horsch DrillManager Operating Instructions Manual

Operating Instructions

Art.: 80660206 en

Read carefully prior to starting up!

Keep operating instructions in a safe place!

10/2012

DrillManager

Software 8.52

- Translation of the Original Operating Instructions -

Machine Identication

The corresponding data is to be entered into the list below upon

receiving the machine:

Serial number: .......................................

Machine type: .......................................

Year of construction: .......................................

Initial installation: .......................................

Fittings: .............................................................

..........................................................................

..........................................................................

..........................................................................

Publication date of Operation Manual: 10/2012

Latest change:

Address of Retailer: Name: ......................................................................

Road: ......................................................................

Town/City: ......................................................................

Tel.: ......................................................................

Customer No.:

Retailer: ......................................................................

Address of HORSCH: HORSCH Maschinen GmbH

92421 Schwandorf, Sitzenhof 1

92401 Schwandorf, Postbox 1038

Tel.: +49 (0) 9431 / 7143-0

Fax: +49 (0) 9431 / 41364

E-mail: info@horsch.com

Customer No.:

HORSCH: ......................................................................

80660206 DrillManager en

2

Table of contents

DrillManager ..................................................4

Description......................................................4

Wiring loom of machine ................................7

Installing the DrillManager ..............................9

Installation on tractors with

ISOBUS equipment ......................................9

Installation on tractors without

ISOBUS equipment ......................................9

Terminal .......................................................10

Operation ....................................................11

Terminal settings ........................................12

Menu overview .............................................14

Screen display work mask ............................15

Adapting the work screen ...........................15

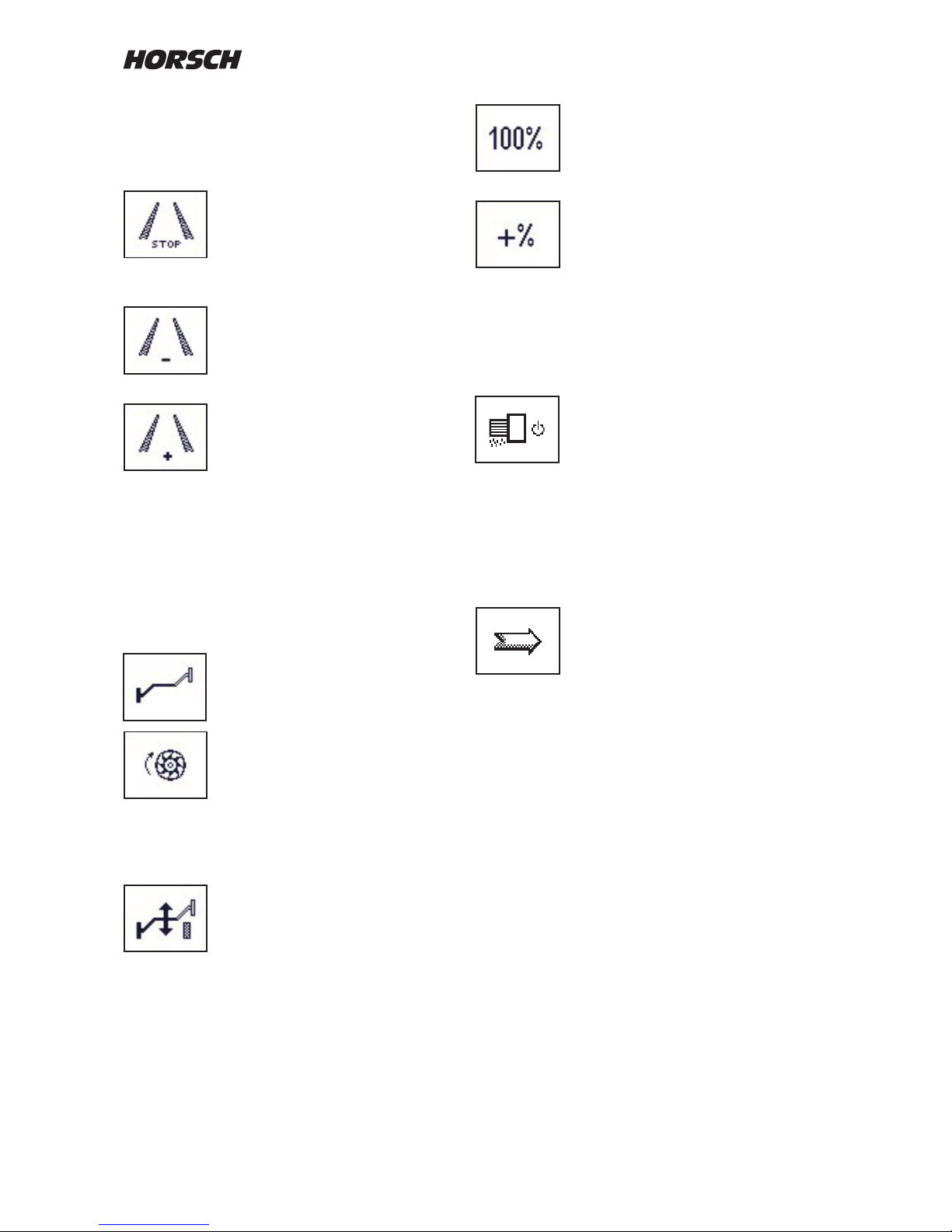

Function symbols..........................................16

Bout marker and hydraulic control ..............17

Half width shut o .......................................18

Menu overview Calibration .........................20

Seed calibration ............................................21

Rotor selection ............................................24

Seed Check ................................................29

Performance data .......................................29

Input of machine data ................................30

Joining of hoppers ....................................34

Tram line rhythm .........................................39

Seed ow monitoring ...................................52

Entering sensor numbers for FGS ..............52

Setting the sensitivity ..................................53

Seed ow monitoring ..................................53

Alarm message ...........................................54

Seed ow diagnose ....................................54

Diagnostics program.....................................55

Alarm overview ...........................................57

3

4

DrillManager

The HORSCH DrillManager is an electronic

control unit for drills and their components.

It regulates, monitors and controls all connected

assemblies in the drill.

You should only start up the DrillManager

after you have read the operating

instructions and are familiar with the

operation.

Strict compliance with the applicable accident

prevention instructions and other established

regulations concerning technical and industrial

health and safety is mandatory when working

with the DrillManager.

Description

The HORSCH DrillManager is a complete

system in which the modules included in the

equipment must only be activated.

