horsch SW 600 Owner's Manual

Seed Wagon

Issued February 2017

Owner’s Manual

Serial Numbers:

SW600 SN 230060017001 – Current

SW 600

www.horsch.com

2 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

SW600 Owner’s Manual – Version 1.2 07/2018 3

www.horsch.com

Contents

Introduction - Safety & Guidelines ......................................................................................................... 8

Machine Registration (Important Notice to Dealer/Owner!) .................................................................... 8

Warranty Guidelines .............................................................................................................................. 9

Machine Registration Form: Customer’s Copy ......................................................................................11

Machine Registration Form: Dealer’s Copy...........................................................................................13

Machine Registration Form: HORSCH’s Copy ......................................................................................15

Delivery Form: DEALERS’s Copy .........................................................................................................17

Product Specification ............................................................................................................................19

In These Operating Instructions ............................................................................................................20

Authorized Operators ...........................................................................................................................20

Protective Clothing ...............................................................................................................................20

Infor mation R egardi ng Safety ...............................................................................................................21

Safety Symbols on the Machine: ..........................................................................................................22

Use for the Intended Purpose ...............................................................................................................33

Operational Safety ................................................................................................................................33

Road Traffic Safety ...............................................................................................................................35

Hydraulic System ..................................................................................................................................36

Hydraulic Function Precautions .........................................................................................................37

Safety Measures in Case of Injury from Oil ....................................................................................37

Pressure Accumulator .......................................................................................................................37

Electrical Sys tem ..................................................................................................................................39

Extracting Stuck Machine Safety & Guidelines .....................................................................................40

Service and Maintenance .....................................................................................................................40

Transport & Installation .........................................................................................................................42

Connecting the ISO Bus System ..........................................................................................................43

Connecting the Hydraulic System .........................................................................................................43

Connecting the Road Lighting Equipment .............................................................................................44

Technical Data .....................................................................................................................................45

Configuration ........................................................................................................................................46

Undercarriage & Track System Specifications ......................................................................................47

Description – SW (Seed Wagon) ..........................................................................................................48

Seed Tank ........................................................................................................................................48

4 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Axle .................................................................................................................................................. 48

Tire Specifications ............................................................................................................................ 48

Seed Wagon Tank Lid Adjustment ....................................................................................................... 49

Pneumatic System ............................................................................................................................... 50

Hydraulic Fan(s) ............................................................................................................................... 51

Technical Data: ................................................................................................................................ 51

Mode of Operation ............................................................................................................................ 52

Adjusting Fan RPM........................................................................................................................... 52

Retightening the Fan Impeller ........................................................................................................... 52

Adjustment of Fan Sensor ................................................................................................................ 53

Air System ........................................................................................................................................... 54

Metering Unit w/ Electric Motor ......................................................................................................... 55

Rotors for Various Grain Types ........................................................................................................ 55

Meter Roller Alignment ..................................................................................................................... 56

Roller Seed Rate Chart .................................................................................................................... 57

Roller Replacement .......................................................................................................................... 60

Roller Replacement with Full Tank ................................................................................................... 61

Assembly Instructions ....................................................................................................................... 62

Functional Test ................................................................................................................................. 63

Canola Brushes ................................................................................................................................ 64

Calibrating the Seed Quantity .............................................................................................................. 64

ISO Bus System ................................................................................................................................... 67

Scale System ....................................................................................................................................... 68

Operation ......................................................................................................................................... 68

Service & Maintenance ........................................................................................................................ 69

Lubrication ........................................................................................................................................ 69

Grease ............................................................................................................................................. 70

Trailed Track System ........................................................................................................................... 71

General Information .......................................................................................................................... 71

Track System Components .............................................................................................................. 72

Frame ........................................................................................................................................... 72

Axles ............................................................................................................................................. 72

Idlers and Mid-rollers .................................................................................................................... 72

Tensioning system ........................................................................................................................ 72

SW600 Owner’s Manual – Version 1.2 07/2018 5

www.horsch.com

Rubber track ..................................................................................................................................72

Specifications, Dimensions & Weight Limitation ................................................................................73

Transport Limitations.........................................................................................................................73

Turning Radius Limitations ................................................................................................................74

Track Break-in Procedure .................................................................................................................74

Track Syste m In s ta llation ..................................................................................................................74

Handling the Tracks .......................................................................................................................74

Track Syste m In s ta llation ...............................................................................................................75

Track Maintenance ...........................................................................................................................77

General Information .......................................................................................................................77

Track Lubrication Table .................................................................................................................78

Track Maintenance Schedule .....................................................................................................78

Daily Maintenance, or every 10 working hours ...........................................................................78

Weekly Maintenance, or every 50 working hours .......................................................................79

Monthly Maintenance, or every 100 working hours ....................................................................79

Annual Maintenance, or every 500 working hours ......................................................................80

Every 5 years, or 2000 working hours ........................................................................................80

Off Se ason Storage ...................................................................................................................80

Track Alignment .........................................................................................................................80

Track Alignment Procedure ........................................................................................................82

Track System Inspection ............................................................................................................83

Adjusting Track Tension .............................................................................................................83

Track Removal ...........................................................................................................................84

Track Installation ........................................................................................................................84

Troubleshooting Track System ..........................................................................................................85

Bolt Tightening Torques – Metric Bolts .................................................................................................86

Bolt Tightening Torques – Imperial/Standard Bolts ...............................................................................87

Metric Conversions Table .....................................................................................................................88

Machine Storage ..................................................................................................................................89

Maintenance .........................................................................................................................................90

Hitch Adjustment & Maintenance ......................................................................................................91

Maintenance Schedule ......................................................................................................................93

Troubleshooting ....................................................................................................................................94

Pneumatic Systems ..........................................................................................................................94

6 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Seed Transfer ................................................................................................................................... 94

Metering System .............................................................................................................................. 95

Faults & Remedies ............................................................................................................................... 96

Support ................................................................................................................................................ 97

Notes: .................................................................................................................................................. 98

Index .................................................................................................................................................... 99

SW600 Owner’s Manual – Version 1.2 07/2018 7

www.horsch.com

Introduction - Safety & Guidelines

Safety is YOUR responsibility!

