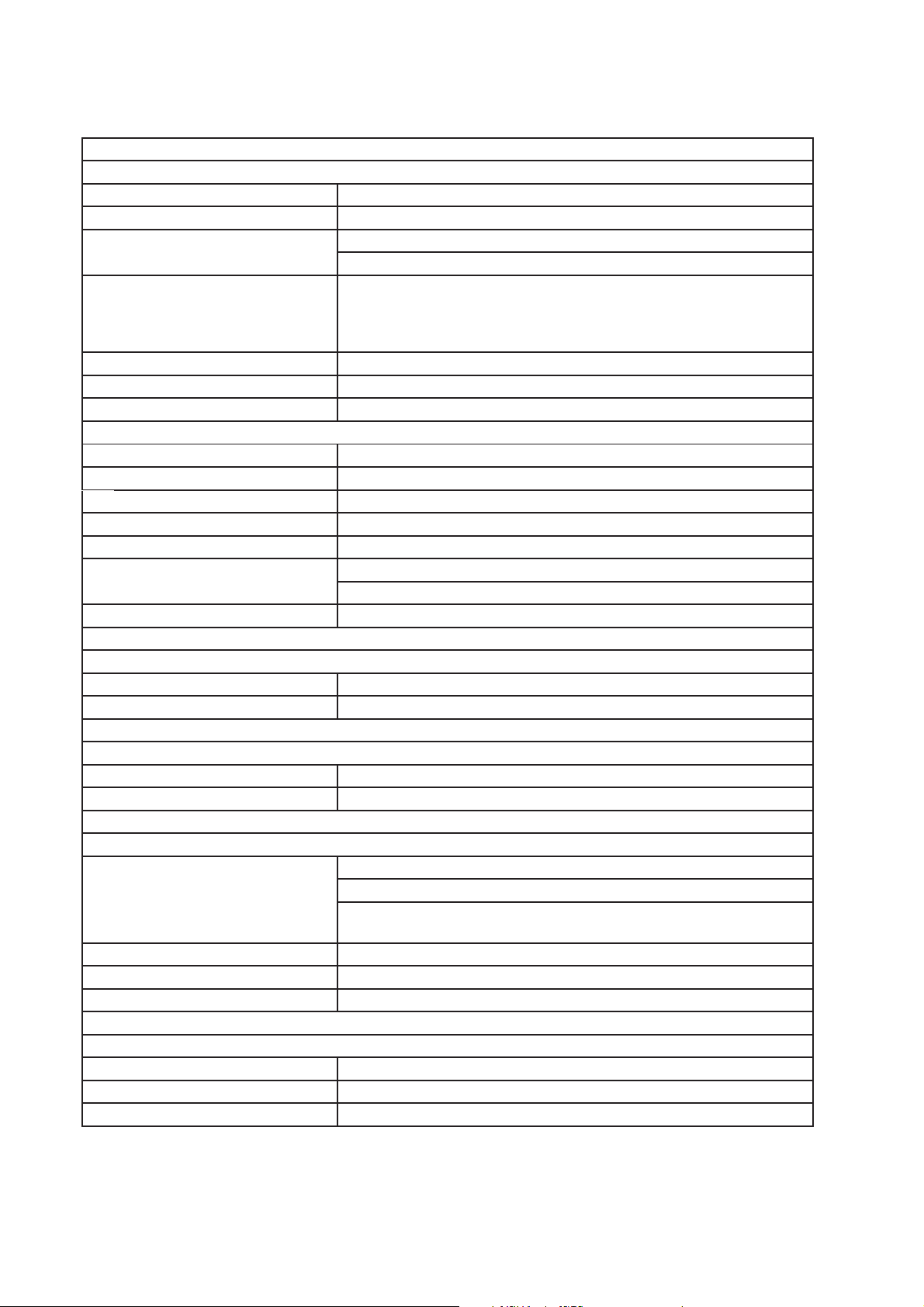

D. Control Board Settings

NOTICE

Failure to maintain factory settings may adversely affect performance and warranty

coverage. For more information, contact your Hoshizaki Service Center.

1) With "on" in display, press and hold the "RESET" button for 3 seconds. Display changes

to "1".

2) Use the "SERVICE 1" and "SERVICE 2" buttons to choose a control board setting.

3) Press the "RESET" button to view the setting’s value. Current value ashes in display.

4) Use the "SERVICE 1" and "SERVICE 2" buttons to change value.

5) Press the "RESET" button to select value. Display returns to control board setting

number.

6) Once display returns to "on" (20 seconds), the new setting is saved.

