Page 1

Supplement for

HE800ETN200, HE800ETN300

HE-ETN200, HE-ETN300

SmartStack™

Ethernet Modules

SUP0740-07

Page 2

SUP0740-07 PREFACE

PREFACE

This manual explains how to use SmartStack Ethernet Modules (ETN200 and ETN300).

Copyright (C) 2006 Horner APG, LLC, 59 South State Avenue, Indianapolis, Indiana 46201. All

rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in

a retrieval system, or translated into any language or computer language, in any form by any

means, electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without the

prior agreement and written permission of Horner APG, LLC.

All software described in this document or media is also copyrighted material subject to the terms

and conditions of the Horner Software License Agreement.

Information in this document is subject to change without notice and does not represent a

commitment on the part of Horner APG, LLC.

Cscape, SmartStack, and CsCAN are trademarks of Horner APG, LLC.

Ethernet/IP is a trademark of the Open DeviceNet Vendor Association (ODVA), Inc.

Ethernet Global Data, EGD, Service Request Transfer Protocol, SRTP, CIMPLICITY and Series

90 are trademarks of GE Fanuc Automation North America, Inc.

Internet Explorer is a trademark of Microsoft Corporation.

KEPware is a trademark of KEPware, Inc.

Firefox is a trademark of the Mozilla Foundation.

FileX, NetX and ThreadX are trademarks of Express Logic, Inc.

For user documentation updates, visit our website.

North America:

Tel: 317 916-4274

Fax: 317 639-4279

Web: http://www.heapg.com

Email:

Europe:

Tel: (+) 353-21-4321-266

Fax: (+) 353-21-4321826

Web: http://www.horner-apg.com

Email:

techsppt@heapg.com

tech.support@horner-apg.com

11/30/2009 Page 2 of 98 # 958

Page 3

WARRANTY AND LIABILITY SUP0740-07

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG, LLC ("HE-APG") warrants to the original purchaser that the ETN200 / 300

manufactured by HE-APG is free from defects in material and workmanship under normal use

and service. The obligation of HE-APG under this warranty shall be limited to the repair or

exchange of any part or parts which may prove defective under normal use and service within two

(2) years from the date of manufacture or eighteen (18) months from the date of installation by

the original purchaser whichever occurs first, such defect to be disclosed to the satisfaction of

HE-APG after examination by HE-APG of the allegedly defective part or parts. THIS WARRANTY

IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE AND OF

ALL OTHER OBLIGATIONS OR LIABILITIES AND HE-APG NEITHER ASSUMES, NOR

AUTHORIZES ANY OTHER PERSON TO ASSUME FOR HE-APG, ANY OTHER LIABILITY IN

CONNECTION WITH THE SALE OF THIS ETN200 / 300. THIS WARRANTY SHALL NOT

APPLY TO THIS ETN200 / 300 Module OR ANY PART THEREOF THAT HAS BEEN SUBJECT

TO ACCIDENT, NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. HE-APG MAKES NO

WARRANTY WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT SUPPLIED BY

HE-APG. THE TERM "ORIGINAL PURCHASER", AS USED IN THIS WARRANTY, SHALL BE

DEEMED TO MEAN THAT PERSON FOR WHOM THE ETN200 / 300 IS ORIGINALLY

INSTALLED. THIS WARRANTY SHALL APPLY ONLY WITHIN THE BOUNDARIES OF THE

CONTINENTAL UNITED STATES.

In no event, whether as a result of breach of contract, warranty, tort (including negligence) or

otherwise, shall HE-APG or its suppliers be liable of any special, consequential, incidental or

penal damages including, but not limited to, loss of profit or revenues, loss of use of the products

or any associated equipment, damage to associated equipment, cost of capital, cost of substitute

products, facilities, services or replacement power, down time costs, or claims of original

purchaser's customers for such damages.

To obtain warranty service, return the product to your distributor with a description of the

problem, proof of purchase, post paid, insured and in a suitable package.

ABOUT PROGRAMMING EXAMPLES

Any example programs and program segments in this manual or provided on accompanying

media are included solely for illustrative purposes. Due to the many variables and requirements

associated with any particular installation, Horner APG cannot assume responsibility or liability for

actual use based on the examples and diagrams. It is the sole responsibility of the system

designer utilizing the ETN200 / 300 to appropriately design the end system, to appropriately

integrate the ETN200 / 300 and to make safety provisions for the end equipment as is usual and

customary in industrial applications as defined in any codes or standards which apply.

Note: The programming examples shown in this manual are for illustrative purposes

only. Proper machine operation is the sole responsibility of the system integrator.

11/30/2009 Page 3 of 98 # 958

Page 4

TABLE OF CONTENT SUP0740-07

TABLE OF CONTENTS

PREFACE.........................................................................................................................2

LIMITED WARRANTY AND LIMITATION OF LIABILITY ...............................................3

CHAPTER 1: INTRODUCTION.......................................................................................7

1.1 Ethernet Modules Overview........................................................................................... 7

1.2 Ethernet Network Example ............................................................................................ 8

1.3 Ethernet System Requirements and Interoperability ..................................................... 9

1.4 Ethernet Module Specifications...................................................................................... 9

1.5 Additional Technical Resources................................................................................... 10

1.6 Technical Support ........................................................................................................ 10

CHAPTER 2: INSTALLATION ......................................................................................11

2.1 Built-In Ethernet Module............................................................................................... 11

2.2 User-Installed Ethernet Module.................................................................................... 11

2.3 Network Administrator Installation Notes..................................................................... 12

2.3.1 UDP and TCP Ports................................................................................................. 12

2.3.2 EGD Unicast and Multicast IP Addressing.............................................................. 12

2.3.3 Internet Connectivity................................................................................................ 13

2.3.4 IMPORTANT: Wireless Network Considerations ................................................... 13

2.4 Safety...........................................................................................................................14

CHAPTER 3: GENERAL CONFIGURATION................................................................ 15

3.1 Ethernet Module Configuration .................................................................................... 15

3.2 Ethernet Module IP Address........................................................................................ 21

3.2.1 Static IP Address ..................................................................................................... 21

3.2.2 Static IP Address with CAN ID................................................................................. 21

3.2.3 IP Address from OCS Register................................................................................22

CHAPTER 4: CSCAN OVER ETHERNET PROTOCOL...............................................23

4.1 CsCAN over Ethernet Overview................................................................................... 23

4.2 CsCAN over Ethernet Configuration............................................................................ 23

4.3 CsCAN over Ethernet Operation.................................................................................. 24

4.4 CsCAN over Ethernet Downloading Precautions......................................................... 24

4.4.1 How to Prevent Losing Communication................................................................... 25

4.4.2 How to Recover from Lost Communication............................................................. 25

4.5 CsCAN over Ethernet Security..................................................................................... 26

CHAPTER 5: INTERNET CONTROL MESSAGE PROTOCOL (ICMP).......................29

5.1 ICMP Overview ............................................................................................................ 29

5.2 ICMP Configuration......................................................................................................29

5.3 ICMP Operation............................................................................................................ 30

CHAPTER 6: ETHERNET GLOBAL DATA PROTOCOL (EGD) .................................31

6.1 EGD Overview.............................................................................................................. 31

6.2 EGD Terminology......................................................................................................... 31

6.3 EGD Configuration....................................................................................................... 32

