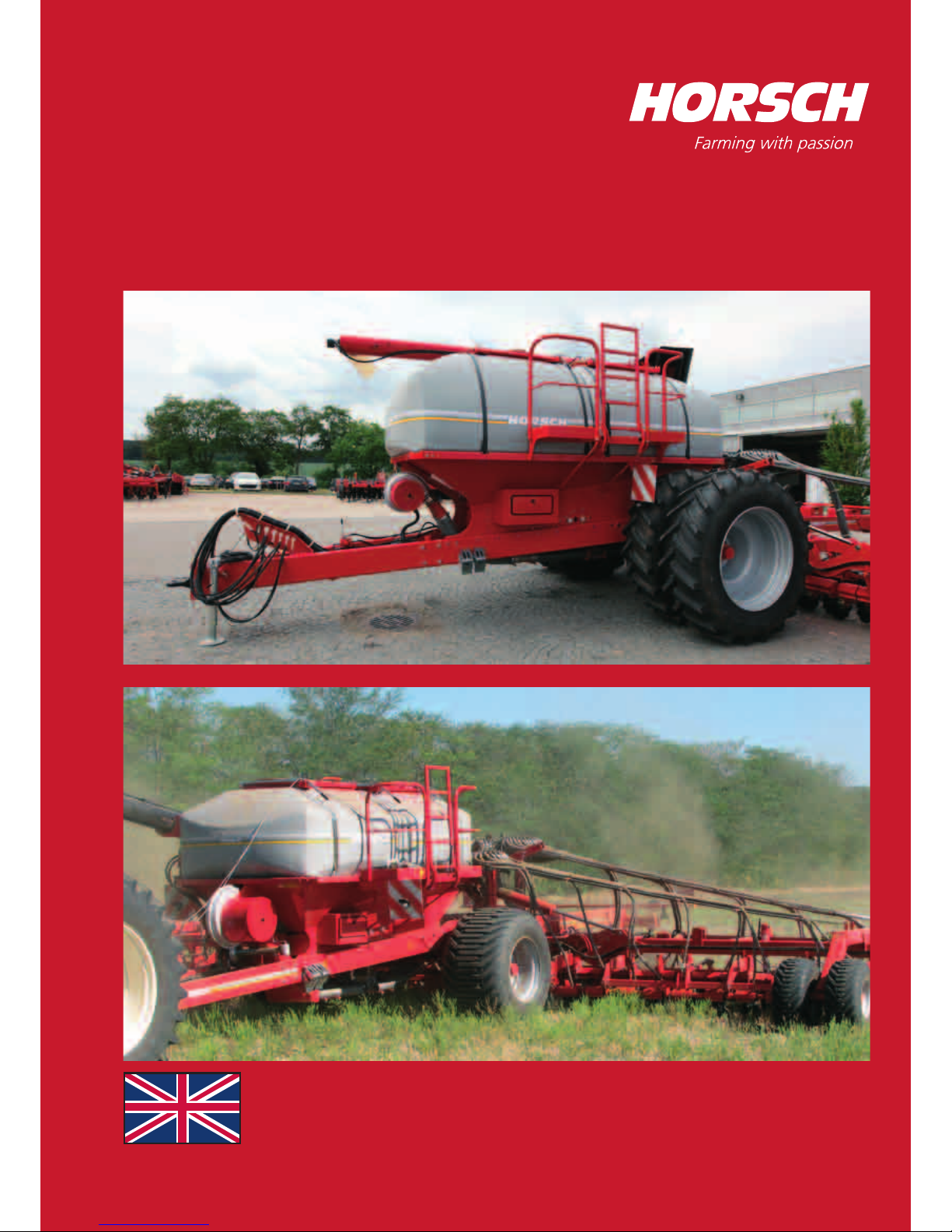

horsch SW 12000 SD Operating Instructions Manual

Operating Instructions

Art.: 80790201 en

Read carefully prior to starting up!

Keep operating instructions in a safe place!

07/2011

SW 12000 SD

EC Declaration of Conformity

In accordance with EC Directive 2006/42/EC

We, HORSCH Maschinen GmbH

Sitzenhof 1

D-92421 Schwandorf

do solely declare that the product

HORSCH SW 12000 SD

which is the subject of this declaration, fully conforms with the pertinent safety and health requi-

rements specied in EC Directive 2006/42/EC.

