Page 1

Service Manual

Modular Crescent Cuber

Models

KM-1301SAJ/3, SWJ/3, SRJ/3

KM-1601SAJ/3, SWJ/3, SRJ/3

KM-1900SAJ/3, SWJ/3, SRJ/3

KM-2200SWJ3, SRJ3

KM-2600SWJ3, SRJ3

hoshizakiamerica.com

Number: 73216

Issued: 10-27-2017

Revised: 5-30-2018

Page 2

WARNING

Only qualied service technicians should install and service the appliance. To

obtain the name and phone number of your local Hoshizaki Certied Service

Representative, visit www.hoshizaki.com. No installation or service should be

undertaken until the technician has thoroughly read this Service Manual. Likewise,

the owner/manager should not proceed to operate the appliance until the installer

has instructed them on its proper operation. Failure to install, operate, and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage and may result in costly water

damage. Proper installation is the responsibility of the installer. Product failure or

property damage due to improper installation is not covered under warranty.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

installation, maintenance, and service of the appliance.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, send an e-mail message, or write to the Hoshizaki Technical

Support Department for assistance.

Phone: 1-800-233-1940; (770) 487-2331

Fax: 1-800-843-1056; (770) 487-3360

E-mail: techsupport@hoshizaki.com

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

2

Page 3

IMPORTANT

This manual should be read carefully before the appliance is serviced. Read

the warnings and guidelines contained in this manual carefully as they provide

essential information for the continued safe use, service, and maintenance of the

appliance. Retain this manual for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 6

I. Construction and Water/Refrigeration Circuit Diagram ....................................................... 8

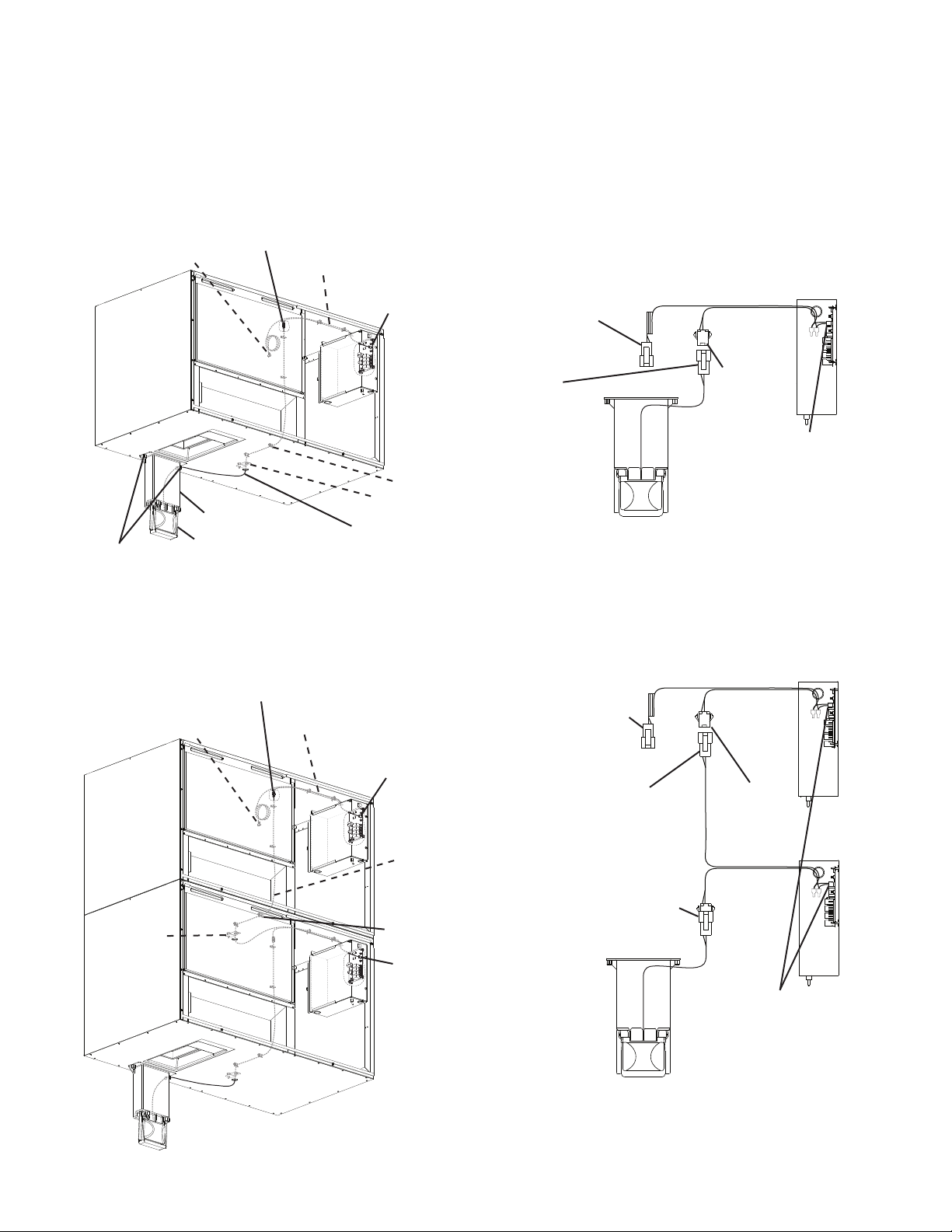

A. KM Construction............................................................................................................ 8

1. Air-Cooled Models (SAJ/3) ....................................................................................... 8

2. Water-Cooled Models (SWJ/3) ................................................................................ 9

3. Remote Models (KM-1301SRJ/3 and KM-1601SRJ/3) .......................................... 10

4. Remote Models (KM-1900SRJ/3, KM-2200SRJ3, KM-2600SRJ3) ........................11

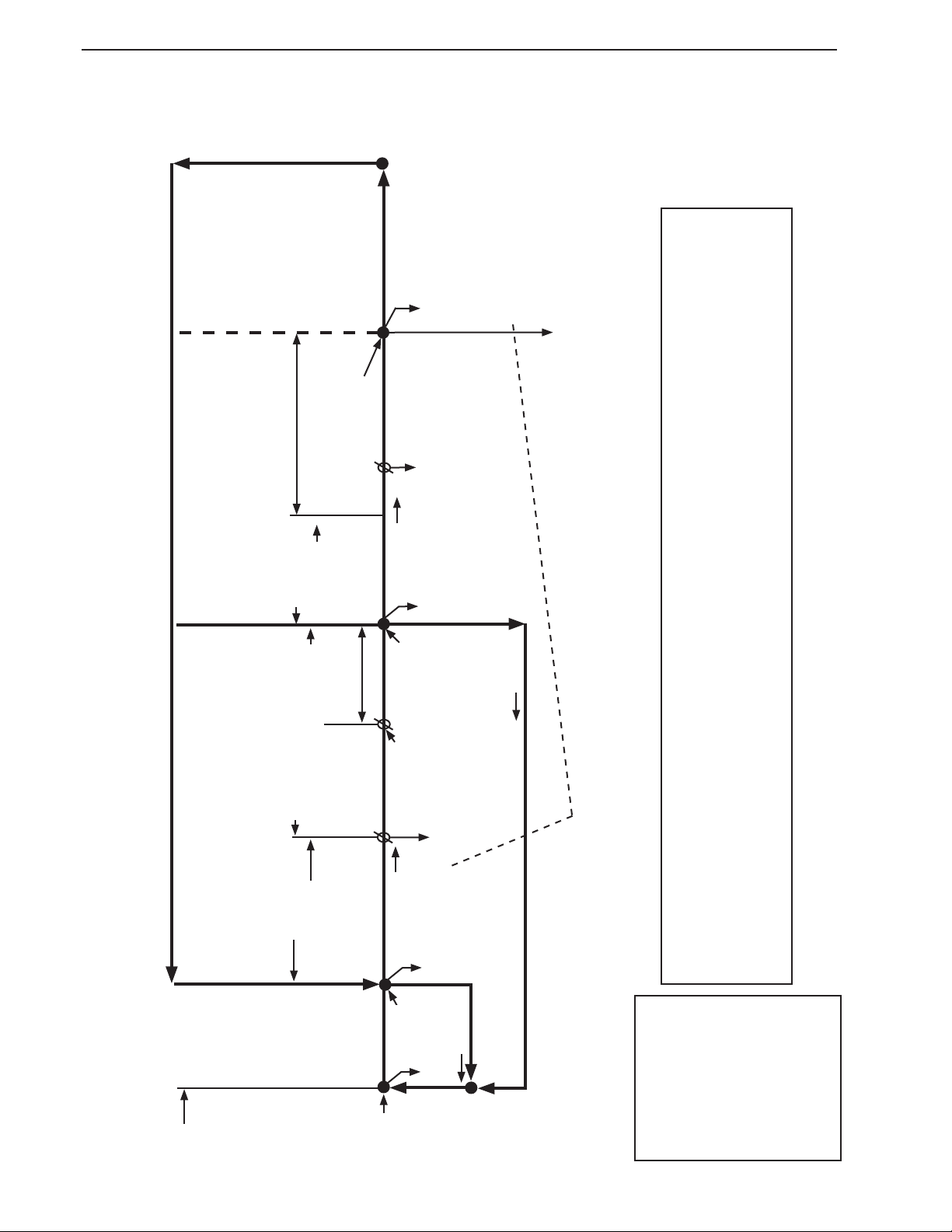

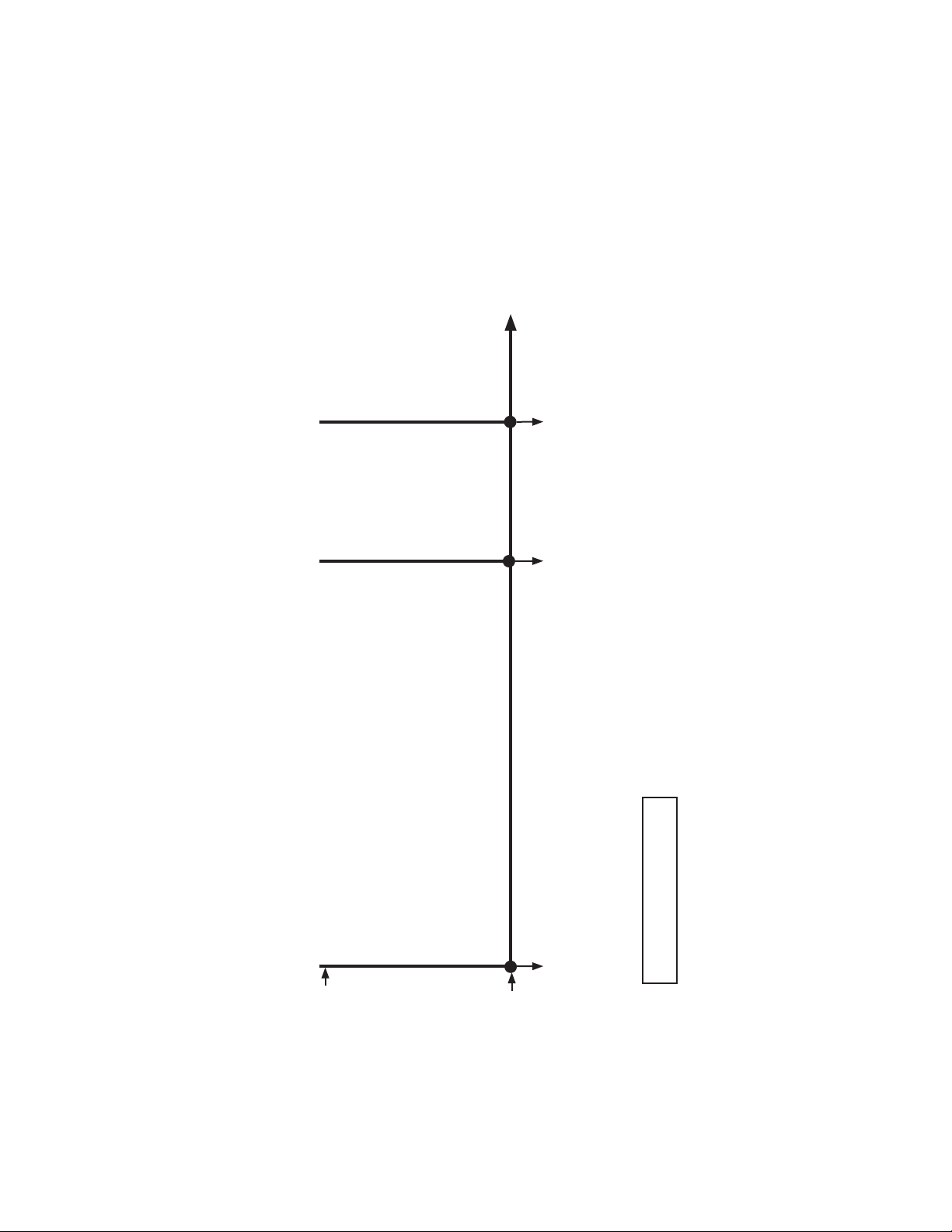

B. Bin Control .................................................................................................................. 12

1. Single Bin Control .................................................................................................. 12

2. Stacked Bin Control ............................................................................................... 12

