horsch AutoForce Operating Instructions Manual

TRANSLATION OF THE ORIGINAL OPERATING INSTRUCTIONS

READ CAREFULLY PRIOR TO STARTING UP!

KEEP OPERATING INSTRUCTIONS IN A SAFE PLACE!

ART.:

ISSUE:

OPERATING INSTRUCTIONS

02

17

12/2017

8072

AutoForce

- Translation of the Original Operating Instructions -

Machine Identication

The corresponding data is to be entered into the list below upon

receiving the machine:

Serial number: ..................................................

Machine type: ...................................................

Year of construction: ........................................

Initial installation: ..............................................

Fittings: .............................................................

..........................................................................

..........................................................................

..........................................................................

Publication date of Operation Manual:

Latest change:

Address of Retailer: Name: ......................................................................

Road: ......................................................................

Town/City: ......................................................................

Tel.: ......................................................................

Customer No.:

Retailer: ......................................................................

Address of HORSCH: HORSCH Maschinen GmbH

92421 Schwandorf, Sitzenhof 1

92401 Schwandorf, Postbox 1038

Tel.: +49 (0) 9431 / 7143-0

Fax: +49 (0) 9431 / 7143-9200

E-mail: info@horsch.com

Customer No.:

HORSCH: ......................................................................

Conrmation of receipt of machinery

Warranty claims become only eective when the rst use of the machine is reported to HORSCH

Maschinen GmbH within a week.

At www.horsch.com under SERVICE PARTNERBEREICH an interactive PDF form is available for down-

load for this purpose (not available in all languages).

By clicking on Send – depending on the email program installed – a mail draft with the completed

form is generated automatically. Alternatively, the form can be sent as email attachment to machine.

registration@horsch.com.

A dierent form of registration (postal mail, by fax, etc.) is not allowed for.

en

02

12/2017

AutoForce

8072 17

Table of contents

AutoForce ......................................................4

Introduction .....................................................4

Checks before starting work ...........................4

Coulter unit ..................................................4

Cams ...........................................................4

Functional principle .....................................5

Forces on the drill unit ....................................5

Operation .......................................................7

AutoForce screen ...........................................7

Manual mode ..................................................7

Maestro RC manual mode..............................8

Automatic mode..............................................8

Automatic mode work screen .........................9

Manual mode work screen ...........................10

Conguration ................................................10

Settings.........................................................11

Section selection ........................................ 11

Sensor row allocation ................................ 11

Section to row allocation ............................12

Calibrating (Teach) the sensors ................. 13

Diagnostics ...................................................14

Maestro 16/18 SW (row spacing > 60 cm) ..14

Maestro 24/36/47/48 SW with

E-Manager software 10.07 ........................14

Maestro CC / RC - 12/18 SW ....................14

Delta Step coulter pressure .......................15

Additional key ............................................15

Water hole mode .......................................16

Error codes ................................................18

Troubleshooting ............................................21

Index ............................................................24

2

3

NOTE

These operating instructions are only valid in

combination with the E-Manager Midi 10.07 or

higher operating manual.

This document only describes the function of the

AutoForce automatic coulter pressure control.

¾ Always follow the operating instructions for

drill and E-Manager to ensure safe operation

of the machine.

AutoForce

Introduction

AutoForce is a system for the automatic coulter

pressure adjustment on the Maestro.

A cam with a sensor is attached to the axle of

the depth guide wheel. The sensor determines

the force acting from the ground on the depth

guide wheel.

The objective is keeping the contact force between depth guide wheel and ground constant,

regardless of the soil conditions.

As a result, the coulter unit adapts to dierent

soil conditions to ensure consistent placement

depth.

The systems may have a single or multi-section

design. For systems with one section springs are

attached to the drill unit in the track.

For systems with several sections, the respective last section is reserved for the track. Springs

can be retrotted.

NOTE

The user is responsible for the quality of sowing

in spite of the AutoForce automatic coulter pressure control.

¾ Check the quality of sowing and placement

depth in the eld several times a day.

¾ Check the calibration values of the sensors

several times a day. Observe the section

Calibration (teach) of sensors.

Checks before starting

work

Coulter unit

¾ Observe the basic setting of the coulter unit

to ensure the function of AutoForce.

¾ Adjust the parallelograms of the units hori-

zontally.

¾ With the Maestro 16/24/36 SW check the

setting of the coulter rail in addition.

¾ Observe the operating instructions of the

respective machine.

