Page 1

MAN0848-02 21 August 2007 PAGE 1

To download the XLE User

in this

3

.

6

2

2

[

9

2

m

m

]

001XLE002

Apply 10

when usin

g CsCAN network.

XLE OCS Model: HE

-

XE103

-

10

001XLE029-R2

Jumper

NET 1

(CsCAN)

Power

DIP

Specifications / Installation HE-XE103-10

1 Specifications

Digital DC Inputs XLE103-10

Inputs per Module

Commons per

Module

Input Voltage

Range

Absolute Max.

Voltage

Input Impedance

Input Current

Upper Threshold 0.8 mA -1.6 mA

Lower Threshold 0.3 mA -2.1 mA

Max Upper

Threshold

Min Lower

Threshold

OFF to ON

Response

ON to OFF

Response

HSC Max.

Switching Rate

Thermistor

Inputs, Medium

Resolution

Number of

Channels

Input Ranges

Safe input voltage

range

Input Impedance

(Clamped @ -0.5

VDC to 12 VDC)

Nominal Resolution

%AI at 10K Ohm

Conversion Speed

Max. Error at 25°C

reading / ambient

Additional error for

reading / ambient

temperatures other

than 25°C

Filtering

Clock Accuracy +/- 7 Minute/Month at 20C

12 including 4 configurable

HSC inputs

1

12 VDC / 24 VDC Output Type Sourcing / 10 K Pull-Down

35 VDC Max.

10 kΩ

Positive

Logic

10 kHz Totalizer/Pulse,Edges

5 kHz Frequency/Pulse,Width

9.59K ohm pulled up to

All channels converted once

Using specified linearization

160 Hz hash (noise) filter

1-128 scan digital running

Highest usable frequency for PWM output is 65 KHz

Negative Logic

8 VDC

3 VDC

1 ms

1 ms Min. Load None

2.5 kHz Quadrature

XLE103-10

2

10K OHM

Thermistor

Half Bridge

4.8 VDC

10 Bits

15,008 counts

per ladder scan

±0.5°F or ±0.3°C

in ladder program

TBD

average filter

12 Digital DC Inputs / 12 Digital Outputs

HE-XE103-10 Specifications

Digital DC

Outputs

Outputs per

Module

Commons per

Module

Absolute Max.

Voltage

Output

Protection

Max. Output

Current per

point

Max. Total

Current

Max. Output

Supply Voltage

Minimum Output

Supply Voltage

Max. Voltage

Drop at Rated

Current

Max. Inrush

Current

OFF to ON

Response

ON to OFF

Response

Output

Characteristics

Required Power

(Steady State)

Required Power

(Inrush)

Primary Power

Range

Relative Humidity

Operating

Temperature

Terminal Type

CE

See Compliance Table at

http://www.heapg.com/Support/compliance.htm

UL

Weight 12.5 oz. (354.36 g)

2 10K Thermistor Inputs

XLE103-10

12 including 2 configurable

PWM outputs

1

28 VDC Max.

Short Circuit

0.5 A

4 A Continuous

30 VDC

10 VDC

0.25 VDC

650 mA per channel

1 ms

1 ms

Current Sourcing (Pos logic)

General Specifications

130 mA @ 24 VDC

30 A for 1 ms @ 24 VDC

10 – 30 VDC

5 to 95% Non-

condensing

0°C to +50°C

Screw Type,5 mm

Removable

Want More Information?

Manual (MAN0805), refer

to Technical Support

document.

2 Panel Cut-Out and Dimensions

Note: Max. panel thickness: 5 mm.

Refer to XLE User

Manual (MAN0805) for

panel box information

and a handy checklist of

requirements.

Note:

The tolerance to meet

NEMA standards is

± 0.005” (0.1 mm).