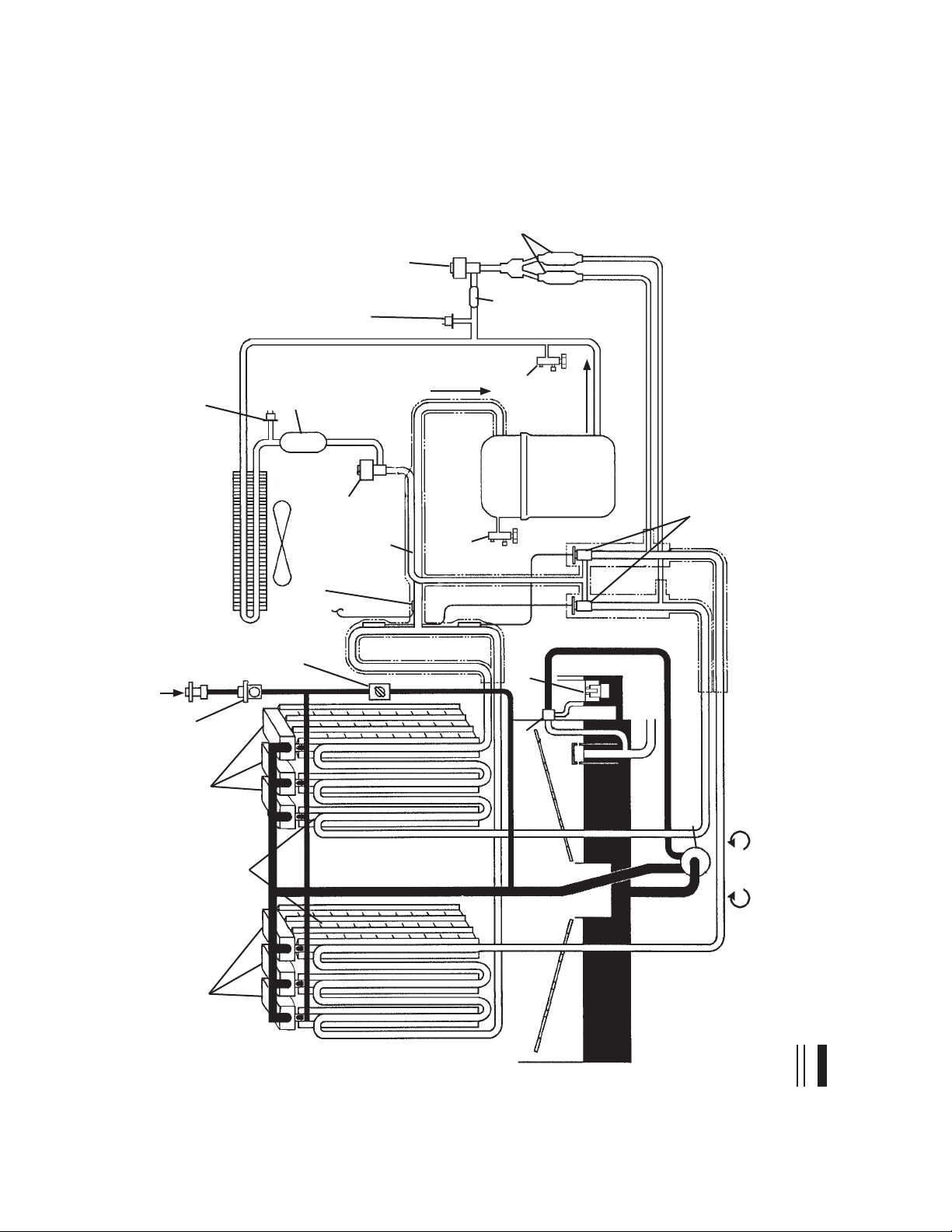

C. Water/Refrigeration Circuit Diagram ............................................................................ 13

1. Air-Cooled Models (SAJ/3) ..................................................................................... 13

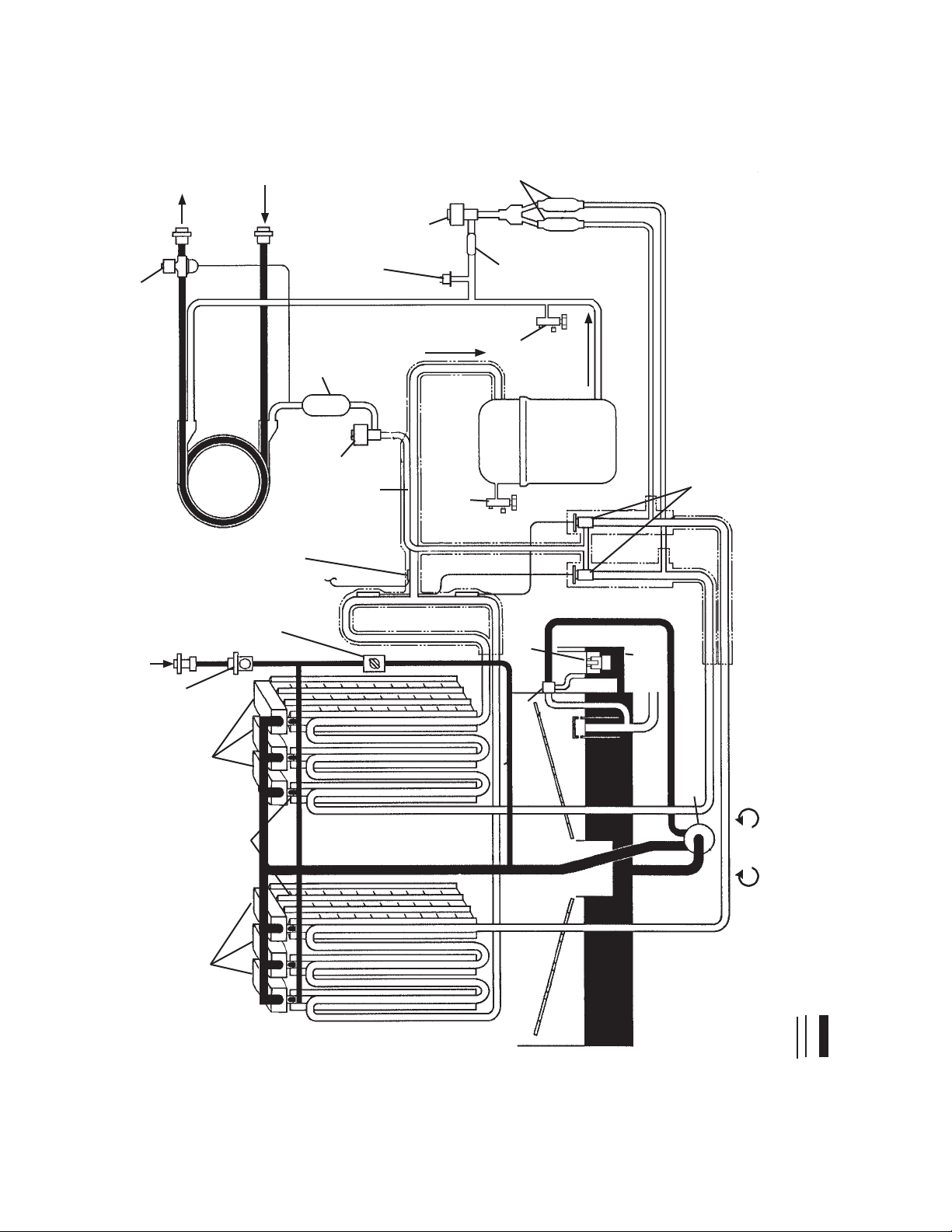

2. Water-Cooled Models (SWJ/3) .............................................................................. 14

3. Remote Models (SRJ/3) ........................................................................................ 15

II. Sequence of Operation and Service Diagnosis ............................................................... 16

A. Sequence of Operation Flow Chart ............................................................................. 16

1. Operation Flow Chart ............................................................................................ 16

2. Shutdown Flow Chart ............................................................................................ 17

3. Freeze-Time Correction Chart ............................................................................... 18

B. Service Diagnosis ....................................................................................................... 19

C. Freeze-Time Correction Cycle (90 min.) ..................................................................... 26

D. Control Board Check ................................................................................................... 28

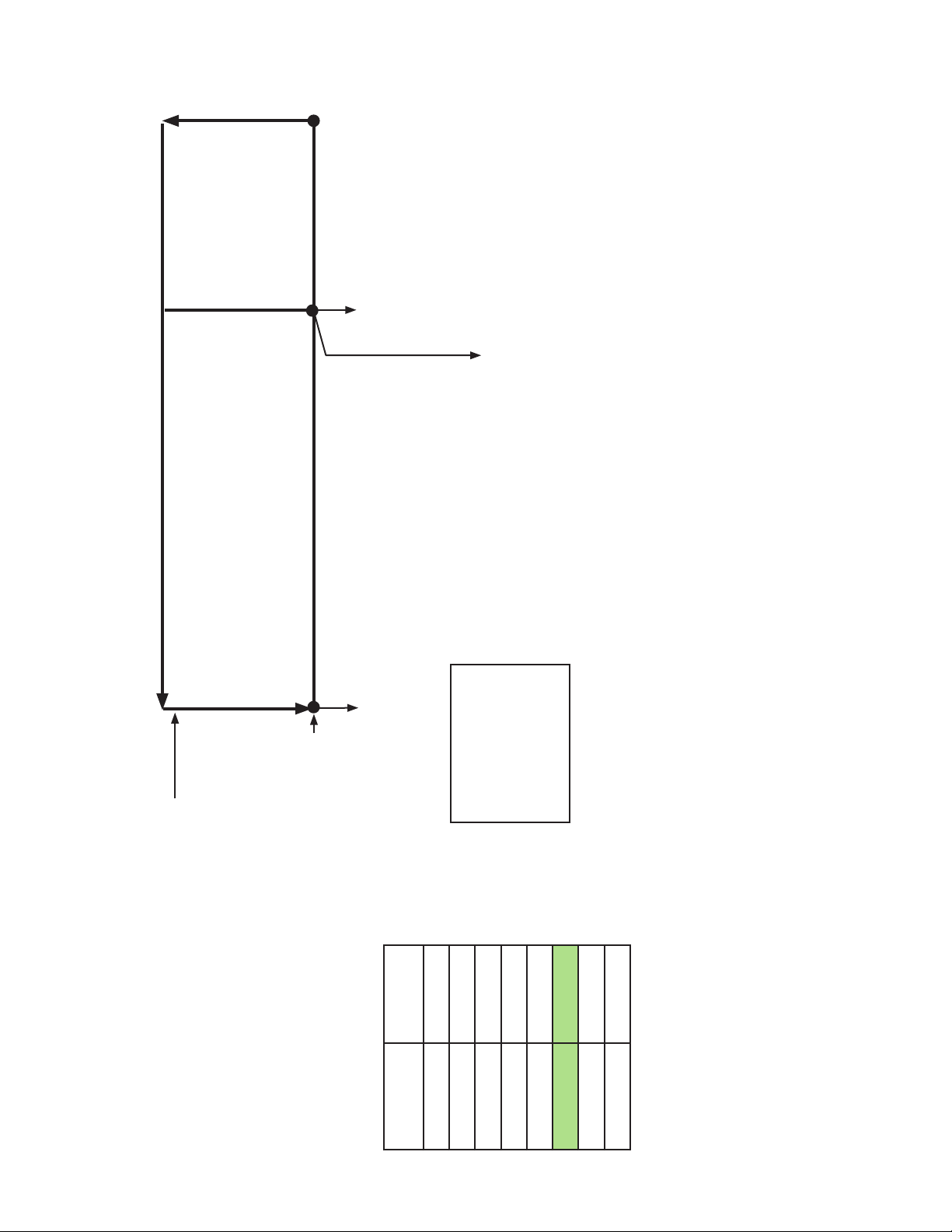

E. Bin Control Check ....................................................................................................... 29

1. Bin Control Check .................................................................................................. 29

2. Bin Control Cleaning .............................................................................................. 30

F. Float Switch Check and Cleaning ................................................................................ 31

1. Float Switch Check ................................................................................................ 31

2. Float Switch Cleaning ............................................................................................ 32

G. Thermistor Check ........................................................................................................ 33

H. Control Switch ............................................................................................................. 33

I. Diagnostic Tables .......................................................................................................... 34

J. Freeze-Up Check List .................................................................................................. 38

3

Page 4

III. Controls and Adjustments ............................................................................................... 39

A. Control Board Layout .................................................................................................. 40

B. LED Lights and Audible Alarm Safeties ....................................................................... 41

C. Settings and Adjustments ............................................................................................ 42

1. Default Dip Switch Settings .................................................................................... 42

2. Harvest Time (S4 dip switch 1 & 2)........................................................................ 43

3. Pump-Out Time/Harvest Time During Pump-Out (S4 dip switch 3 & 4) ................. 43

4. Pump-Out Frequency Control (S4 dip switch 5) ..................................................... 44

5. Harvest Pump Time (Harvest Assist) (S4 dip switch 6) ......................................... 44

6. Harvest Pump Time (Harvest Assist)/Freeze-Time Correction (S4 dip switch 7) .. 45

7. Factory Use (S4 dip switch 8)................................................................................. 45

8. Freeze Timer (S4 dip switch 9 & 10) ...................................................................... 46

9. Float Switch Selector (S5 dip switch 1) ................................................................. 46

10. Rell Counter (S5 dip switch 2 and 3) .................................................................. 46

IV. Refrigeration Circuit and Component Service Information.............................................. 48

A. Refrigeration Circuit Service Information .................................................................... 48

B. Component Service Information .................................................................................. 51

C. Water Regulating Valve Adjustment (water-cooled models) ........................................ 52

V. Maintenance .................................................................................................................... 53

