Page 1

Service Manual

Modular Cubelet Serenity Series

Models

FS-1001MLJ-C with SRC-10J

FS-1022MLJ-C with SRC-10J

FS-1500MLJ-C with SRC-14J

hoshizakiamerica.com

Number: 73222

Issued: 3-22-2018

Page 2

WARNING

Only qualied service technicians should install and service the appliance. To

obtain the name and phone number of your local Hoshizaki Certied Service

Representative, visit www.hoshizaki.com. No service should be undertaken until

the technician has thoroughly read this Service Manual. Failure to service and

maintain the appliance in accordance with this manual will adversely affect safety,

performance, component life, and warranty coverage and may result in costly water

damage. Proper installation is the responsibility of the installer. Product failure or

property damage due to improper installation is not covered under warranty.

Hoshizaki provides this manual primarily to assist qualied service technicians in the

service of the appliance.

Should the reader have any questions or concerns which have not been satisfactorily

addressed, please call, send an e-mail message, or write to the Hoshizaki Technical

Support Department for assistance.

Phone: 1-800-233-1940; (770) 487-2331

Fax: 1-800-843-1056; (770) 487-3360

E-mail: techsupport@hoshizaki.com

618 Highway 74 South

Peachtree City, GA 30269

Attn: Hoshizaki Technical Support Department

Web Site: www.hoshizaki.com

NOTE: To expedite assistance, all correspondence/communication MUST include the

following information:

• Model Number

• Serial Number

• Complete and detailed explanation of the problem.

2

Page 3

IMPORTANT

This manual should be read carefully before the appliance is serviced. Read

the warnings and guidelines contained in this manual carefully as they provide

essential information for the continued safe use, service, and maintenance of the

appliance. Retain this manual for any further reference that may be necessary.

CONTENTS

Important Safety Information ................................................................................................. 5

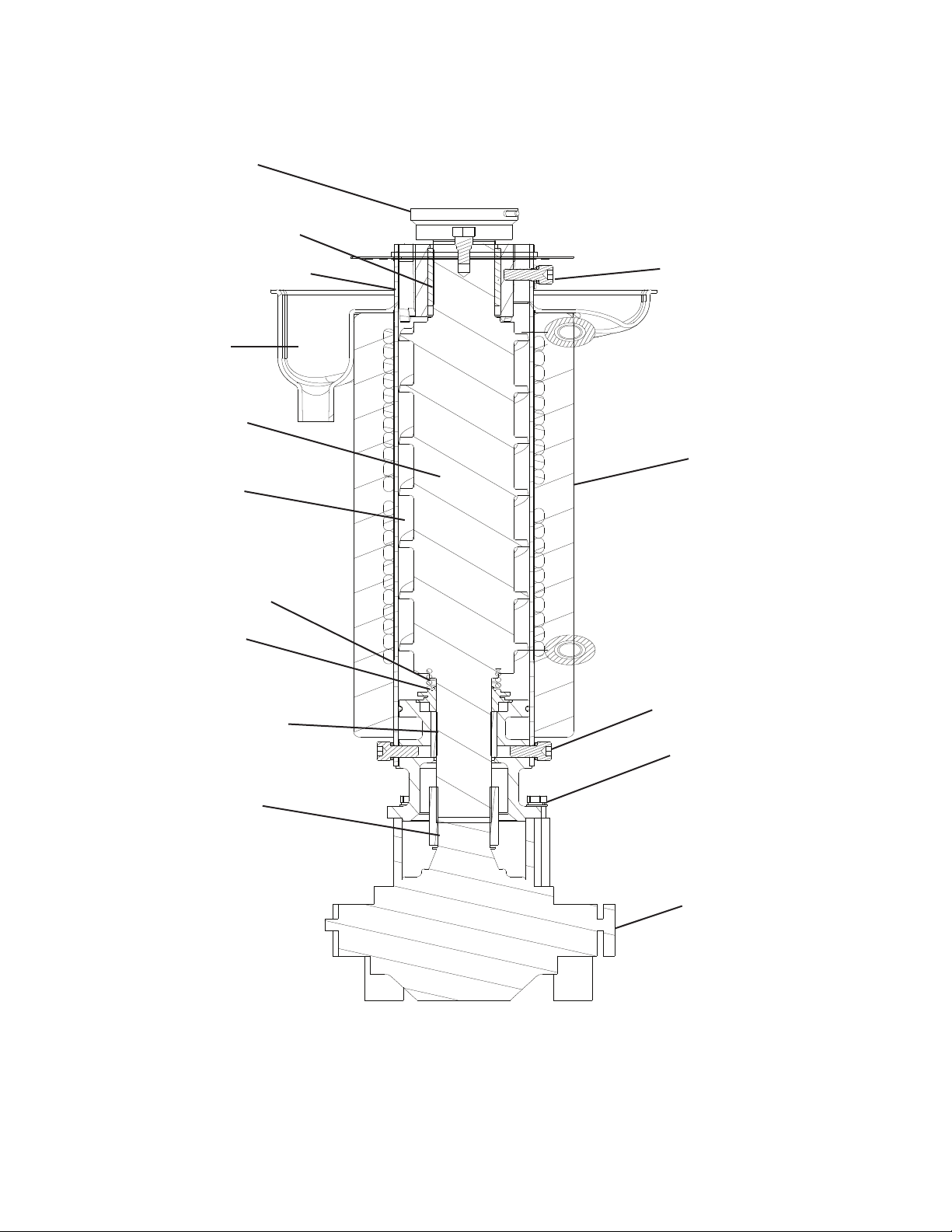

I. Construction and Water/Refrigeration Circuit Diagram ....................................................... 8

A. Construction .................................................................................................................. 8

1. Icemaker .................................................................................................................. 8

2. Condensing Unit ...................................................................................................... 9

3. Icemaking Unit ....................................................................................................... 10

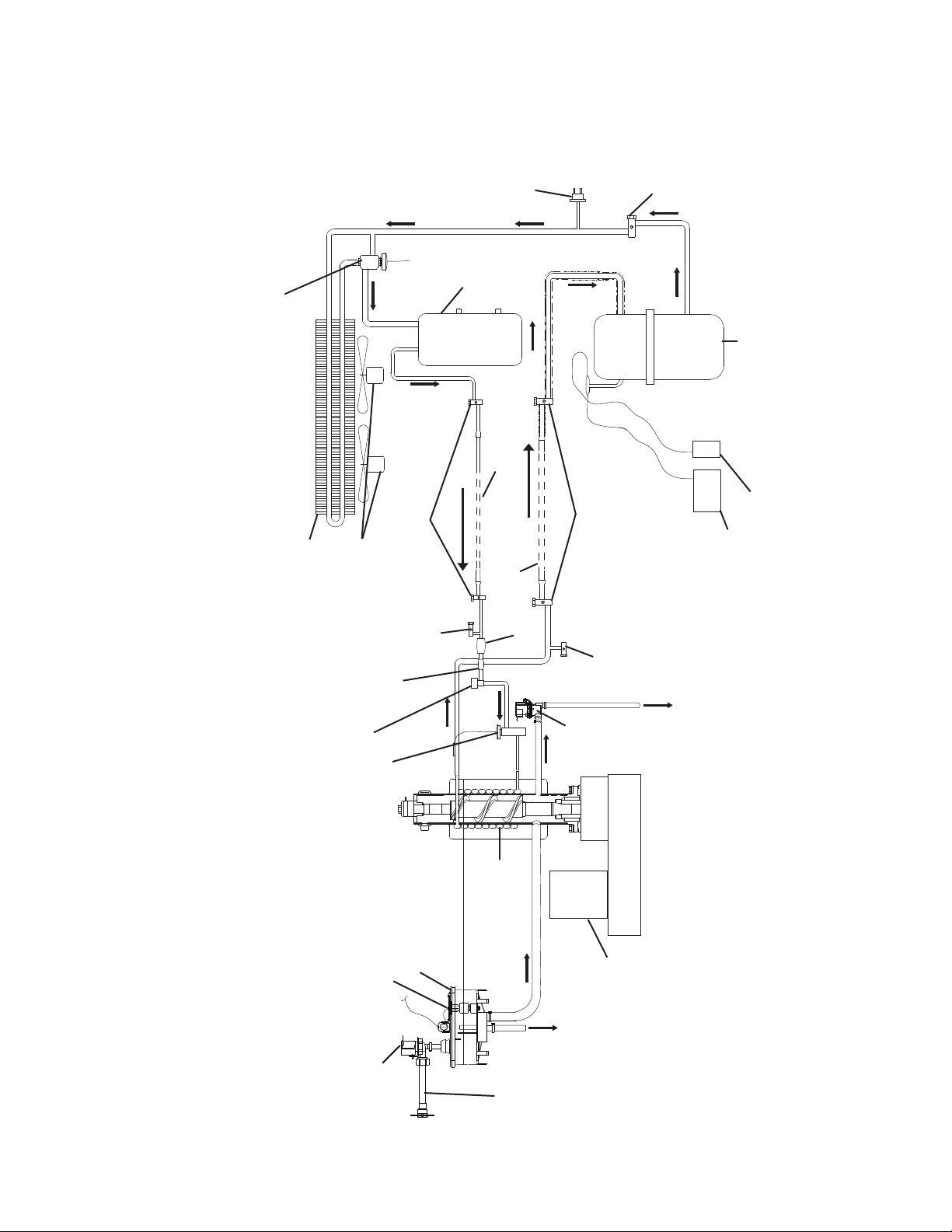

B. Water/Refrigeration Circuit Diagram .............................................................................11

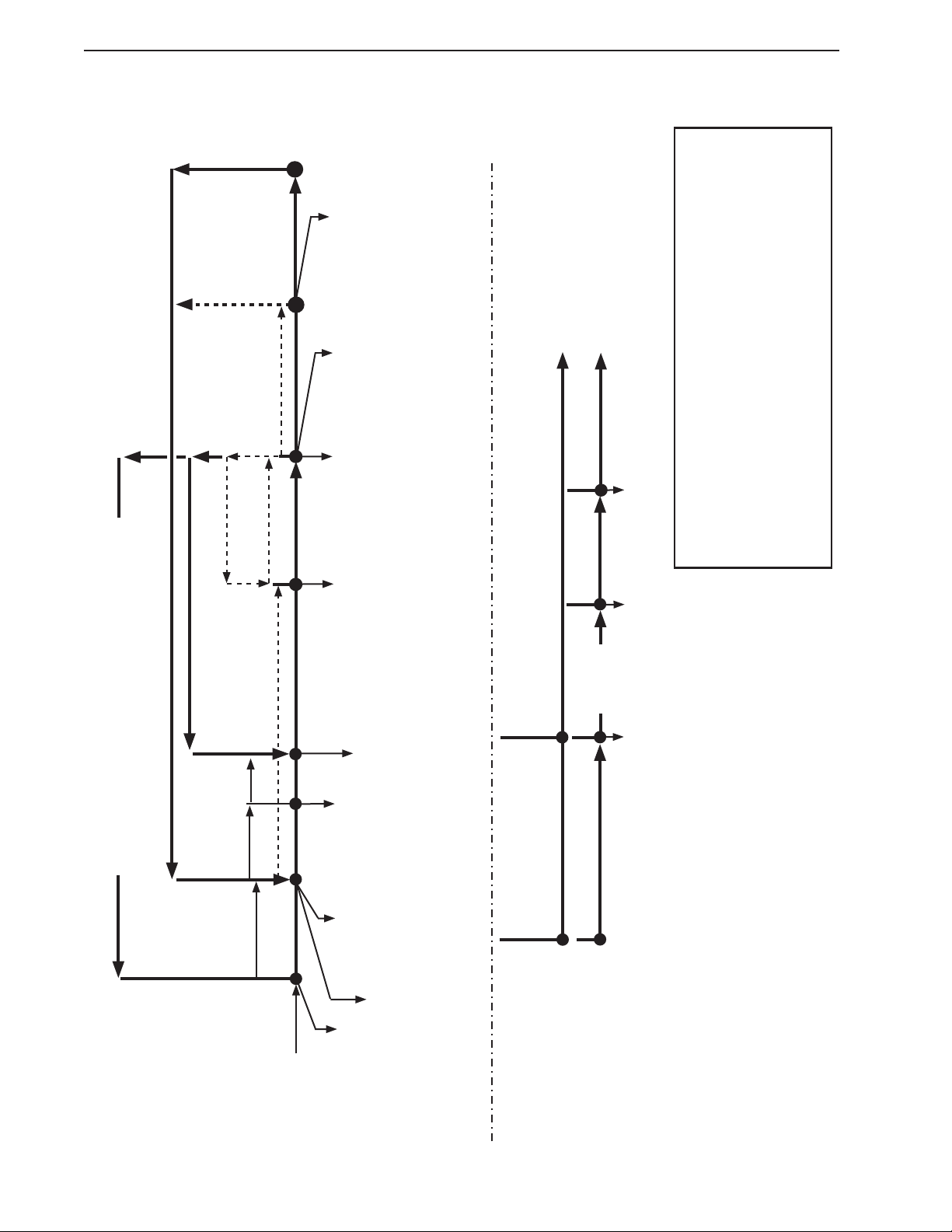

II. Sequence of Operation and Service Diagnosis ............................................................... 12

A. Sequence of Operation Flow Chart ............................................................................. 12

1. Operation Flow Chart ............................................................................................. 12

2. Shutdown Flow Chart ............................................................................................ 13

B. Service Diagnosis ....................................................................................................... 14

C. Control Board Check ................................................................................................... 21

D. Bin Control Check ....................................................................................................... 26

E. Power Switch and Control Switch ................................................................................ 28

1. Power Switch .......................................................................................................... 28

2. Control Switch ........................................................................................................ 28

F. Float Switch Check and Cleaning ................................................................................ 29

G. Diagnostic Tables ........................................................................................................ 31

III. Controls and Adjustments ............................................................................................... 34

A. Control Board .............................................................................................................. 34

1. Control Board Layout ............................................................................................. 35

2. LED Lights and Audible Alarm Safeties ................................................................. 36

3. Ice Purge Cycle Bypass ......................................................................................... 36

B. Controls and Adjustments ........................................................................................... 37

1. Default Dip Switch Settings .................................................................................... 37

2. BC (Infrared Sensor) Shutdown Delay (S1 dip switch 1, 2, 3) .............................. 38

3. Drain Frequency Control (S1 dip switch 4) ............................................................ 38

4. Continuous Dispensing Timer (S1 dip switch 5 & 6) .............................................. 38

5. Bin Control Selector (S1 dip switch 7) ................................................................... 39

6. BC (Mech. Stand-Alone or Backup (only)) Shutdown Delay (S1 dip switch 8) ...... 39

7. Shutdown Sequence (S1 Dip Switch 9) ................................................................. 39

8. Factory Use (S1 Dip Switch 10) ............................................................................. 39

IV. Refrigeration Circuit and Component Service Information.............................................. 40

A. Refrigeration Circuit Service Information .................................................................... 40

B. Component Service Information .................................................................................. 43

V. Maintenance .................................................................................................................... 52

VI. Disposal .......................................................................................................................... 54

3

Page 4

VII. Technical Information ..................................................................................................... 55

