horsch Maestro 24 SW AHL Operating Instructions Manual

TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS

READ CAREFULLY PRIOR TO STARTING UP!

KEEP OPERATING INSTRUCTIONS IN A SAFE PLACE!

ART.:

ISSUE:

OPERATING INSTRUCTIONS

02

26

02/2018

8043

Maestro 24 SW AHL

- Translation of the Original Operating Instructions -

Machine Identication

The corresponding data is to be entered into the list below upon

receiving the machine:

Serial number: ..................................................

Machine type: ...................................................

Year of construction: ........................................

Initial installation: ..............................................

Fittings: .............................................................

..........................................................................

..........................................................................

..........................................................................

Publication date of Operation Manual:

Latest change:

Address of Retailer: Name: ......................................................................

Road: ......................................................................

Town/City: ......................................................................

Tel.: ......................................................................

Customer No.:

Retailer: ......................................................................

Address of HORSCH: HORSCH Maschinen GmbH

92421 Schwandorf, Sitzenhof 1

92401 Schwandorf, Postbox 1038

Tel.: +49 (0) 9431 / 7143-0

Fax: +49 (0) 9431 / 7143-9200

E-mail: info@horsch.com

Customer No.:

HORSCH: ......................................................................

Conrmation of receipt of machinery

Warranty claims become only eective when the rst use of the machine is reported to HORSCH

Maschinen GmbH within a week.

At www.horsch.com under SERVICE PARTNERBEREICH an interactive PDF form is available for down-

load for this purpose (not available in all languages).

By clicking on Send – depending on the email program installed – a mail draft with the completed

form is generated automatically. Alternatively, the form can be sent as email attachment to machine.

registration@horsch.com.

A dierent form of registration (postal mail, by fax, etc.) is not allowed for.

en

02

12/2017

Maestro 24 SW AHL

8043 26

EC Declaration of Conformity

Exchangeable equipment

(Directive 2006/42/EC)

The manufacturer HORSCH Maschinen GmbH

Sitzenhof 1

D- 92421 Schwandorf

hereby declares, that the product,

Designation of machine: Drill unit

Machine type: Maestro 24 SW AHL from serial number: 24591296

this declaration refers to, conforms with all relevant fundamental health and safety requirements of

the EC directive 2006/42/EC.

For proper implementation of the health and safety requirements mentioned in the EC-directive,

the following standards and technical specications have been used:

• DIN EN ISO 4254-1 2013-10

• DIN EN 14018 2010-02

• DIN EN ISO 12100 2011-03

Schwandorf, 20/07/2016 Klaus Winkler

Place and date Documentation ocer

________________________ ________________________

Michael Horsch Philipp Horsch

(Managing director) (Managing director)

Table of contents

Introduction ...................................................4

Foreword ........................................................4

Notes on representation .................................4

Service............................................................5

Warranty claim processing .............................5

Consequential damage...................................5

Safety and accident prevention ..................6

Intended use ...................................................6

Qualication of personnel ...............................7

Children in danger ..........................................8

Personal protective outt ................................8

Safety in trac ................................................8

Safety in operation..........................................9

Fertiliser and dressed seed ..........................12

Environmental protection ..............................12

Retrots ........................................................12

Care and maintenance .................................13

Danger zone .................................................14

Safety stickers ..............................................15

Structure......................................................18

Overview.......................................................18

Hydraulics .....................................................19

Identication of hydraulic hoses ...................24

Aluminium clips.............................................24

Lighting .........................................................25

Instruction stickers ........................................26

Technical data .............................................29

Type plate .....................................................30

Requirements for the tractor .........................31

Commissioning ...........................................34

Delivery.........................................................34

Transport ......................................................34

Installation ....................................................34

Operation .....................................................35

Commissioning / Tractor change ..................35

Adjust the height of drawbar

eye/spherical cap .......................................35

Connecting/Parking ......................................35

Connecting ...................................................35

Transport position .........................................37

Parking .........................................................38

Folding ..........................................................39

Menu “Folding” ...........................................40

Folding .......................................................40

Unfolding ....................................................44

Use in the eld ..............................................47

At the headland ..........................................47

Checks..........................................................49

Aligning the seed bar ....................................50

Pneumatic system ......................................51

Hopper ..........................................................51

Railing...........................................................52

Fan - vacuum................................................53

Seed on Demand system .............................54

Retightening the fan ange ........................56

Liquid fertiliser ..............................................57

Centrifugal pump .......................................57

Filling the hopper .......................................57

Draining the hopper ...................................57

Flow meter .................................................57

Filter ...........................................................57

Section Control ..........................................58

Flow View System .....................................58

Enter the quantity .......................................59

Calibration ..................................................59

Nozzles ......................................................60

Placement ..................................................62

2

Single grain metering .................................63

Single grain metering unit .............................64

Overview ....................................................64

Components in the metering unit ...............66

Adjusting the metering unit ........................73

Checks .......................................................77

Problems and rectication .........................78

Downpipe......................................................80

Single grain coulter discs..............................82

Depth guide rollers .......................................83

Trap roller .....................................................84

Setting the drilling depth ...............................85

Adjusting the coulter pressure ......................87

Press rollers..................................................88

Clearing stars (option) ..................................92

Troubleshooting Maestro ..............................94

Optional equipment ....................................95

ContourFarming............................................95

AutoForce .....................................................95

Care and Maintenance ...............................96

Maintenance intervals...................................97

Storage .........................................................97

Lubricating the machine ...............................97

Maintenance overview

Maestro 16/24/36 SW ...................................98

Lubrication points .......................................102

Waste disposal .........................................105

Appendix ...................................................106

Tightening torques ......................................106

Index ..........................................................108

3

Introduction

Foreword

Before commissioning the machine, read and

strictly comply with the operating instructions. In

doing so, you will avoid accidents, reduce repair

costs and downtime and increase the reliability

and service life of your machine. Pay attention

to the safety notes!

HORSCH will not assume liability for any damage or malfunctions resulting from failure of

complying with the operating instructions.

These operating instructions will assist you in

getting to know your machine and using it correctly for its intended purposes.

The operating instructions must be read and

strictly adhered to by all persons working on or

with the machine e.g.:

• Operation (including preparation, fault recti-

cation during work, care)

• Maintenance (maintenance, inspection)

• Transport

The trained personnel of our service and sales

partners will train and instruct you in the operation and care of your machine. By submitting the

acknowledgement of receipt you have conrmed

proper acceptance of the machine.

The warranty period starts with the date of

delivery.

We reserve the right to alter illustrations as well

as technical data and weights contained in these

operating instructions for the purpose of improving the machine.

The illustrations in these operating instructions

show dierent versions of the implement and

dierent equipment variants.

Notes on representation

Warning notes

These operating instructions distinguish be-

tween three dierent types of warning notes.

The following signal words with warning sym-

bols are used:

DANGER

Highlights a danger that will lead to death or

severe injury if it is not avoided.

WARNING

Highlights a danger that may lead to death or

severe injury if not avoided.

CAUTION

Highlights a danger that can lead to injuries if

not avoided.

Please read the warning notes given in these

operating instructions!

Instructions

NOTE

Identies important notes.

Take-action instructions are indicated by arrow

points:

¾ ...

¾ Keep the order of the instructions. Alternatively,

instructions may be numbered consecutively.

The designations right, left, front and rear apply as

seen in travel direction.

4

Service

HORSCH Company would like you to be completely satisfied with your machine and our

services.

If you encounter any problems, please feel free

to contact your sales partner.

The service sta of our sales partners and the

service employees at HORSCH will always be

available to assist you.

In order to be able to solve technical problems

as quickly as possible, we ask you kindly to

support us.

Please help the service personnel by providing

the following information to avoid unnecessary

queries.

• Customer number

• Name of customer representative

• Name and address

• Machine model and serial number

• Purchasing date and operating hours or

area performance

• Type of problem

Warranty claim

processing

Warranty claim forms must be submitted to

HORSCH through your local HORSCH sales

partner.

Consequential damage

The machine has been manufactured by

HORSCH with greatest care. However, despite

the intended use deviations in placing quantity

up to total failure may be caused by e.g.:

• damage caused by external inuences

• wear of wear items

• missing or damaged cultivation tools

• incorrect drive motor speeds and travel

speeds

• incorrect setting of the unit (incorrect con-

nection, non-observance of setting tables)

• failure to comply with the operating instruc-

tions

• dierences in the composition of seed or

fertiliser (i.e. grain size distribution, density,

geometrical shape, dressing, sealing)

• blockages or seed bridging (i.e. caused by

foreign bodies, non-smooth seeds, sticky

dressing, moist fertiliser)

• neglect and improper care and maintenance

Therefore, it is crucial to always check your machine before and during use for correct operation

and adequate application accuracy.