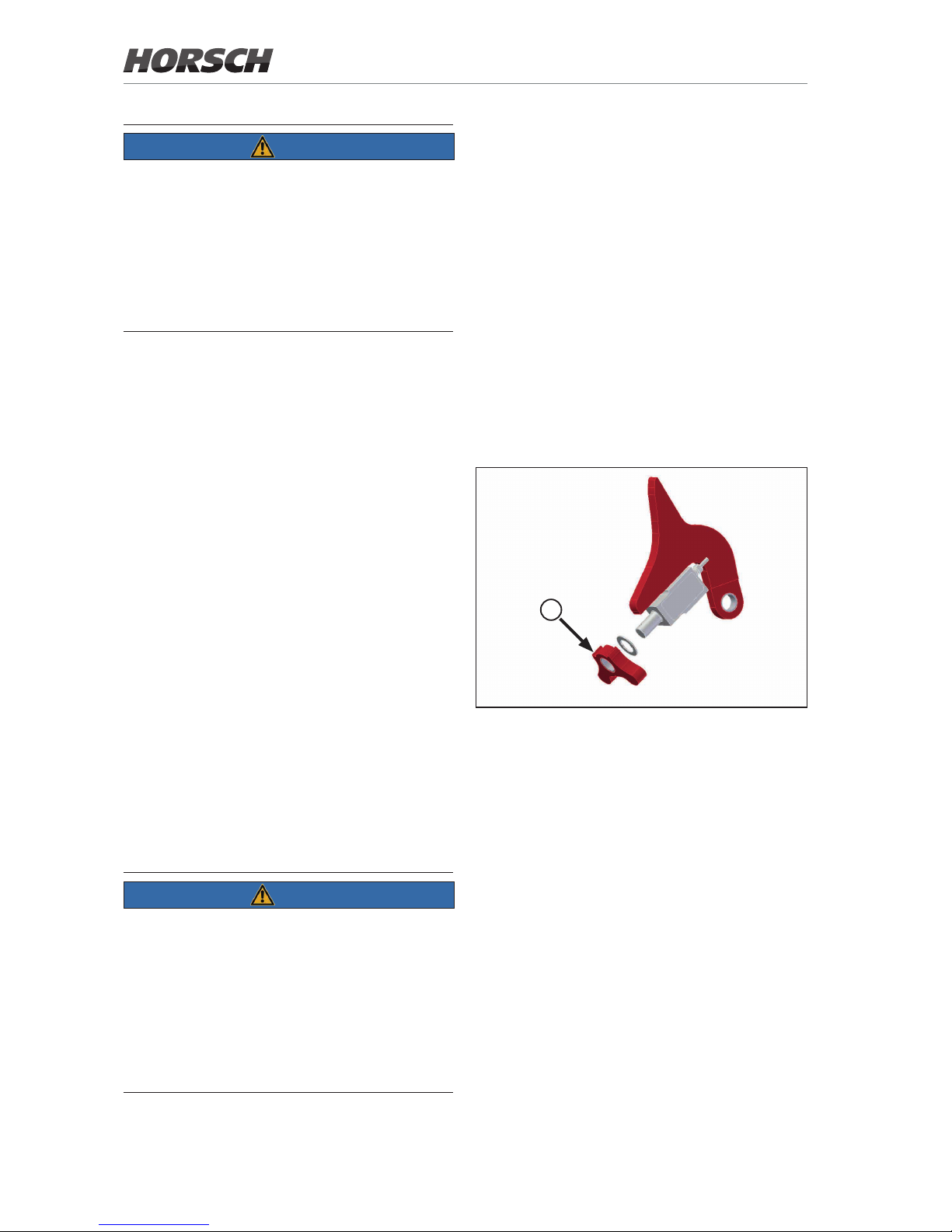

Cams

A

Sensors with cams (A)

¾ Check cams for wear.

Unequal wear of cams causes dierent placement depths.

¾ Replace the cams if necessary.

