Page 1

NO.:

ISSUED:

REVISED:

73079

DEC. 8, 1998

DEC. 16, 2003

HOSHIZAKI

STACKABLE CRESCENT CUBER

MODEL

KM-1600SWF

KM-1600SRF

KM-1600SWF3

KM-1600SRF3

SERVICE MANUAL

Page 2

IMPORTANT

Only qualified service technicians should attempt to service or maintain this icemaker.

No service or maintenance should be undertaken until the technician has thoroughly

read this Service Manual.

HOSHIZAKI provides this manual primarily to assist qualified service technicians in the

service and maintenance of the icemaker.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call or write to the HOSHIZAKI Technical Support Department for

assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City , GA 30269

Attn: HOSHIZAKI T echnical Support Department

Phone: 1-800-233-1940 T echnical Service

(770) 487-2331

Fax: (770) 487-3360

NOTE: T o expedite assistance, all correspondence/communication MUST include the following

information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem

2

Page 3

Please review this manual. It should be read carefully before the icemaker is serviced or

maintenance operations are performed. Only qualified service technicians should service and

maintain the icemaker. This manual should be made available to the technician prior to

service or maintenance.

CONTENTS

PAGE

I. SPECIFICATIONS .............................................................................................................5

1. KM-1600SWF (Water-cooled) ......................................................................................5

2. KM-1600SRF (Remote air-cooled)...............................................................................6

3. KM-1600SWF3 (Water-cooled) ....................................................................................7

4. KM-1600SRF3 (Remote air-cooled).............................................................................8

5. CONDENSING UNIT, URC-20F ..................................................................................9

II. GENERAL INFORMATION .............................................................................................11

1. CONSTRUCTION...................................................................................................... 11

[a] KM-1600SWF, KM-1600SWF3 ............................................................................11

[b] KM-1600SRF, KM-1600SRF3..............................................................................12

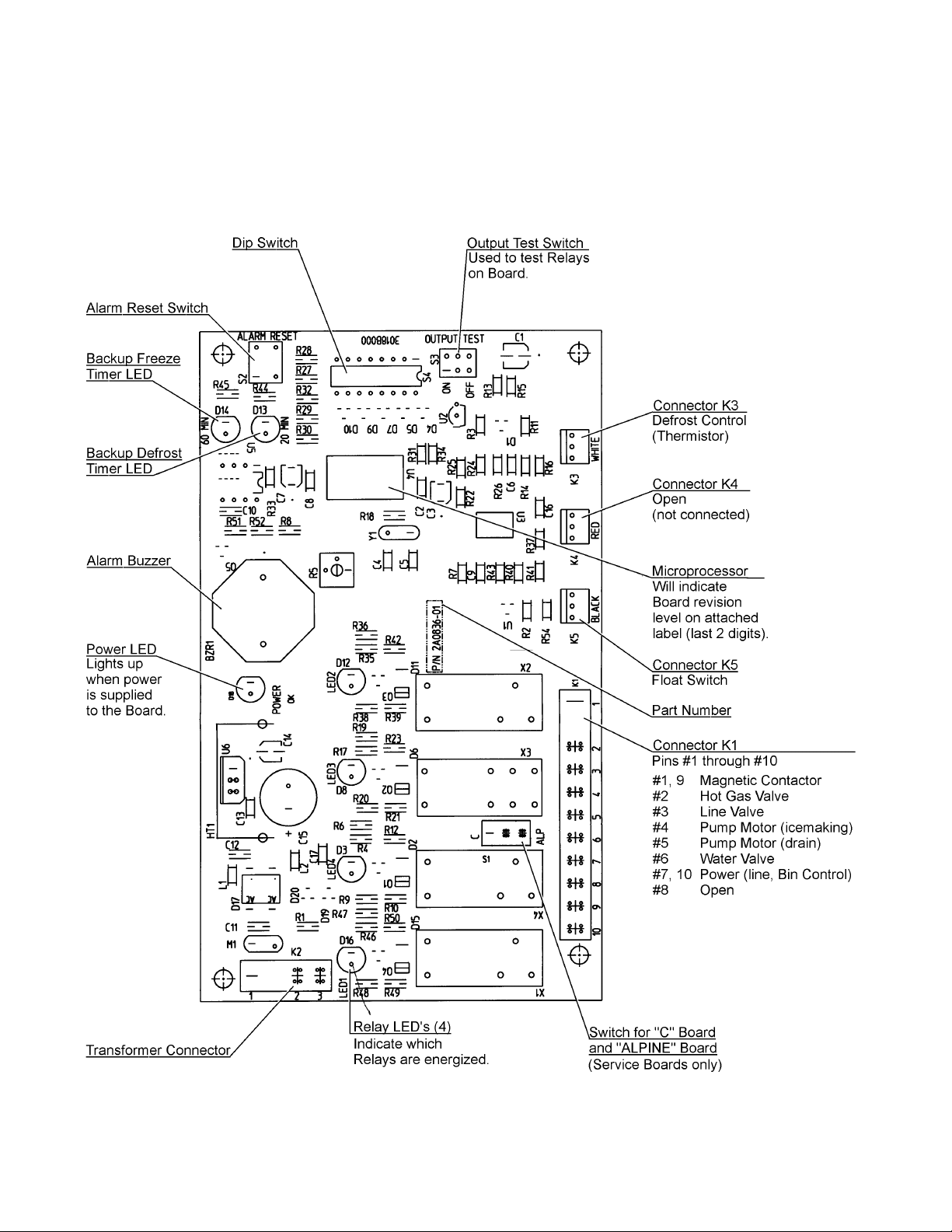

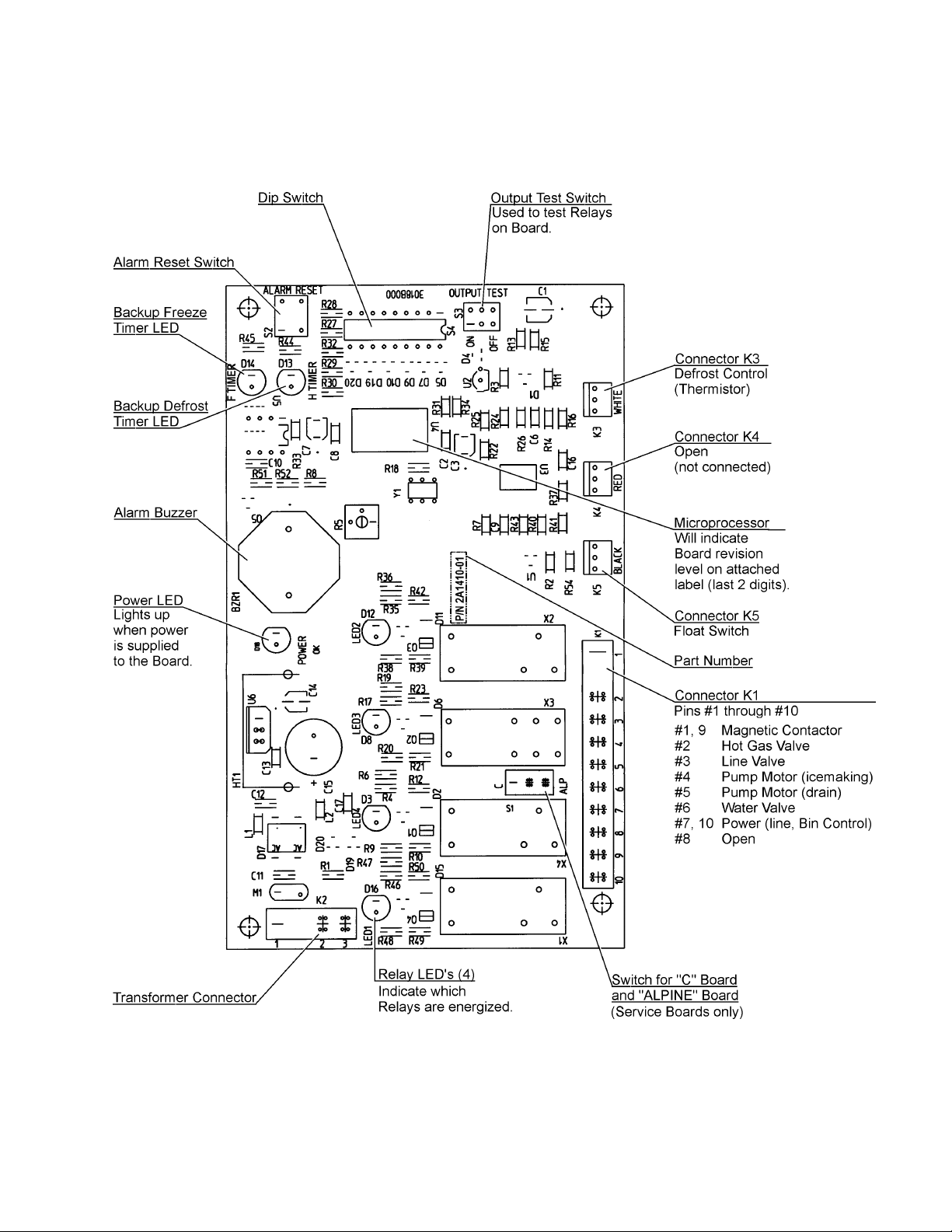

2. CONTROLLER BOARD.............................................................................................13

[a] SOLID-STATE CONTROL ...................................................................................13

[b] CONTROLLER BOARD.......................................................................................1 3

[c] SEQUENCE ......................................................................................................... 18

[d] CONTROLS AND ADJUSTMENTS ....................................................................21

[e] CHECKING CONTROLLER BOARD ..................................................................24

III. TECHNICAL INFORMATION ........................................................................................26

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT...................................................26

[a] KM-1600SWF, KM-1600SWF3 ............................................................................26

[b] KM-1600SRF, KM-1600SRF3..............................................................................27

2. WIRING DIAGRAMS..................................................................................................28

[a] KM-1600SWF, KM-1600SRF ...............................................................................28

[b] KM-1600SWF3, KM-1600SRF3 ...........................................................................29

3. TIMING CHART .........................................................................................................30

4. PERFORMANCE DATA ............................................................................................32

[a] KM-1600SWF.......................................................................................................32

[b] KM-1600SRF .......................................................................................................33

[c] KM-1600SWF3.....................................................................................................34

[d] KM-1600SRF3 .....................................................................................................35

IV. SERVICE DIAGNOSIS .................................................................................................36

1. NO ICE PRODUCTION..............................................................................................36

2. EVAPORATOR IS FROZEN UP................................................................................39

3. LOW ICE PRODUCTION ...........................................................................................39

4. ABNORMAL ICE........................................................................................................40

5. OTHERS ....................................................................................................................40

3

Page 4

V. REMOVAL AND REPLACEMENT OF COMPONENTS ............................................... 41

1. SERVICE FOR REFRIGERANT LINES ................................................................... 41

[a] REFRIGERANT RECOVERY ............................................................................. 41

[b] EVACUATION AND RECHARGE ...................................................................... 41

2. BRAZING .................................................................................................................. 42

3. REMOVAL AND REPLACEMENT OF COMPRESSOR........................................... 43

4. REMOVAL AND REPLACEMENT OF DRIER ......................................................... 44

5. REMOVAL AND REPLACEMENT OF EXPANSION VALVE................................... 45

6. REMOVAL AND REPLACEMENT OF HOT GAS VALVE,...........................................

LINE VALVE AND GAS VALVE................................................................................ 46

7. REMOVAL AND REPLACEMENT OF EVAPORATOR ........................................... 47

8. REMOVAL AND REPLACEMENT OF WATER-REGULATING VALVE ......................

- WATER COOLED MODEL ONLY.......................................................................... 48

9. ADJUSTMENT OF WATER-REGULATING VALVE ....................................................

- WATER COOLED MODEL ONLY.......................................................................... 49

10. REMOVAL AND REPLACEMENT OF CONDENSING PRESSURE ...........................

REGULATOR (C.P.R.) - REMOTE AIR-COOLED MODEL ONLY ............................ 50

11. REMOVAL AND REPLACEMENT OF THERMISTOR ............................................. 51

12. REMOVAL AND REPLACEMENT OF FAN MOTOR................................................ 52

13. REMOVAL AND REPLACEMENT OF WATER VALVE ........................................... 52

14. REMOVAL AND REPLACEMENT OF PUMP MOTOR............................................. 5 3

15. REMOVAL AND REPLACEMENT OF SPRAY TUBES ........................................... 54

VI. MAINTENANCE AND CLEANING INSTRUCTIONS .................................................. 55

1. PREPARING THE ICEMAKER FOR LONG STORAGE........................................... 55

2. CLEANING PROCEDURE ....................................................................................... 57

[a] CLEANING PROCEDURE ................................................................................. 58

[b] SANITIZING PROCEDURE................................................................................ 5 9

3. MAINTENANCE........................................................................................................ 60