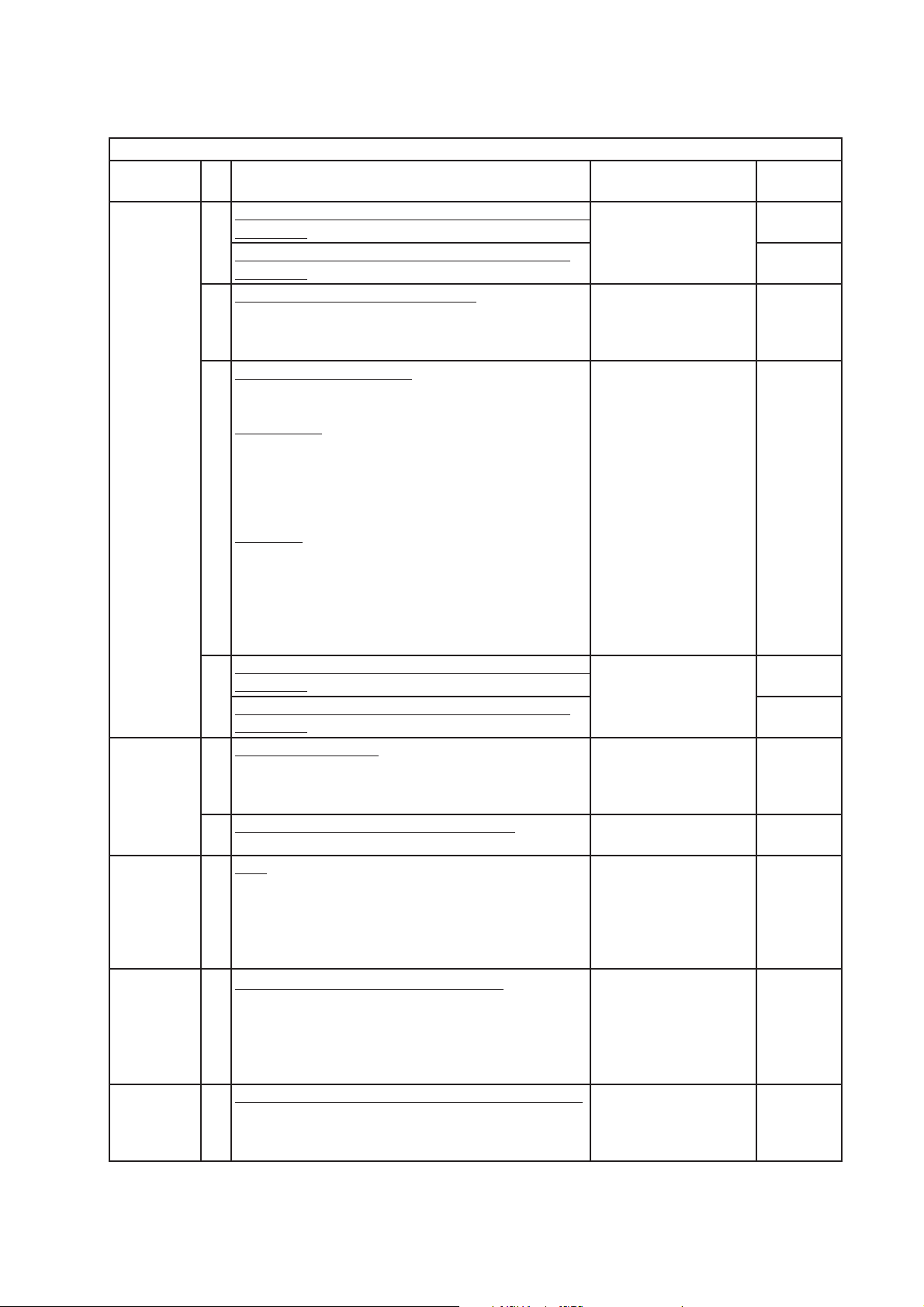

Control Board (CB) Setting Menu

IM-500SAA

Category No. Item Range

Basic 1

Water

Supply

Harvest Cycle Termination Temperature

Temperature to complete harvest cycle.

2

Freeze Cycle Termination Temperature

Integrated with freeze cycle termination time (CB

Setting 3) to control length of freeze cycle after

evaporator (cube control) thermistor temperature

drops to 32°F (0°C). To use this setting for dimple

size adjustment, see "III.H.1. Dimple Diameter."

Freeze Cycle Termination Time

3

Integrated with freeze cycle termination temperature

(CB Setting 2) to control length of freeze cycle after

evaporator (cube control) thermistor temperature

drops to 32°F (0°C).

Ambient Temperature Correction Value for Freeze

4

Cycle Termination

DO NOT ADJUST

Ambient Temperature Correction Rate for Freeze

5

Cycle Termination

DO NOT ADJUST

Freeze Cycle Backup Timer

6

Maximum allowed freeze time to prevent possible

freeze-up issues.

Harvest Cycle Water Supply Time: Water

10

Temperature 48°F (9°C) or Lower

When set to "99", inlet water valve energized until

harvest cycle termination temperature (CB Setting 1)

is reached.

Harvest Cycle Water Supply Time: Water

11

Temperature Higher Than 48°F (9°C)

When set to "99", inlet water valve energized until

harvest cycle termination temperature (CB Setting 1)

is reached.

2 to 20°C

(1°C increments)

-5 to -40°C

(0.5°C increments. The

"." in the lower, right

corner of the display

indicates .5°C.)

5 to 90 min.

(1 min. increments)

10 to 50°C

(1°C increments)

10 to 100% (00 = 100)

(1% increments)

45 to 90 min.

(5 min. increments)

1 to 99 sec,

99 = continuous

(1 sec. increments)

1 to 99 sec,

99 = continuous

(1 sec. increments)

Default

5

-18.5

10

10

100

45

95

30

20

Page 21

Control Board (CB) Setting Menu

Category No. Item Range

Water

Supply,

continued

Other 21

Model 30

Harvest

Cycle High

Temperature

Control

Water

Regulating

Valve

12

Freeze Cycle Water Supply Time 1: Partial Drain (CB

Setting 14)

Freeze Cycle Water Supply Time 1: Full Drain (CB

Setting 14)

Water Temperature Correction Value

13

Value added to correct the difference between

the temperature at the evaporator (cube control)

thermistor and actual water supply temperature.

Partial/Full Drain Selection

14

Controls timing for inlet water valve and pump motor

in the freeze cycle.

Partial Drain: Pump motor energizes after freeze

cycle water supply time 1 (CB Setting 12) timer

terminates. During the rst freeze cycle after startup

or following a bin control initiated shutdown and

restart, freeze cycle water supply times 1 and 2 (CB

Settings 12 and 15) are doubled.

Full Drain: Pump motor energizes after freeze cycle

water supply time 1 (CB Setting 12) timer terminates.

If full drain is selected, change freeze cycle making

water supply times 1 and 2 (CB Settings 12 and 15)

to the full drain times listed in this table and move

the water tank drain pipe to the drain position. For

details, see "III.H.2. Ice Clarity."

Freeze Cycle Water Supply Time 2: Partial Drain (CB

15

Setting 14)

Freeze Cycle Water Supply Time 2: Full Drain (CB

Setting 14)

Stackable Bin Control

Allows for stacked units to be controlled through one

bin control.