The complete system consists of the following

components:

¾ Computer

¾ Monitor

¾ Modules, depending on machine type and

equipment, for:

one to three metering drives for seed, fertiliser

or liquid fertiliser

hydraulic control for raising, wings and bout

marker indicator control

half-side control

Seed ow monitoring

¾ Sensors for:

fan

forward speed (radar)

hopper empty indicator (2 channels)

¾ connection for work signal

¾ switch for calibration

All components and sensors are connected to

computer and monitor by means of the wiring

loom.

The computer receives the information, evaluates

these and displays the operating status and data

on the monitor.

If entered or xed default values are exceeded

or fallen short of, or in case of malfunctions the

monitor display is interrupted and the fault is

indicated.

The monitor thereby identies the corresponding

component or the limit value that has been

exceeded.

Depending on the version the machine is

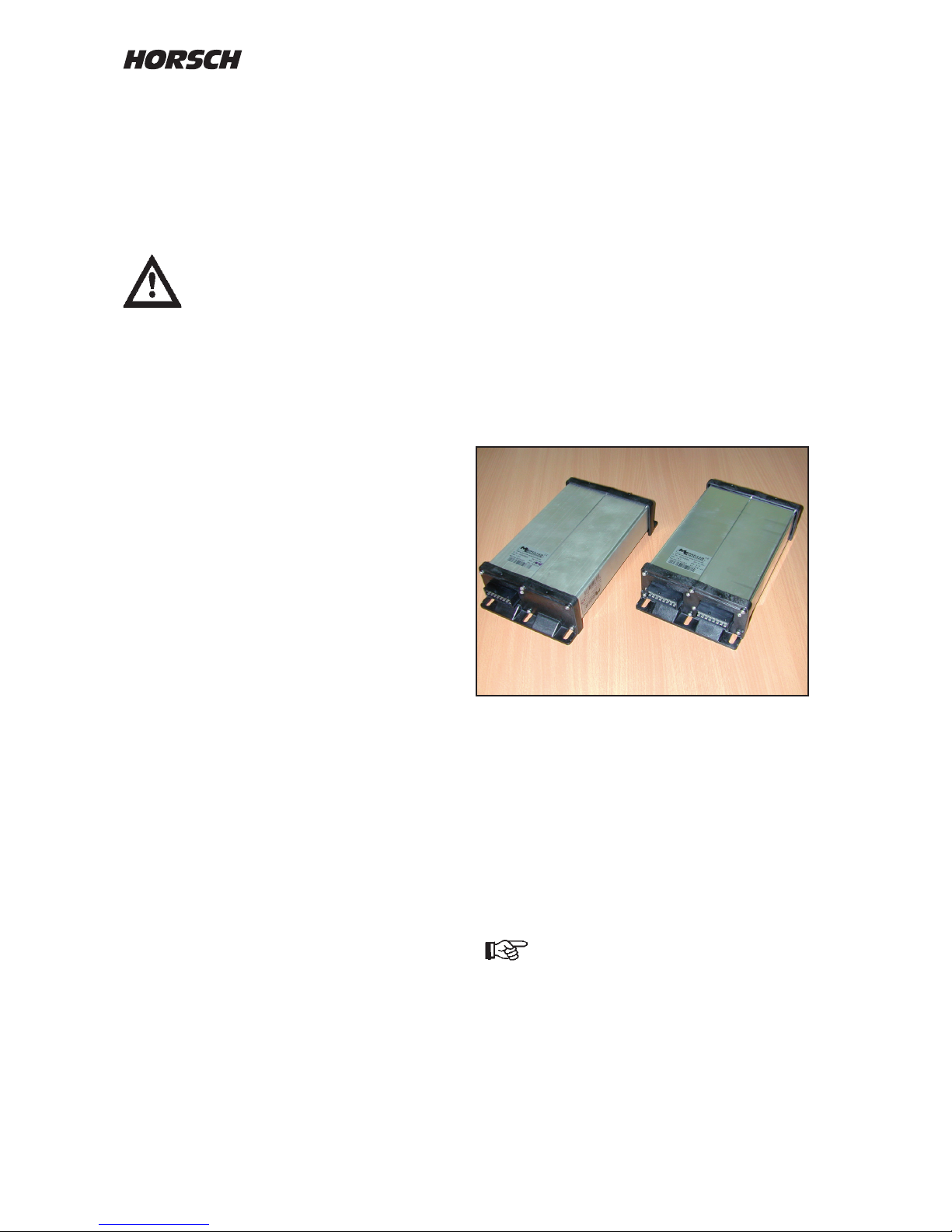

equipped with one or two computers.

Computer with one and two 16-pin plugs

Stickers on the computer inform about the

hardwar status, the software status is displayed

in the “Diagnose” menu.

Maintenance

The system is maintenance free. You should

keep an eye on the computer and the cable

connections when washing the machine.

Do not clean the computer, the plugs

and any of the electronic components

with high pressure cleaning equipment

or a direct water jet.

5

Description of the computer

Computers with black plastic end plates have

program “version 8.xx” installed.

These computers can be operated with HORSCH

terminals, external ISOBUS terminals and with

ISOBUS compatible tractor terminals.

Machines with two computers

On machines with two metering drives two

computers are installed in the machine and

tightly connected together with a cable.

On drills which are temporarily combined with

an additional metering drive, like DuoDrill or

Maistro, the computers of both machines are

connected with a 16-pin plug.

The socket of this connection has an integrated

ISO-Bus termination and can thus can only be

replaced by an original cable in case of a repair.

Computer version

The computer is available in three dierent

hardware versions, whereby two of these

versions look optically exactly the same. It is

therefore very important to look for the article

numbers when carrying out repair work.

No. 00345005 (standard computer)

¾ Installed in all machines with just one

computer;

¾ Is able to control two metering drives;

¾ Is always programmed with the master

version 8.xx 49;

¾ Cable inlet: One 16-pin plug;

No. 00345069 (dual computer)

¾ Installed as master computer in all machines

with two computers;

¾ In connection with the second computer this

computer is able to control three metering

drives or two metering drives and the Maistro;

¾ Is always programmed with the master

version 8.xx 49;

¾ Cable inlet: Two 16-pin plugs;

No. 00345091 (additional computer)

¾ Is used a second computer in machines with

two computers

¾ Supports the main computer in the control of

the third metering drive

¾ Is always programmed with the slave version

8.xx 4a;

¾ Cable inlet: One 16-pin plug

Programs

The programs can be identied by their ending,

e.g. 8.xx 49 for the master version and 8.xx 4a

in the slave version. This ending can only be

recognized during programming.

