Page 1

Hoshizaki America, Inc.

Hoshizaki

Commercial Refrigerators & Freezers

Undercounter & Worktop Series

Models

Refrigerators

HUR40A(-D) HWR40A(-D)

“A Superior Degree

of Reliability”

www.hoshizaki.com

HUR68A(-D) HWR68A(-D)

HUR96A(-D) HWR96A(-D)

Freezers

HUF40A(-D) HWF40A(-D)

HUF68A(-D) HWF68A(-D)

SERVICE MANUAL

Number: 73123

Issued: 2-4-2005

Revised: 9-30-2008

Page 2

IMPORTANT

Only qualied service technicians should attempt to service or maintain this

unit. No such service or maintenance should be undertaken until the technician

has thoroughly read this Service Manual.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service and maintenance of the unit.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, write or send an e-mail message to the Hoshizaki Technical

Support Department for assistance.

HOSHIZAKI AMERICA, INC.

618 Highway 74 South

Peachtree City, GA 3069

Attn: Hoshizaki Technical Support Department

Phone: 1-800-33-1940 Technical Support

(770) 487-331

Fax: 1-800-843-1056

(770) 487-3360

E-mail: techsupport@hoshizaki.com

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number __________________________

• Serial Number __________________________

• Complete and detailed explanation of the problem.

ENERGY STAR

®

Products earning the ENERGY STAR prevent greenhouse gas emissions by meeting strict

energy efciency guidelines set by the U.S. Environmental Protection Agency and the

U.S. Department of Energy. Several models of Hoshizaki undercounters have earned the

ENERGY STAR. To easily determine if your unit has earned the ENERGY STAR, see the

nameplate attached to the right wall on the inside of the cabinet.

Page 3

Please review this manual. It should be read carefully before the unit is serviced or

maintenance operations are performed. Only qualied service technicians should service

and maintain the unit. This manual should be made available to the technician prior to

service or maintenance.

CONTENTS

I. Specications ..................................................................................................................... 5

A. Nameplate Ratings ....................................................................................................... 5

B. Dimensions ................................................................................................................... 5

1. HUR40A, HUF40A .................................................................................................. 6

1a. HUR40A-D, HUF40A-D ......................................................................................... 6

. HWR40A, HWF40A ................................................................................................. 7

a. HWR40A-D, HWF40A-D ....................................................................................... 7

3. HUR68A, HUF68A .................................................................................................. 8

3a. HUR68A-D, HUF68A-D ......................................................................................... 8

4. HWR68A, HWF68A ................................................................................................. 9

4a. HWR68A-D, HWF68A-D ....................................................................................... 9

5. HUR96A ................................................................................................................ 10

5a. HUR96A-D .......................................................................................................... 10

6. HWR96A ............................................................................................................... 11

6a. HWR96A-D ......................................................................................................... 11

II. General Information ........................................................................................................ 1

A. Construction ................................................................................................................ 1

B. Sequence of Operation and Timing Charts ................................................................ 13

1. Refrigerators – Continuous Operating Mode ........................................................ 13

. Freezers – Continuous Operating Mode ............................................................. 15

3. Refrigerators – Energy Saving Operating Mode .................................................. 17

4. Freezers – Energy Saving Operating Mode ......................................................... 19

C. Control Board ............................................................................................................. 1

1. Start-Up Delay ....................................................................................................... 1

. Control Board Layout ............................................................................................

D. Settings and Diagnostics ............................................................................................ 3

1. Gaining Access to Settings and Diagnostics ......................................................... 3

. Temperature Display ............................................................................................. 4

a) Switching the Display Between Fahrenheit and Celsius (F5) .......................... 4

b) Adjusting the Setpoint Temperature ................................................................ 4

c) Cabinet Temperature Correction (calibration factor) ........................................ 5

3. Settings and Diagnostics Menu ............................................................................. 6

a) Defrost Interval (F0) ......................................................................................... 7

b) Defrost Termination Temperature (F1) ............................................................ 7

c) Setpoint Temperature Differential (F) ............................................................ 8

d) High Temperature Alarm Delay Time (F3) ....................................................... 9

e) Low Temperature Alarm Delay Time (F4) ....................................................... 9

f) Temperature Display Scale (F5) ....................................................................... 30

g) Alarm History (F6) ............................................................................................ 30

h) Compressor Run Time (F7) ............................................................................. 31

3

Page 4

4. Operating Modes ................................................................................................... 31

a) Continuous ....................................................................................................... 3

b) Energy Saving ................................................................................................. 3

c) Automatic Corrections Made During Energy Saving Operating Mode ............. 3

E. Perimeter Frame Heater ............................................................................................. 3

III. Service Diagnosis ........................................................................................................... 33

A. Alarm Codes ............................................................................................................... 33

1. Alarm Display Priority ............................................................................................ 34

. Alarm Details and Countermeasures .................................................................... 35

a. High Temperature Alarm (E1) .......................................................................... 35

b. Low Temperature Alarm (E) ........................................................................... 36

c. Defrost Alarm (E3) ........................................................................................... 37

d. High Pressure Alarm (E4) ................................................................................ 37

e. Clogged Filter Alarm (E7) ................................................................................ 38

f. Defrost Temperature Sensor Malfunction Alarm (E8) ....................................... 39

g. Clogged Filter Sensor Malfunction Alarm (E9) ................................................. 40

h. Control Board Error Alarms (EA and ED) ........................................................ 41

B. Diagnosis Chart .......................................................................................................... 4

C. Thermistor Check ....................................................................................................... 45

IV. Removal and Replacement of Components .................................................................. 46

A. Service for Refrigerant Lines ...................................................................................... 46

1. Refrigerant Recovery ............................................................................................ 46

. Brazing .................................................................................................................. 46

3. Evacuation and Recharge .................................................................................... 47

B. Removal and Replacement of Refrigeration Unit........................................................ 48

C. Removal and Replacement of Compressor ................................................................ 48

D. Removal and Replacement of Evaporator .................................................................. 49

E. Removal and Replacement of Capillary Tube / Suction Line Assembly ..................... 51

F. Removal and Replacement of Thermistors ................................................................. 5

G. Removal and Replacement of Door Gasket ............................................................... 53

H. Removal and Replacement of Defrost Heater ............................................................ 53

I. Removal and Replacement of Control Board ............................................................... 54

J. Removal and Replacement of Fan Motors .................................................................. 55

K. Door Re-Hinging and Drawer Conversion .................................................................. 55

V. Cleaning and Maintenance Instructions .......................................................................... 56

A. Cleaning ...................................................................................................................... 56

B. Maintenance ............................................................................................................... 57

VI. Wiring Diagrams ............................................................................................................ 58

A1. HUR40A, HWR40A (auxiliary code Q5 and earlier).................................................. 58

A. HUR40A(-D), HWR40A(-D) (auxiliary code Q6 and later) ....................................... 59

B. HUF40A(-D), HWF40A(-D) ......................................................................................... 60

C1. HUR68A, HWR68A (auxiliary code Q5 and earlier) ................................................. 61

C. HUR68A(-D), HWR68A(-D) (auxiliary code Q6 and later) ........................................ 6

D. HUF68A(-D), HWF68A(-D) ......................................................................................... 63

E. HUR96A(-D), HWR96A(-D) ........................................................................................ 64

4

Page 5

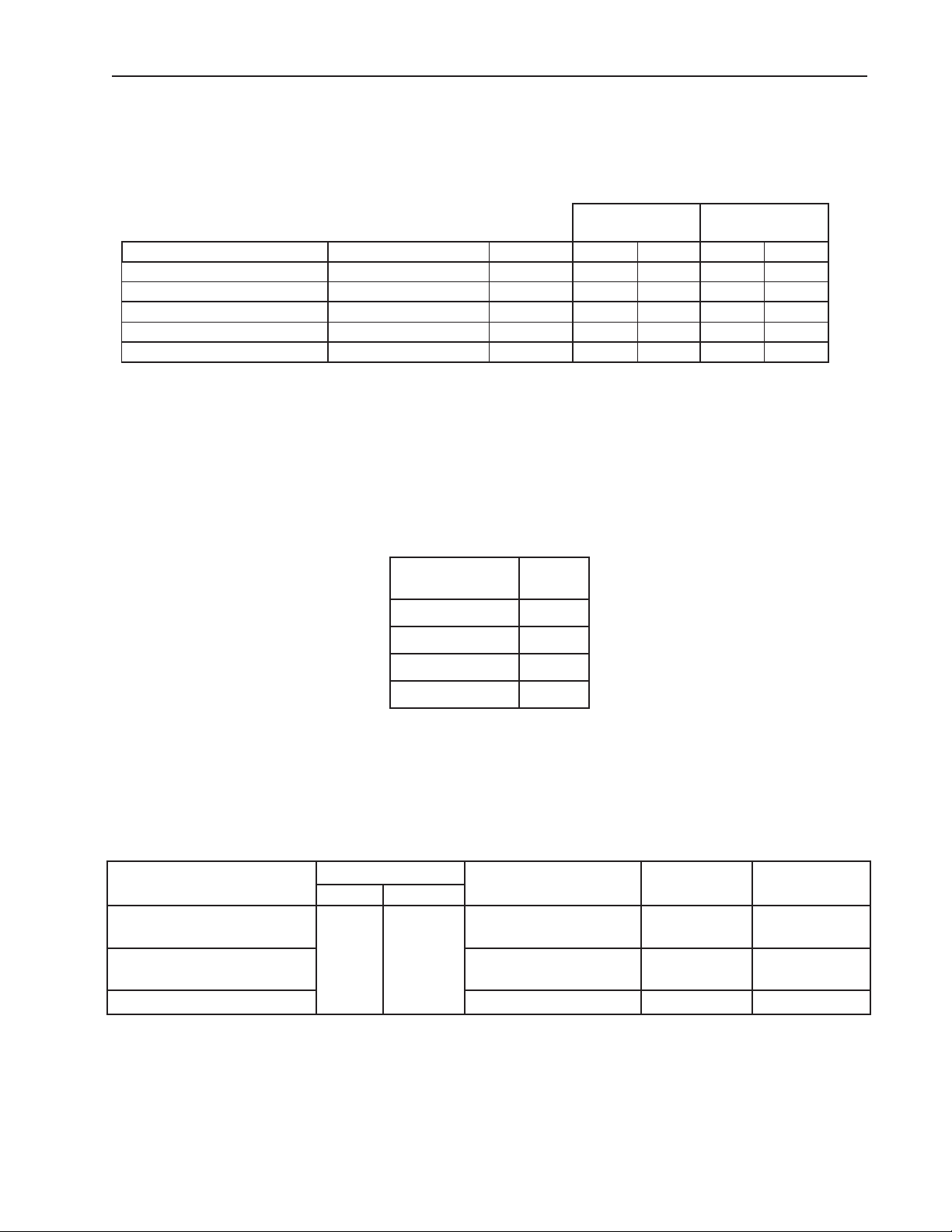

I. Specications

A. Nameplate Ratings

Design Pressure

(PSIG)

Model AC Supply Voltage Amperes HI LO 404A 134a

HUR40A(-D), HWR40A(-D) 115/60/1 5.0 40 10 15.

HUR68A(-D), HWR68A(-D) 115/60/1 5.0 40 10 15.

Refrigerant

(oz.)

HUR96A(-D), HWR96A(-D) 115/60/1 6.0 40 10 15.

HUF40A(-D), HWF40A(-D) 115/60/1 5.5 450 50 14.1

HUF68A(-D), HWF68A(-D) 115/60/1 10.0 450 50 13.0

Undercounter Model Names

The undercounter models covered in this service manual initially had different model

names. If you have a unit with an auxiliary code of N-6 and a serial number ending in "H",

refer to the table below.

Model Name on

Nameplate

UR1-SSB HUR40A

UR-SSB

Current

Name

HUR68A

UF1-SSB HUF40A

UF-SSB

HUF68A

B. Dimensions

Door Opening mm Total Refrigerated

Model

HUR40A(-D), HWR40A(-D),

HUF40A(-D), HWF40A(-D)

HUR68A(-D), HWR68A(-D),

HUF68A(-D), HWF68A(-D)

HUR96A(-D), HWR96A(-D) 9.1 6.6 1

Width Height

570. 616.

Volume ft

18.8 17.1 8

3

8.5 7.6 4

Total Shelf

Space ft

2

Hotel Pan

Capacity (-D)