6.4 EGD Produced Exchange Configuration ..................................................................... 33

6.4.1 Creating EGD Produced Exchanges....................................................................... 34

6.4.2 Defining EGD Produced Exchange I/O Blocks........................................................35

6.5 EGD Consumed Exchange Configuration ................................................................... 36

6.5.1 Creating EGD Consumed Exchanges..................................................................... 37

6.5.2 Defining EGD Consumed Exchange I/O Blocks...................................................... 39

11/30/2009 Page 4 of 98 # 958

Page 5

SUP0740-07 TABLE OF CONTENT

6.6 EGD Operation............................................................................................................. 40

6.7 EGD Status Words.......................................................................................................40

6.7.1 EGD Produced Exchange Status Words................................................................. 40

6.7.2 EGD Consumed Exchange Status Words............................................................... 41

6.8 EGD Example 1............................................................................................................ 41

6.8.1 EGD Example 1 – Configuring Node 1....................................................................42

6.8.2 EGD Example 1 – Configuring Node 2....................................................................47

6.8.3 EGD Example 1 – Starting EGD Communication between Node 1 and Node 2..... 51

6.9 EGD Example 2............................................................................................................ 52

6.9.1 EGD Example 2 – Adding a Status Block................................................................ 52

6.9.2 EGD Example 2 – Adding an OCS Timestamp Block............................................. 53

6.9.3 EGD Example 2 – Adding a Filler Block.................................................................. 55

CHAPTER 7: SERVICE REQUEST TRANSFER PROTOCOL (SRTP) .......................57

7.1 SRTP Overview............................................................................................................ 57

7.2 SRTP Configuration..................................................................................................... 57

7.3 SRTP Operation........................................................................................................... 58

CHAPTER 8: MODBUS TCP SLAVE PROTOCOL...................................................... 59

8.1 Modbus Overview......................................................................................................... 59

8.2 Modbus Configuration.................................................................................................. 60

8.3 Modbus Operation........................................................................................................ 60

CHAPTER 9: ETHERNET/IP PROTOCOL ................................................................... 63

9.1 Ethernet/IP Overview...................................................................................................63

9.2 Ethernet/IP Configuration.............................................................................................64

9.3 Ethernet/IP Operation .................................................................................................. 65

CHAPTER 10: FTP SERVER PROTOCOL...................................................................67

10.1 FTP Overview............................................................................................................... 67

10.2 FTP Configuration........................................................................................................ 67

10.3 FTP Operation..............................................................................................................68

10.4 FTP File Accessing ...................................................................................................... 68

CHAPTER 11: HTTP SERVER PROTOCOL................................................................71

11.1 HTTP Overview............................................................................................................ 71

11.2 HTTP Configuration ..................................................................................................... 71

11.3 HTTP Operation........................................................................................................... 72

11.4 Web Content - Storing.................................................................................................. 72

11.5 Web Content - Dynamic Data ...................................................................................... 73

11.5.1 Static Html Files................................................................................................... 73

11.5.2 Dynamic Html Files – Reading OCS Register Data (readreg.htm)..................... 73

11.5.2.1 Reg Parameter – OCS Register Read Reference......................................73

11.5.2.2 Fmt Parameter – OCS Register Read Format ........................................... 74

11.5.2.3 Ffs Parameter – OCS Register Read Auto-Refresh................................... 74

11.5.2.4 Fnt Parameter – OCS Register Read Font................................................. 75

11.5.3 Dynamic Html Files – Writing OCS Register Data (writereg.htm)....................... 75

11.5.3.1 Reg Parameter – OCS Register Write Reference...................................... 76

11.5.3.2 Fmt Parameter – OCS Register Write Format............................................ 76

11.6 Web Content - Authoring.............................................................................................. 77

11.6.1 Web Server Example Applications...................................................................... 77

11.6.2 Web Authoring Reference Material.....................................................................77

11.6.3 Web Authoring Tools........................................................................................... 77

CHAPTER 12: EMAIL (SMTP PROTOCOL).................................................................79

12.1 Overview ...................................................................................................................... 79

12.2 Email Configuration:.....................................................................................................79

A. E-Mail Status Register Configuration.................................................................. 80

11/30/2009 Page 5 of 98 # 958

Page 6

TABLE OF CONTENT SUP0740-07

B. Additional E-Mail Configuration........................................................................... 80

C. Email Message Configuration ............................................................................. 83

C.1. Email Directory .................................................................................................... 83

C.2. Outgoing Messages............................................................................................. 86

12.3 Email Status..................................................................................................................... 89

CHAPTER 13: ASCII OVER TCP/IP .............................................................................91

13.1 Overview ........................................................................................................................... 91

13.2 Configuration..................................................................................................................... 91

13.3 Sending ASCII characters to the client............................................................................. 93

13.4 Receiving ASCII characters from the client ...................................................................... 94

13.5 Status Information............................................................................................................. 94

INDEX.............................................................................................................................95