The following harmonised standards and technical specications were applied for correct interpretation of the safety and health requirements specied in the EC Directive:

DIN EN ISO 12100 Safety of machines

DIN EN 14018 Safety of drills

Schwandorf, 11.05.2010 Person responsible for documentation:

Place and Date Gerhard Muck

____________________ ____________________

M. Horsch P. Horsch

(Managing Director) (Development and Construction)

Operating instructions: 07/2011 80790201 SW 12000 SD en

I hereby conrm receipt of the operating instructions for the above mentioned machine.

I have been instructed by a HORSCH service technician or authorised dealer in the operation and

functions of the machine, as well as in the safety requirements.

........................................................................

Name of the service technician

Machine Registration

No warranty claims will be accepted if this machine registration form is

not returned !

I am aware that a warranty claim will only be valid if this form has been fully completed, signed and

returned to HORSCH Maschinen GmbH, or has been given to the Service Technician, immediately

after rst instruction.

................................................................... ........................................................................

Place, date of rst instruction Buyer’s signature

Dealer

Name: ............................................................

Street: ............................................................

Postal code: ...................................................

Place: .............................................................

Tel.: ................................................................

Fax:.................................................................

E-mail: ...........................................................

Customer No. : ...............................................

Customer

Name: ............................................................

Street: ............................................................

Postal code: ...................................................

Place: .............................................................

Tel.: ................................................................

Fax:.................................................................

E-mail: ...........................................................

Customer No. : ...............................................

.

Type of machine: ............................................

Serial number: ................................................

Delivery date: .................................................

To

HORSCH Maschinen GmbH

Postfach 10 38

D-92401 Schwandorf

Fax: +49 (0) 9431 / 41364

Demonstration machine – initial use

Demonstration machine - relocation

Demonstration machine nal sale - use

New machine nal sale – initial use

Customer‘s machine - relocation

- Translation of the Original Operating Instructions -

Machine Identication

The corresponding data is to be entered into the list below upon

receiving the machine:

Serial number: ..................................................

Machine type: ...................................................

Year of construction: ........................................

Initial installation: ..............................................

Fittings: .............................................................

..........................................................................

..........................................................................

..........................................................................

Publication date of Operation Manual: 07/2011

Latest change:

Address of Retailer: Name: ......................................................................

Road: ......................................................................

Town/City: ......................................................................

Tel.: ......................................................................

Customer No.:

Retailer: ......................................................................

Address of HORSCH: HORSCH Maschinen GmbH

92421 Schwandorf, Sitzenhof 1

92401 Schwandorf, Postbox 1038

Tel.: +49 (0) 9431 / 7143-0

Fax: +49 (0) 9431 / 41364

E-mail: info@horsch.com

Customer No.:

HORSCH: ......................................................................