READ AND UNDERSTAND THIS MANUAL BEFORE YOU OPERATE THIS MACHINE

Learn how to operate and service your machine correctly. Failure to do so could result in personal injury

and/or equipment and property damage. HORSCH will not accept any responsibility for any damage or

malfunctions resulting from failure to comply with the Operator’s Manual.

If the information found in this manual is not completely understood or if there are any questions, contact

HORSCH Customer Service.

HORSCH cares about your safety! This machine is designed to provide maximum possible safety; but

no machine design can prevent operator error or carelessness.

The Owner’s Manual provides instructions for the safe operation and maintenance of this machine.

Make sure the machine is in good operating condition.

Check service schedule in book.

This manual should be considered a permanent part of your machine and should remain with the machine

if you no longer own it. Right hand and left hand are determined by facing the direction of forward travel

respectively.

HORSCH r eserves the right to alter illustrations as well as technical data and weights contained in this

manual at any time without notice.

This data is the property of HORSCH. All use and/or reproduction not specifically authorized by HORSCH

are prohibited.

All information, illustrations and specifications in this manual are based on the latest information available

at the time of publication. The right is reserved to make changes at any time without notice.

Some illustrations may show optional equipment. Illustrations may show shields, guards, etc., opened or

removed. All shields, guards, etc. must be in place during operation.

Machine Registration (Important Notice to Dealer/Owner!)

Please complete the Machine Registration Form on the next few pages and return to HORSCH within 10

(ten) business days, from date of delivery to owner. Accurately record all the numbers to help in tracing

the machine. Your dealer needs these numbers when you order parts. NO WARRANTY CLAIMS WILL

BE ACCEPTED IF THIS MACHINE REGI STRATION IS NOT RETURNED. The warranty period begins

on the date of delivery. See further noted information in the Warranty Guidelines section on the following

page.

8 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Warranty Guidelines

1. The period of warranty for material defects relating to HORSCH products will be 12 months. In the

case of written deviations from the statutory provisions, these agreements shall apply.

They shall become effective upon delivery of the machine to the end customer, unless the unit is

stored during seasonal months, whereas the machine is not utilized. The machine will then have a

warranty start date when it is put in to service. During this waiver period the machine is not to be

used or show evidence of usage or the warranty date will be set back to the original sold or delivery

date. Registration must be completed within 10 day s of machine usage. Failure to co mply may result

in warranty start date reverting back to original purchase or delivery date.

All wear item parts are excluded from the warranty.

2. Warranty claims must be submitted to the HORSCH Customer Service Department in Mapleton, ND

via your dealer. It is only possible to process claims which have been completed correctly and

submitted no later than four weeks after the damage occurred. No warranty claims will be accepted

to machines under the warranty waiver start date, except any related Technical Service Bulletins.

3. In the case of deliveries made under the warranty whi ch are subject to the return of the old parts, the

warranty claim, together with the old parts, must be returned to HORSCH within 4 weeks after the

damage occurred.

4. In the case of deliveries made under the w arranty, w hich are not subject to the return of the old parts,

these parts must be kept for the purpose of f urther dec isions for a period of four weeks after receipt

of the warranty claim.

5. Warranty repairs to be carried out by outside companies, or repairs which are expected to ta ke more

than 2 working hours, must be approved in advance with HORSCH Customer Service Department.

200 Knutson St.

(701) 532-1000

service.us@horsch.com

For other related warranty items such as tire warranty issues, contact your nearest distributor.

A complete list of dealers can be found at the following web sites.

Firestone Tires - http://www.firestoneag.com/default-eng.aspx

Titan Tires - http://www.titan-intl.com/ or 1-800-USA-BEAR.

HORSCH, LLC

Mapleton, ND 58059 USA

SW600 Owner’s Manual – Version 1.2 07/2018 9

or 1-800-435-4437.

www.horsch.com

10 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Machine Registration Form: Customer’s Copy

NOTE: No Warranty Claims will be accepted if this Machine Registration Form is not returned!

To:

HORSCH, LLC

200 Knutson St. SE Tel: 701-532-1000 Email: service.us@horsch.com

Mapleton, ND 58059 Fax: 701-532-1101

Machine Product & Model: __________________________ New Machine Final Sale – Initial use

Customer’s Machine – Transfer

Serial Number: ___________________________________ Demonstration Machine – Initial use

Sold Date: _______________________________________

In Service Date: Est. Acres: ____________________

Operating Instructions:

I hereby confirm receipt of the Owner’s Manual and Parts Catalog for the above mentioned machine.

I have been instructed and informed by a HORSCH factory trained Service Technician / authorized Dealer

representative in the opera t ion and func tions of the m achine, as well as in the safety requirements.