A. Specication and Performance Data Sheets ............................................................... 55

1. FS-1001MLJ-C with SRC-10J ................................................................................ 55

2. FS-1022MLJ-C with SRC-10J ................................................................................ 56

3. FS-1500MLJ-C with SRC-14J ............................................................................... 57

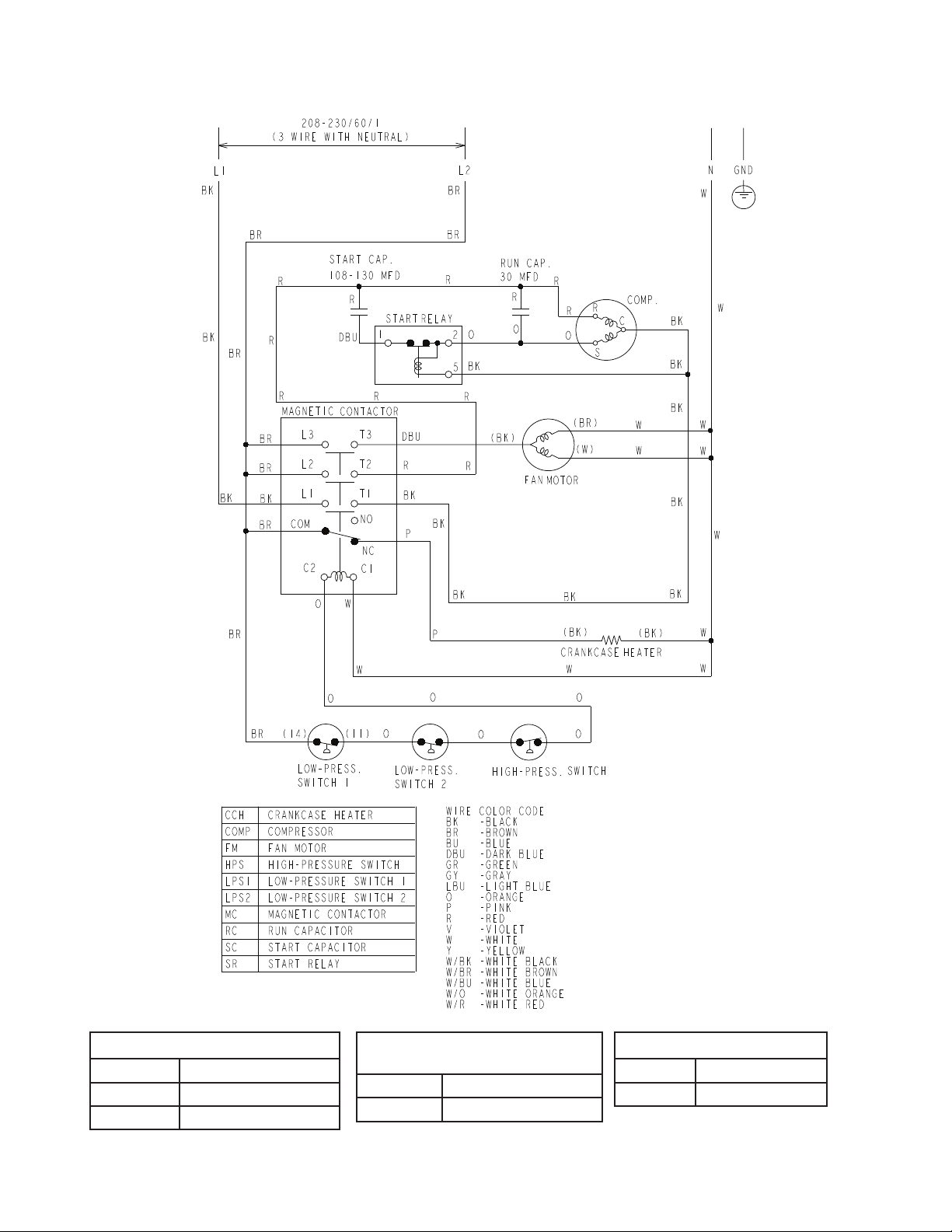

B. Wiring Diagrams .......................................................................................................... 58

1. FS-1001MLJ-C and FS-1022MLJ-C ...................................................................... 58

2. FS-1500MLJ-C ...................................................................................................... 59

3. SRC-10J Condensing Unit .................................................................................... 60

4. SRC-14J Condensing Unit .................................................................................... 61

4

Page 5

Important Safety Information

Throughout this manual, notices appear to bring your attention to situations which could

result in death, serious injury, damage to the appliance, or damage to property.

WARNING Indicates a hazardous situation which could result in death or

serious injury.

NOTICE Indicates a situation which could result in damage to the

appliance or property.

IMPORTANT Indicates important information about the use and care of the

appliance.

WARNING

The appliance should be destined only to the use for which it has been expressly

conceived. Any other use should be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for injury or damage resulting from

improper, incorrect, and unreasonable use. Failure to service and maintain the

appliance in accordance with this manual will adversely affect safety, performance,

component life, and warranty coverage and may result in costly water damage.

To reduce the risk of death, electric shock, serious injury, or re, follow basic

precautions including the following:

• Only qualied service technicians should install and service the appliance.

• The appliance must be installed in accordance with applicable national, state, and

local codes and regulations. Failure to meet these code requirements could result in

death, electric shock, serious injury, re, or damage to the appliance.

• The appliance must be installed in accordance with applicable national, state, and

local codes and regulations.

• To reduce the risk of electric shock, do not touch the icemaker power switch or plug

with damp hands. Make sure the icemaker power switch is in the "OFF" position

before plugging in or unplugging the icemaker.

• Before Servicing: FS: Move the icemaker's power switch to the "OFF" position.

Unplug the icemaker from the electrical outlet. SRC: Turn off the power supply

to the remote condensing unit. Place the disconnect (if applicable) in the off

position. Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

• Do not make any alterations to the icemaker or condensing unit. Alterations could

result in electric shock, injury, re, or damage to the appliance.

5

Page 6

WARNING, continued

FS

• The icemaker requires an independent power supply of proper capacity. See the

nameplate for electrical specications. Failure to use an independent power supply

of proper capacity can result in a tripped breaker, blown fuse, damage to existing

wiring, or component failure. This could lead to heat generation or re.

• THE ICEMAKER MUST BE GROUNDED. The icemaker is equipped with a

NEMA5-15 three-prong grounding plug

hazards. It must be plugged into a properly grounded, independent 3-prong wall

outlet. If the outlet is a 2-prong outlet, it is your personal responsibility to have

a qualied electrician replace it with a properly grounded, independent 3-prong

wall outlet. Do not remove the ground prong from the power cord and do not use

an adapter plug. Failure to properly ground the icemaker could result in death or

serious injury.

• Do not use an extension cord.

• Do not use an icemaker with a damaged power cord. The power cord should not be

altered, jerked, bundled, weighed down, pinched, or tangled. Such actions could

result in electric shock or re. To unplug the icemaker, be sure to pull the plug, not

the cord, and do not jerk the cord.

• Do not place ngers or any other objects into the ice discharge opening.

to reduce the risk of potential shock

SRC

• The remote condensing unit requires an independent power supply of proper

capacity. See the nameplate for electrical specications. Failure to use an

independent power supply of proper capacity can result in a tripped breaker, blown

fuse, damage to existing wiring, or component failure. This could lead to heat

generation or re.

• Electrical connection must be hard-wired to the remote condensing unit and must

meet national, state, and local electrical code requirements. Failure to meet these

code requirements could result in death, electric shock, serious injury, re, or

damage.

• THE REMOTE CONDENSER UNIT MUST BE GROUNDED. The power supply and

ground connection to the remote condenser unit are supplied from the icemaker.

Failure to properly ground the remote condenser unit could result in death or

serious injury.

• Wire routing (conduit) and disconnect (if required) must meet national, state, and

local electrical code requirements. Failure to meet these code requirements could

result in death, electric shock, serious injury, re, or damage.

6

Page 7

NOTICE

• Follow the instructions in this manual carefully to reduce the risk of costly water

damage.

• In areas where water damage is a concern, install in a contained area with a oor

drain.

• Install the appliance in a location that stays above freezing. Normal operating

ambient temperature must be within 45°F to 100°F (7°C to 38°C).

• Do not leave the icemaker on during extended periods of non-use, extended

absences, or in sub-freezing temperatures. To properly prepare the icemaker for

these occasions, follow the instructions provided in the instruction manual.

• Do not place objects on top of the appliance.

• The dispenser unit/ice storage bin is for ice use only. Do not store anything else in

the dispenser unit/ice storage bin.

7

Page 8

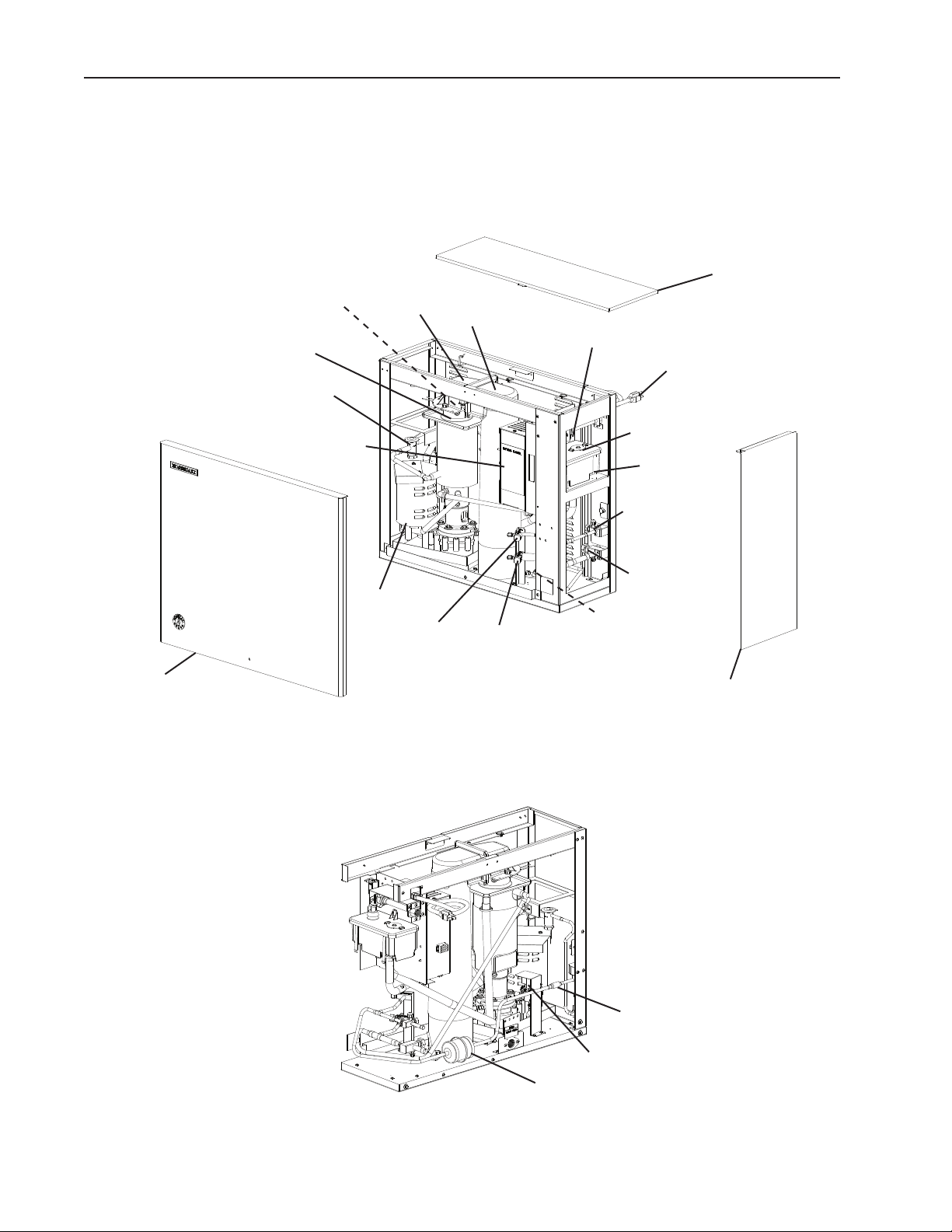

I. Construction and Water/Refrigeration Circuit Diagram

A. Construction

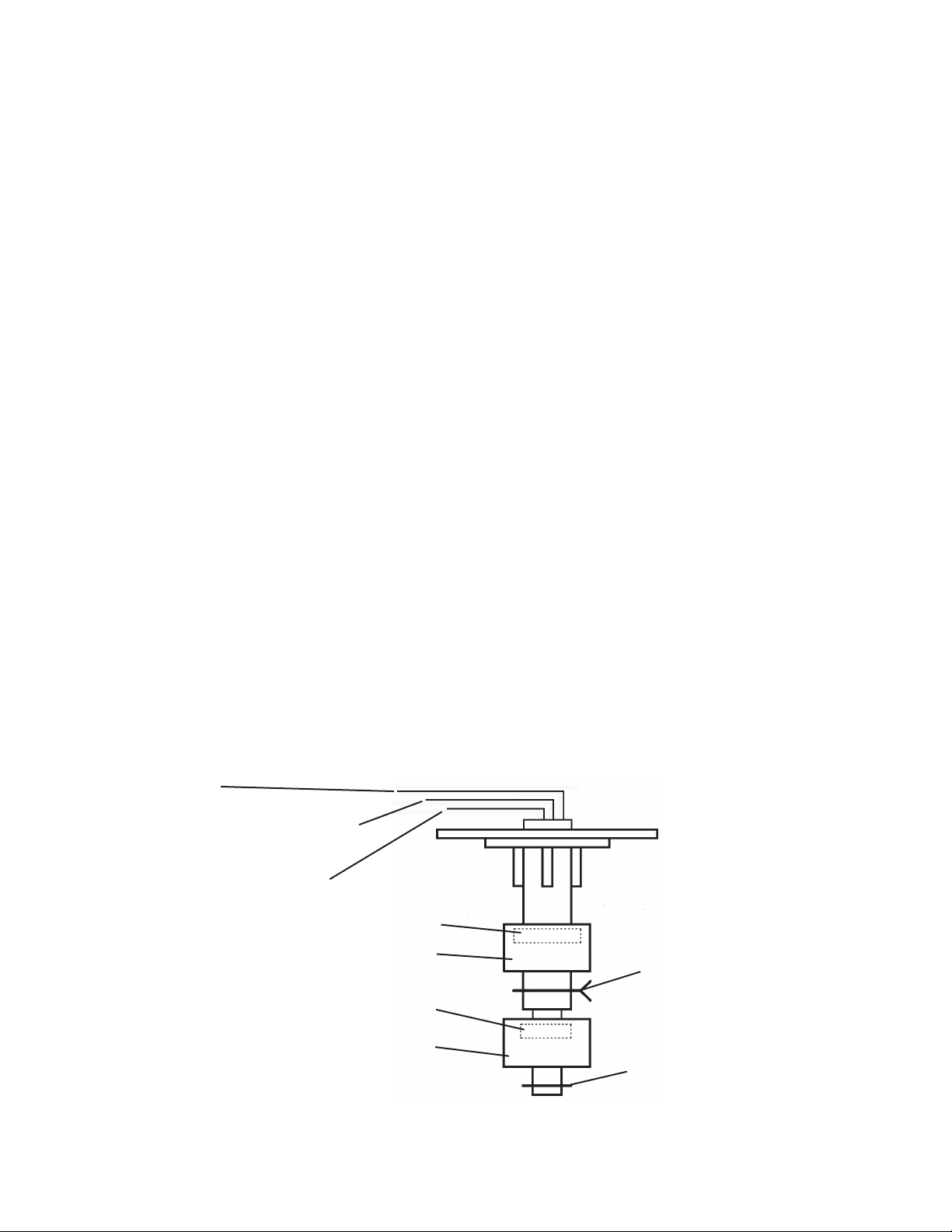

1. Icemaker

Front View

Front Panel

Cutter, Extruding Head,

Evaporator

Evaporator

Heater

Thermostatic

Expansion Valve

Control Box

Spout

Gear Motor

Liquid Line

Service Valve

Ice Chute

Inlet Water Valve

Suction Line

Service Valve

Top Panel

Power Cord

Float Switch

Reservoir

Liquid Line

Shutoff Valve

Suction Line

Shutoff Valve

BC

(infrared sensor)