4

Page 5

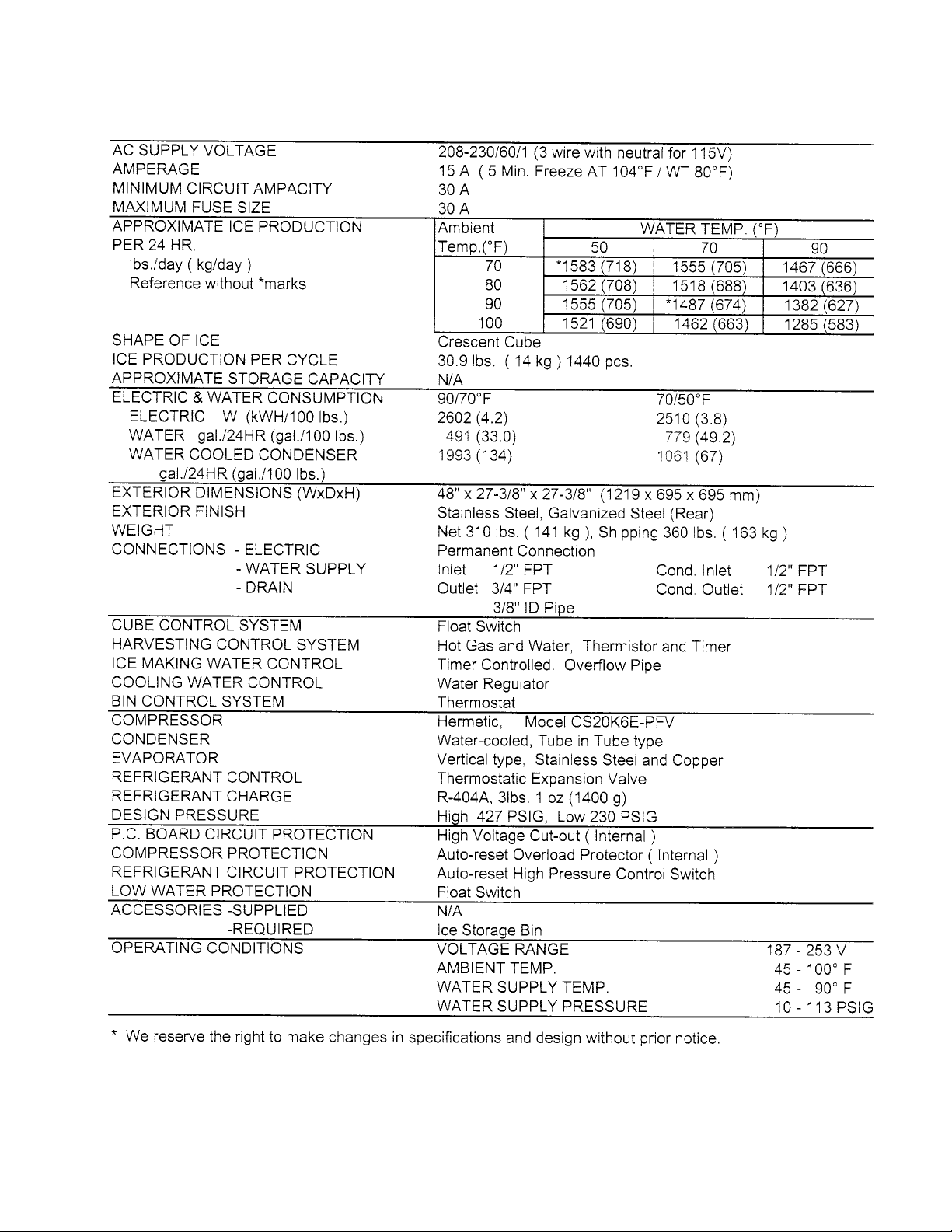

I. SPECIFICATIONS

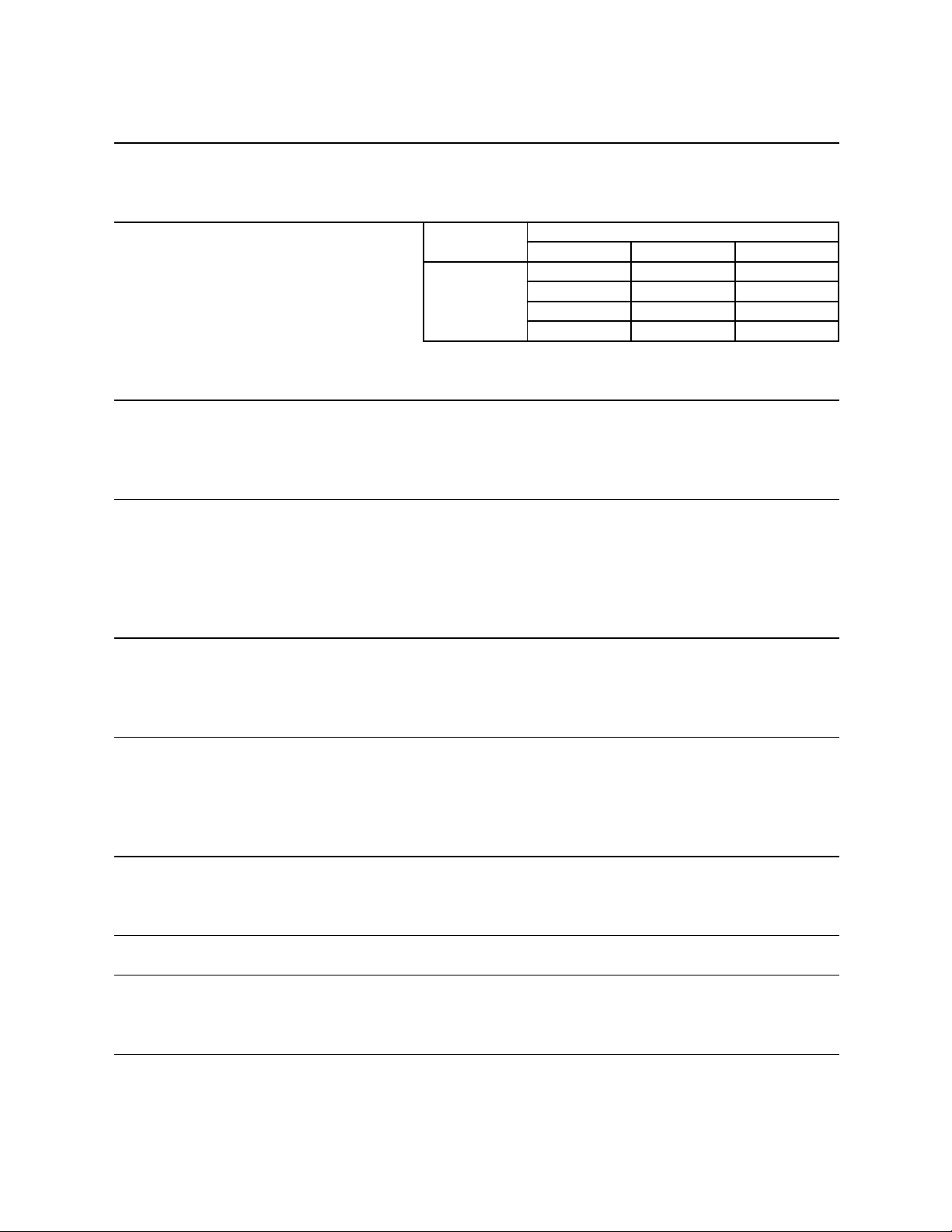

1. KM-1600SWF

5

Page 6

2. KM-1600SRF

EGATLOVYLPPUSCA

EGAREPMA

YTICAPMATIUCRICMUMINIM

EZISESUFMUMIXAM

.RH42REP

)yad/gk(yad/.sbl

skram*tuohtiwecnerefeR08

ECIFOEPAHSebuCtnecserC

ELCYCREPNOITCUDORPECI.scp0441)gk41(.sbl9.03

).sbl001/HWk(WCIRTCELE

RETAWELBATOP

).sbl001/.lag(RH42/.lag

HSINIFROIRETXE

THGIEW

CIRTCELE-SNOITCENNOC

NIARD-

METSYSLORTNOCEBUC

METSYSLORTNOCGNITSEVRAH

LORTNOCRETAWGNIKAMECI

LORTNOCRETAWGNILOOC

METSYSLORTNOCNIB

ROSSERPMOC

RESNEDNOC

ROTAROPAVE

LORTNOCTNAREGIRFER

EGRAHCTNAREGIRFER

ERUSSERPNGISED

NOITCETORPROSSERPMOC

NOITCETORPRETAWWOL

DEILPPUS-SEIROSSECCA

DERIUQER-

SNOITIDNOCGNITAREPOEGNAREGATLOV

NOITCUDORPECIETAMIXORPPAtneibmA

YTICAPACEGAROTSETAMIXORPPAA/N

NOITPMUSNOCRETAW&CIRTCELEF°07/09

)HxDxW(SNOISNEMIDROIRETXE

YLPPUSRETAW-

NOITCETORPTIUCRICDRAOB.C.P

NOITCETORPTIUCRICTNAREGIRFER

1/06/032-802

A03

A03

)F°(.pmeT

07

05

)946(0341*)246(5141)906(3431

)V511roflartuenhtiweriw3(

)F°08TW/F°401TAezeerF.niM5(A12

)F°(.PMETRETAW

07

09

)446(9141)336(6931)885(5921

09

001

)08.5(5692

)5.63(405

TPF"2/1telnI

TPF"4/3teltuO

epiPDI"8/3

hctiwStaolF

A/N

tatsomrehT

hctiwStaolF

A/N

.PMETTNEIBMA

)246(5141)626(0831*)585(0921

)826(3831)616(9531)745(7021

F°05/07

)76.4(5182

)8.85(148

noitcennoCtnenamreP

epiPwolfrevO.dellortnoCremiT

972-VFP-E6K02SCledoM,citemreH

evlaVnoisnapxEcitatsomrehT

)g0076(.zo21.sbl41,A404-R

GISP032woL,GISP764hgiH

)lanretnI(tuo-tuCegatloVhgiH

.PMETYLPPUSRETAW

ERUSSERPYLPPUSRETAW

)mm596x596x9121("8/3-72x"8/3-72x"84

)raeR(leetSdezinavlaG,leetSsselniatS

)gk361(.sbl063gnippihS,)gk921(.sbl582teN

remiTdnarotsimrehT.retaWdnasaGtoH

dednemmocerF02-CRUtinUresnednoC,etomerdelooc-riA

reppoCdnaleetSsselniatS.epytlacitreV

F02-CRUnorotalugeRerusserPgnisnednoC

).zo11.sbl7tinu.dnoC.zo1.sbl7rekamecI(

)lanretnI(rotcetorPdaolrevOteser-otuA

hctiwSlortnoCerusserPhgiHteser-otuA

tinUresnednoCetomeR,niBegarotSecI

V462-781

F°001-54

F°09-54

-01GISP311

We reserve the right to make changes in specifications and design without prior notice.

6

Page 7

3. KM-1600SWF3

AC SUP P LY VOLTAGE 208-230/60/3

AM P E RA GE 9.5 A ( 5 M in. Freeze A T 104°F / WT 80°F)

MINIMUM CIRCUIT AMPACITY 20 A

MAXIMUM FUSE SIZE 20 A

APPROXIMATE ICE PRODUCTION Ambient WATER TEMP. (°F)

PE R 24 HR. Temp.(°F) 50 70 90

lbs . /day ( k g/ day ) 70 *1500 (680) 1495 (678) 1451 (658)

Reference without *m ark s 80 1496 (679) 1489 (675) 1423 (646)

90 1495 (678) *1484 (673) 1426 (647)

100 1473 (668) 1470 (667) 1373 (623)

SHAPE OF ICE Crescent Cube

ICE PRODUCTION PER CYCLE 30.9 lbs. ( 14 k g ) 1440 pc s.

APPROXIMATE STORAGE CAPACITY N/A

ELE CTRIC & WATER CONSUMP TION 90/70°F 70/50°F

ELECTRIC W (kWH/100 lbs.) 2597 (4.2) 2563 (4.1)

POTABLE WATER 463 (31.2) 887 (59.1)

WATER COOLED CONDENSER 1914 (129.0) 1005 (67.0)

gal./24HR (gal./100 lbs.)

EXTERIOR DIMENSIONS (WxDx H) 48" x 27-3/ 8" x 27 3/ 8" (1219 x 695 x 695 mm)

EXTERIOR FINISH St ai nless Steel, G alvanized Steel (Rear)

WEIGHT Net 310 lbs . ( 141 kg ), S hippi ng 360 lbs. ( 163 k g )

CONNECTIONS - ELECTRIC Permanent - Connec t i on

- WATER SUPPLY Inlet 1/2" FPT Cond. Inlet 1/2" FPT

- DRAIN Outlet 3/4" FPT Cond. Outlet 1/2" FPT

3/8" OD P i pe

CUBE CONTROL SYSTEM Float S wi tc h

HARVESTING CONTROL SYSTEM Hot Gas and Wat er, Thermis tor and Timer

ICE MAK ING W ATER CONTROL Timer Controlled. Overfl ow P i pe

COOLING WATER CONTROL Water Regulator

BIN CO NTROL SYSTEM Thermost a t

COMPRE SSO R Hermetic, Model CS20K 6 E-P F V

CONDENSER Water-cooled, Tube in tube t ype

EV A PORATOR Vert ical t ype, S t ai nless S teel and Copper

REFRIGERA NT CONTROL Thermostat i c Ex pansion Val ve

REFRIGERA NT CHARGE R-404A, 3 lb. 1 oz. ( 1400 g )

DESIGN PRESSURE High 427 PSIG, Low 230 PSIG

P.C. BOA RD CIRCUIT PRO TE CTION High Voltage Cu t-out ( Internal )

COMPRE S SOR PROTECTION Aut o-res et O verload Prot ector ( Internal )

REF R IGERANT CIRCUIT PROTE CTION Au to-reset Hi g h Pres sure Co ntrol Switch

LOW W ATER PROTECTION Float Switch

ACCESSORIES -SUPPLIED N/A

-REQUIRED Ice Storage Bin

OPE RA TING CONDITIONS VOLTAGE RA NGE 187 - 253 V

AM B IENT TEM P. 45 -100° F

WATER SUPPLY TEMP. 45 - 90° F

WATER SUPPLY PRESSURE 10 - 113 PSIG

We reserve t he right to mak e c hanges in specific at i ons and design without pri or not i c e.