Compensation claims for damages that have

not occurred on the machine are excluded. This

also means that any liability for consequential

damages caused by travel and operating faults

is excluded.

5

Safety and accident

prevention

The following warnings and safety notes apply

to all sections in these operating instructions.

The machine has been built in accordance with

latest technical standards and generally accepted safety regulations. However, risks for

life and limb of the operator or third parties and

impairment of the machine or other material assets can occur during use.

Please read and comply with the following safety

notes, before you start to use the machine!

Intended use

The machine is intended for the singulation

and placement of seed as well as metering

and placement of liquid fertiliser on agricultural

areas.

The intended use also includes taking note of

and observing the information and instructions

given in these operating instructions, observing

all pictograms and warnings on the machine,

observing all maintenance and repair intervals

and complying with the dened technical limits

and areas of application.

When participating with the machine in public

road trac, the respective national registration

and trac law must also be complied with.

Any other kind of use of the machine contradicting the above, especially

• connection/attachment to an agricultural trac-

tor that is not suitable

• using the machine as a means of transport

• operating the machine while persons are still

in the danger zone (this includes in particular

transport rides on the machine)

• carrying out maintenance and/or repair work

on a machine that has not been shut down or

is not secured against restarting

are considered not as intended.

Horsch does not assume any liability for damages resulting from the unintended use of the

machine.

Spare parts

Genuine spare parts and accessories from

HORSCH have been specially designed for this

machine.

Spare parts and accessories which are not delivered by us have not been tested or approved

by us.

Installation or use of non-original HORSCH

products may have a detrimental effect on

specic design features of the machine and

impair the safety of machine operators and the

machine itself.

HORSCH will not assume liability whatsoever for

damage resulting from the use of non-original

parts and accessories.

If the component to be replaced is marked with

a safety sticker, these stickers must also be

ordered and attached to the spare part.

6

Operating Instructions

Intended use also includes strict compliance with

the operating instructions and adherence to the

operating, maintenance and repair instructions

specied by the manufacturer.

The operating instructions are a part of the

machine!

The machine is solely intended for use as described in the operating instructions. Failure to

comply with the operating instructions can result

in severe or even fatal physical injuries.

¾ Read and follow the corresponding sections

in the operating instructions before starting

work.

¾ Store the operating instructions and keep for

future use.

¾ Pass the operating instructions on to a later

user.

Qualication of personnel

Unintended use of the machine can lead to severe or even fatal physical injuries. In order to

prevent accidents, each person involved in work

with the machine must meet the following general

minimum requirements:

¾ The person must be physically able to keep

the machine under control.

¾ The person is able to perform work with the

machine safely within the scope of these operating instructions.

¾ The person is acquainted with the function of

the machine within the scope of its work and

is able to assess and avoid any work related

dangers. The person is able to recognize and

avoid work related dangers.

¾ The person has understood the operating

instructions and is able to implement the information given in the operating instructions

accordingly.

¾ The person is fully familiar with the safe opera-

tion of the vehicle.

¾ The person knows all applicable road trac

regulations and is in possession of a valid

driving permit for road travel.

¾ A person being instructed must only work with

or on the machine under the supervision of

an experienced person.

The owner of the machine must

¾ regulate the area of responsibility, compe-

tence and monitoring of personnel.

¾ if necessary train and instruct the personnel.

¾ make the operating instructions accessible for

the machine operator.

¾ ensure that the operator has read and under-

stood the operating instructions.

Groups of operators

Persons who work with the machine must have

been trained for the dierent activities involved.

Instructed operators

These persons must have been trained for

their respective activities by the owner or other

qualied experts. This refers to the following

activities:

• Road transportation

• Application and set-up work

• Operation

• Maintenance

• Troubleshooting and repair

Operators trained by HORSCH

Furthermore, for certain activities the corresponding personnel must have been trained by

service personnel from HORSCH. This refers to

the following activities:

• Loading and transport

• Commissioning

• Troubleshooting and repair

• Waste disposal

Certain work concerning maintenance and repair

must only be carried out by an expert workshop.

Such work is identied with the additional comment Workshop work.

7

Children in danger

Children are not able to assess dangers and may

behave unpredictably. Children are therefore

especially endangered:

¾ Keep children away from the machine.

¾ Especially before drive o and before trigger-

ing machine movements you must make sure

that the danger zone is free of children.

¾ Shut down the tractor before leaving it.

Children can trigger dangerous machine

movements. An insuciently secured machine parked without being attended poses

a danger for playing children!

Personal protective outt

Missing or incomplete protective equipment

increases the risk of health damage. Personal

protective equipment includes, e.g.:

¾ tight tting clothes / protective clothing, pos-

sibly a hair net

¾ safety shoes

¾ safety gloves

¾ safety goggles to protect the eyes against

dust or spray, when working with fertiliser or

liquid fertiliser (follow the instructions of the

fertiliser manufacturer)

¾ respirator masks and protective gloves when

handling dressing or dressed seed (follow

the instructions of the pickling agent manufacturers)

¾ Determine the personal protective equipment

for the respective work assignment.

¾ Provide effective protective equipment in

proper condition.

¾ Never wear rings, bracelets or other jewellery.

Safety in trac

DANGER

No passengers are allowed to ride on the

machine!

¾ Pay attention to the permissible transport

widths and heights. Pay attention to the transport height when passing under bridges and

low hanging overhead power lines.

¾ Do not exceed the permissible axle load, tyre

load bearing capacity and total weight, in order

to ensure sucient steering and braking capabilities. The front axle must be loaded with at

least 20% of the tractor weight.

¾ For machines without brake select the weight

of the tractor and the speed so that the machine can be managed securely under all

conditions.

For road transport the machine must be set to

transport position. The machine must have been

folded up and secured, see chapter Folding and

Connecting and Transport position.

¾ Clean soil from the folding areas before fold-

ing up. Otherwise there could be damage to

the mechanics.

¾ If present: Secure the hydraulic cylinders on

undercarriage and drawbar in transport position against uncontrolled movements using

aluminium clips, see chapters Connecting and

Transport position.

¾ Assemble lighting, warning and protective

features and check the function.

¾ Before road travel clean the entire machine

from picked up dirt.

Handling is aected by the connected equipment.

¾ Consider the wide overhang and the centrifu-

gal mass of the implement as well as the lling

capacities, especially when cornering.

For transport on public roads, only drive

with empty seed hopper.

8

Pay attention to the permissible top

speed in accordance with the type approval for transport on public roads!

The specications in the type approval

document or in the technical data are

decisive for the design dependent top

speed.

Always match the travel mode to the

road conditions to avoid accidents and

damage to the undercarriage.

Consider your personal abilities, carriage

way, trac, sight and weather conditions.

Pay attention also to the notes in chapter

Commissioning!

The hydraulic cylinders on the undercar-

riage must be lled up with spacers, the

machine must be lowered on these spacers.

Safety in operation

Commissioning

The operational safety of the machine cannot be

guaranteed without orderly performed commissioning. This can lead to accidents with severe

or even fatal physical injuries.

¾ The machine must only be put into operation

after receiving instructions by employees of

the authorized dealer or a HORSCH employee.

¾ The machine registration form must be com-

pleted and returned to HORSCH.

Only use the machine with all protective features

and safety relevant installations, such as e.g.

detachable safety features, in place and fully

functional.

¾ Check nuts and bolts, especially the ones on

wheels and cultivation tools regularly for tight

t and retighten if necessary.

¾ Check tyre pressure regularly.

Damage to the machine

Damage to the machine can impair the operational safety of the machine and cause accidents. This can lead to severe or even fatal

physical injuries.

The following machine parts are particularly

important for safety:

¾ Hydraulics

¾ Brakes

¾ Connecting features

¾ Protective features

¾ Lighting

If in doubt about the safety-relevant status of

the machine, e.g. in case of leaking operating

uids, visible damage or unexpected changes

in travel behaviour:

¾ Immediately shut down and secure the ma-

chine.

¾ If possible locate and rectify the faults by fol-

lowing these operating instructions.

¾ Rectify possible causes for damage (e.g. re-

move coarse dirt and tighten loose screws).

¾ Have damage that could aect safety and

that cannot be rectied by you rectied by a

qualied expert workshop.

Coupling and unhitching

Faulty coupling of the machine and pulling tool

of the tractor causes dangers, which could result

in severe accidents.

¾ Caution with negative drawbar load!

With an empty hopper and under certain operating conditions the machine may have a

negative drawbar load.

The rear axle of the tractor is unloaded. This

has a negative eect on the steering and

braking characteristics.

Caution when unhitching!

Always fold the wings in or rest them on the

ground beforehand.

9

¾ Only park the machine on a rm and level sur-

face. Before unhitching the towed machine,

lower it to the ground. The machine could

otherwise strike up! The seed wagon could

tip backwards!