TABLE OF FIGURES.....................................................................................................97

11/30/2009 Page 6 of 98 # 958

Page 7

SUP0740-07 CH.1

CHAPTER 1: INTRODUCTION

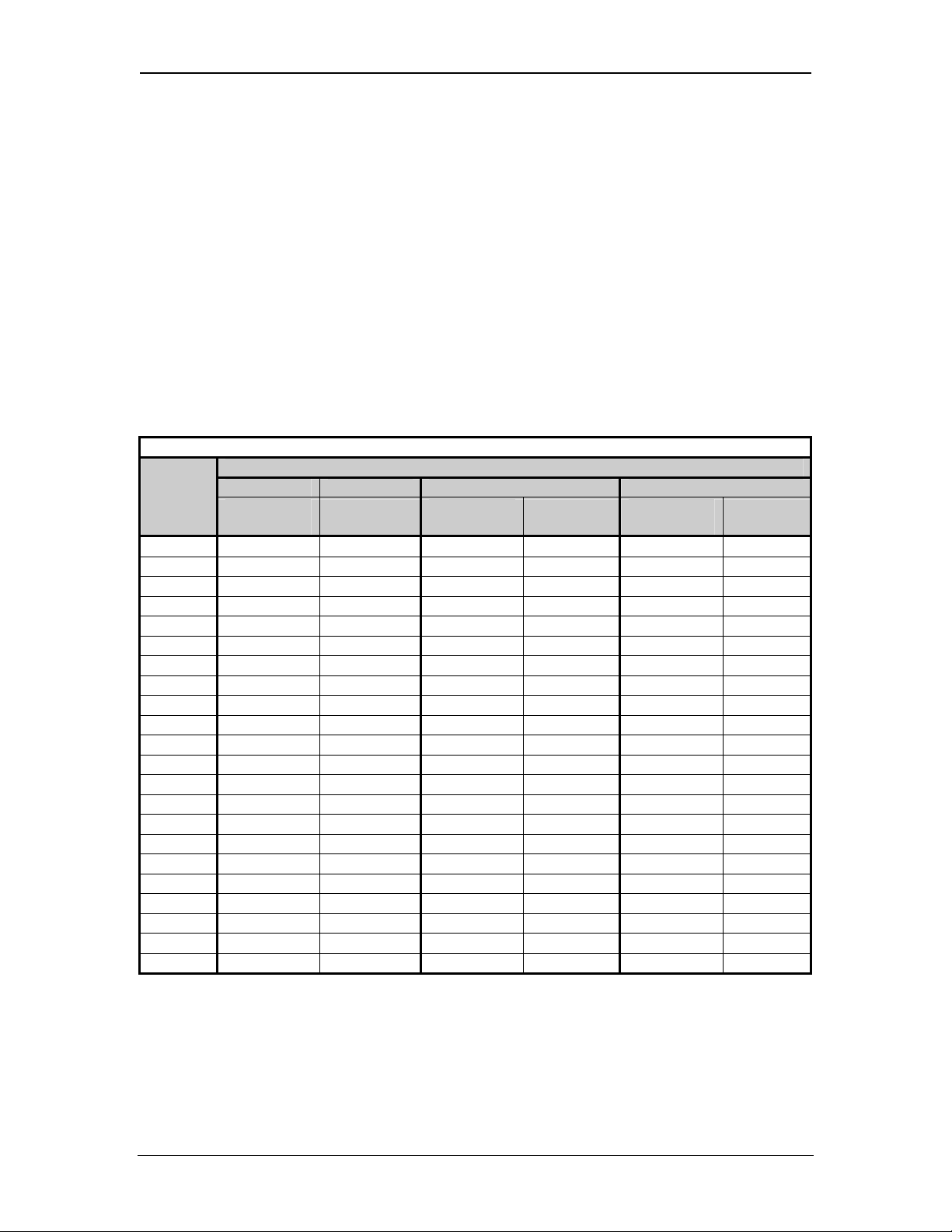

1.1 Ethernet Modules Overview

Note: HE800ETN200 and HE800ETN300 have metal cases. HE-ETN200 and HE-ETN300 have

plastic cases. The modules are alike except that they have different case materials. In this

supplement, Ethernet modules are referred to as ETN200 / 300 regardless of the type of case

material used.

Ethernet Modules are built-in or user-installed into Horner OCS controllers to provide advanced

Ethernet communication capabilities. Although this manual specifically addresses ETN200 and

ETN300 Ethernet Modules, it is useful to compare them to our legacy Ethernet modules (ETN100

and ETN116). Table 1.1 illustrates the compatibility between various OCS Models and Ethernet

modules. Table 1.2 summarizes the protocols and features supported by each type of Ethernet

module.