7

Page 8

4. KM-1600SRF3

EGATLOVYLPPUSCA

EGAREPMA

YTICAPMATIUCRICMUMINIM

EZISESUFMUMIXAM

NOITCUDORPECIETAMIXORPPAtneibmA)F°(.PMETRETAW

.RH42REP)F°(.pmeT

)yad/gk(yad/.sbl07

skram*tuohtiwecnerefeR08

ECIFOEPAHSebuCtnecserC

ELCYCREPNOITCUDORPECI.scp0441)gk41(.sbl9.03

YTICAPACEGAROTSETAMIXORPPAA/N

NOITPMUSNOCRETAW&CIRTCELEF°07/09F°05/07

).sbl001/HWk(WCIRTCELE

ETAWELBATOP

R

.sbl001/.lag(RH42/.lag

)

)HxDxW(SNOISNEMIDROIRETXE

HSINIFROIRETXE

THGIEW

CIRTCELE-SNOITCENNOC

YLPPUSRETAW-

NIARD-

METSYSLORTNOCEBUC

METSYSLORTNOCGNITSEVRAH

LORTNOCRETAWGNIKAMECI

LORTNOCRETAWGNILOOC

METSYSLORTNOCNIB

ROSSERPMOC

RESNEDNOC

ROTAROPAVE

LORTNOCTNAREGIRFER

EGRAHCTNAREGIRFER

ERUSSERPNGISED

NOITCETORPTIUCRICDRAOB.C.P

NOITCETORPROSSERPMOC

NOITCETORPTIUCRICTNAREGIRFER

NOITCETORPRETAWWOL

DEILPPUS-SEIROSSECCA

DERIUQER-

SNOITIDNOCGNITAREPOEGNAREGATLOV

3/06/032-802

)F°08TW/F°401TAezeerF.niM5(A11

A02

A02

05

07

09

)366(1641*)746(6241)916(5631

)156(4341)626(0831)595(1131

09

001

)01.5(0092)75.4(5772

254

A/N

A/N

)7.92(

hctiwStaolF

tatsomrehT

hctiwStaolF

377

TPF"2/1telnI

TPF"4/3teltuO

epiPDI"8/3

.PMETTNEIBMA

)746(6241)806(1431*)875(4721

)936(9041)106(5231)055(3121

)9.25(

noitcennoCtnenamreP

epiPwolfrevO.dellortnoCremiT

972-5FT-E6K02SCledoM,citemreH

evlaVnoisnapxEcitatsomrehT

)g0076(.zo21.sbl41,A404-R

GISP032woL,GISP764hgiH

)lanretnI(tuo-tuCegatloVhgiH

.PMETYLPPUSRETAW

ERUSSERPYLPPUSRETAW

)mm596x596x9121("8/3-72x"8/3-72x"84

)raeR(leetSdezinavlaG,leetSsselniatS

)gk361(.sbl063gnippihS,)gk921(.sbl582teN

remiTdnarotsimrehT.retaWdnasaGtoH

dednemmocerF02-CRUtinUresnednoC,etomerdelooc-riA

reppoCdnaleetSsselniatS.epytlacitreV

F02-CRUnorotalugeRerusserPgnisnednoC

).zo11.sbl7tinu.dnoC.zo1.sbl7rekamecI(

)lanretnI(rotcetorPdaolrevOteser-otuA

hctiwSlortnoCerusserPhgiHteser-otuA

tinUresnednoCetomeR,niBegarotSecI

V462-781

F°001-54

F°09-54

-01GISP311

.ecitonroirptuohtiwngiseddnasnoitacificepsnisegnahcekamotthgirehtevresereW*

8

Page 9

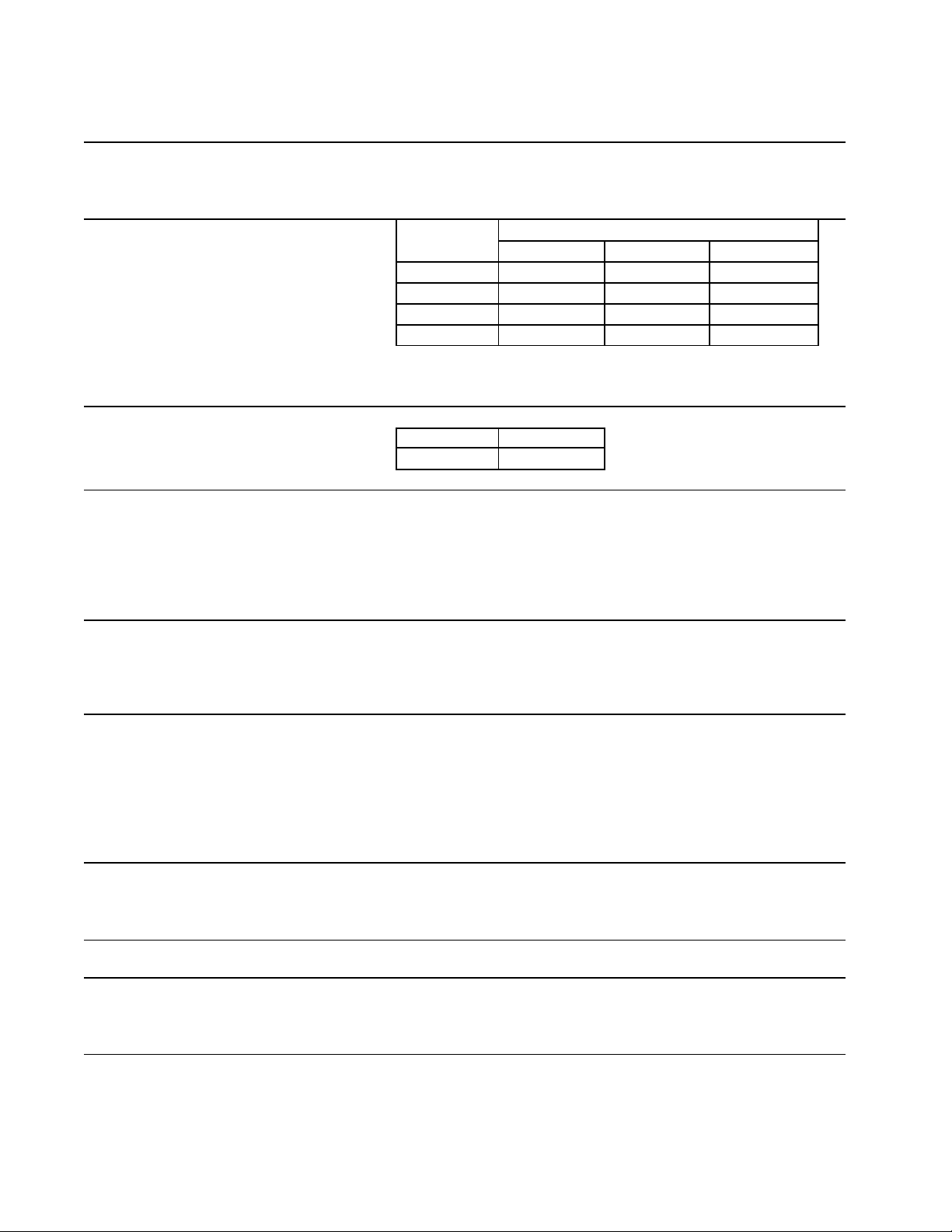

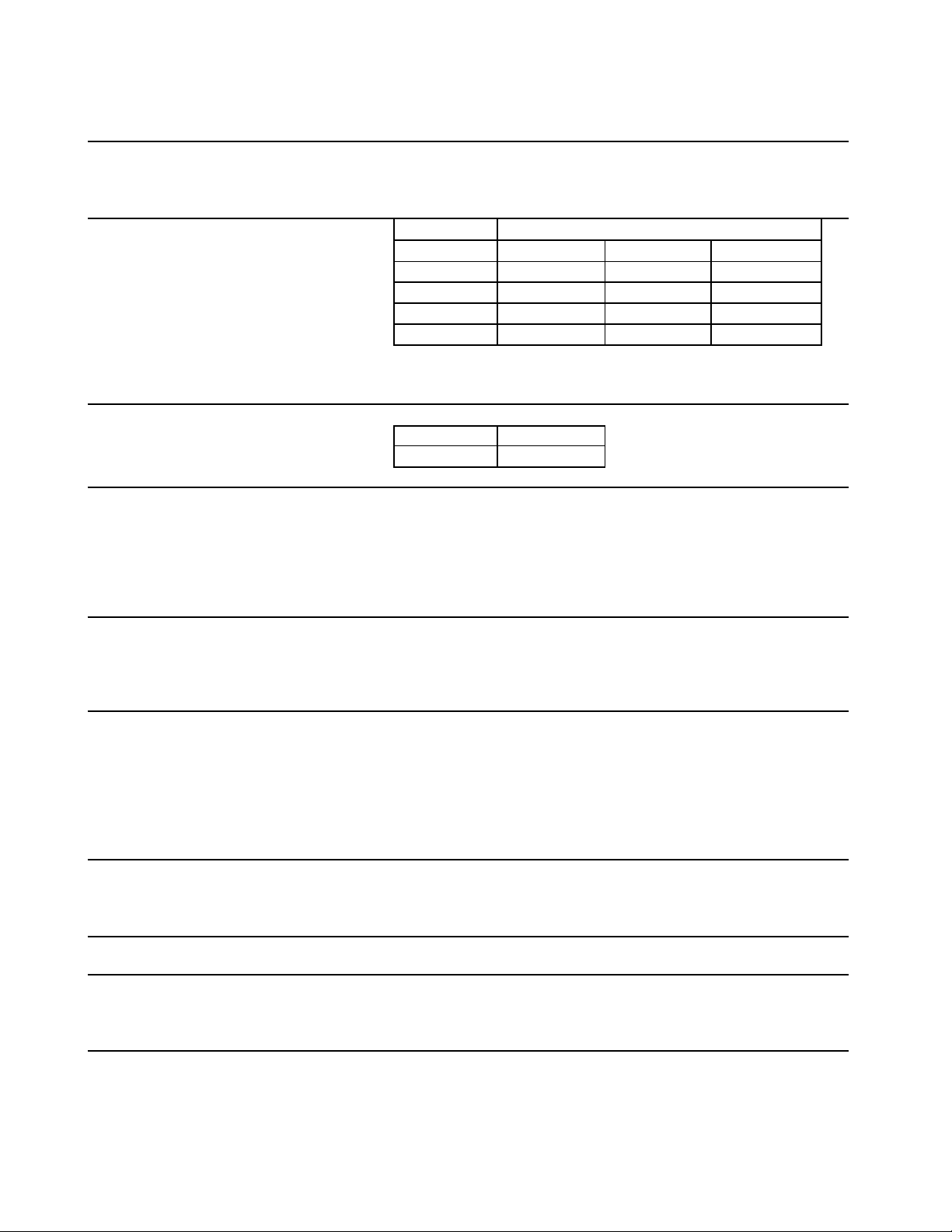

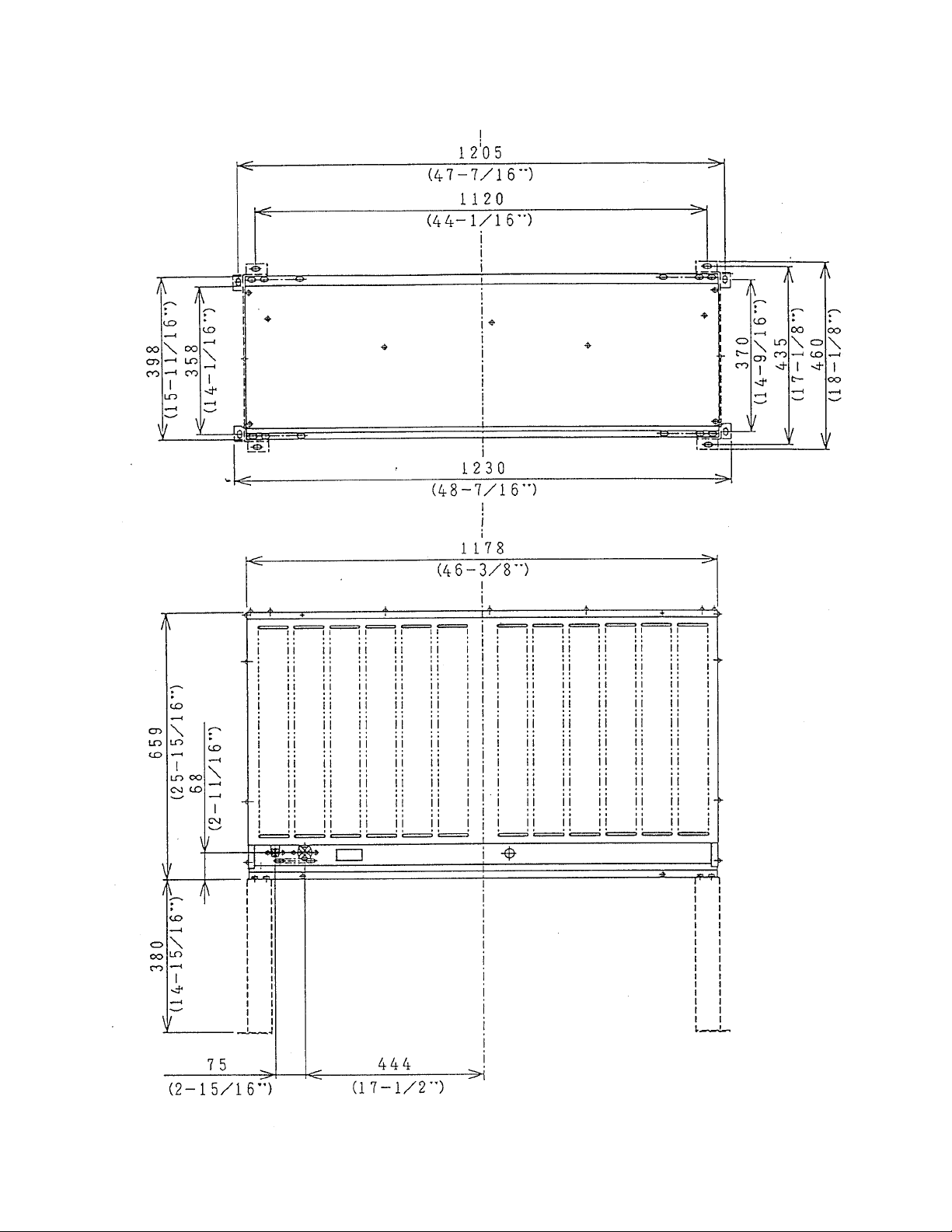

5. CONDENSING UNIT

URC-20F

9

Page 10

MODEL: URC-20F

SPECIFICATIONS

EXTERIOR

DIMENSIONS (W x D x H)

REFRIGERANT CHARGE

URC-20F

WEIGHT

CONNECTIONS

REFRIGERANT

ELECTRICAL

CONDENSER

HEAD PRESSURE CONTROL

AMBIENT CONDITION

Galvanized Steel

46 - 3/8" x 15 - 11/16" x 25 - 15/16"

(1178 x 398 x 659 mm)

R404A 7 lbs.11 oz. (3500 g)

Net 104 lbs. (47 kg)

Shipping 150 lbs. (52 kg)

One Shot Couplings (Aeroquip)

Permanent Connection

Air-cooled

Condensing Pressure Regulator

Min. -20°F - Max. +122°F

(-29°C to +50°C)