¾ Strictly comply with all operating instructions:

• These operating instructions (chapter Con-

necting, Transport position and Parking)

• Operating instructions of the tractor

• if necessary the operating instructions for

the propshaft

¾ Exercise special caution when reversing the

tractor. Never stand between tractor and

machine.

¾ Secure the machine against rolling away.

Hydraulics

The hydraulic system is under high pressure.

Escaping uid can penetrate the skin and cause

serious injuries. In the event of injury, consult a

doctor immediately.

The machine's hydraulics has several functions,

which can cause injury to persons or damage to

the machine if operated incorrectly.

¾ Do not connect hydraulic hoses to the tractor,

before both hydraulic systems on machine

and tractor are de-pressurised.

¾ Lower all hydraulically lifted parts (e.g. wings,

packer, undercarriage, etc.) to the ground

before performing any work on the hydraulic

system. Depressurise the hydraulics on the

tractor and implement side.

¾ The hydraulic system is under high pressure.

Check all lines, hoses and screwed connections regularly for leaks and any visible

external damage!

¾ Hydraulic components on unsecured machine

parts must not be dismantled.

¾ Use only appropriate means when searching

for leaks. Repair any damage immediately!

Oil sprays can cause injuries and re!

¾ Power sockets and connectors on the hydrau-

lic connections should be marked in order to

exclude operating errors.

¾ In the case of injury, contact a doctor imme-

diately!

¾ Secure and lock the control unit on the tractor

if not in use!

¾ Replace hydraulic hoses at the latest after six

years, see Maintenance overview.

Pressure accumulator

The hydraulic system is equipped with pressure

accumulators.

¾ Do not open or work (welding, drilling) on

pressure accumulators. Even when empty,

the tanks are still preloaded by gas pressure.

The hydraulics must be depressurized before

maintenance!

Brake system

Depending on the equipment, the machines can

be equipped with a pneumatically or hydrauli-

cally operated service brake system.

For road travel the brake system must always

be connected and fully functional.

¾ After coupling the machine and before trans-

portation you should always check the function and condition of the brake system.

¾ Check the setting on the brake pressure

regulator. Turn the lever to the Road symbol

(pneumatic brake) before transport travel.

¾ Always release the parking brake before start-

ing to drive.

¾ Always secure the machine against rolling

away and apply the parking brake before

unhitching.

Adjustments and repair work on the brake system must only be carried out in a professional

workshop or by an operator, who has been

specially trained by HORSCH for this purpose.

10

Overhead lines

When unfolding or folding the wings, the machine may reach the height of overhead lines.

Possible voltage ashover to the machine causing fatal electric shock or re.

¾ Keep a safe distance to electric high voltage

power lines when unfolding or folding the

machine.

¾ Do not unfold or fold the wings in the vicinity

of pylons and power lines.

¾ With the wings unfolded keep a sucient

distance to electric high voltage power lines.

¾ Never leave or access the machine under

overhead lines to avoid possible risks of

electric shock or voltage ashover.

What to do in case of voltage ashover

Voltage ashover generates high electric voltages on the outside of the machine. This results

in extreme voltage dierences at the ground

around the machine. Wide strides, laying on the

ground or supporting yourself with your hands

on the ground can cause life-threatening electric

currents (pace voltage).

¾ Do not leave the cabin.

¾ Do not touch any metal objects.

¾ Do not create a conductive connection to

ground.

¾ Warn persons: DO NOT come near the ma-

chine. Electric voltages at the ground can

cause severe electric shock.

¾ Wait for professional rescuers. The overhead

power line needs to be switched o.

If persons need to leave the cabin despite the

voltage ashover, e.g. in case of a potential lifethreatening risk of re:

¾ Jump away from the machine. Ensure a safe

stand when jumping. Do not touch the outside

of the machine.

¾ Move away from the machine with short step-

ping strides.

Technical limiting values

If the technical limiting values of the machine are

not observed, the machine may get damaged.

This can lead to accidents with severe or even

fatal physical injuries.

The following technical limiting values are of

particular importance for safety:

• permissible total weight

• maximum axle loads

• maximum drawbar load

• top speed

See chapter Technical data, type plate and type

approval.

¾ Also pay attention to the max. permitted loads

for the tractor.

Use in the eld

DANGER

No passengers are allowed to ride on the

machine!

¾ Check the area immediately around the ma-

chine (for children!) before driving o and

commissioning the machine. Ensure sucient

visibility.

¾ Check the condition of the cultivation tools

and their mounting before use.

¾ Ensure sucient stability of the machine in

case of longitudinal or transverse inclination

when working in uneven terrain. Pay attention

to the limiting values for the tractor.

¾ Do not remove any of the mandatory and

supplied protective devices.

¾ Stay clear of the operating range of hydrauli-

cally operated parts.

¾ Use climbing means and steps only at stand-

still.

¾ Do not drive backwards with the machine

lowered. The components have only been

designed for forward travel in the eld and

may be damaged when reversing.

11

Changing equipment / wear items

¾ Only pulling tools may be attached that meet

the technical requirements according to these

operating instructions.

HORSCH does not assume any liability for

damages resulting from the attachment of

non-tting pulling tools as well as incorrect

mounting.

¾ For machines with valid type approval only

pulling tools may be attached that are covered

by the type approval. Attaching pulling tools

not covered by the type approval will void the

registration.

¾ Secure the machine against unintended roll-

ing away!

¾ Secure raised frame parts you have to work

under with suitable supports!

¾ Caution! Danger of injury caused by projecting

parts (e.g. coulters)!

¾ Assume ergonomic working postures with any

assembly work.

¾ Do not use packer tyres or other rotating

parts to climb on the machine. These could

rotate and you could be seriously injured by

falling down.

Fertiliser and dressed

seed

Inappropriate handling of fertiliser and dressed

seed can cause poisoning and death.

¾ Follow the information given in the safety

data sheet of the manufacturer. If necessary

ask the dealer for the corresponding safety

data sheet.

¾ Determine and provide the personal protective

outt as specied by the manufacturer.

Environmental protection

Operating materials such as hydraulic oil, lubricants, etc. can damage the environment and the

health of persons.

¾ Do not allow operating materials to drain out

into the environment.

¾ Take up drained operating materials with

absorbent material or sand, ll it into a leak

tight tank and dispose of in accordance with

statutory regulations.

Retrots

Structural changes not approved by HORSCH

may aect the functionality and operational

safety of the machine and will void any warranty

claim.

HORSCH is not liable for damages to life and

limb as well as property damages resulting from

unapproved retrotting and conversions.

¾ Do not perform any structural changes to the

pulling tool of the machine.

¾ Do not make any structural changes or ex-

tensions to the machine that have not been

approved by HORSCH.

¾ Modications and extensions approved by

HORSCH are only to be performed at an authorized workshop or by an operator who has

been trained by HORSCH for this purpose.

¾ Comply with country-specic instructions for

weights, weight distribution and dimensions.

For equipment inuencing the weight or weight

distribution the regulations concerning towing

facility, support and axle load must be checked

and complied with.

For machines without brakes a brake system

may need to be retrotted if the permissible

weight limits are exceeded.

12

In case of changes concerning data mentioned

on the type plate, a new type plate with updated

data must be attached.

In case of changes which concern the data in

the type approval, this type approval needs to

be renewed.

Care and maintenance

Inappropriate care and maintenance puts the

operational safety of the machine at risk. This

can lead to accidents with severe or even fatal

physical injuries.

¾ Conform to prescribed schedules for repetitive

tests or inspections.

¾ Service the machine according to the

maintenance plan, see chapter Care and

maintenance.

¾ Only perform the work described in these

operating instructions.

¾ Before starting maintenance and service work

park the machine on level and rm ground and

secure it against rolling away.

¾ Depressurise the hydraulic system and lower

or support the implement.

¾ Prior to working on the electrical system,

disconnect it from the electric current supply.

¾ When performing welding work on the ma-

chine, disconnect the cables from computers

and other electronic components. The ground

connection must be as close as possible to

the welding point.

¾ Before cleaning the machine with high pres-

sure cleaner cover all openings, which should

stay clear of water, steam or cleaning agents

for reasons of safety or operation. Do not aim

the water jet directly at electrical or electronic

components, bearings or the fan.

¾ When cleaning with high pressure cleaning

equipment or steam jet keep a distance of at

least 50 cm to machine components.

¾ Hopper, metering units, hoses and coulters

are contaminated with fertilisers and dressed

seed. Wear suitable protective outt when

cleaning. Avoid contact and do not breath

the exhaust air.

¾ After cleaning, check all hydraulic lines for

leaks and loose connections.

¾ Check for chang and signs of damage. Rem-

edy any faults immediately!