2

Table of contents

Introduction .................................................4

Foreword ......................................................4

Warranty claims ............................................4

Intended use .................................................5

Consequential damage ...............................5

Authorised operators ....................................6

Protective clothing ........................................6

Information regarding safety .....................7

Safety symbols .............................................7

Operational safety ........................................9

Road trac safety.........................................9

Accident prevention .................................... 10

Hitching / un-hitching ................................10

Hydraulic connections ..............................10

Pressure accumulator .............................10

Changing implements ............................... 11

In operation ...............................................11

Service and maintenance ........................... 11

Technical data ...........................................12

Execution ................................................12

Dimensions and weights .........................12

Hydraulic coupling ..................................12

Tractor power required ...........................12

Tyres .......................................................12

Lighting .....................................................13

Hydraulic system ........................................14

Transport / installation .............................15

Delivery.......................................................15

Machines with DrillManager ME ...............15

Installation ..................................................15

Hitching and unhitching the machine..........16

Connect the hydraulic system ..................17

Connecting the road lighting equipment ...17

Parking the machine ................................. 17

Setting / Operation ...................................18

Seed and fertiliser hopper ..........................18

Venturi area ................................................ 19

Fan .............................................................19

Pneumatic system .................................... 21

Halfside shut-down (option) ...................... 24

Placing seeds with both hoppers .............. 24

Re-tightening the fan impeller ...................25

Metering unit ............................................. 26

Roller change ...........................................27

Roller change with full hopper ................. 27

Checking the sealing lip ............................28

Roller for ne seeds ..................................28

Rape brushes ........................................... 30

Coarse seeds ...........................................31

Metering unit with Venturi-type injector ....31

Servicing the metering unit .......................32

Checks .......................................................33

Work instructions ........................................ 35

Filling auger ..............................................36

Brake system ............................................38

Hydraulic brake .........................................40

Service and maintenance ........................41

Cleaning .....................................................41

Maintenance intervals.................................41

Preparation for storage ...............................41

Lubricating the machine ...........................42

Hygiene ...................................................42

Handling of lubricants ............................. 42

Service........................................................42

Maintenance schedule................................43

Lubrication points .....................................44

Possible faults - remedy .............................45

3

4

Introduction

Foreword

Before operating the machine, read and strictly

comply with the operating instructions. In doing

so, you will avoid accidents, reduce repair costs

and downtime and increase the reliability and

service life of your machine. Pay attention to

the safety instructions!

HORSCH will not assume liability for any damage or malfunctions resulting from failure to

comply with the operating instructions.

These operating instructions will assist you in

getting to know your machine and in using it

correctly for its intended purposes. First you are

given general instructions in handling the ma-

chine. This is followed by chapters on servicing,

maintenance and the action to be taken should

a malfunction occur.

The operating instructions must be read and

strictly adhered to by all persons working on or

with the machine e.g.

¾ Operation (including preparation, fault recti-

cation during work and servicing)

¾ Maintenance (maintenance and inspection)

¾ Transport

Together with the operating instructions, you

also receive receipt. Field service technicians

will instruct you in the operation and care of

your machine. After this you should return the

machine registration form to HORSCH.

This conrms your formal acceptance receipt

of the machine. The warranty period starts with

the date of delivery.

We reserve the right to alter illustrations as well

as technical data and weights contained in these

operating instructions for the purpose of improv-

ing the machine.

Warranty claims

Warranty claim forms must be submitted through

your local HORSCH dealer to the HORSCH

Service Department in Schwandorf.

Only claims, which have been correctly completed and submitted no later than four weeks

after the defect occurred, can be processed.

Exchange parts, which require the old part to be

returned, are marked with the letter "R".

Please return these components cleaned and

emptied to HORSCH within 4 weeks together

with a warranty claim form and precise fault

description.

Exchange parts, which do not require the old

part to be returned. Please keep such parts for

12 weeks, until a decision has been made on

the action to be taken.

Warranty repairs, which are to be carried out by

a third-party company, or which are expected

to take longer than 10 working hours, must be

agreed upon in advance with the Customer

Service Department.

5

Intended use

The seed wagon is state-of-the-art and designed in accordance with relevant, recognised

safety regulations. However, risks of injury to

the operator or third parties and impairment of

the machine or other tangible assets can occur

during use.

The machine must only be operated for its intended use if in a technically perfect condition,

whilst being aware of safety and risks and in

strict compliance with the operating instructions!

Faults, particularly those which impair safety,

must be remedied immediately.

The machine must only be operated, serviced

and repaired by persons who are familiar with

it and have been made aware of the dangers

involved.

Genuine spare parts and accessories from

HORSCH have been specially designed for this

machine. Spare parts and accessories which

are not delivered by us, have not been tested

or approved by us.

Installation or use of non-original HORSCH

products may have a detrimental effect on

specic design features of the machine and

impair the safety of machine operators and the

machine itself.

HORSCH will not assume liability whatsoever for

damage resulting from the use of non-original

parts and accessories.

The machine is designed to distribute seeds

and fertilisers. Any other use beyond these

limits, e.g. as a means of transport, is deemed

improper.

HORSCH will not assume liability whatsoever

for damage resulting from unintended use. The

risk will be borne solely by the user.

The respective accident prevention regulations

and other generally recognised safety-related,

occupational medical and road trac regulations

are to be adhered to.

Intended use also includes the strict compliance

with the operating instructions and adherence to

the operating, maintenance and repair instruc-

tions specied by the manufacturer.

Consequential damage

The mac hine has bee n manufactured by

HORSCH with great care. Nevertheless, even

when used properly, deviations or complete

failure in the application rate may be caused,

e.g. by:

¾ dierences in the composition of seed or

fertiliser (i.e. grain size distribution, density,

geometrical shape, dressing, sealing).

¾ blockages or seed bridging (i.e. caused by

foreign bodies, non-smooth seeds, sticky

dressing, moist fertiliser).

¾ Worn wearing parts (e.g. metering unit).

¾ Damage caused by external inuences.

¾ incorrect drive motor speeds and driving

speeds.