5

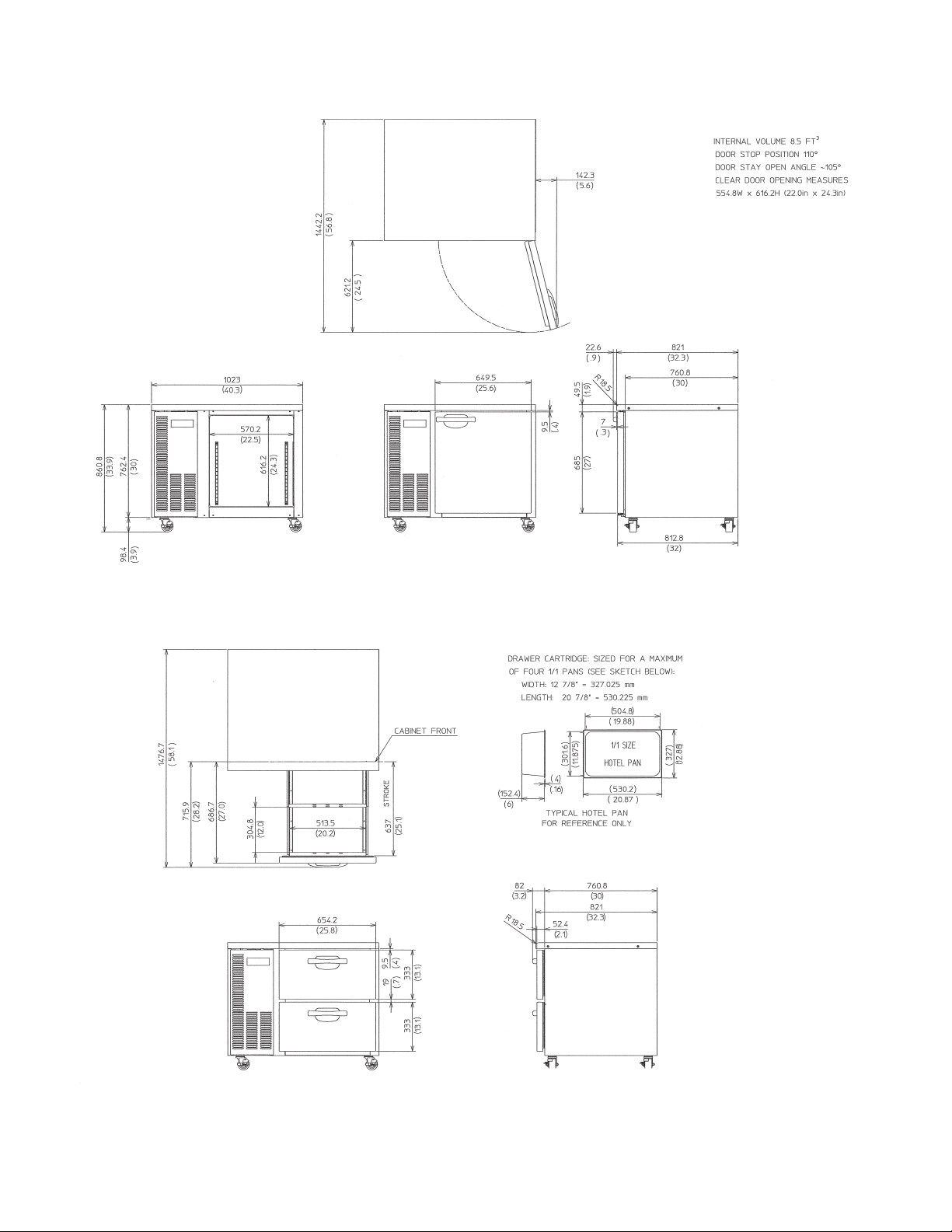

Page 6

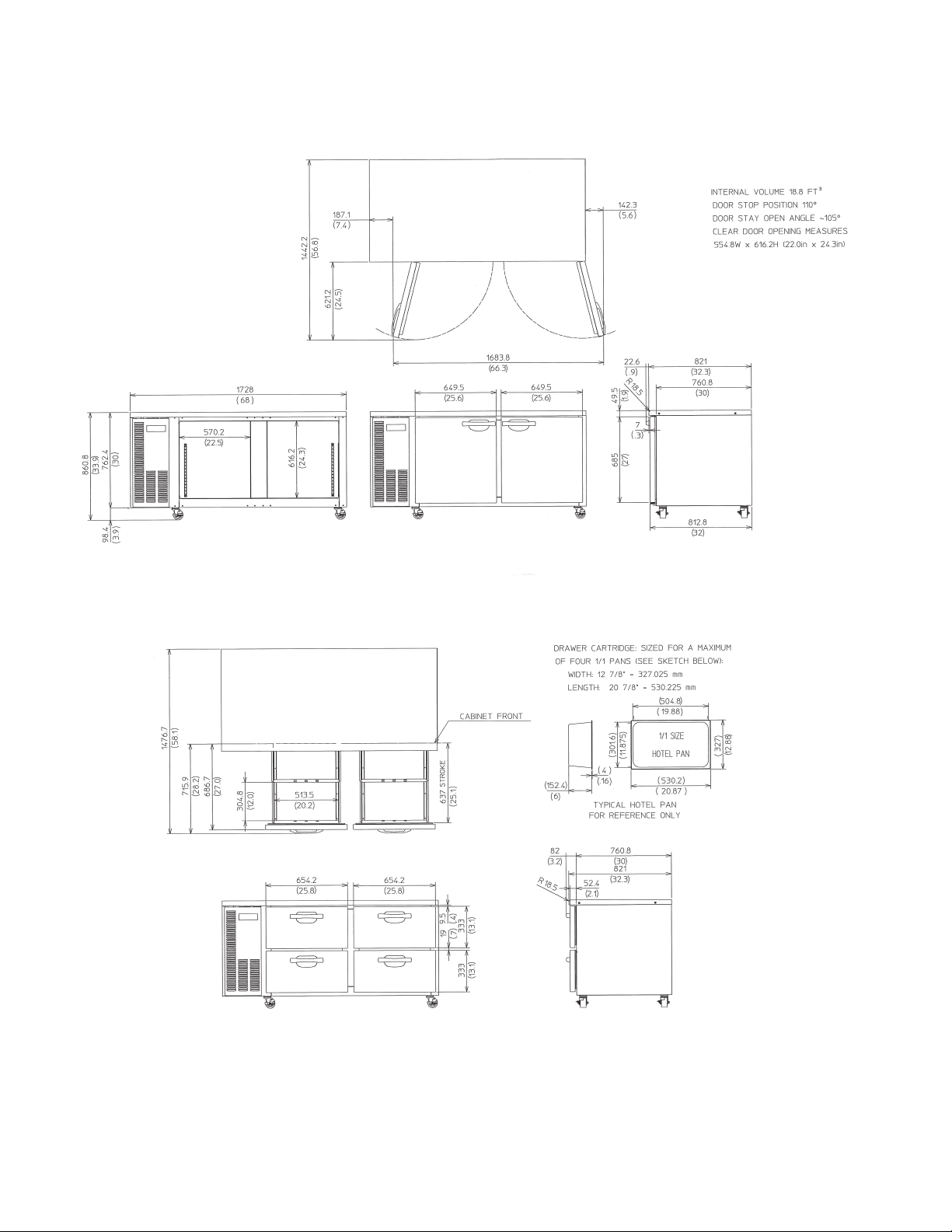

1. HUR40A, HUF40A

Units: mm (in.)

1a. HUR40A-D, HUF40A-D

6

Page 7

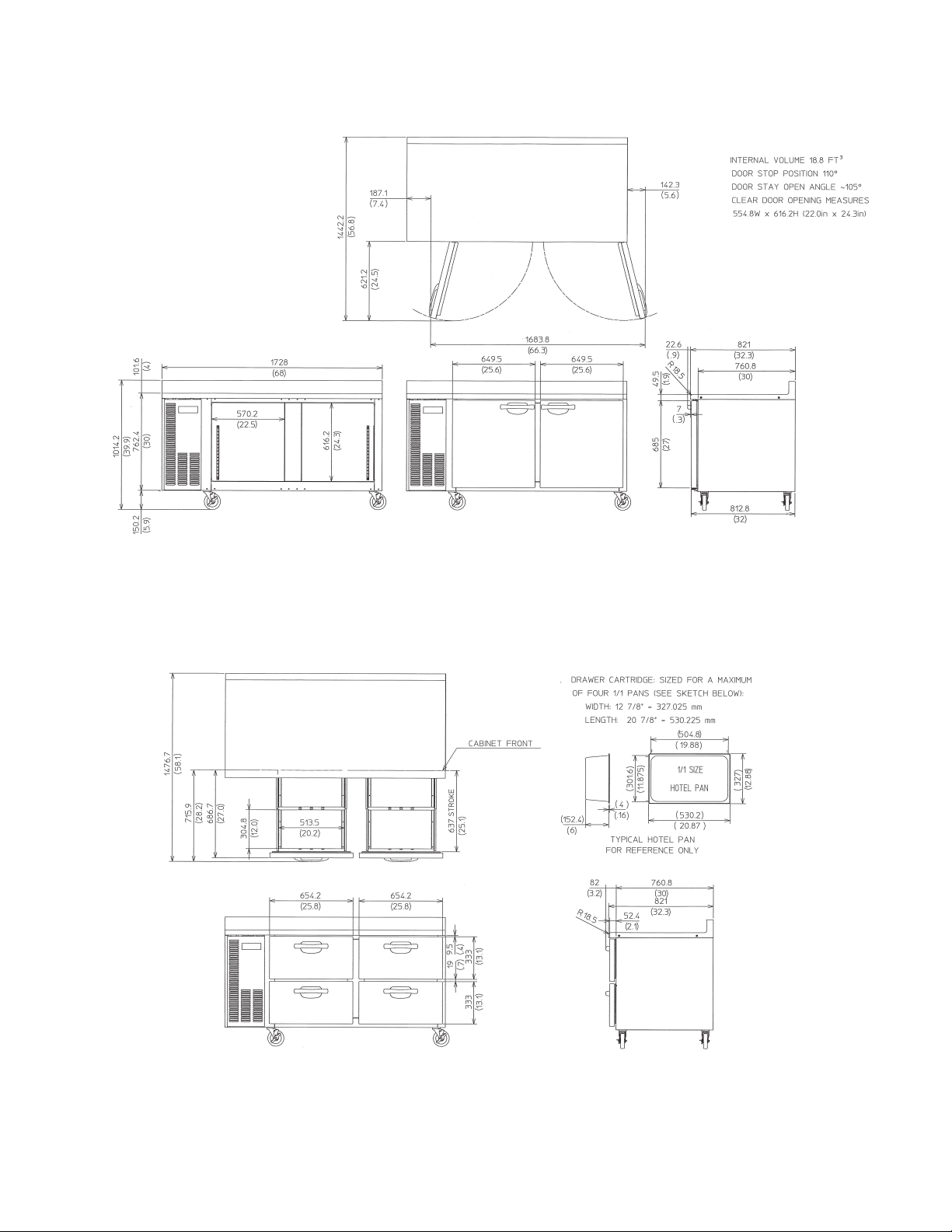

2. HWR40A, HWF40A

Units: mm (in.)

2a. HWR40A-D, HWF40A-D

7

Page 8

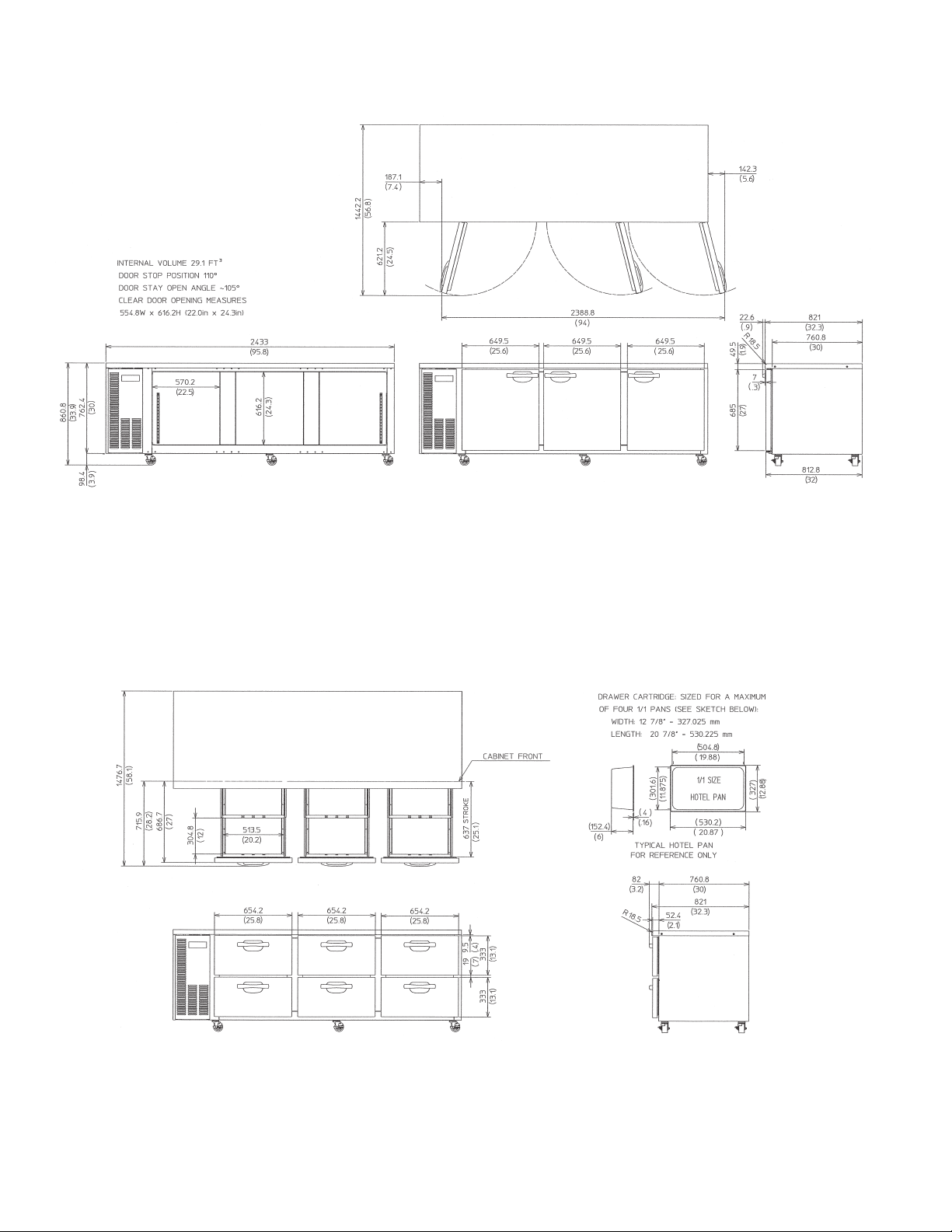

3. HUR68A, HUF68A

Units: mm (in.)