VI. Preparing the Icemaker for Periods of Non-Use ............................................................. 54

VII. Disposal ......................................................................................................................... 56

VIII. Technical Information .................................................................................................... 57

A. Specication and Performance Data ........................................................................... 57

1. KM-1301SAJ .......................................................................................................... 57

2. KM-1301SAJ3 ........................................................................................................ 58

3. KM-1301SWJ ........................................................................................................ 59

4. KM-1301SWJ3 ...................................................................................................... 60

5. KM-1301SRJ with URC-14F .................................................................................. 61

6. KM-1301SRJ3 with URC-14F ................................................................................ 62

7. KM-1601SAJ .......................................................................................................... 63

8. KM-1601SAJ3 ........................................................................................................ 64

9. KM-1601SWJ ......................................................................................................... 65

10. KM-1601SWJ3 ..................................................................................................... 66

11. KM-1601SRJ with URC-22F ................................................................................. 67

12. KM-1601SRJ3 with URC-22F .............................................................................. 68

13. KM-1900SAJ ........................................................................................................ 69

14. KM-1900SAJ3 ...................................................................................................... 70

15. KM-1900SWJ ...................................................................................................... 71

16. KM-1900SWJ3 .................................................................................................... 72

17. KM-1900SRJ with URC-22F ................................................................................ 73

18. KM-1900SRJ3 with URC-22F ...............................................................................74

19. KM-2200SWJ3 .................................................................................................... 75

20. KM-2200SRJ3 with URC-22F ............................................................................. 76

21. KM-2600SWJ3 ..................................................................................................... 77

22. KM-2600SRJ3 with URC-26F ............................................................................. 78

4

Page 5

B. Wiring Diagrams .......................................................................................................... 79

1. Single Phase Models ............................................................................................. 79

a) KM-1301S_J ..................................................................................................... 79

b) KM-1601S_J ..................................................................................................... 80

c) KM-1900S_J ..................................................................................................... 81

2. Three Phase Models .............................................................................................. 82

a) KM-1301S_J3 ................................................................................................... 82

b) KM-1601S_J3 ................................................................................................... 83

c) KM-1900_2200_2600S_J3 ............................................................................... 84

5

Page 6

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, damage to the appliance, or damage to property.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

NOTICE Indicates a situation which could result in damage to the

appliance or property.

IMPORTANT Indicates important information about the use and care of the

appliance.

WARNING

The appliance should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for injury or damage resulting from

improper, incorrect, and unreasonable use. Failure to service and maintain the

appliance in accordance with this manual will adversely affect safety, performance,

component life, and warranty coverage and may result in costly water damage.

To reduce the risk of death, electric shock, serious injury, or re, follow basic

precautions including the following:

• Only qualied service technicians should install and service this appliance.

• The appliance must be installed in accordance with applicable national, state, and

local codes and regulations. Failure to meet these code requirements could result in

death, electric shock, serious injury, re, or damage to the appliance.

• Electrical connection must be hard-wired and must meet national, state, and local

electrical code requirements. Failure to meet these code requirements could result

in death, electric shock, serious injury, re, or damage.

• The icemaker requires an independent power supply of proper capacity. See the

nameplate for electrical specications. Failure to use an independent power supply

of proper capacity can result in a tripped breaker, blown fuse, damage to existing

wiring, or component failure. This could lead to heat generation or re.

• THE ICEMAKER MUST BE GROUNDED. Failure to properly ground the icemaker

could result in death or serious injury.

• To reduce the risk of electric shock, do not touch the control switch with damp

hands.

• Move the control switch to the "OFF" position and turn off the power supply before

servicing. Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

• Do not make any alterations to the appliance. Alterations could result in electric

shock, serious injury, re, or damage.

6

Page 7

WARNING, continued

• The appliance is not intended for use by persons (including children) with reduced

physical, sensory, or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

• Children should be properly supervised around the appliance.

• Do not climb, stand, or hang on the appliance or allow children or animals to do so.

Serious injury could occur or the appliance could be damaged.

• Do not use combustible spray or place volatile or ammable substances near the

appliance. They might catch re.

• Keep the area around the appliance clean. Dirt, dust, or insects in the appliance

could cause harm to individuals or damage to the appliance.

Additional Warning for Remote Models

• THE REMOTE CONDENSER UNIT MUST BE GROUNDED. The power supply and

ground connection to the remote condenser unit are supplied from the icemaker.

Failure to properly ground the remote condenser unit could result in death or

serious injury.

• Wire routing (conduit) and disconnect (if required) must meet national, state, and

local electrical code requirements. Failure to meet these code requirements could

result in death, electric shock, serious injury, re, or damage.

• Move the icemaker control switch to the "OFF" position and turn off the power

supply to the icemaker before servicing the remote condenser unit.

Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

NOTICE

• Follow the instructions in this manual carefully to reduce the risk of costly water

damage.

• In areas where water damage is a concern, install in a contained area with a oor

drain.

• Install the appliance in a location that stays above freezing. Normal operating

ambient temperature must be within 45°F to 100°F (7°C to 38°C).

• Do not leave the appliance on during extended periods of non-use, extended

absences, or in sub-freezing temperatures. To properly prepare the appliance for

these occasions, follow the instructions in "VI. Preparing the Icemaker for Periods of

Non-Use."

• Do not place objects on top of the appliance.

• The dispenser unit/ice storage bin is for ice use only. Do not store anything else in

the dispenser unit/ice storage bin.

7

Page 8

I. Construction and Water/Refrigeration Circuit Diagram

A. KM Construction

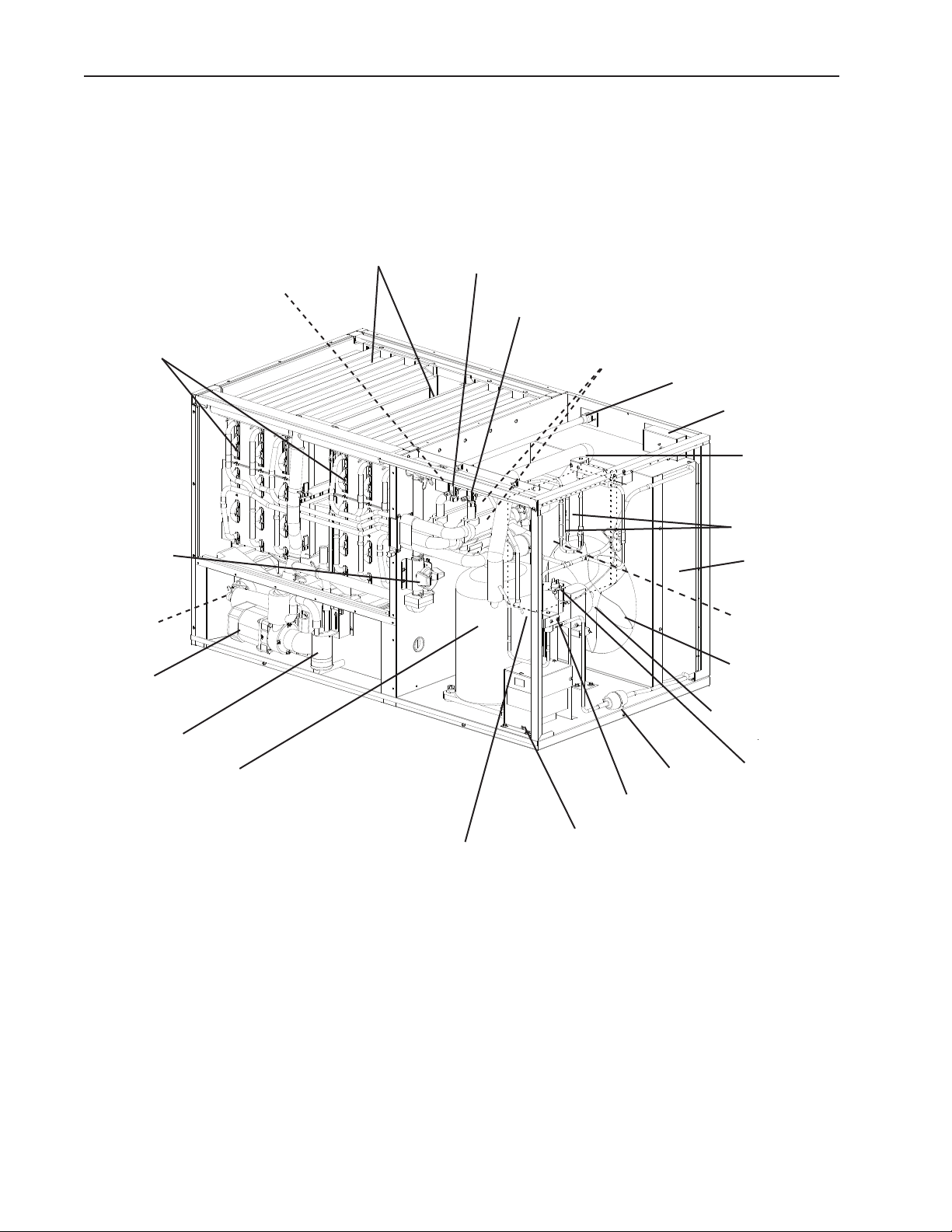

1. Air-Cooled Models (SAJ/3)

Evaporator Assembly

Cleaning Valve

Check Valve

(water)

Water Pump

Inlet Water Valve

Spray Tubes

Low-Side Service Valve

High-Side Service Valve

Thermostatic Expansion Valves

Water Supply Inlet

Junction Box

Hot Gas Valve

Check Valves

(refrigeration)

Condenser

Control Box

Fan Blade

Float Switch

Compressor

Control Switch

Model Shown: KM-1301SAJ3

8

Drier

Liquid Line Valve

Transformer Box

Fan Motor

High-Pressure

Switch

Page 9

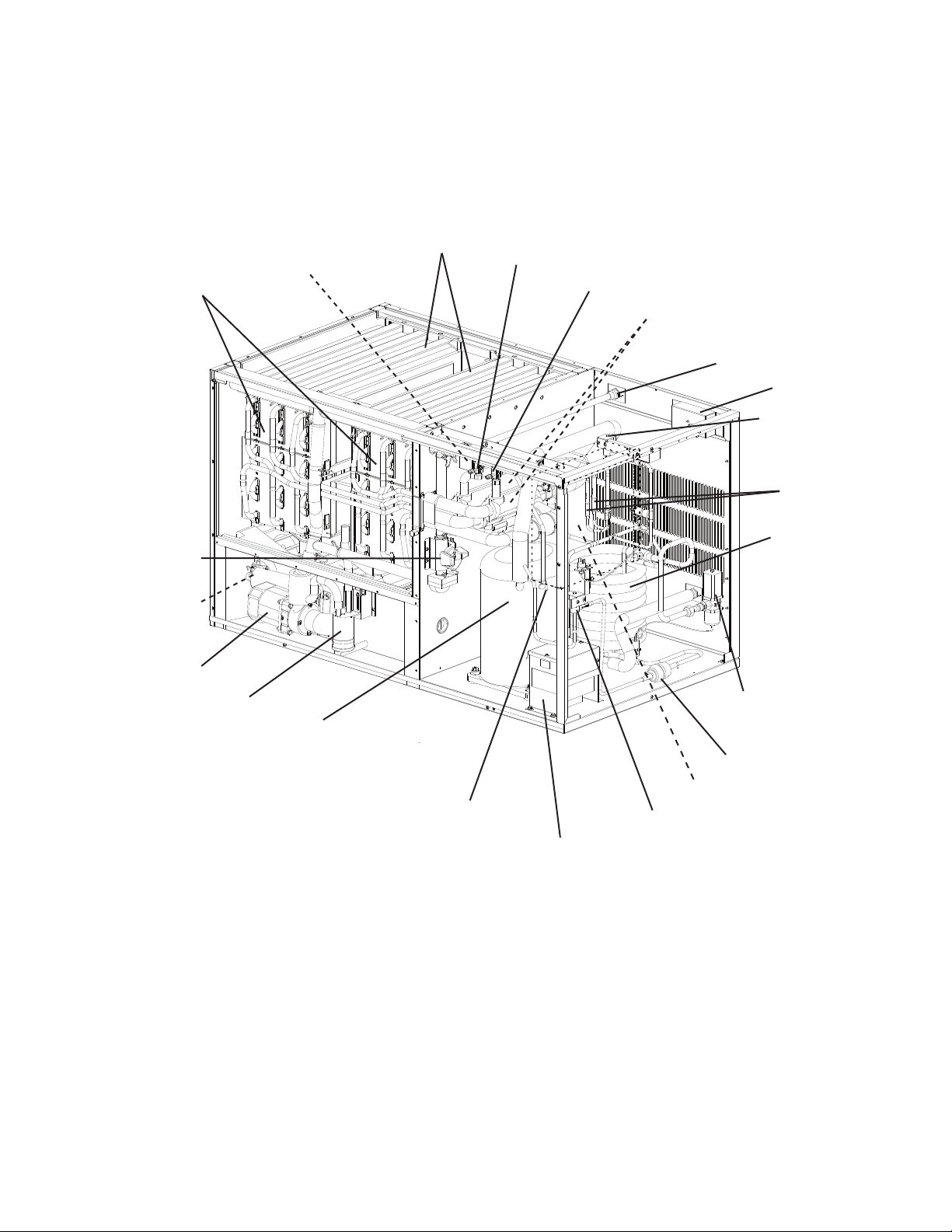

2. Water-Cooled Models (SWJ/3)

Evaporator Assembly

Cleaning Valve

Check Valve

(water)