DO NOT ADJUST

Refrigeration Circuit Cycling when Bin Full

22

DO NOT ADJUST

Type

0: WC, PS, No CondTherm, Ignore CB Setting 34

1: AC, No PS, No CondTherm, Use CB Setting 34

2: AC, No PS, CondTherm, Use CB Setting 34

3: AC, PS, No CondTherm, Use CB Setting 34

DO NOT ADJUST

34

Harvest Cycle High Temperature Control

Active if type setting (CB Setting 30) is set to 1, 2,

or 3. If control board thermistor temperature at the

beginning of harvest cycle is equal to or greater than

the harvest cycle high temperature control setting,

fan motor operates continuously in harvest cycle.

Water Regulating Valve Error Detection Temperature

36

DO NOT ADJUST

0 to 90 sec.

(1 sec. increments)

+0 to +20°C

(1°C increments)

Partial=1; Full=0 1

0 to 90 sec.

(1 sec. increments)

Yes=1; No=0 1

On=1; Off=0 0

0 to 3 3

40 to 70°C

(1°C increments)

0 to 50°C

0=ignore, air-cooled

model

(1°C increments)

IM-500SAA

Default

30

60

11

22

44

48

0

21

Page 22

Control Board (CB) Setting Menu

Category No. Item Range

Compressor 37

Anti-Slush

Control

Hard Water

Control

Water Tank

Ice Control7071

Water Tank

Ice Control

& Ice Bridge

Control

Water Tank

Ice Control

Ice Bridge

Control

Compressor Output Selection

DO NOT ADJUST

Pump De-Energized Time

50

When temperature at evaporator (cube control)

thermistor drops to 37°F (3°C) in the freeze cycle,

pump de-energizes for the length of time set.

Anti-Slush Control Water Supply Time

51

Time inlet water valve is energized while pump is

de-energized if pump de-energized time (CB Setting

50) is greater than 0.

Integrated Value

60

If hard water control water supply time (CB Setting

61) is greater than 0: After evaporator (cube control)

thermistor indicates temperature of 32°F (0°C) in

freeze cycle, inlet water valve energized starting

when percentage of freeze cycle termination

temperature and freeze cycle time integrated value

has been achieved.

DO NOT ADJUST

Hard Water Control Water Supply Time

61

Time inlet water valve is energized after integrated

value (CB Setting 60) conditions are met.

Before using this setting, follow the instructions to

improve ice clarity; see "III.H.2. Ice Clarity."

If control board thermistor temperature is above

the water tank ice control lower temperature setting

72

(CBSetting 74) and equal to or less than the

74

water tank ice control upper temperature setting

(CB Setting 70) when freeze cycle termination

temperature (CB Setting 2) is met, the hot gas valve

energizes/de-energizes/energizes for the times set

by the hot gas valve energized/de-energized times

(CB Settings 71 and 72) to reduce bonding of the

water tank to the evaporator.

Water Tank Ice Control Upper Temperature

70

See CB Setting 70, 71, 72, 74 description above.

Ice Bridge Control Temperature

See CB Setting 73 description below.

Water Tank Ice Control Hot Gas Valve Energized

71

Time

See CB Setting 70, 71, 72, 74 description above.

Water Tank Ice Control Hot Gas Valve De-Energized

72

Time

See CB Setting 70, 71, 72, 74 description above.

Ice Bridge Control Hot Gas Valve De-Energized Time

73

Time hot gas valve is de-energized after 20 sec. in

harvest cycle if control board thermistor temperature

is above the ice bridge control temperature

(CBSetting 70) when freeze cycle termination

temperature (CB Setting 2) is met.

0: X8 (DC Relay) On

1: X1 (AC Relay) On

0 to 90 sec.

0=ignore, no anti-slush

(1 sec. increments)

0 to 5 sec.

(1 sec. increments)

10 to 100%

(00=100)

(1% increments)

0 to 90 sec.

(1 sec. increments)

See Ranges Below See

10 to 60°C

(1°C increments)

0 to 20 sec.

(1 sec. increments)

10 to 60 sec.

(1 sec. increments)

0 to 30 sec.

(1 sec. increments)

IM-500SAA

Default

1

0

0

10

0

Defaults

Below

44

5

25

0

22

Page 23

Control Board (CB) Setting Menu

IM-500SAA

Category No. Item Range

Water Tank

Ice Control

& Harvest

Cycle Low

Temperature

Control

Water Tank Ice Control Lower Temperature

74

See CB Setting 70, 71, 72, 74 description above.

Harvest Cycle Low Temperature Control

If control board thermistor temperature at the

beginning of harvest cycle is equal to or less than

the harvest cycle low temperature control setting, hot

gas valve repeatedly energizes for 40 seconds then

de-energizes for 40 seconds to promote a balanced

harvest across the evaporator plate.

0 to 40°C

(1°C increments)

Default

27

E. Control Board Information Display

1. With unit on, press and hold the "SERVICE 1" button for 3 seconds. Display changes to

"n1".

2. Use the "SERVICE 1" and "SERVICE 2" buttons to move through the list.

3. Press the "RESET" button to view the item’s value.

4. Press the "RESET" button to return to list.

5. Display returns to normal if no buttons are touched for 20 seconds.

Control Board Information Display

No. Item Description

Freeze Cycle Time

n1

During Freeze Cycle: Time since freeze cycle

started.

After Freeze Cycle: Time of previous freeze cycle.

Freeze Cycle Completion Rate

n2

During Freeze Cycle: Percent of freeze cycle

completed.

After Freeze Cycle: Percent of previous freeze

cycle completed.

Current Evaporator (Cube Control) Thermistor

n3

Temperature

Current Control Board Thermistor Temperature °C No

n4

n5

Water Temperature

Temperature at evaporator (cube control)

thermistor 30 seconds after pump motor

energized in freeze cycle plus the water

temperature correction value (Control Board

Setting 13).