Outdoor use

10

Page 11

II. GENERAL INFORMATION

1. CONSTRUCTION

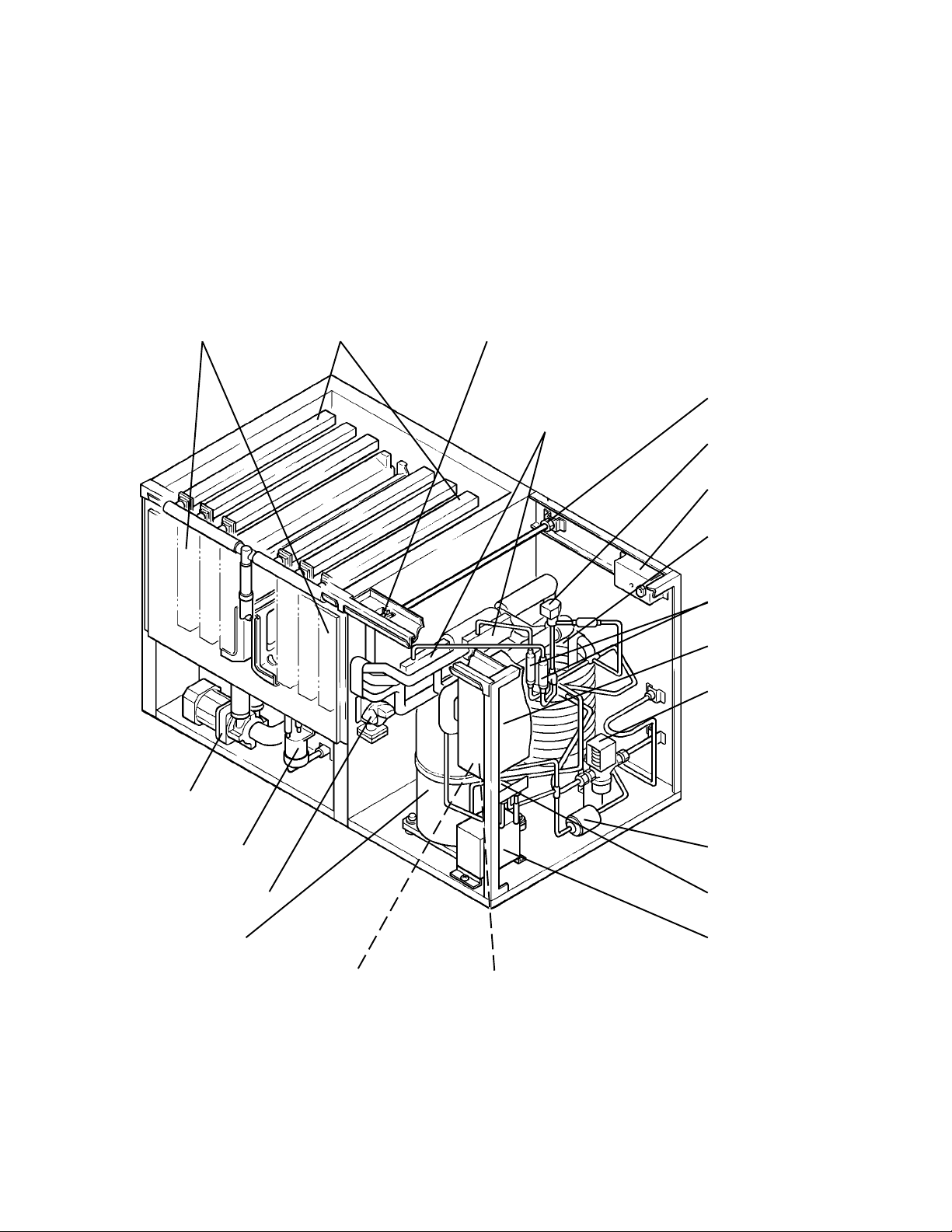

[a] KM-1600SWF, KM-1600SWF3

Evaporator Spray Tube Water Valve

Water Supply Inlet

Expansion Valve

Hot Gas Valve

Junction Box

Water-cooled

Condenser

Check Valve

Control Box

Water Regulator

Water Pump

Float Switch Drier

Cleaning Valve Line Valve

Compressor Transformer Box

(KM-1600SWF3)

Control Switch Bin Control Thermostat Capacitor Box

(KM-1600SWF)

11

Page 12

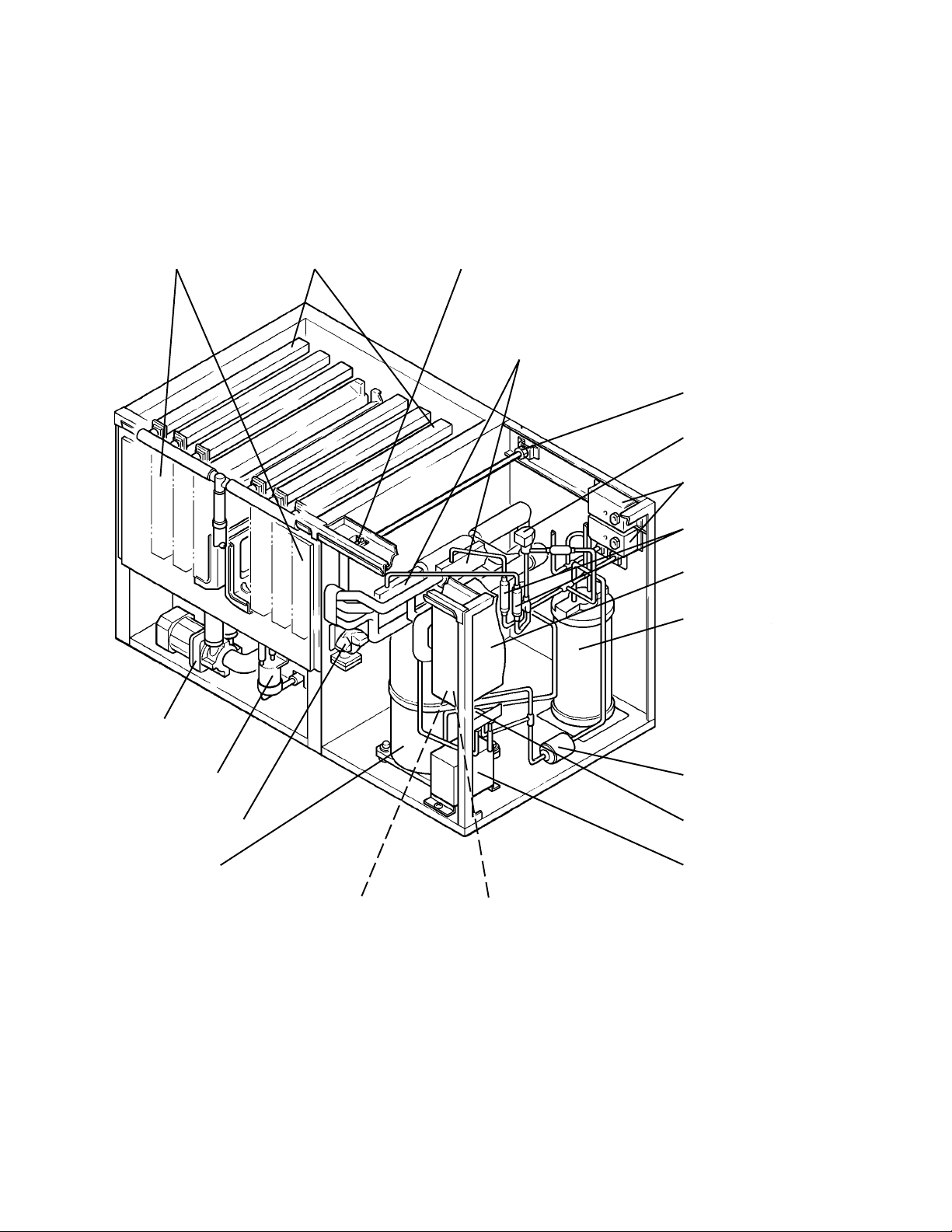

[b] KM-1600SRF, KM-1600SRF3

Evaporator Spray Tube Water Valve

Expansion Valve

Water Supply Inlet

Hot Gas Valve

Junction Box

Check Valve

Control Box

Receiver Tank

Water Pump

Float Switch Drier

Cleaning Valve Line Valve

Compressor Transformer Box

(KM-1600SRF3)

Control Switch Bin Control Thermostat Capacitor Box

(KM-1600SRF)

12

Page 13

2. CONTROLLER BOARD

[a] SOLID-STATE CONTROL

1) A HOSHIZAKI exclusive solid-state control is employed in KM-2000SWF3 and

KM-2000MRF3 Stackable Crescent Cubers.

2) A Printed Circuit Board (hereafter called “Controller Board”) includes a stable and high

quality control system.

3) All models are pretested and factory-adjusted.

[b] CONTROLLER BOARD

CAUTION

1. Fragile, handle very carefully.

2. A controller board contains integrated circuits, which are susceptible to

failure due to static discharge. It is especially important to touch the metal

part of the unit when handling or replacing the board.

3. Do not touch the electronic devices on the board or the back of the board to

prevent damage to the board.

4. Do not change wiring and connections. Do not misconnect K3, K4 and K5,

because the same connector is used for the Thermistor and Float Switch.

K4 is not connected.

5. Always replace the whole board assembly when it goes bad.

6. Do not short out power supply to test for voltage.

PART NUMBER TYPE

2A0836-01 HOSIZAKI-001 (Control Products - 8 Pin)

or 2A1410-01 HOS-001A (Control Products - 10 Pin)

Features of Control Products “E” Controller Board

1) Maximum Water Supply Period - 6 minutes

Water Solenoid Valve opening, in the Defrost (Harvest) Cycle, is limited by the defrost

timer. The Water Valve cannot remain open longer than the maximum period. The Water Valve can close in less than six minutes if the defrost cycle is completed.

13

Page 14

2) Defrost Timer

The defrost cycle starts when the Float Switch opens and completes the freeze cycle. But

the Defrost Timer does not start counting until the Thermistor senses 48°F at the Evaporator outlet. The period from the end of the freeze cycle up to the point of the Thermistor's

sensing varies depending on the ambient and water temperatures.

3) High Temperature Safety - 127 ± 7°F

The temperature of the suction line in the refrigerant circuit is limited by the High Tempera-

ture Safety.

During the defrost cycle the Evaporator temperature rises. The Thermistor senses 48°F

and starts the Defrost Timer. After the Defrost Timer counts down to zero, the normal

freeze cycle begins. If the Evaporator temperature continues to rise, the Thermistor will

sense the rise in temperature and at 127 ± 7°F the Thermistor operates the High Temperature Safety.

This High Temperature Safety shuts down the circuit and the icemaker automatically

stops. To reset the safety, turn the power off and back on again.

This High Temperature Safety protects the unit from excessive temperature. The Control

Board will Beep every 3 seconds. The white Reset Button on the Control Board must be

pressed with power on to reset the Safety.

4) Low Water Safety

If the Pump Motor is operated without water, the mechanical seal can fail. To prevent this

type of failure, the Controller Board checks the position of the Float Switch at the end of

the initial one minute water fill cycle and at the end of each defrost cycle.

If the Float Switch is in the up position (electrical circuit closed), the Controller Board

changes to the ice making cycle. If the Float Switch is in the down position (electrical

circuit open), the Controller Board changes to a one minute water fill cycle before starting

the ice making cycle. This method allows for a Low Water Safety shut down to protect the

Water Pump from mechanical seal failure.

For water-cooled model, if the water is shut off, the unit is protected by the High Pressure

Switch.

5) High Voltage Cut-out

The maximum allowable supply voltage of this icemaker is limited by the High Voltage

Cut-out.

If miswiring (especially on single phase 3 wire models) causes excessive voltage on the

Controller Board, the High Voltage Cut-out shuts down the circuit in 3 seconds and the

icemaker automatically stops. When the proper supply voltage is resumed, the icemaker

automatically starts running again. The Control Board will signal this problem using 7

Beeps every 3 seconds.

6) LED Lights and Audible Alarm Safeties

The red LED indicates proper control voltage and will remain on unless a control voltage

14

Page 15

problem occurs. At startup a 5 second delay occurs while the board conducts an internal

timer check. A short beep occurs when the power switch is turned ON or OFF.

The green LED’s 1-4 represent the corresponding relays and energize and sequence 5

seconds from initial startup as follows:

Sequence Step LED’s on Length: Min. Max. Avg.

1 Minute Fill Cycle LED4 60 sec.

Harvest Cycle LED1, 4, & 2 2 min. 20 min. 3-5 min.

Freeze Cycle LED1 5 min. 60 min. 30-35 min.

Reverse Pump Out LED1, 3, & 2 10 sec. 20 sec. Factory set.

{LED 1 – Comp; LED 2 - HGV/CFM; LED 3 – PM; LED 4 - WV}

The built in safeties shut down the unit and have alarms as follows:

1 beep every 3 sec. = High Evaporator Temperature >127 ° F.

Check for defrost problem (stuck HGV or relay), hot water entering unit, stuck headmaster,

or shorted thermistor.

2 beeps every 3 sec. = Defrost Back Up Timer. Defrost >20 minutes.

Orange LED marked 20 MIN energizes.

Check for open thermistor, HGV not opening, TXV leaking by, low charge, or inefficient

compressor.

3 beeps every 3 sec. = Freeze Back Up Timer. Freeze > 60 minutes.

Yellow LED marked 60 MIN energizes.

Check for F/S stuck closed (up), WV leaking by, HGV leaking by, TXV not feeding properly, low charge, or inefficient compressor.

To manually reset the above safeties, depress white alarm reset button with the power

supply ON.

6 beeps every 3 sec. = Low Voltage. Voltage is 92 Vac or less.

7 beeps every 3 sec. = High Voltage. Control voltage > 147Vac ±5%.

The red LED will de-energize if voltage protection operates.

The voltage safety automatically resets when voltage is corrected.

The Output Test switch “S3” provides a relay sequence test. With power OFF, place S3

ON and switch power to ICE. The correct lighting sequence should be none, 2, 3, 4, 1, & 4,

normal sequence every 5 seconds. S3 should remain in the “OFF” position for normal

operation.

The application switch located between relay X3 & X4 must be set to match the original

board application. Place this switch in the ALP position if there is no white wire supplied

15

Page 16

to the K1 connector. If there is a white wire, place the switch in the C position. If this

switch is placed in the wrong position either the compressor contactor will remain energized with the control switch OFF or the unit will not start.

The dip switches should be adjusted per the adjustment chart published in the Tech

Specs book. 7 & 8 must remain in the OFF position.