3a. HUR68A-D, HUF68A-D

8

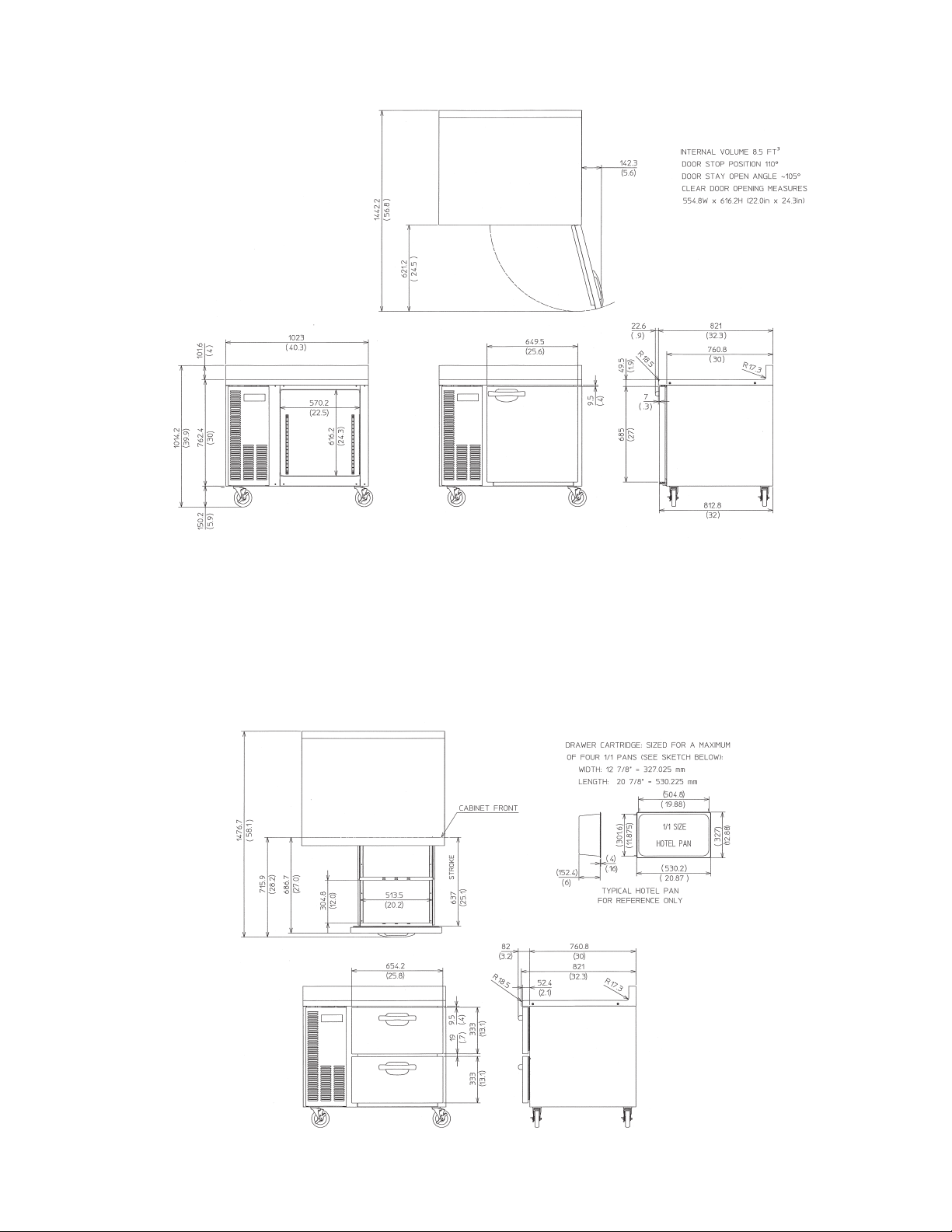

Page 9

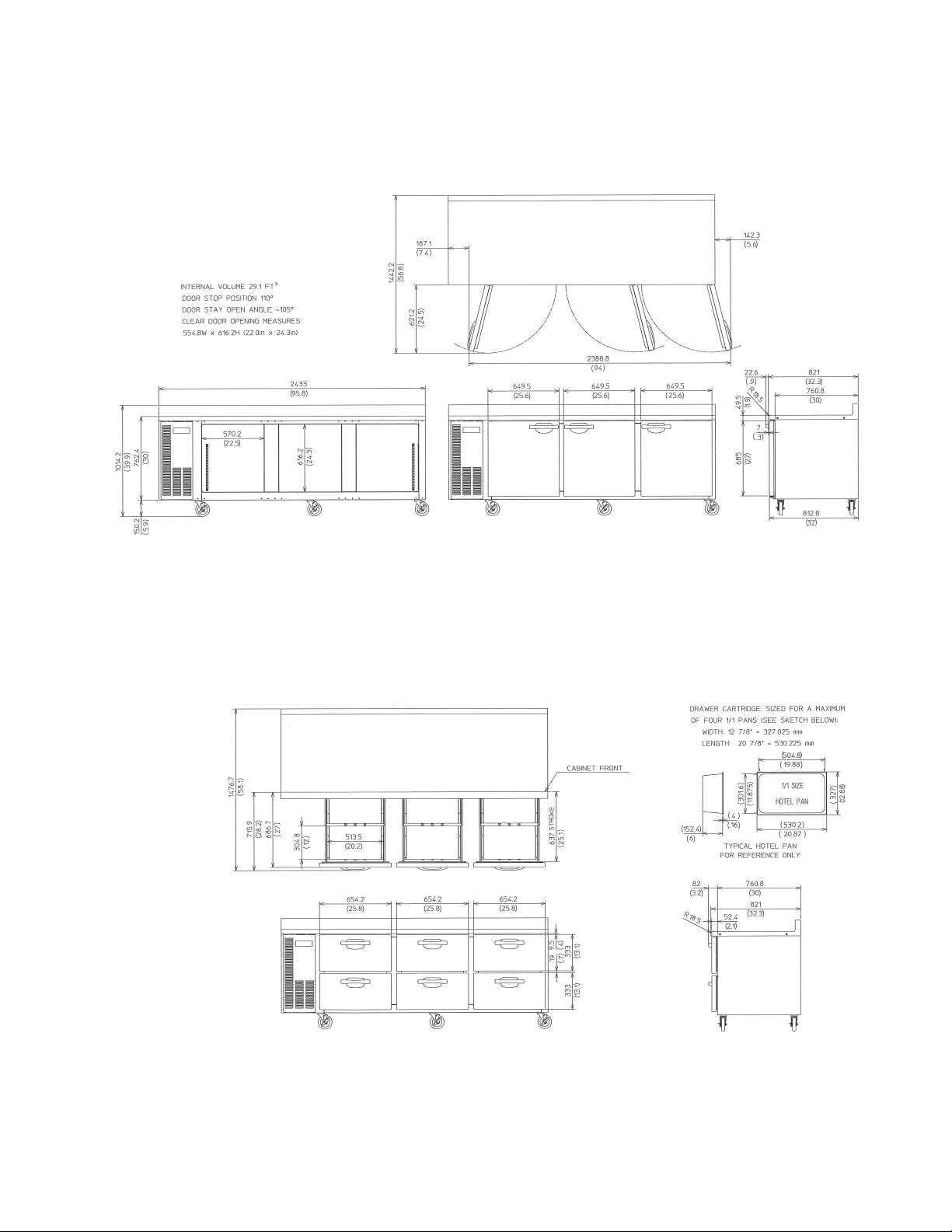

4. HWR68A, HWF68A

Units: mm (in.)

4a. HWR68A-D, HWF68A-D

9

Page 10

5. HUR96A

Units: mm (in.)

5a. HUR96A-D

10

Page 11

6. HWR96A

Units: mm (in.)

6a. HWR96A-D

11

Page 12

II. General Information

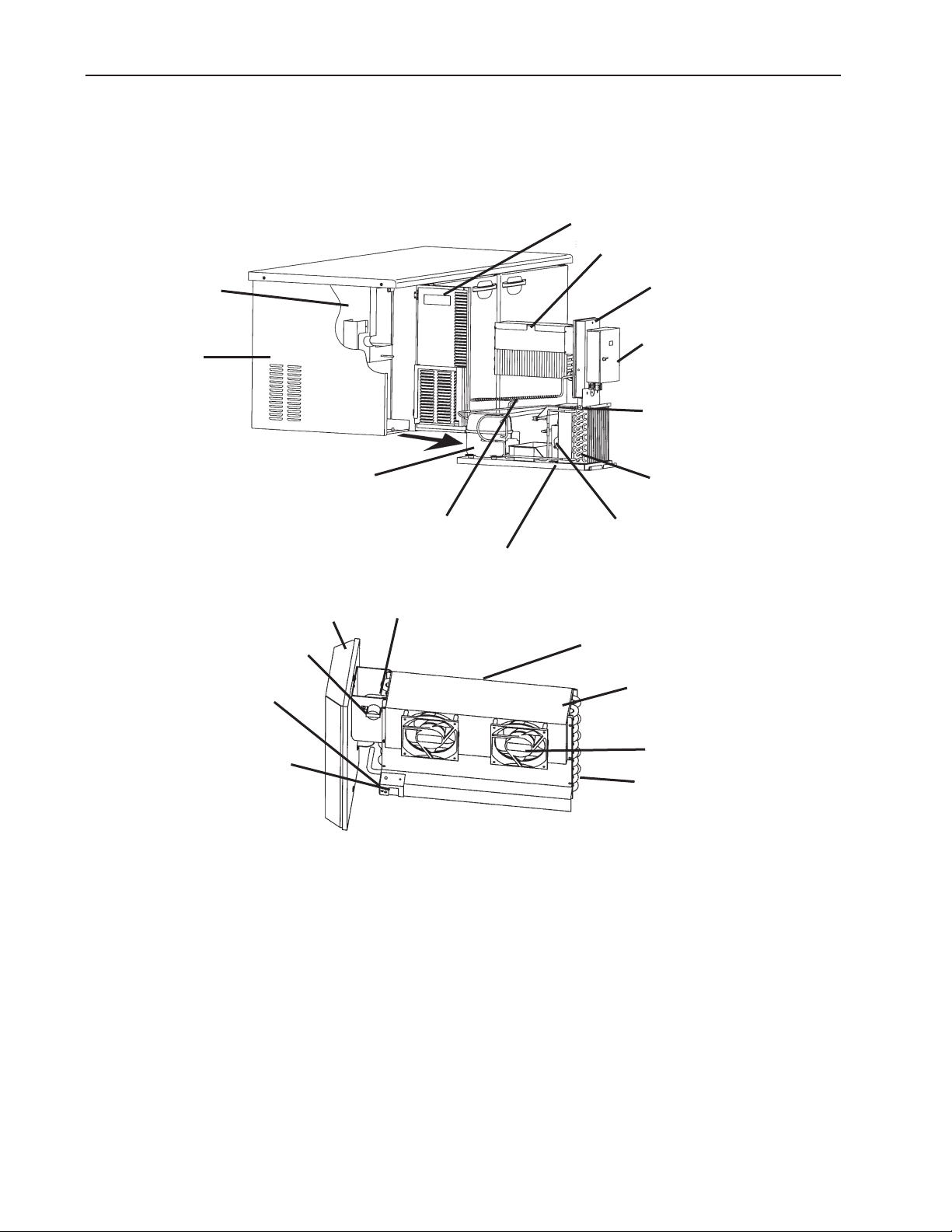

A. Construction

Hoshizaki undercounters feature a cartridge-type refrigeration unit that can be removed

without taking off the top and side panels.

Front Panel

Evaporator Assembly

Evaporator Case

Side Panel

Evaporator Case Cover

Defrost Thermostat

Defrost Heater

Compressor

Capillary Tube/Suction

Line Assembly

Thermal Fuse

Evaporator Case Cover

Control Box

Access Valve (Low-Side)

Condenser

Condenser Fan Motor

Compressor Base

Defrost Thermistor

Evaporator Shroud

Cabinet Thermistor

Evaporator Fan Motor

Evaporator

Evaporator Case

1

Page 13

B. Sequence of Operation and Timing Charts

For details on operating modes, see "II.D.4. Operating Modes."

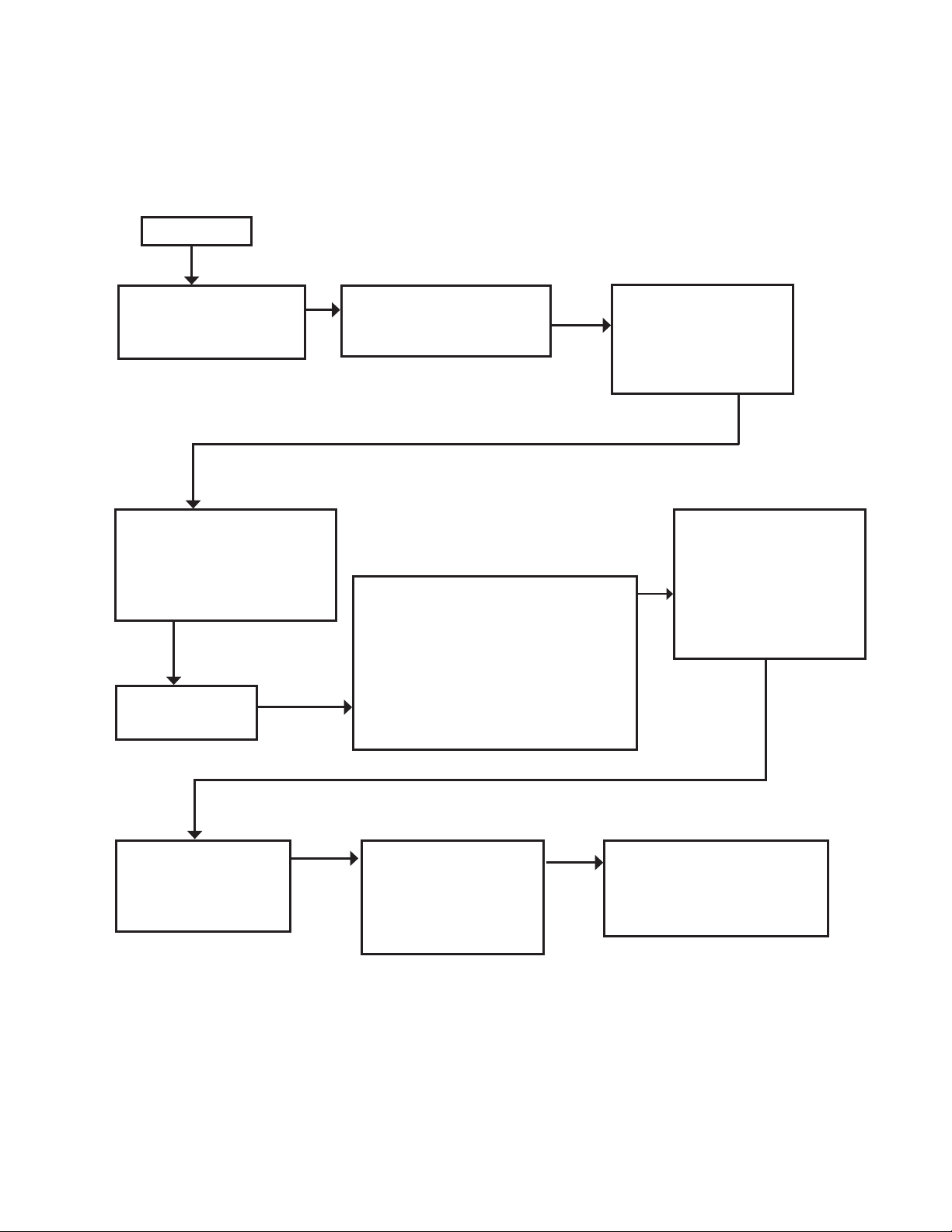

1. Refrigerators – Continuous Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on

. Evaporator fan(s) on

Cycle On (Cut-on

temperature reached)

[Minimum minutes]

1. Compressor start-up

. Condenser fan start-up

Continue as

normal cycling

2-minute Delay

1. Compressor start-up

. Condenser fan start-up

Defrost Start

Preprogrammed time interval

1. Compressor off

. Evaporator fan(s) off

3. Frame heater(s) off (Q6 and later)

4. Condenser fan off

5. Defrost heater on

6. "dF" displayed

Cycle Off (Cut-out

temperature reached)

[Minimum minutes]

1. Compressor off

. Condenser fan off

Defrost End

Defrost thermistor

reaches defrost

termination temperature,

or defrost timer reaches

1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

. Frame heater(s) on

(Q6 and later)

One minute after evaporator

fan start-up "dF" no

longer displayed, cabinet

temperature displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the

"cabinet thermistor."

) The defrost thermistor reads the evaporator temperature.

3) There is a ve second evaporator fan startup delay when the compressor and

fan would otherwise start together.