Current Condenser Thermistor Temperature

n6

Not Applicable to IM-500SAA

0 to 99 min. No

0 to 100%

00 = 100%

°C No

"H" if Higher than 48°F

(9°C)

"L" if 48°F (9°C) or

Lower

°C No

History Cleared by

Pressing and Holding

SERVICE 1 and

SERVICE 2 Buttons

Simultaneously for

5Sec. when Item Value

is Displayed?

No

No

23

Page 24

Control Board Information Display

No. Item Description

Last Completed Freeze Cycle Time

h1

Freeze cycles interrupted by bin control shutdown

or the "RESET" button are not recorded.

Number of Completed Freeze Cycles Since Last

h2

Counter Reset

Counter updates every 10 freeze cycles. Freeze

cycles interrupted by bin control shutdown or the

"RESET" button are not recorded.

Total Number of Completed Freeze Cycles

h3

Counter updates every 10 freeze cycles. Freeze

cycles interrupted by bin control shutdown or the

"RESET" button are not recorded.

Error Log

h4

Displays up to 5 errors with the most recent error

rst. For error details, see "III.G. Error Codes."

Firmware Version

h5

Displays control board's rmware version.

Model Code

h6

The model code puts all settings for a given

model to the correct default settings. The model

code setting mode should only be used when the

control board has been changed, the model code

is incorrect, or to reset all settings to the default.

For details about the model code setting mode,

see "III.F. Model Code Setting Mode."

0 to 99 min. Yes

Displays up to 999,999

cycles. Displays two

digits at a time. For

example, 655,350 cycles

display as follows:

65>off>53>off>50>off>- (repeat)

For example, E5 (most

recent), E4, E3, E2,

E1 (least recent of up

to 5 errors) displays as

follows:

E5>off>E4>off>E3>off>E

2>off>E1>off>- - (repeat)

For example, version

1.0A, displays as follows:

01.>off>0A>off>- (repeat)

Displays two-character

model code.

"00" to "FF"

History Cleared by

Pressing and Holding

SERVICE 1 and

SERVICE 2 Buttons

Simultaneously for

5Sec. when Item Value

is Displayed?

Ye s

No

Ye s

No

No

24

Page 25

F. Control Board Model Code Setting

1. Control Board Replacement

WARNING

• This appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Move the control switch to the "OFF" position and turn off the power supply. Place

the disconnect in the "OFF" position. Lockout/Tagout to prevent the power supply

from being turned back on inadvertently.

1) Move the control switch to the "OFF" position and turn off the power supply. Place the

disconnect in the "OFF" position. Lockout/Tagout to prevent the power supply from

being turned back on inadvertently.

2) Remove the front cover and control box cover.

3) Disconnect all the connectors from the control board.

4) Remove the old control board and install the new control board (

or Later).

5) Connect the connectors to the new control board.

6) Replace the control box cover in its correct position.

7) Turn on the power supply, then move the control switch to the "ICE" position.

8) "00" appears in the display of the new control board.

9) Press the "SERVICE 1" button to increase the rst digit in the display and the

"SERVICE2" button to increase the second digit. Digits appear in the following order:

0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C, D, E, F. When a valid model code is displayed, the dot

in the bottom right of the display turns on. For IM-500SAA, set model code to "08".

10) When the desired model code is displayed, press the "RESET" button to save the

setting. "on" appears in the display.

11) Replace the front panel in its correct position.

2. Checking or Changing the Control Board Model Code

1) With unit on, press and hold the "SERVICE 1" button for 3 seconds. Display changes to

"n1".

2) Use the "SERVICE 1" and "SERVICE 2" buttons to move through the list until "h6" is

displayed.

P01873-01 Version 1.3A

3) Press the "RESET" button to view the current model code. To change the model code,

continue through the remaining steps; otherwise, the display returns to normal if no

buttons are touched for 20 sec.

4) Press and hold the "SERVICE 1" and "SERVICE 2" buttons simultaneously for 15 sec.

"00" appears in display.

25

Page 26

5) Press the "SERVICE 1" button to increase the rst digit in the display and the

"SERVICE2" button to increase the second digit. Digits appear in the following order:

0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, B, C, D, E, F. When a valid model code is displayed, the dot

in the bottom right of the display turns on. For IM-500SAA, set model code to "08".

6) When the desired model code is displayed, press the "RESET" button to save the

setting. "on" appears in the display.

26

Page 27

G. Error Codes

When the control board detects an error, the display shows one of the following error

codes in the display mode. Error codes other than E1 and E2 are displayed as "EE" at

the time of occurrence. To see the actual error code, see the error log.

1. With the unit on, press and hold the "SERVICE 1" button for 3 seconds. Display changes

to "n1".

2. Use the "SERVICE 1" and "SERVICE 2" buttons to move through the list until "h4" is

displayed.

3. Press the "RESET" button to view the error log. Displays up to 5 errors with the most

recent error rst.

4. Press the "RESET" button to return to list. To clear error log history, press and hold the

"SERVICE1" and "SERVICE 2" buttons simultaneously for 5 sec.

5. Display returns to normal if no buttons are touched for 20 sec.

Error Codes

Error

Code

E1

E2

EE

(E3)

EE

(E4)

Problem Corrective Action/Reset Details

Freeze Cycle Backup Timer

Freeze cycle backup timer (Control Board Setting

6) has terminated.

45 min. after water tank starts to close in

preceding harvest cycle, unit stops if the

evaporator temperature is above 32°F (0°C).

Harvest Cycle Backup Timer

Harvest cycle backup timer has terminated.

30 min. after water tank starts to open in harvest

cycle, unit stops if harvest cycle termination

temperature (Control Board Setting 1) has not

been reached.

Water Tank Opening Backup Timer

3-minute opening backup timer starts when water

tank starts to open.