¾ Screw connections loosened for the purpose

of care and maintenance work must be

retighten after work is completed.

¾ Do not clean new machines with a steam jet

of a high pressure cleaner. The paint takes

approx. 3 months to cure and could thus be

damaged if this time has not yet expired.

¾ All other maintenance and repair tasks,

which are not described in the operating

instructions, must only be carried out by

an authorized professional workshop or

by an operator who has been trained by

HORSCH for this purpose.

13

Danger zone

The area marked red indicates the danger zone

of the machine:

The danger zone around the machine poses the

following endangerments:

• Accidental operation of the hydraulic system

can trigger dangerous movements of the

machine.

• With the drive still running, machine parts may

rotate or swing out.

• Hydraulically raised machine parts can lower

slowly and unnoticed.

Failing to pay attention to the danger zone can

result in severe or even fatal physical injuries.

¾ Do not stand under lifted loads. Lower such

loads to the ground rst.

¾ Instruct persons to leave the danger zone

around the machine and tractor before any

machine movements.

¾ Before working in the danger zone of the ma-

chine or between machine and tractor: Shut

down the tractor!

This also applies for short-term inspection work.

Many accidents happen because of carelessness and running machines!

¾ Pay attention to the information in all operat-

ing instructions.

14

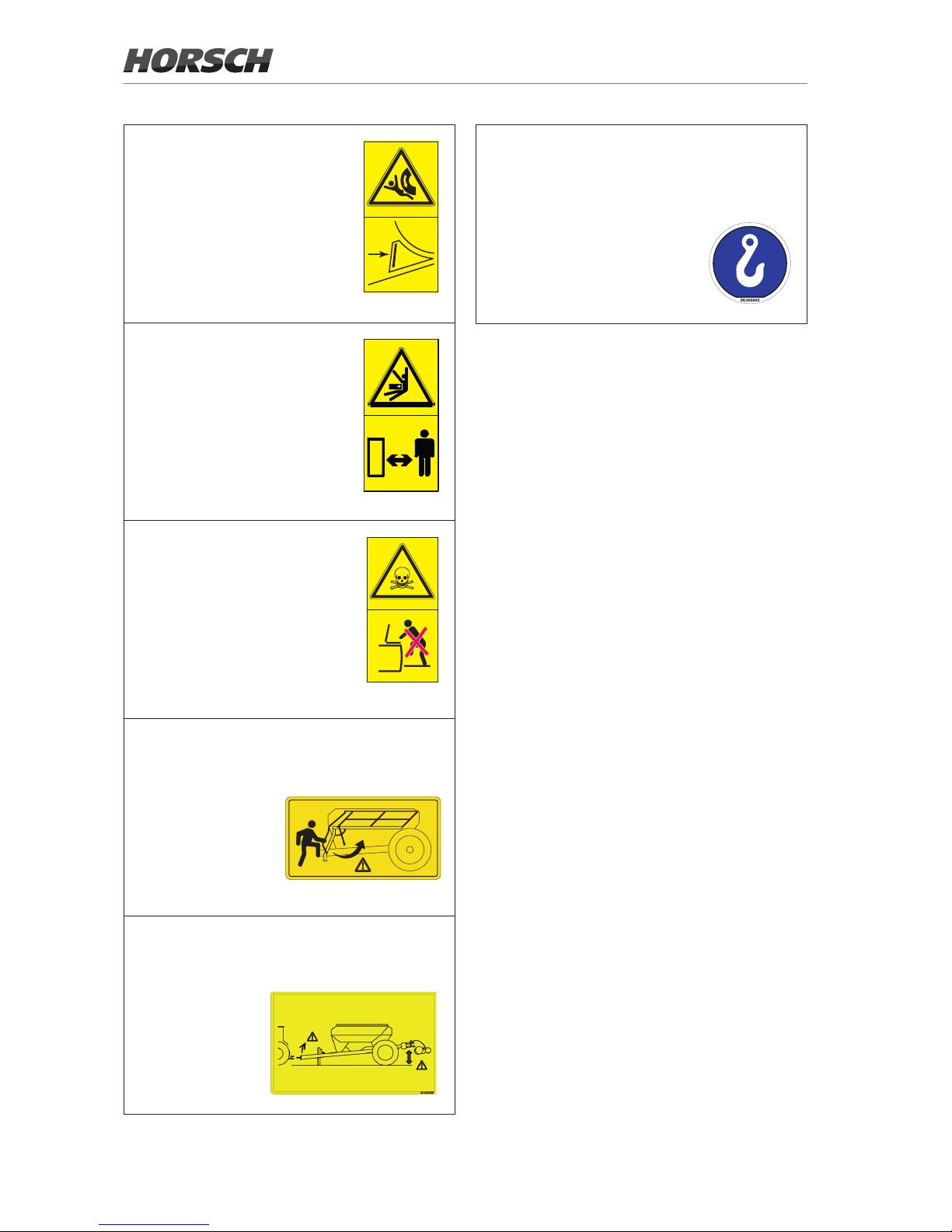

Safety stickers

Safety stickers on the machine warn of hazards

at dangerous points and are an important part

of the safety equipment of the machine. Missing safety stickers increase the risk of severe or

even fatal injuries.

¾ Clean soiled safety stickers.

¾ Damaged or illegible safety stickers must be

replaced immediately.

¾ Provide spare parts with the specied safety

stickers.

No passengers are allowed to

ride on the machine!

00380054

Before commissioning the machine you need to read and follow the operating instructions!

00380055

Caution for uids spraying out

under high pressure, follow the

notes in the operating instructions!

00380133

Never reach into areas where

there is a risk of crushing as long

as parts could still be moving!

00380134

Stay clear of the operating

range of foldable machine parts!

00380135

Shut the engine down and pull

o the key before starting maintenance and repair work.

00380294

The pressure accumulator is

charged with gas or oil pressure. Dismantle and repair

only in strict compliance with

the instructions in the technical

manual.

00380252

In order to prevent eye injuries,

do not look directly at the beam

area when the radar sensor is

switched on!

00380894

15

Secure the machine with wheel

chocks before uncoupling or

parking.

00381116

Keep sucient safety distance

to the slewing range of the

machine.

00381117

04001456

Danger of poisoning - Never

climb into the tank.

Fold the railing up before accessing. Fold

the railing down before folding up the machine.

00385752

In case of a negative drawbar load the

drawbar may jerk upward when unhitching!

Lower the seed bar all the way before

unhitching!

00380986

Loading hook;

hook the load suspension gear (chains,

ropes etc.) into this loading hook during

loading.