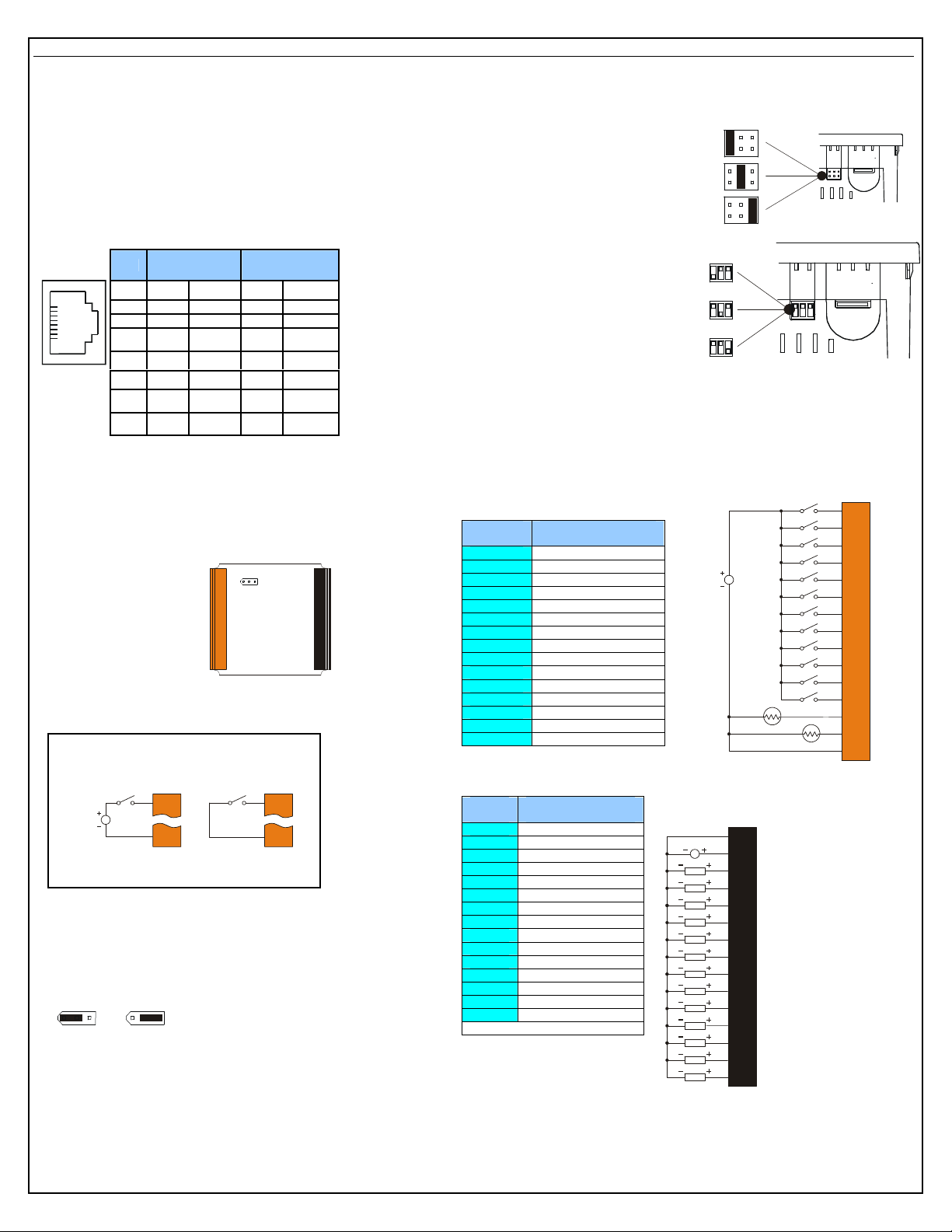

3 Ports / Connectors / Cables

Note: The case of the XLE is black, but for clarity, it is shown in a

lighter gray color.

MJ2

(RS-232 / RS-485)

MJ1

(RS-232 / RS-485)

To Remove Back Cover:

Unscrew 4 screws located on

the back of the unit.

Lift lid.

I/O Jumpers (Not Shown): I/O Jumpers (JP) are located

internally. To access, remove back cover of unit.

Wiring Connectors (J1 – J4), I/O Jumpers (JP1-3), and

External Jumpers (RS-485) are described in the Wiring and

Jumpers section of this document.

001ACC009

Power Connector

Power Up:

Connect to Earth Ground.

Screen lights up.

Switch

J1

I/O

Jumper

– 30 VDC.

Memory Slot

3.622 [92mm]

CAUTION: Do not overtighten

screws when screwing the lid

back on.

CAN Connector

Use the CAN Connector

J2

I/O

Page 2

PAGE 2 21 August 2007 MAN0848-02

001XLE036

MJ2 Termination

MJ1 Termination

001XLE037

As seen when looking at the top of the XLE unit. Refer to

for data logging, screen

Application

)

For I/O wiring (discrete), use the

ivalent:

AWG or larger.

following wire type or equivalent:

ugh most

The External Jumpers or DIP

Switches are used for termination of

485 ports. The XLE is

To terminate, select one of the

jumpers shipped with the product and

insert it based upon the option that is

desired or, select the switch and

configure based upon the option that

Q10

Q11

Q12

V+

0V

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

10 - 30VDC

001XLE024

001XLE061

A1

A2

H2

H3

H4

T

JP1

001XLE060

001XLE037-R1

MJ2 Termination

mination

XLE103-10 Specifications / Installation

Section 3 continued

Memory Slot:

Uses Removable Memory

captures, program loading and recipes.

Horner Part No.: HE-MC1

Serial Communications:

MJ1: (RS-232 / RS-485) Use for Cscape programming and

MJ2: (RS-232 / RS-485) Use for Application-Defined

Communications.

-Defined Communications.