If actuator motor's internal position sensor

does not indicate water tank is fully open within

3minutes, display shows "EE" and unit stops for

60 minutes.

If error recurs after unit resumes operation,

display shows "EE" and unit shuts down.

Water Tank Closing Backup Timer

3-minute closing backup timer starts when water

tank starts to close.

If actuator motor's internal position sensor does

not indicate water tank is fully closed within

3minutes, display shows "EE" and unit stops for

60 minutes.

If error recurs after unit resumes operation,

display shows "EE" and unit shuts down.

Check for inlet water valve leaking by, hot gas valve

leaking by, pump motor not pumping, thermostatic

expansion valve not feeding properly, low charge, or

inefficient compressor.

Press the "RESET" button to reset.

Check for open thermistor, HGV not opening, TXV

leaking by, low charge, or inefficient compressor.

Press the "RESET" button to reset.

Check actuator motor and control board.

Press the "RESET" button to reset.

Check actuator motor and control board.

Press the "RESET" button to reset.

27

Page 28

Error Codes

Error

Code

EE

(E5)

EE

(E9)

EE

(EA)

EE

(EC)

EE

(Ed)

Problem Corrective Action/Reset Details

High Evaporator Temperature

If evaporator temperature 140°F (60°C) or higher

for 5sec., unit stops.

Condenser Thermistor Error

If condenser thermistor is open or shorted for

2sec., unit stops.

Note: IM-500SAA does not utilize a condenser

thermistor, therefore E9 error will not occur.

Control Board Error

If model data IC is defective, unit stops.

Evaporator (Cube Control) Thermistor Error

If evaporator thermistor is open or shorted for

2sec., unit stops.

Water Regulating Valve Error

If water regulating valve thermistor detects a

temperature below the water regulating valve

error detection temperature (Control Board

Setting 36), error is displayed but unit continues

to operate.

Note: IM-500SAA does not utilize a water

regulating valve, therefore Ed error will not occur.

Check for harvest problem (stuck HGV or control

board relay), hot water entering unit, or shorted

thermistor.

Press the "RESET" button to reset.

Replace condenser thermistor.

Replace control board.

Replace evaporator thermistor.

Check water regulating valve.

Press the "RESET" button to reset.

H. Quick Adjustments

1. Dimple Diameter

The factory set dimple diameter is 3/16" (5 mm). NOTICE! Do not decrease the dimple

diameter below 3/16" (5 mm).

a) To increase dimple diameter:

1) Remove front panel.

2) Press the "SERVICE 1" button to view the current freeze cycle termination temperature

setting.

3) Press the "SERVICE 1" button to raise freeze cycle termination temperature setting

(Control Board Setting 2). Temperature setting rises in .5°C increments. The "." in the

lower, right corner of the display indicates .5°C. Default is -18.5°C. For reference, raising

freeze cycle termination temperature setting to -13°C will result in a dimple diameter of

approximately 3/8" (10mm).

4) Once the display returns to "on" (20 seconds), the new setting is saved.

b) To decrease dimple diameter:

1) Remove front panel.

2) Press the "SERVICE 2" button to view the current freeze cycle termination temperature

setting.

28

Page 29

3) Press the "SERVICE 2" button to lower freeze cycle termination temperature setting

(Control Board Setting 2). Temperature setting lowers in .5°C increments. The "." in the

lower, right corner of the display indicates .5°C. Default is -18.5°C. NOTICE! Do not

decrease dimple size below 3/16" (5 mm).

4) Once the display returns to "on" (20 seconds), the new setting is saved.