4

Functional principle

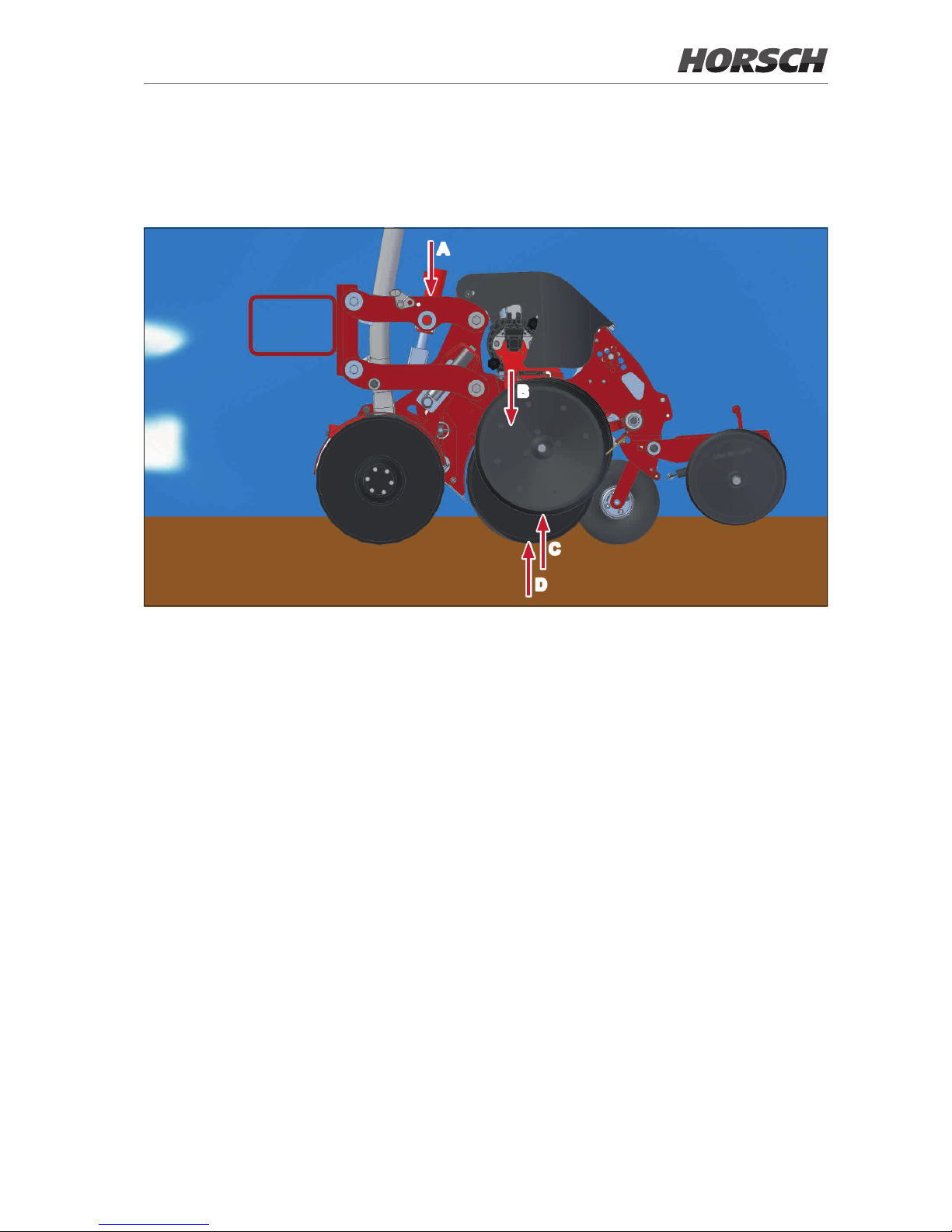

Forces on the drill unit

A

B

C

D

Forces on the drill unit

A hydraulic coulter pressure

B force of the drill unit’s weight

C force between soil and depth guide wheel (target value)

D Force between soil and coulter discs

The target value for the control of the coulter pressure is the force between the soil and the depth

guide wheel (C).

On soft soils, the force of the weight is sucient for the coulter discs to penetrate the soil.

On hard soils, the force between soil and the coulter discs (D) increases. As a result, the force (C)

between the soil and depth guide wheel becomes smaller. The target value is therefore undercut.

The coulter pressure (A) must now be increased hydraulically for the force (C) between soil and

depth guide wheels to correspond to the target value again and the placement depth to remain

constant.

5

For greater clarity, the presentation of the weight force and the force between soil and depth guide

wheel is omitted on the following illustrations.