Right Side

Panel

Rear View

Drier

Model Shown: FS-1001MLJ-C

8

Strainer

Drain Valve

Page 9

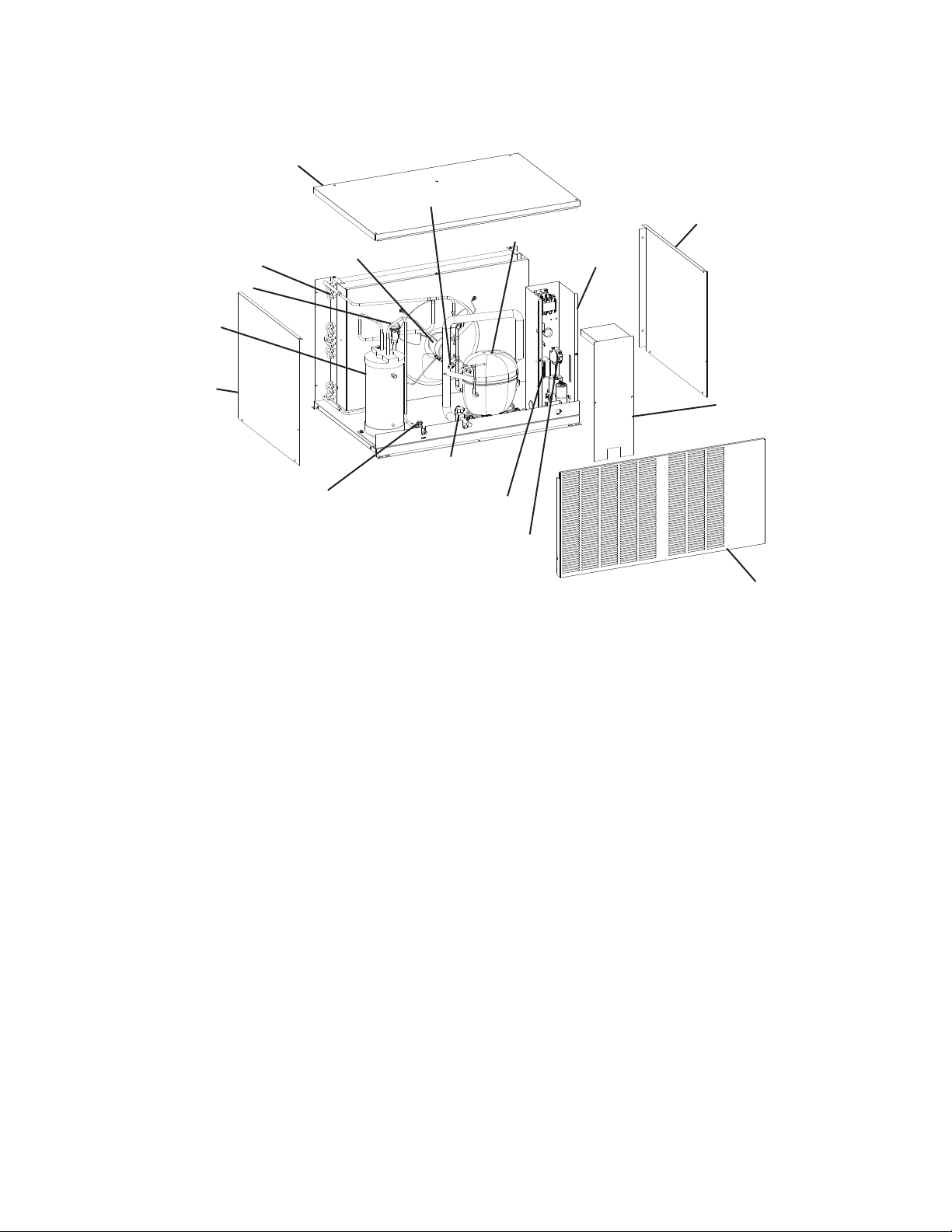

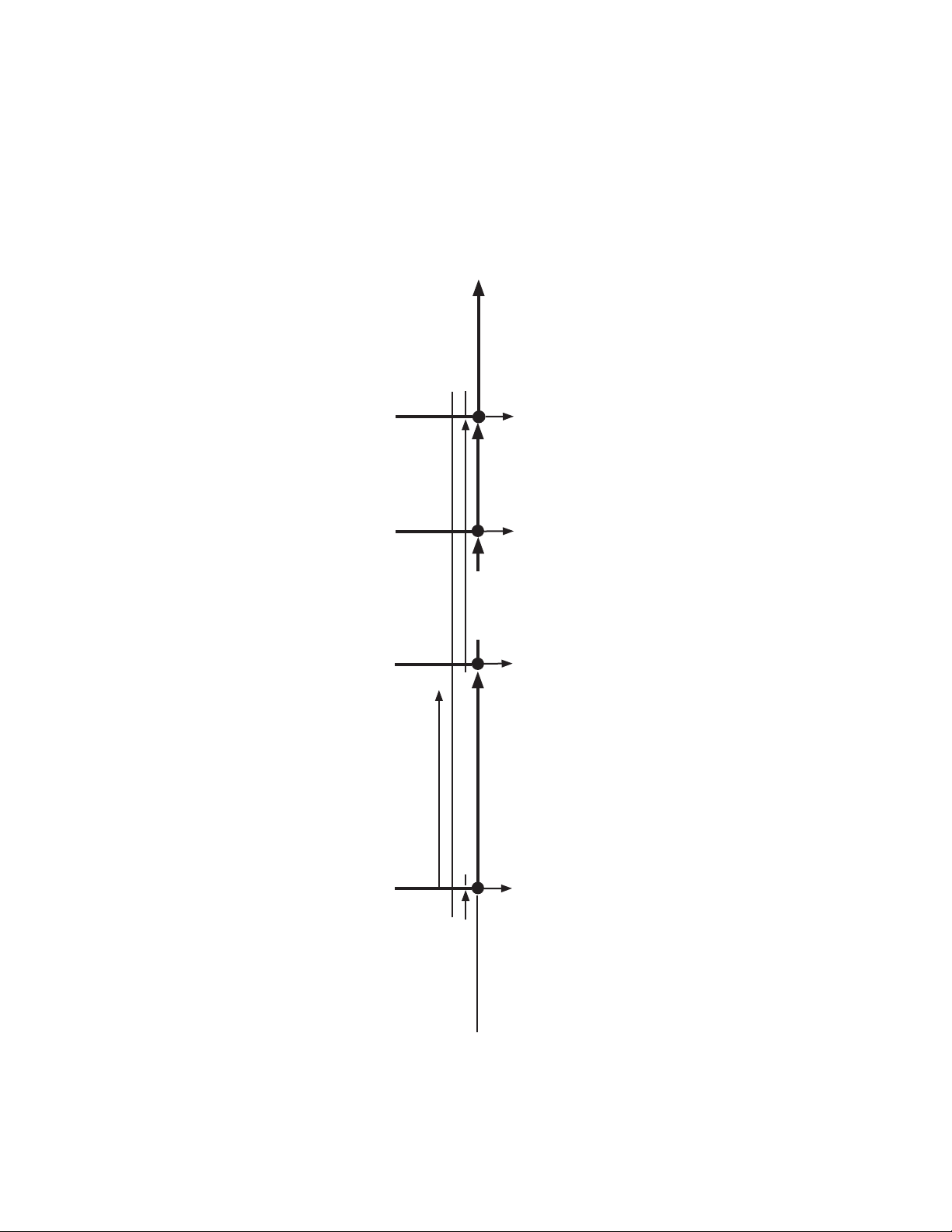

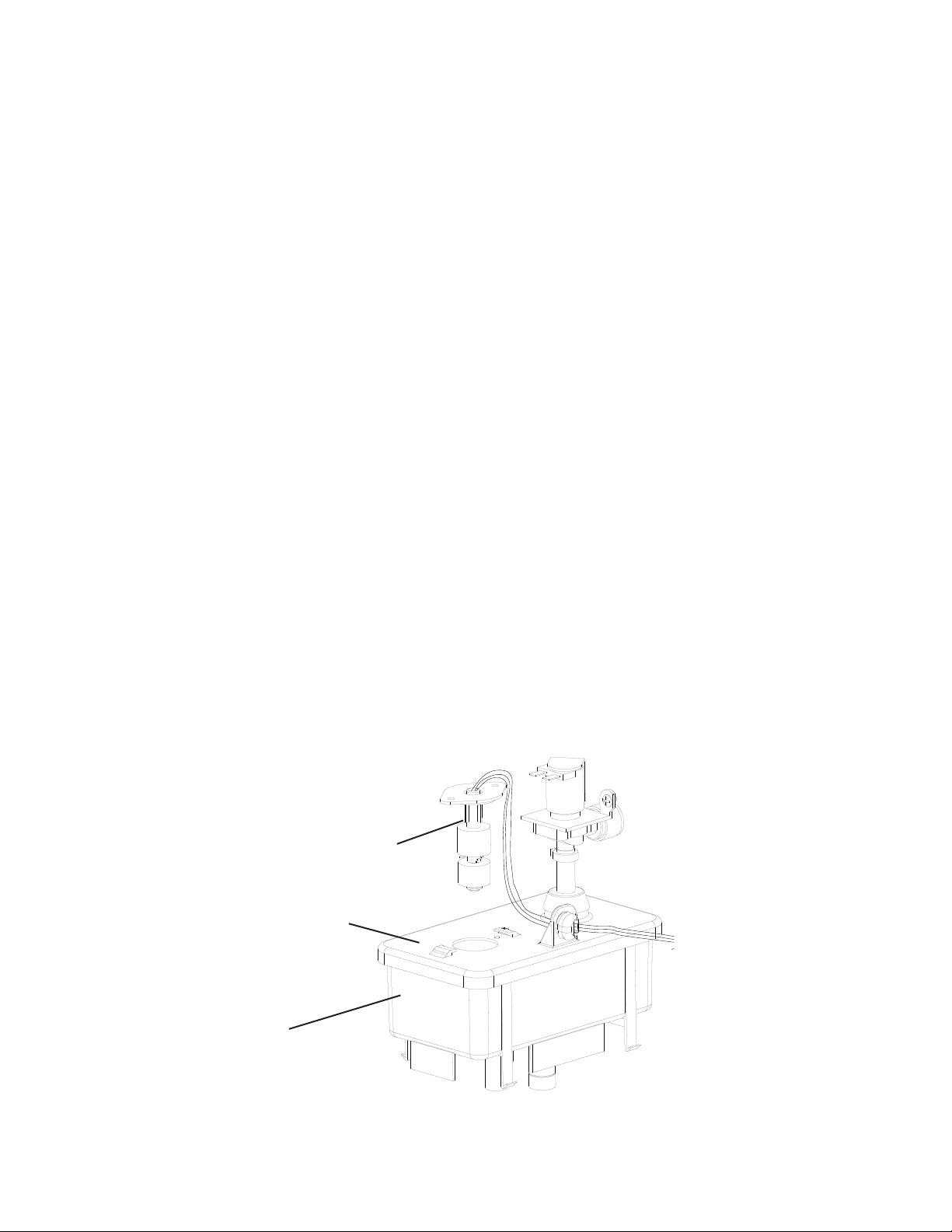

2. Condensing Unit

a) SRC-10J

Top Panel

Condenser

Headmaster (C.P.R.)

Receiver

Left Side Panel

b) SRC-14J

Fan Motor

Liquid Line

Shutoff Valve

Top Panel

High-Pressure Switch

Right Side Panel

Compressor

Control Box

Control Box Cover

Suction Line

Shutoff Valve

Control Low-Pressure

Switch

Safety Low-Pressure

Switch

Louver Panel

Condenser

Headmaster (C.P.R.)

Receiver

Left Side Panel

Fan Motors

Data Pending

High-Side

Service Valve

Compressor

Low-Side

Service Valve

Control Low-Pressure Switch

High-Pressure Switch

Right Side Panel

Control Box

Control Box Cover

Louver Panel

Safety Low-Pressure Switch

9

Page 10

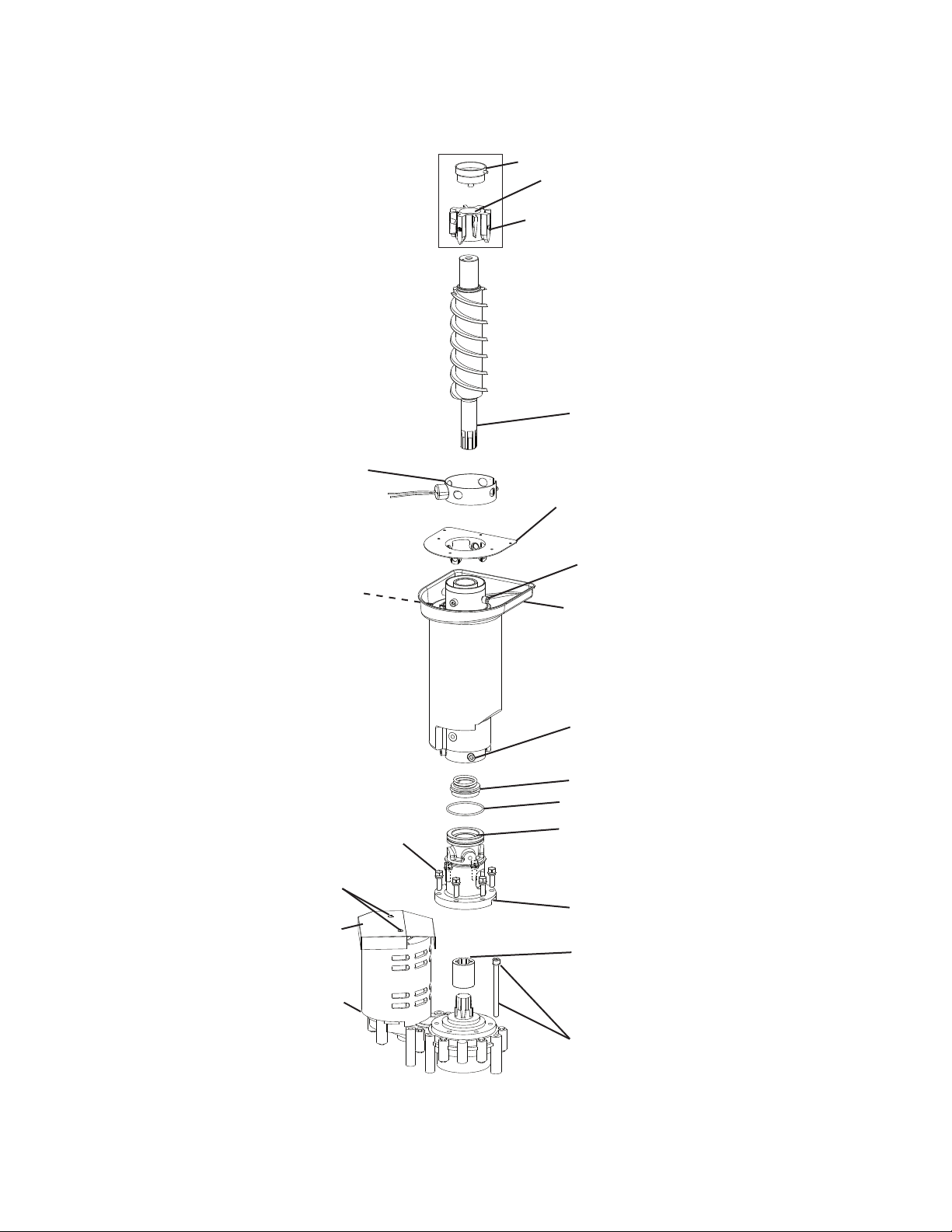

3. Icemaking Unit

Cutter

Extruding Head-Upper Bearing

Evaporator Heater (-C Models)

Drip Pan

Auger

Cylinder

Mechanical-Seal

O-Ring

Lower Housing

Seal Bolt

Insulation

Socket Head Cap Screw

with Split Lock Washer

Hex Bolt and Washer

Spline Coupling

Gear Motor

Model Shown: FS-1500MAJ-C

10

Page 11

B. Water/Refrigeration Circuit Diagram

Receiver

Headmaster (C.P.R.)