Water Pump

Float Switch

Inlet Water Valve

Compressor

Spray Tubes

Low-Side Service Valve

High-Side Service Valve

Thermostatic

Expansion Valves

Water Supply Inlet

Junction Box

Hot Gas Valve

Check Valves

(refrigeration)

Water-Cooled

Condenser

Water Regulating

Valve

Control Switch

Transformer Box

Model Shown: KM-1301SWJ3

9

Drier

Control Box

Liquid Line Valve

Page 10

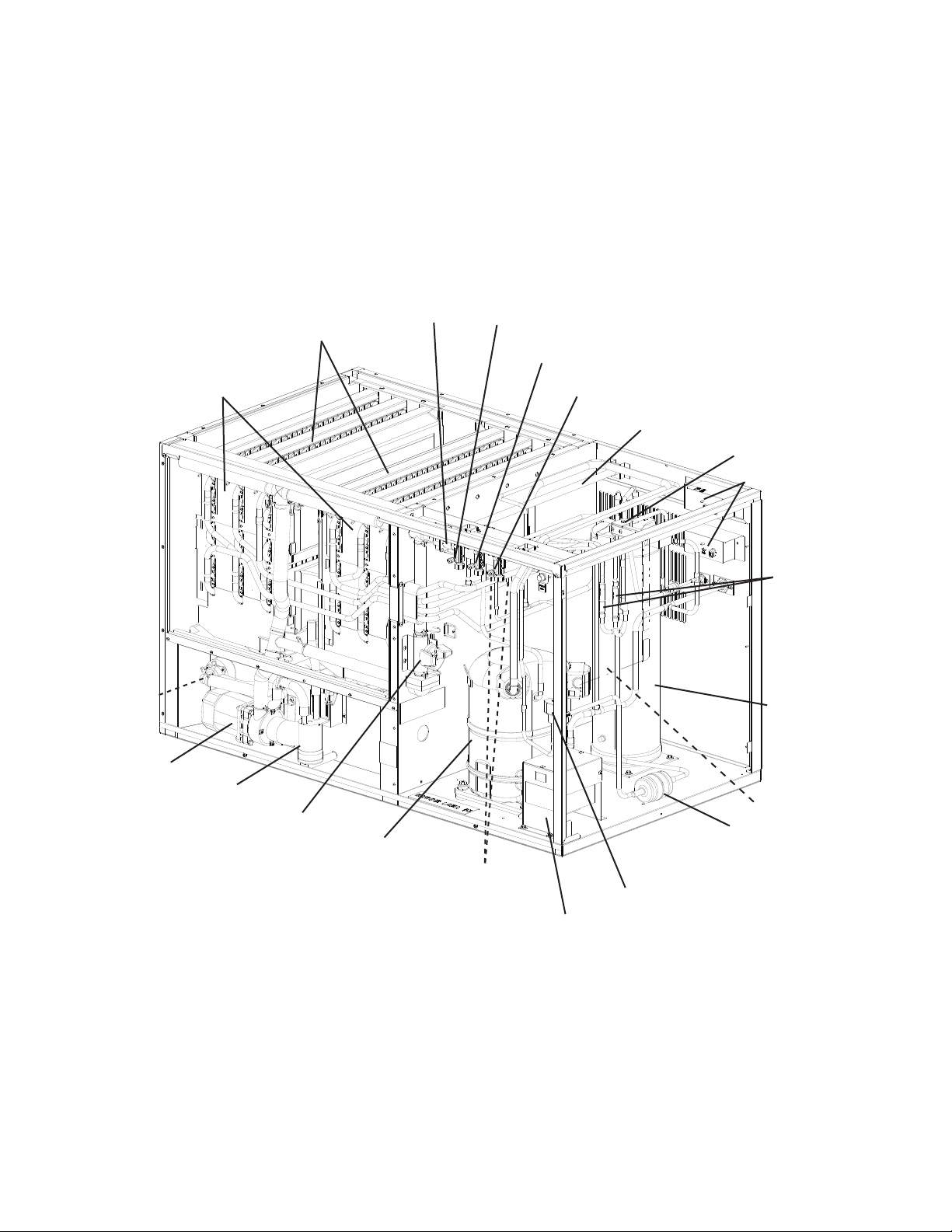

3. Remote Models (KM-1301SRJ/3 and KM-1601SRJ/3)

Evaporator Assembly

Check Valve

(water)

Spray Tubes

Inlet Water Valve

Low-Side Service Valve

High-Side Service Valve

High-Side Liquid Service Valve

Water Supply Inlet

Hot Gas Valve

Junction Boxes

Check Valves

(refrigeration)

Receiver

Water Pump

Float Switch

Cleaning Valve

Compressor

Model Shown: KM-1301SRJ

Thermostatic

Expansion Valves

10

Control Box

Drier

Liquid Line Valve

Transformer Box

Page 11

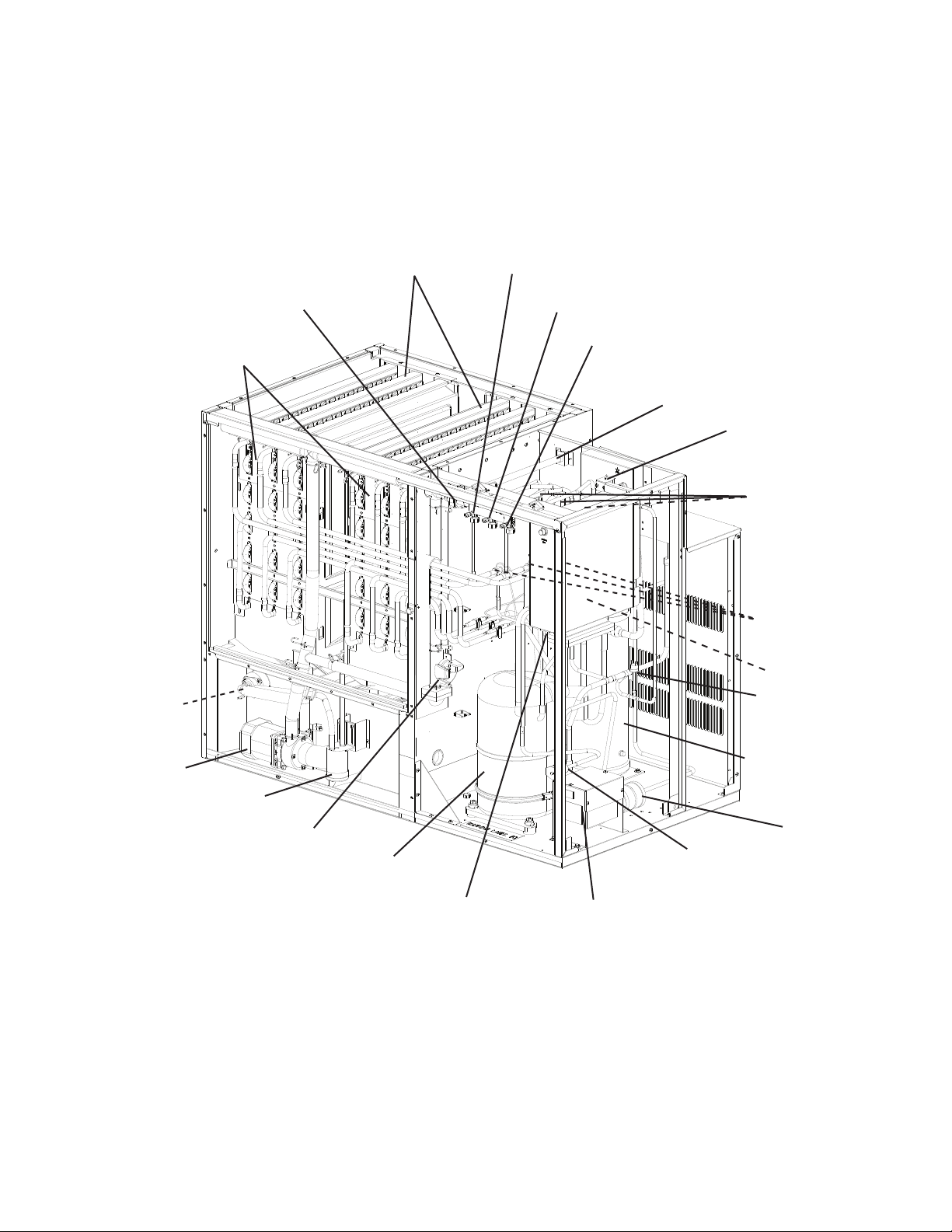

4. Remote Models (KM-1900SRJ/3, KM-2200SRJ3, KM-2600SRJ3)

Evaporator Assembly

Check Valve

(water)

Inlet Water Valve

Spray Tubes

Low-Side Service Valve

High-Side Service Valve

High-Side Liquid Service Valve

Water Supply Inlet

Hot Gas Valve

Check Valves

(refrigeration)

Thermostatic

Expansion Valves

Control Box

High-Pressure

Switch

Water Pump

Float Switch

Cleaning Valve

Compressor

Control Switch

Model Shown: KM-2200SRJ3

Note: KM-2600SRJ3 Includes Headmaster (C.P.R.)

Transformer Box

11

Receiver

Drier

Liquid Line Valve

Page 12

B. Bin Control

1. Single Bin Control

Mechanical Bin Control Connection Overview

Wire Harness

Connector B

(for upper unit)

Thumbscrews

Bin Control Cable Connector to

Wire Harness Connector A

Bin Control Bracket

Bin Control Assembly

2. Stacked Bin Control

Upper Unit Connection Overview

Lower Unit Wire Harness Connector B to

Upper Unit Wire Harness Connector A

Upper Unit Wire Harness

Connector B (not used)

Bin Control

Cable

Bracket

Wire Harness

Control Board

Red K4 Connector

Wire Saddle

Bin Control

Cable Bracket

Bin Control Cable

Upper Unit Wire Harness

Control Board

Red K4 Connector

Lower

Unit Wire

Harness

Wire Saddle

Control Board

Red K4 Connector

Wire Harness

Connector B

(for upper unit)

Bin Control

Cable Connector

Upper Unit Connection Detail

Upper Unit Wire Harness

Connector B (not used)

Lower Unit Wire Harness

Connector B

See "II.D.1. Dispenser

Unit/Ice Storage Bin

and Icemaker Setup"

and "II.D.2. Bin Control

Installation" for the

Lower Unit Connection

Connection Detail

Wire Harness

Connector A

Control Board

Red K4 Connector

Upper Unit

Wire Harness

Connector A

Control Board

Red K4 Connector

12

Page 13

C. Water/Refrigeration Circuit Diagram

1. Air-Cooled Models (SAJ/3)

Hot Gas

Val ve

High-Pressure

Switch

Check

Valves

Strainer

Drier

Fan Speed Control

Pressure Switch

KM-1601SAJ/3

Suction Line

Fan

Condenser

Water Supply

Inlet Water Valve

Spray Tubes

Cleaning Valve

Liquid Line

Thermistor

Val ve

Heat Exchanger

Service

Val ve

Service

Val ve

Float Switch

Check Valve

Discharge Line

Compressor

Thermostatic Expansion Valves

Drain

Water Pump

Pump-Out

Spray Tubes

Evaporator

13

Water

Tank

Freeze/Harvest

Pump Timer

Refrigeration Circuit

Water Circuit

Page 14

2. Water-Cooled Models (SWJ/3)

Check

Valves

Water Regulating Valve

Drain/Return

Condenser

Water Supply

High-Pressure

Switch

Hot Gas

Val ve

Strainer

Drier

Service

Val ve

Discharge Line

Suction Line

Liquid Line

Val ve

Service

Val ve

Compressor

Thermostatic Expansion Valves

Heat Exchanger

Thermistor

Cleaning Valve

Float Switch

Drain

Water Supply

Inlet Water Valve

Spray Tubes

Check Valve

Water Pump

Pump-Out

Evaporator

Freeze/Harvest

Pump Timer

Water

Tank

Refrigeration Circuit

Water Circuit

Spray Tubes

14

Page 15

3. Remote Models (SRJ/3)

Service

Val ve

Fusible Plug

High Pressure

Hot Gas

Switch

Check

Valves

Val ve

Strainer

KM-2500SRH3: Headmaster

located in icemaker

Condenser

Water

Service

Val ve

Discharge Line

Suction Line

Receiver

Drier

Headmaster

(C.P.R.)

Service

Liquid Line

Val ve

Fan

Heat Exchanger

Val ve

Compressor

Expansion Valves

Thermistor

Cleaning Valve

Supply

Inlet Water Valve

Float Switch

Check Valve

Drain

Water Pump

Spray Tubes

Spray Tubes

Evaporator

15

Water

Tank

Pump-Out

Freeze/Harvest

Pump Timer

Refrigeration Circuit

Water Circuit

Page 16

II. Sequence of Operation and Service Diagnosis

A. Sequence of Operation Flow Chart

1. Operation Flow Chart

10th cycle

(S4 dip switch 5)

2 sec., then reverses

for 10/20 sec.