16

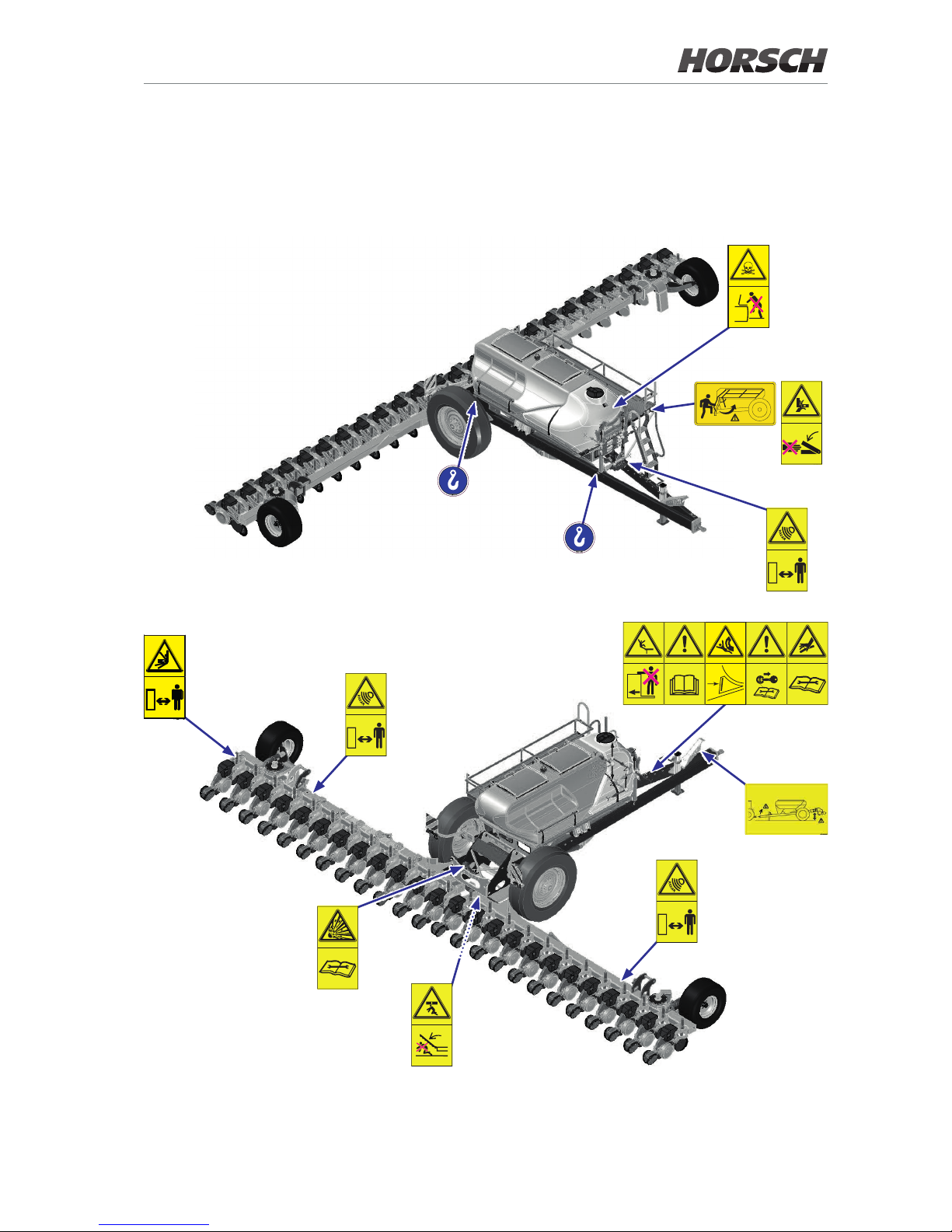

Safety stickers with the addition “2x” can be found on either side of the machine.

Position of the safety stickers (depending on equipment)

2x

2x

17

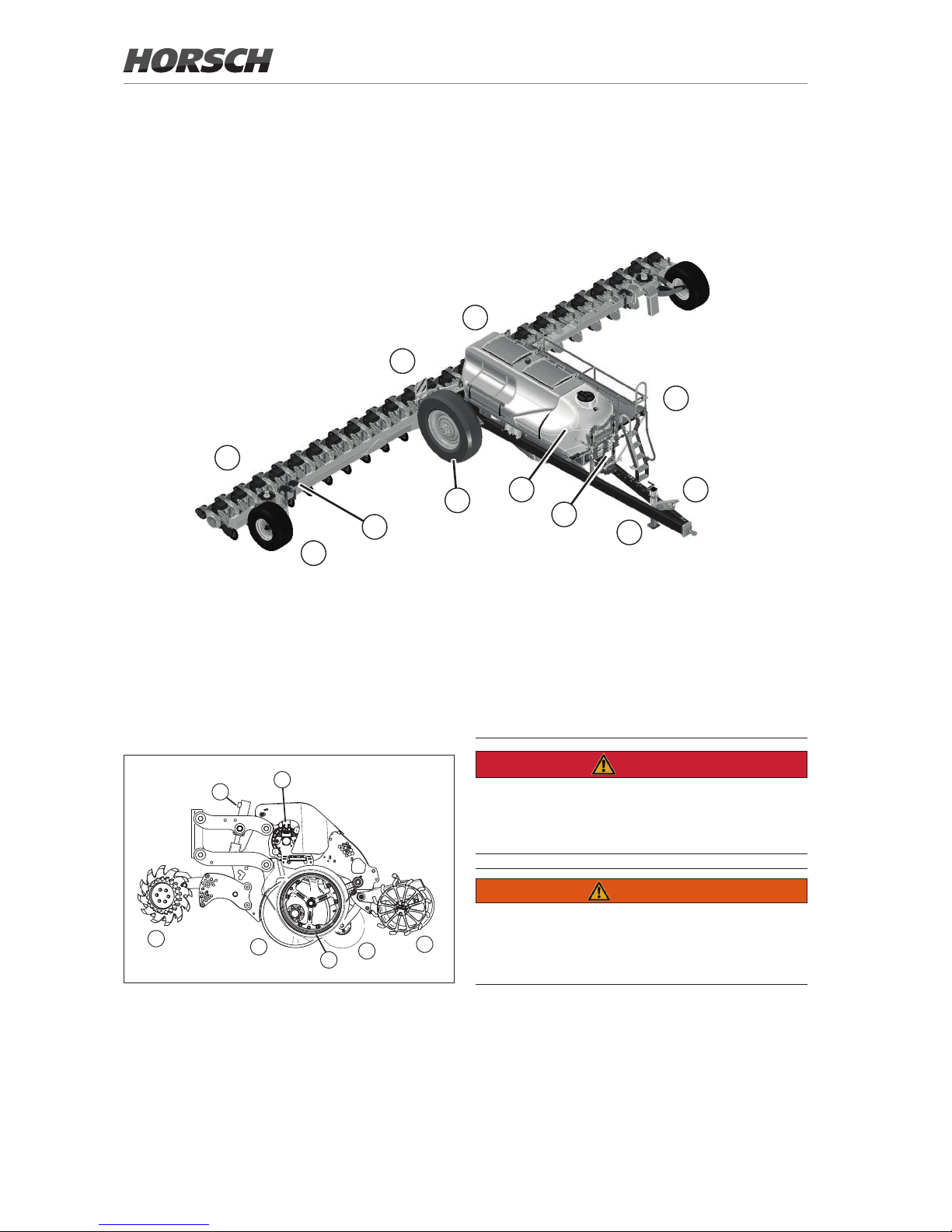

Drill unit

1 Single grain metering unit

2 Hydraulic cylinder for coulter pressure

3 Clearing stars

4 Coulter discs single grain placement

5 Wheels depth guidance

6 Trap roller

7 Finger pressure roller

Structure

Overview

Maestro 24 SW ammonium nitrate - carbonyl diamide

solution

1 Vacuum fan

2 Support wheel

3 Lighting

4 Seed hopper

5 Fertiliser hopper

6 Access steps

7 Support

8 Hose bracket

9 Liquid fertiliser system

10 Undercarriage tyres

11 Wheel sensor

DANGER

Danger of serious accidents

Transport rides on the machine, especially the

steps (7) and platform are prohibited!

WARNING

Danger of injury

¾ Do not look into the beam area of the radar

sensor (11).

1

2

3

6

7

10

4

8

11

5

9

3

4

6

7

2

5

1

18

Hydraulics

WARNING

Accidental hydraulic movements (e.g. caused

by passengers or children) can lead to severe

accidents and injuries!

¾ Secure or lock the control units on the tractor.

¾ Instruct persons to leave the slewing range of

foldable machine parts.

¾ Switch all control units to the locked position

before switching on the tractor again.

¾ Connect the hydraulic lines only when the

hydraulics have been de-pressurized on both

machine and equipment sides.

NOTE

¾ Operate the machine with mineral oils.

Do not mix mineral oils with organic or ester

oils!

The hydraulic circulation of the tractor must

contain mineral-based hydraulic oil.

¾ Oil purity acc. to ISO 4406: 18/16/13

¾ Always plug in all hydraulic lines! Otherwise

components may get damaged because of

interrelated functions.

¾ With all hydraulic movements slow down the

control unit before the machine components

reach the stop position.

¾ Ensure cleanliness and tight t of all plug-and-

socket connections!

¾ Observe the notes on hydraulics and pressure

accumulator in chapter Safety and responsibility!