13

Page 14

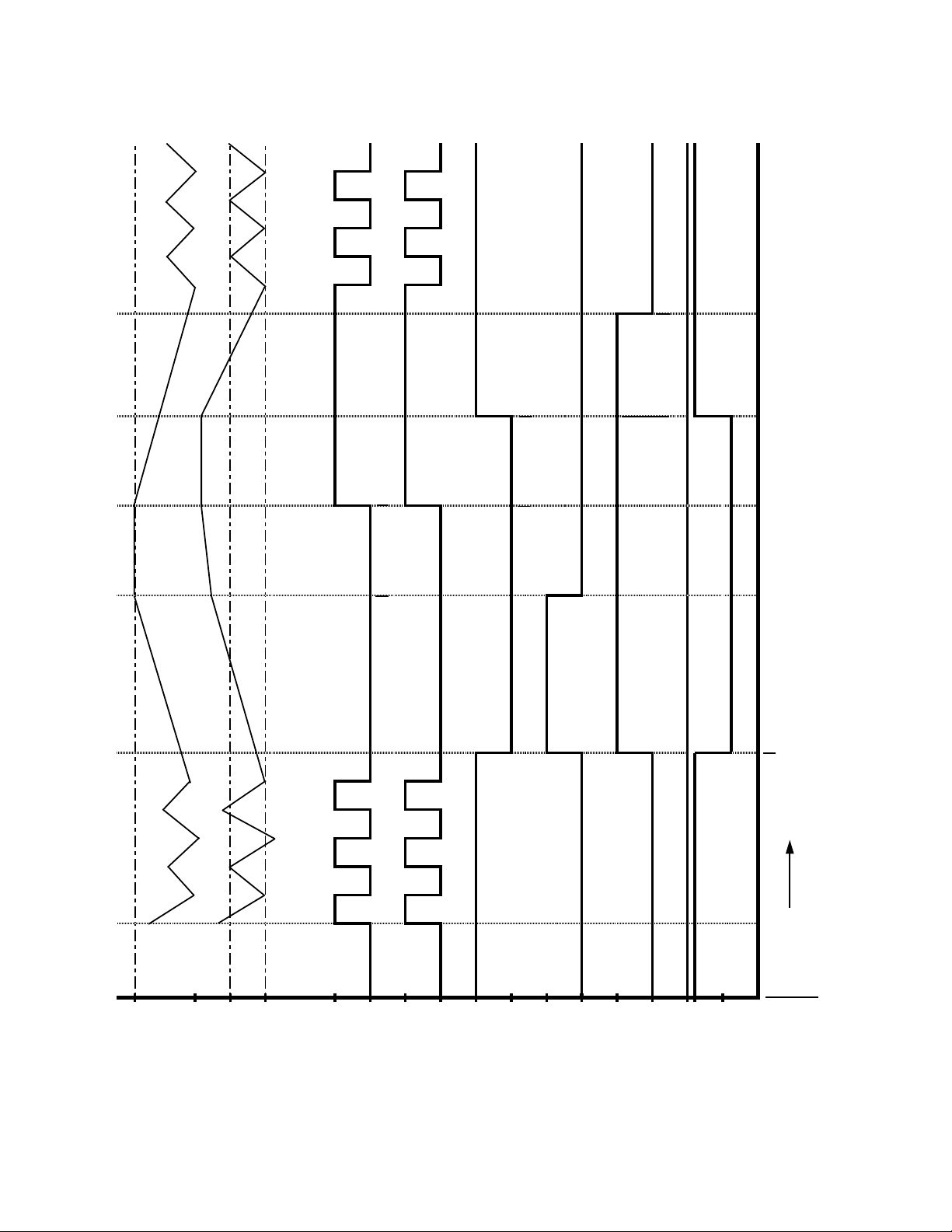

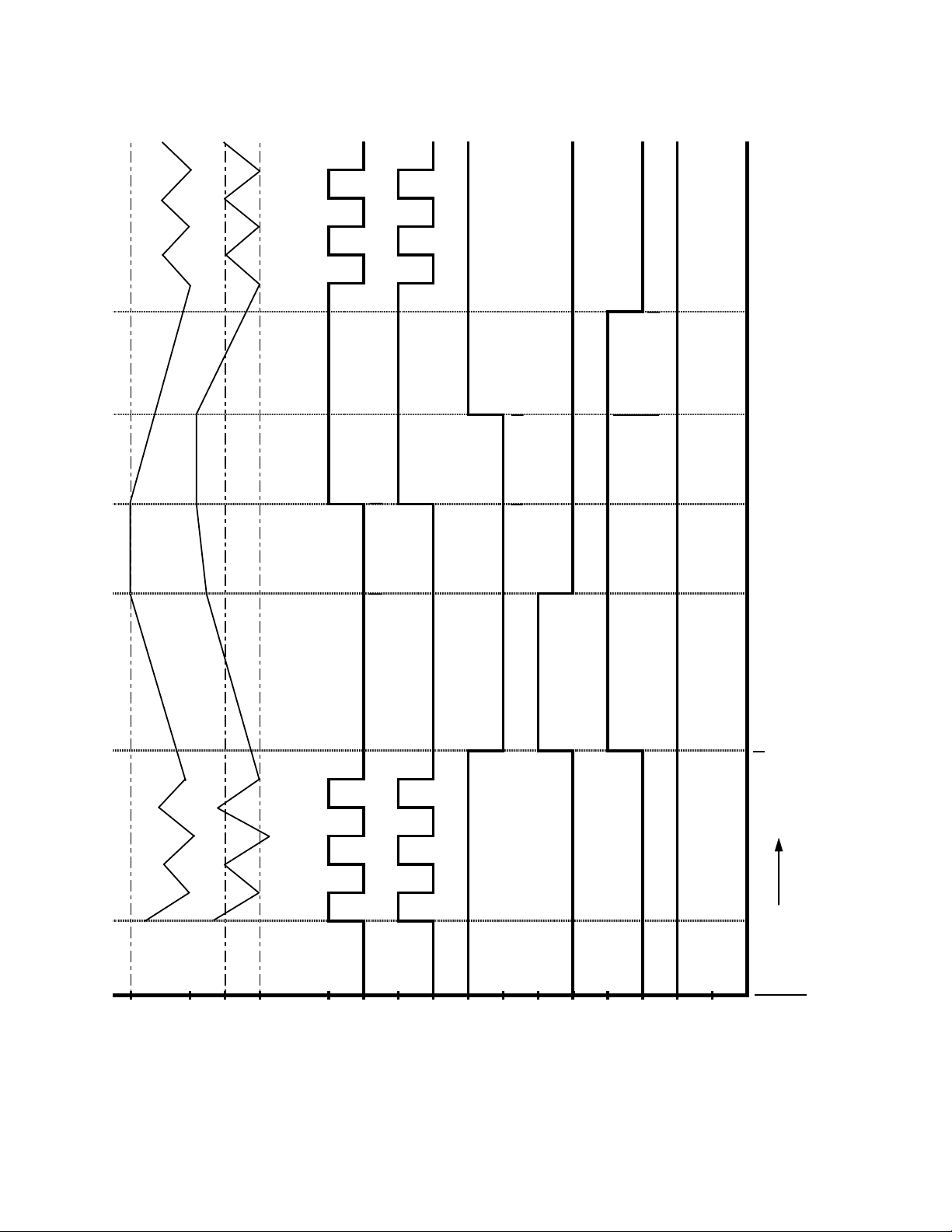

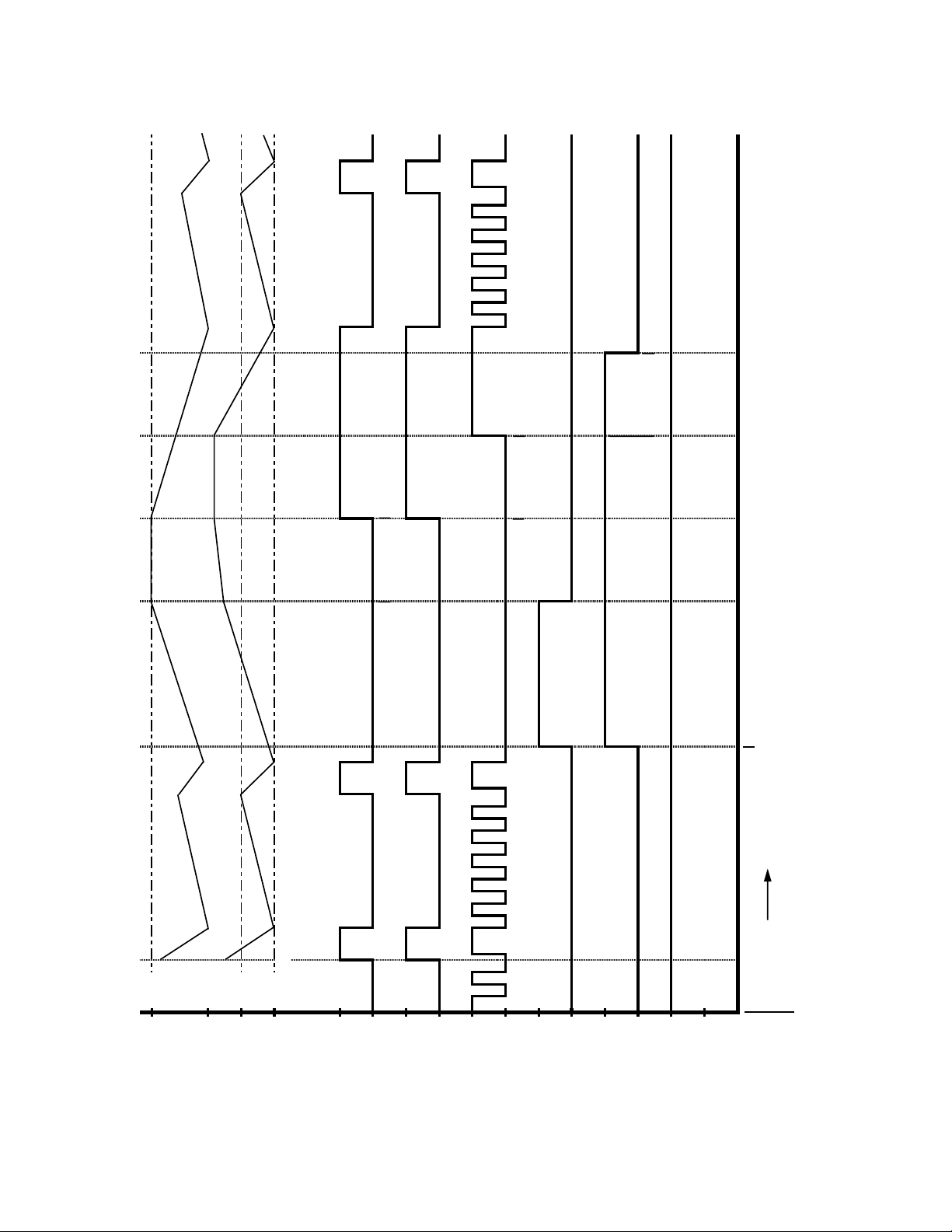

b) Timing Chart

N

O

FF

O

NO

FF

O

FFO

NO

N

O

F

FO

)+

(

la

i

tnere

f

fiD

+

t

niop

t

eS

)

--( laitne

r

effiD + t

ni

opt

e

S

gni

nae

m

oN

NO

F

F

O

N

O

F

F

O

rotsimrehT tenibaC

rotsimr

e

hT tsorfeD

osserpmoC

r

n

aF

r

e

s

n

e

dno

C

n(s)

a

F

r

o

t

a

r

o

p

a

v

E

r

e

t

a

e

H

t

s

o

r

f

e

D

.

n

i

m

2

)

y

aleD

t

rat

S

(

N

O

r

e

w

o

P

emiT

sr

uo

h

6

)

el

b

a

t

suj

d

A

t

ra

t

S

t

s

o

r

f

e

D

(

.nim

5

)yale

D

niarD(

.n

i

m

5

)ya

l

eD naF(

r

o

t

a

cid

n

I

t

sor

f

eD

.nim 1

)

ya

leD ya

l

ps

i

D

(

.n

im

2

)NO

.n

i

M

(

.

n

im

2

)

F

FO

.n

i

M

(

e

ru

tarep

meT

noi

t

ani

m

re

T

t

sor

feD

.

n

im

06

<

)

noi

t

a

ruD

t

s

o

r

feD

.

x

aM

(

TIME-TEMPERATURE CONTROL CHART ENERGY SAVING MODE

REFRIGERATORS

1AND,ATER

1AND%ARLIER

Frame Heater(s)

Refrigerators – Continuous Operating Mode

14

Page 15

2. Freezers – Continuous Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on

. Evaporator fan(s) on

Cycle On (Cut-on

temperature reached)

[Minimum minutes]

1. Compressor start-up

. Condenser fan start-up

Continue as

normal cycling

2 minute delay

1. Compressor start-up

. Condenser fan start-up

Defrost Start

Preprogrammed time interval

1. Compressor off

. Evaporator fan(s) off

3. Condenser fan off

4. Defrost heater on

5. "dF" displayed

Cycle Off (Cut-out

temperature reached)

[Minimum minutes]

1. Compressor off

. Condenser fan off

Defrost end

Defrost thermistor

reaches defrost

termination

temperature, or defrost

timer reaches 1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

Eight minutes after evaporator

fan start-up "dF" no longer

displayed, cabinet temperature

displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the

"cabinet thermistor."

) The defrost thermistor reads the evaporator temperature.

3) There is a ve second evaporator fan startup delay when the compressor and

fan would otherwise start together.

15

Page 16

b) Timing Chart

N

O

F

F

O

N

O

FF

O

)+(

la

i

tnere

f

f

i

D

+

tniop

teS

)--( laitnere

f

fiD + tniopteS

gn

inaem

oN

F

FO

N

O

N

O

F

F

O

N

O

F

F

O

N

O

F

F

O

otsimrehT teni

b

aC

r

o

ts

imr

eh

T

t

s

o

r

f

e

D

r

osserpmoC

r

n

aF

r

e

sn

e

dn

oC

n(s)

a

F

ro

t

aro

p

a

v

E

e

t

a

e

H

t

s

o

r

f

e

D

r

.n

i

m

2

)ya

le

D

tra

t

S

(

NO

r

e

wo

P

em

iT

sru

o

h

6

)e

lba

tsu

j

dA

t

ra

tS

tso

r

fe

D

(

.

ni

m 5

)ya

leD n

ia

rD(

.

n

i

m 5

)yaleD

na

F(

o

t

a

c

i

d

n

I

t

s

o

r

f

e

D

r

.nim

8

)yaleD y

a

lpsiD(

.

n

i

m

2

)

N

O

.

n

iM(

.

n

im

2

)

F

F

O

.n

iM(

e

ru

tarepme

T

no

i

tan

imre

T

tsorf

e

D

.

n

im

06

<

)no

i

taru

D

tso

r

fe

D

.xaM

(

TIME-TEMPERATURE CONTROL CHART [NOT DURING ENERGY SAVING MODE] FOR

REFRIGERATORS & FREEZERS WITH AUXILIARY CODE _____ AND BEFORE

Frame Heater(s)