8

1

4 Wiring and Jumpers

Pin MJ1 Pins MJ2 Pins

TXD OUT TXD OUT

8

RXD IN RXD IN

7

0 V Ground 0 V Ground

6

NC

5

RTS OUT TX- OUT

4

CTS IN TX+ OUT

3

RX- /

2

TX-

RX+ /

1

TX+

No

Connect

IN /

OUT

IN /

OUT

NC

Connect

RX- IN

RX+ IN

No

Wire according to the type of inputs / outputs used and select the appropriate jumper

option.

Wiring Specifications

following wire type or equ

Belden 9918, 18 AWG or larger.

For shielded Analog I/O wiring,

use the following wire type or

equivalent: Belden 8441, 18

For CAN wiring, use the

Belden 3084, 24 AWG or larger.

Location of I/O jumper (JP1

and wiring connectors

(J1 & J2).

J1 J2

Positive Logic vs. Negative Logic Wiring

The XLE can be wired for Positive Logic inputs or

Negative Logic inputs.

I1

12-24VDC

0V

0V

Positive Logic In Negative Logic In

I1

Note: The Cscape Module Setup configuration must match

4.1. I/O Jumper Setting (JP1)

the selected I/O (JP) jumper settings.

JP1 Digital DC Inputs

Positive Logic

Negative Logic

Default

Some XLes have jumpers to set RS485 port termination, tho

use DIP Switches.

the RSshipped un-terminated.

is desired.

4.2. External DIP Switch Settings (or Jumpers Settings)

Section 3 for the location of the External Jumpers.

Factory Use

(default – none)

(default – none)

(default – none)

Factory Use

(default – none)

(default – none)

MJ1 Ter

(default – none)

4.3. Wiring Examples

Note: The wiring examples show

Positive Logic input wiring.

J1

Orange

XE103-10

Name

I1 IN1

I2 IN2

I3 IN3

12-24VDC

I4 IN4

I5 IN5

I6 IN6

I7 IN7

I8 IN8

H1 HSC1 / IN9

H2 HSC2 / IN10

H3 HSC3 / IN11

H4 HSC4 / IN12

A1 Thermistor 1

A2 Thermistor 2

0V Ground

J2

Black

XE103-10

Name

0V Ground

XE103-10 J2 Black

Positive Logic

Digital Out

V+ V+ *

NC No Connect

Q12 OUT12

Q11 OUT11

Q10 OUT10

LOAD

LOAD

Q13

Q9 OUT9

Q8 OUT8

Q7 OUT7

Q6 OUT6

Q5 OUT5

Q4 OUT4

Q3 OUT3

Q2 OUT2 / PWM2

Q1 OUT1 / PWM1

V+* Supply for Sourcing Outputs

Q9

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

XE103-10 J1 Orange

Positive Logic

Digital In

I1

I2

I3

I4

I5

I6

I7

I8

H1

T

0V

Page 3

MAN0848-02 21 August 2007 PAGE 3

60201004080

20

Scans

0

6

%

C

o

m

p

l

e

t

e

[

]

Constant

Specifications / Installation XLE103-10

5 Analog Conditioning

5.1 Filter

Filter Constant sets the level of digital filtering according to the following

chart.

100

1 2 3 4 5

0 7

90

80

70

60

50

40

30

10

0

Digital Filtering.

The illustration above demonstrates the effect of digital

Filter

filtering (set with Filter Constant) on module response to a

temperature change.

It is recommended that the filter constant for the HE-XE103-10 be set to a

value of 7. This will minimize noise and jitter, improve effective resolution,

and provide adequate speed for most temperature monitor and control

applications.

Thermistors are measured using a half-bridge circuit that exhibits variable resolution

and the associated increased measurement range.

Best resolution is at 25°C, 77°F. With a constant 0.1°C resolution circuit, the

measurement range would only extend from –26°C to + 76°C.

Linearization must be performed by the user in the ladder application code, using 26

internal %R registers per channel. The example below uses %R1-26 to linearize one

channel - %AI1. Linearization consists of the following example steps.

1. Load the desired linearization coefficients into a table on First Scan using a Move

Constant Data block.

5.2 Thermistor Linearization

Temperature, degrees C Resolution, degrees C

-55 1.05

-35 0.36

-15 0.17

5 0.11

25 0.1

45 0.13

65 0.22

85 0.30

105 0.55

125 0.85

145 1.35

Registers (Real) Degrees C Degrees F

R0011 -1.94454e-028 -3.50017e-028

R0013 2.40268e-023 4.32483e-023

R0015 -1.24101e-018 -2.23381e-018

R0017 3.46655e-014 6.23979e-014

R0019 -5.69403e-010 -1.02493e-009

R0021 5.62368e-006 1.01226e-005

R0023 -0.0353121 -0.0635617

R0025 163.878 326.981

2. Load %AI0001 into %R0001 as a Real.

3. Perform the Real Math Expression

%R3 = (((%R11*%R1+%R13)*%R1+%R15)*%R1+%R17)

The expression rung may be copied, substituting %AI0002 and %R00011 for %AI0001 and

%R0007, and used to linearize the second channel. Contact Horner APG for an example file

containing the above program.