19

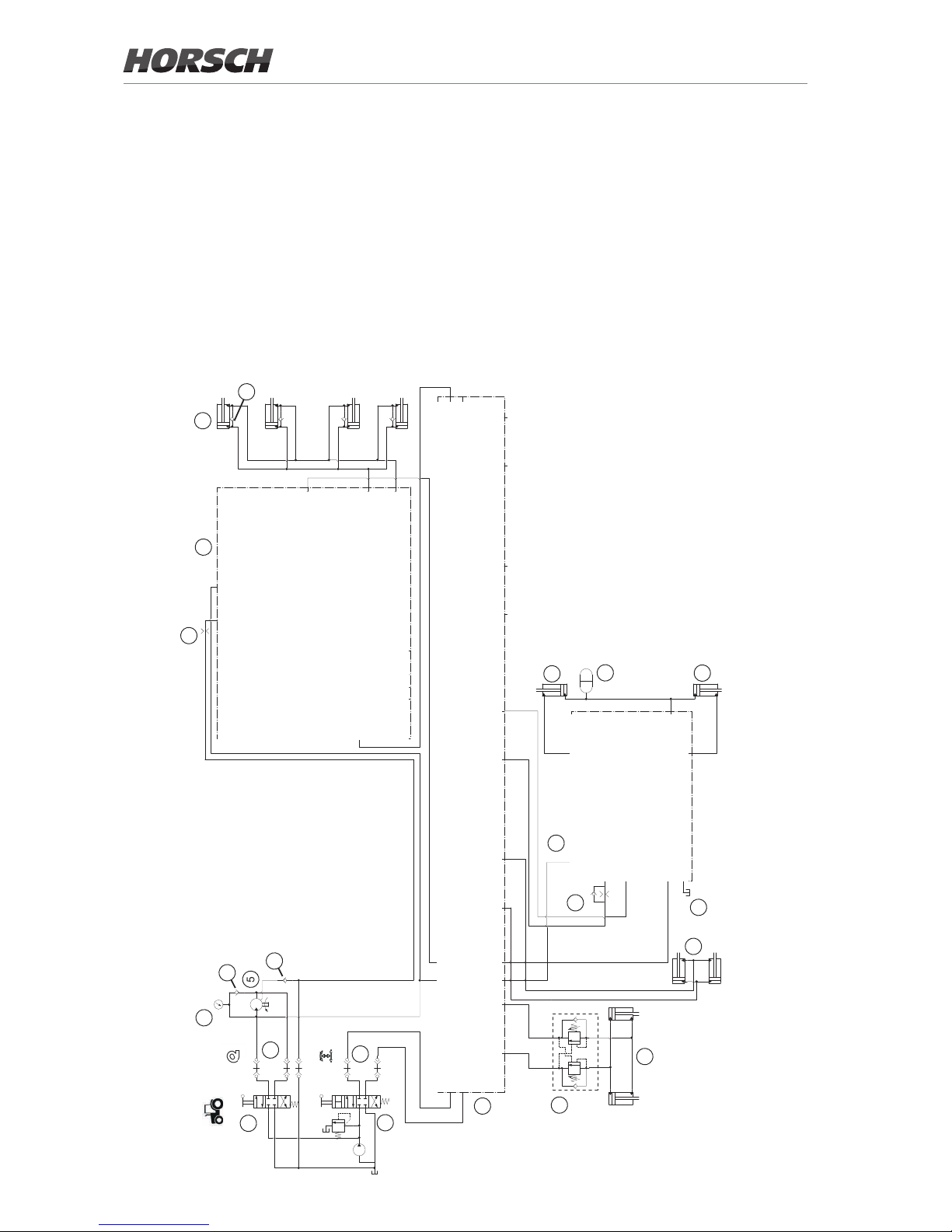

Seed wagon

1 Tractor control unit

2 Tractor hydraulic coupling

3 Pressure gauge

4 Check valve

5 Axial piston motor 5 cm³

6

Restrictorø 0.8 mm

7 Valve block coulter pressure

8 Coulter pressure hydraulic cylinder

9 Check valve

10 Valve block

11 Dual-acting counterbalancing valve

12 Hydraulic cylinder Lift/Lower

13 Hydraulic cylinders for support

wheels (Only 24 SW / 36 SW)