• Factory set for every

4. Pump-Out Cycle

• Pump motor stops for

(S4 dip switch 3 & 4)

FS in control

FS opens or freeze

timer terminates

Comp energized

FM*/FMR energized

HGV energized

PM de-energizes for 2 sec.,

then reverses for 10/20 sec.

Anti-Slush

Thermistor temperature

reaches 36°F (2.2°C)

(5.8 kΩ).

PM de-energized for

FM* de-energized

LLV de-energized

10 sec.

CB: 2A7664-02

When freeze time differential exceeded,

freeze-time correction cycle starts.

See "II.A.3. Freeze-Time Correction

Chart."

FS closed

50 sec.

Comp energized

FM energized

FMR energized

PM energized

LLV energized

HGV de-energized

FS check

FS open

3. Freeze Cycle

• Min. freeze time: 5 min.

• Max. freeze time: freeze timer setting

(S4 dip switch 9 & 10).

5-min.

minimum

freeze timer

in control

Harvest Pump

Time

Operation Flow Chart

PM energized

1 to 3-min. harvest timer in

control (S4 dip switch 1 & 2)

Thermistor

in control

HPT setting (S4 dip switch 6), whichever is

shorter.

• WV time: 6 min. or the length of harvest minus

2. Harvest Cycle

• Max. harvest time: 20 min.

WV de-energized

FS closed

Comp energized

Thermistor temperature reaches

48°F (9°C) (3.9 kΩ or less).

Harvest timer starts.

FM*/FMR energized

HGV energized

WV energized

FM* – FM energized in 2. Harvest Cycle and

4. Pump-Out Cycle when connected to CB

K1 connector pin #9.

Components Energized when the Control Switch is in the "WASH" Position

The "WASH" position on the control switch is used when cleaning and sanitizing the unit. When in the "WASH" position,

power is supplied to the pump motor. With the cleaning valve closed, the cleaner and sanitizer ow over the outside of the

evaporator plate assembly. With the cleaning valve open, the cleaner and sanitizer ow over both the outside and the inside

of the evaporator plate assembly.

Note: Close the cleaning valve after cleaning and sanitizing are complete, otherwise the unit will not restart when the control

switch is placed in the "ICE" position.

WV energized

FS open

16

If FS is open, Comp stops and cycle

returns to 1-Min. ll.

Legend:

BC–bin control

CB–control board

Comp–compressor

FM*–fan motor

FMR–fan motor-remote

FS–oat switch

HGV–hot gas valve

HPT–harvest pump time

LLV –liquid line valve

PM–pump motor

WV–inlet water valve

Fill Cycle

1. 1-Minute

Cycle

Steps

FS check

Startup

Page 17

2. Shutdown Flow Chart

3. Ice Level Lowered

Icemaker starts at

"1. 1-Minute Fill Cycle."

To 1. 1-Minute Fill Cycle

BC closed

(BC actuator paddle disengaged)

Green "BC CLOSED" LED on

Yellow "BC OPEN" LED off

2. Icemaker Off

All components

de-energized.

Yellow "BC OPEN" LED continues.

All components de-energized.

Shutdown Flow Chart

Control board 2A7664-02 retains freeze-time

correction count data between bin control restarts.

to 15 sec. into the freeze cycle if

activated at the end of the harvest cycle.

15 sec. before the 5-min. short cycle

protection timer terminates.

Otherwise, at the end of the next harvest

cycle.

BC open (BC actuator paddle engaged)

Green "BC CLOSED" LED off

Yellow "BC OPEN" LED on

Legend:

BC–bin control

1. Bin Full

Shutdown Delay:

• Fill Cycle–15 sec. after activation.

• Harvest Cycle–At the end of the harvest cycle, or up

• Freeze Cycle– 15 sec. after activation if activated at least

Shutdown

and Restart

BC Operation

17

Page 18

3. Freeze-Time Correction Chart

2. 10-Minute Fill/Overow

WV energized

Comp de-energized

FMR de-energized

HGV de-energized

PM de-energized

After 5th 10-Minute Harvest Pump Cycle with WV

Freeze-Time Correction Cycle Complete.

Go to Step "3. Freeze Cycle" in Operation Flow Chart.

repeat step 1 for 5th and nal time.

• Do not adjust S4 dip switch 7 out of the factory position.

• After step 2 completes 4th sequence (80 min. completed),

1. 10-Minute Harvest Cycle with WV

Comp energized

FMR energized

HGV energized

PM energized

WV energized

2A7664-02 Freeze-Time Correction Flow Chart

Cycle Steps

Steps 1 and 2 repeat

4 times (total 80 min.),

then step 1 repeats for

a 5th time to complete

Freeze-Time Correction

Start

Legend:

Comp–compressor

FM–fan motor

FMR–fan motor-remote

HGV–hot gas valve

PM–pump motor

WV–inlet water valve

Appliance Cycle Reset and Alarm Reset:

Cycle Reset: Power Supply or Control Switch Turned Off and On

again: Appliance turns off, then re-starts at 1.Fill Cycle.

Alarm Reset: CB "ALARM RESET" pressed during or after a

freeze-time correction cycle with power supply on:

Appliance continues cycle with no interruption or reset.

CB red "POWER OK" LED blinking:

CB red "POWER OK" LED resets to solid.

CB yellow "EXT HARVEST" LED blinking:

Cycle.

Differential

Value in Sec.

3 254

4 309

5 349

6 380

7 406

8 427

9 446

10 462

CB yellow "EXT HARVEST: LED turns off.

Freeze Time Differential Exceeded.

Minimum and Maximum Freeze times

have exceeded differential parameters.

Freeze-Time Correction function is

enabled when S4 Dip Switch 7 is in the

"ON" position. CB monitors freeze time.

After 3freeze cycles, CB compares the

minimum and maximum differential of

the 3 freeze cycle times. Every freeze

cycle time after the third freeze cycle

time is added to the minimum/maximum

calculation.

Example: After 8 cycles, if the differential

between the shortest cycle (minimum)

and the longest cycle (maximum) is equal

to or greater than 427 sec. a freeze-time

correction cycle is initiated:

Number of

Freeze Cycles

18

Note: When 1st freeze-time correction

cycle is initiated, CB "POWER OK"

LED starts blinking. On 2nd freeze-time

correction cycle, if CB "POWER OK"

LED has been reset, CB "POWER OK"

LED starts blinking. If CB "POWER OK"

had not been reset after 1st freeze-time

correction cycle CB "POWER OK" LED

continues to blink.

After 3rd freeze-time correction cycle in

36hours, CB yellow "EXT HARVEST"

LED starts blinking.

Appliance continues to operate and LEDs

continue to blink until ALARM RESET

button is pressed with power on.

Page 19

B. Service Diagnosis

WARNING

• The appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Risk of electric shock. Control switch in "OFF" position does not de-energize all

loads Use extreme caution and exercise safe electrical practices.

• Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

• Before servicing the appliance, move the control switch to the "OFF" position and

turn off the power supply.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the appliance is serviced. Make sure that none have fallen

into the dispenser unit/ice storage bin.

• Make sure all food zones in the appliance and dispenser unit/ice storage bin are

clean after service.

The diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components. Before proceeding, check for correct installation, proper voltage

per nameplate, and adequate water supply. Check CB using the steps in "II.D. Control

Board Check." Check dip switch settings to assure that S4 dip switch 3, 4, 7, 8, 9, 10 and

S5 dip switch 1 through 5 are in the factory default position. S4 dip switch 1, 2, 5, 6 are

cleaning adjustments and the settings are exible. For factory default settings, see "III.C.1.

Default Dip Switch Settings."

Note: • When checking high voltage (115VAC), always choose a white (W) neutral wire to

establish a good neutral connection.

• On models with a main transformer, the neutral (W) is provided through MT.

To conrm a good neutral, check for 60VAC from white (W) neutral to ground

(GND). If 60VAC is present, neutral is good. If 60VAC is not present, check

208-230VAC main power supply to MT. If 208-230VAC is present, check MT

continuity.

• When checking voltage from the CB K1 connector (10 pin connector), pull CB

K1connector out slightly to allow room for multimeter test leads contact.

1) Turn off the power supply, then access the control box. Move the control switch to the

"OFF" position. Clear any ice from BC.

2) Check that BC is closed and the 115VAC 10A fuse is good.

19

Page 20

1. Operation Diagnosis

3) Power On: Turn on the power supply, then move the control switch to the "ICE" position.

A 5-sec. delay occurs. CB red "POWER OK" LED and green "BC CLOSED" LED turn

on. If yellow "BC OPEN" LED is on (indicating a full bin), check BC. Move ice away from

BC actuator paddle. If yellow "BC OPEN" LED stays on, see "II.D. Bin Control Check.".

Note: • CB red "POWER OK" LED remains on unless the 10.5VAC power supply is

interrupted (K2 connector).

• Check CB using the steps in "II.C.Control Board Check."

• Conrm CB green "BC CLOSED" LED is on. If CB yellow "BC OPEN" LED is on,

remove ice from BC. If no ice is around BC and yellow "BC OPEN" LED is on,

see "II.D.2. Bin Control Check."

a) Power On Diagnosis: If CB red "POWER OK" LED is off, conrm 10A fuse is good.

Check for 115VAC at control switch #1 (BR) to neutral (W) then at control switch

#2(P) to neutral (W). If 115VAC is present on #1 (BR) and not on #2(P), replace

control switch. If 115VAC is present on control switch #2 (P), check for 115VAC at

HPS (P) to neutral (W) then HPS (BK) to neutral (W). If115VAC is present at HPS

(P) and not at HPS (BK), HPS is open. See HPS Diagnosis below. If115VAC is

present at HPS (BK), check for 10.5VAC at CB K2#1 red wire to CB K2 #2 red wire.

If10.5VAC is not present, check that the cleaning valve interlock switch is closed.

Next, check CT continuity. If open, replace CT.

b) HPS Diagnosis: Conrm condenser coil is not clogged or restricted. Let refrigeration

circuit pressures equalize. If HPS does not reset and pressures are equalized,

replace HPS. Ifpressures are not equalized, reclaim refrigerant and diagnose

refrigeration circuit restriction. Check that there are no restrictions in the refrigeration

circuit.

Harvest Cycle: HGV, strainer, or check valve.

Freeze Cycle: FM, FMR, TXV, HM, LLV, WRV, strainer, check valve, drier, damaged

line set or tting, and fan blade for binding.

Conrm that the location meets installation requirements. See the appliance's

instruction manual for details.

4) 1-Min. Fill Cycle – LED 4 is on. WV and X11 relay energize. After 1 min., CB checks for

a closed FS. If FS is closed, the harvest cycle begins. If harvest cycle begins (Comp,

HGV, FMR energized), continue to step 5a. If FS is open, WV remains energized until

FS closes (low water safety protection during initial start up and at the end of each

harvest). Diagnosis: Check that water enters the water tank. If not, check that the water

supply line shut-off valve is open and screens or external lters are clear. Check for

115VAC at CB K1 #6 (O) to neutral (W). If 115VAC is not present, replace CB. If 115VAC

is present, and WV does not energize, check for 115VAC at WV. If 115VAC is present,

check coil continuity. Ifopen, replace WV. If the water tank lls, but the appliance fails to

start harvest (Comp energized), check for open FS. See "II.E. Float Switch Check and

Cleaning." If FS is closed and CB fails to start the harvest cycle after 1 min., replace CB.

20

Page 21

5a) Initial Harvest Cycle – LEDs 1, 4, and 2 are on. WV and X11 relay continue. Comp,

FM* (if connected to CB K1 connector pin #9), FMR, HGV, and X10 relay energize.

CBmonitors the warming of the evaporator via the thermistor located on the suction

line. When the thermistor reaches 48°F (9°C), CB reads 3.9 kΩ from the thermistor

and turns harvest termination over to the harvest timer (S4 dip switch 1 & 2 and S5dip

switch 4). WV and X11 relay are energized during harvest for a maximum of 6 min. or

the length of harvest minus HPT setting (S4 dip switch 6), whichever is shorter. See

step 5b below.

a) Comp Diagnosis: Check that evaporator is warming. Ifnot, conrm that Comp

energizes. If not, check for 115VAC at CB K1 #1 (V) or #9 (V) to neutral (W).

If115VAC is not present, check for 115VAC at CB K1 #7 (BR) or #10 (BR) to neutral

(W). If115VAC is present at #7 (BR) or #10 (BR) and not at #1 (V) or #9 (V), replace

CB. If 115VAC is present, check for 115VAC at CR or MC solenoid. If 115VAC is

present, conrm contacts are closed. If not, replace CR or MC. If CR or MC contacts

are closed, check Comp external overload, Comp start and run capacitors, Comp

start relay, and Comp motor winding.

b) HGV Diagnosis: If Comp is energized and evaporator is not warming, check that

HGV energizes and opens. Check for 115VAC at CB K1 #2 (P) to neutral (W).

If115VAC is not present and LED 2 is on, replace CB. If 115VAC is present, check for

115VAC at HGV coil and check HGV coil continuity. Replace as needed.

c) LLV Diagnosis: Conrm that LLV is de-energized and closed (not bypassing).

Ifenergized, replace CB. If de-energized and bypassing, replace LLV.

d) FM* Diagnosis (if connected to CB K1 connector pin #9):

KM-1301SAJ3: Check that FM* is energized and fan blades are turning. If not, check

FM* capacitor, motor winding, and fan blade for binding. Note: FM* is energized at

full speed RPMs (1600) during the harvest cycle and only capable of 1 speed.