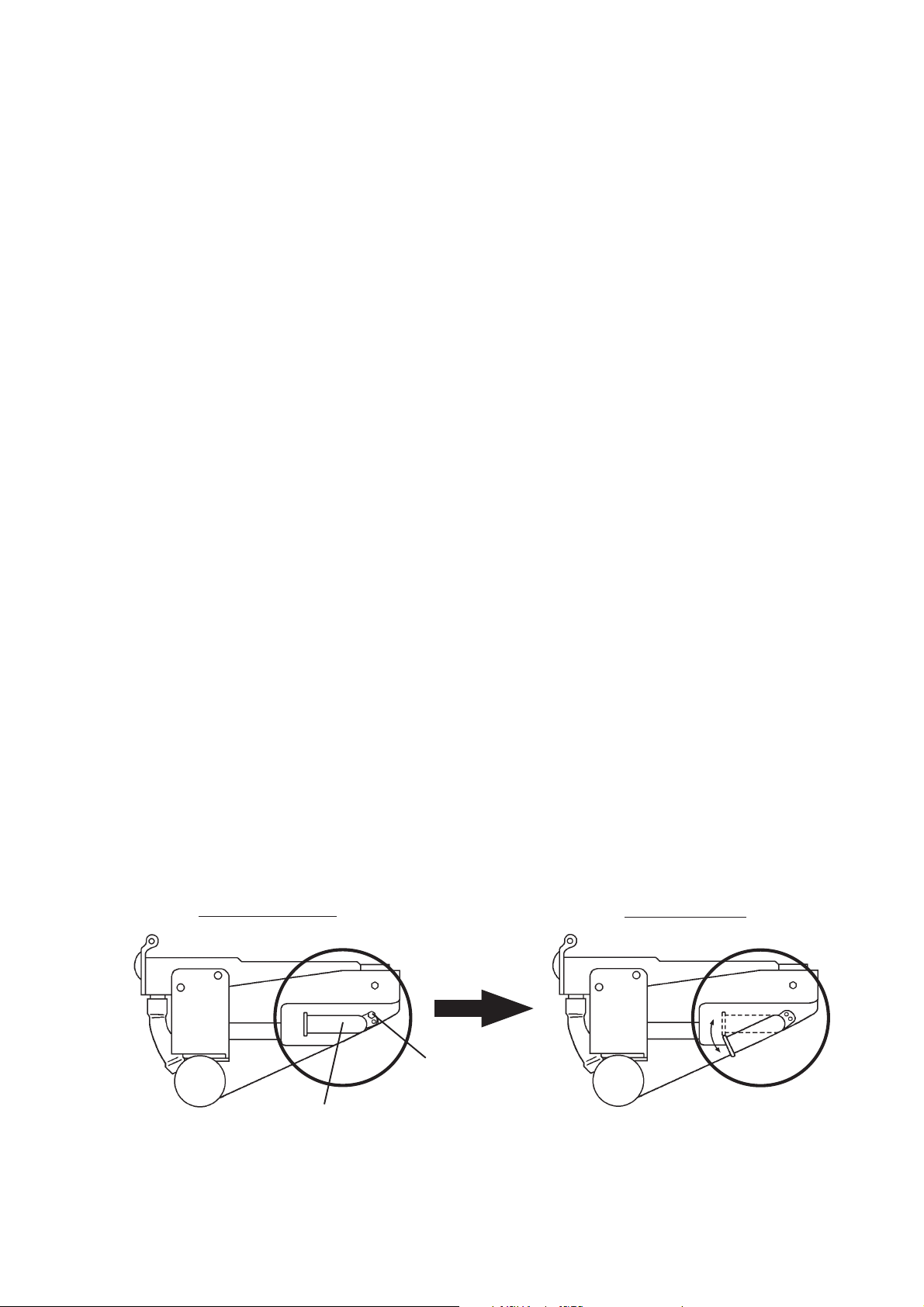

2. Ice Clarity

In hard water conditions, white ice may be produced. In such cases, install a water lter

and/or water softener, then follow the instructions below.

1) Move the control switch to the "OFF" position, then turn off the power supply.

2) Remove the front panel.

3) Remove the screw, then move the water tank drain pipe to the drain position. See Fig. 2.

Use the screw to secure the water tank drain pipe in the drain position.

4) Turn on the power supply, then move the control switch to the "ICE" position.

5) Press and hold the "RESET" button for 3 seconds. "1" appears in the display.

6) Press the "SERVICE 1" button until "12" appears in the display. Press the "RESET"

button. The current icemaking water supply time value ashes in the display. Press the

"SERVICE 1" or "SERVICE 2" buttons to change the setting to "60".

7) Press the "RESET" button to save the setting and return to the menu.

8) Using the same procedure as above, change the full/partial drain setting (Control Board

Setting 14) from "1" (partial drain) to "0" (full drain).

9) Using the same procedure as above, change the additional icemaking water supply time

setting (Control Board Setting 15) to "44".

10) Once the display returns to "on" (20 seconds), the new setting is saved.

11) Replace the front panel in its correct position.

Note: If white ice continues to be an issue, set hard water setting water supply time

(Control Board Setting 61) to "15". This results in the inlet water valve energizing

for 15 seconds part way through the freeze cycle and diluting the water in the

water tank. Do not increase this setting beyond 15 seconds; otherwise, freeze

cycle times may become long and bridging may occur in the ice storage bin.

Normal Position

Screw

Drain Position

Water Tank Drain Pipe

Fig. 2

29

Page 30

IV. Refrigeration Circuit and Component Service Information

WARNING

• This appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Move the control switch to the "OFF" position and turn off the power supply. Place

the disconnect in the "OFF" position. Lockout/Tagout to prevent the power supply

from being turned back on inadvertently.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the icemaker is serviced. Make sure that none have fallen

into the dispenser unit/ice storage bin.

• Make sure all food zones in the icemaker and dispenser unit/ice storage bin are

clean after service.

A. Refrigeration Circuit Service Information

WARNING

• Repairs requiring the refrigeration circuit to be opened must be performed by

properly trained and EPA-certied service personnel.

• Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). Do not use R-404A as a mixture with

pressurized air for leak testing.

NOTICE

• Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

• Do not leave the system open for longer than 15 min. when replacing or servicing

parts. The Polyol Ester (POE) oils used in R-404A applications can absorb

moisture quickly. Therefore it is important to prevent moisture from entering the

system when replacing or servicing parts.

• Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

1. Refrigerant Recovery

The icemaker is provided with refrigerant access valves. Using proper refrigerant practices,

recover the refrigerant. Store the refrigerant in an approved container. Do not discharge the

refrigerant into the atmosphere.

30

Page 31

2. Brazing

WARNING

• R-404A itself is not ammable at atmospheric pressure and temperatures up to

176°F (80°C).

• R-404A itself is not explosive or poisonous. However, when exposed to high

temperatures (open ames), R-404A can be decomposed to form hydrouoric

acid and carbonyl uoride both of which are hazardous.

• Do not use silver alloy or copper alloy containing arsenic.

1) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.

Note: Because the pipes in the evaporator case are specially coated to resist corrosion,

it is important to make connections outside the evaporator case when possible. If

it is necessary to braze inside the evaporator case, use sandpaper to remove the

coating from the brazing connections before unbrazing the components.

NOTICE

• Always install a new drier every time the sealed refrigeration system is opened.

• Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

2) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). Do not use R-404A as a mixture with

pressurized air for leak testing.

3. Evacuation and Recharge (R-404A)

1) Attach a vacuum pump to the system. Be sure to connect the charging hoses to both

high and low-side refrigerant access valves.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump. Open the gauge manifold valves. Never allow the oil in the

vacuum pump to ow backwards.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period depends

on pump capacity.

4) Close the low-side valve and high-side valve on the gauge manifold.

31

Page 32

5) Disconnect the gauge manifold hose from the vacuum pump and attach it to a

refrigerant service cylinder. Remember to loosen the connection and purge the air

from the hose. For the required refrigerant charge, see the nameplate. Hoshizaki

recommends only virgin refrigerant or reclaimed refrigerant which meets ARI Standard

700 (latest edition) be used.

6) A liquid charge is required when charging an R-404A system (to prevent fractionation).