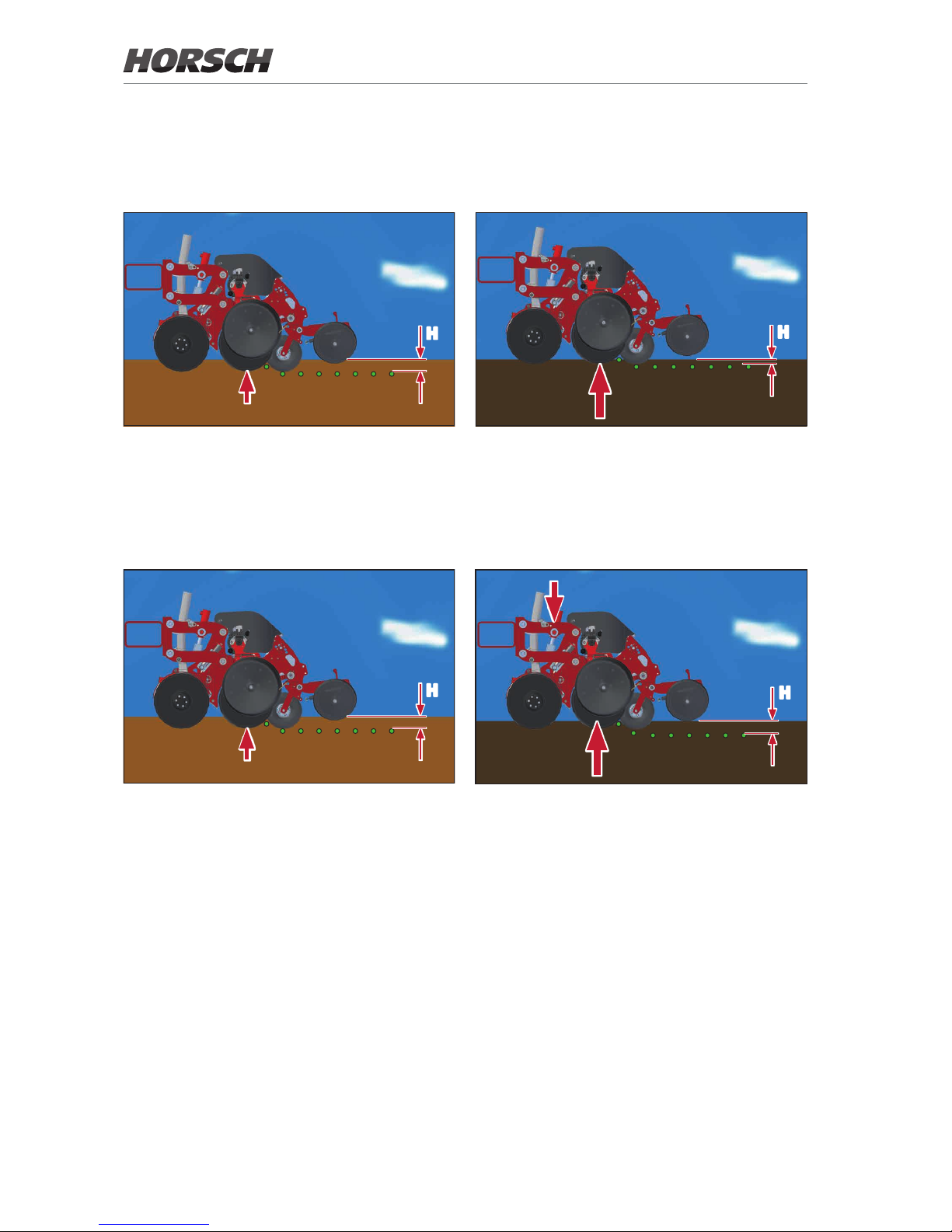

Maestro without AutoForce

H

H

Sowing on soft, moist or light soil

Placement depth H is maintained. The force

acting from the soil on the coulter discs is

relatively low.

Sowing on hard soil, clod-type soil or rocky soil

The force acting on the coulter discs increases.

The placement depth decreases.

Maestro with AutoForce

H

H

Sowing on soft, moist or light soil

Placement depth H is maintained. The force

acting from the soil on the coulter discs is

relatively low.

Sowing on hard soil, clod-type soil or rocky soil

Additional coulter pressure is hydraulically

applied to the drill unit to allow deeper penetration of the soil.

Placement depth H remains consistent.