KM-1601SAJ/3: Check that FM* is energized and fan blades are turning. If not, check

FM capacitor, motor winding, and fan blade for binding. Note: KM-1601SAJ/3 FM* is

capable of 2speeds and is energized at slower RPMs (700) during the harvest cycle

through the fan speed control pressure switch. If FM* is operating at high-speed

RPMs (1600) during the harvest cycle, check condition of the fan speed control

pressure switch.

When open, head pressure <190 +- 10 PSIG RPMs at 700.

When closed, head pressure >250 +- 10 PSIG RPMs at 1600.

e) WRV Diagnosis: Conrm WRV is not leaking by. If WRV is leaking by, conrm HGV

is open and LLV is closed. Next, check for proper refrigerant pressures. If refrigerant

pressures are correct, adjust or replace WRV. See "IV.C. Water Regulating Valve

Adjustment (water-cooled models)."

21

Page 22

5b) Harvest Pump Time (Harvest Assist) – LEDs 1, 3, and 2 are on. When the

thermistor reaches 48°F (9°C), CB reads 3.9 kΩ from the thermistor and turns harvest

termination over to the harvest timer (S4 dip switch 1 & 2 and S5 dip switch4).

WhenWV de-energizes, LED 4 turns off, X11 relay de-energizes and LED 3turns on.

PM energizes. Comp, FM* (if connected to CB K1 connector pin #9), FMR, HGV, and

X10relay continue.

Diagnosis: Place a thermometer on the suction line next to the thermistor. Has it

warmed to 48°F (9°C) or warmer? Conrm thermistor status. See "II.F. Thermistor

Check." If the thermistor reading is in proper range, dip switch 7 is on, and PM does

not energize before harvest terminates, replace CB. If WV continues, check for 115VAC

at CB K1 #6 (O). If115VAC is present, and LED 4 is off, replace CB. If LED 3is on

and PM is not energized, check for 115VAC at CB K1 #5(DBU). If115VAC is not

present, replace CB. If 115VAC is present and PM is not energized, check for 115VAC

at X10relay terminal #7 (Y) to neutral (W). If 115VAC is not present, check for 115VAC

at X10 relay terminal #3 (P) to neutral (W) and X10 relay terminal #5 (Y) to neutral (W).

If 115VAC is present on terminal #3(P) and not on terminal #5 (Y), replace X10 relay.

If 115VAC is present on X10 relay terminal #7 (Y) and PM is not energized, check for

115VAC at X10 relay terminal #4 (R) to neutral (W) and terminal #6 (DBU) to neutral

(W). If 115VAC is present on terminal #6(DBU) and not on terminal #4 (R), replace

X10relay. If 115VAC is present on X10relay terminal #4 (R), check control switch

contact continuity between terminals #4(R) and #5(R). Ifcontacts are open, replace

control switch. If contacts are closed and 115VAC is present between control switch

terminal #5(R) and neutral (W), check PM capacitor and motor winding continuity.

5c) Initial Harvest Cycle Termination Diagnosis: When the thermistor reaches 48°F

(9°C), CB reads 3.9 kΩ from the thermistor and turns harvest termination over to

the harvest timer (S4 dip switch 1 & 2 and S5 dip switch 4). Check discharge line

temperature. For a thermistor check, see "II.F.Thermistor Check." If 1-min. ll cycle

starts after harvest timer terminates, check that FS is clean and operating properly, see

"II.E. Float Switch Check and Cleaning." If FS is closed, CB proceeds to the next cycle.

Ifnot, replace CB.

Note: The minimum total time allowed by CB for a complete harvest cycle is based on

S5 dip switch 4. Maximum harvest time allowed is 20min.

NOTICE! S4 dip switch 7 must remain on. Otherwise, PM will not energize during

the last seconds of harvest.

6) Freeze Cycle – LED 1 is on. Comp, FM* (if connected to CB K1 connector pin #9),

FMR, and PM continue. FM (if not connected to CB K1 connector pin #9) and LLV

energize. HGV and X10 relay de-energize. Appliance is held in freeze by a 5-min. short

cycle protection timer. After 5-min. short cycle protection timer terminates and FS opens,

freeze cycle terminates.

Note: PM power supply switches from CBK1 #5(DBU) in harvest to K1 #4 (R) in freeze.

Anti-Slush: When anti-slush is enabled (S5 dip switch 5 "ON"), PM de-energizes when

thermistor reaches 36°F (2.2°C) (5.8kΩ) for 10 sec. then, energizes for the remainder of

the freeze cycle.

22

Page 23

a) Freeze Cycle Diagnosis: Conrm Comp, FM* (if connected to CB K1 connector pin

#9), FMR, and PM continue. Conrm that FM (if not connected to CB K1 connector

pin #9) and LLV energize. Conrm WRV opens. Next, conrm HGV and X10 relay

de-energize. During the rst 5 min. of freeze, conrm evaporator is cooling. If not,

conrm WV de-energized (not leaking by), HGV de-energized (not bypassing), LLV

and FM (if not connected to CB K1 connector pin #9) energize, TXV and HM operate

correctly, WRV opens, Comp is efficient, and refrigerant charge is correct. See

"VIII.A. Specication and Performance Data."

b) Comp, FM*, and FMR Diagnosis: If Comp. FM* (if connected to CB K1 connector

pin #9), and FMR de-energize once freeze begins, check that appliance has not

shut off on HPS ("POWER OK" LED off). If so, check "3)b) HPS Diagnosis" above.

If"POWER OK" LED is on, check for 115VAC at CB K1 #1 (V) or #9 (V) to neutral

(W). If 115VAC is not present and LED 1 is on, replace CB.

Comp: If 115VAC is present, check for 115VAC at CR or MC coil. If 115VAC is

present, check CR or MC coil and contact continuity. Replace as needed. If CR or

MC is okay, check Comp start relay and start and run capacitors. Next, check Comp

motor winding continuity. If Comp is energized but evaporator is not cooling, check

for an inefficient Comp. See "VIII.A. Specication and Performance Data."

FM*: If Comp is energized but FM* is not, check capacitor, motor winding, and fan

blade for binding.

FMR: If Comp is energized but FMR is not, check for 115VAC at the FMR junction

box. If 115VAC is not present, check icemaker wiring connections. If 115VAC is

present, check for voltage at condenser unit. If115VAC is not present, check eld

wiring connections. If 115VAC is present, check FMR capacitor, motor winding, and

fan blade for binding.

c) WV and HGV Diagnosis: If WV is energized, check for 115VAC at CB K1 #6 (O) to

neutral (W). If 115VAC is present after PM energizes in harvest cycle, replace CB.

If115VAC is not present, replace WV (bypassing). If HGV did not close at the end of

harvest, check for 115VAC at CB K1 #2 (P) to neutral (W). If 115VAC is present and

LED 3 is off, replace CB. If 115VAC is not present, replace HGV (bypassing).

d) PM Diagnosis: Conrm water is owing over evaporator from PM and not WV. If PM

de-energizes once freeze begins, check for 115VAC at CB K1 #4 (R) to neutral (W).

If 115VAC is not present, replace CB. If 115VAC is present and PM is de-energized,

check for 115VAC at control switch #5 (R) to neutral (W). If 115VAC is present at CB

K1 #4 (R) and not at control switch #5 (R), check control switch continuity between

#5 (R) and #4 (R). Replace as needed. If 115VAC is present at control switch #5 (R)

to neutral (W), check PM capacitor and motor winding continuity.

e) FM and LLV Diagnosis: If FM (if not connected to CB K1 connector pin #9) or LLV

does not energize, check for 115VAC at CB K1#3 (BK) to neutral (W). If 115VAC is

not present, replace CB. If 115VAC is present:

For FM, check capacitor, motor winding, and blade for binding.

For LLV, check coil voltage and continuity.

23

Page 24

f) Refrigerant Pressures, HM, and TXV Diagnosis: If evaporator is still not cooling,

check refrigerant pressures. See "VIII.A. Specication and Performance Data."

Next, check HM operation. If refrigeration pressures are above HM setpoint and

HMis bypassing, replace HM. Check TXV for proper operation. Remove TXV bulb

and hold it in your hand, refrigerant low-side pressure should rise, place TXV bulb in

ice water, refrigerant low-side pressure should drop. A 10 to 15 pound pressure swing

between warm and cold conditions indicate a good TXV. If a 10 to 15 pound swing is

not present, replace TXV.

g) WRV Diagnosis: WRV is factory set and generally no adjustment is required.

IfWRV fails to open in freeze, check for proper refrigerant pressures. See "VIII.A.

Specication and Performance Data." If refrigerant pressures are correct and WRV

does not open, adjust or replace as needed. See "IV.C. Water Regulating Valve

Adjustment (water-cooled models)."

h) Freeze Termination Diagnosis: After 5 min. in freeze, disconnect CB K5 FS

connector. 15 sec. later appliance should switch out of the freeze cycle (15 second

delay after FS opens before terminating the freeze cycle). If appliance remains in

freeze longer than 15 sec. after FS removed, replace CB. If appliance switches with

FS removed but would previously not switch out of freeze with FS connected (long

freeze - 3 beep alarm), see "II.E. Float Switch Check and Cleaning."

Note: Normal freeze cycle will last 20 to 40 min. depending on model and conditions.

Cycle times and pressures should follow performance data provided in this

manual. See "VIII.A. Specication and Performance Data."

i) Short Freeze Cycle Diagnosis: Conrm water tank lls and overows during ll and

harvest cycles. If not, check water supply lters, shut-off valve, WV screen. Ifwater

tank empties before 5 min. timer terminates and freeze cycle is short, check that CV

is not leaking by (water owing down the potable drain). If CV is leaking by, remove

and clean CV, replace rubber seat and spring if necessary. If water tank is full, see

"II.E. Float Switch Check and Cleaning." for erratic FS.

7) Pump-Out Cycle – LEDs 1, 3, and 2 are on (10/20 second pump-out). Timing of the

rst pump-out is determined by S4 dip switch 5. See the table below.

"J" Control Board Settings

S4 Dip

Switch

Setting

No. 5

OFF Every 10 cycles After 11th freeze cycle

ON Every cycle After 2nd freeze cycle

Pump-Out

Frequency

1st Pump-Out

"J" Control Board

Comp, FM* (if connected to CB K1 connector pin #9), and FMR continue, HGV

energizes. If S4dip switch 3 & 4 are set to 3 off and 4 on, LED 4 turns on and WV

and X11 relay energize, energizing X10relay. NOTICE!S4dip switch 3 & 4 must

not be set to 3 off and 4 on. Otherwise, PM will rotate in freeze cycle direction

instead of pump-out direction. FM (if connected to CB K1 connector pin #3) and

LLVde-energize. PM stops for 2 sec., then reverses for 10/20 sec. depending on

pump-out timer (S4dip switch 3 & 4) setting. When the pump-out timer terminates,

24

Page 25

pump-out is complete. The pump-out frequency control (S4 dip switch 5) is factory set,

and generally no adjustment is required. However, the pump-out frequency control can

be set to have a pump-out occur every 10 cycles or every cycle. For details, see "III.C.4.

Pump-Out Frequency Control (S4 dip switch 5)."

Pump-Out Diagnosis: In the freeze cycle before pump-out (see table above), after

5min. of freeze disconnect CB black K5 connector (FS connector). Check that PM

stops and re-starts. Next, check that PM rotation is correct (water owing down the

drain through CV). If PM does not stop and re-start, check that CB LEDs 1, 3, and

2are on. If not, replace CB. IfLEDs1,3, and 2 are on and PM does not energize,

check for 115VAC at CB K1 #5 (DBU) to neutral (W). If 115VAC is not present, replace

CB. If115VAC is present, check that X10 relay is de-energized. If not, check X11 relay

status. If X11 relay is energized, replace CB. If X11 relay is de-energized and X10 relay

is energized, replace X11 relay (contacts sticking). If X10 relay is de-energized, check

for 115VAC at terminal #6 (DBU) to neutral (W) and terminal #2 (DBU) to neutral (W).

If 115VAC is present on terminal #6 (DBU) and not on terminal #2 (DBU), replace

X10relay. If PM is energized and rotating in pump-out rotation, make sure the drain line

is not clogged and that CV is clean and operating properly.

Conrm FM (if connected to CB K1 connector pin #3) and LLV de-energize. If FM is

energized, conrm where FM is connected on CB. If connected to CB K1 connector

pin #9, FM should be energized. If connected to CB K1 connector pin #3 and FM is

energized, replace CB. If LLV is energized with LEDs 1, 3, and 2 on, replace CB.

8) Normal Harvest Cycle – Same as the initial harvest cycle. Return to step 5a) above.

Note: Appliance continues to cycle until BC is satised, power is switched off or

freeze-time correction cycle is initiated. The appliance always restarts at the

1-min. ll cycle.

2. Shutdown Diagnosis

1) See "II.E.1. Bin Control Check."

3. Freeze-Time Correction Cycle Diagnosis

1) See "II.C. Freeze-Time Correction Cycle."