On machines with dual computers the new and

old computer versions must not be combined.

When replacing an old computer it may be

necessary to replace both computers.

The programs in both computers must also be of

the same version, e.g. 8.52 49 only with 8.52 4a.

In case of incorrectly combined program

versions errors and malfunctions may

occur.

6

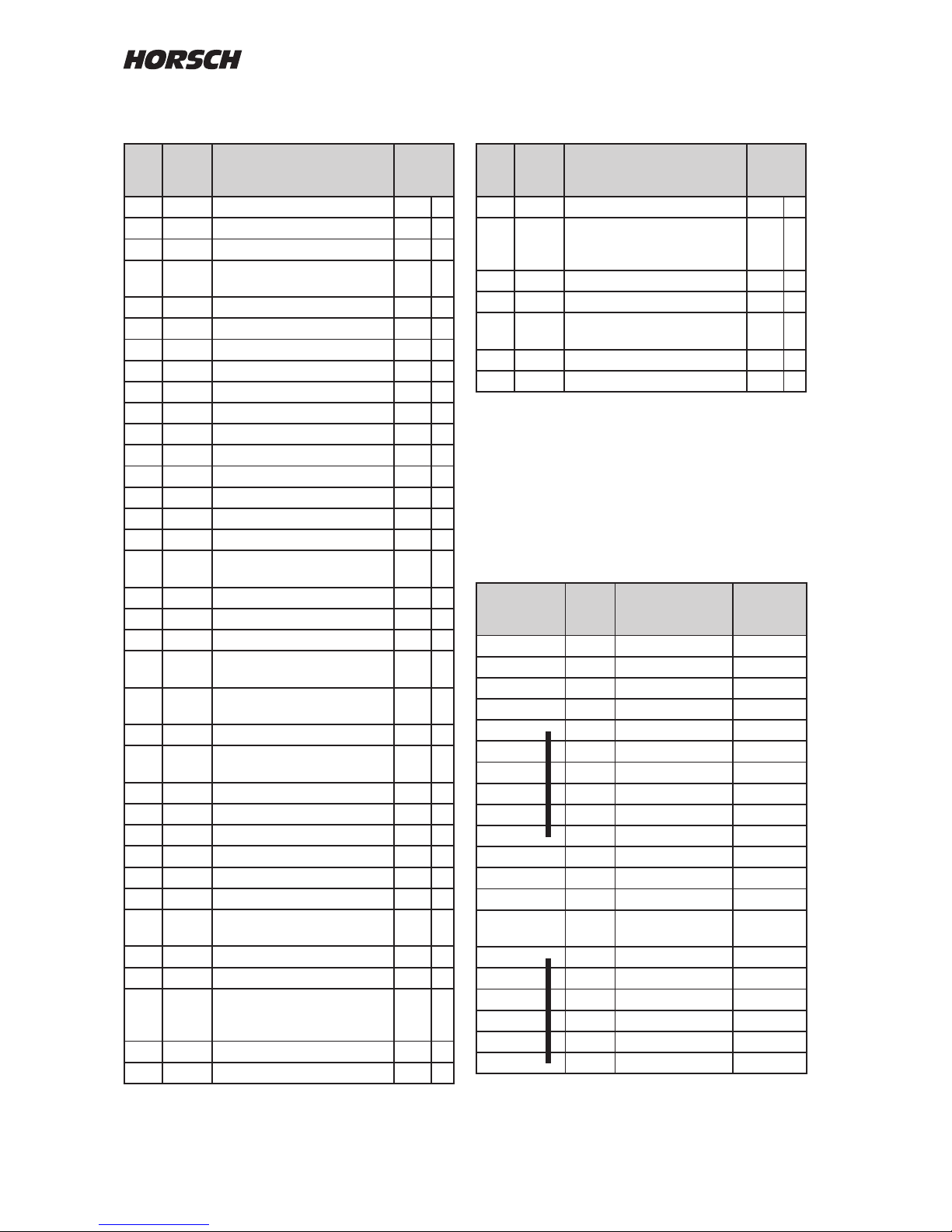

Pin

No.

Colour Function Colour

/ No. of

part

37 bl/rd Radar signal gn

38 br/wh Rotary speed 2 (right)

Metering unit 2 lling level

sensor

gn

39 gn/wh Fan signal gn

40 rd/ye Hopper 1 lling level sensor gn

41 bk/ye Metering unit 1 lling level

sensor

gn

42 bl Ground 0 V power

Ring ye Shielding (motor) ye 6

Cable assignment on on connecting cable

20 and 16 pin plug

Plug

20 pin on

tractor

Cable

No.

Function Plug

16 pin on

Computer

A 1 1 1

A 2 2 Can Low 2

A 3 3 Can GND 3

A 4 4 0 Volt electronics 4

A 5 5 0 Volt power 5

A 6 6 0 Volt power 6

A 7 7 0 Volt power 7

A 8 8 0 Volt power 8

A 9

A 10

B 1 9 9

B 2 10 Can High 10

B 3 11 Can EN 11

B 4 12 12 Volt

electronics

12

B 5 13 12 Volt power 13

B 6 14 12 Volt power 14

B 7 15 12 Volt power 15

B 8 16 12 Volt power 16

B 9

B 10

Cable assignment on the 42 pin plug

Pin

No.

Colour Function Colour

/ No. of

part

1 gr Motor 2 plus 12 V power rd

2 gn Half width signal right 3

3 ye Half width signal left 4

4 gr Rotary speed 1 (left)