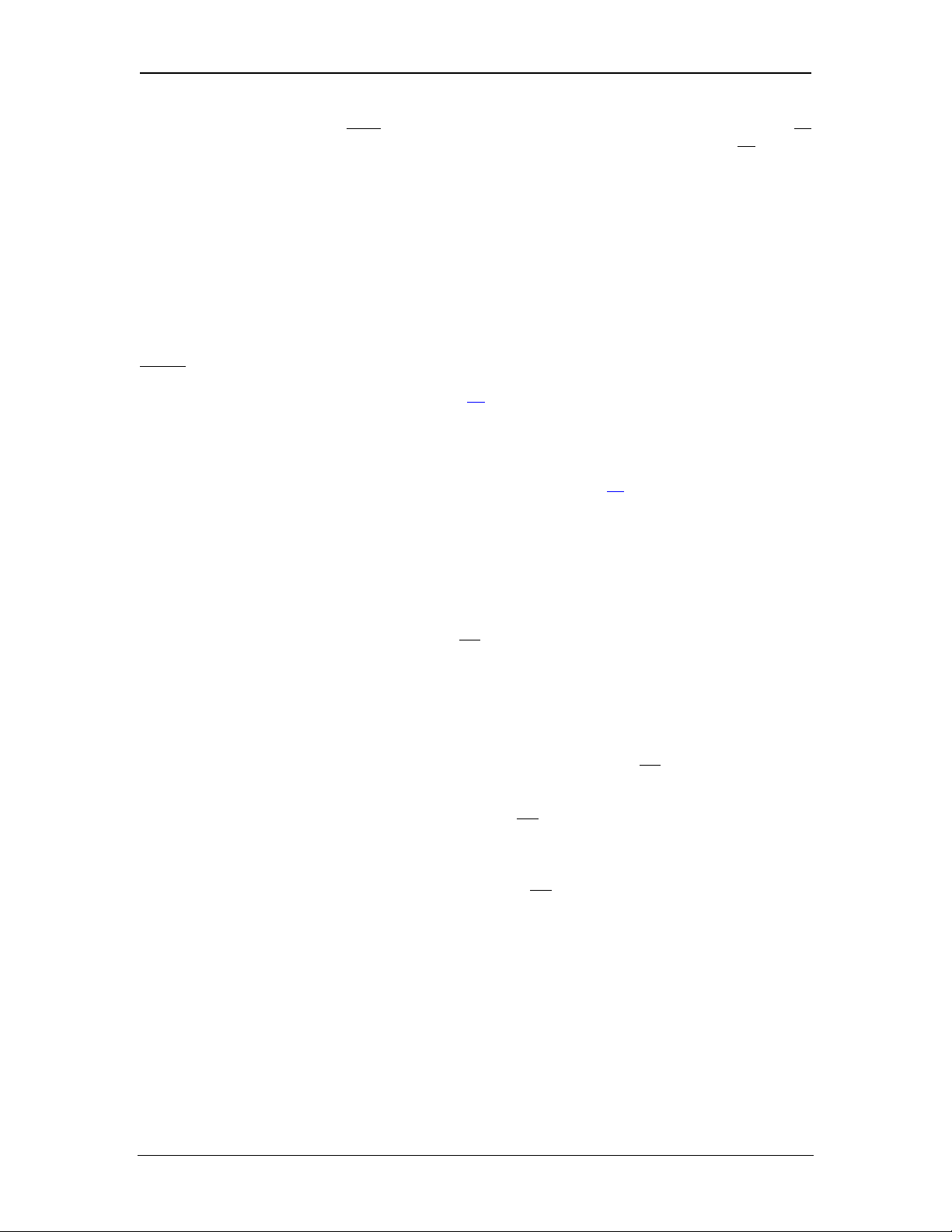

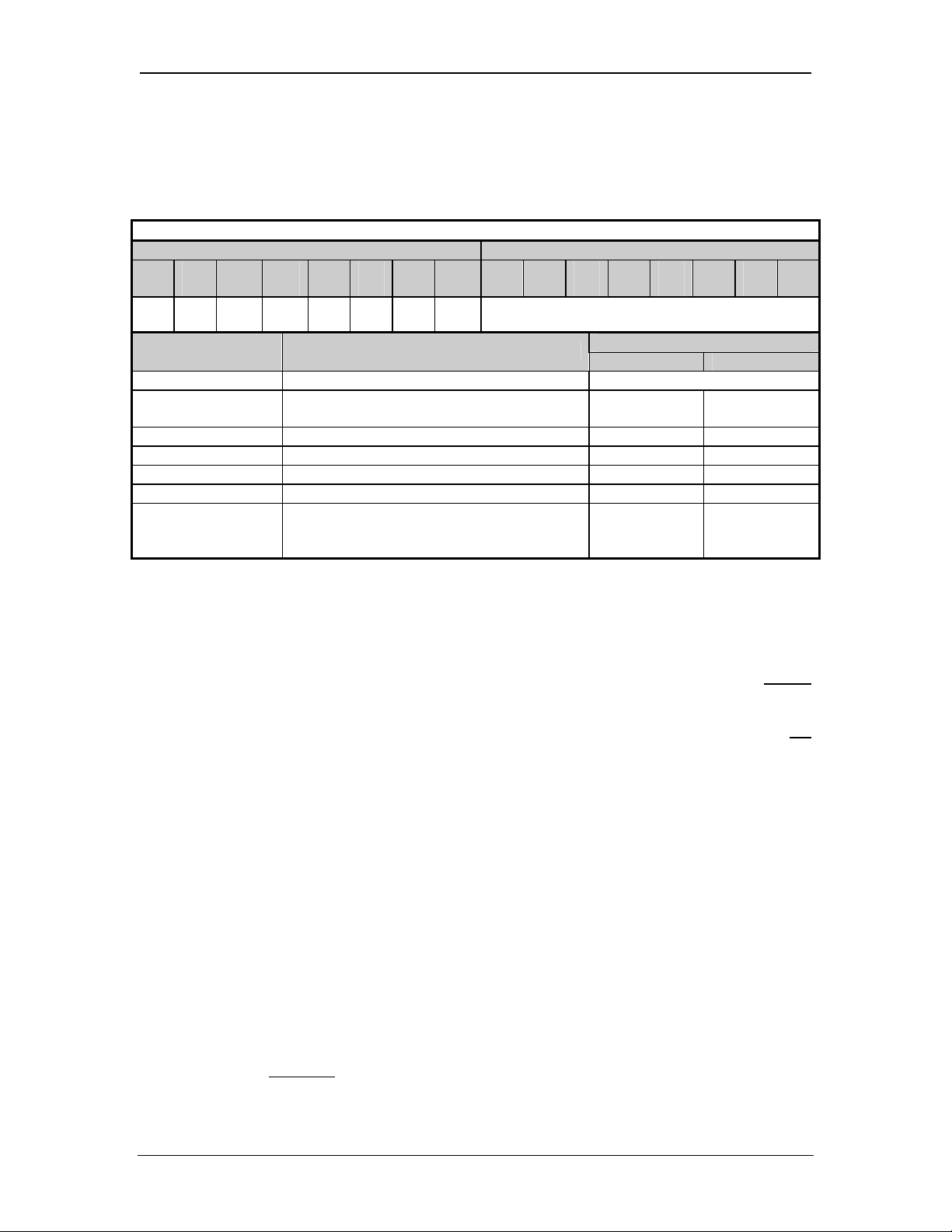

Table 1.1 – OCS Model / Ethernet Module Compatibility

Ethernet Module Types

OCS

Model

OCS100

OCS200

RCS210

OCS110

OCS210

OCS250

RCS116

RCS250

OCS301

OCS351

OCS451

OCS551

OCS651

NX221

NX251

QX351

QX451

QX551

QX651

QX751

XL6e

RX371

ETN100 ETN116 ETN200 ETN300

UserInstalled

√

√

√

√

√

√

√

√

Built-In

√

√

UserInstalled

√

√

√

√

√

√

√

√

Built-In

UserInstalled

√

√

√

√

√

√

√

√

Built-In

√

√

√

√

√

√

√

√

√

11/30/2009 Page 7 of 98 # 958

Page 8

CH.1 SUP0740-07

)

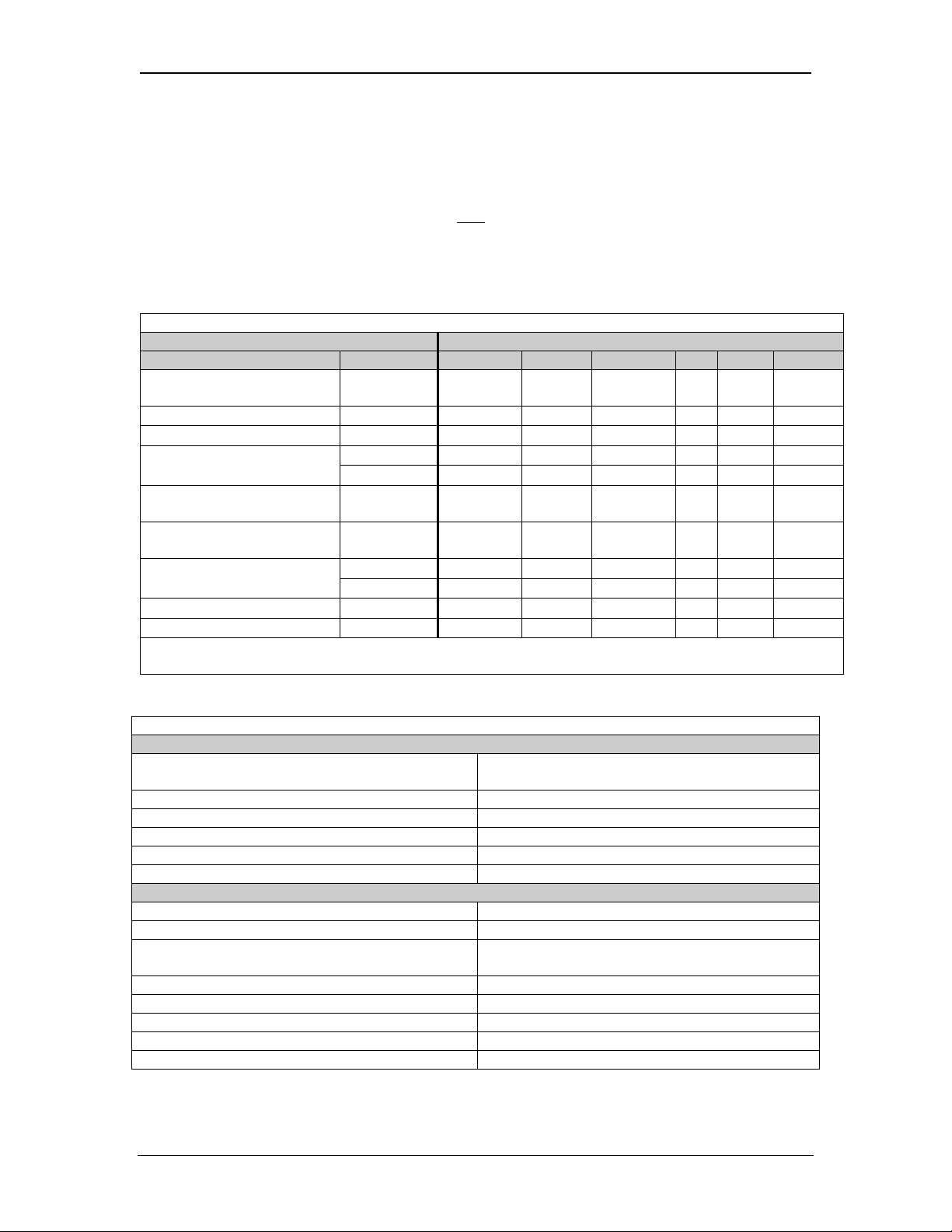

Table 1.2 – Ethernet Module Protocols and Features

Feature

Protocol / Feature Description

ETN100 ETN116 ETN200 ETN300

ICMP Ping Internet Control Message Protocol

EGD (Peer) GE Fanuc Ethernet Global Data

SRTP Server

Modbus TCP

Slave

CsCAN TCP

Server

Ethernet / IP

Server

¾ FTP

Server

¾ HTTP

Server

Half / Full

Duplex

GE Fanuc Service Request

Transfer Protocol

Modbus over Ethernet

Horner APG CsCAN over

Ethernet

ODVA CIP over Ethernet

File Transfer Protocol

HyperText Transfer Protocol (Web

Server)

Auto-Negotiated Ethernet Mode

* SMTP Email

10 / 100 Mbps Auto-Negotiated Ethernet Speed

Extended

Registers

Access to %R2049-%R9999

Ethernet Module Types Protocol /

√ √ √ √

√ √ √ √

√ √ √ √

√ √ √ √

√ √

√ √

√ √

√ √

√ √

√

√ √

√

¾ FTP & HTTP protocols are supported only by OCS Models with built-in Ethernet and

Compact Flash/Micro SD, such as OCS451, OCS551, OCS651, NX221, NX251, QX351,

QX451, QX551, QX651, QX751 and XL6e.