Place the service cylinder on the scales; if the service cylinder is not equipped with

a dip tube, invert the service cylinder, then place it on the scales. Open the high-side

valve on the gauge manifold.

7) Allow the system to charge with liquid until the proper charge weight is met.

8) If necessary, add any remaining charge to the system through the low-side.

NOTICE!To prevent compressor damage, use a throttling valve or liquid

dispensing device to add the remaining liquid charge through the low-side

refrigerant access valve with the icemaker running.

9) Close the high and low-side gauge manifold valves, then disconnect the gauge manifold

hoses.

10) Cap the refrigerant access valves to prevent a possible leak.

B. Component Service Information

NOTICE

When replacing a component listed below, see the notes to help ensure proper

operation.

Component Notes

Compressor Install a new start capacitor, run capacitor, and start relay.

Thermostatic

Expansion Valve

Hot Gas Valve • Replace the strainer if applicable.

Fan Motor Install a new capacitor.

Pump Motor Install a new capacitor.

Actuator Motor Install a new capacitor.

Evaporator

(Cube Control)

Thermistor

• Attach the thermostatic expansion valve bulb to the suction line in the same location

as the previous bulb.

• The bulb should be between the 10 and 2 o'clock positions on the tube.

• Secure the bulb with the clamp and holder, then insulate it.

• Use copper tube of the same diameter and length when replacing valve lines.

• Attach the new thermistor to the same location on the evaporator as the previous

thermistor.

• Smoothly ll the recessed area of the thermistor holder with high thermal conductive

type sealant. Hoshizaki America part number 4A0683-01 (Silicone Heat Sink

Compound 10-8108 manufactured by GC Electronics), KE-4560 RTV (manufactured

by ShinEtsu Silicones), or equivalent are recommended.

• Attach the new thermistor in position on the evaporator and press down the

thermistor holder over the thermistor.

• Be very careful to prevent damage to the leads.

32

Page 33

Water Pan

Assembly

Refer to illustration for assembly.

1. Water Tank

2. Water Plate Bracket

3. Bracket

4. Spring Hook Screw

5. Pump Tubing (Suction)

6. Pump Tubing (Discharge)

7. Pump Motor Bracket

8. Water Plate

9. Overow Pipe

10. Screw (for Overow Pipe)

11. Nylon Tie

12. O-ring

J. Pump Motor Assembly

S1-4. Tapping Screw

S5. Machine Screw

Icemaking

Assembly and

Cam Mechanism

Refer to illustration for assembly.

33

G. Water Pan Assembly

1. Evaporator

2. Bolt

3. Collar (Spacer)

4. Bearing

5. Actuator Motor

7. Shaft

9. Actuator Motor Bracket

10. Cam Shaft Bearing

11. Spring Pin

13. Cam Arm (B)

14. Cam Shaft

15. Snap Pin

16. Split Pin

17. Spring

18. Washer (A)

19. Washer (B)

20. Washer (C)

21. Thermistor Holder

22. Label (for Overow Pipe)

23. Thermistor (Cube Control)

26. Frame

27. Frame

28. Wire Saddle

29. Washer

30. Cam Arm (A)

31. Change Lever

S1-5. Machine Screw

Page 34

V. Maintenance

The maintenance schedule below is a guideline. More frequent maintenance may be

required depending on water quality, the appliance's environment, and local sanitation

regulations

WARNING

• Only qualied service technicians should service the appliance.

• To reduce the risk of electric shock, do not touch the control switch or service

switch with damp hands

• Before servicing: Move the control switch to the "OFF" position and turn off the

power supply. Place the disconnect in the "OFF" position.

Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after any maintenance is done to the icemaker. Make sure that

none have fallen into the dispenser unit/ice storage bin.

Maintenance Schedule

Frequency Area Task

Daily Scoop Clean the ice scoop using a neutral cleaner. Rinse thoroughly after

cleaning.

Bi-Weekly Air Filters Inspect. Wash with warm water and neutral cleaner if dirty.

Monthly External Water

Filters

Icemaker Exterior Wipe down with a clean, soft cloth. Use a damp cloth containing a

Yearly Icemaker and

Dispenser Unit/Ice

Storage Bin Liner

Water Supply Inlet Close the icemaker water supply line shut-off valve and drain the water

Condenser Inspect. Clean if necessary by using a brush or vacuum cleaner. More

Water Hoses Inspect the water hoses and clean/replace if necessary.

Check for proper pressure and change if necessary.

neutral cleaner to wipe off oil or dirt build up. Clean any chlorine staining

(rust colored spots) using a non-abrasive cleanser.

Clean and sanitize per the cleaning and sanitizing instructions provided

in the instruction manual or maintenance label on the icemaker.

system. Clean the water supply inlet screen.

frequent cleaning may be required depending on location.

34

Page 35

VI. Preparing the Icemaker for Periods of Non-Use

NOTICE

• When storing the appliance for an extended time or in sub-freezing temperatures,

follow the instructions below to prevent damage.

• To prevent damage to the water pump, do not operate the appliance with the

control switch in the "WASH" position when the water tank is empty.

When the appliance is not used for two or three days under normal conditions, it is

sufficient to move the control switch to the "OFF" position. When storing the appliance for

an extended time or in sub-freezing temperatures, follow the instructions below.

1. Remove the water from the icemaker water supply line:

1) Turn off the power supply.

2) Move the control switch to the "OFF" position.

3) Close the icemaker water supply line shut-off valve and open the icemaker water supply

line drain valve.

4) Allow the icemaker water supply line to drain by gravity.

5) Attach compressed air or carbon dioxide supply to the icemaker water supply line drain

valve.

6) Move the control switch to the "ICE" position and turn on the power supply.

7) Blow the icemaker water supply line out using compressed air or carbon dioxide.

2. Drain the water tank:

1) Turn off the power supply.

2) Remove the front panel.

3) Remove the screw, and move the tank drain pipe to the drain position.