Freezers – Continuous Operating Mode

16

Page 17

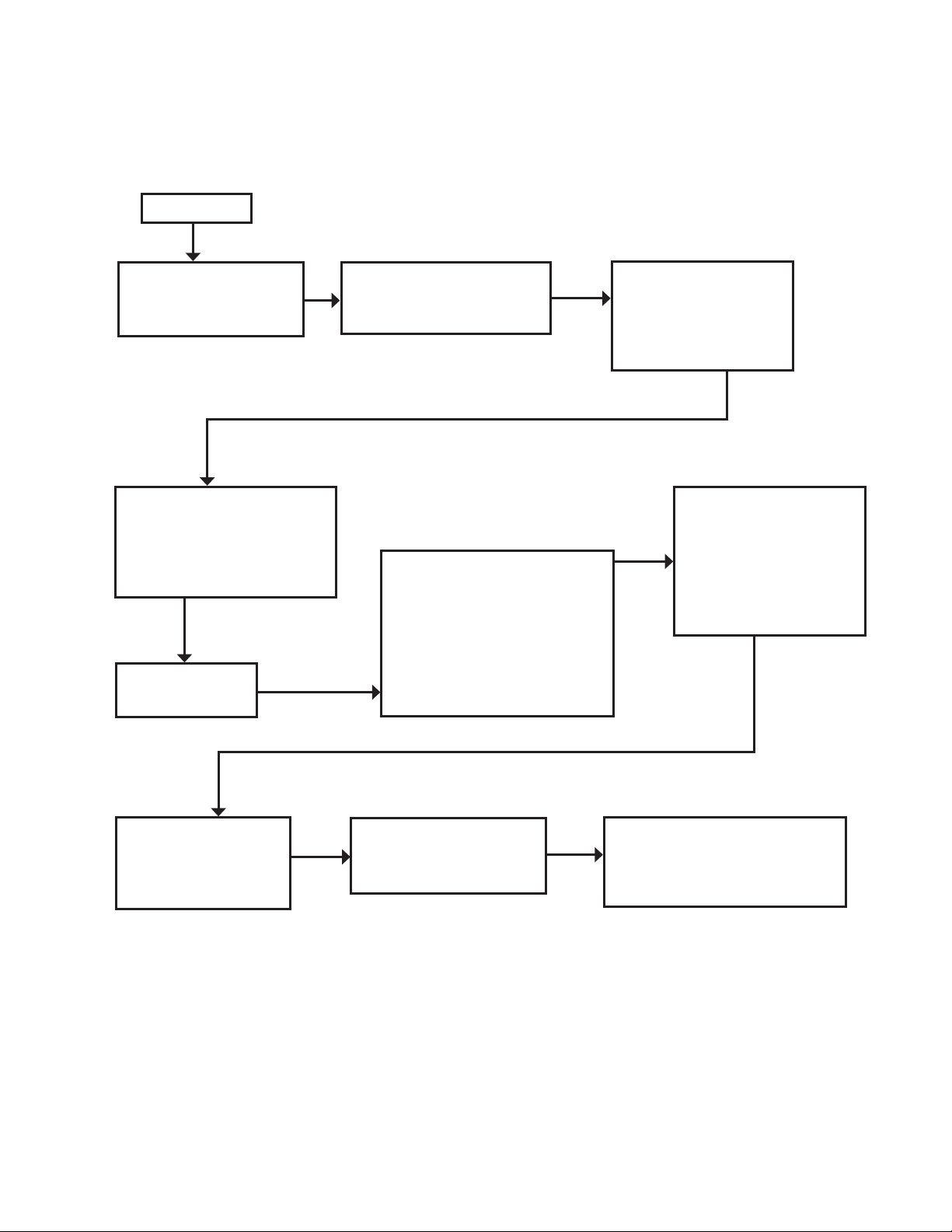

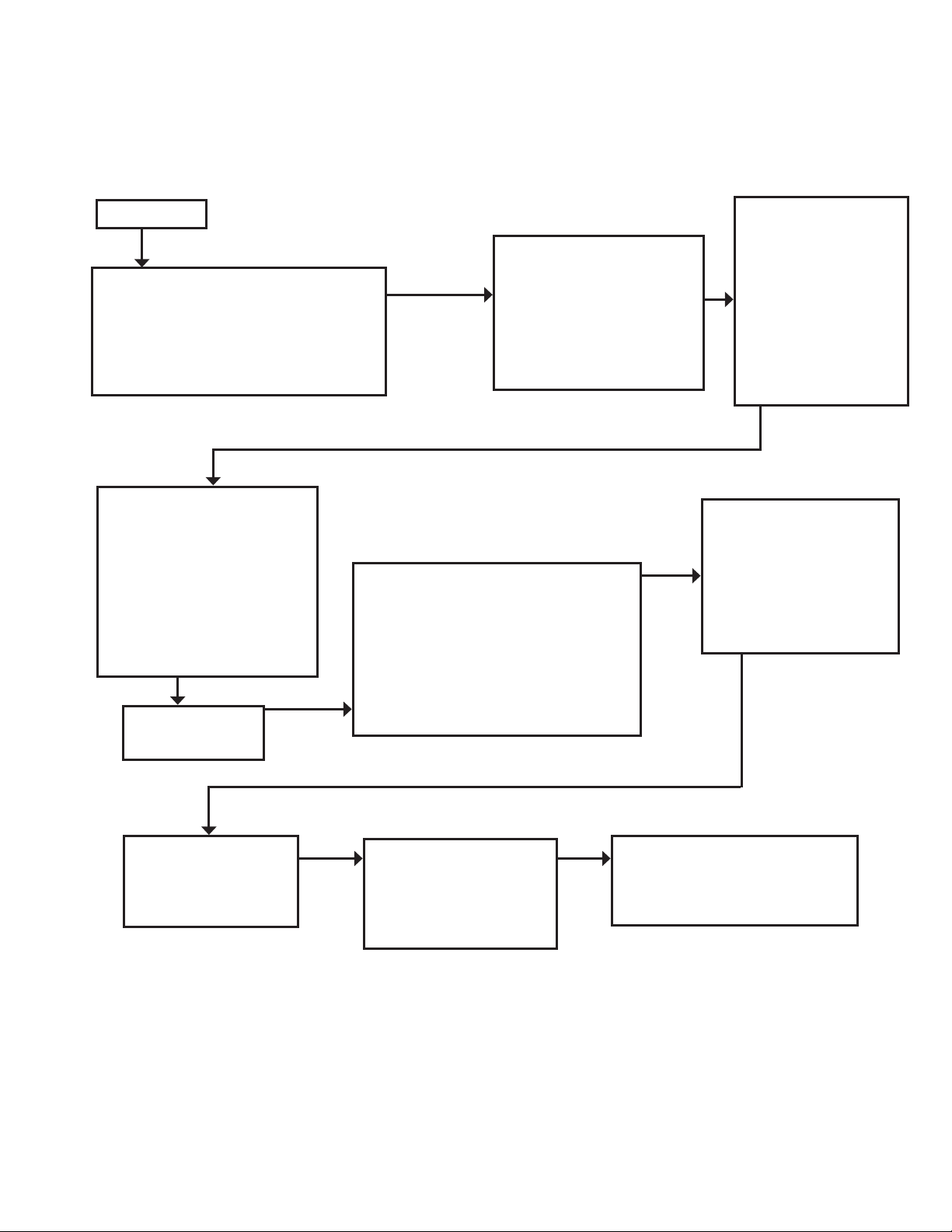

3. Refrigerators – Energy Saving Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on continuously

(Q5 and earlier)

Frame heater(s) cycle on and off

(Q6 and later)

. Evaporator fan(s) cycles on and off

Cycle On (Cut-on

temperature reached)

[Minimum minutes]

1. Compressor start-up

. Condenser fan start-up

3. Frame heater(s) on

(continuously)

4. Evaporator fan(s) on

(continuously)

Continue as

normal cycling

Defrost Start

Preprogrammed time interval

1. Compressor off

. Frame heater(s) off (Q6 and later)

3. Evaporator fan(s) off

4. Condenser fan off

5. Defrost heater on

6. "dF" displayed

2-minute Delay

1. Compressor start-up

. Condenser fan start-up

3. Frame heater(s) on

(continuously)

4. Evaporator fan(s) on

(continuously)

Cycle Off (Cut-out

temperature reached)

[Minimum minutes]

1. Compressor off

. Condenser fan off

3. Frame heater(s)

cycle on and off

(Q6 and later)

4. Evaporator fan(s)

cycles on and off

Defrost End

Defrost thermistor

reaches defrost

termination temperature,

or defrost timer reaches

1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

. Frame heater(s)

on (Q6 and later)

One minute after evaporator

fan start-up "dF" no longer

displayed, cabinet temperature

displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the "cabinet

) The defrost thermistor reads the evaporator temperature.

thermistor."

17

Page 18

b) Timing Chart

NO

FFO

NO

FFO

)+(

l

a

i

t

n

e

r

ef

f

i

D

+

t

n

i

o

p

teS

)-

-(

l

a

it

n

er

ef

f

i

D

+

tniopt

e

S

g

n

i

n

a

e

m

oN

FFO

NO

NO

FFO

NO

FFO

NO

FFO

r

ots

imre

h

T

t

enib

a

C

rotsimrehT tsorfeD

o

ss

e

r

pm

o

C

r

n

a

F

r

es

n

ed

n

o

C

n(s)

a

F

r

o

t

a

r

o

p

a

v

E

e

t

a

e

H

t

s

o

rf

e

D

r

.

n

im

2

)y

a

l

e

D

t

r

a

t

S

(

NO

rew

o

P

e

miT

s

ruoh

6

)

e

l

b

ats

u

j

d

A

t

r

atS

t

so

r

fe

D(

.

n

im 5

)yaleD nia

r

D(

.ni

m

5

)yale

D

naF

(

r

ota

c

i

d

n

I

t

s

o

rfe

D

.nim 1

)yaleD yalpsiD(

eru

t

arepmeT

n

o

i

tanimreT tsorfeD

.ni

m

0

6

<

)

n

o

it

ar

uD

t

s

o

r

f

e

D

.

x

a

M(

tn

et

t

i

m

r

e

tn

I

noit

a

r

epO

)

s

d

o

ir

eP FFO r

os

s

er

p

m

o

C

l

lA

(

t

n

ettimretnI

no

i

tarep

O

)s

d

o

i

re

P

F

FO

r

oss

e

rpmoC

ll

A(

TIME-TEMPERATURE CONTROL CHART [DURING ENERGY SAVING MODE] FOR

REFRIGERATORS

WITH AUXILIARY CODE _____ AND AFTER

*

*

neh

w

y

ale

d

pu tr

a

t

s

naf rotaropave dnoc

e

s

eviF

r

eh

t

e

g

ot

t

r

ats e

s

i

w

reh

t

o dluo

w

naf dn

a

r

osse

r

pm

o

c

1AND%ARLIER

1AND,ATER

*

*

Frame Heater(s)

.n

im

2

)NO

.n

i

M

(

.

n

im

2

)

F

FO

.n

i

M

(

Refrigerators – Energy Saving Operating Mode

18

Page 19

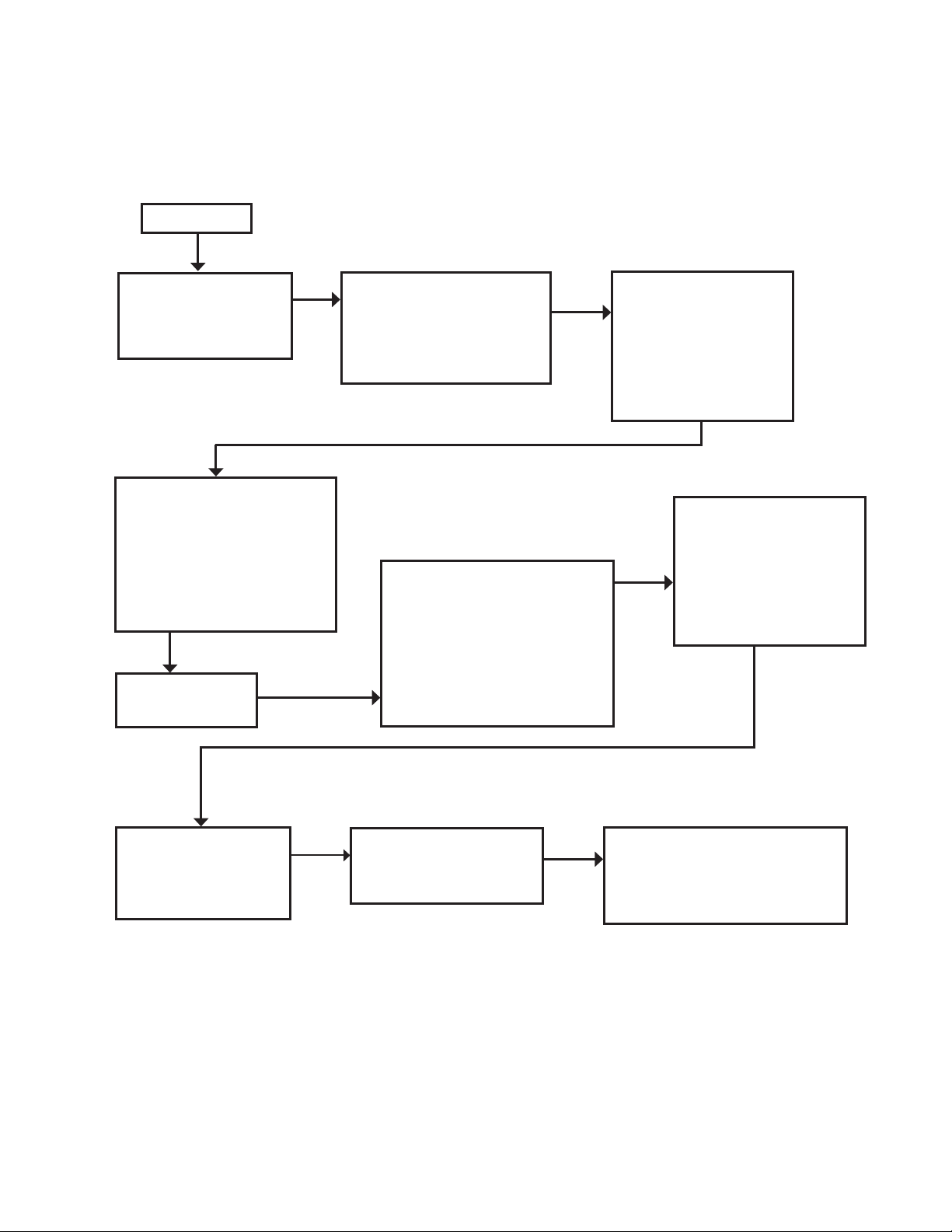

4. Freezers – Energy Saving Operating Mode

a) Sequence of Operation

POWER ON

Board Self Check

1. Frame heater(s) on

. Evaporator fan(s)

cycles on and off

Cycle On (Cut-on

temperature reached)

[Minimum minutes]

1. Compressor start-up

. Condenser fan start-up

3. Evaporator fan(s) on

(continuously)

Continue as

normal cycling

2-minute Delay

1. Compressor start-up

. Condenser fan start-up

3. Evaporator fan(s) on

(continuously)

Defrost Start

Preprogrammed time interval

1. Compressor off

. Evaporator fan(s) off

3. Condenser fan off

4. Defrost heater on

5. "dF" displayed

Cycle Off (Cut-out

temperature reached)

[Minimum minutes]

1. Compressor off

. Condenser fan off

3. Evaporator fan(s)

cycles on and off

Defrost End

Defrost thermistor

reaches defrost

termination temperature,

or defrost timer reaches

1 hour

Defrost heater off

Five minutes after

defrost heater off

1. Compressor on

. Condenser fan on

Five minutes after

compressor start-up

1. Evaporator fan(s) on

Eight minutes after evaporator

fan start-up "dF" no longer

displayed, cabinet temperature

displayed

Note:

1) Cut-on, cut-off, and cabinet temperature are read by the same sensor, called the "cabinet

) The defrost thermistor reads the evaporator temperature.

thermistor."