________________________________________________

Name of the Service Technician / Dealer representative

Dealer Customer

Name: ______________________________ Name: _______________________________________

Address: ____________________________ Address: _____________________________________

City/State/Zip: ________________________ City/State/Zip: _________________________________

County: _____________________________ County: ______________________________________

Tel: ________________________________ Tel: _________________________________________

Fax: ________________________________ Fax: ________________________________________

E-mail: ______________________________ E-mail: ______________________________________

Customer No: _________________________ Customer No: _________________________________

I am aware that a W arranty Claim will only be valid if, after the receipt of the machine, this f orm has been fully

completed, signed and returned to HORSCH, LLC.

______________________________________ ______________________________________

Place, Date Customer’s Signature

NOTE: After Signing, remove and/or copy this page. Keep signed delivery checklist in machine file at the dealership.

SW600 Owner’s Manual – Version 1.2 07/2018 11

www.horsch.com

12 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Machine Registration Form: Dealer’s Copy

NOTE: No Warranty Claims will be accepted if this Machine Registration Form is not returned!

To:

HORSCH, LLC

200 Knutson St. SE Tel: 701-532-1000 Email: service.us@horsch.com

Mapleton, ND 58059 Fax: 701-532-1101

Machine Product & Model: __________________________ New Machine Final Sale – Initial use

Customer’s Machine – Transfer

Serial Number: ___________________________________ Demonstration Machine – Initial use

Sold Date: _______________________________________

In Service Date: Est. Acres: ____________________

Operating Instructions:

I hereby confirm receipt of the Owner’s Manual and Parts Catalog for the above mentioned machine.

I have been instructed and informed by a HORSCH factory trained Service Technician / authorized Dealer

representative in the opera t ion and func tions of the m achine, as well as in the safety requirements.

________________________________________________

Name of the Service Technician / Dealer representative

Dealer Customer

Name: ______________________________ Name: _______________________________________

Address: ____________________________ Address: _____________________________________

City/State/Zip: ________________________ City/State/Zip: _________________________________

County: _____________________________ County: ______________________________________

Tel: ________________________________ Tel: _________________________________________

Fax: ________________________________ Fax: ________________________________________

E-mail: ______________________________ E-mail: ______________________________________

Customer No: _________________________ Customer No: _________________________________

I am aware that a W arranty Claim will only be valid if, after the receipt of the machine, this f orm has been fully

completed, signed and returned to HORSCH, LLC.

______________________________________ ______________________________________

Place, Date Customer’s Signature

NOTE: After Signing, remove and/or copy this page. Keep signed delivery checklist in machine file at the dealership.

SW600 Owner’s Manual – Version 1.2 07/2018 13

www.horsch.com

14 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Machine Registration Form: HORSCH’s Copy

NOTE: No Warranty Claims will be accepted if this Machine Registration Form is not re tu rned!

To:

HORSCH, LLC

200 Knutson St. SE Tel: 701-532-1000 Email: service.us@horsch.com

Mapleton, ND 58059 Fax: 701-532-1101

Machine Product & Model: __________________________ New Machine Final Sale – Initial use

Customer’s Machine – Transfer

Serial Number: ___________________________________ Demonstration Machine – Initial use

Sold Date: _______________________________________

In Service Date: Est. Acres: ____________________

Operating Instructions:

I hereby confirm receipt of the Owner’s Manual and Parts Catalog for the above mentioned machine.

I have been instructed and informed by a HORSCH factory trained Service Technician / authorized Dealer

representative in the opera t ion and func tions of the m achine, as well as in the safety requirements.

________________________________________________

Name of the Service Technician / Dealer representative

Dealer Customer

Name: ______________________________ Name: _______________________________________

Address: ____________________________ Address: _____________________________________

City/State/Zip: ________________________ City/State/Zip: _________________________________

County: _____________________________ County: ______________________________________

Tel: ________________________________ Tel: _________________________________________

Fax: ________________________________ Fax: ________________________________________

E-mail: ______________________________ E-mail: ______________________________________

Customer No: _________________________ Customer No: _________________________________

I am aware that a W arranty Claim will only be valid if, after the receipt of the machine, this f orm has been fully

completed, signed and returned to HORSCH, LLC.

______________________________________ ______________________________________

Place, Date Customer’s Signature

NOTE: After Signing, remove and/or copy this page. Keep signed delivery checklist in machine file at the dealership.

SW600 Owner’s Manual – Version 1.2 07/2018 15

www.horsch.com

16 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Delivery Form: DEALERS’s Cop y

Serial Number: ……………………………………

At the time the machine is delivered, the following checklist is a reminder of information which

should be conveyed directly to the customer. Check off each item as it is fully explained to

customer.

[ ] Make the customer aware of all safety precautions that must be exercised while using this

machine. Point out all Warning and Caution safety labels/decals on the machine.

[ ] Point out the location of the Serial Number Tag (product identification numbers), for future

reference of the machine.

[ ] Giv e the Owner’s Manual to the customer. Encourage customer to read the manual in its entirety.

[ ] Explain all operating adjustments.

[ ] Review recommended procedures for attaching and detaching machine from tractor.

[ ] Make the customer aware of all safety precautions that must be observed when transporting the

machine in field and on public roads.