Hopper 2 lling level sensor

gn

5 pu Hydr. boutmarker left 1

6 rd Hydr. boutmarker right 2

7 bk Tram line +/- right 1

8 vi Tram line -/+ right 2

9 or Tram line +/- left 3

10 br/gn Tram line -/+ left 4

11 wh/rd Pre-emergence marker right 5

12 gn/bl Pre-emergence marker left 6

13 - - -

14 - - -

15 gn Motor 1 minus power bl 1

16 rd/bl Work position signal br

17 ye/bk Motor 1 current

measurement

18 wh/bk Half width signal middle gn

19 rd/bk Hydr. "Lift" 3

20 br/ye Hydr. "Wings" and horn 4

21 rd/wh Liquid fertiliser ball valve +/-

Fan control +/-

br

22 rd/gn Liquid fertiliser ball valve -/+

Fan control -/+

bl

23 - - -

24 br/bk Liquid fertiliser solenoid

valve

25 bl/ye Half width motor +/- 1

26 bl/gn Half width motor -/+ 2

27 - - -

28 br Motor 2 minus power bl

29 rd Motor 1 plus 12 V power rd 2

30 gr/rd Calibration switch signal br

31 gn/gr Motor 2 current

measurement

32 br Sensors all 12 V plus br 4

33 wt Sensors all 0 V electr. wt 3

34 gn/pk Liquid fertiliser. Sensor /

signal coulter pressure

adjustment

gn

35 ye/bl Motor 2 signal gn

36 gn/bk Motor 1 signal gn 5

7

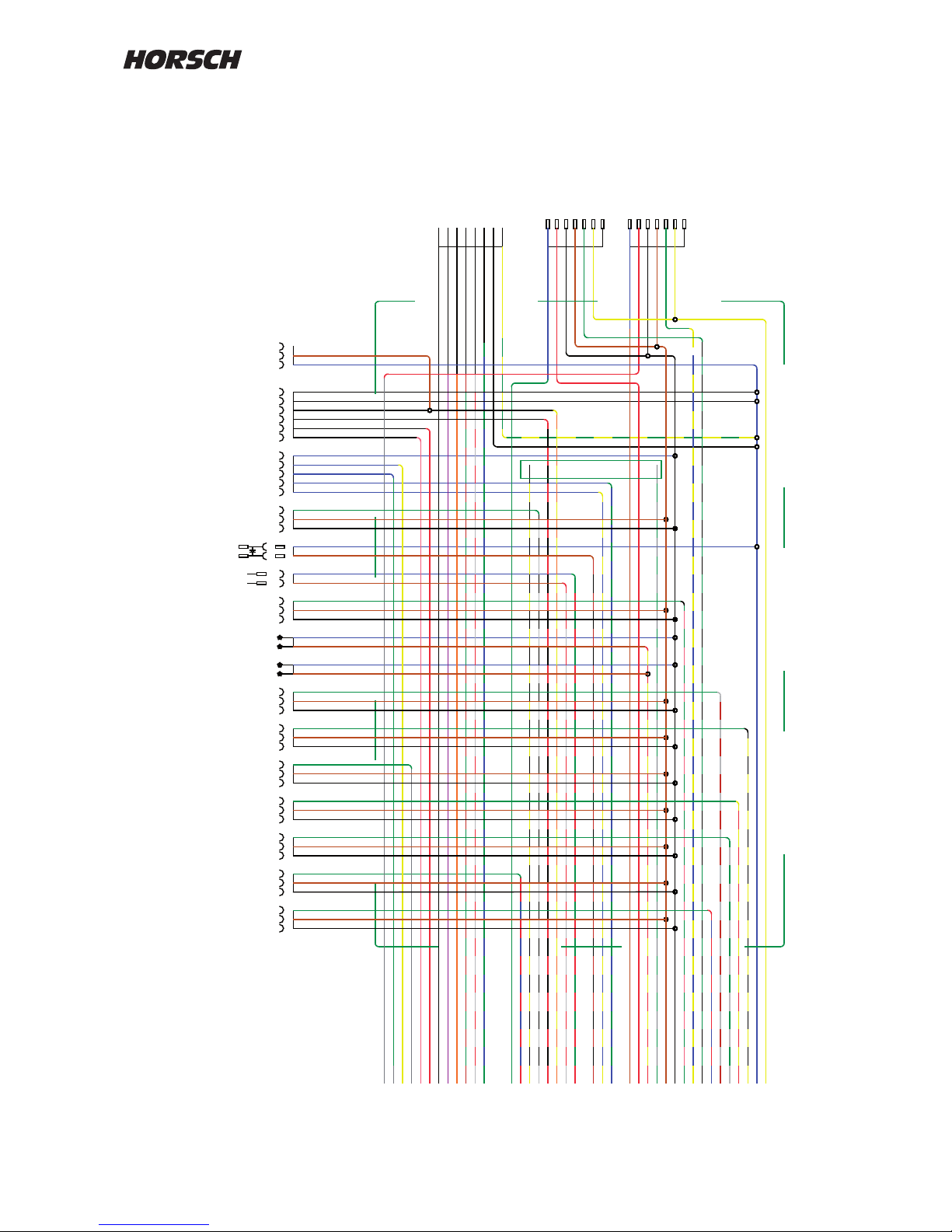

Wiring loom of machine

The wiring loom is adapted to match the

corresponding machine type and prefabricated

with plugs for all equipment variants.

In order to avoid malfunctions caused by dirt,

all open plugs must be closed with blind caps

or similar.

Wiring loom

Pin assignment in all 3 pin plugs

1 - ground cable, white

2 + plus cable, brown

3 signal cable, green

Plug designations:

A Work signal

B1 Bridging metering unit 1

B2 Bridging metering unit 2

D1 Speed monitoring, shaft 1

D2 Speed monitoring, shaft 2

G Fan

H Horn

R Radar - speed

S Signal middle position of half width

SV Coulter pressure adjustment

T1 Filling level monitoring seed hopper 1

T2 Filling level monitoring seed hopper 2

K Ball valve (liquid fertiliser)

D Flow sensor (liquid fertiliser)

2 pole at plug with diode - shut-o valve

Cable 8 pole automatic tram line control set

to "Magnet".

1 + Valves right

2 + Valves right

3 + valves left

4 + valves left

5 + Pre emergence markers right

6 + Pre-emergence markers left

7 - Ground all

8 - Ground all

Cable 8 pole automatic tram line control set

to "Motor".

1 + / - Motor right

2 - / + Motor right

3 + / - Motor left

4 - / + Motor left

5 + Pre emergence markers right

6 + Pre-emergence markers left

7 - Ground

8 - Ground

6 pole hydraulic control, "Lift", "Wings" and

"Bout marker".

1 + Bout marker left

2 + Bout marker right

3 + Lifting / lowering

4 + Wings

5 - Ground all

6 - Ground all

5-pin half width control

1 Adjustment motor + / 2 Adjustment motor - / +

3 Signal right

4 Signal left

5 Signal output

7-pin Motor metering drive

1 - blue

2 + red

3 white

4 brown

5 green

6 yellow

8

ed jul 11

DatumEntw.DateinameZeichnungsnummerMaschine Zeichnung

-

+

sig

1234567

Motor -

Motor +

Sensor -

Sensor +

Sensor Signal

Abschirmung

-

+

sig

1234567

Motor -

Motor +

Sensor -

Sensor +

Sensor Signal

Abschirmung

124567gn/ge

Motor rechts +/-

Motor rechts -/+

Motor links +/-

Motor links -/+

Vorauflaufmarkierer rechts +

Vorauflaufmarkierer links +

Masse für 5 und 6

Masse für 5 und 6

3

-

+

sig

-

+

sig

-

+

sig

-

+

sig

-

+

sig

-

+

sig

FGS

Motor 1

Motor 2

Verteiler

-

+

sig

-

+

3

Masse Spuranz.