4) Close the icemaker water supply line.

5) Turn on the power supply.

6) Press the the "RESET" button. The water tank will start to open.

Note: This procedure is necessary to protect the icemaker from freezing up at

subfreezing temperatures.

7) Turn off the power supply when the water tank has fully opened.

8) Move the tank drain pipe to the normal position, and secure it with the screw.

9) Replace the front panel.

35

Page 36

VII. Disposal

The appliance contains refrigerant and must be disposed of in accordance with

applicable national, state, and local codes and regulations. Refrigerant must be

recovered by properly certied service personnel.

36

Page 37

VIII. Technical Information

Y

A

A

A

r

A

A

We reserve the right to make changes in specications and design without prior notice.

A. Specication Data

1. IM-500SAA

AC SUPPLY VOLTAGE

AMPERAGE

MINIMUM CIRCUIT AMPACIT

MAXIMUM FUSE SIZE

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PER 24 HR. Temp.(°F) 50 70 90

lbs./day ( kg/day ) 70 *500 (227) 481 (218) 447 (203)

Reference without *marks 80 485 (220) 456 (207) 417 (189)

SHAPE OF ICE

ICE PRODUCTION PER CYCLE

APPROXIMATE STORAGE CAPACITY

ELECTRIC & WATER CONSUMPTION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 990(5.45) 920(4.40)

WATER gal./24HR (gal./100 lbs.) 86(19.8) 105(21.0)

CEC/CEE TIER LEVEL

ENERGY STAR YES

EXTERIOR DIMENSIONS (WxDxH)

EXTERIOR FINISH Stainless Steel, Galvanized Steel (Rear)

WEIGHT

CONNECTIONS - ELECTRIC

- WATER SUPPLY Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT

CUBE CONTROL SYSTEM

HARVESTING CONTROL SYSTEM Hot Gas, Thermistor and Timer

ICE MAKING WATER CONTROL Timer Controlled. Overflow Pipe

COOLING WATER CONTROL N/A

BIN CONTROL SYSTEM

COMPRESSOR

CONDENSER

EVAPORATOR

REFRIGERANT CONTROL Thermostatic Expansion Valve

REFRIGERANT CHARGE

DESIGN PRESSURE

P.C. BOARD CIRCUIT PROTECTION High Voltage Cut-out ( Internal )

COMPRESSOR PROTECTION Auto-reset Overload Protector ( Internal )

REFRIGERANT CIRCUIT PROTECTION Auto-reset High Pressure Control Switch

LOW WATER PROTECTION

ACCESSORIES -SUPPLIED

-REQUIRED Ice Storage Bin

OPERATING CONDITIONS VOLTAGE RANGE

115/60/1

11.5 A ( 5 Min. Freeze AT 104°F / WT 80°F)

20 A

20

90 481 (218) *435 (197) 397 (180)

100 471 (214) 426 (193) *363 (165)

Cube Ice

6.9.lbs. (3.15kg) 140 pcs.

N

/

1

44" x 27.6" x 21.7" (1118 x 700 x 550 mm)

Net 196 lbs. (89 kg), Shipping 220 lbs. (100 kg)

Permanent-Connection

Thermistor and Timer

Mechanical Level Switch with Delay

Hermetic, Model NT6222GKV

ir-Cooled, Fin and tube type

Cell type, Coppe

R-404A 1lb, 10.5oz (750g)

High 350PSIG, Low 220PSIG

N

/

N

/

AMBIENT TEMP. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE

and Tin dipping

104 - 127 V

10 - 113 PSIG

37

Page 38

B. Performance Data

y

Pressure data is recorded at 5 min. into freezing cycle. The data not in bold

should be used for reference only.

1. IM-500SAA

APPROXIMATE ICE

PRODUCTION PER 24 HR.

lbs./day kg./da

APPROXIMATE ELECTRIC

CONSUMPTION

watts 100/38

APPROXIMATE WATER

CONSUMPTION PER 24 HR.

gal./day m3/day

FREEZING CYCLE TIME

min. 100/38

HARVEST CYCLE TIME

min. 100/38

HEAD PRESSURE

PSIG kg/cm2G

SUCTION PRESSURE

PSIG kg/cm2G

AMBIENT TEMP.

(ºF/ºC)

70/21 500 227 481 218 447 203

80/27 485 220 456 207 417 189

90/32 481 218 435 197 397 180

100/38 471 214 426 193 363 165

70/21

80/27

90/32

70/21 105 0.40

80/27 101 0.38 92 0.35 84 0.32

90/32 99 0.38 86 0.33 78 0.30

100/38 91 0.34 84 0.32 71 0.27

70/21

80/27

90/32

70/21

80/27

90/32

70/21 210 14.8

80/27 226 15.9 260 18.2 281 19.7

90/32 231 16.3 283 19.9 306 21.5

100/38 234 16.5 288 20.3 327 23.0

70/21 42 3.0 45 3.1 48 3.4

80/27 44 3.1 48 3.4 52 3.6

90/32 45 3.1 51 3.6 55 3.8

100/38 45 3.2 52 3.6 58 4.1

WATER TEMP. (ºF/ºC)

50/10 70/21 90/32

920

936

941

945

17

18

18

19

3.6

3.2

3.0 1.5

2.4

941

968

990

996

99 0.38 92 0.35

18

20

22

23

3.0

2.2

1.6

1.6

231 16.3 255 18.0

967

993

1016

1040

20

23

24

27

2.0

2.0

1.4

TOTAL HEAT OF REJECTION FROM CONDENSER 4,500 BTU/h [AT 90ºF (32ºC) / WT 70ºF (21ºC)]

TOTAL HEAT OF REJECTION FROM COMPRESSOR 1,000 BTU/h [AT 90ºF (32ºC) / WT 70ºF (21ºC)]

38

Page 39

C. Wiring Diagram

1. IM-500SAA

39

Loading...

Loading...