¾ * SMTP is supported by OCS that have inbuilt ethernet port like the NX, QX, XL6e.

1.2 Ethernet Network Example

Ethernet Module configuration is done through Cscape Programming Software. Figure 1.1

illustrates an example of a network containing ETN200 and ETN300.

Series

90-30

CDC200

CCU

(Conveyor

Controller)

RCS Mini OCS OCS #2

CsCAN

Note: An Ethernet Hub or Multicast

Router is recommended for Ethernet

Global Data (EGD) protocol, because a

Switch might not

be able to pass

OCS #1

ETN200

Ethernet Hub

Ethernet

CAT5 UTP Ethernet

Cable

Series

90-30

CPU364

PC

(Running

Cscape

ETN300

OCS #3

CAN

Cable

Figure 1.1– Example of an Ethernet Network

11/30/2009 Page 8 of 98 # 958

Page 9

SUP0740-07 CH.1

1.3 Ethernet System Requirements and Interoperability

Full Ethernet functionality requires:

¾ PC running Cscape Programming Software Version 7.0c or later (for configuration)

¾ OCS controller with built-in or user-installed Ethernet Module (ETN200 / ETN300)

¾ FTP & HTTP protocols supported only

by OCS Models with built-in Ethernet and

Compact Flash/Micro SD.

The server protocols, supported by the ETN200 / ETN300 have been tested for interoperability

with Cscape and several 3

rd

party client software packages (Table 1.3).

Table 1.3 – Ethernet Module Server Protocol Interoperability

Client Software Package Ethernet Module Server Protocol

Name Version CsCAN SRTP Modbus EIP FTP HTTP

Cscape Programming

Software

GE Proficy View * 5.50.3655

GE Fanuc Cimplicity HMI 3.2

GE Fanuc Cimplicity PE

KEPware OPC / DDE

Server

Pyramid EIP Scanner

Demo

Microsoft Internet Explorer

7.0c

√

5.0

6.1

4.84.227

3.51

5.50.4522

6.0.2900

SmartFTP 1.5.990

Mozilla Firefox 1.0.7

√

√

√

√ √

√ √

√

√ √

√ √

√

√

* When selecting the PLC Access Driver for SRTP mode using Proficy View software, be sure to

select GE Fanuc TCP/IP.

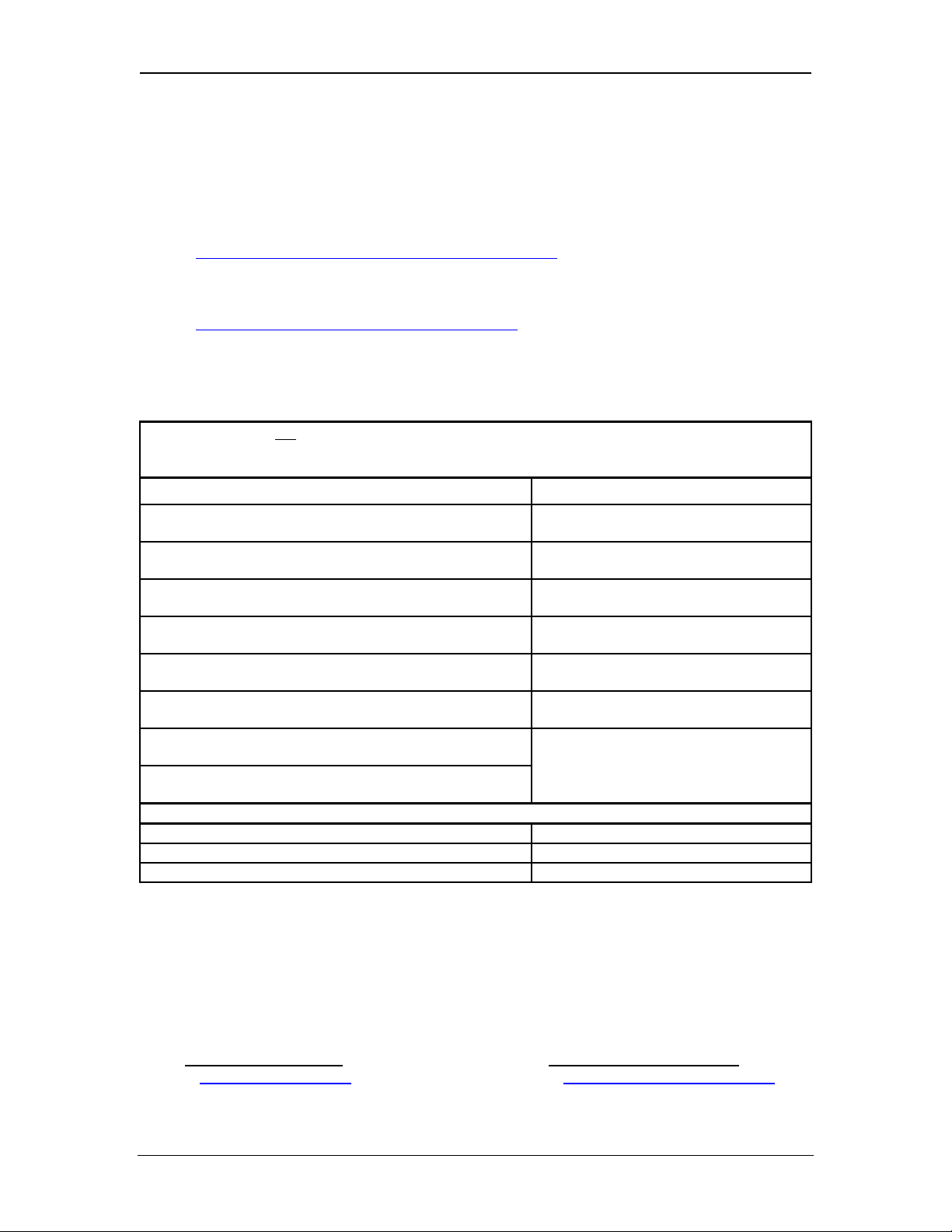

1.4 Ethernet Module Specifications Table 1.4 – Specifications

General

Ethernet Speeds

10 BaseT Ethernet (10 Mbps)

100 BaseTx Fast Ethernet (100 Mbps)

Ethernet Modes Half or Full Duplex

Ethernet Auto-Negotiation Both 10 / 100 Mbps and Half / Full Duplex

Ethernet Connector Type Shielded RJ-45

Ethernet Cable Type Recommendation CAT5 (or better) UTP

Ethernet Port (Applicable to QX351and XL6e) Auto MDI/MDI-X

Application Protocols

ICMP Ping Only

CsCAN TCP Server Maximum Connections = 8

EGD (Ethernet Global Data)

Maximum Data Bytes per Exchange = 1,400

Maximum Exchanges = 127

SRTP Server Maximum Connections = 16

Modbus TCP Slave Maximum Connections = 16

Ethernet / IP Server Maximum Connections = 2

FTP Server Maximum Connections = 4

HTTP Server Maximum Connections = 1

11/30/2009 Page 9 of 98 # 958

Page 10

CH.1 SUP0740-07

1.5 Additional Technical Resources

It is assumed that the user has a working knowledge of Ethernet networks and Horner OCS /

RCS controllers. The following references are available to assist the user in these areas.