(Control Products HOSHIZAKI001 Board)

16

Page 17

(Control Products HOS-001A Board)

17

Page 18

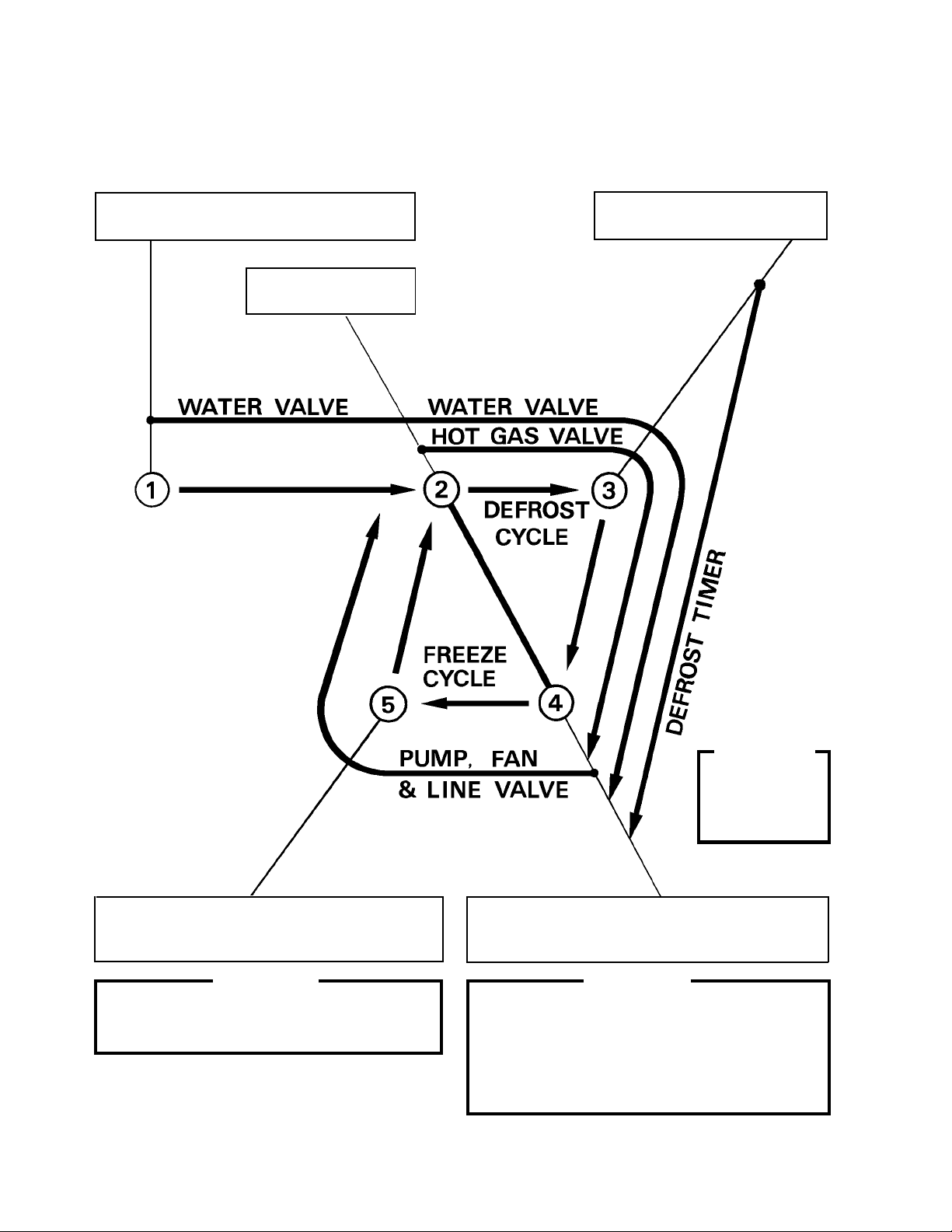

[c] SEQUENCE

1st Cycle [KM-1600SWF, KM-1600SWF3, KM-1600SRF and KM-1600SRF3]

1. Unit energized and Control Switch to “ICE”

position. Water supply cycle starts.

2. After 1 minute.

Defrost cycle starts.

3. Thermistor reads 48°F.

Defrost Timer starts counting.

5. After the first 5 minutes in freeze cycle.

Ready to complete freeze cycle when Float

Switch circuit opens.

IMPORTANT

Board never accepts freeze completion signal

within the first 5 minutes in freeze cycle.

IMPORTANT

Water Valve

opening is limited

to 6 minutes.

4. Defrost Timer stops counting.

Defrost cycle is completed and freeze cycle

starts.

IMPORTANT

1. Board never accepts defrost completion signal

within the first 2 minutes in defrost cycle.

2. Defrost cycle time is limited to 20 minutes even

if Defrost Timer does not stop counting.

18

Page 19

2nd Cycle and after with pump drain [KM-1600SWF, KM-1600SWF3, KM-1600SRF and

KM-1600SRF3]

IMPORTANT

Freeze cycle time is limited to 60 minutes even

if Float Switch does not open.

1. Float Switch opens and signals to complete

freeze cycle.

Drain timer starts counting.

&

2. Drain timer stops counting.

Pump drain is completed

3. Thermistor reads 48° F.

Defrost Timer starts

counting.

IMPORTANT

Water Valve

opening is limited to 6

minutes.

5. After the first 5 minutes in freeze cycle.

Ready to complete freeze cycle when Float

Switch circuit opens.

IMPORTANT

Board never accepts freeze completion signal

within the first 5 minutes in freeze cycle.

4. Defrost Timer stops counting.

Defrost cycle is completed and freeze cycle

starts.

IMPORTANT

1. Board never accepts defrost completion

signal within the first 2 minutes in defrost

cycle.

2. Defrost cycle time is limited to 20 minutes

even if Defrost Timer does not stop counting.

19

Page 20

2nd Cycle and after with no pump drain [KM-1600SWF, KM-1600SWF3, KM-1600SRF

and KM-1600SRF3]

IMPORTANT

Freeze cycle time is limited to 60 minutes even

if Float Switch does not open.

1. Float Switch opens and signals to complete

freeze cycle.

2. Thermistor reads 48° F.

Defrost Timer starts counting.

IMPORTANT

Water Valve

opening is limited to 6

minutes.

4. After the first 5 minutes in freeze cycle.

Ready to complete freeze cycle when Float

Switch circuit opens.

IMPORTANT

Board never accepts freeze completion signal

within the first 5 minutes in freeze cycle.

3. Defrost Timer stops counting.

Defrost cycle is completed and freeze cycle

starts.

IMPORTANT

1. Board never accepts defrost completion

signal within the first 2 minutes in defrost

cycle.

2. Defrost cycle time is limited to 20 minutes

even if Defrost Timer does not stop counting.

20

Page 21

[d] CONTROLS AND ADJUSTMENTS

The Dip Switch is factory-adjusted to the following positions:

DIP SWITCH NO. 1 2 3 4 5 6 7 8 9 10

KM-1600SWF, OFF OFF ON ON ON ON OFF OFF OFF ON

SWF3

KM-1600SRF, ON OFF ON

SRF3

Switch Nos. 1 and 2:

Used for adjustment of the Defrost Timer.

The Defrost Timer starts counting when the Thermistor reads a certain temperature

at the Evaporator outlet.

Switch Nos. 3 and 4:

Used for adjustment of the Drain Timer.

When a freeze cycle is completed, the Pump Motor stops, and the icemaker

resumes operation in 2 seconds. Then the Pump Motor drains the Water Tank

for the time determined by the Drain Timer. The Drain Timer also determines

the time to restrain completion of a defrost cycle, i.e. the minimum defrost time.

ON ON

ON

OFF OFF OFF OFF

Switch Nos. 5 and 6:

Used for adjustment of the Drain Counter.

The Pump Motor drains the Water Tank at the frequency determined by the Drain

Counter.

Switch Nos. 7 and 8:

Used only for checking the Controller Board. Usually set in OFF position.

Switch Nos. 9 and 10:

Used for adjustment of Freeze Timer.

The Freeze Timer determines maximum

freeze cycle time. Upon termination of

Freeze Timer, machine initiates the

harvest cycle. After 2 consecutive timer

terminations, machine will shut down,

possibly indicating a problem.

21

Page 22

1) Defrost Control

A thermistor (Semiconductor) is used for a defrost control sensor. The resistance varies

depending on the Suction Line temperatures. The Thermistor detects the temperature of

the Evaporator outlet to start the Defrost Timer. No adjustment is required. If necessary,

check for resistance between Thermistor leads, and visually check the Thermistor mounting, located on the Suction Line next to the Evaporator outlet.

Temperature (°F) Resistance (kΩ)

0 14.401

10 10.613

32 6.000

50 3.871

70 2.474

90 1.633

Check a thermistor for resistance by using the following procedures.

(i) Disconnect the connector K3 on the board.

(ii) Remove the Thermistor. See “V. 11. REMOVAL AND REPLACEMENT OF THERMIS-

TOR.”

(iii) Immerse the Thermistor sensor portion in a glass containing ice and water for 2 or 3

minutes.

(iv) Check for a resistance between Thermistor leads.

Normal reading is within 3.5 to 7 kΩ. Replace the Thermistor if it exceeds the normal

reading.

2) Defrost Timer

No adjustment is required under normal use, as the Defrost Timer is adjusted to the suit-

able position. However, if necessary when all the ice formed on the Evaporator does not

fall into the bin in the harvest cycle, adjust the Defrost Timer to a longer setting by adjusting

the Dip Switch (No. 1 & 2) on the Controller Board.

SETTING TIME

Dip Switch Dip Switch

No. 1 No. 2

OFF OFF 60 seconds

ON OFF 90 seconds

OFF ON 120 seconds

ON ON 180 seconds

22

Page 23

3) Drain Timer

The Drain Timer is factory-adjusted, and no adjustment is required.

SETTING TIME

Dip Switch Dip Switch

No. 3 No. 4 T1 T2

OFF OFF 10 seconds 150 seconds

ON OFF 10 seconds 180 seconds

OFF ON 10 seconds 120 seconds

ON ON 20 seconds 180 seconds

T1: Time to drain the Water Tank

T2: Time to restrain defrost completion

4) Drain Counter

CAUTION

Do not adjust the Drain Counter, or the Evaporator may freeze up.

The Drain Counter is factory-adjusted to drain the Water Tank every 10 cycles, and no

adjustment is required. However, where water quality is bad and the icemaker needs a

pump drain more often, the Drain Counter can be adjusted as shown in the table below:

SETTING FREQUENCY

Dip Switch Dip Switch

No. 5 No. 6

OFF OFF every cycle

ON OFF every 2 cycles

OFF ON every 5 cycles

ON ON every 10 cycles

23

Page 24

5) Freeze Timer

CAUTION

Adjust to proper specification, or the unit may not operate correctly.

Two new dip switches numbered 9 and 10 have been added to the improved “E” board to

better prevent possible freeze ups. These settings come factory set to the default setting

of 60 min. (OFF, OFF). Check the adjustment chart published in the Tech Specs for

proper settings. If the old board does not have these two dip switches, (only 8 instead of

10), leave setting as OFF, OFF.

SETTING TIME

Dip Switch Dip Switch

No. 9 No. 10

OFF OFF 60 min.

ON OFF 70 min.

OFF ON 50 min.

ON ON 60 min.

6) Bin Control

CAUTION

When the ambient temperature is below 45°F, the Bin Control Thermostat

operates to stop the icemaker even if the Ice Storage Bin is empty. When

the Thermostat is set in the prohibited range, the icemaker operates continuously even if the Ice Storage Bin is filled with ice. Setting in the prohibited range might cause severe damage to the icemaker resulting in failure.

No adjustment is required under normal use, as the Bin Control is factory-adjusted.

Adjust it, if necessary, so that the icemaker stops automatically within 10 seconds after

ice contacts the Bin Control Thermostat Bulb.

[e] CHECKING THE CONTROLLER BOARD

1) Visually check the sequence with the icemaker operating.

2) Visually check the Controller Board by using the following procedures.

(i) Adjust the Defrost Timer to minimum position.

Disconnect the Thermistor from the Controller Board.

Connect a 1.5 kΩ - 3.5 kΩ resistor to the Connector K3 (pins #1 and #2), and energize

the unit.

24

Page 25

After the 1 minute ± 5 second water supply cycle and the 2 minute ± 10 second defrost

cycle, the unit should start the freeze cycle.

(ii) After the above step (i), disconnect the Float Switch leads from the Controller Board

within the first 5 minutes of the freeze cycle.

The unit should go into the defrost cycle after the first 5 minutes ± 20 seconds of the

freeze cycle.

(iii) Reconnect the Float Switch Connector to the Controller Board. After the first 5

minutes of the freeze cycle, disconnect the Float Switch leads from the Controller

Board.

At this point, the unit should start the defrost cycle.

(iv) After Step (iii), de-energize the unit and confirm that the Defrost Timer is in the

minimum position. Disconnect the resistor from the Controller Board, and energize

the unit.

After the 1 minute water supply cycle, the defrost cycle starts.

Re-connect a 1.5 kΩ - 3.5 kΩ resistor to the Connector K3 (pins #1 and #2) after

the first 2 minutes of the defrost cycle.

The unit should start the freeze cycle after 1 minute ± 5 seconds from the resistor

connection.

3) Check the Controller Board by using test program of the Controller Board.

The Output Test Switch “S3” provides a relay sequence test. With power OFF, place S3

ON and switch power to ICE. The correct lighting sequence should be none, 2, 3, 4, 1,

and 4, normal sequence every 5 seconds. S3 should remain in the “OFF” position for

normal operation.

25

Page 26

III. TECHNICAL INFORMATION

1. WATER CIRCUIT AND REFRIGERANT CIRCUIT

[a] KM-1600SWF, KM-1600SWF3

26

Page 27

[b] KM-1600SRF, KM-1600SRF3

27

Page 28

2. WIRING DIAGRAMS

KM-1600SWF, KM-1600SRF

KM-1600SWF

Pressure Switch

Cut-out 384 PSIG

+ 21.3

- 0

Cut-in 284 ± 21.3 PSIG

KM-1600SRF

Pressure Switch

Cut-out 412 PSIG

Cut-in 327 ± 21.3 PSIG

28

+ 21.3

- 0

Page 29

KM-1600SWF3, KM-1600SRF3

KM-1600SRF3

Pressure Switch

Cut-out 384 PSIG

+ 21.3

- 0

Cut-in 284 ± 21.3 PSIG

29

KM-1600SRF3

Pressure Switch

Cut-out 412 PSIG

+ 21.3

- 0

Cut-in 327 ± 21.3 PSIG

Page 30

3. TIMING CHART KM-1600SWF, SWF3, SRF, SRF3

*1 The icemaker does not complete a defrost cycle in the first 2 or 3 minutes.

See "II. 2. [d] CONTROLS AND ADJUSTMENTS."

30

Page 31

*1 The icemaker does not complete a defrost cycle in the first 2 or 3 minutes.