¾ incorrect setting of the unit (incorrect connec-

tion, non-observance of setting tables).

Therefore, it is crucial to always check your

machine before and during operation for correct

operation and adequate application accuracy.

Compensation claims for damages which have

not been caused by the machine, are excluded.

This also includes that any liability for consequential damages caused by drill and control

commands, is excluded.

6

In these operating instructions

The operating instructions distinguish between

three dierent types of warning and safety instructions. The following graphic symbols are

used:

important instructions!

if there is a risk of injury!

if there is a risk to life and limb!

It is important that all the safety instructions

contained in these operating instructions and

all the warning signs on the machine are read

thoroughly

Ensure that the warning signs are legible and

replace signs that are missing or damaged.

These instructions must be followed in order

to prevent accidents. Inform other users of the

warnings and safety instructions.

Do not carry out any operations which may aect

the safe use of the machine.

Authorised operators

Only those persons who have been authorised

and instructed by the operator may operate the

machine. Operators must be at least 16 years

of age.

The operator must hold a valid driving licence.

He is responsible for third parties in the operat-

ing area.

The person in charge must

¾ make the operating instructions available to

the operator.

¾ Ensure that the operator has read and under-

stood the operating instructions.

The operating instructions are a component part

of the machine.

Protective clothing

For operation and maintenance you need:

¾ snug tting clothing.

¾ protective gloves to protect against sharp-

edged machine parts.

¾ protective goggles to protect the eyes against

dust or spray, when working with fertiliser or

liquid fertiliser. Strictly observe the handling

instructions given by the fertiliser manufac-

turer.

¾ when handling dressing or dressed seed

wear a respirator mask and protective gloves.

Strictly observe the handling instructions

given by the dressing manufacturer.

7

Information regarding

safety

The following warnings and safety instructions

apply to all sections in these operating instruc-

tions.