High-Pressure

Switch

Discharge Line

Shutoff Valve

SRC

FS

Condenser

Pump-Down

Fan Motors

Solenoid Valve

Liquid Line

Shutoff Valve

Liquid Line

Service Valve

Strainer

Liquid Line

Suction Line

Drier

Suction Line

Shutoff Valve

Suction Line

Service Valve

Drain

Valve

Control Low-Pressure Switch

Drain Outlet

Compressor

Safety Low-Pressure Switch

Inlet

Water

Expansion Valve

Float Switch

Valve

Reservoir

Evaporator

Water Level

Gear

Motor

Overow

Water

Supply

Line

11

Page 12

II. Sequence of Operation and Service Diagnosis

A. Sequence of Operation Flow Chart

1. Operation Flow Chart

WV continues

GM de-energized

Low Water Safety

Shutdown

90. sec. PT terminates

unit shuts down and

1-beep alarm continues.

When UFS closes, alarm

resets and 2. Ice Purge

Cycle starts.

Normal Operation

UFS open

WV energized

PDS de-energized

(CLPS opens)

Comp de-energized

FMR de-energized

GM continues

90 sec.

90 sec. FT exceeded, 90

sec. PT starts and 1-beep

Purge Timer

Rell

alarm sounds

FT Maximum

90 sec.

LFS closed

FT off (90 sec.)

UFS closed

FZT starts (30 min.)

FT terminated

WV de-energized

Comp continues

EH continues

FMR continues

GM continues

PDS continues

Low Water Safety

FMR-fan motor-remote

FT-ll timer (low water safety)

FZT-freeze timer

GM-gear motor

LFS-lower oat switch

PDS-pump-down solenoid valve

PT-purge timer

UFS-upper oat switch

WV-inlet water valve

to "1. Fill Cycle" above

4. Icemaker Restart

10-min. DT terminated

DV de-energized

1-in-12 DT reset

Legend:

BC-bin control (infrared sensor)

CB-control board

CCH-crankcase heater

CLPS-control low-pressure switch

Comp-compressor

DC-drain cycle

DT-drain timer

DV-drain valve

EH-evaporator heater

3. 10-Min. Drain

UFS open

LFS open (WV on)

FT starts (90 sec.)

FZT terminated

WV energized

Comp continues

EH continues

FMR continues

GM continues

PDS continues

DV energized

GM de-energized

Operation Flow Chart

4. 1-in-12 Drain Cycle - Although the factory default 1-in-1 drain cycle

is recommended, a 1-in-12 drain cycle is available. For 1-in-12 drain cycle

sequence, see "3. 1-in-12 Hour Drain Cycle & Restart (optional)."

3. Freeze Cycle

2. Ice Purge Cycle

1. Fill Cycle

1-in-1 drain cycle. DV opens for 2 sec.

every hour (CB S1 Dip Switch 4).

To bypass, press the

"SERVICE" button after

30-min. FZT

DV de-energizes, no interruption

in ice production

2. Continued Operation

FZT exceeded (LFS does not

open): CB shuts down icemaker

Icemaker status does not change.

5 min.

GM starts.

5 or 30 sec.

(S1 Dip Switch 7)

and sounds a 5-beep alarm.

PDS energized

CLPS closed

Comp energized

FMR energized

EH continues

GM continues

EH energized

GM energized

DV energizes for 2 sec.

1. DT Initiates DC

Continued uninterrupted

operation

LFS closed

UFS closed

FZT starts

FT terminated

WV de-energized

FT Maximum

90 sec.

5 min.

2. Ice Purge Cycle

1. DT Initiates DC

Comp de-energized

FMR de-energized

PDS de-energized

GM continues

1. Startup

Power Switch "ON"

Control Switch in "ICE"

POWER OK LED on

BC Green LED on

If Fill > 90 sec. FT

1-beep alarm sounds

WV continues

When UFS closes

alarm resets and

Startup

WV energized

BC Yellow LED off

2. Ice Purge Cycle starts.

2. 1-in-1 Drain Cycle

(CB S1 dip switch 4 "OFF")

& Restart (optional)

(CB S1 dip switch 4 "ON")

3. 1-in-12 Drain Cycle

Note: CCH energizes when power is supplied to SRC.

CCH de-energizes when Comp is energized.

See "VII.B.3. SRC-10J Condensing Unit."

12

Page 13

2. Shutdown Flow Chart

to "2. Ice Purge Cycle" in

Icemaking and Drain Cycle

Chart

BC Green LED on

BC Yellow LED off

4. Icemaker Restart

BC de-activated

3. Icemaker Off

GM de-energized

EH continues

5 min.

2. Ice Purge Cycle

PDS de-energized

(CLPS opens)

Comp de-energized

FMR de-energized

GM continues

EH continues

Shutdown Flow Chart

1. Bin Full

BC delay determined by CB S1 dip

BC Yellow LED (ashing or steady)

switch 1, 2, 3

BC activated

1. BC (infrared sensor) Shutdown

BC Green LED on

BC Yellow LED off

If BC fails to shutdown the icemaker.

See "II.D. Bin Control Check."

13

Page 14

B. Service Diagnosis

WARNING

• The appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Risk of electric shock. Use extreme caution and exercise safe electrical practices.

• Moving parts (e.g., fan blade) can crush and cut. Keep hands clear.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the appliance is serviced. Make sure that none have fallen

into the dispenser unit/storage bin.

• Make sure all food zones in the icemaker and dispenser unit/storage bin are clean

after the unit is serviced.

1. Ice Production Check

To check production, prepare a bucket or pan to catch the ice and a set of scales to

weigh the ice. After the appliance has operated for 10 to 20 min., catch the ice production

for 10 min. Weigh the ice to establish the batch weight. Multiply the batch weight by

144 for the total production in 24 hours. When conrming production or diagnosing

low production, reference production information found in "VII.A. Specication and

Performance Data Sheets."

14

Page 15

2. Diagnostic Procedure

This diagnostic procedure is a sequence check that allows you to diagnose the electrical

system and components. Before proceeding, check for correct installation, proper voltage

per appliance nameplate, and adequate water pressure (10 PSIG to 113 PSIG). Check

that both the 24VAC circuit fuse and the 115VAC GM fuse are good.

Note: • When checking high voltage (115VAC), always choose a neutral (W) wire to

establish a good neutral connection.

• When checking low voltage (24VAC), always choose a neutral (LBU) wire to

establish a good neutral connection.

• When checking control board DC voltage (5VDC), always place the red positive

test lead from the multimeter to CB K5 pin closest to CB K4 connector.

See "II.C. Control Board Check."

• When checking BC (infrared sensor) (20VDC), check that BC (infrared sensor)

green LED is on. This green LED conrms 20VDC power from CB K6to BC

(infrared sensor) and remains on constantly. If green LED is not on, check for

20VDC from CB K6 #1 (DBU) to CB K6 #3 (BR).

See "II.D. Bin Control Check."

• To speed up the diagnostic process, the 5-min. ice purge cycle may be bypassed

by pressing the "SERVICE" button on the control board after the gear motor

starts. WARNING! Risk of electric shock. Care should be taken not to touch

live terminals.

• If the icemaker is in alarm, see "III.A.2. LED Lights and Audible Alarm Safeties."

• EH energizes when "GM" LED turns on.

• CB X1 relay energizes PDS. After PDS energizes, CPLS closes, then MC

energizes, energizing Comp and FMR.

• CB monitors the following switches with 5VDC during the icemaking process:

Control Switch (CS), Compressor Control Relay (CCR), Float Switch (FS). When

5VDC is present across any of these switches, the switch is open.

1) Remove the front panel, then move the power switch to the "OFF" position. Move the

control switch to the "DRAIN" position, then move the power switch back to the "ON"

position. Replace the front panel in its correct position.

2) Allow the water system to drain for 5 min.

3) Remove the front panel. Move the power switch to the "OFF" position, then unplug the

appliance from the electrical outlet.

4) Remove the control box cover and access CB.

5) Check the CB S1 dip switch settings, see "III.B.1. Default Dip Switch Settings" to assure

that they are in the correct positions. For proper operation of BC (infrared sensor),

conrm that S1 dip switch 7 is in the "ON" position.

15

Page 16

6) Startup – CB "POWER OK" LED is on. Plug the icemaker back into the electrical

outlet, then move the power switch to the "ON" position. Move the control switch to the

"ICE" position. CB "POWER OK" LED and BC green LED turn on.

Diagnosis CB "POWER OK" LED: If CB"POWER OK" LED is off, check for proper

supply voltage (115VAC) input to CT. If 115VAC is not present, check the power switch

and breaker. Next, check for proper 24VAC output voltage from CT. Check CBK8

#1 (W/R) to #2 (LBU) for 24VAC. If 24VAC is not present and 1A 24VAC fuse is good,

replace CT. If 24VAC is present and CB "POWER OK" LED is off, replace CB.

Diagnosis BC (infrared sensor): Check that BC green LED is on. If CB "POWER

OK" LED is on and BC green LED is off, check CB K6 #1 (DBU) to CB K6 #3 (BR)

for 20VDC. If20VDC is not present, conrm S1 dip switch 7 is in the "ON" position.

IfS1dip switch 7 is in the "ON" position and 20VDC is not present, replace CB. IfBC

yellow LED is on or ashing, move ice away from lens. If no ice is present, clean the

lens with a warm, clean damp cloth. If BC yellow LED is still on or ashing after cleaning

the lens, replace BC.

7) Fill Cycle – "WTRIN" LED is on. Reservoir is empty and LFS and UFS are open.

FTstarts. WV energizes and ll cycle starts. LFS closes. Nothing happens at this time.

Reservoir continues to ll until UFS closes. When UFS closes, FT terminates, WV

de-energizes and CB "WTRIN" LED turns off. FZTand 30-sec. GM delay timer start.

IfUFS remains open longer than 90 sec. after LFS opens, FTexceeded and CB sounds

a 1-beep alarm. WVremains energized until UFS closes. Alarm resets automatically

when UFS closes. Diagnosis: If reservoir is empty and "WTRIN" LED is off, conrm

LFS status.

See "II.F.1. Float Switch Check." If LFS is open and "WTRIN" LED is off, replace

CB. If"WTRIN" LED is on, check that the reservoir lls. If not, check water supply

line shut-off valve, water lters, and WVscreen. If "WTRIN" LED is on and WV is off,

check CB K2 #8(O) to a neutral (LBU) for 24VAC. If 24VAC is not present, check CB

K2#9(W/R) to a neutral (LBU) for 24VAC. If 24VAC is present on CB K2 #9(W/R)and

not on CB K2 #8 (O), replace CB. If 24VAC is present on CB K2 #8(O), check

continuity through WV solenoid. If open, replace WV. If WV is energized and rell

exceeds FT with no water in the reservoir, check for DV leaking. Ifreservoir is full and

overowing check for open UFS. See "II.F.1. Float Switch Check." If UFS is closed,

check that WV de-energizes. If not, check CB K2 #8 (O) to a neutral (LBU) for 24VAC.

If 24VAC is present, replace CB. IfWV de-energizes and water continues to ll the

reservoir, replace WV.

16

Page 17

8) Ice Purge Cycle – "GM" LED is on. 30-sec. GM delay timer terminates, GM, EH,

and CCR energize. Once CCR energizes, 5VDC circuit closes through CCR terminal

#3(W/O) and terminal #5 (W/O) and CB K9 #5 (W/O) and K9 #6 (W/O). After 5VDC

circuit closes, 5-min. ice purge timer starts. Tobypass the 5-min. Ice Purge Cycle, press

the "SERVICE" button on CB after the "GM" LED turns on. WARNING! Risk of electric

shock. Care should be taken not to touch live terminals.

Diagnosis: If "GM" LED is off, check that UFS closes and WV de-energizes. If UFS

is closed, 30 sec. has passed, and "GM" LED remains off, replace CB. If "GM" LED is

on and GM is off, check CB K1 #3 (BK) to a neutral (W) for 115VAC. If 115VAC is not

present, check 115VAC power supply. If 115VAC is present, check CB K1 #2(P) to a

neutral (W). If 115VAC is present on CB K1 #3 (BK) and not on CB K1 #2 (P), replace

CB. If 115VAC is present on CB K1 #2 (P), check GM fuse, GM internal protector,

GM windings and capacitor, and GM coupling between auger and GM. When GM

energizes, CCR energizes starting 5-min. ice purge timer.

9) Freeze Cycle – "COMP" and "GM" LEDs are on. Note: CB X1 relay energizes the

PDS (pump-down solenoid) not the MC (magnetic contactor). The 5-min. ice purge

timer terminates. GM, EH, and CCR continue. PDS energizes. Once the refrigeration

circuit low-side pressure reaches 29 PSIG, CLPS closes, energizingMC, MC then

energizes Comp and FMR. CCH de-energizes. Iceproduction starts 4 to 6 min. after

Comp energizes depending on ambient and water conditions. As ice is produced, the

water level in the reservoir drops. UFS opens. Nothing happens at this time. When LFS

opens, WV energizes and rell cycle begins, FZT terminates, and FTstarts.

FZT: 30-Min. Freeze Safety Timer – FZT starts when UFS closes and terminates

when LFS opens. If LFS does not open within 30 min. of UFS closing, CB shuts down

the icemaker and sounds a 5-beep alarm. See "III.A.2.LED Lights and Audible Alarm

Safeties." To reset, turn the power supply off and on again. See "II.G. Diagnostic Tables"

for troubleshooting details.

Icemaker Diagnosis (CCR): 5-min. ice purge timer terminates, CB "COMP" LED is

on and PDS energizes. If not, check for 5VDC between CB K5 connector pin closest

to CB K4 connector and CB K9connector #5(W/O). If 5VDC is not present, replace

CB. If 5VDC is present, check for 5VDC between CB K5 connector pin closest to CB

K4 connector and CB K9connector #6(W/O). If 5VDC is present and CB "Comp"

LED is off (PDS not energized), replace CB. If 5VDC is not present, check for 115VAC

between CCR terminal #7(O) to CCR terminal #8(W) for 115VAC. If115VAC is not

present (GM not energized), see step 8 above. If 115VAC is present and CCR contacts

are open (5VDCpresent between terminals #3(W/O) and #5(W/O)), check CCR

solenoid voltage and solenoid continuity. Replace CCR if necessary.

Icemaker Diagnosis (PDS): If"COMP" LED is on and PDS is not energized, check

CB X1 relay black (BK) wire to a neutral (W) and CB X1 relay violet (V) wire to a neutral

(W) for 115VAC. If115VAC is present on CB X1black (BK) wire and not on CBX1

violet(V) wire, replace CB. If115VAC is present on CBX1 violet(V) wire and PDS is

not energized, check for 115VAC at PDS (V) to a neutral (W) for 115VAC. If 115VAC is

present and PDS is not energized, check PDS solenoid for continuity. If open or if PDS

is sticking closed, replace PDS.