See "II. 2. [d] CONTROLS AND ADJUSTMENTS."

31

Page 32

4. PERFORMANCE DATA

[a] KM-1600SWF

32

Page 33

[b] KM-1600SRF

ETAMIXORPPAtneibmA)C°/F°(.pmeTretaW

NOITCUDORPECI)C°/F°(.pmeT01/0512/0723/09

.RH42REP12/07)946(0341*)246(5141)906(3431

72/08)446(9141)336(6931)885(5921

23/09)246(5141)626(0831*)585(0921

)yad/gk(yad/.sbl83/001)826(3831)616(9531)745(7021

CIRTCELEETAMIXORPPA12/075182*95826092

NOITPMUSNOC72/08848271827592

23/0995825692*9003

sttaw83/001468257920503

RETAWETAMIXORPPA12/07)281.3(148*)808.2(247)393.2(236

.RH42REPNOITPMUSNOC72/08)798.2(567)613.2(216)559.1(615

3

)yad/83/001)857.2(927)418.1(974)151.1(403

m(yad/.lag

EMITELCYCGNIZEERF12/0752*6282

.nim83/001628223

EMITELCYCTSEVRAH12/075.5*8.43.4

.nim83/0019.49.25.2

ERUSSERPDAEH12/07)8.51(522*)5.61(532)0.81(652

2

)G83/001)0.71(242)7.81(562)4.12(503

mc/gk(GISP

ERUSSERPNOITCUS12/07)7.2(83*)8.2(93)9.2(14

2

)G83/001)8.2(04)1.3(34)3.3(74

mc/gk(GISP

23/09)808.2(247)609.1(405*)315.1(004

72/08627292

23/096282*03

72/089.48.37.3

23/098.40.3*7.2

72/08)4.61(332)5.71(942)2.91(372

23/09)5.61(532)3.81(062*)9.91(382

72/08)8.2(93)9.2(14)1.3(34

23/09)8.2(93)0.3(34*)2.3(54

RESNEDNOCMORFNOITCEJERFOTAEHLATOT ])C°12(F°07TW/)C°23(F°09TA[h/UTB05291

ROSSERPMOCMORFNOITCEJERFOTAEHLATOT )C°12(F°07TW/)C°23(F°09TA[h/UTB5223

EMULOVRESNEDNOC 412)F02-CRU(NI.UC

.elcycgnizeerfnisetunim5tsrifdedrocersiataderusserP:etoN

Note: Pressure data is recorded first 5 minutes into freezing cycle. The data without * marks should be used

.ecnereferrofdesuebdluohsskram*tuohtiwatadehT

for reference only.

We reserve the right to make changes in specifications and design without prior notice.

33

Page 34

[c] KM-1600SWF3

APPROXIMATE ICE

PRODUCTION PER 24 HR.

lbs./day kg./day

APPROXIMATE ELECTRIC

CONSUMPTI ON

watts 100/38

A PPR OXIMATE WATER

CONS UMPTION P ER 24 HR.

gal./day m3/day 100/38 2348 8.89 2585 9.79 4078 15.44

FRE EZING CYCLE TIME

min. 100/38

HARVEST CYCLE TIME

min. 100/38

HEAD PRESSURE

PSIG kg/cm2G

SUCTION PRESSURE

PSIG kg/cm2G

AMBIENT TEMP.

(ºF/ºC) 50/10 70/21 90/32

70/21

80/27 1496 679 1489 675 1423 646

90/32 1495 678

100/38 1473 668 1470 667 1373 623

70/21

80/27

90/32

70/21

80/27 2000 7.57 2221 8.41 3213 12.16

90/32 2034 7.70

70/21

80/27

90/32

70/21

80/27

90/32

70/21

80/27 271 19.1 273 19.2 276 19.4

90/32 271 19.1

100/38 272 19.1 276 19.4 280 19.7

70/21

80/27 41 2.9 42 3.0 45 3.2

90/32 41 2.9

100/38 42 2.9 44 3.1 48 3.4

1500

2563

2570

2573

2601

1892

24

24

25

25

5.0

4.4

4.3

4.0

270

40

WATER TEM P. ( ºF/ ºC )

680 1495 678 1451 658

1484

7.16

19.0

2.8 41 2.9 43 3.0

2034 7.70 2741 10.38

2377

271 19.1 274 19.3

275

43

673

2573

2586

2597

2615

9.00

25

25

26

26

4.3

3.3

2.5

2.4

19.3

3.0

1426 647

2634

2673

2675

2746

3264 12.35

26

26

27

28

3.8

3.2

2.2

2.0

278 19.5

46 3.2

TOTAL HE AT OF RE JECTION FROM CO NDENSER

TOTA L HE A T OF REJECTION FROM COMPRE S S O R 3100 BTU/h [A T 90ºF (32º C) / WT 70ºF (21ºC)]

WATER FLOW F OR CONDENSER 155 gal. / h (A T 100ºF (38º C) / WT 90ºF (32ºC))

PRESSURE DROP OF COOLING WATER LINE less than 10 PSIG

17560 BTU/h [A T 90ºF (32ºC) / WT 70ºF (21ºC)]

Note: Pressure data is recorded first 5 minutes into freezing cycle. The data NOT in bold should be used

for reference only.

We reserve the right to make changes in specifications and design without prior notice.

34

Page 35

[d] KM-1600SRF3

ETAMIXORPPAtneibmA)C°/F°(.pmeTretaW

NOITCUDORPECI)C°/F°(.pmeT01/0512/0723/09

.RH42REP12/07)366(1641*)746(6241)916(5631

72/08)156(4341)626(0831)595(1131

23/09)746(6241)806(1431*)875(4721

)yad/gk(yad/.sbl83/001)936(9041)106(5231)055(3121

CIRTCELEETAMIXORPPA12/075772*21821582

NOITPMUSNOC72/08308206823982

23/0921820092*6392

sttaw83/001618290920792

RETAWETAMIXORPPA12/07)529.2(377*)965.2(976)472.2(106

.RH42REPNOITPMUSNOC72/08)456.2(107)101.2(555)219.1(505

3

)yad/83/001)575.2(086)456.1(734)942.1(033

m(yad/.lag

EMITELCYCGNIZEERF12/0752*6272

.nim83/001627213

EMITELCYCTSEVRAH12/075.5*8.43.4

.nim83/0019.49.25.2

ERUSSERPDAEH12/07)8.51(522*)5.61(532)7.71(252

2

)G83/001)8.61(042)6.81(462)7.02(592

mc/gk(GISP

ERUSSERPNOITCUS12/07)6.2(73*)7.2(83)9.2(14

2

)G83/001)7.2(93)9.2(14)3.3(74

mc/gk(GISP

23/09)965.2(976)017.1(254*)074.1(883

72/08526292

23/096272*92

72/089.48.37.3

23/098.40.3*7.2

72/08)4.61(332)5.71(942)8.81(762

23/09)5.61(532)3.81(062*)6.91(872

72/08)6.2(83)7.2(93)0.3(34

23/09)7.2(83)8.2(04*)1.3(44

RESNEDNOCMORFNOITCEJERFOTAEHLATOT ])C°12(F°07TW/)C°23(F°09TA[h/UTB00022

ROSSERPMOCMORFNOITCEJERFOTAEHLATOT )C°12(F°07TW/)C°23(F°09TA[h/UTB0543

EMULOVRESNEDNOC 412)F02-CRU(NI.UC

Note: Pressure data is recorded first 5 minutes into freezing cycle. The data without * marks should be used

for reference only.

.elcycgnizeerfnisetunim5tsrifdedrocersiataderusserP:etoN

.ecnereferrofdesuebdluohsskram*tuohtiwatadehT

We reserve the right to make changes in specifications and design without prior notice.

35

Page 36

IV. SERVICE DIAGNOSIS

1. NO ICE PRODUCTION

PROBLEM POSSIBLE CAUSE REMEDY

[1] The icemaker a) Power Supply 1. “OFF” position. 1. Move to “ON” position.

will not start 2. Loose connections. 2. Tighten.

3. Bad contacts. 3. Check for continuity and

replace.

4. Voltage too high. 4. Check and get

recommended voltage.

b) Fuse (Inside Fused 1. Blown out. 1. Check for short circuit

Disconnect, if any) and replace.

c) Control Switch 1. “OFF” position. 1. Move to “ICE” position.

2. Bad contacts. 2. Check for continuity and

replace.

d) Bin Control 1. Tripped with bin filled 1. Remove ice.

Thermostat with ice.

2. Ambient temperature 2. Increase ambient

too cool. temperature.

3. Set too warm. 3. See “II.2.[d]

CONTROLS AND

ADJUSTMENTS, 5) Bin

Control.”

4. Bulb out of position. 4. Place in position.

5. Bad contacts or leaks in 5. Check for continuity and

bulb. replace.

e) High Pressure 1. Bad contacts. 1. Check for continuity and

Control replace.

f) Transformer 1. Thermal fuse blown out 1. Replace.

or coil winding opened.

g) Wiring to 1. Loose connections or 1. Check for continuity and

Controller Board open. replace.

h) Thermistor 1. Leads short-circuit or 1. See “II.2.[d] CONTROLS

open and High AND ADJUSTMENTS, 1)

Temperature Safety Defrost Control.”

operates.

i) Hot Gas Solenoid 1. Continues to open in 1. Check for power off in

Valve freeze cycle and High freeze cycle and replace.

Temperature Safety

operates.

j) Water Supply Line 1. Water supply off and 1. Check and get

water supply cycle does recommended

not finish. pressure.

2. Condenser water 2. Check and get

pressure too low or off recommended

and Pressure Control pressure.

opens and closes fre-

quently to finally operate

High Temperature Safety.

k) Water Solenoid 1. Mesh filter or orifice gets 1. Clean.

clogged and water supply

cycle does not finish.

2. Coil winding opened. 2. Replace.

3. Wiring to Water Valve. 3. Check for loose

connection or open, and

replace.

36

Page 37

PROBLEM POSSIBLE CAUSE REMEDY

l) Controller Board 1. Defective 1. See "II.2[e] CHECKING

CONTROLLER BOARD."

m) Interlock Switch 1. OFF position. 1. Move to ON position.

(Cleaning Valve) 2. Bad contacts. 2. Check for continuity and

replace.

[2] Water a) Float switch 1. Connector disconnected. 1. Place in position.

continues to 2. Leads opened or defective 2. Check and replace.

be supplied, switch.

and the ice- 3. Float does not move freely. 3. Clean or replace.

maker will not b) Controller Board 1. Defective. 1. Replace.

start.

[3] Compressor a) Wash Switch 1. WASH position. 1. Move to ICE position.

2. Bad contacts. 2. Check and replace.

b) High Pressure 1. Dirty Air Filter or 1. Clean.

Controller Condenser.

2. Ambient or condenser 2. Reduce ambient temp.

water temp. too warm.

3. Refrigerant overcharged. 3. Recharge.

4. Condenser water pressure 4. Check and get

too low or off. [Water- recommended pressure.

cooled model only].

5. Fan not operating. [Except 5. See chart 1 - [6].

water-cooled model].

6. Refrigerant line or 6. Clean and replace Drier.

components plugged.

c) Water Regulator 1. Set too high. 1. Adjust lower.

d) Overload Protector 1. Bad contacts. 1. Check for continuity and

replace.

2. Voltage too low. 2. Increase voltage.

3. Refrigerant overcharged or 3. Recharge.

undercharged.

4. Line Valve continues to 4. Check Line Valve's

close in freeze cycle and operation in freeze cycle

Overload Protector and replace.

operates.

e) Starter 1. Bad contacts. 1. Check and replace.

2. Coil winding opened. 2. Replace.

f) Start Capacitor or 1. Defective. 1. Replace.

Run Capacitor

g) Magnetic Contactor 1. Bad contacts. 1. Check for continuity and

replace.

2. Coil winding opened. 2. Replace.

h) Compressor 1. Wiring to Compressor. 1. Check for loose

connection or open, and

replace.

2. Defective. 2. Replace.

3. Protector tripped. 3. Reduce temperature.

i) Controller board 1. Defective. 1. See "II.2. [e] CHECKING

CONTROLLER BOARD."

[4] Water a) Water Solenoid 1. Diaphragm does not close. 1. Check for water leaks

continues to Valve with icemaker off.

be supplied in b) Controller Board 1. Defective. 1. See "II.2.[e] CHECKING

freeze cycle. CONTROLLER BOARD."

37

Page 38

PROBLEM POSSIBLE CAUSE REMEDY

[5] No water a) Water Supply Line 1. Water pressure too low and 1. Check and get

comes from water level in Water Tank recommended pressure.

Spray Tubes. too low.

Water Pump b) Water Solenoid 1. Dirty mesh filter or orifice 1. Clean.

will not start, or Valve and water level in Water

freeze cycle Tank too low.

time is too c) Water System 1. Water leaks. 1. Check connections for

short.. water leaks, and replace.

2. Clogged. 2. Clean.

d) Pump Motor 1. Motor winding opened. 1. Replace.

2. Bearing worn out. 2. Replace.

3. Wiring to Pump Motor. 3. Check for loose

connection or open, and

replace.

4. Defective Capacitor. 4. Replace.

5. Defective or bound impeller. 5. Replace and clean.

6. Mechanical Seal worn out. 6. Check and replace.

e) Controller Board 1. Defective. 1. See "II.2. [e] CHECKING

CONTROLLER BOARD.

[6] Fan Motor will a) Fan Motor 1. Motor winding opened. 1. Replace.

not start, or is 2. Bearing worn out. 2. Replace.

not operating. 3. Wiring to Fan Motor. 3. Check for loose

connection or open, and

replace.

4. Defective Capacitor. 4. Replace

5. Fan blade bound. 5. Check and replace.

b) Controller Board 1. Defective. 1. See "II.2. [e] CHECKING

CONTROLLER BOARD."

[7] All components a) Refrigerant 1. Undercharged. 1. Check for leaks and

run but no ice recharge.

is produced. 2. Air or moisture trapped. 2. Replace Drier, and

recharge.

b) Compressor 1. Defective valve. 1. Replace.

c) Hot Gas Solenoid 1. Continues to open in freeze 1. Check and replace.

Valve cycle.

d) Line Valve 1. Continues to close in 1. Check and replace

freeze cycle.

e) Water Supply Line 1. Condenser water pressure 1. Check and get

[Water-cooled model too low or off and Pressure recommended pressure.

only] Control opens and closes

frequently.