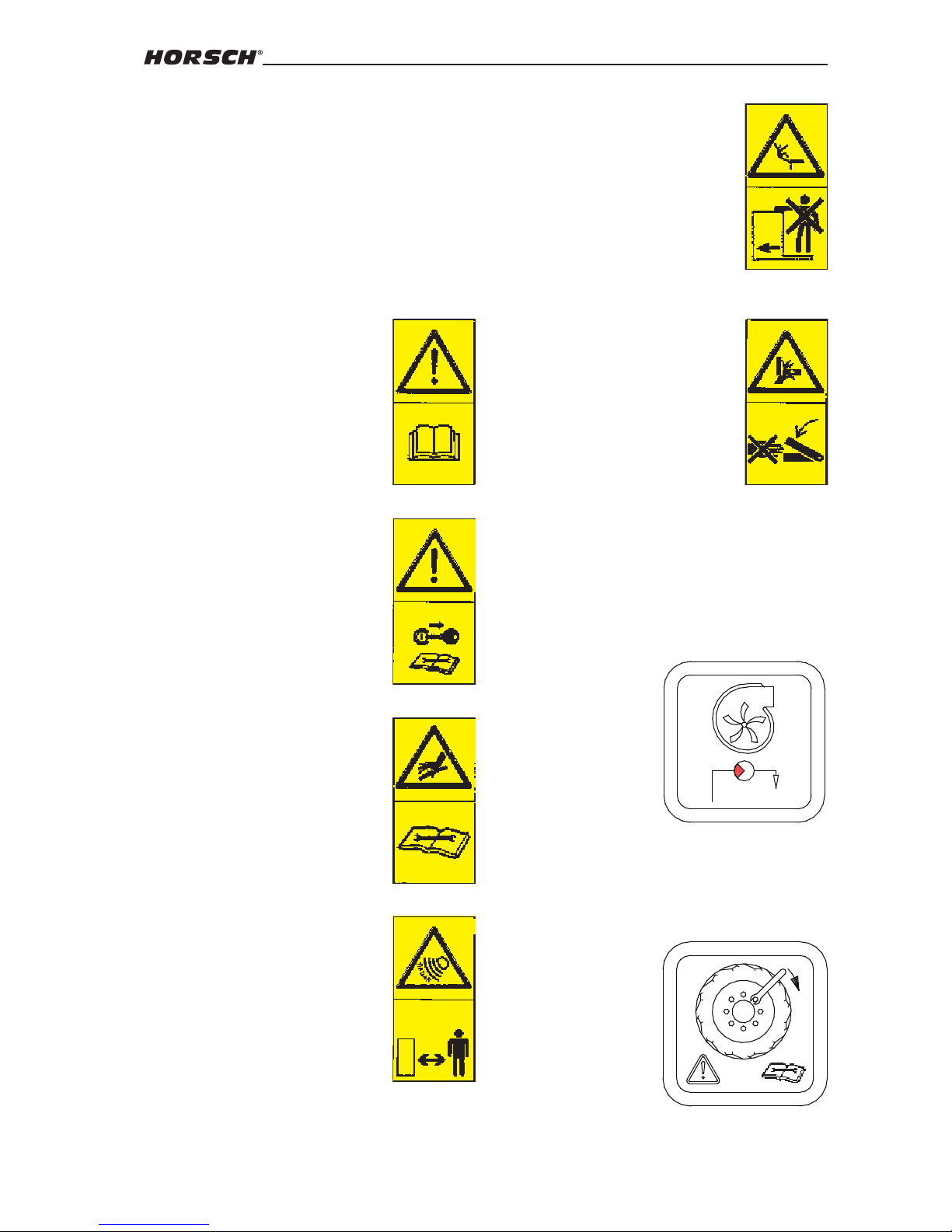

Safety symbols

On the machine

Retighten the wheel nuts / wheel bolts after 50

km or 10 hours. Tighten every day - see maintenance overview.

Watch out for uids spraying out

under high pressure, follow the

operating instructions

00380133

Never reach into areas where there

is a risk of crushing, as long as parts

could still be moving!

00380134

No passengers are allowed to ride

on the machine!

00380054

Read and adhere to the operating

instructions before starting up the

machine!

00380055

In order to prevent eye injuries, do

not look directly at the beam area

when the radar sensor is switched

on!

00380894

Switch the engine o and pull out

the key before starting maintenance

and repair work.

00380294

The return ow pressure at the fan drive must

not exceed 5 bar, as otherwise the hydraulic

motor may be destroyed.