Heben

1234567891011121314151617181920212223242526272829303132333435363738394041

42

gngegrrsrtswviorbr / gn

ws / rt

gn / bl

gn

rt / bl

ge / sw

ws / sw

rt / sw

br / ge

rt / ws

rt / gn

br / sw

bl / ge

bl / gnbrrt

gr / rt

gn / grbrws

gn / rs

ge / bl

gn / sw

bl / rt

br / ws

gn / ws

rt / ge

sw / geblge

Radar

Arbeitssig

Tank 1

Tank 2 /

Welle 1

Dosier 1

Abdrehen 1

Abdrehen 2

Dosier 2 /

Welle 2

Gebläse

Fl. Dünger sen /

Schardruckverst.

Halbs. Mittelst.

Kugelhahn /

Gebläseregelung

Abschaltvent.

Halbs. Mot u.

links u. rechts

Hydraulik

M1

M2

Spuranr. l

Spuranr. r

Klappen

Masse He. u. Kl.

rt

gn

1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 4 5 64 51 2 1 2

+ / -

- / +

+ / -

- / +

sig r.

sig l.

sig

Platine Strommessung

gr

1 2 3

Hupe

1 2 3

mit Hupe u Radar Stecker in AMP 3 pol. Kabelfarben am 42 pol geändert durch ME seit ca. 2008

Wiring loom - drill

9

Installing the DrillManager

The DrillManager is delivered with an ISOBUS

compatible software and and ISOBUS connecting

cable.

The ISOBUS functions can be utilized with the

HORSCH terminal, the Comfort terminal or the

tractor's ISOBUS terminal.

Installation on tractors with

ISOBUS equipment

In case of existing ISOBUS equipment on the

tractor, the drill can be controlled from the tractor

terminal or from an additional terminal.

Control with tractor terminal

¾ Plug the machine connecting cable into the

ISOBUS socket on the tractor and switch on

the terminal.

¾ When switching on, the control screens are

automatically loaded and the drill can be

controlled with the tractor terminal.

Control with an additional terminal

¾ Plug the machine connecting cable into the

ISOBUS socket on the tractor.

¾ Fasten the terminal at a suitable place in the

cabin. The vision on the road should not be

impaired.

¾ Connect the terminal to the ISOBUS socket in

the cabin by using the supplied cable.

¾ When switching on, the control screens are

loaded and the drill can be controlled with

the terminal.

Installation on tractors without

ISOBUS equipment

For all tractors without ISOBUS equipment the

basic equipment must be installed in the tractor

during the initial installation.

The cables for the basic equipment must be

directly connected to the tractor battery.

The cables must be protected against chang

and the insulation must not be damaged.

Basic equipment ISOBUS

The battery connections must have good contact. Assembly faults will lead to voltage drop

and indenable error messages and failures.

¾ Assemble the terminal bracket in a suitable

place within the view and the operating range

of the driver.

¾ Fasten the ISOBUS socket in a suitable place

at the rear end of the tractor.

¾ Route the thick cable to the battery, extend

it if necessary.

¾ Connect both fuse holders tightly and durably

with the cable.

¾ Connect the two red cables tightly with battery

plus and the two black cables with battery

negative.

¾ Plug the connecting cable in at the bottom of

the terminal.

10

Terminal

The terminal is plugged on the pre-assembled

bracket in the tractor and connected to the

computer by means of a cable.