19

Page 20

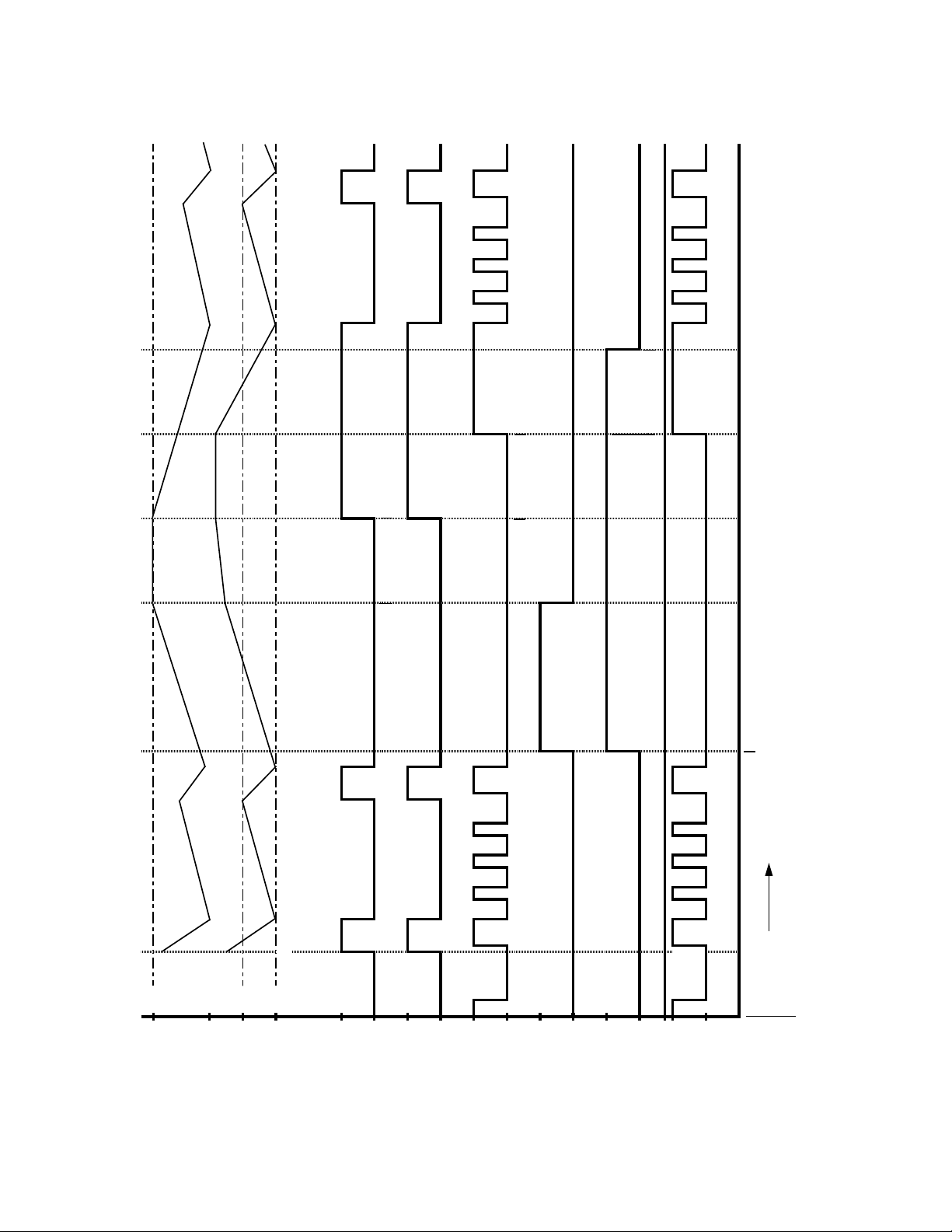

b) Timing Chart

nehw

y

ale

d

pu

t

rat

s

naf

rot

a

ro

p

ave

dno

c

es

evi

F

NO

F

F

O

N

O

F

F

O

)

+

( lait

n

er

ef

fiD

+ t

nio

pt

eS

)

-

-( l

ait

ne

r

effiD + tni

o

pteS

gninaem

oN

F

F

O

NO

N

O

F

F

O

NO

F

F

O

N

O

F

F

O

rot

s

im

r

ehT

tenibaC

rotsimrehT tsorf

e

D

ro

s

s

e

rp

moC

n

aF

r

e

snednoC

n(s)

aF

rot

aropa

v

E

r

e

t

aeH t

so

r

f

eD

.n

i

m

2

t

r

atS(

al

eD

)y

N

O

r

e

w

o

P

e

m

iT

s

r

u

o

h

6

)

el

ba

t

suj

d

A

-

t

ra

t

S

ts

or

feD

(

.nim

5

)ya

l

eD

niarD(

.

n

im 5

)yal

eD

naF

(

ro

t

a

cidn

I

t

so

r

f

eD

.n

i

m

8

)yaleD yalpsiD(

erutarepmeT noi

t

animreT tsorfeD

.

n

i

m

0

6

<

)

noi

ta

ru

D t

s

o

rf

eD

.x

a

M(

tn

e

tt

i

mre

t

nI

n

oi

tare

p

O

)sd

oi

reP

F

F

O

r

oss

e

rp

m

oC ll

A

(

tn

e

tt

i

mre

tn

I

n

oi

tare

p

O

)sd

o

ireP

F

F

O ross

e

rp

m

oC

l

lA(

TIME-TEMPERATURE CONTROL CHART [DURING ENERGY SAVING MODE] FOR

FREEZERS

(ALL UNITS)

re

h

tego

t

t

r

a

t

s

esiwr

e

hto

dl

uow

n

a

f

dna

r

o

ss

e

rp

m

o

c

*

*

*

*

Frame Heater(s)

.n

im

2

)NO

.n

i

M

(

.

n

im

2

)

F

FO

.n

i

M

(

Freezers – Energy Saving Operating Mode

0

Page 21

C. Control Board

• A Hoshizaki exclusive solid-state control board is employed in all Hoshizaki

refrigerators and freezers.

• All models are pretested and factory-adjusted.

CAUTION

1. Fragile, handle very carefully.

. The control board contains integrated circuits, which are susceptible to

failure due to static discharge. It is especially important to touch the metal

part of the unit when handling or replacing the board.

3. Do not touch the electronic devices on the board or the back of the board to

prevent damage to the board.

4. Do not attempt to repair the board in the eld. Always replace the whole

board assembly if it goes bad.

5. Do not short out power supply to test for voltage.

6. Keep the thermistor leads, clogged lter sensor leads, and pressure switch

leads at least 1.5" away from high voltage leads (AC 100 volts or more) to

protect against electrical noise.

1. Start-Up Delay

The start circuit of the compressor is timed such that at power-up and during any

compressor off time, there will be at least a -minute delay before the compressor will

start. This delay is controlled through the control board. To bypass the startup delay,

move the power switch to the "OFF" position. Then press and hold the up arrow key

while moving the power switch to the "ON" position.

Note: The compressor must run a minimum of three minutes during each run cycle.

1

Page 22

2. Control Board Layout

Board Part

Number

Chip Revision

K51 (5 pin)

(not used)

K101 (3 pin)

Transformer

K151 (10 pin)

Thermistor

Wiring

Harness

Rear

K311 (6 pin)

Relay Wiring

Harness

Board Part

Number

SW 135

Display

Setpoint

LED 13

Lit for

Negative

Values

LED 14

Temperature

and Alarm

Display

Front

SW 134

Raise

Setpoint

SW 133

Lower

Setpoint

SW 13

Manual

Defrost

SW 131

Energy

Saving/

Service

Button

Relays

F101

3 Amp Fuse

(not used)

K361 (9 pin)

(not used)

(not used)

Note: Fuse at position F101 on board is not currently used. The board can function

without this fuse.

Relay Wiring Harness (K311)

(brown) Compressor Relay

(red) Evaporator Fan Relay

(orange) Defrost Heater Relay

Thermistor Wiring Harness (K151)

(gray) Clogged Filter Sensor

(orange) Defrost Thermistor

(black) Cabinet Thermistor

(white) Jumper Wire (limits access to settings and

diagnostics menu - not present on all units)

(light blue) High Pressure Switch

Page 23

D. Settings and Diagnostics

Various settings and diagnostic information can be controlled via the display panel. The

display panel is located behind the front panel. To open the front panel, grip the outer

edge of the panel near the top and bottom and pull it open. This permits access to the

display panel and control box. The unit has a minute startup delay. To bypass the

startup delay, move the power switch to the "OFF" position. Then press and hold the up

arrow key while moving the power switch to the "ON" position. Follow the instructions

and warnings below and on the display panel for safe and efcient operation of the unit.

1. Gaining Access to Settings and Diagnostics

Generally, the only two settings that can change are the temperature display scale

(°F or °C) and the temperature setpoint. The restriction to these two settings is achieved

by the presence of a jumper between connector K151 pins 7 and 8 on the control board.

To access other settings, the jumper must be removed. To see if the jumper is present

press and hold both the button and the unmarked, blank button for 5 seconds. If

"F5" appears in the display window, the jumper is present and must be removed in order

to access other settings. If "F0" is displayed, no jumper is present and all settings are

unrestricted and accessible. See the rest of this section for details about each setting.

Note: If there is no input for 60 seconds, the display will revert to normal.

3

Page 24

2. Temperature Display

• Displays the cabinet temperature. The factory setting is °F. To change the display to the

°C scale, see "a) Switching the Display Between Fahrenheit and Celsius (F5)" below.

• The cabinet temperature is updated every 30 seconds.

• During defrost, "dF" is displayed in place of the cabinet temperature.

a) Switching the Display Between Fahrenheit and Celsius (F5)

The factory setting is °F. To change the display to °C, follow the steps below.

1) Press and hold both the button and the unmarked, blank button for 5 seconds.

"F5" appears in the display window. (If "F0" is displayed, press the MANUAL

DEFROST button until "F5" appears.)

) Press the

unmarked, blank button to display the current setting (default: "F"). Press

the up or down button to switch to °C. Press the unmarked, blank button

again to save the setting.

3) Press and hold both the button and the unmarked, blank button for 5 seconds.

The cabinet temperature will be displayed using the newly saved temperature scale.

4) Afx the "°C" label supplied with the unit to the display panel, covering "°F" but not the

display window.

b) Adjusting the Setpoint Temperature

The setpoint temperature is the temperature at which the compressor turns on. To set

the setpoint temperature, follow the steps below.

1) Press the button to display the current setpoint temperature.

) To change the setpoint, press and hold the

button while pressing the up or

down button to raise or lower the setpoint.

Model Allowable Setpoint Range Default

Refrigerator (auxiliary code Q5 and earlier)

Refrigerator (auxiliary code Q6 and later)

Freezer (Door)

Freezer (Drawer)

+1 to +53°F

(-6 to +1°C)

-13 to +19°F

(-5 to -7°C)

39°F

(4°C)

37°F

(3°C)

0°F

(-18°C)

°F

(-17°C)

3) After 10 seconds, the new setpoint will be saved automatically.

Note: For refrigerators, the temperature differential for the compressor to turn off is

-4.5°F (-.5°C) for auxiliary code Q5 and earlier and -3.6°F (-.0°C) for auxiliary

code Q6 and later. For 1-section freezers, it is -6.3°F (-3.5°C) and for -section

freezers, it is -3.6°F (-.0°C).

4

Page 25

c) Cabinet Temperature Correction (calibration factor)

In cases where there is a discrepancy between the actual cabinet center temperature

and the displayed temperature for a particular model, a calibration factor is used to

correct the displayed temperature.

WARNING

This unit has been factory tested with the default settings listed. Avoid using

this function except to conrm that the setting is correct. If set incorrectly, the

display could show an acceptable temperature even though the temperature

is out of the proper range. This value should only be changed after consulting

with the factory.

To view the current value, follow the steps below.

1) Turn the power on while pressing the up button. The current correction calibration

factor will be shown. If "18" is displayed, the value is 1.8°F (1.0°C). See the table below

for the default values.

Cabinet Temperature Correction (Calibration Factor)

Model Setting Range 1-Section 2-Section 3-Section

Refrigerator

Freezer

-9.9 to 9.9°F in 0.9°F increments

(-9.5 to 9.5°C in 0.5°C increments)

00 (0.0°F)

(00 (0.0°C))

18 (1.8°F)

(10 (1.0°C))

Default

45 (4.5°F)

(5 (.5°C))

) If it is determined through discussion with the factory that the setting needs to be

changed, press the up or down button to increase or decrease the value.

3) Press the button to save the new value.

4) Turn the power off and then back on. The unit will start running with the new value.

[Example]

When the average cabinet temperature is 5.4°F

(3.0°C) higher than the thermistor detected

temperature, change the correction calibration

factor to 5.4°F (3.0°C).

36 (3.6°F)

( 0 (.0°C))

5

Page 26

3. Settings and Diagnostics Menu

To gain access to the settings, see "II.D.1. Gaining Access to Settings and Diagnostics."

Once inside this menu, press the MANUAL DEFROST button to scroll through the menu

and the unmarked, blank button at any point to view the current setting. Press the

MANUAL DEFROST button to return to the menu screen.

Default

Refrigerator Freezer

Auxiliary Code

Q5 and

Code Item Setting and Display Range

F0 Defrost Interval 1 to 1 hours in 1 hour increments 6 6 6

F1 Defrost Termination

Temperature

Setpoint

F

Temperature

Differential

(upper and lower)

F3 High Temperature

Alarm Delay Time

F4 Low Temperature

Alarm Delay Time

F5 Temperature Dis-

play

F6 Alarm History Displays alarm history - maximum 8

F7 Compressor Run

Time

F8 Not Used NA NA NA

F9 Not Used NA NA NA

Refrigerator: 59 to 68°F (15 to 0°C) in

one degree increments

Freezer: 41 to 68°F (5 to 0°C) in one

degree increments

0 to 6.3°F in increments of .9°F

(0 to 3.5°C in increments of .5°C)

0 to 180 minutes in 60 minute

increments

(0=0; 1=60; =10; 3=180 minutes)

0 or 60 minutes

(0=0; 1=60 minutes)

Fahrenheit or Celsius

alarms

Displays run time between two most

recent defrosts

earlier

59°F 59°F 41°F

0°F, -45°F

(0°C,

-.5°C )

(decimal

is not

displayed)

1 1 1

°F °F °F

NA NA NA

NA NA NA

Q6 and

later

0°F, -36°F

(.0, -

.0°C)

(decimal

is not

displayed)

1

section2section

0°F, -63°F

(0°C,

-3.5°C)

(decimal

is not

displayed)

0°F, -36°F

(.0,

-.0°C)

(decimal

is not

displayed)

6

Page 27

a) Defrost Interval (F0)

This unit is preset at the factory to defrost once every 6 hours for general conditions.

However, if it is determined that this interval does not suit actual conditions, the interval

can be changed. To change the defrost interval, follow the steps below.

1) Make sure the jumper is removed between connector K151 pins 7 and 8 on the control

board. Otherwise you will not be able to access this setting. For details, see "D.1.

Gaining Access to Settings and Diagnostics."

) Press and hold both the

If "F0" is not displayed, press the MANUAL DEFROST button until "F0" appears in the

display window.

3) Press the unmarked, blank button to display the current setting (default: "6"). Press

the up or down button to increase or decrease the number of hours between

each defrost. The interval can be from 1 to 1 hours in increments of 1 hour.

4) Press the unmarked, blank button to save the setting.

5) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

6) If a jumper was present between connector K151 pins 7 and 8 , reconnect it after all

setting and diagnostic work is complete.

Note:

• The defrost is a heated defrost, and therefore has a tendency to raise cabinet

temperature.

• When the unit goes into defrost during energy saving mode, evaporator fan(s)

and/or perimeter frame heaters will turn off.

• Cabinet temperature is not displayed during defrost; "dF" is displayed in its place.

• The change in the defrost setting will take effect immediately. The next defrost will

take place after the newly set time interval has elapsed.

• Initiating a manual defrost will restart the defrost timer.

• The evaporator temperature must be below the defrost completion temperature for

any defrost (manual or auto) to be initiated.

button and the unmarked, blank button for 5 seconds.

b) Defrost Termination Temperature (F1)

To change the defrost termination temperature, follow the steps below.

1) Make sure the jumper is removed between connector K151 pins 7 and 8 on the control

board. Otherwise you will not be able to access this setting. For details, see "D.1.

Gaining Access to Settings and Diagnostics."