00380242

max. 5 bar

00380359

8

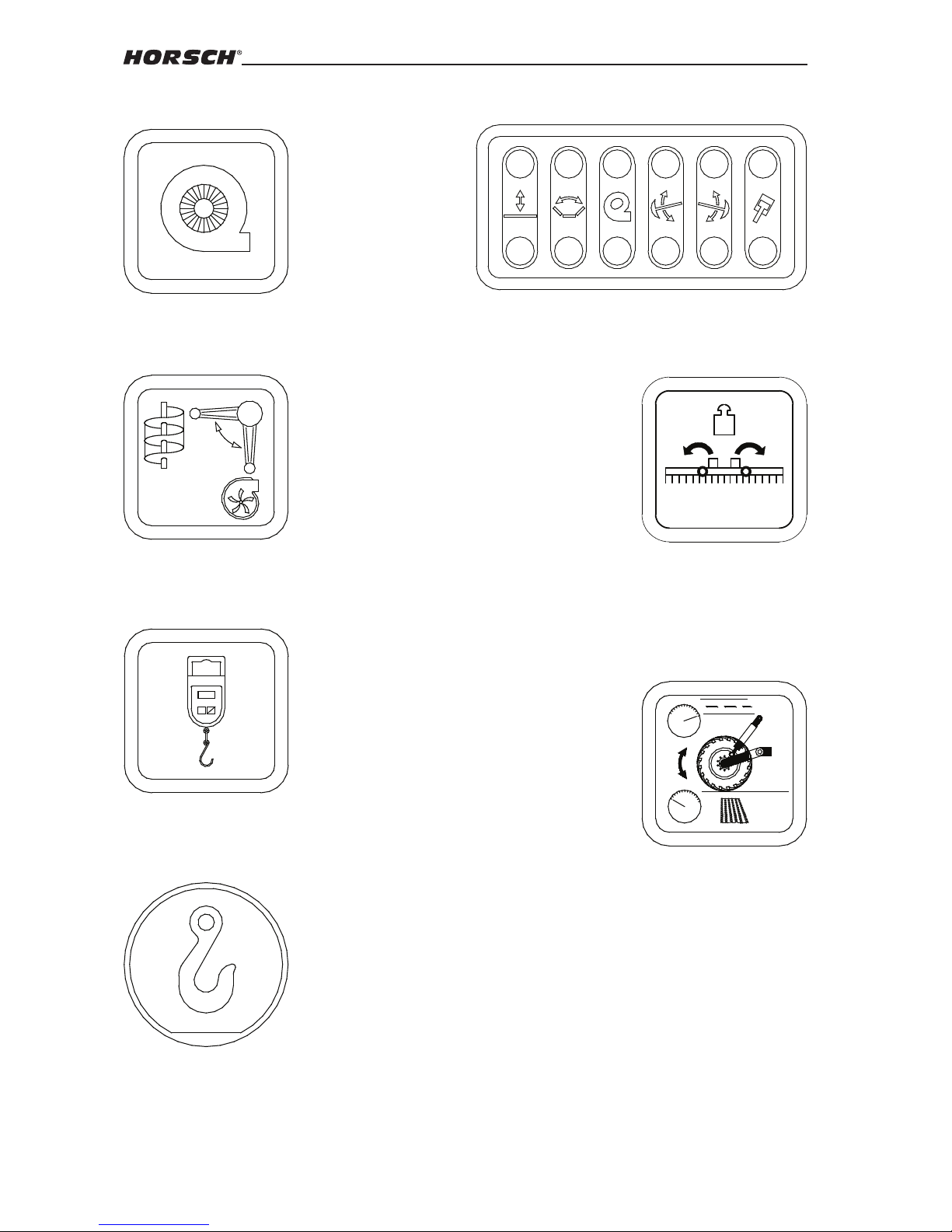

Lifting hook; attach lifting tackle (chains, ropes,

etc.) here when performing loading work.

Attach the scales here when calibrating.

00380880

00380879

OFF

ON

ZERO

HZ

SZ

HK

SK

B

A

R1

R2

L1

L2

Z1

Z2

00384071

Connection of hydraulic couplings

00384068

Pressure display for fan drive

00380882

Changeover fan drive / lling auger

For uniform weight distribution load the outer

wings with max. 70 kg

00384072

0

bar

0

bar

The hydraulic circuit "Packer" must only be under pressure during road travel

In the eld it should not be under pressure switch to oating position.

00384070

max. 70 bar

kg

9

Operational safety

The machine must only be put into operation

after receiving instructions by employees of the

authorized dealer or a HORSCH employee. The

machine registration form has to be completed

and returned to HORSCH.

All protective features and safety equipment,

such as detachable protective devices, must be

correctly in place and reliably functioning before

the machine is put into operation.

¾ Check and tighten nuts and screws at regular

intervals.

¾ Check tyre pressure regularly.

¾ In case of malfunctions stop and secure the

machine immediately!

Road trafc safety

The valid road trac regulations are to be observed when travelling on public roads, paths

and areas.

Do not exceed the max. permissible widths

and attach light system, warning and protective

devices.

Also observe transport height depending on the

coupled machine!

Do not exceed the permissible axle loads, tyre

carrying capacities and total weights, in order

to ensure sucient steering and braking capabilities. Handling is aected by the connected

equipment. It is important to take into account

the large overhang and the centrifugal mass of

the implement, particularly when cornering.

Clean all soil o the machine before driving on

public roads.

Passengers are strictly forbidden to ride on the

machine!

On public roads travel at a maximum speed

of 25 km/h and only with am empty seed

hopper.

00110681 00110682

00110687

00110687

00110687

00110681 00110682

00110683 00110684

00110687

Hydraulic valve block

Filling auger

Machine up / down

Unfold / fold machine

Tools

Bout markers

Fan

Identication marks on hydraulic hoses

The symbol is always found on the hose requiring pressure to bring the machine to transport

position (raising, folding, etc.).

10

Hydraulic connections

¾ Do not connect hydraulic lines to the tractor,

before both hydraulic systems (machine and

tractor) are de-pressurised.

¾ The hydraulic system is under high pressure.

Check all lines, hoses and screwed con-

nections regularly for leaks and any visible

external damage!

¾ Only use appropriate aids when checking for

leaks. Repair any damage immediately! Oil

sprays can cause injuries and re!

¾ In the case of injury, contact a doctor im-

mediately!

Power sockets and connectors on the hydraulic

connections between the tractor and machine

should be colour-coded in order to exclude op-

erating errors.

The control unit on the tractor must

be secured or locked when not in use

or when the machine is in transport

position, in order to prevent accidents

caused by unintended hydraulic movements or movements caused by persons other than the operator (children,

passengers).

Pressure accumulator

Ending on the hitched up drill a pressure ac-

cumulator may be installed.