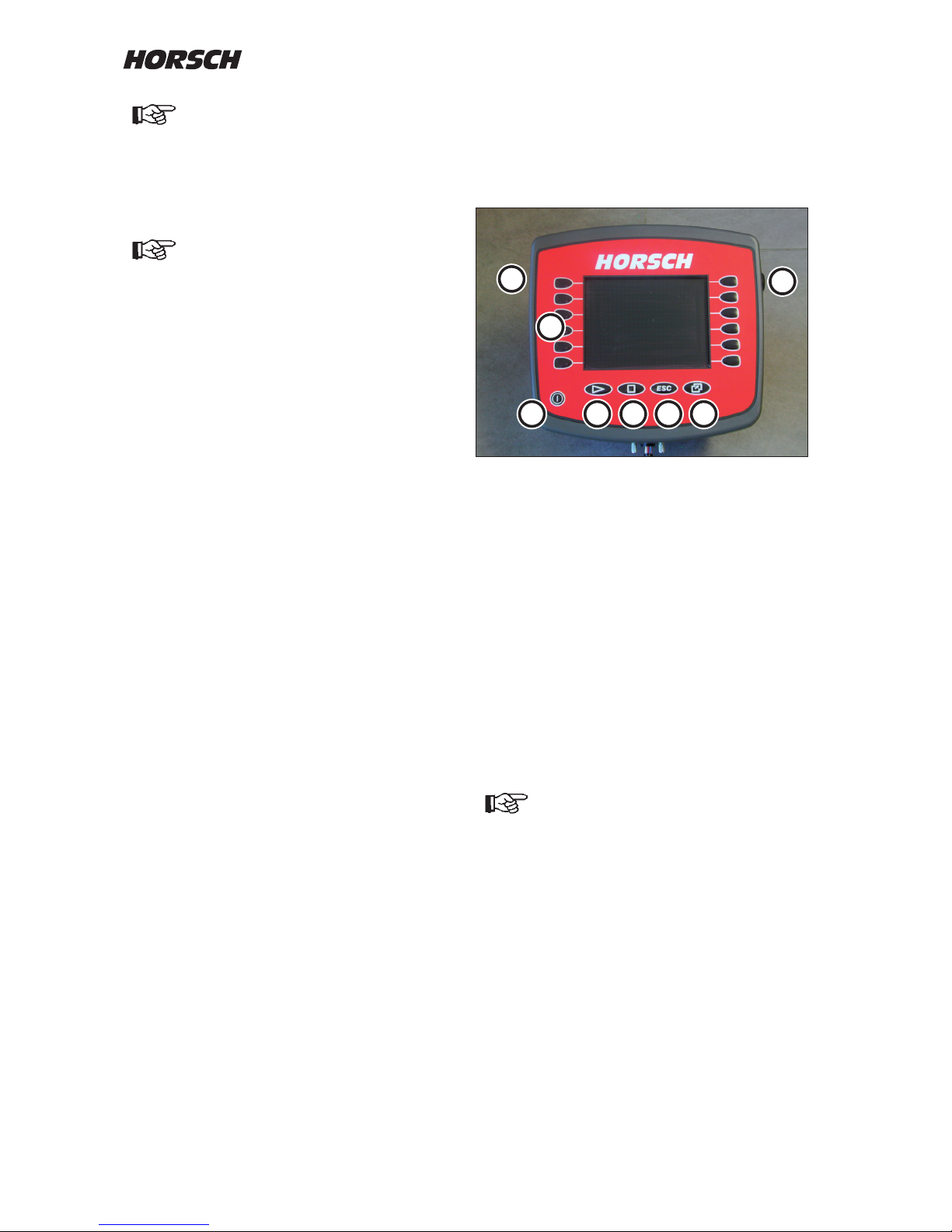

Terminal with colour display and keyboard

1. On/O button

2. Function keys

3. not assigned

4. not assigned

5. ESC-button

- Cancel input

- Exit mask

- Hide warning messages and alarms

6. Invoking / exiting selection menu

7. Rotary button

- Selection, input and conrmation

8. Connection of USB plug

The keys (2) on the display have no fixed

functions assigned to them. They will always

switch the function currently displayed.

The displayed screen contents may

vary from the illustration depending on

the respective program version.

4

3

1

2

7

6

8

5

The cables must under no circumstances be connected to any other

plugs in the cab.

The plugs are unable to transfer the

required current (A). Voltage losses

and drilling faults will occur.

The terminal should not obstruct the

eld of vision to the road.

11

Operation

Switching on

Press the "On/O" button momentarily.

After a ne w star t and af ter changing or

reprogramming the computer the data will be

loaded from the computer.

Restart the system

Once the terminal has been connected to the

ISOBUS of the tractor, the computer is not

automatically restarted when the terminal is

switched o and on.

To rest art the system you mu s t

disconnect the connecting cable to the

machine for a short moment.

It is highly recommended to make a note of the

machine and adjustment data before running

an update.

In case of update of minor extent the data will

be maintained.

With extensive updates and if new graphics

have to be displayed, the old adjustment and

performance data may be lost.

With some system dependent faults it may be

necessary to delete the control masks from the

terminal and to upload these again from the

computer by restarting.

The pool will in this case saved again in the

terminal.

Deleting the pool

Choose the "Service" area. In the menu "File

management" select "Pools" and delete the rst

le for the drill and the second le for the single

grain metering.

The switch the terminal o for a moment. The

masks will be loaded new during a restart.

12

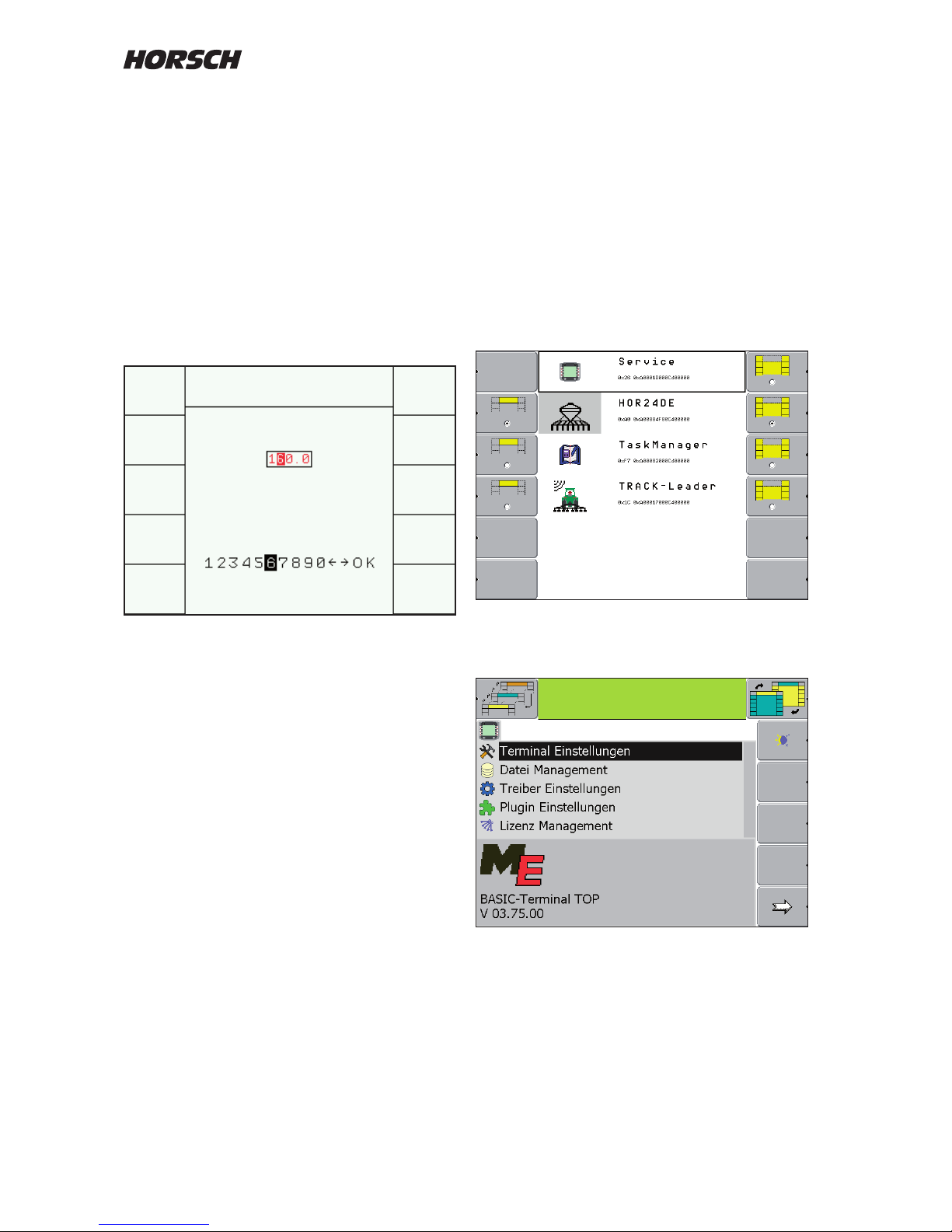

Terminal settings

The settings for the terminal:

¾ brightness /display)

¾ volume (alarm)

¾ date / time

¾ language selection

¾ measuring units

¾ keyboard illumination

are set in the "Service" menu option.