17

Page 18

Condensing UnitDiagnosis: Conrm that CLPS closes. Once CLPS closes, MC

energizes, energizing Comp and FMR. If not, check condensing unit 208-230VAC

power supply, breakers, disconnects. Next, conrm 115VAC from CLPS BK wire to

neutral (W). If 115VAC is not present, check wiring connections and power supply.

CLPS: When PDS is energized, CLPS closes when refrigeration circuit low-side

pressure reaches 29 PSIG. If CLPS is open, check that refrigeration circuit low-side

pressure has reached 29 PSIG. If refrigeration circuit low-side pressure is too low,

conrm proper TXV operation, check for refrigerant restrictions (drier, PDS), and correct

refrigerant charge. Recover, evacuate, and recharge if necessary. If refrigeration circuit

low-side pressure reaches 29 PSIG and CLPS does not close, replace CLPS.

SLPS: If SLPS is open, manually reset SLPS. If manually resetting SLPS does not

close contacts, replace SLPS. After resetting, conrm proper TXV operation, check for

refrigerant restriction (drier, PDS), and correct refrigerant charge. Recover, evacuate,

and recharge if necessary.

HPS: If HPS is open, HPS automatically resets when refrigeration circuit high-side

pressure is within an acceptable range. If HPS does not reset (open), allow pressures

to equalize and HPS to reset. If refrigeration circuit high-side pressure does not drop,

recover, evacuate, and recharge if necessary. Before restarting the appliance, check

for dirty or clogged condenser. Once the appliance is restarted, check for proper FMR

operation and fan blade for binding. Check receiver, service valves, PDS, and drier

for refrigeration circuit restriction. Also check for proper HM operation. If high-side

refrigerant pressures have returned to an acceptable range and HPS does not close,

replace HPS.

MC: If MC energizes and Comp does not energize, check for 115VAC at MC C2 (O) to

neutral (W). If 115VAC is not present, check CLPS, SLPS, and HPS contacts. If 115VAC

is present, check MC coil continuity. If open, replace MC. If closed, check MC L1 and

MCL2to a neutral (W) for 115VAC. If 115VAC is not present on either L1or L2, check

incoming power supply. If 115VAC is present on both L1 and L2 and Comp does not

start, check MC T1 (BK) to MC T2 (R) for 208-230VAC. If 208-230VAC is not present,

replace MC. If 208-230VAC is present, check Comp start relay, start capacitor, run

capacitor, and Comp motor windings. If FMR does not energize, check MC T3 (DBU) to

a neutral (W) for 115VAC. If 115VAC is present and FMR does not energize, check fan

motor capacitors and motor windings. If 115VAC is not present, replace MC.

18

Page 19

10) Rell Cycle – "GM", "COMP", and "WTRIN" LEDs are on.

LFS opens. WVenergizes and FT starts. GM, CCR, EH, PDS, MC, Comp, and FMR

continue. LFS closes. Nothing happens at this time. Reservoir continues to ll until UFS

closes. When UFS closes, WV de-energizes, FT terminates, and FZT starts. IfUFS

remains open longer than 90 sec. after LFS opens, FT exceeded and CB sounds a

1-beep alarm. WVremains energized until UFS closes. Alarm resets automatically when

UFS closes.

Diagnosis – Conrm that the water level has dropped and the UFS and LFS are open.

See "II.F.1. Float Switch Check." Check that "WTRIN" LED is on. IfLFS is open and

"WTRIN" LED is off, replace CB. If "WTRIN" LED is on, check that the reservoir lls.

Ifnot, check water supply line shut-off valve, water lters, and WVscreen. If"WTRIN"

LED is on and WV is off, check CB K2 #8(O) to a neutral (LBU) for 24VAC. If 24VAC is

not present, check CB K2 #9(W/R) to a neutral (LBU) for 24VAC. If 24VAC is present

on CB K2 #9 (W/R)and not on CB K2#8 (O), replace CB. If 24VAC is present on

CB K2#8(O),check continuity through WV solenoid. If open, replace WV. If WV is

energized and rell exceeds FT with no water in the reservoir, check for DV leaking. If

reservoir is full and overowing check for open UFS. See "II.F. Float Switch Check and

Cleaning." If UFS is closed, check that WVdeenergizes. If not, check CB K2 #8 (O)

to a neutral (LBU) for 24VAC. If 24VAC is present, replace CB. If WV de-energizes and

water continues to ll the reservoir, replace WV.

FT: 90-Sec. Low Water Safety Timer – When LFS opens, 90-sec. low water safety

timer starts. If UFS does not close within 90 sec. after LFS opens (FTexceeded),

CBsounds a 1-beep alarm and a 90-sec. shutdown cycle starts.

See "III.A.2.LED Lights and Audible Alarm Safeties." PDS de-energizes. Refrigeration

circuit low-side pressure drops to 9PSIG, opening CLPS. CLPS opens, de-energizing

MC, which de-energizes Comp and FMR. GM, CCR, and EH continue. 90-sec. purge

timer terminates, GM, EH, and CCR de-energize. WV and 1-beep alarm continue until

UFS closes.

19

Page 20

11) Drain Cycle

a) 1-in-1 Drain Cycle: DV energizes once every hour when the 1-in-1 drain cycle is

activated (S1 dip switch 4 in the "OFF" position (factory default position)).

GM and PDS continue. DV energizes for 2 sec. every hour. This setting is recommended

for optimum icemaker performance. The 1-in-1 drain cycle allows any sediment to drain

from the evaporator without interrupting the icemaking process.

b) 1-in-12 Drain Cycle (optional): DV energizes once every 12 hours when the 1-in-12

drain cycle is activated (S1 dip switch 4 in the on position (optional)). 12-hour drain

cycle timer terminates, PDS de-energizes, GM continues. The 5-min. ice purge timer

starts. When the 5-min. ice purge timer terminates, GM de-energizes. 10-min. DT starts,

DV energizes. After 10-min. DT terminates, DV de-energizes and 12-hour drain cycle

timer starts. Icemaking cycle starts.

c) Manual Drain: Manual drain is used when servicing evaporator components and

cleaning and sanitizing the unit. When the unit is making ice and the control switch is

moved to the "DRAIN" position, there is a 3-sec. delay, then PDS de-energizes and

the 5-min. ice purge timer starts. When the 5-min. ice purge timer terminates, GM

de-energizes. DV energizes to drain the evaporator and reservoir. To avoid the 5-min.

shutdown delay, turn off the power supply, then move the control switch to the "DRAIN"

position. Turn on the power supply. DV energizes to drain the evaporator and reservoir.

DV de-energizes when the control switch is moved to the "ICE" position

12) Shutdown – BC (infrared sensor): When ice activates BC, yellow LED starts ashing

when ice is at the outer limit of its range and turns steady as ice nears. After BC

yellow LED turns on (ashing or steady), BC shutdown delay timer (S1 dip switch

1, 2, 3) starts. For a typical dispenser unit application, a 100-sec. shutdown delay

is recommended. When used with a standard Hoshizaki storage bin, any shutdown

delay setting is acceptable. See "III.B.2. BC (Infrared Sensor) Shutdown Delay (S1 dip

switch 1, 2, 3)." Once BC shutdown delay timer terminates, PDS de-energizes and the

5-min. ice purge timer starts. Unit is in pump-down mode. When the refrigerant low-side

pressure drops to 9PSIG, CLPS opens, MC de-energizes, de-energizing Comp and

FMR. CCH energizes. When the 5-min. ice purge timer terminates, GM, EH, CCR

de-energize. Icemaker Diagnosis: BC yellow LED not ashing or on with ice near.

See "II.D. Bin Control Check." PDS remains energized after BC shutdown delay timer

terminates. Check for 115VAC from CB X1 relay V wire to neutral (W). If 115VAC is

present, replace CB. If 115VAC is not present, check PDS for mechanical failure.

Condensing Unit Diagnosis: When PDS de-energizes and closes, pump-down starts.

Conrm refrigerant low-pressure drops to 9PSIG and CLPS opens. If refrigerant

low-pressure reaches 9 PSIG and CLPS does not open, replace CLPS. If Comp and

FMR remain energized after CLPS opens, replace MC.

Legend: BC–bin control (infrared sensor); CB–control board; CCH–crankcase heater;

CCR–compressor control relay; CLPS–control low-pressure switch;

Comp–compressor; DV–drain valve; EH–evaporator heater;

FMR–fan motor-remote; FT–90-sec. low water safety timer; FZT–30-min. freeze

safety timer; GM–gear motor; HM–headmaster (C.P.R.); HPS–high-pressure

switch; LFS–lower oat switch; MC–magnetic contactor; PDS–pump-down

solenoid valve; SLPS–safety low-pressure switch; UFS–upper oat switch;

WV–inlet water valve

20

Page 21

C. Control Board Check

2A8054-01

Before replacing a control board that does not show a visible defect and that you suspect

is bad, always conduct the following check procedure. This procedure will help you verify

your diagnosis.

1) Check CB S1 dip switch settings to assure that they are in the factory default position.

For factory default settings, see "III.B.1. Default Dip Switch Settings."

Note: S1 dip switch 7determines bin control application:

BC (infrared sensor): S1 dip switch 7in the "ON" position.

BC (mech. stand-alone or backup(only)) (Standard Ice Storage Bin): S1 dip switch

7 in the "OFF" position.

2) Move the power switch to the "ON" position and move the control switch to the "ICE"

position. The CB "POWER OK" LED turns on. Diagnosis "POWER OK" LED: Check

that the CB "POWER OK" LED is on. Ifnot, check for proper supply voltage (115VAC)

input to the control transformer (power switch, breaker, and fuse). Next, check for proper

low-voltage (24VAC) output from the control transformer and the 1A fuse is good. Check

for 24VAC at CB K8 #1 (W/R) to CB K8 #2(LBU). If 24VAC is present and CB "POWER

OK" LED is off, replace CB.

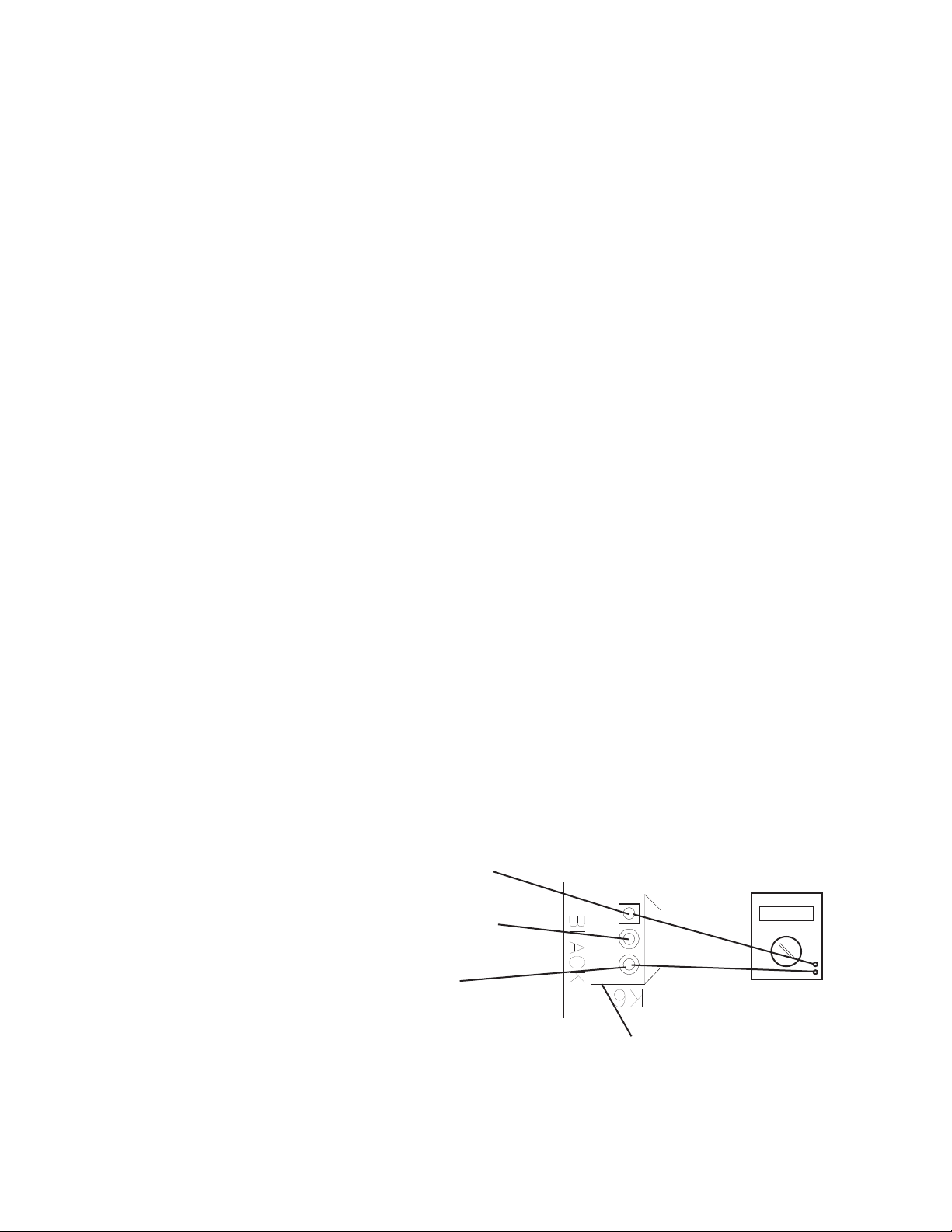

3) BC (infrared sensor) Power Supply (K6 connector): CB supplies 20VDC to BC

and BC green LED is on. Diagnosis: Check that BC green LED is on. If not, check

for 20VDC between CB K6 #1 (DBU) and CB K6 #3(BR). See Fig. 1. If 20VDC is not

present, replace CB. If 20VDC is present, conrm that the yellow LED is not ashing or

steady. If BC yellow LED is on or ashing, move ice away from lens. If no ice is present,

clean the lens with a warm, clean damp cloth. If cleaning the lens does not work,

replace BC (infrared sensor).

BC (infrared sensor) (20VDC)

Closed

20VDC K6 #1 (DBU) to K6 #3 (BR)

20VDC K6 #1 (DBU) to K6 #2 (W)

0VDC K6 #2 (W) to K6 #3 (BR)

BC (infrared sensor) (20VDC)

Open (yellow LED ashing or steady)

20VDC K6 #1 (DBU) to K6 #3 (BR)

0VDC K6 #1 (DBU) to K6 #2 (W)

20VDC K6 #2 (W) to K6 #3 (BR)

K6 #3

Brown (BR)

K6 #2

White (W)

K6 #1

Dark Blue (DBU)

21

Fig. 1

Red Positive

Test Lead

3

2

1

Black Negative

Test Lead

Multimeter

• K6 Connector

BC (Infrared Sensor)

20VDC

Page 22

4) 5VDC Output Checks:

2A8054-01

CB K9 Connector: Control Switch (CB K9 #1 and #2) (open contacts for icemaking,

closed contacts for drain), Jumper (CB K9 #3 and #4), Compressor Control Relay

(K9 #5 and #6).

Float Switch (K8 #5 (common), #6 (lower), and #7 (upper)).

When checking 5VDC control voltage, always place the red positive test lead from

the multimeter to the CB white K5 pin closest to the CB red K4 connector. See Fig. 2.

Then place the black negative test lead from the multimeter to the corresponding pin to

complete the 5VDC check.