14 Check valve

15 Valve block

16 Hopper

17 Hydraulic cylinder for wings

18 Pressure accumulator

19 Hydraulic cylinder for wings

9

-

+

-

+

1

1

2

2

3

6

7

10

11

12

15

17

18

19

16

8

5

4

14

13

4

B

A

T

A

T

B

A6

A1

D2

U2 U1

D1

A2 A3

A3

A3.1

B3.1

A3.2

X

A6

T

A4 A5B2 B3

B3

B4 B5

A7

B7

B1

20

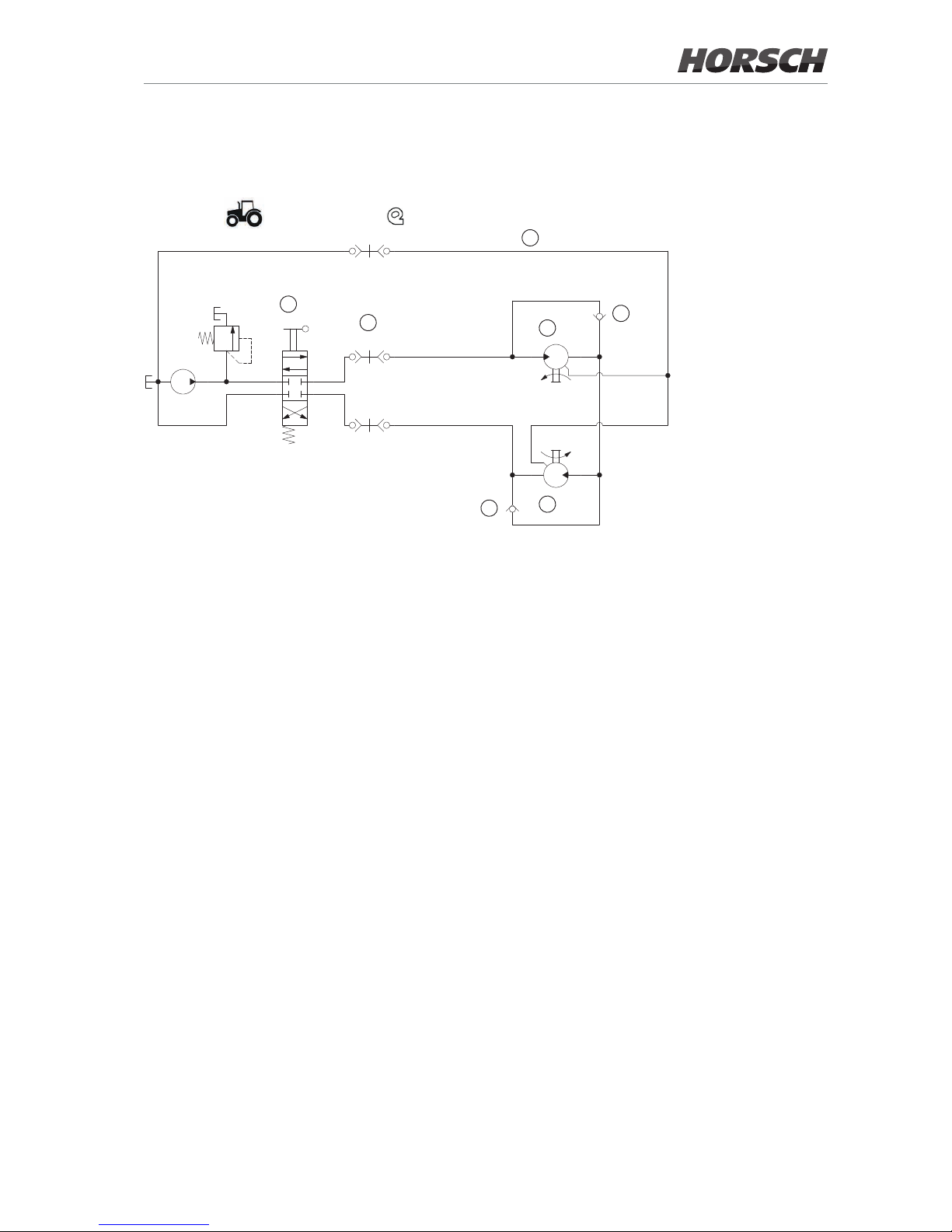

Fan – vacuum

1 Tractor control unit

2 Tractor hydraulic coupling

3 Axial piston motor 10 cm³

4 Check valve

5

Leak oil line

1

2

3

3

4

5

4

BBA

A

T

T

21

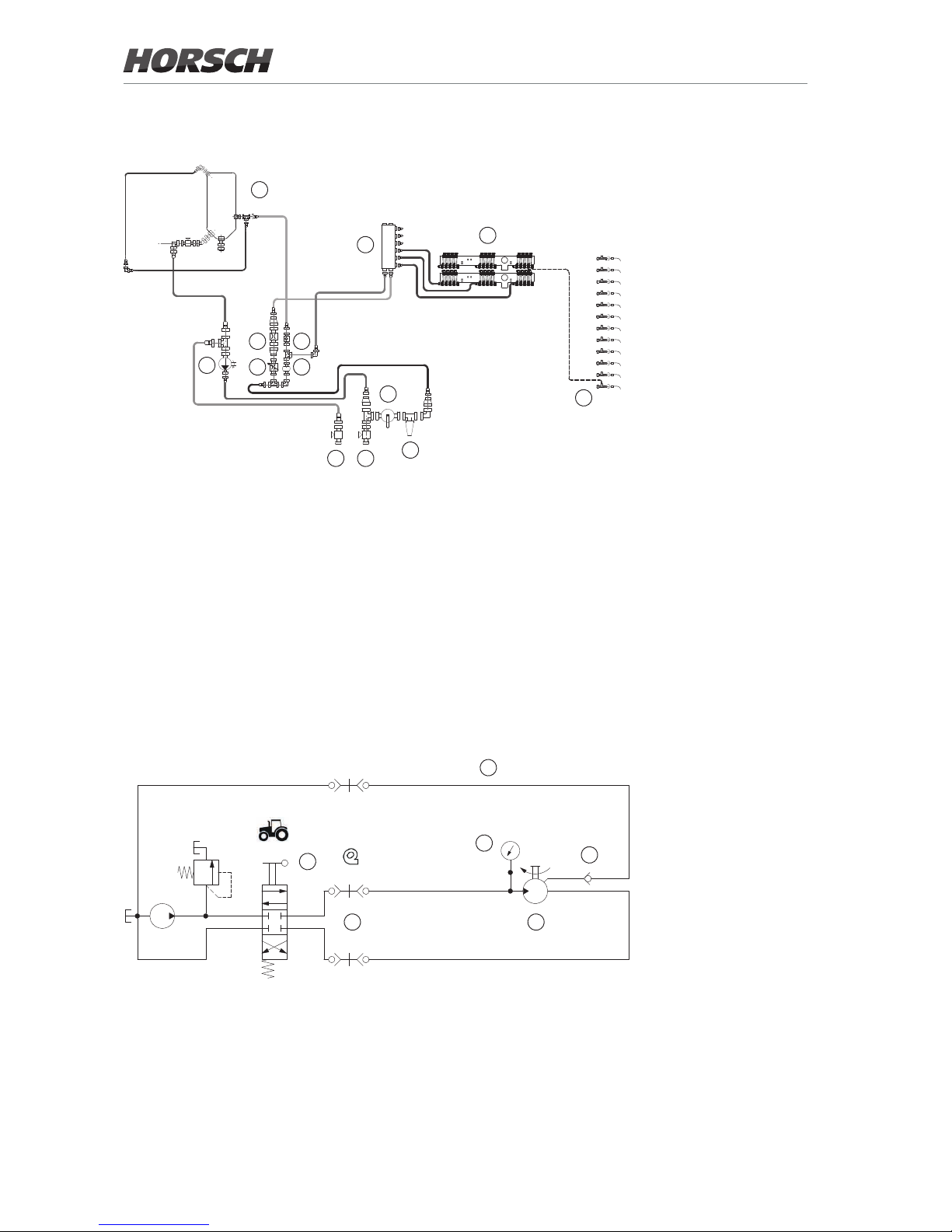

Liquid fertiliser

1 Tractor control unit

2 Tractor hydraulic coupling

3 Pressure gauge

4 Centrifugal pump

5 Check valve

6

Leak oil line

1

2

3

4

5

6

T

IN

OUT

Liquid fertiliser system – pump drive

1 Centrifugal pump

2 Filling neck

3 Discharge pipe

4 2-way working valve

5 Filter

6 Control valve

7 Flow meter

8

Pressure relief valve

9

Check valve

10

Valve block

11

Flow View System

12

Nozzles (hose connection drawn only for one nozzle)

13

Hopper

12

13

11

10

2

1

6 8

9

7

3

4

5

22

A6

G 3/ 8"A7G 3/ 8"B7G 3/ 8"

A

G1/4"

T

G 1/ 2"

P

G 1/ 4"

FA

FT

FX

FP

SVP2

KV

KE

B

G 3/ 8"

A

G 3/ 8"

FA

FT

FX

FP

SVP1

ASB30

+

1

253

4

6

7

9 8

10

11

12

13

1 Tractor hydraulic coupling

2 Axial piston motor 10 cm³

3 Check valve

4 Check valve

5 Pressure gauge

6

Restrictor ø 0.8 mm

7

Valve block

8

Pressure gauge Section 1

9

Pressure gauge Section 2

10

AutoForce hydraulic cylinder

11

Connection A6 - valve block ow divider

12

Connection A - valve block Maestro control block

13

Leak oil line

AutoForce 2-sectional

A6

FA

FP

FX

FT

A7 B7 BA

A

T

P

23

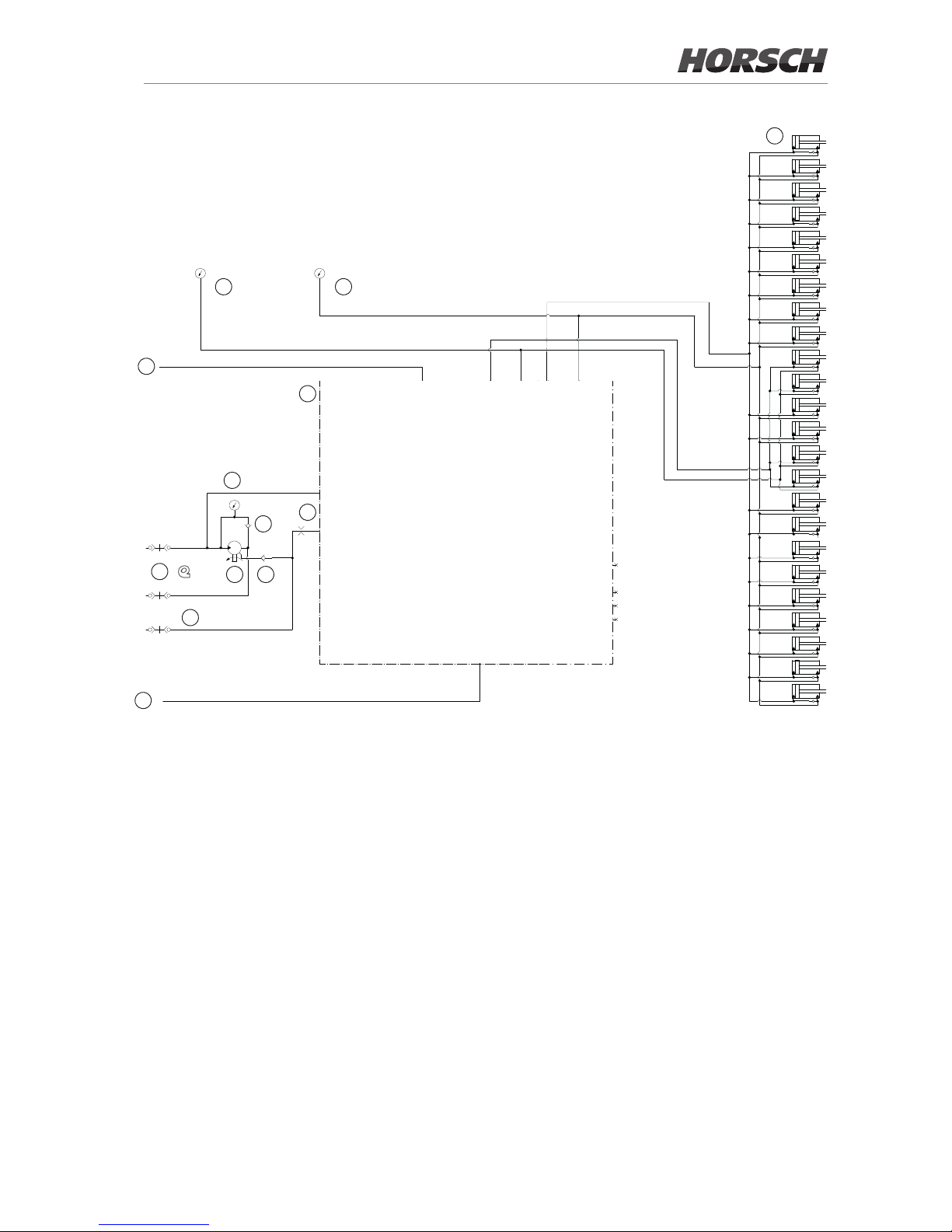

Aluminium clips

The aluminium clips are placed on the piston

rods of hydraulic cylinders, depending on the

operating states, see chapter Operation.

Dierent aluminium clips

The thickness of the clips diers according to

colour:

Colour

blue red yellow black silver

Thickness

7 mm 10 mm 19 mm 30 mm 50 mm

WARNING

Risk of injury on the hydraulic cylinders!

Limbs may be pinched by unintentional retraction of the piston rods.

¾ When attaching or removing the clips the

machine must be parked with the parking

brake pulled.

Nobody may be about in the area of the tractor

cab at this time.

¾ Lock control units mechanically or electrically,

depending on the version.

¾ Make sure when placing or removing clips that

the control units are not operated by any other

person.

Identication of hydraulic hoses

The symbol is always located above the hose

that requires pressure to bring the machine in

transport position (lift out, folding, etc.).

Hydraulic valve block

Fan

24

Lighting

1. 7-pin plug

2. Rear light, right

2.1 Lamp, direction indicator

2.2 Lamp, tail light

2.3 Lamp, brake light

3. Rear light, left

3.1 Lamp, brake light

3.2 Lamp, tail light

3.3 Lamp, direction indicator

Plugs and cable assignment

No. Desig. Colour Function

1 L yellow Indicator left

2 54 g -- -3 31 white Earth

4 R green Indicator right

5 58 R brown Rear light, right

6 54 red Brake light

7 58 L black Rear light, left

WARNING

Trac accidents caused by defective lighting.