) Press and hold both the

"F0" should appear in the display window. Press the MANUAL DEFROST button until

"F1" appears in the display window.

button and the unmarked, blank button for 5 seconds.

7

Page 28

3) Press the unmarked, blank button to display the current setting. Press the up or

down button to increase or decrease the defrost termination temperature.

Note: The defrost termination temperatures can be adjusted within the following ranges:

• Refrigerator: 59 to 68°F (15 to 0°C) in one degree increments

• Freezer: 41 to 68°F (5 to 0°C) in one degree increments

4) Press the unmarked, blank button to save the setting.

5) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

6) If a jumper was present between connector K151 pins 7 and 8, reconnect it after all

setting and diagnostic work is complete.

c) Setpoint Temperature Differential (F2)

To change the differential, follow the steps below.

1) Make sure the jumper is removed between connector K151 pins 7 and 8 on the control

board. Otherwise you will not be able to access this setting. For details, see "D.1.

Gaining Access to Settings and Diagnostics."

) Press and hold both the

"F0" should appear in the display window. Press the MANUAL DEFROST button until

"F" appears in the display window.

3) Press the unmarked, blank button to display the current + setting (the decimal

between the digits is not shown). Press the up or down button to increase or

decrease the + (plus) differential in .9°F increments.

Note:

• Both the + and - values can be adjusted between 0.0 and 6.3°F in .9°F increments

(0.0 to 3.5°C in .5°C increments).

• You cannot set both + and - to 0.0.

4) Press the unmarked, blank button to save the + setting and move to the - (minus)

differential setting.

5) Press the up or down button to increase or decrease the - (minus) differential in

.9F increments.

Note:

• Both the + and - values can be adjusted between 0.0 and 6.3°F in .9°F increments

(0.0 to 3.5°C in .5°C increments).

• You cannot set both + and - to 0.0.

button and the unmarked, blank button for 5 seconds.

6) Press the unmarked, blank button to save the - (minus) setting. The - (minus) sign

will turn off and the display will change to the + (plus) differential setting.

7) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

8) If a jumper was present between connector K151 pins 7 and 8, reconnect it after all

setting and diagnostic work is complete.

8

Page 29

d) High Temperature Alarm Delay Time (F3)

To change the high temperature alarm delay time, follow the steps below.

1) Make sure the jumper is removed between connector K151 pins 7 and 8 on the control

board. Otherwise you will not be able to access this setting. For details, see "D.1.

Gaining Access to Settings and Diagnostics."

) Press and hold both the

button and the unmarked, blank button for 5 seconds.

"F0" should appear in the display window. Press the MANUAL DEFROST button until

"F3" appears in the display window.

3) Press the unmarked, blank button to display the current setting. Press the up or

down button to increase or decrease the high temperature alarm delay time.

Note: The time can be adjusted between 0 and 180 minutes in 60 minute increments.

The display corresponds to time as follows:

Display Detection Time

(minutes)

0 0

1 60

10

3 180

4) Press the unmarked, blank button to save the setting.

5) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

6) If a jumper was present between connector K151 pins 7 and 8, reconnect it after all

setting and diagnostic work is complete.

e) Low Temperature Alarm Delay Time (F4)

To change the low temperature alarm delay time, follow the steps below.

1) Make sure the jumper is removed between connector K151 pins 7 and 8 on the control

board. Otherwise you will not be able to access this setting. For details, see "D.1.

Gaining Access to Settings and Diagnostics."

) Press and hold both the

button and the unmarked, blank button for 5 seconds.

"F0" should appear in the display window. Press the MANUAL DEFROST button until

"F4" appears in the display window.

3) Press the unmarked, blank button to display the current setting. Press the up or

down button to increase or decrease the low temperature alarm delay time.

Note: The time can be 0 or 60 minutes. The display corresponds to time as follows:

Display Detection Time

(minutes)

0 0

1 60

9

Page 30

4) Press the unmarked, blank button to save the setting.

5) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

6) If a jumper was present between connector K151 pins 7 and 8, reconnect it after all

setting and diagnostic work is complete.

f) Temperature Display Scale (F5)

For information about switching the display between °F and °C, see "D..a) Switching

the Display Between Fahrenheit and Celsius (F5)."

g) Alarm History (F6)

To view the alarm history, follow the steps below.

1) Make sure the jumper is removed between connector K151 pins 7 and 8 on the control

board. Otherwise you will not be able to access this setting. For details, see "D.1.

Gaining Access to Settings and Diagnostics."

) Press and hold both the

button and the unmarked, blank button for 5 seconds.

"F0" should appear in the display window. Press the MANUAL DEFROST button until

"F6" appears in the display window.

3) Press the unmarked, blank button to display the alarm history. The alarms will be

displayed in reverse chronological order (newest to oldest - up to 8 alarms). When "--"

is displayed, you have reached the end of the alarm history and the display will begin

again.

Note: The alarms are as follows:

Alarm Code Description

E1 High Temperature Alarm

E

E3 Defrost Alarm

E4 High Pressure Alarm

E7 Clogged Filter Alarm

E8 Defrost Temperature Sensor Malfunction Alarm

E9 Clogged Filter Sensor Malfunction Alarm

EA EEPROM Write Error Alarm

ED EEPROM Verication or Read Error Alarm

Low Temperature Alarm

4) To reset the alarm history, press and hold both the unmarked, blank button and the

MANUAL DEFROST button for 5 seconds.

5) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

6) If a jumper was present between connector K151 pins 7 and 8, reconnect it after all

setting and diagnostic work is complete.

30

Page 31

h) Compressor Run Time (F7)

To display the compressor run time between the two most recent defrosts, follow the

steps below.

1) Make sure the jumper is removed between the connector K151 pins 7 and 8 on the

control board. Otherwise you will not be able to access this feature.

) Press and hold both the

button and the unmarked, blank button for 5 seconds.

"F0" should appear in the display window. Press the MANUAL DEFROST button until

"F7" appears in the display window.

3) Press the unmarked, blank button to display the run time. The number displayed

indicates what percent of the time the compressor was running.

4) Press the MANUAL DEFROST button to return to the menu screen. Press and hold

both the button and the unmarked, blank button for 5 seconds to exit the setting

mode and return to the temperature display.

5) If a jumper was present between connector K151 pins 7 and 8, reconnect it after all

setting and diagnostic work is complete.

4. Operating Modes

Hoshizaki undercounters and worktops feature two operating modes, energy saving and

continuous. Always use the default setting of your unit. To determine the default setting

of your unit, see the chart below.

Model Default Setting

Refrigerator (auxiliary code Q5 and earlier) Continuous Operating Mode

Refrigerator (auxiliary code Q6 and later) Energy Saving Operating Mode

Freezer - 1 section Continuous Operating Mode

Freezer - section

Energy Saving Operating Mode

To determine the operating mode your unit is in, look at the unit's cabinet temperature

display. If a period does not appear after the temperature, the unit is in continuous

operating mode. If a period appears after the temperature, the unit is in energy saving

operating mode.

To switch between operating modes, press and hold the unmarked, blank button for

5 seconds.

Note: It takes 5 seconds for this setting to be saved. Once saved, the setting you made

will be remembered even if the power is turned off.

Continuous

(no period after temperature)

Energy Saving

(period after temperature)

31

Page 32

a) Continuous

The evaporator fan runs constantly (except in defrost). The frame heaters are on

continuously.

b) Energy Saving

The evaporator fan runs when the compressor is on, but only intermittently when

the compressor is off. The frame heaters cycle on and off with the evaporator fan

for refrigerators auxiliary code Q6 and later, but are on continuously for refrigerators

auxiliary code Q5 and earlier and all freezers. Intermittent fan operation saves energy by

reducing heat leak, especially around the gasket, and by extending compressor off time.

Fan on/off time is dependent on the setpoint temperature.

Model Setpoint Temperature

3 to 30°F

Refrigerator

Freezer

(-5 to -1°C)

3 to 5°F

(0 to 11°C)

-13 to +19°F

(-5 to -7°C)

Off Time

(seconds)

90 15

150 15

30 30

On Time

(seconds)

c) Automatic Corrections Made During Energy Saving Operating Mode

(1) Temperature Display Correction

When the unit is in energy saving mode and the evaporator fan shuts off, the

temperature at the cabinet thermistor drops due to its close proximity to the evaporator.

Therefore, the temperature at the cabinet thermistor does not accurately reect the

true cabinet temperature. To compensate for this, the cabinet temperature registered

at compressor shutoff is displayed for 10 seconds after shutoff when in energy saving

mode. After 10 seconds, the cabinet temperature plus 1.8°F (1°C) will be displayed.

Once the compressor turns back on, the display will return to the normal display.

(2) Temperature Differential Correction

During energy saving mode, the cabinet temperature tends to be higher than during

normal operation because the evaporator fan operates only intermittently when the

compressor is off. The upper setpoint differential for turning the compressor on is

automatically adjusted to compensate.

E. Perimeter Frame Heater

This unit is equipped with a perimeter frame heater. This prevents the formation of

condensate on the front frame of the unit under high humidity conditions.

Note: On refrigerators with auxiliary code Q6 and later, perimeter frame heater(s)

operate together with the evaporator fan(s).

3

Page 33

III. Service Diagnosis

A. Alarm Codes

If an error occurs, the alarm code and cabinet temperature are displayed in 1-second

intervals. See the table below for a general description of the problem, then see the rest

of this section for detailed instructions.

Alarm Signals

Alarm Code Problem Notes

E1

High Temperature Alarm

Cabinet temperature has exceeded set

temperature by 14.4°F (10°C) for more than

x hours. The default value of x is "" ( hours).

When temperature returns to setpoint range,

alarm code "E1" will clear.

The value of x can be changed under F3 on the

Settings and Diagnostics Menu.

(0=No delay; 1=1 hour; = hours; 3=3 hours)

E2

E3

E4

E7

E8

E9

EA

ED

Low Temperature Alarm

Cabinet temperature has remained below

setpoint by 9°F (5°C) for more than y hours.

The default value of y is "1" (1 hour).

Defrost Alarm

Defrost has taken longer than 1 hour. Control

board has terminated defrost.

High Pressure Alarm

Compressor discharge pressure is outside

normal operating range. Pressure switch has

been triggered 5 or more times in 1 hour.

Condenser lter may need cleaning.

Clogged Filter Alarm

Condenser temperature is outside of normal

operating range. Condenser lter needs

cleaning.

Defrost Temperature Sensor Malfunction Alarm

Defrost temperature sensor has failed.

Clogged Filter Sensor Malfunction Alarm

Clogged lter sensor has failed.

EEPROM Write Error Alarm

Control board is defective.

EEPROM Verication or Read Error Alarm

Control board is defective.

When temperature returns to setpoint range,

alarm code "E" will clear.

The value of y can be changed under F4 on the

Settings and Diagnostics Menu.

(0=No delay; 1=hour)

E3 may alternate with "dF" instead of the

temperature.

Clean lter if necessary. Allow time for

pressure switch to react, then turn power off

and back on again to reset.

If switch trips 5 times in 1 hour, and the

above steps do not clear alarm code, see the

procedure contained in this section.

Clean lter. Allow time for sensor to react, then

turn power off and back on again to reset.

After replacing sensor, alarm will reset.

After replacing sensor, alarm will reset.

After replacing the control board, alarm will

reset.

After replacing the control board, alarm will

reset.

33

Page 34

1. Alarm Display Priority

If multiple alarms occur simultaneously, only the alarm with the higher priority is

displayed.

Error Code Priority Description

ED 1 EEPROM Verication or Read Error Alarm

EA EEPROM Write Error Alarm

E8 3

E9 4 Clogged Filter Sensor Malfunction Alarm

E4 5 High Pressure Alarm

E7 6 Clogged Filter Alarm

E3 7 Defrost Alarm

E1 8 High Temperature Alarm

E

Defrost Temperature Sensor Malfunction

Alarm

9 Low Temperature Alarm

34

Page 35

2. Alarm Details and Countermeasures

a. High Temperature Alarm (E1)

If the cabinet temperature exceeds the setpoint temperature by 14.4°F (8°C) or more for

more than x hours, "E1" is displayed. The default value of x is "" ( hours). The value

of x can be changed under F3 on the Settings and Diagnostics Menu. (0=No delay; 1=1;

=; 3=3 hours)

Note:

• After the machine has been turned off and then turned back on, the high

temperature alarm feature is not active until the cabinet temperature reaches the

lower setpoint temperature differential.

• The high temperature alarm feature operates even during defrost.

Reset Options

The alarm will automatically reset once the cabinet temperature reaches the lower setpoint

temperature differential.

Possible Causes

• The door is opened frequently or is not completely closed.

• Trouble with the compressor or a gas leak.

• Trouble with the cabinet thermistor (black).

35

Page 36

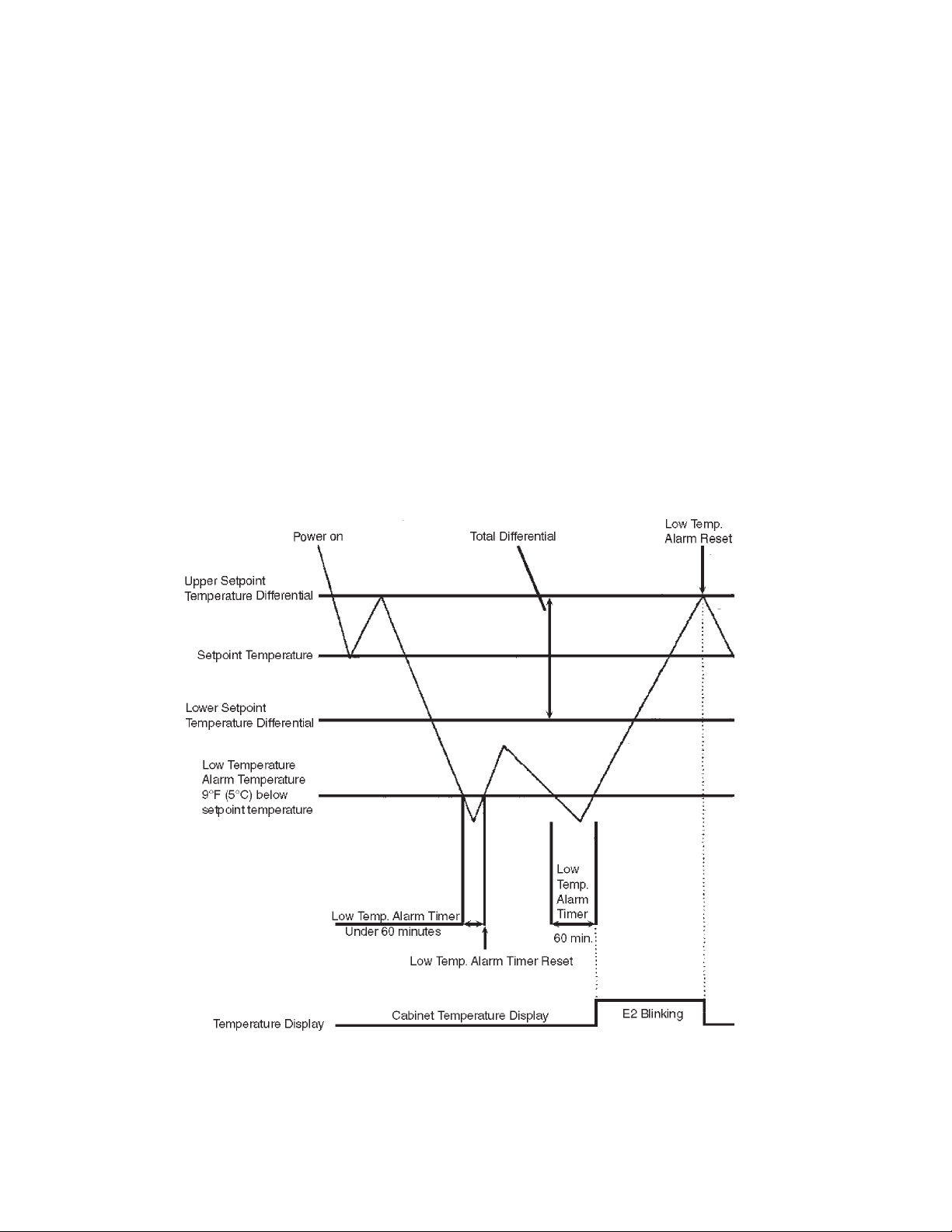

b. Low Temperature Alarm (E2)

If the cabinet temperature drops below the setpoint temperature by 9°F (5°C) or more for

more than y minutes, "E" is displayed. The default value of y is "1" (1 hour). The value

of y can be changed under F4 on the Settings and Diagnostics Menu. (0=No delay; 1=1

hour)

Note:

• The low temperature alarm timer starts once the cabinet temperature drops 9°F

(5°C) below the setpoint temperature.