For a technical summary of Ethernet and other information, refer to:

http://www.techfest.com/networking/lan/ethernet.htm

For Horner OCS / RCS controller technical support, refer to:

http://www.heapg.com/Pages/techsupport.html

The following information serves as a general listing of Horner controller products and other

references of interest and their corresponding manuals numbers. Visit our website listed in the

Technical Support section in this chapter to obtain user documentation and updates.

Note: This list is not

intended for users to determine which products are appropriate for their

application; controller products differ in the features that they support. If assistance is required,

see the Technical Support section in this document.

Controller Manual Number

QX Series

QX351

QX Series

(e.g., HE-QX451, HE-QX551, HE-QX651)

QX Series

QX751

NX Series

(e.g., HE-NX220, HE-NX221, HE-NX250, HE-NX251)

Color Touch OCS

(e.g., OCS 451, OCS 551, OCS 651)

XL Series

XL6e

MAN0892

MAN0798

MAN0890

MAN0781

MAN0465

MAN0883

Operator Control Station

(e.g., OCS1XX / 2XX; Graphic OCS250)

Remote Control Station

MAN0227

(e.g., RCS210, RCS250)

Other Useful References

CAN Networks MAN0799

Cscape Programming and Reference MAN0313

Wiring Accessories and Spare Parts Manual MAN0347

1.6 Technical Support

For assistance and manual updates, contact Technical Support or visit our website at the

following locations:

North America:

Tel: 317 916-4274

Fax: 317 639-4279

Web: http://www.heapg.com

Email:

techsppt@heapg.com

Europe:

Tel: (+) 353-21-4321-266

Fax: (+) 353-21-4321826

Web: http://www.horner-apg.com

Email:

tech.support@horner-apg.com

11/30/2009 Page 10 of 98 # 958

Page 11

SUP0740-07 CH.2

CHAPTER 2: INSTALLATION

2.1 Built-In Ethernet Module

As shown in Table 1.1 (page

in to the OCS unit, requiring no

the RJ-45 Ethernet connector on OCS451, OCS551 and OCS651 units.

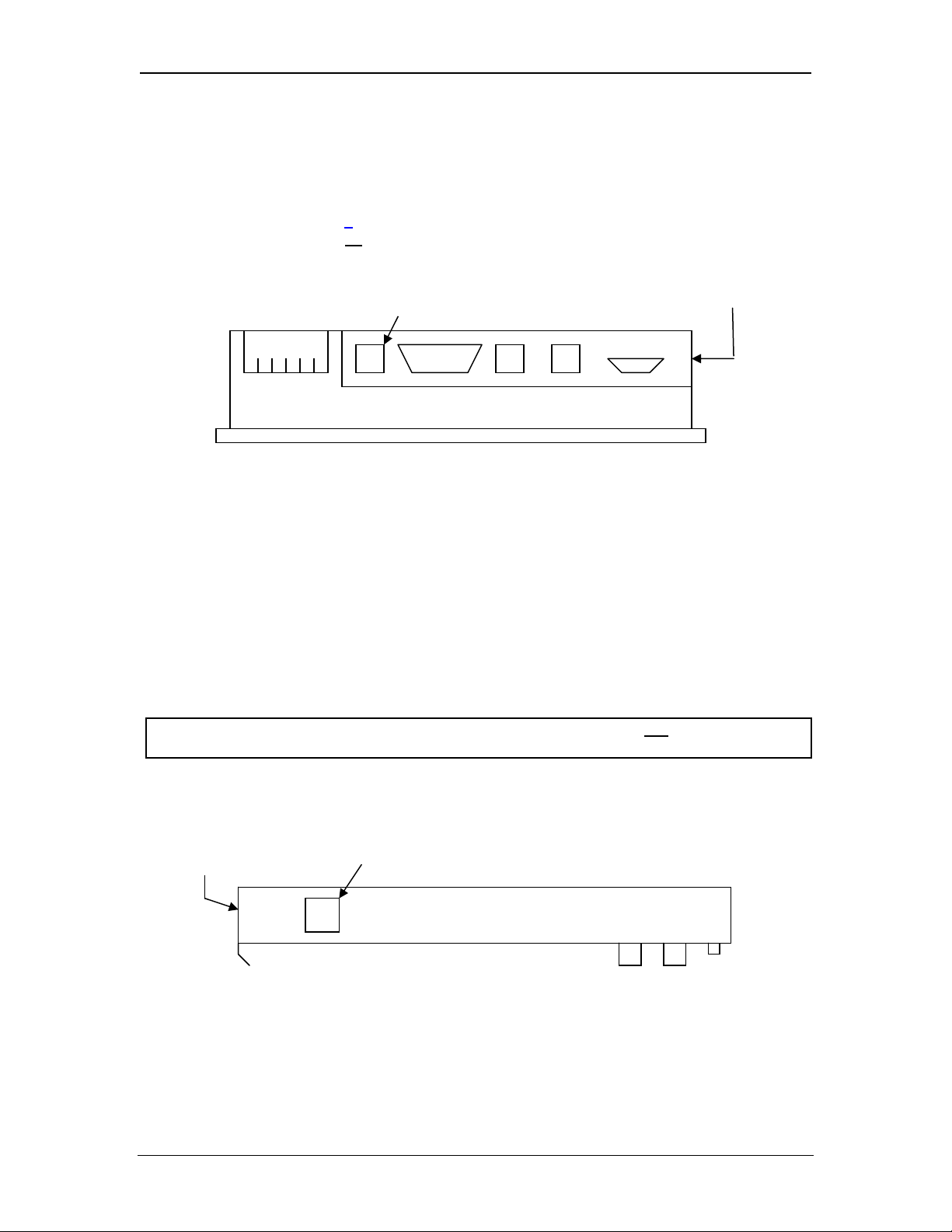

Figure 2-1 – SVGA Color Graphics OCS Bottom View

7), for some OCS Models, the SmartStack Ethernet Module is built-

user-installation. For example, Figure 2.1 shows the location of

Ethernet Connector (OCS551 and OCS651) Ethernet Connector

(OCS451)