¾ Ensure cleanliness and tight t of the plug-and-

socket connections.

¾ Check the lighting before setting o.

¾ Check warning boards and lighting equipment

for cleanliness.

25

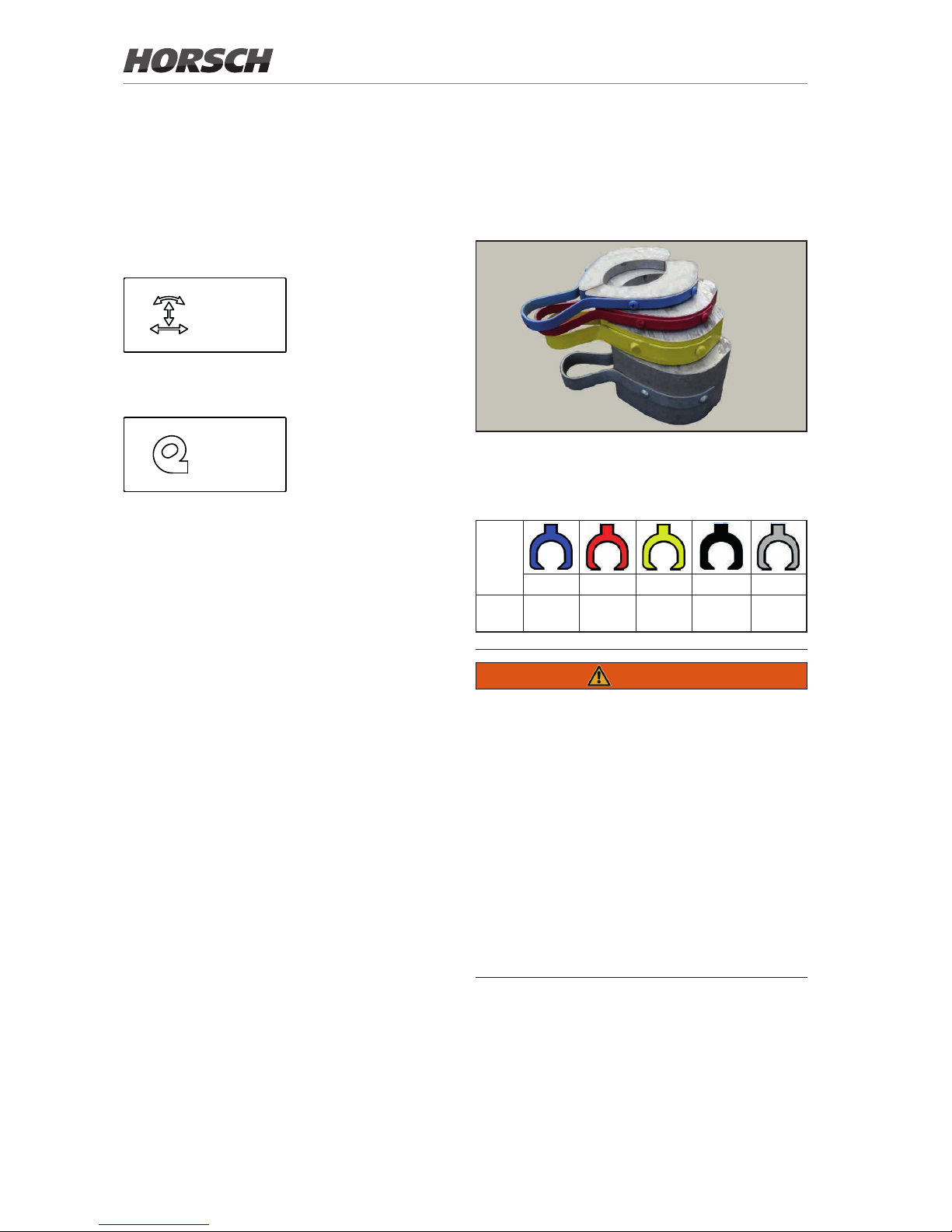

Instruction stickers

¾ Clean soiled stickers.

¾ Damaged or illegible stickers must be

replaced immediately.

¾ Apply the specied stickers to spare parts.

Always plug in all hydraulic lines. Otherwise

components could be damaged because of

interconnected hydraulic functions.

00380212

..

. ...

..

. ...

Tighten with the appropriate torque

00385488

300

00385489

510

Adjustable scrapers

3

5

7

0038

4062

9

1

Retighten the wheel nuts / wheel bolts for

the rst time after 50 km or 10 hours.

Retighten every day – see maintenance

overview.

00380359

Ensure leak tightness of seed hopper and

the entire pneumatic system to avoid leaks.

Leaks will cause sowing faults. Air losses

reduce the placing quantity; they may even

drop to zero.

SSS

00380210

SSSSS

SSSS

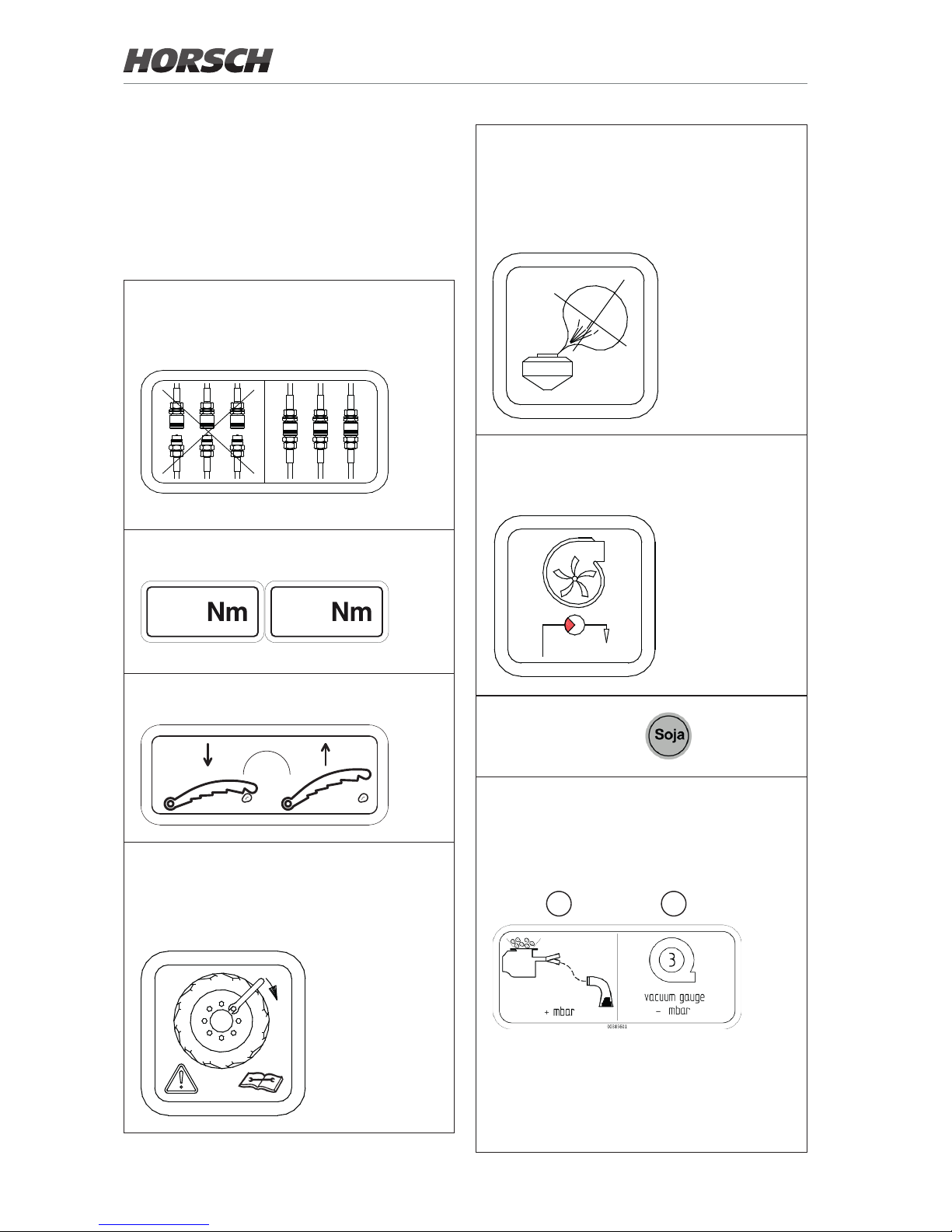

The return ow pressure at the fan drive

must not exceed 5 bar, as otherwise the

hydraulic motor may be destroyed.

00380242

max. 5 bar

Soy

Pressure gauge

1 Seed on demand

2 Vacuum fan

1 2

26

Loading...

Loading...