[ ] When the machine is transported on a road or highway at night, or during the day, accessory

lighting and devices should be used for adequate warning to operators of other vehicles. In this

regard, tell the customer to check local governmental regulations. The machine should be

equipped with road lighting and slow moving vehicle sign.

[ ] Explain to the customer that the life expectancy of this or any other machine depends on regular

lubrication as directed in the Owner’s Manual. Follow all maintenance and lubrication schedules

for the machine.

[ ] Discuss with the customer the use of proper tools and equipment for servi ce of the machine.

[ ] Have customer record Serial Number(s) in the Product Specification section.

[ ] To the best of my knowledge, this machine has been delivered ready for field use and the

customer has been fully informed as to proper operation and care.

Signed: ................................................................................. (Customer)

Signed: ................................................................................. (Dealer Representative)

Date: .....................................................................................

SW600 Owner’s Manual – Version 1.2 07/2018 17

www.horsch.com

18 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Product Specification

Each machine manufactured and assembled is serialized and provided a number for tracking purposes.

There is a model number, which is the category for product family of the machine, and there is a serial

number.

The serial number may also be known as, or part of, a Product Identification Number. This number is a

formulated number which details the machines build information for tracking purposes and easy

identification later during time of service, maintenance and replacement part ordering. The Serial

number, along with Model number of the machine, can be found on the Serial Number Tag.

HORSCH, LLC has placed a Serial Number Tag (reference picture below) on the machine with the above

mentioned information. It is located on the main frame cross member tube directly behind the front hitch,

just off center towards the left hand side of each machine.

Record the Model and Serial number of the machine below. Retain this page for customer use only ! For

future reference, the information will be used whenever the machine is being serviced, for ordering

replacement parts or when requesting information for the machine such as replacement Owner’s Manual

or a Parts Catalog. Be sure to provide both, the model number and serial number, when contacting your

dealer, for better assistance and quicker support of your machine.

Date of Purchase: __________________________

Dealer Information:

Name: _______________________________

Address: _____________________________

Phone: _______________________________

SW600 Owner’s Manual – Version 1.2 07/2018 19

HORSCH, LLC

Serial Number Tag

www.horsch.com

In These Operating Instructions

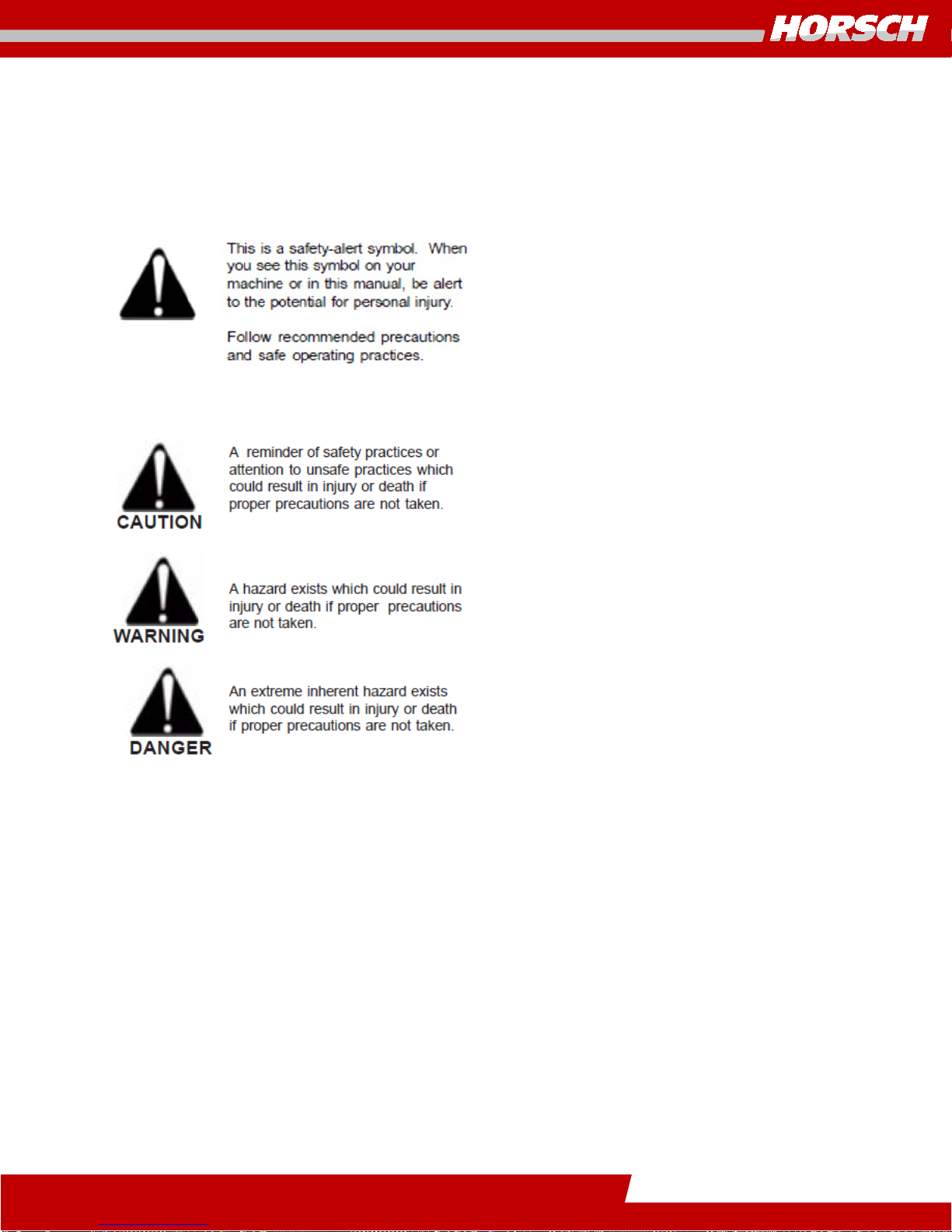

The operating instructions distinguish between three different types of warning and safety instructions.