2.2 User-Installed Ethernet Module

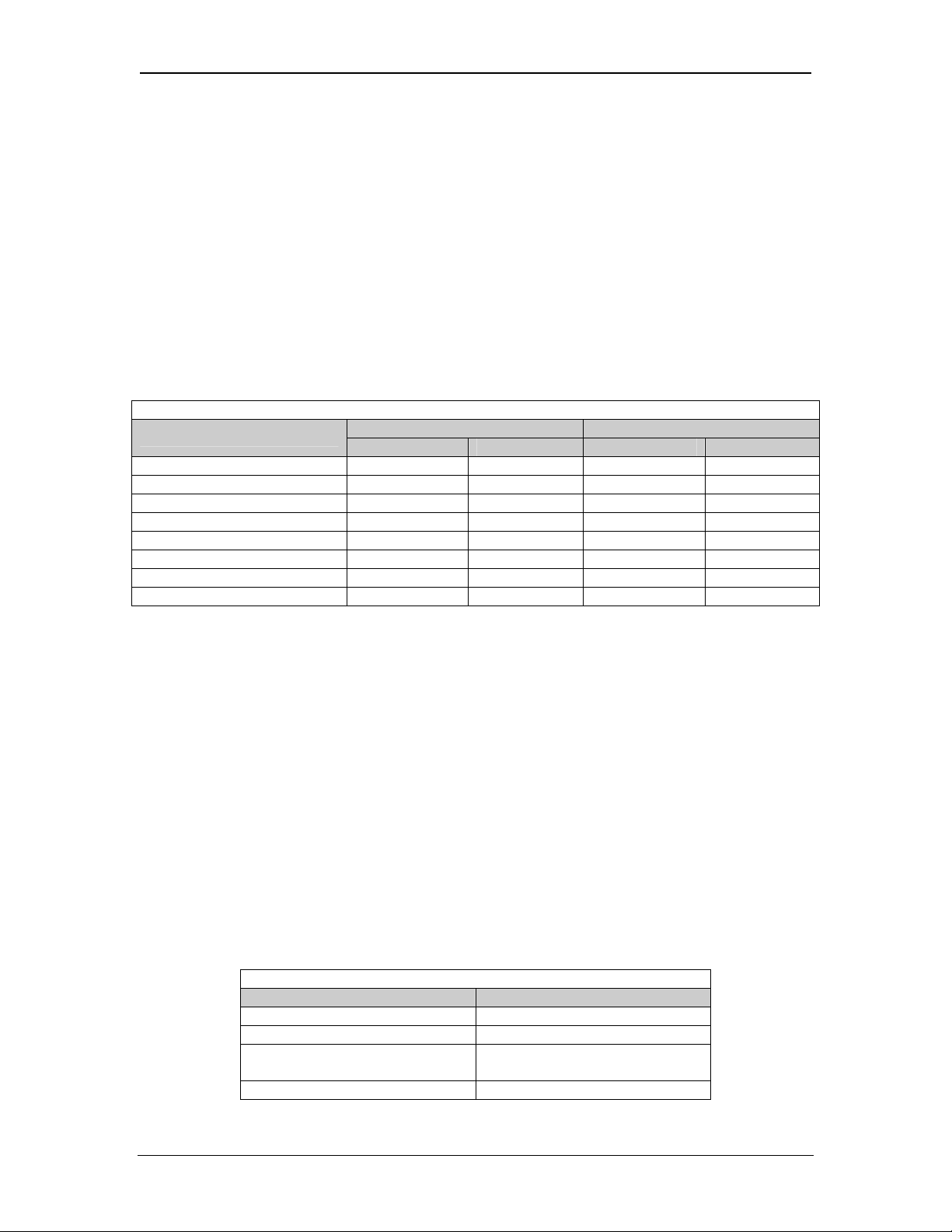

For other OCS or RCS Models, the SmartStack Ethernet Module must be user-installed on the

back of the OCS / RCS unit. Figure 2.2 shows the locations of the Ethernet RJ-45 connector and

LED indicators on the user-installed SmartStack Ethernet Module.

Note: Normally, a user-installed Ethernet Module occupies the first I/O slot on the back of the

OCS or RCS unit. The only exception to this rule occurs if a FOX100 Module is also

installed. In this case, the FOX100 Module occupies the first I/O slot, and the Ethernet

Module is installed into the second I/O slot.

Caution: For proper functioning and to avoid possible damage, do not install more than

For more details on installing SmartStack I/O modules, refer to Chapter 2 of the Control Station

Hardware Manual (MAN0227), which also provides a handy checklist concerning panel box

layout and minimum clearance requirements.

Link & Activity LEDs Ethernet Connector

four SmartStack Modules on the back of an OCS or RCS controller.

Figure 2-2– User-Installed Ethernet Module Side View

11/30/2009 Page 11 of 98 # 958

Page 12

CH.2 SUP0740-07

2.3 Network Administrator Installation Notes

When connecting an Ethernet Module to a local network, the following information is provided to

the Network Administrator, as an aid in configuring Ethernet Hubs, Routers, Switches, Gateways

and Servers.

2.3.1 UDP and TCP Ports

Each protocol supported by the Ethernet Module (except ICMP) uses one or more UDP and/or

TCP Ports as the destination port for all messaging, as shown in Table 2.1. (Note: Any port can

be used as the source port.) Required port usage for the supported proto col s should be taken into

account when configuring Ethernet Routers and Gateways.

Table 2.1 – Ethernet Protocol UDP and TCP Port Usage

Ethernet Protocol

Hexadecimal Decimal Hexadecimal Decimal

UDP Port TCP Port

EGD 4746 18246

SRTP 4745 18245

Modbus 01F6 502

CsCAN 4845 18501

Ethernet / IP 08AE 2222 AF12 44818

FTP 0014 and 0015 20 and 21

HTTP 0050 80

* SMTP 0035 53 0019 25

Note: * SMTP connects via TCP connection using default port 25 (user configurable), but in

Cscape | Messaging | Email feature if user selects 'Obtain SMTP Server IP Address

from DNS Server' then UDP connection will be used to obtain Server IP, in such case UDP

port 53(Decimal) will be used.

2.3.2 EGD Unicast and Multicast IP Addressing

When using Ethernet Global Data (EGD) protocol for peer-to-peer communication, there are two

methods for sending data: (1) send to a single device or (2) send to a group of devices.

When sending to a single device (method 1), EGD protocol uses Unicast IP Addressing. This

means that the IP header’s 32-bit Destination IP Address will contain the intended recipient’s

unique IP Address.

When sending to a group of devices (method 2), EGD protocol uses Multicast IP Addressing.

This means that the IP header’s 32-bit Destination IP Address will contain one of the 32 Multicast

IP Addresses shown in Table 2.2.

Table 2.2 – EGD Multicast IP Addressing

Group ID Multicast IP Address

1 224.0.7.1

2 224.0.7.2

:

:

:

:

32 224.0.7.32

11/30/2009 Page 12 of 98 # 958

Page 13

SUP0740-07 CH.2

Ethernet Switches normally don’t support Multicast IP Addressing, while Ethernet Hubs do

support Multicast IP Addressing. Some Ethernet Routers, known as Multicast Routers, do

support

Multicast IP Addressing, by using Internet Group Management Protocol (IGMP).

Note: For those customers wanting to use Multicast Routers to connect EGD devices, the

Ethernet Module automatically handles IGMP communication with Multicast Routers.

For more information regarding EGD protocol, refer to Chapter 6 of this manual.

2.3.3 Internet Connectivity

Since the Ethernet Module uses a standard TCP/IP protocol stack (powered by NetX and

ThreadX), it can communicate beyond the local network, and on the Internet, for all protocols

EGD. To do so, the Ethernet Module must be configured with the IP Address of a Network

except

Gateway server, which allows communication outside the local network. See Default Gateway

configuration under step 5 of Section 3.1 (page

18) in this manual for details.

Note: As network complexity increases, due to Ethernet Hubs, Routers, Switches, Gateways,

and the Internet, the worst-case network delay increases. In many cases, the client

software must be configured to account for this time lag. For example, Cscape’s Timeout

can be adjusted as shown under step 2 of Section 4.2 (page

24) in this manual.

2.3.4 IMPORTANT: Wireless Network Considerations

When using wireless equipment with industrial networks, make sure the system is designed and

installed by personnel that have been trained to use wireless networks in industrial environments.

Site surveys, selection of equipment and installation can be critical in network performance.

In general the 802.11b- based equipment is not

a good choice in industrial environments. The

frequencies and modulation techniques used in the “b” standard are very susceptible to multipath interference in industrial environments (large metal objects, dense walls and floors, etc.)