Legend: BC–bin control; CB–control board; Comp–compressor; CR–compressor relay;

CT–control transformer; CV–check valve; FM–fan motor; FMR–fan motor remote;

FS–oat switch; HGV–hot gas valve; HM–headmaster (C.P.R.); HPS–high-pressure

switch; L LV–liquid line valve; MC–magnetic contactor; PM–pump motor;

TXV–thermostatic expansion valve; WRV–water regulating valve; WV–inlet water

valve

25

Page 26

C. Freeze-Time Correction Cycle (90 min.)

Freeze-Time Correction function is enabled when S4 Dip Switch 7 is in the "ON" position

and initiates when the minimum and maximum freeze times have exceeded differential

parameters. Freeze-time correction timer and count starts at the beginning of the 2nd

freeze cycle after startup from power off condition. Freeze-time correction timer and count

continues and retains its freeze-time correction timer and count during a BC off cycle

and resumes its freeze-time correction timer and count on the 2nd freeze cycle after BC

restart. If freeze-time differential is exceeded (see table below), freeze-time correction

cycle starts and CB red "POWER OK" LED blinks. When freeze-time correction cycle

occurs 3 or more times within a 36 hour period, CB yellow "EXT HARVEST" LED blinks

with CB red "POWER OK" LED. Appliance starts in freeze cycle after a freeze-time

correction cycle. Toreset CB LEDs, press ALARM RESET button on CB with power on.

CB resets LEDs and appliance continues cycle without interruption.

1) Freeze Time Differential Initiation: CB starts monitoring freeze times on the second

freeze time. After 3freeze cycles (4th total), CBbegins to compare minimum and

maximum freeze time cycles. Every freeze cycle time after the rst freeze cycle

time is added to the freeze time list. Minimum and maximum freeze time differential

comparisons begin on the third cycle and are monitored up to 10cycles. On the 11th

cycle the rst freeze cycle time is dropped to maintain the 10 maximum number of

cycles.

Example: After 8 cycles (excluding rst cycle), if the differential between the

shortestcycle (minimum) and the longets cycle (maximum) is equal to or greater than

427 sec. a freeze-time correction cycle is initiated:

Number of

Freeze Cycles

3 254

4 309

5 349

6 380

7 406

8 427

9 446

10 462

Differential

Value in Sec.

26

Page 27

2) Freeze-Time Correction Sequence:

First occurrence within 36 hr., minimum and maximum freeze times have exceeded

differential parameters. CB "POWER OK" LED starts blinking. Freeze-Time Correction

Cycle starts.

Second occurrence within 36 hr., minimum and maximum freeze times have exceeded

differential parameters. If not reset, CB "POWER OK" LED continues blinking. If reset

from rst occurrence, CB "POWER OK" LED starts blinking. Freeze-Time Correction

Cycle starts.

Third occurrence within 36 hr. minimum and maximum freeze times have exceeded

differential parameters. CB yellow "EXT HARVEST" LED starts blinking. Also, If not

reset, CB "POWER OK" LED continues blinking. If reset, CB "POWER OK" LED starts

blinking.Freeze-Time Correction Cycle starts.

Total freeze-time correction cycle last for 90min. At the end of 80min., the nal step

initiates and nal Harvest Pump Time (Harvest Assist) with WV (10-min.) starts. Once

the nal Harvest Pump Time (Harvest Assist) with WV (10-min.) terminates

(90 min. complete), normal freeze cycle begins.

2a) 10-Min. Harvest Pump Time (Harvest Assist) with WV: CB "POWER OK" LED

blinking. CB LEDs 1, 4, 3, and 2 are on and Comp, FMR, HGV, PM, and WV energize.

10-min. timer starts. Once 10-min. timer terminates, CB LEDs 1, 3, and 2 turn off and

Comp, FMR, HGV, and PM de-energize. WV continues.

2b) 10-Min. Fill: CB LED 4 on and WV energized. 10-min. timer starts.

2c) Final 10-Min. Harvest Pump Time (Harvest Assist) with WV: CB "POWER OK" LED

blinking. Once 10-min. timer terminates, CB LEDs 1, 4, 3, and 2 are on and Comp,

FMR, HGV, and PM energizes. WV continues. 10-min. timer starts. Once 10-min.

timer terminates, normal freeze cycle begins. CB LED 1 on and Comp, FMR, and PM

continue. HGV and WV de-energize.

Note: After 3rd Freeze-Time Correction Cycle in 36 hours, CB signals with blinking CB

yellow "EXT HARVEST" LED. Appliance continues normal operation.

CB "POWER OK" LED and CB yellow "EXT HARVEST" LED continue blinking in

normal operation sequence.

3) Appliance Cycle Reset and CB Alarm Reset:

Cycle Reset: Power supply or control switch turned off and on again: Appliance turns

off, then re-starts at 1.Fill Cycle.

Alarm Reset: CB "ALARM RESET" pressed during or after a freeze-time correction

cycle with power supply on: Appliance continues cycle with no interruption or reset.

CB red "POWER OK" LED blinking: CB red "POWER OK" LED resets to solid.

CB yellow "EXT HARVEST" LED blinking: CB yellow "EXT HARVEST: LED turns off.

Legend: BC–bin control; CB–control board; Comp–compressor; CR–compressor relay;

CT–control transformer; CV–check valve; FM–fan motor; FMR–fan motor remote;

FS–oat switch; HGV–hot gas valve; HM–headmaster (C.P.R.); HPS–high-pressure

switch; L LV–liquid line valve; PM–pump motor; TXV–thermostatic expansion valve;

WRV–water regulating valve; WV–inlet water valve

27

Page 28

D. Control Board Check

Before replacing CB that does not show a visible defect and that you suspect is bad,

always conduct the following check procedure. This procedure will help you verify your

diagnosis.

Alarm Reset: If CB is in alarm (beeping), press the "ALARM RESET" button on CB

while CB is beeping. WARNING!Risk of electric shock. Care should be

taken not to touch live terminals. Once reset, the icemaker starts at the

1-minute ll cycle. For audible alarm information, see "III.B. LED Lights and

Audible Alarm Safeties."

1) Check the dip switch settings to assure that S4 dip switch 3, 4, 7, 8, 9, 10 and S5 dip

switch 1 through 5 are in the factory default position. S4 dip switch 1, 2, 5 are cleaning

adjustments and the settings are exible. For factory default settings, see "III.C.1.

Default Dip Switch Settings."

2) Move the control switch to the "ICE" position. If the red "POWER OK" LED is on, control

voltage is good, continue to step 3. If the "POWER OK" LED is off, check CT secondary

circuit. CT output is 10.5VAC at 115VAC primary input. If the secondary circuit has

proper voltage and the red LED is off, replace CB.

If the secondary circuit does not have proper voltage, check CT primary circuit. Check

for 115VAC at CB K1 connector pin #10 (BR) to neutral (W) for 115VAC. Always choose

a white (W) neutral wire to establish a good neutral connection when checking voltages.

For additional checks, see "II.G.1. No Ice Production."

3) The "OUTPUT TEST" button provides a relay sequence test. Make sure the control

switch is in the "ICE" position, then press the "OUTPUT TEST" button. For the correct

lighting sequence, see the table below. Note that the order of the LEDs from the outer

edge of the control board is 1, 4, 3, 2. Components (e.g., compressor) cycle during the

test.

Following the test, the icemaker begins operation at the 1-minute ll cycle. If the LEDs

do not light as described above, replace CB.

4) To verify voltage output from CB to the components, slide the CB K1 connector out far

enough to allow multimeter lead contact. With the icemaker in the cycle to be tested,

check output voltage from the corresponding pin on CB K1 connector to a neutral

(Wwire). If output voltage is not found and the appropriate LED is on, replace CB.

5) Conrm BC communication and shutdown sequence: Move the control switch to the

"ICE" position. Once the ll cycle starts press and hold the BC actuator paddle. CB

shuts down the appliance after 15 sec.. If not, conrm BC status. See "II.E.1. Bin Control

Check." If BC checks ok, replace CB.

Legend: CB–control board; CT–control transformer

28

Page 29

E. Bin Control Check

1. Bin Control Check

This appliance uses a lever-actuated proximity switch to control the ice level in the

storage bin. No adjustment is required.

To check BC, follow the steps below.

1) Turn off the power supply.

2) Remove the front panel, then move the control switch to the "OFF" position.

3) Remove the control box cover, then clear any ice away from

Connection Detail

BC.

4) Check BC wire harness connections. See Fig. 1.

5) Disconnect BC connector from CB K4 connector.

6) Check for continuity across the wires of

BC connector. When the actuator paddle is

not engaged, BC switch is closed. If open,

check that the wire harness connector is

Wire Harness

Connector B

(for upper unit)

Bin Control

Cable Connector

Wire Harness

Connector A

Control Board

Red K4 Connector

properly connected and that the actuator

paddle is not sticking. Clean if necessary.

Fig. 1

See "II.E.2.b) Bin Control Cleaning." If BC

switch still reads open, replace BC.

7) Press and hold the actuator paddle; check for continuity across the wires of BC

connector. When the actuator paddle is engaged, BC switch is open. If closed, check

that the actuator paddle is not restricted. Clean if necessary. See "II.D.2.b) Mechanical

Bin Control Cleaning." If BC switch still reads closed, replace BC.

8) Reconnect BC connector to CB K4 connector, then move the control switch to the "ICE"

position. Turn on the power supply.

9) Check that CB green "BC CLOSED" LED is on.

10) Allow the icemaker to cycle on. Press and hold the actuator paddle. CB yellow

"BCOPEN" LED should turn on and the icemaker should shut down according to the

chart below. If it does not, replace CB.

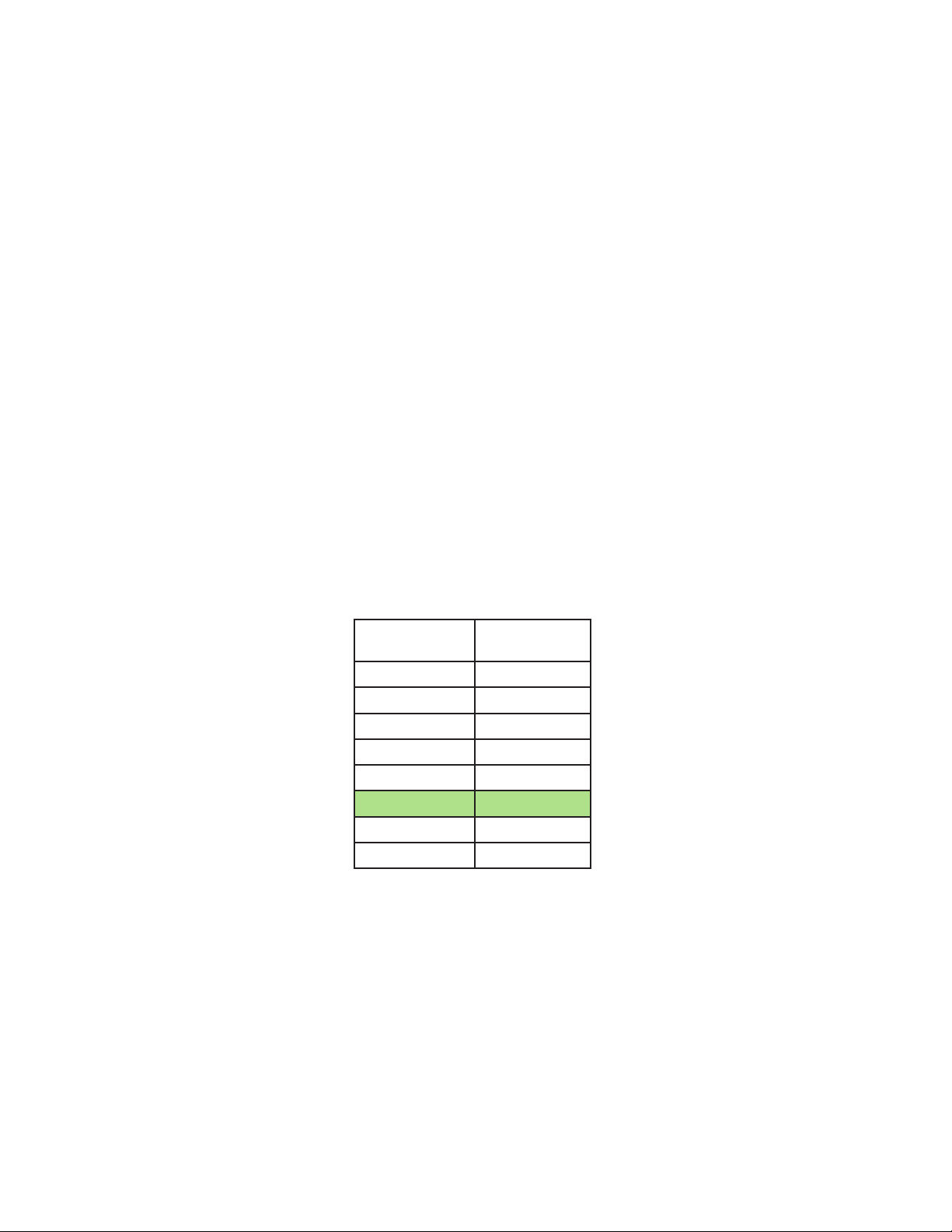

Cycle at

Mechanical Bin

Control Activation

Fill Cycle 15 sec. after activation.

Harvest Cycle At the end of the harvest cycle, or up to 15 sec. into the freeze cycle if activated at the

Freeze Cycle 15 sec. after activation if activated at least 15 sec. before the 5-min. short cycle

Shutdown

end of the harvest cycle.

protection timer terminates. Otherwise, at the end of the next harvest cycle.