The following graphic symbols are used:

Important instructions!

If there is a risk of injury!

If there is a risk to life and limb!

It is important that all th e saf ety instruct ions cont ained in these oper ating ins tructi ons and all the warni ng signs on

the machine are read thoroughly and understood prior to operation of the machine.

Ensure that the warning signs are legible and replace any signs that are missing or damaged.

These instructions m ust be followed in order t o prevent accide nts. Inform other users of the warnings an d safety

instructions and the location of this Owner’s Operators Manual.

Do not carry out any operations which may affect the safe use of the machine.

Authorized Oper ators

Only those persons who have been authorized and instructed by the operator may operate the machine. Operators

must be at least 16 years of age.

The operator must hold a valid driving license. They are responsible for third parties in the operating area.

The person in charge must:

Make the operating instructions available to the operator.

•

Ensure that the operator has read and understood the operating instructions.

•

The operating instructions are a key component of the machine.

Protective Clothing

For operation and maintenance of this machine, you will need:

Snug fitting clothing; no loose articles or strings.

•

Safety gloves and goggles to protect against dirt and sharp edged machine parts.

•

20 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Information Regarding Safety

The following warnings and safety instructions apply to all sections in these operating instructions. All

users must follow recommended precautions and safe operating practices.

Recognize Safety Information

Understand Safety Symbols

SW600 Owner’s Manual – Version 1.2 07/2018 21

www.horsch.com

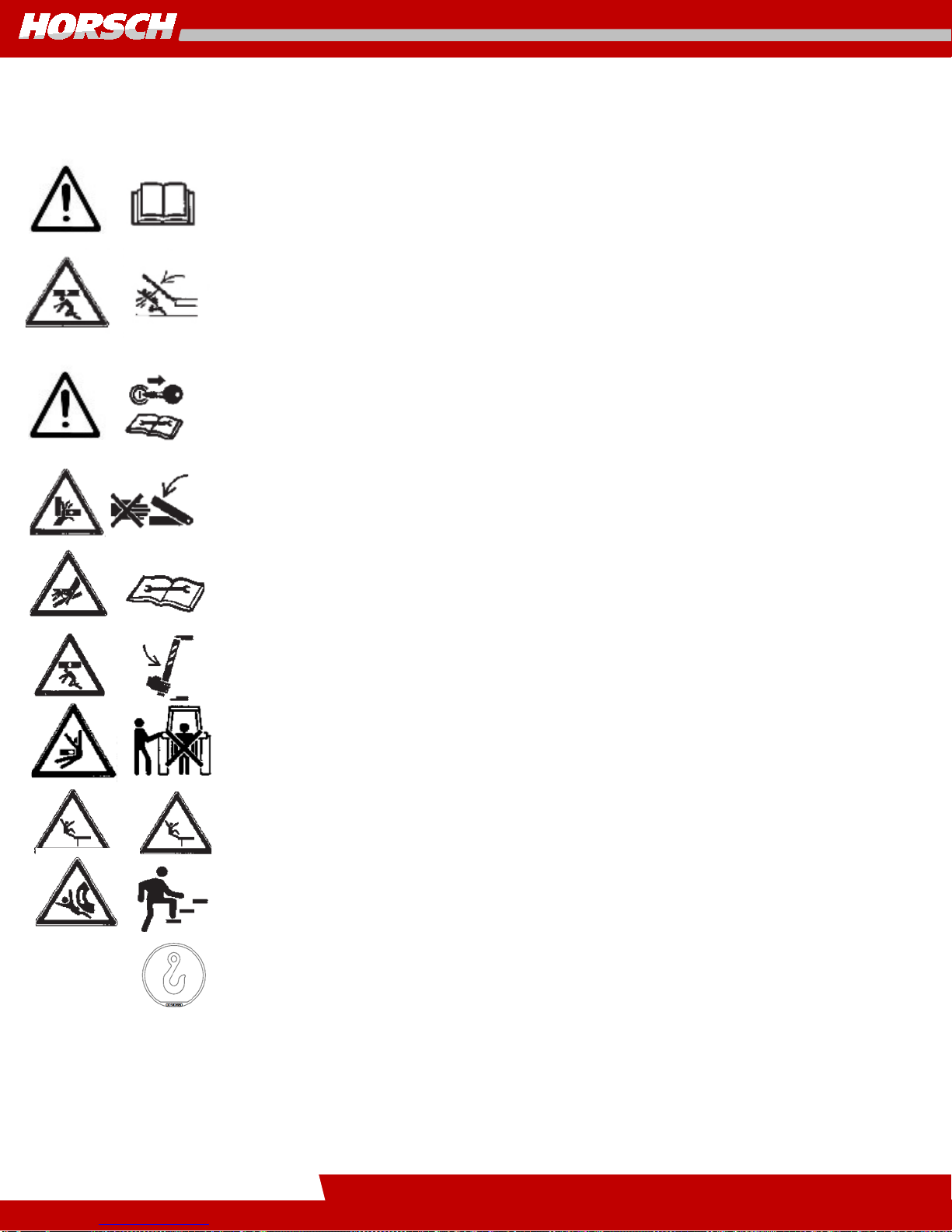

Safety Symbols on the Machine:

Read and adhere to the operating instructions before starting up the

machine!