6

Operation

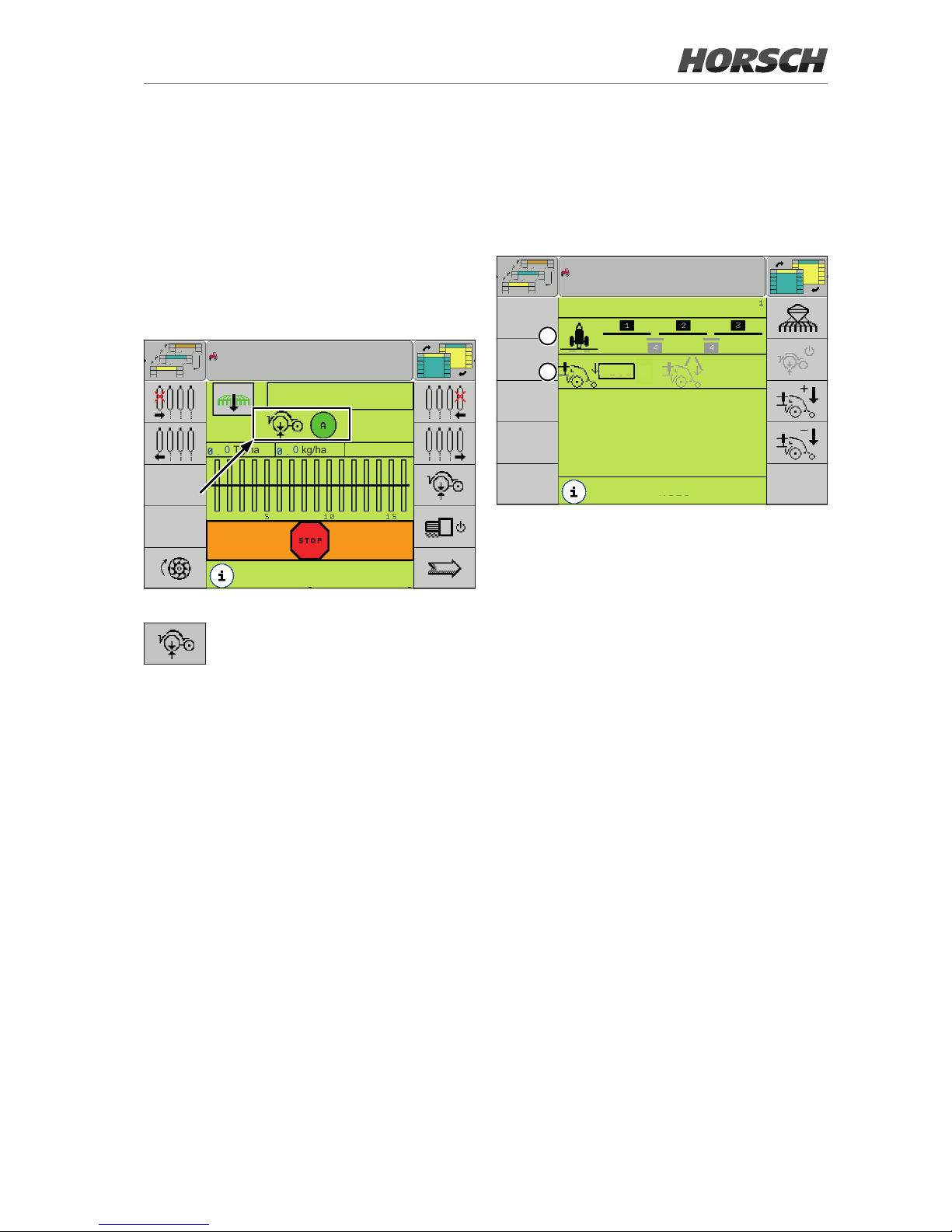

AutoForce screen

The AutoForce screen can be accessed via the

corresponding button on the working screen or

the additional key.

Depending on the terminal, the button can be

selected by rotary wheel or touch.

0.0

km/h

0 Tg/ha 0 kg/ha

maize

Working screen - Button to access the AutoForce screen

Softkey for accessing the AutoForce

screen.

Manual mode

The manual mode is active is the automatic

mode is disabled.

The manual mode must be used if no control

is possible.

AutoForce

200

kg

200

kg

Manual

res. 30.0

ha

16689

m

1

2

AutoForce screen - manual mode

1. The diagram shows the layout of the sections.

The standard sections are shown in black,

the sections in the tracks in grey.

2. The target values for the standard sections

(black) and the sections in the tracks (grey)

can be entered here.

The hydraulic valve is then pressurised with

a constant value.

Target value range for manual mode:

150 - 350 kg.

7

Loading...

Loading...