38

Page 39

2. EVAPORATOR IS FROZEN UP

PROBLEM POSSIBLE CAUSE REMEDY

[1] Freeze cycle a) Float Switch 1. Leads short-circuit or 1. Check and replace.

time is too defective switch.

long. 2. Float does not move freely. 2. Clean or replace.

b) Water Solenoid 1. Diaphragm does not close. 1. Check for water leaks

Valve with icemaker off.

c) Controller Board 1. Defective. 1. See "II.2[e] CHECKING

CONTROLLER BOARD."

[2] All ice formed a) Evaporator 1. Scaled up. 1. Clean.

on Evaporator b) Water Supply Line 1. Water pressure too low. 1. Check and get

does not fall recommended pressure.

into bin in c) Water Solenoid 1. Dirty mesh filter or orifice. 1. Clean.

harvest cycle. Valve 2. Diaphragm does not close. 2. Check for water leaks

with icemaker off.

d) Ambient and/or 1. Too cool. 1. Increase temperature.

water temperature

e) Line Valve 1. Continues to open in 1. Check operation in

harvest cycle. harvest cycle and replace.

f) Thermistor 1. Out of position or loose 1. See "V. 11. REMOVAL

attachment. AND REPLACEMENT OF

THERMISTOR."

g) Controller Board 1. Defrost Timer is set too 1. Adjust longer, referring

short. to "II. 2. [d] CONTROLS

AND ADJUSTMENT, 2)

Defrost Timer."

2. Defective. 2. See "II. 2.[e] CHECKING

CONTROLLER BOARD."

[3] Others a) Spray Tubes 1. Clogged. 1. Clean.

2. Out of position. 2. Place in position.

b) Water System 1. Dirty. 1. Clean.

c) Refrigerant 1. Undercharged. 1. Check for leaks and

recharge.

d) Expansion Valve 1. Bulb out of position or 1. Place in position.

loose attachment.

2. Defective. 2. Replace.

e) Hot Gas Solenoid 1. Coil winding opened. 1. Replace.

Valve 2. Plunger does not move. 2. Replace.

3. Wiring to Hot Gas Valve. 3. Check for loose

connection or open, and

replace.

3. LOW ICE PRODUCTION

PROBLEM POSSIBLE CAUSE REMEDY

[1] Freeze cycle a) See chart 1 - [3], and check dirty Air Filter or Condenser, ambient or water

time is long. temperature, water pressure, Water Regulator or refrigerant charge.

b) See chart 2 - [1], and check Float Switch, Water Solenoid Valve or Controller

Board.

[2] Harvest cycle a) See chart 2 - [2], and check Controller Board, Thermistor, Evaporator, ambient

time is long and/or water temperature, water supply line, Water Solenoid Valve, Line Valve,

or Gas Valve.

39

Page 40

4. ABNORMAL ICE

PROBLEM POSSIBLE CAUSE REMEDY

[1] Small Cube a) Ice Cube Guide 1. Out of position. 1. Place in position.

Circulated water falls into

bin.

b) See chart 1 - [5], and check water supply line, Water Solenoid Valve, water system,

Pump Motor or Controller Board.

c) Drain Valve 1. Dirty. 1. Clean.

[2] Cloudy or a) See chart 2 - [1] and - [3], and check Float Switch, Water Solenoid Valve,

irregular cube Controller Board, Spray Tubes, water system, refrigerant charge or Expansion

Valve.

b) Spray Guide 1. Dirty. 1. Clean.

c) Water Quality 1. High hardness or contains 1. Install a water filter or

impurities. softener.

5. OTHERS

PROBLEM POSSIBLE CAUSE REMEDY

[1] Icemaker will a) Bin Control 1. Set too cold. 1. Adjust warmer.

not stop when Thermostat 2. Defective. 2. Replace.

bin is filled

with ice.

[2] Abnormal a) Pump Motor 1. Bearings worn out. 1. Replace.

noise b) Fan Motor 1. Bearings worn out. 1. Replace.

2. Fan blade deformed. 2. Replace fan blade.

3. Fan blade does not move 3. Replace.

freely.

c) Compressor 1. Bearings worn out, or 1. Replace.

cylinder valve broken.

2. Mounting pad out of 2. Reinstall

position.

d) Refrigerant Lines 1. Rub or touch lines or other 1. Replace.

surfaces.

[3] Ice in storage a) Bin Drain 1. Plugged. 1. Clean.

bin often

melts.

40

Page 41

V. REMOVAL AND REPLACEMENT OF COMPONENTS

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after the

equipment is serviced.

IMPORTANT

1. The Polyol Ester (POE) oils used in R-404A units can absorb moisture quickly.

Therefore it is important to prevent moisture from entering the system when

replacing or servicing parts.

2. Always install a new filter drier every time the sealed refrigeration system is

opened.

3. Do not leave the system open for longer than 5 minutes when replacing or

servicing parts.

1. SERVICE FOR REFRIGERANT LINES

[a] REFRIGERANT RECOVERY

The icemaker unit is provided with two Refrigerant Access Valves–one on the low-side and one

on the high-side line. Using proper refrigerant practices recover the refrigerant from the Access

Valves and store it in an approved container. Do not discharge the refrigerant into the atmosphere.

[b] EVACUATION AND RECHARGE [R-404A]

1) Attach Charging Hoses, a Service Manifold and a Vacuum Pump to the system. Be sure to

connect charging hoses to both High and Low -side Access Valves.

IMPORTANT

The vacuum level and Vacuum Pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the Vacuum Pump. Never allow the oil in the Vacuum Pump to flow backward.

3) Allow the Vacuum Pump to pull down to a 29.9" Hg vacuum. Evacuating period depends on

pump capacity.

41

Page 42

4) Close the Low-side Valve and High-side Valve on the Service Manifold.

5) Disconnect the Vacuum Pump, and attach a Refrigerant Service Cylinder to the High-side line.

Remember to loosen the connection, and purge the air from the Hose. For water-cooled

models, see the Nameplate for the required refrigerant charge. For remote air-cooled models, see the Charge Label in the machine compartment. Hoshizaki

recommends only virgin refrigerant or reclaimed refrigerant which meets ARI Standard

No. 700-88 be used.

6) A liquid charge is recommended for charging an R-404A system. Invert the service cylinder. Open the High-side, Service Manifold Valve.

7) Allow the system to charge with liquid until the pressures balance.

8) If necessary, add any remaining charge to the system through the Low-side. Use a throttling valve or liquid dispensing device to add the remaining liquid charge through the Lowside access port with the unit running.

9) Close the two Refrigerant Access Valves, and disconnect the Hoses and Service Manifold.

10) Cap the Access Valves to prevent a possible leak.

2. BRAZING

1. Refrigerant R-404A itself is not flammable at atmospheric pressure and

temperatures up to 176° F.

2. Refrigerant R-404A itself is not explosive or poisonous. However, when

exposed to high temperatures (open flames) R-404A can be decomposed to

form hydrofluoric acid and carbonyl fluoride both of which are hazardous.

3. Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

4. Do not use silver alloy or copper alloy containing Arsenic.

5. Do not use R-404A as a mixture with pressurized air for leak testing. Refrigerant leaks can be detected by charging the unit with a little refrigerant, raising the

pressure with nitrogen and using an electronic leak detector.

DANGER

Note: All brazing-connections inside the Evaporator Case are clear-paint coated. Sandpaper

the brazing connections before unbrazing the components. Use a good abrasive cloth to

remove coating.

42

Page 43

3. REMOVAL AND REPLACEMENT OF COMPRESSOR

IMPORTANT

Always install a new Drier every time the sealed refrigeration system is opened.

Do not replace the Drier until after all other repair or replacement has been

made.

Note: When replacing a Compressor with a defective winding, be sure to install the new Start

Capacitor and Start Relay supplied with the replacement Compressor. Due to the

ability of the POE oil in the compressor to absorb moisture quickly, the Compressor

must not be opened more than 15 minutes for replacement or service. Do not mix

lubricants of different compressors even if both are charged with R-404A, except when

they use the same lubricant.

1) Turn off the power supply.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the Terminal Cover on the Compressor, and disconnect the Compressor Wiring.

5) Remove the Discharge and Suction Pipes using brazing equipment.

6) Remove the Hold-down Bolts, Washers and Rubber Grommets.

7) Slide and remove the Compressor. Unpack the new Compressor package. Install the

new Compressor.

8) Attach the Rubber Grommets of the prior Compressor.

9) Sandpaper the Suction, Discharge and Process Pipes.

10) Place the Compressor in position, and secure it using the Bolts and Washers.

11) Remove plugs from the Suction, Discharge and Process Pipes.

12) Braze the Process, Suction and Discharge lines (Do not change this order), while purging

with nitrogen gas flowing at the pressure 3-4 PSIG.

13) Install the new Filter Drier.

43

Page 44

14) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

15) Evacuate the system, and charge it with refrigerant. For water-cooled models, see the

Nameplate for the required refrigerant charge. For remote air-cooled models, see the

Charge Label in the machine compartment.

16) Connect the Terminals, and replace the Terminal Cover in its correct position.

17) Replace the panels in their correct positions.

18) Turn on the power supply.

4. REMOVAL AND REPLACEMENT OF DRIER

IMPORTANT

Always install a new Drier every time the sealed refrigeration system is opened.

Do not replace the Drier until after all other repair or replacement has been

made.

1) Turn off the power supply.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the Drier.

5) Install the new Drier, with the arrow on the Drier, in the direction of the refrigerant flow.

Use nitrogen gas at the pressure of 3-4 PSIG when brazing the tubings.

6) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

7) Evacuate the system, and charge it with refrigerant. For water-cooled models, see the

Nameplate for the required refrigerant charge. For remote air-cooled models, see the

Charge Label in the machine compartment.

8) Replace the panels in their correct positions.

9) Turn on the power supply.

44

Page 45

5. REMOVAL AND REPLACEMENT OF EXPANSION VALVE

IMPORTANT

Sometimes moisture in the refrigerant circuit exceeds the Drier capacity and

freezes up at the Expansion Valve. Always install a new Drier every time the

sealed refrigeration system is opened. Do not replace the Drier until after all other

repair or replacement has been made.

1) Turn off the power supply.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the insulation and the Expansion Valve Bulb on the suction line.

5) Remove the Expansion Valve Cover, and disconnect the Expansion Valve using brazing

equipment.

6) Braze the new Expansion Valve, with nitrogen gas flowing at the pressure of 3-4 PSIG.

WARNING

1. Do not heat the wall. Place a steel barrier for protection.

2. Always protect the valve body by using a damp cloth to prevent the valve from

overheating. Do not braze with the valve body exceeding 250°F.

7) Install the new Drier.

8) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

9) Evacuate the system, and charge it with refrigerant. For water-cooled models, see the

Nameplate for the required refrigerant charge. For remote air-cooled models, see the

Charge Label in the machine compartment.

10) Attach the Bulb to the suction line in position. Be sure to secure it with clamps and to

insulate it.

11) Place the new set of Expansion Valve Covers in position.

12) Replace the panels in their correct positions.

13) Turn on the power supply.

45

Page 46

6. REMOV AL AND REPLACEMENT OF HOT GAS VALVE, LINE V A LVE AND

GAS V AL VE

CAUTION

Always use a copper tube of the same diameter and length when replacing

the hot gas lines; otherwise the performance may be reduced.

IMPORTANT

Always install a new Drier every time the sealed refrigeration system is

opened.

Do not replace the Drier until after all other repair or replacement has been

made.

1) Turn off the power supply.

2) Remove the panels.

3) Recover the refrigerant and store it in an approved container.

4) Remove the screw and the Solenoid.

5) Disconnect the Hot Gas Valve or Line Valve using brazing equipment.

6) Install the new valve.

WARNING

Always protect the valve body by using a damp cloth to prevent the valve

from overheating. Do not braze with the valve body exceeding 250°F.

7) Install the new Drier.

8) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

9) Evacuate the system, and charge it with refrigerant. For water-cooled models, see the

Name plate for the required refrigerant charge. For remote air-cooled models, see the

Charge Label in the machine compartment.

10) Cut the leads of the Solenoid allowing enough lead length to reconnect using closed

end connectors.

46

Page 47

11) Connect the new Solenoid leads.

12) Attach the Solenoid to the valve body, and secure it with a screw.

13) Replace the panels in their correct positions.

14) Turn on the power supply.

7. REMOVAL AND REPLACEMENT OF EVAPORATOR

IMPORTANT

Always install a new Drier every time the sealed refrigeration system is opened.

Do not replace the Drier until after all other repairs or replacement have been made.

1) Turn off the power supply.

2) Remove the panels and the Top Insulation over the Evaporator.

3) Recover the refrigerant and store it in an approved container.

4) Remove the Spray Tubes and the Insulations at the “U” shaped notch where the

refrigeration tubings pass through the molded chassis.

5) Remove the Insulation Tube, and disconnect the Evaporator Inlet Tubing at the Tee next to

the Expansion Valve.

6) Lift up the Evaporator, and disconnect the Evaporator Outlet Tubing.

7) Install the new Evaporator.

8) Install the new Drier.

9) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

10) Evacuate the system, and charge it with refrigerant. For water-cooled models, see the

Nameplate for the required refrigerant charge. For remote air-cooled models, see the

Charge Label in the machine compartment.

11) Replace the removed parts in the reverse order of which they were removed.

12) Replace the Top Insulation and the panels in their correct positions.

13) Turn on the power supply.

47

Page 48

8. REMOV AL AND REPLACEMENT OF WA TER REGULATING V ALVE - W ATERCOOLED MODEL ONLY

IMPORTANT

Always install a new Drier every time the sealed refrigeration system is opened.

Do not replace the Drier until after all other repair or replacement has been made.

1) Turn off the power supply.

2) Close the Water Supply Line Shut-off Valve.

3) Remove the panels.

4) Recover the refrigerant and store it in an approved container.

5) Disconnect the Capillary Tube at the Condenser outlet using brazing equipment.

6) Disconnect the Flare-connections of the valve.

7) Remove the screws and the valve from the Bracket.

8) Install the new valve, and braze the Capillary Tube.

9) Install the new Drier.

10) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

11) Evacuate the system, and charge it with refrigerant. See the Nameplate for the required

refrigerant charge.

12) Connect the Flare-connections.

13) Open the Water Supply Line Shut-off Valve.

14) Check for water leaks.

15) Replace the panels in their correct positions.

16) Turn on the power supply.