Stay clear of swinging area of retractable and extendible machine parts!

Switch the engine off and pull out the key before starting maintenance and repair

work!

Never reach into areas where there is a risk o f crushing, as long as parts coul d still

be moving!

Watch out for fluids spraying out under high pressure, follow the operating

instructions!

It is only permitted to remain in the danger zone if the safety support is in place!

When hitching up the machine and when operating the hydraulic system, no persons should be between the machines!

No passengers are allowed to ride on the machine!

Do not climb on rotatable parts. Use mounting steps provided for this purpose!

Lifting hook; attach lifting tackle (chains, ropes, etc.) here when performing loading

work!

22 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Follow Safety Instruct ions

Carefully read all safety messages in this manual and on the machine safe ty decals. Keep sa fety decals

in good condition. Replace missing or damaged safety decals. Be sure new equipment components and

repairs parts include the current safety decals.

Learn how to operate the machine and how to use controls properly. Do not let anyone operate without

instruction.

Keep the machine in proper working condition.

Unauthorized modifications to the machine may impair the function and/or safety and affect the ma chine

life and thus void the Warranty.

Operate Safely

Do not make field adjustments while machine is in motion.

Do not enter tank unless another person is present and hydraulic hoses are disconnected from the tractor.

Operate machine from the tractor seat only.

Do not operate close to the edge of a ditch, creak, gully or steep embankment.

Avoid holes, ditches and obstructions which may cause tractor, seed wagon, or seeding tool to roll over,

especially on hillsides.

Avoid sharp turn on hillsides.

Slow down when turning or traveling over rough ground, and when turning on inclines.

Shut off tractor and shift in to ‘Park’ or set brakes when leaving tractor. Remove key when leaving tractor

unattended.

SW600 Owner’s Manual – Version 1.2 07/2018 23

www.horsch.com

Stay Clear of Air Hoses

Stay clear of hoses when fan is running. Seed or fertilizer blowing out at high speed can cause eye and

other personal injuries. Never attempt to clear blockage from air hoses or seeding tool boots while fan

is running.

Use a Signal Person

Use a signal person to direct movement of the tractor/seed wagon/seeding tool combination whenever

the tractor operator’s view is obstructed.

Designate one individual as the Signal Person. Always have the signal person stand in clear view. Be

sure signal person stays a safe distance away from the machine when it is moving.

Prior to starting the tractor, discuss hand signals and what each signal means to avoid misunderstandings

and confusion which could result in a serious injury or fatal accident for someone.

Keep all bystanders away whenever the machine is in motion.

Do not stand between seed wagon and implement while machine is in motion.

Wear Protective Clothing

Wear close fitting clothing and safety equipment appropriate to the job. Operating equipment safely

requires the full attention of the operator. Do not wear radio or music headphones while operating

machine.

24 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Keep Shields in Place

Do not operate seed wagon without safety shields in place.

Rotating parts can crush or dismember, causing a fatal accident or personal injury.

Shut off tractor and disconnect hydraulic hoses before removing shields for adjustment or service.

Use a Safety Chain

A safet y c h ain will help control drawn equipment should it accidentally separate from the drawbar of the

tractor. A safety chain of the proper strength rating is provided with the machine as s tandard equipment.

Using the appropriate adapter parts, attach the chain to the tractor drawbar support or other specified

anchor location. Provide only enough slack in the chain to permit turning.