Red positive test lead to white

K5 connector pin closest to

red K4 connector

Red Positive

Test Lead

5VDC

Multimeter

Black Negative

Test Lead

Control Board K9 Connector

Control Switch

white/black (W/BK)

Yellow Jumper (Y)

Compressor Control Relay

(terminals #3 and #5)

white/orange (W/O)

Fig. 2

a. Control Switch – CB K9 #1 (W/BK) and CB K9 #2 (W/BK): 5VDC is present

between CB white K5 connector, pin closest to CB red K4 connector and CB K9

#1(W/BK) at all times. If 5VDC is not present, replace CB. When the control switch is

in the "ICE" position, the control switch contacts are open. 0VDC is present between

CB white K5 connector, pin closest to CB red K4 connector and CB K9 #2 (W/BK).

When in the "ICE" position, 5VDC is present from CB K9 #1 (W/BK) to CB

K9#2 (W/BK). When the control switch is in the "DRAIN" position, the control switch

contacts are closed. 5VDC is present between CB white K5 connector, pin closest

to CB red K4 connector, to CB K9 #1 (W/BK) or #2(W/BK). If 5VDC is not present,

replace CB. 0VDC is present from CB K9 #1 (W/BK) to CB K9 #2 (W/BK).

b. Compressor Control Relay (CCR) – CB K9 #5(W/O) and CB K9 #6 (W/O): 5VDC

is present from CB white K5 connector, pin closest to CB red K4 connector, to CB

K9#5 (W/O) at all times. If 5VDC is not present, replace CB. When CCR terminals

#3 (W/O) and #4 (W/BK) are open (CCR de-energized), 5VDC is present between

CB K9 #5 (W/O) and CB K9 #6 (W/O). When CCR terminals #3(W/O) and

#4 (W/BK) are closed (CCR energized), 5VDC is present between CB K9 #5 (W/O)

and CB K9 #6 (W/O). When CCR terminals #3 (W/O) & #5 (W/O) are open CB may

be in an 8-beep alarm. See "III.A.2. LED Lights and Audible Alarm Safeties."

22

Page 23

c. Float Switch (LFS and UFS) – CB K8 #5 (BK) (common), CB K8 #6(R) (upper),

and CB K8 #7 (BU) (lower): 5VDC is present from CB white K5 connector pin closest

to CB red K4 connector to CB K8 #5(BK) (common) at all times. If not, replace CB.

5VDC is present from CB white K5 connector pin closest to CB red K4connector

to CB K8 #6 (R) (upper) and CB K8 #7 (BU) (lower) when FS is open. If 5VDC

is present between CB K8 #5 (BK) and CB K8 #6 (R) (upper) or CB K8 #7 (BU)

(lower), FS is open. Forfurther FS diagnostics, see "II.F. Float Switch Check and

Cleaning."

5) Fill "WTRIN" LED is on: 24VAC is present at CB K2 #9 (W/R) at all times. If not,

conrm 24VAC from CB K2 #9(W/R) to a neutral (LBU). When LFS open at startup

or opens during normal operation, "WTRIN" LED turns on, ll timer (FT) starts, freeze

timer (FZT) terminates (only during normal operation), and WV energizes. If LFS is

open and "WTRIN" LED is off, conrm LFS status. See "II.F. Float Switch Check and

Cleaning." If LFS is open and "WTRIN" LED is off, replace CB. If "WTRIN" LED is on

and WV is not energized, check for 24VAC at CB K2 #8(O) to a neutral (LBU). If24VAC

is not present on CB K2 #8(O), replace CB. "WTRIN" LED turns off once UFS closes.

If not, conrm UFS status. See "II.F. Float Switch Check and Cleaning." IfUFS is closed

and "WTRIN" LED is on, replace CB. If "WTRIN" LED is off and WV is open, check for

24VAC at CB K2 #8 (O). If 24VAC is present at CB K2 #8 (O), replace CB. If 24VAC is

not present, check WV diaphragm.

6) Ice Purge Cycle "GM" LED is on: When UFS closes, GM delay timer starts (5 or

30sec. depending on CB S1 dip switch #7). OnceGM delay timer terminates, "GM"

LED turns on, GM and EH energize and 5-min. ice purge timer starts. If GM does not

energize 30 sec. after UFS closes, conrm UFS status. See "II.F. Float Switch Check

and Cleaning." If UFS is closed and GM LED does not turn, replace CB. If "GM" LED

is on and GM and EH are off, check for 115VAC from CBK1#3 (BK)to a neutral

(W). Ifnot, check 115VAC power supply connections from power switch. If 115VAC is

present, check for 115VAC from CB K1 #2 (P)to a neutral (W). If 115VAC is present on

CB K1 #3 (BK)and not on CB K1 #2 (P), replace CB.

23

Page 24

7) Freeze Cycle "GM" and "COMP" LED are on: The 5-min. ice purge timer terminates

or the ice purge cycle bypass button ("SERVICE") is pressed, "COMP" LED turns on.

To bypass the 5-min. Ice Purge Cycle, press the "SERVICE" button on CB after the

"GM" LED turns on. WARNING! Risk of electric shock. Care should be taken not to

touch live terminals. 115VAC is present between CB X1 relay power supply black (BK)

and neutral (W) at all times. If not, check 115VAC power supply wire connections from

power switch. If "COMP" LED is not on after 5-min. ice purge timer terminates, replace

CB. When "COMP" LED turns on, PDS energizes. If "COMP" LED is on and PDS does

not energize, check for 115VAC between CB X1 relay violet (V) wire and a neutral (W).

If 115VAC is not present, conrm X1 relay black (BK) to a neutral (W). If 115VAC is

present on X1 relay black (BK) and not on X1 relay violet (V), replace CB.

8) Rell "WTRIN" LED is on: See "5) Fill "WTRIN" LED is on:") above.

Legend: BC–bin control (infrared sensor); CB–control board; CCR/–compressor control

relay; EH–evaporator heater; FS–oat switch; GM–gear motor; LFS–lower oat

switch; PDS–pump-down solenoid valve; UFS–upper oat switch; WV–inlet water

valve

24

Page 25

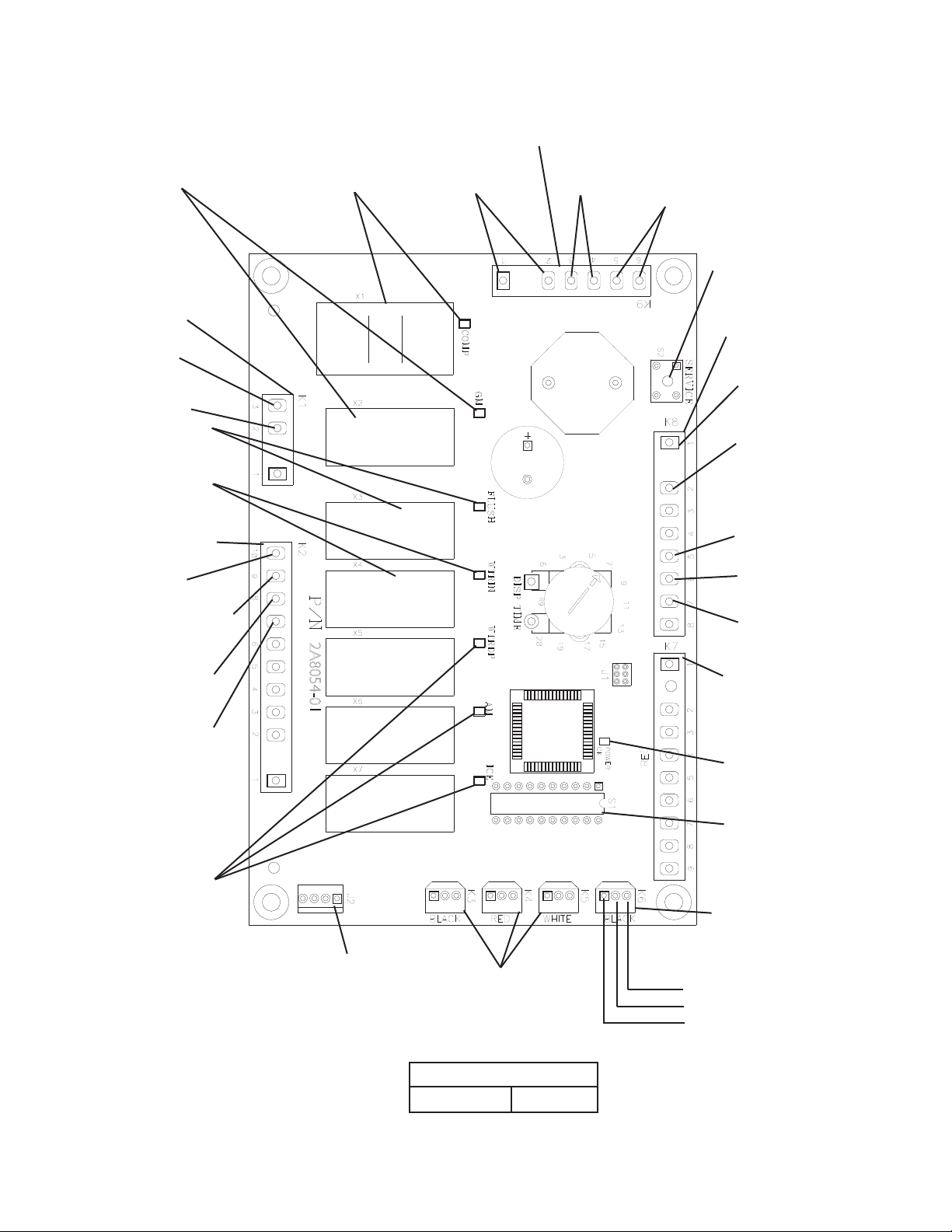

• "GM" LED

(X2 Relay)

GM

• "COMP" LED

(X1 Relay)

PDS

• K9 Connector (5VDC)

Control Switch

#1 & #2 (white/black)

High-Pressure Switch

(not used on this model)

#3 & #4 (yellow)

Compressor Control Relay

Circuit #5 & #6 (white/orange)

• S2 "SERVICE" Button

(Ice Purge Cycle Bypass)

• K1 Connector

(115VAC)

115VAC Input

#3 (brown)

GM, EH, CCR

#2 (white/black)

• "FLUSH" LED

(X3 Relay) (drain)

DV

• "WTRIN" LED

(X4 Relay)

WV

• K2 Connector

(24VAC)

Drain Valve

#10 (w/bu)

Control Transformer

24VAC Input

#9 (white/red)

Inlet Water Valve

#8 (o)

Control Transformer

24VAC Input

#7 (white/red)

2A8054-01

• K8 Connector

(24VAC and 5VDC)

Control Transformer

24VAC Input

#1 (white/red)

Control Transfomer

24VAC Neutral

#2 (light blue)

(DRAIN)

Float Switch-Common

#5 (black) (5VDC)

Upper Float Switch

#6 (red)

Lower Float Switch

#7 (blue)

• K7 Connector-Open

• "POWER OK" LED

Water Dispensing

Valve, Agitation

Motor, and Ice

Dispensing LEDs

(not used on this

model)

• J2 Connector-Open

• K3 Connector-Open

• K4 Connector-Open

• K5 Connector-Open

"F-C" Control Board

Part Number

2A8054-01

25

• S1 Dip Switch

3 2 1

• K6 Connector (20VDC)

Bin Contro (infrared sensor)

(dark blue)

(white, signal (common))

(brown (ground))

Page 26

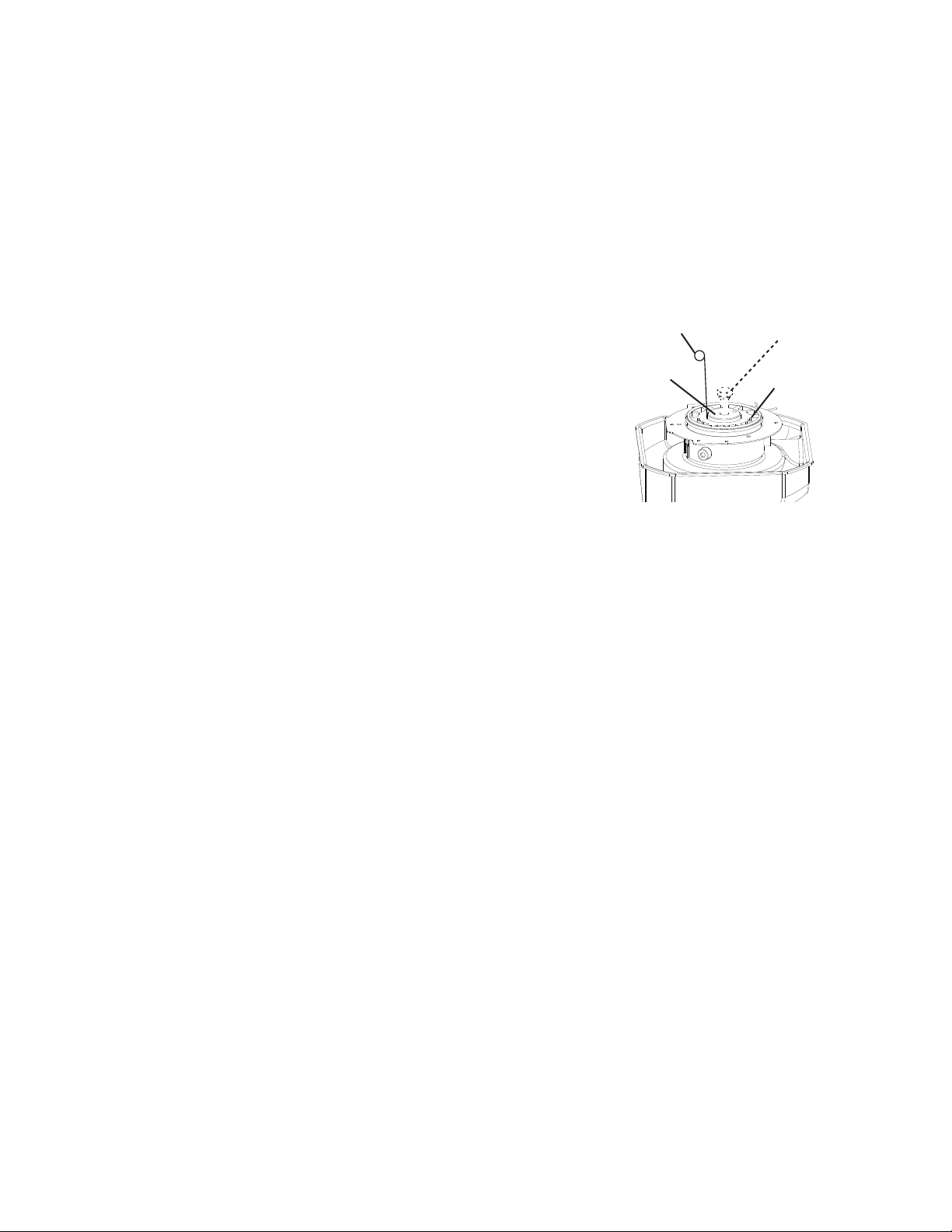

D. Bin Control Check

IMPORTANT

Make sure S1 dip switch 7 is in the "ON" position. This allows the control board to

monitor the BC (infrared sensor).

1) Remove the front panel.

2) Move the power switch to the "OFF" position, then unplug the appliance from the

electrical outlet.

3) Remove the control box cover and access CB. Conrm that S1 dip switch 1, 2, 3 are

in the proper position for your application. See "III.B.2. BC (Infrared Sensor) Shutdown

Delay (S1 dip switch 1, 2, 3)."