Legend: BC–bin control; CB–control board

29

Page 30

2. Bin Control Cleaning

Scale may build up on BC. Scale can cause the actuator paddle and magnet to stick. In

this case, BC should be cleaned.

WARNING

CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the icemaker is serviced. Make sure that none have fallen

into the dispense unit/ice storage bin.

1) Turn off the power supply.

2) Remove the front panel, then move the control switch to the "OFF" position.

3) Clear any ice away from BC.

4) Disconnect BC connector from CB K4 connector, then remove BC from the icemaker.

5) Remove the actuator paddle from the switch mount. See Fig. 2.

6) Wipe down BC with a mixture of 1 part of Hoshizaki "Scale Away" and 25 parts of warm

water. Rinse the parts thoroughly with clean water.

7) Reassemble BC and replace it in its correct position.

Note: If the magnet was removed for cleaning, be sure to replace it in its correct

position.

8) Reconnect BC connector to CB K4 connector, then move the control switch to the "ICE"

position.

9) Replace the control box cover in its correct position.

10) Turn on the power supply to start the automatic icemaking process.

11) Replace the front panel in its correct position.

Legend: BC–bin control

KM-xxxxS_H/3

BC Bracket

Switch Mount

Actuator

Paddle

Bin Control Proximity

Switch Closed

(calling for ice)

Bin Control

Proximity Switch

Open (bin full,

icemaker off or

shutting down)

Magnet

BC Connector

Fig. 2

30

Page 31

F. Float Switch Check and Cleaning

FS is used to determine that there is sufficient water in the water tank after the 1-min.

ll cycle and after each harvest cycle. FS is also used to determine that the appropriate

volume of water has been converted into ice before switching out of the freeze cycle. No

adjustment is required.

1. Float Switch Check

To check FS, follow the steps below.

1) Turn off the power supply.

2) Remove the front panel, then move the control switch to the "OFF" position.

3) Remove the insulation panel, then remove the drain plug located on the lower front part

of the ice chute. See Fig. 3. Allow the water tank to drain.

4) Replace the drain plug in its correct position. Be careful not to cross thread it.

5) Remove the control box cover.

Drain Plug

Cleaning Valve

6) Disconnect FS connector from CB

K5connector.

7) Check for continuity across FS leads. With

the water tank empty, FS should be open.

If open, continue to step 8. If closed, follow

the steps in "II.E.2. Float Switch Cleaning."

After cleaning FS, check it again. Replace if

necessary.

8) Reconnect FS connector to CB K5

connector, then replace the control box

Ice Chute

Fig. 3

Float Switch Assembly

cover in its correct position.

9) Move the control switch to the "ICE" position. Replace the insulation panel and front

panel in their correct positions, then turn on the power supply. After 1 min., the 1-min.

ll cycle should end and the initial harvest cycle should begin. If the initial harvest cycle

begins, FS is good and the check is complete. If the initial harvest cycle does not begin,

continue to step 10.

10) Turn off the power supply.

11) Remove the front panel. Move the control switch to the "OFF" position.

12) Remove the control box cover.

13) Disconnect FS connector from CB K5 connector.

14) Check for continuity across FS leads. With the water tank full, FS should be closed.

IfFS is closed and the icemaker will not switch from the 1-min. ll cycle to the initial

harvest cycle, replace CB.

If FS is open, conrm that the water tank is full. If the water tank is not full, check the

water supply, water lters, and inlet water valve. If the water tank is full, follow the

steps in "II.E.2. Float Switch Cleaning." After cleaning FS, check it again. Replace if

necessary.

Legend: CB–control board; FS–oat switch

31

Page 32

2. Float Switch Cleaning

Depending on local water conditions, scale may build up on FS. Scale on the switch can

cause the oat to stick. In this case, FS should be cleaned.

1) Turn off the power supply.

2) Remove the front panel, then move the control switch to the "OFF" position.

3) Remove the insulation panel, then remove the drain plug located on the lower front part

of the ice chute. See Fig. 3. Allow the water tank to drain.

4) Replace the drain plug in its correct position. Be careful not to cross thread it.

5) Disconnect the vent tube and the ush tube from the top of FS, then remove FS

assembly and remove the rubber boot from the bottom of FS assembly. See Fig. 4.

6) Remove the retainer rod from the bottom of FS housing, then remove the oat.

Becareful not to bend the retainer rod excessively when removing it.

7) Wipe down FS housing, shaft, oat, and retainer rod with a mixture of 1 part Hoshizaki

"Scale Away" and 25 parts warm water. Clean the inside of the rubber boot and hose

with cleaning solution. Rinse the parts thoroughly with clean water.

8) Reassemble FS assembly and replace it and the rubber boot in their correct positions.

Reconnect the vent tube and the ush tube.

9) Move the control switch to the "ICE" position.

10) Replace the insulation panel and front panel in their correct positions.

11) Turn on the power supply to start the automatic icemaking process.

Legend: CB–control board; FS–oat switch

Vent

Flush

Shaft

Float Switch

Housing

Float

Retainer Rod

Rubber Boot

and Hose

Fig. 4

32

Page 33

G. Thermistor Check

To check thermistor resistance, follow the steps below.

1) Turn off the power supply.

2) Remove the front panel. Move the control switch to the "OFF" position.

3) Remove the control box cover.

4) Remove the thermistor from the refrigerant tubing.

5) Immerse the thermistor sensor portion in a glass containing ice and water for 2 or 3 min.

6) Disconnect the thermistor connector from CB K3 connector and check the resistance

between thermistor leads. Normal range is 4.7 to 6.2 kΩ. If outside the normal range,

replace the thermistor. See "IV.B. Component Service Information." If within the normal

range, continue to the next step.

7) Replace the thermistor in its correct position. See "IV.B. Component Service

Information."

8) Reconnect the thermistor connector to CB K3 connector.

9) Replace the control box cover in its correct position.

10) Move the control switch to the "ICE" position.

11) Replace the front panel in its correct position.

12) Turn on the power supply.

13) Once the harvest cycle starts (Comp energizes), begin timing the harvest cycle.

14) The harvest timer and harvest cycle should terminate within 2 to 5 min. If the harvest

cycle does not terminate within 2 to 5 min., replace CB.

Legend: CB–control board; Comp–compressor

Thermistor Lead Cable Tie

Foam Insulation Thermistor Holder

Fig. 5

H. Control Switch

The control switch has three positions: "OFF" for power off, "ICE" for icemaking, and

"WASH" to energize the pump motor when cleaning and sanitizing. WARNING! Control

switch in "OFF" position does not de-energize all loads. Risk of electric shock.

Use extreme caution and exercise safe electrical practices.

33

Page 34

I. Diagnostic Tables

1. No Ice Production

No Ice Production - Possible Cause

1. Power Supply a) Off, blown fuse, or tripped breaker.

b) Not within specications.

2. Main Transformer

(if applicable)

3. Fuse (Control Box) a) Blown.

4. Control Switch a) In "OFF" or "WASH" position.

5. High-Pressure Switch a) Dirty condenser.

6. Control Transformer

(115VAC/10.5VAC)

7. Control Board

See "II.D. Control Board Check"

8. Bin Control

See "II.E. Bin Control Check."

9. Water Supply a) Water supply off or improper water pressure.

10. Inlet Water Valve a) Screen or orice clogged.

11. Float Switch

See "II.F. Float Switch Check

and Cleaning"

12. Compressor a) Compressor relay/magnetic contactor contacts bad or coil winding

13. Hot Gas Valve a) Closed in harvest cycle.

14. Thermistor

See "II.G. Thermistor Check"

15. Pump Motor a) Motor winding open.

a) Voltage tap switch not set to proper voltage.

b) Coil winding open or shorted.

b) Bad contacts.

b) Fan motor not operating.

c) Refrigerant overcharged.

d) Bad contacts.

e) Refrigerant lines or components plugged.

a) Coil winding open or shorted.

a) In alarm.

b) Yellow "BC OPEN" LED on (bin full).

c) Defective.

a) Tripped with bin lled with ice.

b) Actuator does not move freely.

c) Defective.

b) External water lters clogged.

b) Coil winding open.

c) Water valve open in freeze cycle.

a) Float does not move freely.

b) Defective.

open.

b) Start capacitor or run capacitor defective (single phase model).

c) Internal protector open.

d) Start relay contacts bad or coil winding open (single phase model).

e) Compressor defective.

b) Open in freeze cycle.

a) Loose, disconnected, or defective.

b) Bearing worn out or locked rotor.

c) Defective capacitor.

d) Mechanical seal worn out.

34

Page 35

No Ice Production - Possible Cause

16 Thermostatic Expansion Valve a) Bulb loose.

b) Operating erratically.

1 7. Liquid Line Valve a) Closed in freeze cycle.

b) Open in harvest cycle.

18. Fan Motor a) Motor winding open.

b) Bearing worn out or locked rotor.

c) Defective capacitor.

19. Water System a) Water leaks causing short freeze time.

2. Low Ice Production

Low Ice Production - Possible Cause

1. Appliance in Freeez-Time

Correction Cycle

1. Evaporator a) Scaled up.

2. Spray Tubes and/or Spray

Guides

3. Refrigerant Charge a) Low.

4. Water Supply a) Low water pressure.

5. Control Board

See "II.D. Control Board Check"

6. Thermistor

See "II.G. Thermistor Check"

7. Hot Gas Valve a) Erratic or closed.

8. Inlet Water Valve a) Screen or orice clogged.

9. Compressor a) Inefficient or off.

10. Liquid Line Valve a) Erratic or open.

11. Thermostatic Expansion Valve a) Defective.

1. Low Water Supply a) Water lters clogged.

2. Inlet Water Valve a) Screen or orice clogged.

3. Float Switch a) Float does not move freely.

4. Splash Guard a) Missing or defective.

5. Check Valve a) Dirty.

6. Control Board a) Defective.

a) See "II.C.Freeze-Time Correction Cycle."

Long Harvest Cycle

a) Dirty.

b) Out of position.

b) External water lters clogged.

c) Insufficient water line size.

Minimum 3/8" Nominal ID (10 mm Nominal OD in the EU) water

tubing or equivalent.

d) Too cold.

a) Thermistor connection loose (K3).

b) Defective.

a) Loose, disconnected, or defective.

Short Freeze Cycle

b) Defective.

b) Defective.

35

Page 36

Low Ice Production - Possible Cause

Long Freeze Cycle

1. Evaporator a) Scaled up, dirty.

2. Float Switch

See "II.F. Float Switch Check and

Cleaning"

3. Inlet Water Valve a) Leaking by.

4. Hot Gas Valve a) Erratic or open.

5. Condenser a) Clogged.

6. Control Board

See "II.D. Control Board Check"

7. Refrigerant Charge a) Low.

8. Thermostatic Expansion Valve a) Bulb loose.

9. Compressor a) Inefficient or off.

10. Pump Motor a) RPM too slow.

11. Liquid Line Valve a) Erratic or restricted.

12. Headmaster (C.P.R.)

(remote models)

a) Scaled up, dirty.

b) Float sticking.

c) Defective switch.

a) Float switch connection loose (K5).

b) Defective.

b) Defective.

a) Not bypassing.

3. Freeze-Up

Defrost and clean the icemaker prior to diagnosing freeze-up. Fill out a freeze-up checklist.

See "II.J. Freeze Up Check List," the Hoshizaki America Technician's Pocket Guide, or

contact your local distributor for a copy of the freeze-up checklist.

Freeze-Up - Possible Cause

Harvest Cycle

1. Evaporator a) Scaled up.

b) Damaged.

2. Cube Guides a) Out of position.

b) Damaged.

3. Spray Tubes and/or Spray

Guides

4. Water Supply a) Low water pressure.

5. Inlet Water Valve a) Screen or orice clogged.

6. Float Switch

See "II.F. Float Switch Check and

Cleaning"

7. Refrigerant Charge a) Low.

a) Dirty.

b) Out of position.

b) External water lters clogged.

c) Insufficient water line size.

Minimum 3/8" Nominal ID (10 mm Nominal OD in the EU) copper

water tubing or equivalent.

b) Defective.

a) Dirty, sticking.

b) Defective.

36

Page 37

Freeze-Up - Possible Cause

8. Control Board

See "II.D. Control Board

Check" and "III.D. Settings and

Adjustments"

9. Bin Control

See "II.E. Bin Control Check"

10. Thermistor

See "II.G. Thermistor Check"

11. Thermostatic Expansion Valve a) Defective.

12. Hot Gas Valve a) Closed or restricted.

13. Liquid Line Valve a) Open.

1. Evaporator a) Scaled up.

2. Spray Tubes and/or Spray

Guides

3. Refrigerant Charge a) Low.

4. Control Board

See "II.D. Control Board Check"

5. Inlet Water Valve a) Leaking by.

6. Float Switch

See "II.F. Float Switch Check and

Cleaning"

7. Pump Motor a) RPM too slow.

8. Thermostatic Expansion Valve a) Bulb loose or defective.

9. Liquid Line Valve a) Restricted.

10. Headmaster (C.P.R.)

(remote models)

a) Harvest timer (S4 dip switch 1 & 2) set too short.

b) Harvest pump time (harvest assist) (S4 dip switch 7) not in factory

default position.

c) Defective.

a) Actuator does not move or defective.

a) Loose, disconnected, or defective.

Freeze Cycle

b) Damaged.

a) Dirty.

b) Out of position.