SW600 Owner’s Manual – Version 1.2 07/2018 25

www.horsch.com

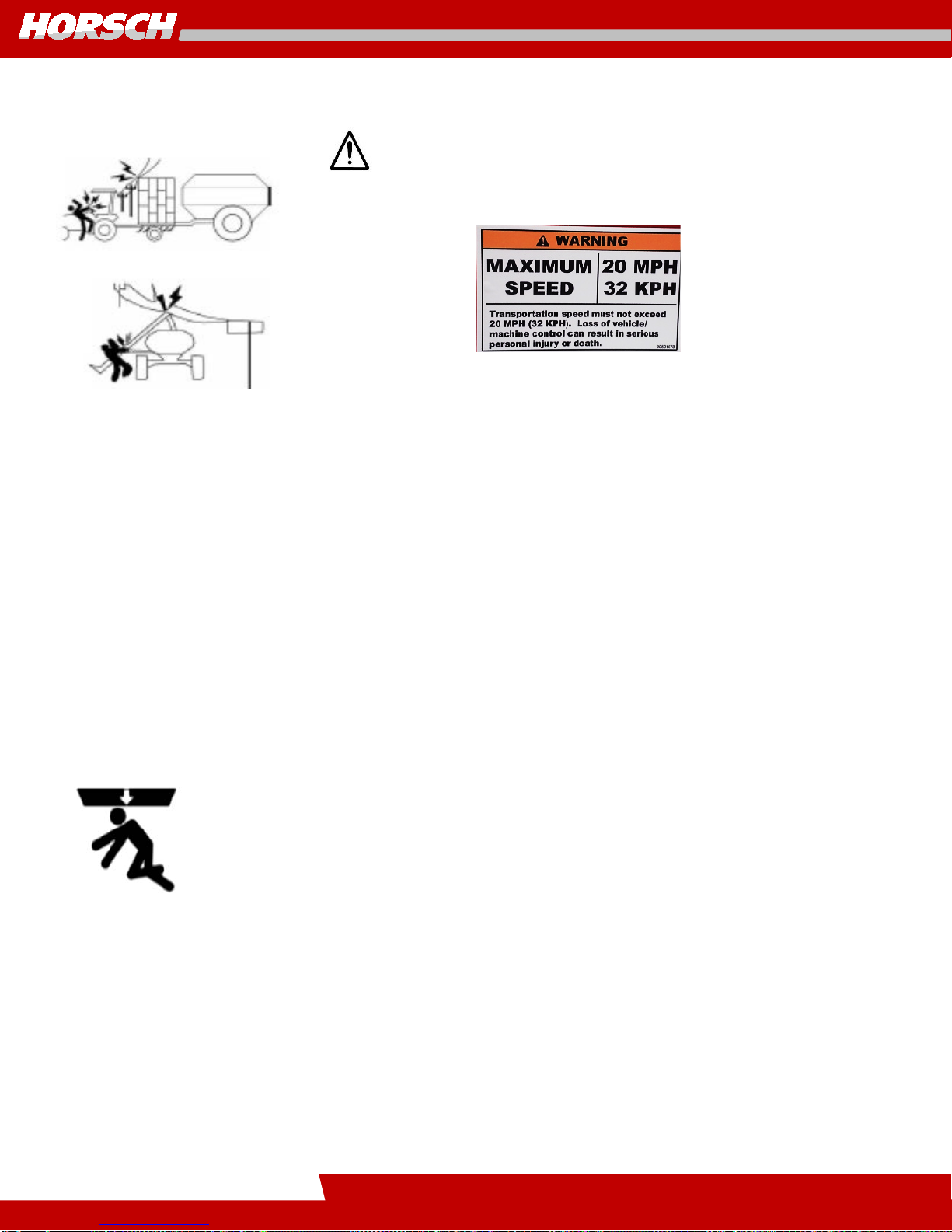

Transport Safety

DO NOT EXCEED A MAXIMUM TRANSPORTATION SPEED OF 20 MPH (32

KPH) DURING TRANSPORTATION. LOSS OF VEHICLE/MACHINE CONTROL CAN

RESULT IN SERIOUS PERSONAL INJURY OR DEATH!

Front Hitch decal

Keep away from overhead power lines. Serious injury or fatal accident may occur. Proceed cautiously

under overhead power lines and around utility poles. Know the transport height of your machine.

Do not position conveyor when near electric power lines.

Electrocution can occur without direct contact with overhead electric power lines.

Do not transport with an underweight tractor.

Prevent collisions between motorist and slow moving equipment on public roads. Frequently check for

traffic from the rear, especially in turns, and use the turn signals where necessary.

Always use the flashing warning lights, day and night, when transporting o n public roads. Keep reflective

material and SMV (Slow Moving Vehicle) sign clean and visible.

Passengers on the machine are strictly forbidden.

Danger Zone

Only enter the Danger Zone when the lifting cylinder depth stops/safety stops are inserted.

26 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Handle Pesticides and Fertilizers Carefull y

Chemicals may cause eye, skin or breathing problems. Wear face mask, or breathing apparatus, gloves

and goggles.

Keep dust away from skin and hair.

Keep containers low when pouring. Let the wind blow the fumes and dust AWAY from you and other

bystanders when mixing with seed or when filling the tank.

Wear a filtered respirator if you cannot avoid dust.

Wear goggles to protect your eyes.

Wash exposed skin areas frequently. Do not leave pesticide on your skin!

Do not smoke while handling pesticides.

Properly dispose of pesticide containers, unused pesticides and left over treated seed and fertilizer.

Read and observe manufacturers recommendations.

Store pesticides in original containers with clearly visible and intact labels. Store in a separate, plainly

marked locked building.

SW600 Owner’s Manual – Version 1.2 07/2018 27

www.horsch.com

Use Handrails and Steps

Falling is a major cause of personal injury.

When you get on and off machine, always maintain a three-point contact with steps and handrails and

face the machine. Do not use any controls as handrails or supports.

Never jump on or off the machine. Never mount or dismount a moving machine.

Do not ride on the machine. Do not stand on the tanks or catwalk.

Keep Riders off Machines

Keep riders off the machine at all times when in operation and in motion.

Riders are subject to injury, such as being struck by foreign objects and being thrown off the machine.

Riders also obstruct the operator’s view, resulting in the machine being operated in an unsafe manner.

Passengers on the machine are strictly forbidden.

28 SW600 Owner’s Manual – Version 1.2 07/2018

www.horsch.com

Use Safety Light and Devices

Prevent collisions between other road users, slow moving tractors with attachments or towed equipment,

and self-propelled machines on public roads. Frequently check for traffic from the rear, especially in

turns, use turn signals where necessary.

Use headlight, flashing warning lights, and turn signals day and night. Follow local regulations for

equipment lighting and marking. Keep lighting and marking visible and in good working order. Replace

or repair lighting and marking that has been damaged or lost.