48

Page 49

9. ADJUSTMENT OF WA TER REGULATING V ALVE - W ATER-COOLED MODEL

ONLY

The Water Regulating Valve (also called “WATER REGULATOR”) is factory-adjusted. No adjustment is required under normal use. Adjust the Water Regulator, if necessary, using the following

procedures.

1) Attach a pressure gauge to the high-side line of the system. Or prepare a thermometer to

check for the condenser drain temperature.

2) Rotate the adjustment screw by using a flat blade screwdriver, so that the pressure gauge

shows 270 PSIG or the thermometer reads 104–115°F, 5 minutes after a freeze cycle or

icemaking process starts. When the pressure exceeds 270 PSIG, or the condenser drain

temperature exceeds 115°F, rotate the adjustment screw counterclockwise. See Fig. 1.

3) Check that the pressure or the condenser drain temperature holds a stable setting.

Fig. 1

49

Page 50

10. REMOVAL AND REPLACEMENT OF CONDENSING PRESSURE

REGULATOR (C.P.R.) - REMOTE AIR-COOLED MODEL ONLY

IMPORTANT

Always install a new Drier every time the sealed refrigeration system is opened.

Do not replace the Drier until after all other repair or replacement has been made.

1) Turn off the power supply.

2) Remove the panels from the remote condenser unit.

3) Recover the refrigerant and store it in an approved container.

4) Before heating, break off the stub on the dome to release the dome charge.

5) Disconnect the C.P.R. using brazing equipment.

6) Install the new C.P.R. Use nitrogen gas at the pressure of 3-4 PSIG when brazing the C.P.R.

WARNING

Always protect the C.P.R. body by using a damp cloth to prevent the C.P.R.

from overheating. Do not braze with the C.P.R. body exceeding 250°F.

7) Install the new Drier in the icemaker.

8) Check for leaks using nitrogen gas (140 PSIG) and soap bubbles.

9) Evacuate the system and charge it with refrigerant. See the Charge Label in the machine

compartment in the icemaker.

10) Replace the panels in their correct positions.

11) Turn on the power supply.

50

Page 51

11. REMOVAL AND REPLACEMENT OF THERMISTOR

CAUTION

1. Fragile, handle very carefully.

2. Always use a recommended sealant (High Thermal Conductive Type),

Model KE4560RTV manufactured by SHINETSU SILICONE,

Part Code 60Y000-11, or Part Code 4A0683-01 equivalent.

3. Always use a recommended foam insulation (Non-absorbent Type) or equivalent.

1) Turn off the power supply.

2) Remove the panels.

3) Remove the Control Box Cover.

4) Disconnect the Thermistor leads from

the K3 Connector on the Controller Board.

5) Remove the Plastic Cable Ties, Foam

Insulation, Thermistor Holder and

Thermistor. See Fig. 2.

6) Scrape away the old sealant on the

Thermistor Holder and the Suction Pipe.

7) Wipe off moisture or condensation on the Suction Pipe.

8) Smoothly apply recommended sealant (KE4560RTV, Part Code 60Y000-11 or 4A0683-01)

to the Thermistor Holder concave.

9) Attach the new Thermistor to the Suction Pipe very carefully to prevent damage to the

leads. And secure it using the Thermistor Holder and recommended foam insulation.

Thermistor Lead Cable Tie

Foam Insulation Thermistor Holder

Fig. 2

10) Secure the insulation using the Plastic Cable Ties.

11) Connect the Thermistor leads through the bushing of the Control Box to the K3 Connector

on the Controller Board.

Note: Do not cut the leads of the Thermistor while installing it.

51

Page 52

12) Replace the Control Box Cover and the panels in their correct positions.

13) Turn on the power supply.

12. REMOVAL AND REPLACEMENT OF FAN MOTOR

Note: When replacing a Fan Motor with defective winding, it is recommended

that a new capacitor be installed.

1) Turn off the power supply.

2) Remove the panels.

3) Remove the Junction Box Cover from the remote condenser unit (Remote Air-cooled model).

4) Remove the closed end connectors from the Fan Motor leads.

5) Remove the Fan Motor Bracket and Fan Motor.

6) Install the new Fan Motor, and replace the removed parts in the reverse order of which they

were removed.

7) Replace the panels in their correct positions.

8) Replace the Junction Box Cover in its correct position (Remote Air-cooled model).

9) Turn on the power supply.

13. REMOV AL AND REPLACEMENT OF W ATER VAL VE

1) Turn off the power supply.

2) Close the Water Supply Line Shut-off Valve.

3) Remove the Front Panel.

4) Remove the Valve Outlet Tubing by releasing the Clamp.

5) Remove the Bracket from the unit.

6) Remove the Fitting Nut and Water Valve.

7) Disconnect the Terminals from the Water Valve.

52

Page 53

8) Install the new Water Valve, and replace the removed parts in the reverse order of which

they were removed.

9) Open the Water Supply Line Shut-off Valve.

10) Turn on the power supply.

11) Check for leaks.

12) Replace the Front Panel in its correct position.

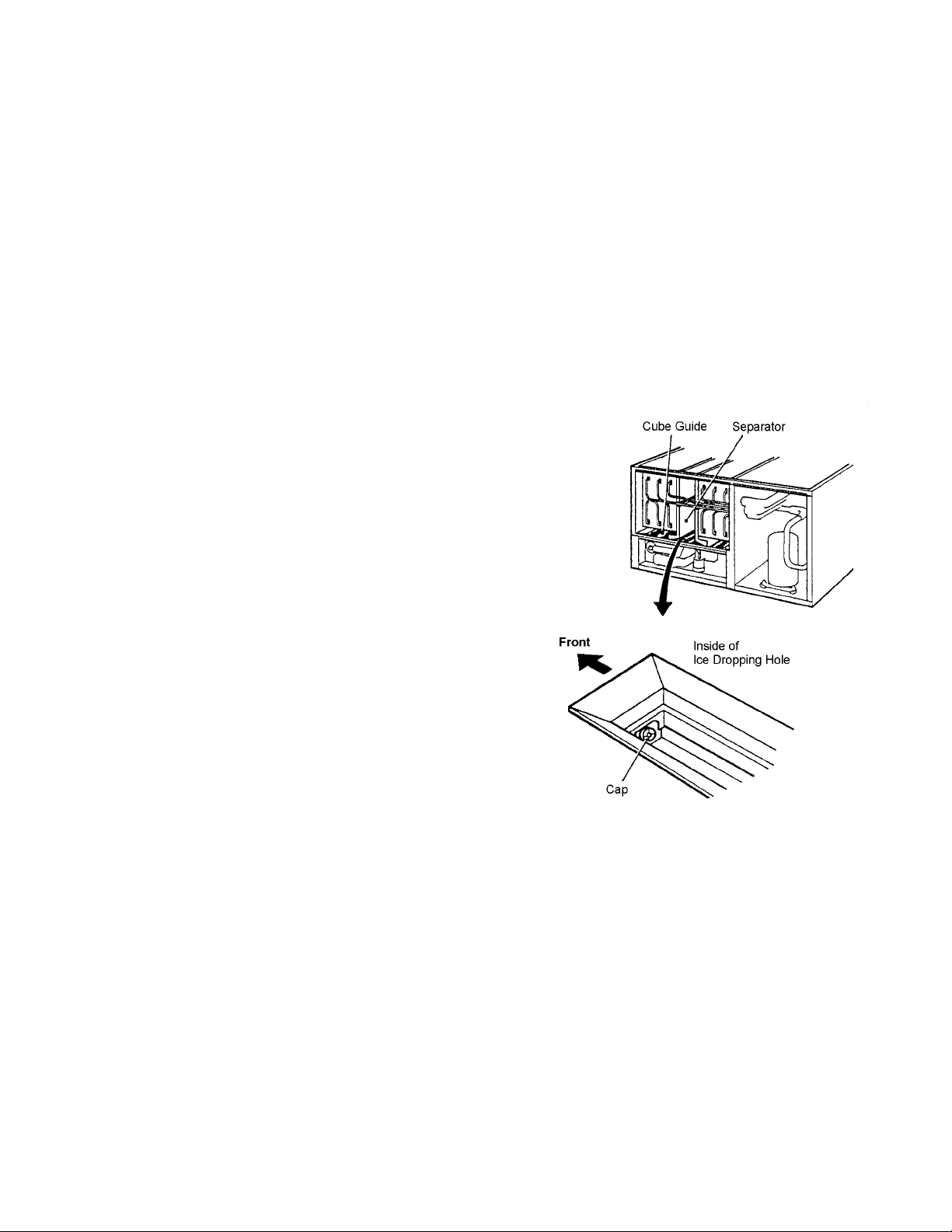

14. REMOVAL AND REPLACEMENT OF PUMP MOTOR

1) Turn off the power supply.

2) Remove the Front Panel.

3) Drain the Water Tank by removing the

Insulation Panel and the cap at the front of

the ice dropping hole. See Fig. 3.

4) Replace the removed parts in their correct

positions.

5) Disconnect the Pump Suction and

Discharge Hoses.

6) Remove the screws and the Pump

Motor Bracket.

7) Remove the closed end connectors from

the Pump Motor leads.

8) Remove the two screws and the Pump

Motor Bracket.

9) Remove the Pump Housing, and check the Impeller.

10) If the Impeller is defective, install a new Impeller.

11) Install the new motor or new parts, and replace the removed parts in the reverse

order of which they were removed.

Fig. 3

12) Turn on the power supply, and check for leaks.

13) Replace the Front Panel in its correct position.

53

Page 54

15. REMOVAL AND REPLACEMENT OF SPRAY TUBES

1) Turn off the power supply.

2) Remove the Front Panel and the Insulation Panel.

3) Remove the Rubber Hoses from the Spray Tubes (Water Supply Pipe).

4) Release the Clamps, and disconnect the Rubber Hoses.

5) Remove the Spray Tubes by squeezing the side tabs.

6) Install the new Spray Tubes, and replace the removed parts in the reverse order of which

they were removed.

7) Replace the panels in their correct positions.

8) Turn on the power supply.

54

Page 55

VI. CLEANING AND MAINTENANCE INSTRUCTIONS

1. PREPARING THE ICEMAKER FOR LONG STORAGE

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after

any maintenance or cleaning is done to the equipment.

W ARNING

When shutting off the icemaker for an extended time, drain out all water from the water

tank and remove the ice from the Storage Bin. The Storage Bin should be cleaned

and dried. Drain the icemaker to prevent damage to the water supply line at

subfreezing temperatures, using air or carbon dioxide. Shut off the icemaker until

the proper ambient temperature is resumed.

• When the icemaker is not used for two or three days, it is sufficient to only move the Control

Switch to the “OFF” position, unless the icemaker will be at subfreezing temperatures.

[1] On water-cooled model only, first remove the water from the water-cooled condenser:

1) Remove the Front Panel.

2) Move the Control Switch, on the Control Box, to the “OFF” position.

3) Wait 3 minutes.

4) Move the Control Switch to the “ICE” position.

5) Allow 5 minutes for the icemaker to fill with water and the Water Pump to start operating.

6) Close the Water-cooled Condenser Water Supply Line Shut-off Valve.

7) Open the Drain Valve for the water-cooled condenser water supply line.

8) Allow the line to drain by gravity.

9) Attach compressed air or carbon dioxide supply to the Condenser Water Line Drain Valve.

10) Quickly blow the water-cooled condenser out using compressed air or carbon dioxide until

water stops coming out.

55

Page 56

[2] Remove the water from the potable water supply line:

1) Remove the Front Panel. (Except water-cooled model)

2) Move the Control Switch, on the Control Box, to the “OFF” position.

3) Wait 3 minutes.

4) Close the Potable Water Supply Line Shut-off Valve and open the Potable Water Supply

Line Drain Valve.

5) Allow the line to drain by gravity.

6) Attach compressed air or carbon dioxide supply to the Potable Water Line Drain Valve.

7) Move the Control Switch to the “ICE” position.

8) Blow the potable water line out using compressed air or carbon dioxide.

[3] Drain the Potable Water Tank:

1) Turn off the power supply.

2) Move the Control Switch to the “OFF”

position.

3) Drain the Water Tank by removing the

Insulation Panel and the Cap located

on the front bottom part of the Ice

Dropping Hole. See Fig. 3.

4) Replace the removed parts in their

correct positions.

5) Remove all ice from the Storage Bin,

and clean the Storage Bin.

6) Replace the Front Panel in its correct

position.

7) Close the Drain Valve.

Fig. 3

56

Page 57

2. CLEANING PROCEDURE

Ensure all components, fasteners and thumbscrews are securely in place after

any maintenance or cleaning is done to the equipment.

1. HOSHIZAKI recommends cleaning this unit at least once a year. More

frequent cleaning, however, may be required in some existing water

conditions.

2. To prevent injury to individuals and damage to the icemaker, do not use

ammonia type cleaners.

3. Always wear liquid-proof gloves for safe handling of the cleaning and

sanitizing solution. This will prevent irritation in case the solution comes

into contact with skin.

IMPORTANT

W ARNING

IMPORTANT

1. The Cleaning Valve is used to allow solution flow to the inside of the

Evaporator during the cleaning and sanitizing operation. It should be

closed for all icemaking operation. The Compressor will not operate

unless this valve is completely closed.

2. To open the Cleaning Valve, the Valve Handle should be parallel to the

valve body. To close the valve, the Valve Handle should be at a right

angle to the valve body.

57

Page 58

[a] CLEANING PROCEDURE

1) Dilute 38 fl. oz. of the recommended cleaner Hoshizaki “Scale Away” or “LIME-A-WAY”

(Economics Laboratory, Inc.) with 7 gal. of water.

2) Remove all ice from the Evaporator and the Storage Bin.

Note: To remove cubes on the Evaporator, turn off the power supply and turn

it on after 3 minutes. The defrost cycle starts and the cubes will be

removed from the Evaporator.

3) Turn off the power supply.

4) Remove the Front Panel and then remove the Insulation Panel, by first removing

the thumbscrew, lifting the panel slightly and pulling it toward you.

5) Drain the Water Tank by removing the Cap located on the front bottom part of the

Ice Dropping Hole. See Fig. 3.

6) Replace the cap in its correct position.

7) Pour the cleaning solution into the Water Tank.

8) Fully open the Cleaning Valve on the left side wall of the machine compartment.

9) Move the Control Switch, on the Control Box, to the “WASH” position.

10) Replace the Insulation Panel and the Front Panel in their correct positions.

11) Turn on the power supply, and start the washing process.

12) Turn off the power supply after 30 minutes.

13) Remove the Front Panel and the Insulation Panel.