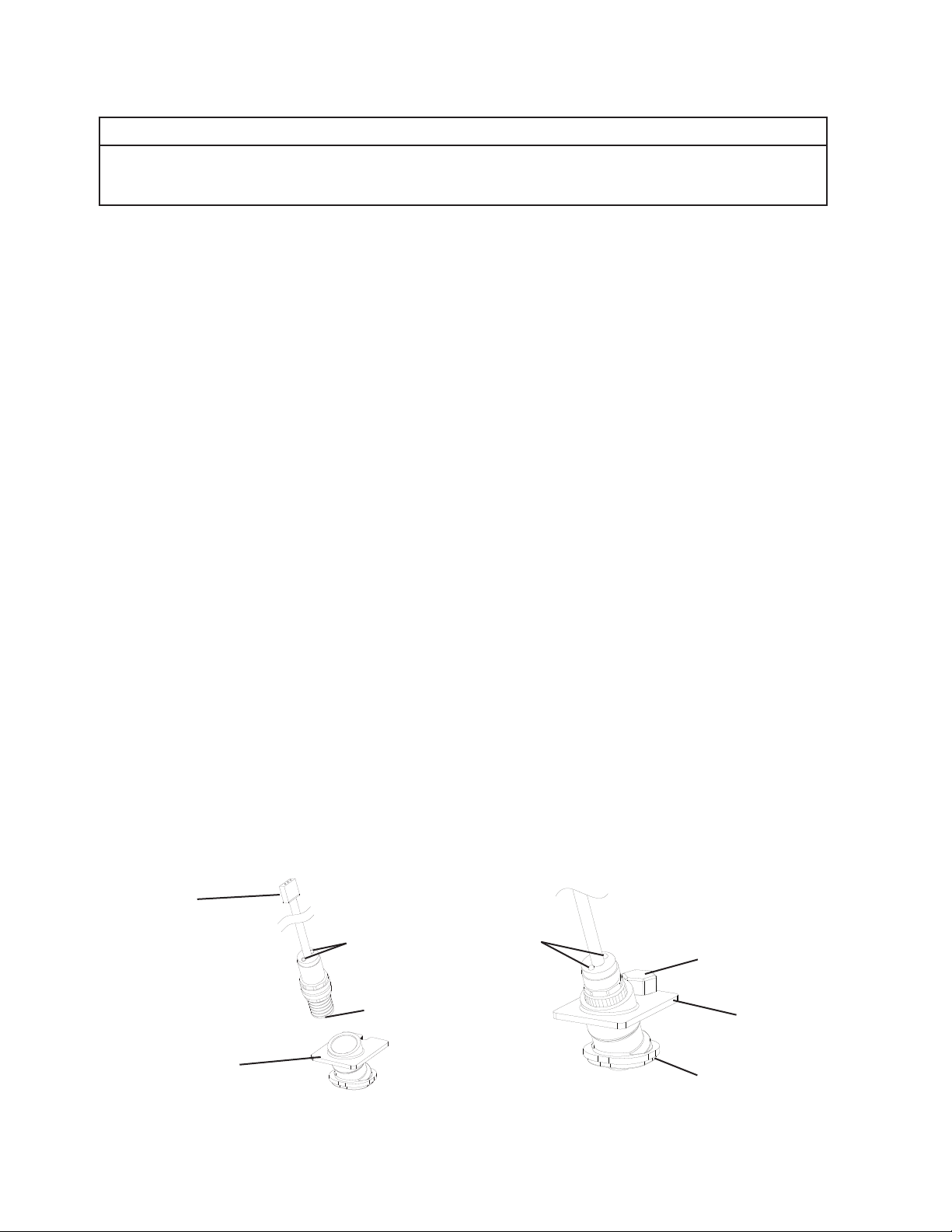

4) Conrm that BC is connected to CB K6 connector. Wipe down the lens with a warm,

clean, damp cloth. If the bottom of the icemaker is not accessible in your application,

remove the thumbscrew securing the BC housing, then remove the housing from the

base. See Fig. 3.

5) Make sure the control switch is in the "ICE" position, then plug the icemaker into the

electrical outlet.

6) Move the power switch to the "ON" position to start the automatic icemaking process.

Check that BC green LED is on. The BC green LED conrms 20VDC from CB to BC

and remains on constantly. Diagnosis: If the BC green LED is not on, conrm 20VDC

at CB K6 pin #1 (DBU) to CB K6 pin #3 (BR). If 20VDC is present and the BC green

LED is off, replace BC. If not, see step "3) BC (infrared sensor) Power Supply," under

"II.C. Control Board Check."

7) Make sure CB "GM" LED is on. There is a delay of at least 30 sec. before CB "GM" LED

turns on after power-up. After CB "GM" LED turns on, press CB "SERVICE" button to

bypass the 5-min. ice purge cycle. WARNING! Risk of electric shock. Care should be

taken not to touch live terminals.

8) "GM" and "COMP" LEDs are on. Use an object to cover the lens. BC yellow LED turns

BC (infrared sensor)

Connector

(20VDC from

K6 connector on

control board)

Housing

LEDs

Lens

LEDs

Thumbscrew

Housing

Lens

Fig. 3

26

Page 27

on (ashing or steady). BC yellow LED ashes when ice is at the outer limit of its

range and turns steady as ice nears. After BC yellow LED turns on (ashing or steady),

BCshutdown delay timer starts . See "III.B.2. BC (Infrared Sensor) Shutdown Delay

(S1dip switch 1, 2, 3)." PDS should de-energize immediately after the shutdown delay

timer terminates. 5 min. later, GM should de-energize.

Diagnosis: If BC yellow LED is not on after covering the lens, replace BC. If the

appliance remains on after BC shutdown delay timer terminates and the 5-min. ice

purge timer terminates, replace CB.

9) Remove the object covering the lens. If you removed BC housing from the base, replace

it in its correct position, and secure it with the thumbscrew.

10) Move the power switch to the "OFF" position, then unplug the appliance from the

electrical outlet.

11) Replace the control box cover in its correct positions.

12) Plug the appliance into the electrical outlet.

13) Move the power switch to the "ON" position to start the automatic icemaking process.

14) Replace the front panel in its correct position.

Legend: BC–bin control (infrared sensor); CB–control board; GM–gear motor;

PDS–pump-down solenoid valve

27

Page 28

E. Power Switch and Control Switch

The power switch and control switch are used to control the operation of this appliance.

They are located on the control box.

1. Power Switch

The power switch has 2 positions, "OFF" and "ON." When the power switch is in the

"OFF" position, no power is supplied to the components. When in the "ON" position,

power is supplied to the control transformer and control board. The control board then

supplies 5VDC to the control switch for unit operation.

2. Control Switch

The control switch has 2 positions, "ICE" and "DRAIN."

When the control switch is in the "ICE" position (open), icemaking begins.

When the control switch is in the "DRAIN" position (closed), the drain valve energizes.

a) ICE

When the control switch is in the "ICE" position, the control board reads an open

circuit through the control switch contacts and starts the icemaking process.

b) DRAIN

When the control switch is in the "DRAIN" position, the control board reads a closed

circuit through the control switch and the drain valve energizes.

28

Page 29

F. Float Switch Check and Cleaning

1. Float Switch Check

1) Remove the front panel, then move the power switch to the "OFF" position.

2) Move the control switch to the "DRAIN" position.

3) Move the power switch to the "ON" position.

4) Allow the water to drain from the evaporator, then move the power switch to the "OFF"

position and the control switch to the "ICE" position.

5) Unplug the appliance from the electrical outlet.

6) Remove the control box cover.

7) Disconnect FS connector from CB K8 connector and check FS continuity. Both the UFS

and LFS should be open. Check continuity between CB K8 #5 (BK) (common) and CB

K8 #6(R) (UFS). Next, check continuity between CB K8 #5 (BK) (common) and CB K8

#7 (BU) (LFS). If both are open, continue to step 8. If either are closed, follow the steps

in "II.F.2. Float Switch Cleaning." After cleaning FS, check UFS and LFS again. Replace

if necessary.

8) Reconnect FS connector to CB K8 connector.

9) Plug the appliance into the electrical outlet, then move the power switch to the "ON"

position and let the water reservoir ll.

10) Once the reservoir is full and GM starts, move the power switch to the "OFF" position.

11) Unplug the appliance from the electrical outlet.

12) Disconnect FS connector from CB K8 connector and check FS continuity. Both the UFS

and LFS should be closed. Check continuity between CB K8 #5 (BK) (common) and

CB K8 #6 (R) (UFS). Next, check continuity between CB K8 #5 (BK) (common) and CB

K8#7 (BU) (LFS). If either are open, follow the steps in "II.F.2. Float Switch Cleaning."

After cleaning FS, check UFS and LFS again. Replace if necessary.

Red (R)

(upper oat switch)

Black (BK)

(common)

Dark Blue (DBU)

(lower oat switch)

Magnet (towards top)

Upper Float (blue)

Magnet (towards top)

Spring Retainer Clip

Lower Float (white)

Plastic Retainer Clip

Fig. 4

29

Page 30

13) Replace CB K8 connector in its correct position. Replace the control box cover in its

correct position.

14) Plug the appliance into the electrical outlet, then move the power switch to the "ON"

position to start the automatic icemaking process.

15) Replace the front panel in its correct position.

2. Float Switch Cleaning

Depending on local water conditions, scale may build up on FS. Scale on FS can cause

inconsistent operation of UFS and LFS. In this case, both UFS and LFS should be

cleaned and checked.

1) Remove the front panel, then move the power switch to the "OFF" position.

2) Unplug the appliance from the electrical outlet.

3) Remove FS assembly from the reservoir cover. See Fig. 5.

4) Wipe down FS assembly with a mixture of 1 part Hoshizaki "Scale Away" and 25 parts

warm water. Rinse the assembly thoroughly with clean water.

5) While not necessary, the oats can be removed from the shaft during cleaning. If you

remove them, note that the blue oat is on top (UFS) and the white oat is on bottom

(LFS). The oats must be installed with the magnets inside them towards the top of the

switch. See Fig.4. Installing the oats upside down will affect the timing of FS operation.

6) Rinse the oat switch assembly thoroughly with clean water and replace in its correct

position.

7) Plug the appliance into the electrical outlet, then move the power switch to the "ON"

position to start the automatic icemaking process.

8) Replace the front panel in its correct position.

Legend: CB–control board; FS–oat switch; GM–gear motor; LFS–lower oat switch;

UFS–upper oat switch

Float Switch Assembly

Reservoir Cover

Reservoir

Fig. 5

30

Page 31

G. Diagnostic Tables

Before consulting the diagnostic charts, check for correct installation, proper voltage per

appliance nameplate, and adequate water supply. Check control board using the steps in

"II.C. Control Board Check."

1. No Ice Production

No Ice Production - Possible Cause

Startup

1. Power Supply-FS a) Unplugged, off, blown fuse, or tripped breaker.

b) Not within specications.

c) Loose connection.

d) Bad contacts.

Power Supply-SRC a) Off, tripped breaker

b) Not within specications.

c) Loose connection.

d) Bad contacts.

2. Water Supply a) Water supply off or improper water pressure.

b) External water lters clogged.

3. Power Switch a) "OFF" position.

b) Bad contacts.

4. Control Transformer

(115VAC/24VAC)

5. 1A Fuse (Control Box) a) Blown.

6. Control Board

See "II.C. Control Board Check"

7. Control Switch a) In "DRAIN" position.

8. BC (infrared sensor) a) No power, lens dirty, or defective.

1. Control Board a) No power to inlet water valve.

2. Inlet Water Valve a) Screen or orice clogged.

3. Float Switch a) Float does not move freely.

4. Drain Valve a) Valve seat clogged and water leaking.

5. Hoses a) Disconnected.

1. Control Board a) No power to gear motor.

2. Gear Motor a)Blown fuse.

a) Coil winding open or shorted.

a) In alarm.

b) Defective

b) Bad contacts.

b) Control board dip switch 7 off.

Fill Cycle

b) No power to oat switch or not reading oat switch condition.

b) Coil winding opened.

b) Defective.

Ice Purge Cycle

b) No power to compressor control relay.

b) Internal protector open.

c) Defective.

31

Page 32

Freeze Cycle

1. Compressor Control Relay a) No voltage from gear motor.

b) Defective.

2. Control Board a)No power to pump-down solenoid valve or not reading compressor

control relay condition. Defective.

3. Pump-Down Solenoid Valve a) Defective.

4. Control Low-Pressure Switch a) Refrigerant pressure too low.

b) Out of adjustment or defective.

5. Safety Low-Pressure Switch

(manual reset)

6. High-Pressure Switch a) Dirty condenser.

7. Magnetic Contactor a) Defective.

8. Condensing Unit Fan Motor(s) a) Defective capacitor.

9. Compressor a) Start or run capacitor defective.

10. Refrigerant Line a) Gas leaks.

11. Thermostatic Expansion Valve

(TXV) (not adjustable)

12. Evaporator a) Dirty.

13. Headmaster (C.P.R.) a) Not operating properly and liquid line temperature too warm.

14. Drain Valve a) Dirty, leaking by.

15. Water System a)Water leaks.

1. Float Switch a) Dirty/sticking.

2. Inlet Water Valve a) Clogged or defective.

3. Water Supply a) Off.

4. Control Board a) No power to oat switch or not reading oat switch condition.

a) Refrigerant pressure too low.

b) Defective.

b) Fan(s) not operating.

c) Ambient temperature too warm.

d) Refrigerant overcharged.

e) Refrigerant line or component restricted.

b) Fan blade binding.

c) Defective.

b) Start relay defective.

c) Defective.

b) Refrigerant line or component restricted.

a) Defective.

b) Damaged or defective.

b) Defective.

Rell

b) Defective.

b) No power to inlet water valve.

32

Page 33

Shutdown

1. Bin Control (infrared sensor)

See "II.D. Bin Control Check."

2. Control Board a) Control board dip switches set incorrectly.

1. Drain Valve a) Screen or orice clogged.

2. Control Board a) Defective.

a) Dirty lens.

b) Defective.

c) Control board (no power to IS).

b) In alarm.

c) Defective.

Drain Cycle

b) Defective.

33

Page 34

III. Controls and Adjustments

A. Control Board

• A Hoshizaki exclusive control board is employed in Hoshizaki Modular Flakers.

• All models are pre-tested and factory adjusted.

• For a control board check procedure, see "II.C. Control Board Check."

NOTICE

• The control board is fragile; handle very carefully.

• The control board contains integrated circuits, which are susceptible to failure

due to static discharge. It is especially important to touch the metal part of the

icemaker before handling or replacing the control board.

• Do not touch the electronic devices on the control board or the back of the control

board.

• Do not change wiring and connections. Do not misconnect terminals.

• Do not short out power supply to test for voltage.

• Always replace the whole control board assembly if it goes bad.