Press button (6) to open the selection menu.

Turn the rotary wheel to mark and confirm

"Service".

Turn the rotary wheel to mark and confirm

"Terminal setting".

Setting and changing inputs

Before initial start-up some settings must be

entered in to the system.

The selection, input and conrmation of text or

numericals is accomplished via the rotary button.

Use the rotary button to place the marking over

the numerical or the term and press the rotary

button to conrm.

For the terms / words all selectable possibilities

appear, for the numericals the table with the

numbers 1 - 10 with two arrows and OK.

Changing numerical values

If the number is not to be changed, press the

rotary button to conrm the number.

To change the number with the rotary button

select the desired number and press the rotary

button to conrm.

The system will automatically change to the

next number.

With the arrow keys the desired cipher can be

directly selected.

For the terms mark the new term / word with the

rotary button and press to conrm.

13

Place and conrm the marking with the rotary

wheel.

Turn the rotary wheel to change the value or

e.g. choose the country specic language and

conrm again.

e.g. language selection

Adapt the settings for brightness, contrast and

keyboard illumination to the light conditions and

your personal appreciation.

Set the volume as loud as possible. Alarm

messages should be audible in your tractor,

even when used in the eld.

Once the settings have been made the terminal

must be switched o and on again.

Depending on the changes, e.g. in language or

the measuring units, the terminal must rst load

the new language or measuring units from the

computer of the machine.

The following languages are currently available:

German de

English en

French fr

Danish da

Polish pl

Czech cs

Romanian ro

Spanish es

Swedish sv

Hungarian hu

Serbian sr

Russian ru

Estonian et

Lithuanian li

Latvian lv

Bulgarian bg

Croatian hr

Finnish

Italian it

Settings and activation for GPS functions like

- Task Manager

- TRACK Leader II

- Section Controll etc.

are described in a dedicated instruction manual.

14

ed sep 08

DatumEntw.DateinameZeichnungsnummer

ed sep 08

DatumEntw.DateinameZeichnungsnummerMaschine Zeichnung

ed sep 08

DatumEntw.DateinameZeichnungsnummer

ed sep 08

DatumEntw.DateinameZeichnungsnummerMaschine Zeichnung

ed sep 08

DatumEntw.DateinameZeichnungsnummerMaschine Zeichnung

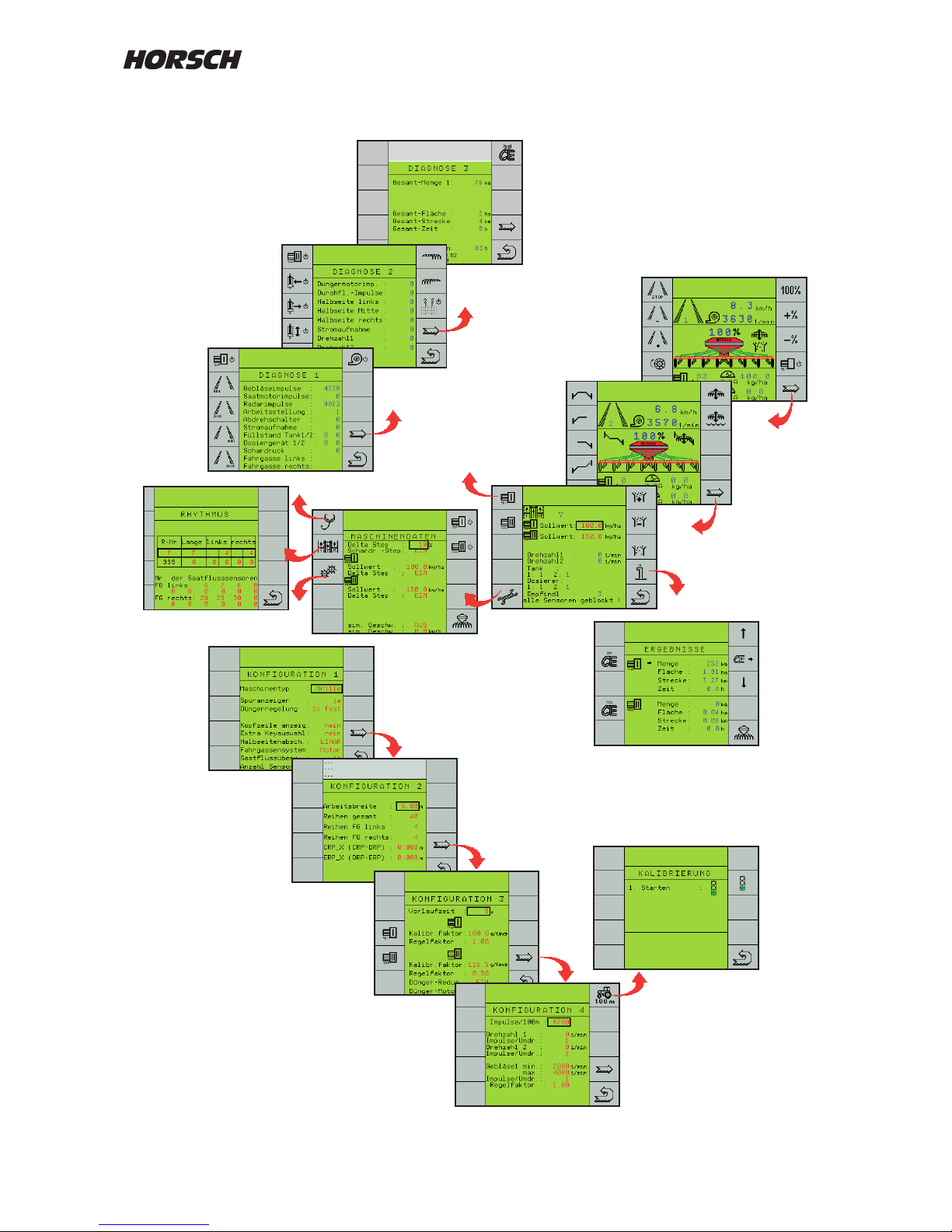

Menu overview

Start

Diagnostic

Work screens

Machine data

for calibration

Performance data

Drive a distance of 100 m

Setting the tram lines

5 sec.