• The low temperature alarm feature operates even during defrost.

Reset Options

The alarm will automatically reset once the cabinet temperature reaches the upper setpoint

temperature differential.

Possible Causes

• Ambient temperature is low.

• Trouble with the cabinet thermistor (black).

36

Page 37

c. Defrost Alarm (E3)

If the defrost thermistor does not turn off in one hour after defrost begins, "E3" is

displayed. When "E3" is displayed, the next step in the defrost termination process

(drain - fan delay - defrost display delay) begins.

Reset Options

To reset the alarm, turn the unit off and then back on.

Possible Causes

• Trouble with the defrost heater.

• The temperature fuse is blown.

• Trouble with the defrost thermistor (orange).

d. High Pressure Alarm (E4)

In order to protect the compressor if the discharge pressure reaches a preset value

(outside the normal operating range), a switch will temporarily stop the compressor.

At another preset pressure, the compressor will attempt to restart. If the switch is

triggered 5 or more times in one hour, "E4" will be displayed.

Reset Options

To reset the alarm, turn the unit off and then back on.

Possible Causes

• The condenser air lter is dirty.

• There is blockage or contamination inside the capillary tube or elsewhere in the

refrigeration circuit.

• The condenser fan motor is locked or otherwise not functioning.

37

Page 38

e. Clogged Filter Alarm (E7)

The unit is equipped with a lter for protecting the condenser from dirt, oils, grease, etc.

The lter promotes clean condenser surfaces and efcient operation and should be

checked twice monthly and cleaned when necessary. The unit is also equipped with a

sensor to determine if this lter is excessively dirty. If the unit detects that the condenser

lter is excessively dirty by sensing a temperature at the condenser outlet of at least

136.4°F (58°C) for over minutes, "E7" will be displayed.

Reset Options

After cleaning the lter, the alarm will automatically reset once the temperature at the

condenser outlet drops below 136.4°F (58°C).

Possible Causes

• The condenser air lter is dirty.

• The condenser fan motor is locked or otherwise not functioning.

IMPORTANT

If this alarm occurs frequently, the compressor discharge temperature is

consistently too high.

Note:

• If the unit is turned off and then back on while the alarm code is displayed, the

alarm may be reset even if the lter is not yet clean. However, the alarm will recur

once the compressor discharge temperature reaches 136.4°F (58°C).

38

Page 39

f. Defrost Temperature Sensor Malfunction Alarm (E8)

If input from the defrost thermistor is below the defrost open circuit detection point

(equivalent to -67°F (-55°C)), "E8" is displayed. "E8" is also displayed when input

from the defrost thermistor is above the defrost thermistor short circuit detection point

(equivalent to 1°F (50°C)) for 10 minutes or more.

Note:

• If this alarm appears, rst make sure that the sensor is properly connected.

• A short circuit will not be detected during the rst hour after power is turned on.

However, a short circuit can be detected immediately by turning on the power

while pressing the button. In this case, "E8" will be displayed immediately if a

short circuit is detected.

• A short circuit will not be detected during defrost or fan delay.

Reset Options

The alarm automatically resets when one of the following conditions is met:

• The input from the defrost thermistor exceeds the open circuit detection point (equivalent

to -67°F (-55°C)).

• The input from the defrost thermistor drops below the short circuit detection point

(equivalent to 1°F (50°C)).

• A functioning defrost thermistor (orange) is installed.

Possible Causes

• Trouble with the defrost thermistor (orange).

39

Page 40

g. Clogged Filter Sensor Malfunction Alarm (E9)

If the input from the clogged lter sensor is below the clogged lter sensor open circuit

detection point (equivalent to -7.6°F (-°C)), "E9" is displayed. "E9" is also displayed

when input from the clogged lter sensor is above the clogged lter sensor short circuit

detection point (equivalent to 186.8°F (86°C)) for 10 minutes or more.

Note:

• If this alarm appears, rst make sure that the sensor is properly connected.

• A short circuit can be detected immediately by turning on the power while pressing

the button. In this case, "E9" will be displayed immediately if a short circuit is

detected.

Reset Options

The alarm automatically resets when one of the following conditions is met:

• The input from the clogged lter sensor exceeds the open circuit detection point

(equivalent to -7.6°F (-°C)).

• The input from the clogged lter sensor drops below the short circuit detection point

(equivalent to 186.8°F (86°C)).

• A functioning clogged lter sensor (gray) is installed.

Possible Causes

• Trouble with the clogged lter sensor (gray).

40

Page 41

h. Control Board Error Alarms (EA and ED)

"EA" is displayed when an EEPROM write error is detected. "ED" is displayed when an

EEPROM verication or read error is detected.

Reset Options

Replacing the control board with a functioning replacement control board will eliminate this

error condition.

41

Page 42

B. Diagnosis Chart

Problem Possible Cause Remedy

[1] Compressor will

not start—no

current draw.

Compressor will

[]

not run—draws

current and trips

on overload.

[3] Compressor runs

intermittently and

trips on overload.

[4] Cabinet

temperature too

high; compressor

will not start.

a)Power Supply 1. "OFF" position. 1. Move to "ON" position.

Loose connection(s). . Tighten or reconnect.

.

3. Failure. 3. Call electrician.

b) Cord and Plug 1. Defective. 1. Replace.

c) Circuit Breaker

(kitchen)

d)Transformer 1. Open coil winding. 1. Check continuity and replace.

e)Wiring to Control Board 1. Loose connection(s). 1. Tighten.

f) Voltage 1. Too low. 1. Call electrician.

g)High Pressure Switch 1. Bad contacts. 1. Check continuity and replace.

h)Thermistor 1. Defective. 1. Check and replace.

i) Control Board 1. Defective. 1. Replace control board.

j) Compressor Overload 1. Defective. (Contacts

k) Compressor 1. Open windings. 1. Check continuity and replace.

l) Relay (Condensing

Unit)

a)Voltage 1. Too low. 1. Call electrician.

b)Start Relay 1. Bad contacts. 1. Replace.

c) Compressor 1. Locked rotor. 1. Replace.

d)Start Capacitor 1. Defective. 1. Check and replace.

a)Voltage 1. Too low. 1. Call electrician.

b)Condenser Filter 1. Clogged. 1. Clean lter.

c) Refrigerant Line or

Component

d)Condenser Fan Motor 1. Failed. 1. Replace.

e)Refrigerant 1. Overcharged. 1. Evacuate and recharge.

f) Location of Unit 1. Restricted air ow to

a)Thermistor 1. Defective. 1. Check and replace.

b)Compressor Relay 1. Defective. 1. Check and replace.

c) Control Board 1. Defective. 1. Replace.

1. Tripped. 1. Check and reset. Call

electrician if breaker trips

repeatedly.

Defective. . Call electrician.

.

Faulty. . Check continuity and replace.

.

Too high. . Call electrician.

.

Has operated 5 or

.

more times in one

hour. (E4 should be

displayed)

open)

1. Bad contacts. 1. Replace.

Open coil winding. . Check and replace.

.

Open coil windings. . Replace.

.

Too high. . Call electrician.

.

1. Plugged or restricted. 1. Clean and replace drier. Clean

Non-condensibles in

.

system.

condenser.

. Determine why pressure

switch is activated.

1. Replace.

and replace capillary tube heat

exchanger assembly.

. Evacuate and recharge.

1. Move unit or increase

ventilation.

4

Page 43

Problem Possible Cause Remedy

[5] Cabinet

temperature too

high.

[6] Cabinet

temperature

display

indicator does

not illuminate

properly.

[7] Cabinet

temperature too

low.

[8] Evaporator does

not defrost

completely.

a)Setpoint and/or

Differential

b)Door 1. Not sealing, opened

c) Defrost 1. Defrost time

d)Refrigerant 1. Leak. 1. Repair leak and recharge.

e)Fan Motor 1. Defective. 1. Check and replace.

f) Air Filter 1. Clogged. 1. Clean.

g)Condenser 1. Dirty. 1. Clean.

h)Thermistor 1. Defective. 1. Check and replace.

i) Control Board 1. Defective. 1. Replace.

j) Outside Heat Source 1. Too close to unit. 1. Separate unit from heat

k) Air Flow 1. Blockage inside

l) Warm Food 1. Warm food recently

a)Power Supply 1. "OFF" position. 1. Move to "ON" position.

b)Control Board 1. Defective. 1. Replace.

a)Setpoint and/or

Differential

b)Frozen Food 1. Frozen food recently

c) Thermistor 1. Defective. 1. Check and replace.

d)Compressor Relay 1. Defective; contacts

e)Control Board 1. Defective. 1. Replace.

a)Defrost Thermistor 1. Defective. 1. Check and replace.

b)Defrost 1. Not enough defrosts

c) Defrost Heaters 1. Defective. 1. Replace heaters.

d)Safety Defrost

Thermostat

e)Defrost Heater

Temperature Fuse

1. Incorrect. 1. Correct setting(s).

See sections "II.D..b)" and

"II.D.3.c)" for defaults.

1. Check for sealing, check for

frequently or open for

long intervals.

insufcient to remove

frost.

Operation in humid

conditions.

interior.

placed in refrigerator.

Loose connection(s). . Tighten or reconnect.

.

3. Failure or tripped

breaker.

1. Incorrect. 1. Correct setting(s).

placed in refrigerator.

welded.

occurring per day.

Operation in humid

conditions.

1. Defective, turning off

heaters prematurely,

or fused open.

1. Blown. 1. Determine why fuse blew.

door open at time of warm

cabinet temperature.

1. See "[8] Evaporator does

not defrost completely."

source.

1. Remove blocakge by removing

or redistributing food product.

1. Allow time for unit to return to

setpoint temperature.

3. Call electrician and/or reset

breaker.

See sections "II.D..b)" and

"II.D.3.c)" for defaults.

1. Allow time for unit to return to

setpoint temperature.

1. Replace.

1. Factory default is once every

6 hours. If coil is frosting too

much, can shorten defrost

interval.

1. Replace safety defrost

thermostat.

Replace fuse.

43

Page 44

Problem Possible Cause Remedy

[9] Defrost cycle

lasts too long.

[10]Condensate

water overow.

[11]Abnormal Noise a) Fasteners 1. Loose fasteners allow

a)Defrost Thermistor 1. Defective. 1. Replace.

b)Control Board 1. Defective. 1. Replace.

c) Defrost 1. Not enough defrosts

occurring per day.

Operation in humid

conditions.

d)Defrost Heater 1. Defective. 1. Replace heaters.

e)Safety Defrost

Thermostat

a)Cabinet Contents 1. Loading of large

b)Location of Unit 1. Unit located near high

c) Seals 1. Poor sealing around

d)Environment 1. Extreme environment

b)Compressor 1. Problem with mount. 1. Properly mount compressor.

c) Fan 1. Fan blade loose. 1. Adjust and tighten.

d) Relay 1. Chattering. 1. Replace.

1. Defective, turning off

heaters prematurely,

or fused open.

volumes of warm,

moist, uncovered

product.

humidity source such

as fryer, steamer, etc.

evaporator, door

gaskets.

and door-opening

conditions.

vibration of part.

Floodback to

.

compressor.

3. Defective. 3. Replace.

Defective motor. . Replace.

.

1. Factory default is once every

6 hours. If coil is frosting too

much, can shorten defrost

interval.

1. Replace safety defrost

thermostat.

1. Cover product with plastic

wrap.

1. Relocate.

1. Adjust or replace.

1. Adjust conditions.

1. Tighten fasteners.

Replace any missing

grommets.

. Check for signs of oodback

to compressor. Evacuate and

recharge if necessary.

44

Page 45

C. Thermistor Check

A thermistor (semiconductor) is used for the cabinet control sensor and defrost termination

sensor. The resistance varies depending on temperature. No adjustment is required. If

necessary, check for resistance between thermistor leads and visually check the thermistor

mounting.

Temperature Resistance (kΩ)

°F °C Cabinet/Defrost Thermistors Clogged Filter Thermistor

0 -17.8 14. -

10 -1. 10.7 -

0.0 6.0 160

3

50 10.0 3.9 100

70 1.1 .5 59

90 3. 1.6 36

Cabinet & Defrost Thermistor T-R Curve

Temperature °F (°C)

Clogged Filter Thermistor T-R Curve

Temperature °F (°C)

To check a thermistor's resistance, follow the steps below.

1) Disconnect the connector for the thermistor in question under the control box and

behind the wire guard.

) Remove the thermistor. See "IV.F. Removal and Replacement of Thermistors."

3) Immerse the thermistor sensor portion in a glass or cup containing ice and water for

or 3 minutes.

4) Check for a resistance between thermistor leads. Normal reading is from 5 to 6.5kΩ

for the cabinet and defrost thermistors and 145 to 175kΩ for the clogged lter sensor.

Replace the thermistor if it exceeds the normal reading.

45

Page 46

IV. Removal and Replacement of Components

IMPORTANT

1. Ensure all components, fasteners, and thumbscrews are securely in place

after the equipment is serviced.

. The Polyol Ester (POE) oils used in all units can absorb moisture quickly.

Therefore it is important to prevent moisture from entering the system when

replacing or servicing parts.

3. Always install a new drier every time the sealed refrigeration system is

opened. Do not replace the drier until after all other repair or replacement

has been made.

4. Do not leave the system open for longer than 15 minutes when replacing or

servicing parts.

A. Service for Refrigerant Lines

WARNING

Use an electronic leak detector or soap bubbles to check for leaks. Add a trace

of refrigerant to the system (if using an electronic leak detector), and then raise

the pressure using nitrogen gas (140 PSIG). DO NOT use R-404A or R-134a

as a mixture with pressurized air for leak testing.

1. Refrigerant Recovery

The undercounter unit is provided with a refrigerant access valve. Using proper

refrigerant practices, recover the refrigerant from the access valve and store it in an

approved container. Do not discharge the refrigerant into the atmosphere.

2. Brazing