SW600 Owner’s Manual – Version 1.2 07/2018 29

www.horsch.com

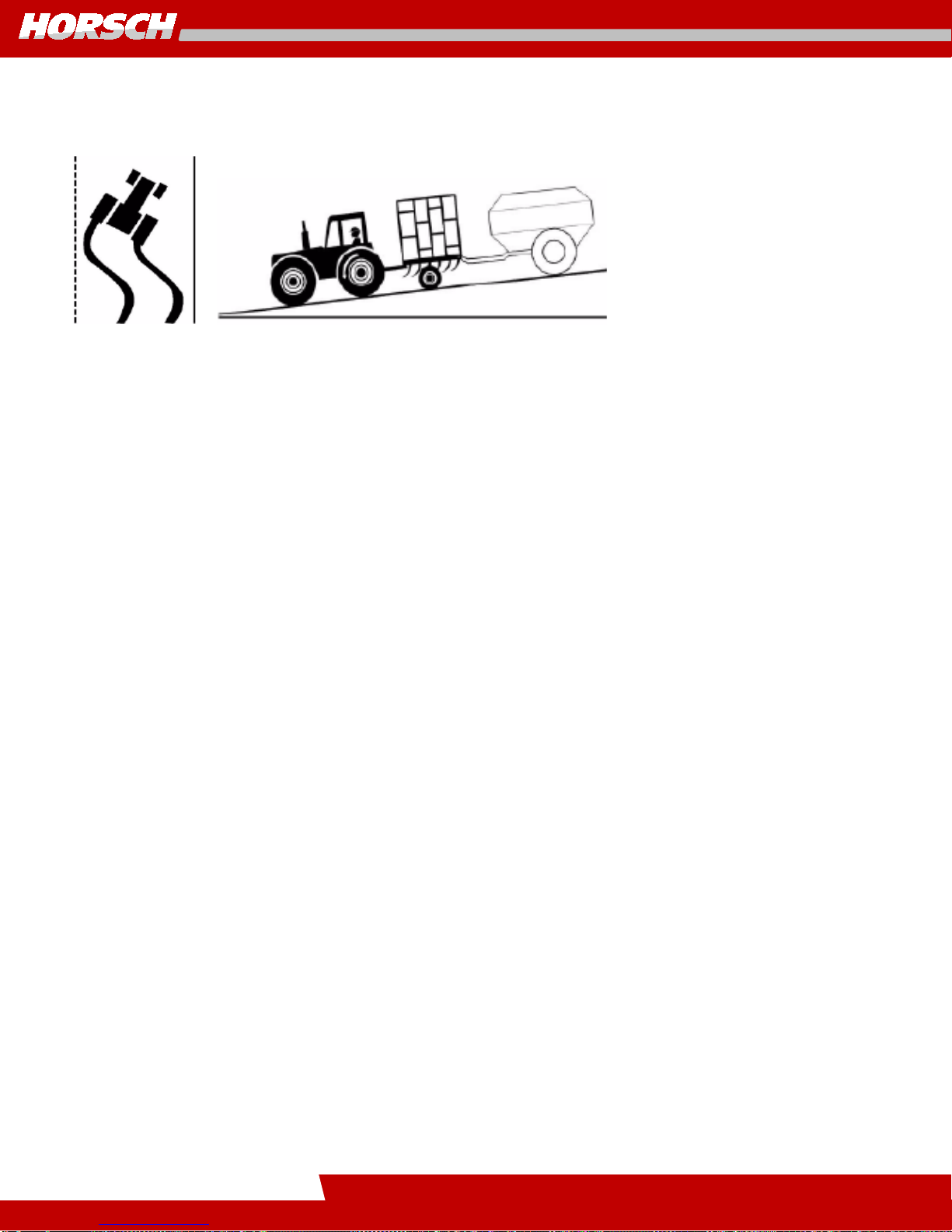

Transport Safel y

Always travel at a reasonable and safe speed. Never exceed 16 mph.

Never transport with any tank more than hal f full. If tanks are full travel speed should not ex ceed 10 mph.

Never transport with fan running.

Shift the tractor in to a lower range or gear when transporting down steep sl opes or hills. Latch the tr actor

left and right brakes together so when in use the tractor brakes evenly. Stop slowly.

Avoid loss of control due to decreased braking ability when transporting down sloped roadways, wet or

muddy roadways or roadways covered with loose gravel or sand.

Avoid steep slopes. Some slopes may exceed tractor braking capability.

Transport only with a properly sized tractor.

Refer to ‘Calculating Minimum Tractor Weight for Saf e Transport’ before transporting down a hill. Shift

tractor to a lower gear and travel at a reduced speed. Reducing the speed maximizes stability and control

and the tractors braking capability.

Use engine braking to reduce speed if available.

Avoid sharp turns or rapid steering corrections on slopes.

Stopping distance increases with speed and weight of towed loads, and on slopes. Towed loads with or

without brakes that are too heavy for the tractor or are towed too fast can cause loss of control. Consider

the total weight of the equipment and its load.

Observe these recommended maximum road speeds, or local speed limits which may be lower:

• Do not tow this implement faster than 20 Mph (32 Km/h)

• Never transport seed wagon when loaded on roadways

• Never tow this implement over 10 mph when fully loaded

Ensure the load does not exceed the recommended weight ratio. Add ballast to recommended maximum

for tractor, lighten the load, or get a heavier towing unit. The tractor must be heavy and powerful enough

with adequate braking power for the towed load. Use additional caution when towing loads under adverse

surface conditions, when turning, and on inclines.

30 SW600 Owner’s Manual – Version 1.2 07/2018

Loading...

Loading...