5.3 Thermistor types

The HE-XE103-10 with the given example ladder code supports Kele Engineering Precon

Type III, 10 KΩ thermistors. It also directly supports the following 10 KΩ (Beta=3574)

thermistors from Yellow Springs Instruments (YSI).

44006 46006

44106 46031

44406 46041

44031 44907

45006 44908

6 I/O Register Map

%I1 to %I24 Digital Inputs

%I25 to %I31 Reserved

%Q1 to %Q16 Digital outputs

%Q21 to %Q32 Reserved

%AI1 to %AI4 Analog inputs

%AI5, %AI6 HSC1 Accumulator

%AI7, %AI8 HSC2 Accumulator

%AI9, %AI10 HSC3 Accumulator

%AI11, %AI12 HSC4 Accumulator

%AQ1, %AQ2 PWM1 Duty Cycle

%AQ3, %AQ4 PWM2 Duty Cycle

%AQ5, %AQ6 PWM Prescale

%AQ7, %AQ8 PWM Period

%AQ9 to %AQ14 Analog outputs

Note: Not all XLe units contain the I/O listed in this table.

Registers PWM HSC Stepper

%AQ1

%AQ2

%AQ3

%AQ4

%AQ5

%AQ6

%AQ7

%AQ8

%Q1 Run

%I30 Ready/Done

%I31

Registers

%I32 Output Fault

%Q17 Clear HSC1 accumulator to 0

%Q18

%Q19 Clear HSC3 Accumulator to 0

%Q20

PWM1 Duty

Cycle

(32 bit)

PWM2 Duty

Cycle

(32 bit)

PWM Prescale

(32 bit)

PWM Period

(32 bit)

Description

Totalizer: Clear HSC2

Quadrature 1-2: Accumulator 1

Reset to max – 1

Totalizer: Clear HSC4

Quadrature 3-4: Accumulator 3

Reset to max – 1

HSC1

Preset

Value

HSC2

Preset

Frequency

Frequency

Accel Count

Value

Run Count

Decel Count

Start

Run

(32 bit)

(32 bit)

(32 bit)

Error

4. Perform the Real Math Expression %R5 =

(((%R3*%R1+%R19)*%R1+%R21)*%R1+%R23)*%R1+%R25

5. Load %R0005 result into another register such as %R0007 to save the temperature

value.

Steps 2 though 5 can be on a single rung.

Page 4

PAGE 4 21 August 2007 MAN0848-02

Wear proper personal protective equipment including safety glasses and insulated gloves when making

use

r documentation.

XLE103-10 Specifications / Installation

7. Safety

When found on the product, the following symbols specify:

Warning: Electrical

Shock Hazard.

WARNING: To avoid the risk of electric shock or burns, always connect the safety (or earth) ground before

making any other connections.

WARNING: To reduce the risk of fire, electrical shock, or physical injury it is strongly recommended to fuse

the voltage measurement inputs. Be sure to locate fuses as close to the source as possible.

WARNING: Replace fuse with the same type and rating to provide protection against risk of fire and shock

hazards.

WARNING: In the event of repeated failure, do not replace the fuse again as a repeated failure indicates a

defective condition that will not clear by replacing the fuse.

WARNING: Only qualified electrical personnel familiar with the construction and operation of this equipment

and the hazards involved should install, adjust, operate, or service this equipment. Read and understand this

manual and other applicable manuals in their entirety before proceeding. Failure to observe this precaution

could result in severe bodily injury or loss of life.

All applicable codes and standards need to be followed in the installation of this product.

Adhere to the following safety precautions whenever any type of connection is made to the module:

Connect the safety (earth) ground on the power connector first before making any other connections.

When connecting to electric circuits or pulse-initiating equipment, open their related breakers.

Do not make connections to live power lines.

Make connections to the module first; then connect to the circuit to be monitored.

Route power wires in a safe manner in accordance with good practice and local codes.

connections to power circuits.

Ensure hands, shoes, and floor are dry before making any connection to a power line.

Make sure the unit is turned OFF before making connection to terminals.

Make sure all circuits are de-energized before making connections.

Before each use, inspect all cables for breaks or cracks in the insulation. Replace immediately if defective.

8 Technical Support

Warning: Consult

Notes

Notes

For assistance and manual updates, contact Technical Support at the following

locations:

North America:

(317) 916-4274

www.heapg.com

email: techsppt@heapg.com

Europe:

(+) 353-21-4321-266

www.horner-apg.com

email: techsupport@hornerirl.ie

Loading...

Loading...