Page 1

COMMISSIONING

To check whether the valve is operating correctly, carry out the following checks after the system is

filled and vented. Ensure that the override lever is back in the Auto position and the insert guide is

removed.

HOTWATERONLY.

Set the room thermostat to minimum or turn the CH off at the programmer.

Set the cylinder thermostat to maximum and turn the HW on at the programmer.

The valve should close Port A. The boiler should fire, pump run and the pipe on the Port B side should

get hot.

CENTRALHEATINGONLY.

Set the cylinder thermostat to minimum or turn the HW off at the programmer.

Set the room thermostat to maximum and turn the CH on at the programmer.

The valve should close Port B. The boiler should fire, pump run and the pipe on the Port A side should

get hot.

APPLICATION

The Z322XL mid-position valve has been designed to control

the water circulation in fully pumped systems, which employs

a single pump for both Hot water and Central heating circuits,

by diverting the flow to either circuit or both simultaneously

using a single valve.

HOTWATERANDCENTRALHEATING.

Set the room and cylinder thermostat to maximum and turn the HW and CH on at the programmer.

The valve should be in the mid-position. The boiler should fire, pump run and the pipes on both Port A

side and Port B should get hot.

Reset both thermostats and the programmer to their normal settings.

Please notethe above assumes that both programmer and thermostats are being used. If this is not

the case, ignore the action described for the item not fitted.

SPARES

The actuator and body for the Z322XL mid-position valve can be purchased separately as spares or as

replacement parts(see page 1).

Email: sales@horstmann.co.uk

Website: www.horstmann.co.uk

Page 4

Horstmann Controls Limited

Bristol

BS4 1UP

t:0117 9788 773 - f:0117 9788 701

LEAFLET No P80955

ISSUE 2

INSTALLATION AND CONNECTION SHOULD ONLY BE CARRIED OUT BY A SUITABLY QUALIFIED PERSON

AND IN ACCORDANCE WITH THE CURRENT EDITION OF THE IEE WIRING REGULATIONS.

A CLASS ‘A’ SWITCH (HAVING CONTACT SEPARATION OF AT LEAST 3MM IN ALL POLES) MUST BE

INCORPORATED IN THE FIXED WIRING AS A MEANS OF DISCONNECTING THE SUPPLY, NORMALLY AT THE

CONSUMER UNIT. THE SYSTEM MUST BE APPROPRIATELY FUSED.

WARNING:ISOLATE MAINS SUPPLY BEFORE COMMENCING INSTALLATION

SPECIFICATION

Motor supply voltage: 230V AC, 50Hz

Power consumption:<6W

Lead supplied:1 meter 4 core cable. Industry standard colours used

No earth connection required as unit is double insulated

Operating flow temperature:-5

Switch rating:3Amps

Maximum ambient temperature:50

Maximum static pressure:8.6 Bar

Maximum differential pressure: 0.5 Bar

Pipe fitting size:22mm compression

Actuator:Maximum time to power

open - 20 seconds

Maximum time to spring

close - 10 seconds

Override lever:For manual operating to

mid-position for system draining or filling.

During normal operation, the lever must be

in the auto position.

(See diagram opposite).

The Z322XL consists of a 3 port valve body (Ref.B322XL) to

which a self-contained actuator (Ref.A322XL) is attached.

o

C to 88oC

o

C

A322XL - ACTUATOR

B322XL - BODY

Page 1

Page 2

Valve position - In the event that mains

power is disconnected the valve

automatically spring-returns to the Hot

water only position.

Position of valve during the various

operation:

HW only - Port A closed

OPERATION

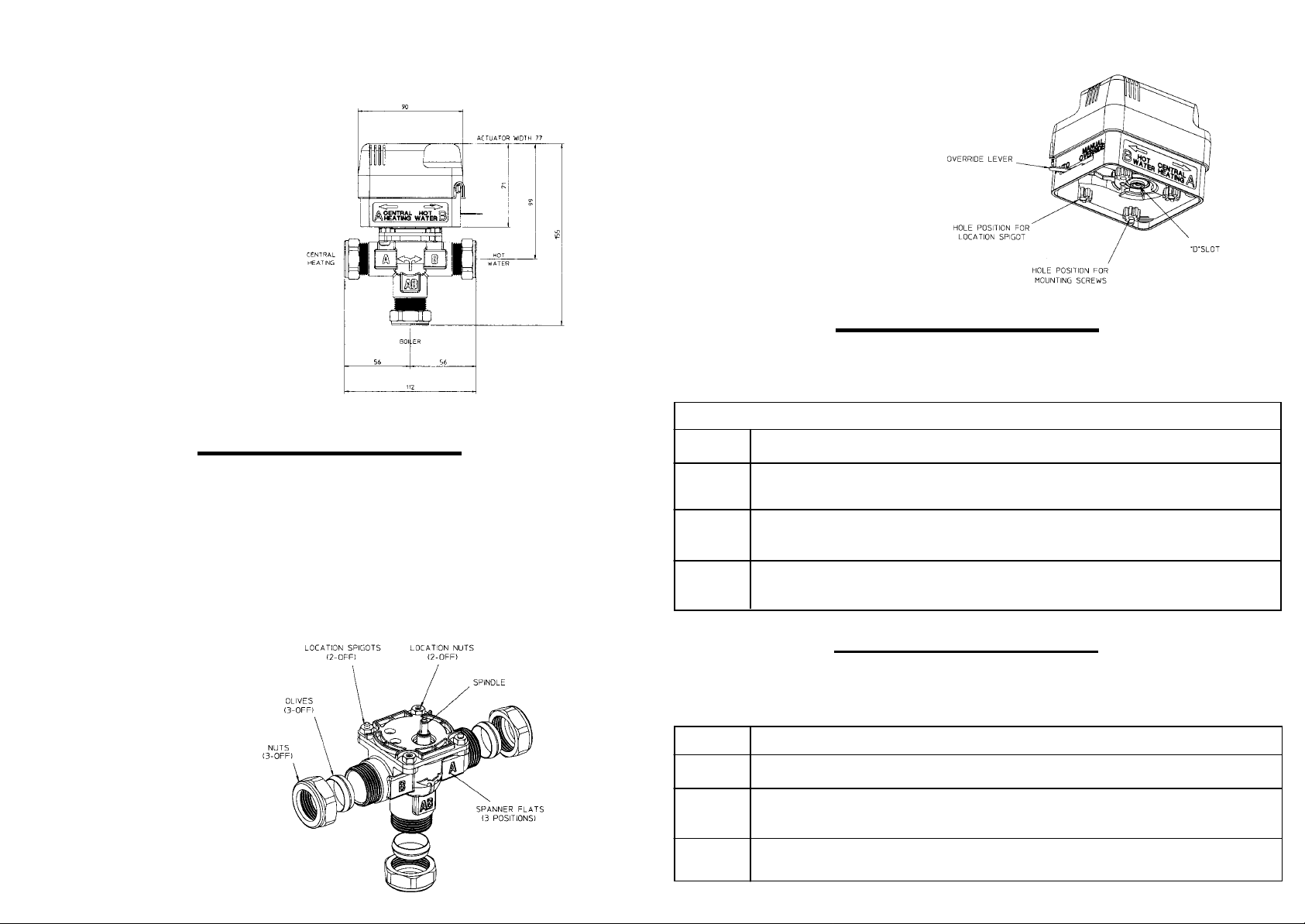

FIT ACTUATOR TO VALVE BODY

Position the actuator on the valve body

lining up the valve spindle with the ‘D’

shape slot. A yellow guide strip has been

inserted behind the Override lever to

assist installation,please remove the

guide once the actuator installation is

complete and before the system is used.

The actuator guide holes should line up

with the spigots on the valve body.

HW & CH - Valve in position AB (Middle)

CH only - Port B closed

The Valve operates both boiler and

pump when either Heating or Hot water

is required.

INSTALLATION

POSITIONING OF VALVE

On new installations ensure that the Z322XL valve is fitted on the flow from the boiler only. Also check

that the actuator head is NOTbelow the horizontal level of the pipework and that neither the open

vent nor the cold feed are isolated. This will ensure system and product safety at all times.

Remember to make allowances for working, maintenance and replacement.

FITTING OF VALVE BODY TO PIPEWORK

Fit the valve body using the

22mm compression fittings

provided with the flow from

the boiler to AB, the radiator

circuit to Port A, and the Hot

water cylinder to Port B.

Tighten the compression nuts

sufficiently to make a

watertight seal, only gripping

the valve by its body.

Take care not to over tighten.

Fix with the screws provided and tighten

lightly. The override lever should now be

on the Port B side.

Set the override lever to manual. Fill, test and thoroughly flush the system (see diagram and

instruction under the Specification section located on page 4 of this guide).

WIRING CONNECTIONS- STANDARD INSTALLATION

The 4 core cable fitted to the actuator can now be connected to the system following the simple

colour-coded guide below.

Wire Colour System Connection

Blue Any Neutral supply.

Orange ‘Call’ terminal of Cylinder Stat if fitted, otherwise the ‘HW ON’ terminal of

the programmer - Also link to Pump/Boiler live.

White ‘Call’ terminal of room Stat if fitted, otherwise the ‘CHON’ terminal of

programmer.

Grey ‘Stat’ terminal of Cylinder Stat if fitted, otherwise the ‘HW OFF’ terminal of

the programmer.

No earth connection is required. Ensure all connections are good and the screw secure. A torque of

0.75Nm is recommended for fixing the wires in place.

USING A ZONEPLUS Z322XL AS A DIVERTER VALVE

The following connections will enable the Z322XL to act as a diverter valve, giving priority to the

Central heating.

Wire Colour System Connection

Blue Any Neutral supply.

Orange ‘Call’ terminal of Cylinder Stat if fitted, otherwise the ‘HW ON’ terminal of

the programmer - Also link to Pump/Boiler live.

Page 2

White+Grey ‘Call’ terminal of room Stat if fitted, otherwise the ‘CHON’ terminal of

programmer.

Page 3

Loading...

Loading...