Do not open or work (welding, drilling) on the

pressure accumulator. Even after being emptied, the accumulator is still preloaded by gas

pressure.

Always de-pressurize the pressure accumulator

before starting work on the hydraulic system.

The pressure gauge should not indicate any

pressure.

The pressure gauge reading should drop to 0

bar. Only then may work be carried out on the

hydraulic system.

Accident prevention

In addition to the operating instructions, it is

important to observe the accident prevention

regulations specied by agricultural trade associations!

Hitching / un-hitching

There is risk of injury to persons when hitching/

un-hitching the machine to the drawbar of the

tractor.

¾ Secure the machine against rolling away.

¾ Take special care when reversing the tractor.

Never stand between tractor and machine.

¾ Only park the machine on a rm and level

surface. Before un-hitching the machine,

lower it to the ground.

11

Service and maintenance

¾ Ensure that regular tests and inspections are

always carried out to schedule, as specied

in the operating instructions.

¾ Prior to performing maintenance and servicing

work, ensure that the machine is positioned

on rm, level ground and that it is properly

secured against rolling away.

¾ De-pressurise the hydraulic system and lower

or support the implement.

¾ Before cleaning the machine with high pres-

sure cleaning equipment cover all openings,

which should stay clear of water, steam or

cleaning agents for reasons of safety or op-

eration. Do not aim the water jet directly at

electrical or electronic components, bearings

or the fan.

¾ After cleaning, check all hydraulic lines for

leaks and loose connections.

¾ Check hoses for chang and signs of other

damage. Remedy any faults immediately!

¾ Prior to working on the electrical system,

disconnect it from the electric power supply.

¾ When performing welding work on the ma-

chine, disconnect the cables from computers

and other electronic components. The ground

connection must be as close as possible to

the welding point.

¾ Re-tighten screwed connections which have

been loosened during servicing and mainte-

nance work.

Do not wash new machines with a

steam-jet or high-pressure cleaner. The

paint takes approx. 3 months to cure

and could thus be damaged if this time

has not yet expired.

Changing implements

¾ Secure the machine against unintended roll-

ing!

¾ Secure lifted frame parts, under which you will

be working, with suitable supports!

In operation

¾ Check the area around the machine (for chil-

dren!) before setting o and starting operation

of the machine. Ensure sucient visibility.

¾ Do not remove any of the mandatory and

supplied protective devices.

¾ Stay clear of the operating range of hydrauli-

cally operated parts.

¾ Only use ascending aids and steps when ma-

chine is at standstill. Passengers are not allowed to ride on the machine during operation!

12

Technical data

Execution

Drill control: ..................................... electronic

Metering unit drive: .......................... electronic

Metering quantity: ....................... 0 - 500 kg/ha

Hydraulic fan:...........................max 5.000 rpm

Dimensions and weights

Width:

Version SW with wheels 650/65 R 38: ....3.00 m

Version SW with wheels 900/60 R 37: ....3.35 m

Version NT

with twin tyres: 20.8 R 42 ....................4.30 m

Version NT with wheels 650/65 R 38: ..3.55 m

Height:

Version SW:..........................................3.68 m

Version SW with lling auger: ...............3.93 m

Version SW lling height:......................3.34 m

Version NT:...........................................3.73 m

Version SW with lling auger: ...............3.98 m

Version SW lling height:......................3.39 m

Length:

Version SW:..........................................7.40 m

Version NT:.........................................6.880 m

Weight:

Version SW with lling auger: ............ 4.450 kg

Axle load: ........................................... 3.500 kg

Tongue load:......................................... 950 kg

Seed hopper capacity: .......................... 6,000 l

Fertiliser hopper capacity: ....................6,000 l

Hydraulic coupling

1 x double acting: .......................Control block

1 x double acting with

ow control valve: ......................................Fan

1 x freeow return: ................................leak oil

Tractor power required

Hydraulic pressure: .............................180 bar

required oil quantity: ...........................45 - 85 l

Tyres

Version SW / NT .......................... 650/65 R 38

Version SW / NT .......................... 900/60 R 37

Version NT with twin tyres ............... 20.8 R 42

K 80

3000

3680 ohne Befüllschnecke

1230

7139,2

2243

3340Einfüllhöhe

3930

1560

Version SW

580/70 R38

1020

6770

3980

3390Einfüllhöhe

4x 20.8 R 42

4286

Version NT

Loading...

Loading...