15

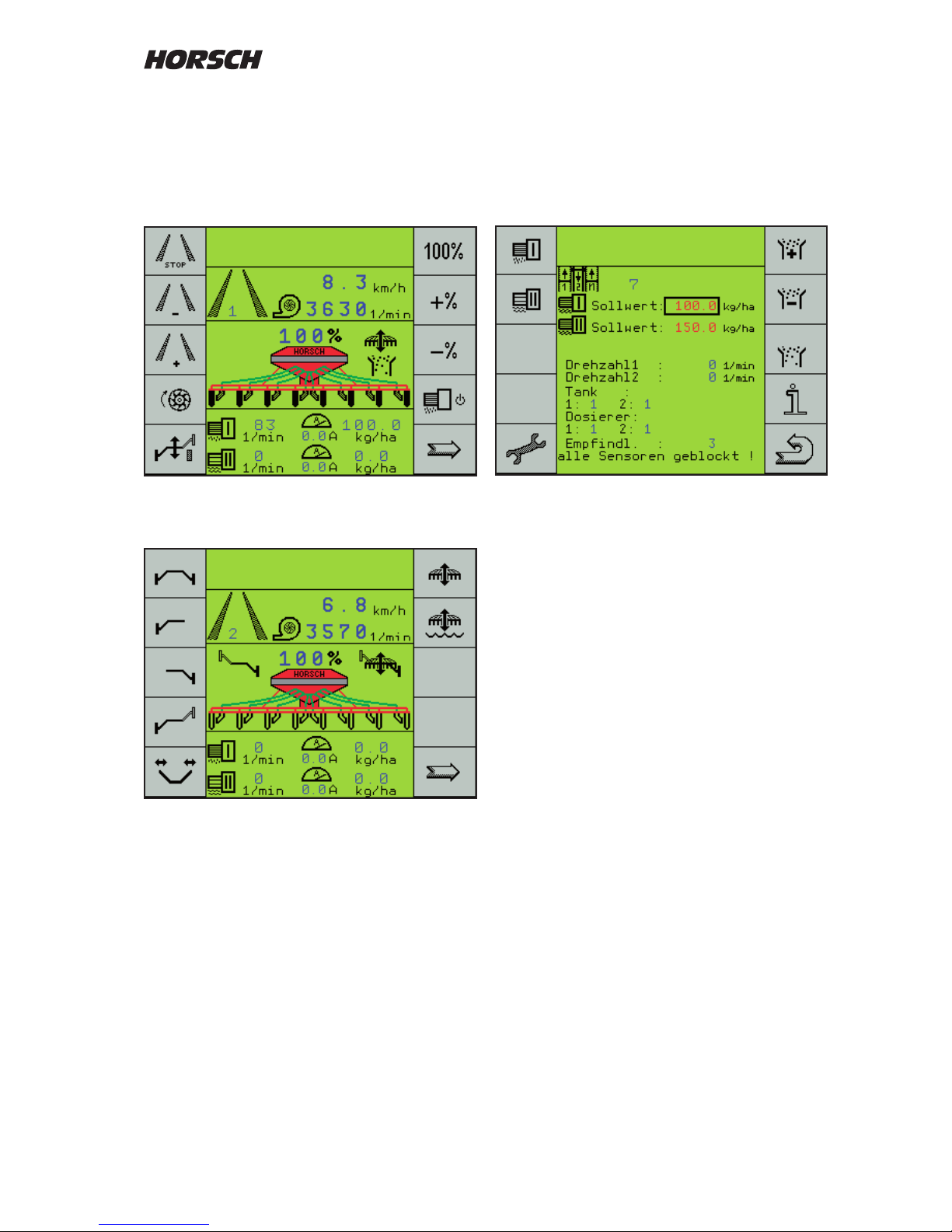

Page three of the work mask is mainly needed

for calibration, to adjust the sensitivity of seed

ow monitoring during operation and for trouble

shooting in case of blockage and with defective

sensors.

Page three of work mask

Pages two and three of the work masks

automatically return to the rst page after

10 seconds during drilling.

The arrow key can also be used to scroll back

to page one.

Adapting the work screen

The rst page of the work screen can be adapted

to your own wishes and practical use, whenever

required.

In this case a new display page is placed in front

of the rst standard page.

You can congure this page yourself in the

menu "Machine configuration" under menu

option "extra key selection" (see machine

conguration).

Screen display work mask

After switching on page one of the work mask

will always be displayed.

The displayed image will always depend on the

setting and the available equipment.

Page one of work mask

Work mask second page

16

Function symbols

The symbols in the display represent the

functions of the corresponding keys.

Stop button for tram line:

The button prevents the rhythm

being switched further after the

machine has been lifted out of

work. The function is indicated with

STOP between the tracks.

The tram line rhythm is increased

by one track with every operation

of the key.

The track number is displayed

between the tracks.

In case of a tram line track the

switched tracks are black under

laid.

In addition, the closed coulter rows

no longer appear in the display

during the sowing.

If the machine is equipped with the hydraulic bout

marker control, the symbol for the alternating

bout marker will appear instead of the

"Tram Line +" symbol when pressing "STOP

Tram Line".

This button can now be used to

change the side for the bout marker.

If stationary with the drill lowered

by pressing the meter fill dril l

function, the metering unit will start

up over a specified time. If the

computer receives a speed signal

during this period, the computer will

take over the control.

Post mode:

The po s t mode disa b l e s the

hydraulic "Lifting" function.

When operating the control unit only

the bout marker will be hydraulically triggered.

The machine remains in working position. The

work signal is hydraulically blocked and the tram

line will not count on.

Seed quantity 100 %:

If the seed quantity had been

adjusted with the +% or -% keys,

pressing this key will switch back to

the default seed quantity in kg/ha.

With the adjustment keys +% or -%

the seed quantity can be set and

reset in several steps.

The seed quantity is displayed in % by the

display above the hopper. The percentage step

can be changed in the machine data. There you

can also select whether only the seed quantity

is to be changed, or also the fertiliser quantity.

Switching the drill function ON / OFF:

With the drill function switched o

the display will show STOP under

the drill.

If the drill function is switched on,

the drill is lowered to work position

and the computer receives a speed

signal,

the computer will start the control

process.

Continue to next page:

If the hydraulic bout marker control

or the half width control is activated,

the next page will show the menu

for bout marker control, lifting and

folding of the machine half width

switch o.

Loading...

Loading...