34

Page 35

1. Control Board Layout

• "GM" LED

(X2 Relay)

GM

• "COMP" LED

(X1 Relay)

PDS

• K9 Connector (5VDC)

Control Switch

#1 & #2 (white/black)

High-Pressure Switch

(not used on this model)

#3 & #4 (yellow)

Compressor Control Relay

Circuit #5 & #6 (white/orange)

• S2 "SERVICE" Button

(Ice Purge Cycle Bypass)

• K1 Connector

(115VAC)

115VAC Input

#3 (brown)

GM, EH, CCR

#2 (white/black)

• "FLUSH" LED

(X3 Relay) (drain)

DV

• "WTRIN" LED

(X4 Relay)

WV

• K2 Connector

(24VAC)

Drain Valve

#10 (yellow)

Control Transformer

24VAC Input

#9 (white/red)

Inlet Water Valve

#8 (white/brown)

Control Transformer

24VAC Input

#7 (white/red)

2A8054-01

(DRAIN)

• K8 Connector

(24VAC and 5VDC)

Control Transformer

24VAC Input

#1 (white/red)

Control Transformer

24VAC Neutral

#2 (light blue)

Jumper

#3 and #4 (gray) (5VDC)

Float Switch-Common

#5 (black) (5VDC)

Upper Float Switch

#6 (red)

Lower Float Switch

#7 (blue)

• K7 Connector-Open

• "POWER OK" LED

Water Dispensing

Valve, Agitation

Motor, and Ice

Dispensing LEDs

(not used on this

model)

• J2 Connector-Open

• K3 Connector-Open

• K4 Connector-Open

• K5 Connector-Open

"F-C" Control Board

Part Number

2A8054-01

35

• S1 Dip Switch

3 2 1

• K6 Connector (20VDC)

Bin Control (infrared sensor)

(dark blue)

(white, signal (common))

(brown (ground))

Page 36

2. LED Lights and Audible Alarm Safeties

At startup, CB green "POWER OK" LED turns on immediately to indicate proper control

voltage and will remain on unless a control voltage problem occurs. For further details,

see "II.B. Service Diagnosis."

Sequence Step LED

Fill Cycle WTRIN WV - Ice Purge Cycle GM GM, EH 5 min. 5 min.

Freeze Cycle (with rell) GM, COMP,

WTRIN* (rell)

1-in-1 Drain Cycle

(S1 dip switch 4 off)

1-in-12 Drain Cycle

(S1 dip switch 4 on)

FLUSH (Drain)

GM, COMP

(only if BC not

satised)

FLUSH (Drain) DV 10 min. 10 min.

Energized

Components Min. Max.

GM, EH, PDS, Comp,

FMR, WV* (rell)

DV

Comp, GM, EH, PDS,

FMR (only if BC not

satised)

- *On until UFS closes. Alarm

sounds after 90 sec.

2 sec. 2 sec.

The built-in safeties shut down the unit and have alarms as listed below.

No. of Beeps

(every 5 sec.)

1 Low Water Safety (FT)

UFS open > 90 sec. after WV energized.

2 Control Switch

In "DRAIN" position longer than 15 min..

3 High-Pressure Switch: N/A on this model. N/A

4 High-Pressure Switch: N/A on this model.

5 Freeze Timer (FZT)

WV off > 30 min. since last WV activation.

6 Low Voltage

(92VAC±5% or less)

7 High Voltage

(147VAC±5% or more)

8 Gear Motor

CCR contacts fail to close.

Type of Alarm Reset Options

Automatic reset once water supply is restored

and UFS closes.

Automatic reset once the control switch is

moved to the "ICE" position.

Manual reset. Turn power off and on again.

CB green "POWER OK" LED turns off if

voltage protection operates.

The control voltage safeties automatically reset

when voltage is corrected.

Manual reset. Turn power off and on again.

Legend: BC–bin control (infrared sensor); CB–control board; CCR–compressor control

relay; DV–drain valve; EH–evaporator heater; FMR–fan motor(s)-remote; FT–ll

timer (90-sec. low water safety timer); FZT–freeze timer (30-min. freeze safety

timer); GM–gear motor; PDS-pump-down solenoid valve; WV–inlet water valve

3. Ice Purge Cycle Bypass

To speed up the diagnostic process, the 5-min. ice purge cycle may be bypassed

by pressing the "SERVICE" button on the control board after the gear motor starts.

WARNING! Risk of electric shock. Care should be taken not to touch live terminals.

36

Page 37

B. Controls and Adjustments

NOTICE

Dip switches are factory set. Failure to maintain factory settings may adversely

affect performance and warranty coverage. For more information, contact your

Hoshizaki Certied Service Representative.

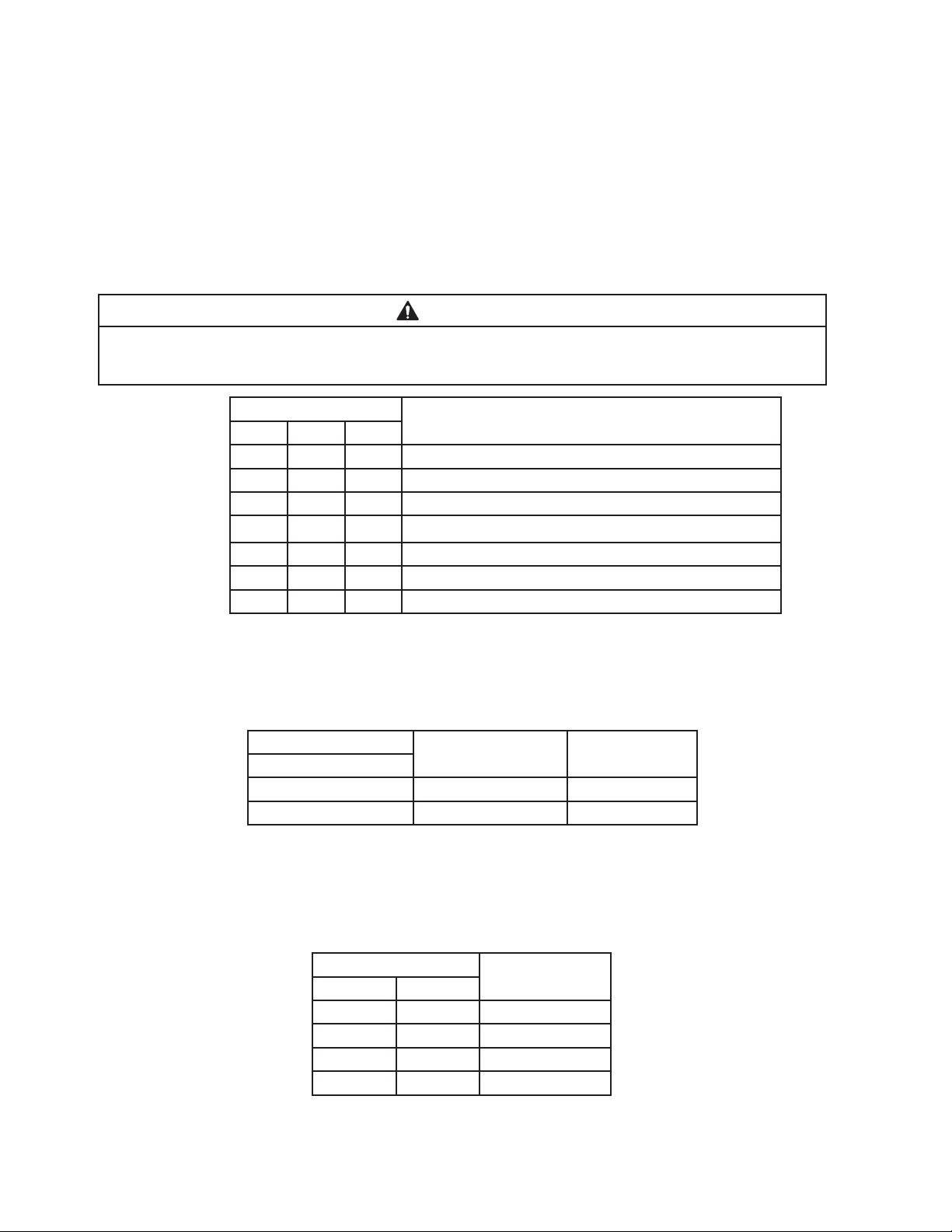

1. Default Dip Switch Settings

The S1 dip switch settings are factory-set to the following positions:

S1 Dip Switch

Model

FS-1001MLJ-C

FS-1500MLJ-C

1 2 3 4 5 6 7 8 9 10

ON OFF OFF OFF OFF OFF ON ON OFF OFFFS-1022MLJ-C

S1 Dip Switch No.

Normally off (factory use)

Shutdown Sequence

Bin Control (BC) (mechanical stand-alone or backup) Shutdown Delay

Bin Control Selector

Continuous Dispensing Timer

(DCM models only, do not adjust on modular icemakers)

Drain Frequency Control

Bin Control Shutdown Delay (BC (infrared sensor))

37

Page 38

2. BC (Infrared Sensor) Shutdown Delay (S1 dip switch 1, 2, 3)

Infrared sensor shutdown delay is the delay between the infrared sensor detecting ice

(infrared sensor yellow LED ashing or steady) and the start of the shutdown sequence.

For dispenser unit applications, the ice level at shutoff may need to be adjusted

depending on the dispenser agitation or dispense method. Increasing the shutdown

delay setting allows for a higher level of ice in the bin before the icemaker shuts down.

For a typical dispenser unit application, a 100-sec. shutdown delay is recommended.

When used with a standard Hoshizaki storage bin, any shutdown delay setting is

acceptable.

WARNING

Increasing the shutdown delay allows a higher level of ice in the dispensing unit/

storage bin before shutdown. This could lead to icemaker movement or ice overow.

S1 Dip Switch Setting

No. 1 No. 2 No. 3

OFF OFF OFF 0 Seconds

ON OFF OFF 100 Seconds (1.6 minutes) (Factory Default)

OFF ON OFF 1100 Seconds (18.3 minutes)

OFF OFF ON 1650 Seconds (27.5 minutes)

ON ON OFF 2200 Seconds (36.7 minutes)

OFF ON ON 0 Seconds

ON ON ON 0 Seconds

Infrared Sensor Shutdown Delay

3. Drain Frequency Control (S1 dip switch 4)

The appliance is factory set for optimum performance with the 1-in-1 drain cycle. This

setting allows for removal of sediment from the evaporator every hour without interrupting

the icemaking process. An optional 1-in-12 drain cycle is available.

S1 Dip Switch Setting

No. 4

OFF (1-in-1) 1 Hour 2 Seconds

ON (1-in-12) 11 Hours 45 Minutes 10 Minutes

Drain Timer Interval Drain Valve Open

4. Continuous Dispensing Timer (S1 dip switch 5 & 6)

DCM models only. The dispense mode switch on DCMs must be in the "CONTINUOUS"

position for this setting to apply. The factory setting allows ice to be dispensed

continuously as long as the dispense solenoid is activated.

S1 Dip Switch Setting

No. 5 No. 6

OFF OFF No Limit

ON OFF 20 Seconds

OFF ON 60 Seconds

ON ON No Limit

Dispense Time

38

Page 39

5. Bin Control Selector (S1 dip switch 7)

The appliance is factory set for infrared sensor bin control operation. No adjustment is

required. In the factory default position (S1 dip switch 7 in the on position), the gear motor

delay after the upper oat switch closes is 30 sec. WARNING! Do not place S1 dip

switch 7 in the off position. This could lead to icemaker movement or ice overow.

S1 Dip Switch

Setting

No. 7

OFF BC (mechanical stand-alone) (Standard Ice Storage Bins Only) 5 seconds

ON

BC (infrared sensor) and Mechanical Bin Control

(mechanical backup)

Bin Control Application Gear Motor Delay

30 seconds

6. BC (Mech. Stand-Alone or Backup (only)) Shutdown Delay (S1 dip switch 8)

Not available when S1 dip switch 7 is on. Factory set for normal operation. No adjustment

is required. This appliance does not utilize a mechanical bin control.

S1 Dip Switch Setting

No. 8

OFF 0.25 Seconds

ON 6.7 Seconds

Mechanical Bin Control

7. Shutdown Sequence (S1 Dip Switch 9)

Factory set for optimum performance. Do not adjust.

S1 Dip Switch

Setting

No. 9

OFF

ON

Slow timing (90s after Mechanical Bin Control delay is satised, the COMP shuts

down; after an additional 60s, the GM shuts down)

Fast timing (after Mechanical Bin Control delay is satised both COMP & GM shuts

down at the same time)

Shutdown Sequence

8. Factory Use (S1 Dip Switch 10)

Factory set for optimum performance. Do not adjust.

Shutdown Delay

39

Page 40

IV. Refrigeration Circuit and Component Service Information

WARNING

• This appliance should be diagnosed and repaired only by qualied service

personnel to reduce the risk of death, electric shock, serious injury, or re.

• Before Servicing: FS: Move the icemaker's power switch to the "OFF" position.

Unplug the icemaker from the electrical outlet. SRC: Turn off the power supply

to the remote condensing unit. Place the disconnect (if applicable) in the off

position. Lockout/Tagout to prevent the power supply from being turned back on

inadvertently.

• Do not make any alterations to the icemaker or condensing unit. Alterations could

result in electric shock, injury, re, or damage to the appliance.

• CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are

securely in place after the appliance is serviced. Make sure that none have fallen

into the dispenser unit/ice storage bin.

• Make sure all food zones in the icemaker and dispenser unit/ice storage bin are

clean after service.

A. Refrigeration Circuit Service Information

WARNING

• Repairs requiring the refrigeration circuit to be opened must be performed by

properly trained and EPA-certied service personnel.

• Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). Do not use R-404A as a mixture with

pressurized air for leak testing.

NOTICE

• Always recover the refrigerant and store it in an approved container. Do not

discharge the refrigerant into the atmosphere.

• Do not leave the system open for longer than 15 min. when replacing or servicing

parts. The Polyol Ester (POE) oils used in R-404A applications can absorb

moisture quickly. Therefore it is important to prevent moisture from entering the

system when replacing or servicing parts.

• Always install a new drier every time the sealed refrigeration system is opened.

Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

40

Page 41

1. Refrigerant Recovery

Using proper refrigerant practices, recover the refrigerant. Recover via the service valves.

Store the refrigerant in an approved container. Do not discharge the refrigerant into the

atmosphere.

2. Brazing

WARNING

• R-404A itself is not ammable at atmospheric pressure and temperatures up to

176°F (80°C).

• R-404A itself is not explosive or poisonous. However, when exposed to high

temperatures (open ames), R-404A can be decomposed to form hydrouoric

acid and carbonyl uoride both of which are hazardous.

• Do not use silver alloy or copper alloy containing arsenic.

1) Braze all ttings while purging with nitrogen gas owing at a pressure of 3 to 4 PSIG.

NOTICE

• Always install a new drier every time the sealed refrigeration system is opened.

• Do not replace the drier until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in the direction of the refrigerant

ow.

• When brazing, protect the drier by using a wet cloth to prevent the drier from

overheating. Do not allow the drier to exceed 250°F (121°C).

2) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the system (if using an electronic leak detector), and then raise the

pressure using nitrogen gas (140 PSIG). Do not use R-404A as a mixture with

pressurized air for leak testing.

3. Evacuation and Recharge (R-404A)

1) Attach a vacuum pump to the system. Be sure to connect the charging hoses to both

high and low-side refrigerant service valves.

IMPORTANT

The vacuum level and vacuum pump may be the same as those for current

refrigerants. However, the rubber hose and gauge manifold to be used for

evacuation and refrigerant charge should be exclusively for POE oils.

2) Turn on the vacuum pump, then open the gauge manifold valves, then open the high

and low-side service valves. Never allow the oil in the vacuum pump to ow backwards.

3) Allow the vacuum pump to pull down to a 29.9" Hg vacuum. Evacuating period depends

on pump capacity.

4) Close the low-side valve and high-side valve on the gauge manifold.

41

Page 42

5) Disconnect the gauge manifold hose from the vacuum pump and attach it to a

refrigerant service cylinder. Remember to loosen the connection and purge the air from

the hose. See the rating label inside the icemaker for the required refrigerant charge.

Hoshizaki recommends only virgin refrigerant or reclaimed refrigerant which meets

AHRI Standard 700 (latest edition) be used.

6) A liquid charge is required when charging an R-404A system (to prevent fractionation).

Place the service cylinder on the scales; if the service cylinder is not equipped with

a dip tube, invert the service cylinder, then place it on the scales. Open the high-side

valve on the gauge manifold.