The 802.11a and 802.11g are less susceptible to this interference.

Using UDP based protocols such as Ethernet Global Data (EGD) must be carefully considered

when using wireless networks. Wireless networks are more likely to lose or damage

communication packets. Many UDP based protocols, including EGD, do not

detect and retransmit

lost or damaged packets and depend on periodic data transmissions to compensate for this lost

data. If your system requires a UDP protocol with a wireless network, make sure it is designed

such that random periods without refreshed data do not

adversely affect the operation of your

system.

Depending on the architecture of the wireless network and the protocols used, wireless networks

often produce collisions and extra data packets that are not

experienced when using a traditional

wire and switch-based network. The extra collisions and traffic coupled with the typically lower

bandwidth and higher latency of wireless networks can cause degradation in performance.

11/30/2009 Page 13 of 98 # 958

Page 14

CH.2 SUP0740-07

2.4 Safety

When found on the product, the following symbols specify:

Warning: Consult user documentation.

Warning: Electrical Shock Hazard.

WARNING: Remove power from the OCS controller, CAN port, and any peripheral equipment

connected to this local system before adding or replacing this or any module.

WARNING: To avoid the risk of electric shock or burns, always connect the safety (or earth)

ground before making any other connections.

WARNING: To reduce the risk of fire, electrical shock, or physical injury it is strongly

recommended to fuse the voltage measurement inputs. Be sure to locate fuses as close to the

source as possible.

WARNING: Replace fuse with the same type and rating to pro vide protection against risk of

fire and shock hazards.

WARNING: In the event of repeated failure, do not

indicates a defective condition that will not

WARNING: Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this

equipment. Read and understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in severe bodily injury or

loss of life.

clear by replacing the fuse.

replace the fuse again as a repeated failure

For detailed installation and a handy checklist

that covers panel box layout requirements and

minimum clearances, refer to the hardware manual of the controller you are using. (See the

Additional References section in this document.)

• All applicable codes and standards need to be followed in the installation of this product.

• For I/O wiring (discrete), use the following wire type or equivalent: Belden 8917, 16 AWG

or larger.

Adhere to the following safety precautions whenever any type of connection is made to the

module.

• Connect the green safety (earth) ground first before making any other connections.

• When connecting to electric circuits or pulse-initiating equipment, open their related

breakers. Do not

make connections to live power lines.

• Make connections to the module first; then connect to the circuit to be monitored.

• Route power wires in a safe manner in accordance with good practice and local codes.

• Wear proper personal protective equipment including safety glasses and insulated gloves

when making connections to power circuits.

• Ensure hands, shoes, and floors are dry before making any connection to a power line.

• Make sure the unit is turned OFF before making connection to terminals. Make sure all

circuits are de-energized before making connections.

• Before each use, inspect all cables for breaks or cracks in the insulation. Replace

immediately if defective.

11/30/2009 Page 14 of 98 # 958

Page 15

SUP0740-07 CH.3

CHAPTER 3: GENERAL CONFIGURATION

Note: The following configuration is required for all applications regardless of the protocols used.

Additional configuration procedures must be performed for each protocol used as described in the

configuration sections of the next several chapters.

3.1 Ethernet Module Configuration

To configure the Ethernet Module, use Cscape Programming Software to perform the following

six steps:

1. On the main Cscape screen, select the Controller menu and its I/O Configure sub-menu to

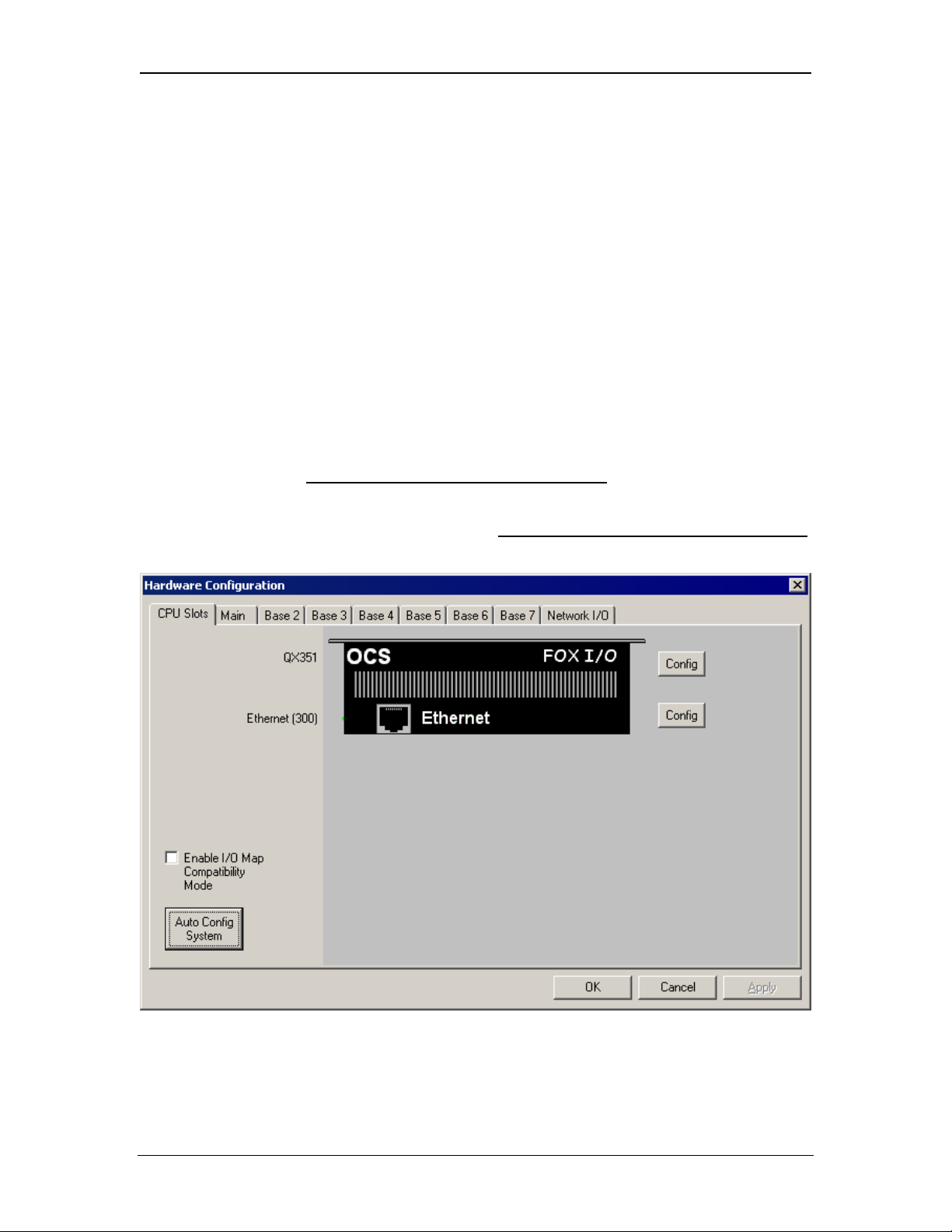

open the I/O Configuration dialog (Figure 3.1 or Figure 3.2).

2. If configuring a different OCS Model than the one shown in the I/O Configuration dialog, click

on the topmost Config button, select the desired OCS Model, and then click OK.

Note: Figure 3.1 shows a typical I/O Configuration dialog for OCS Models, which have Ethernet

Modules built-in. For these models, step 3 should be skipped

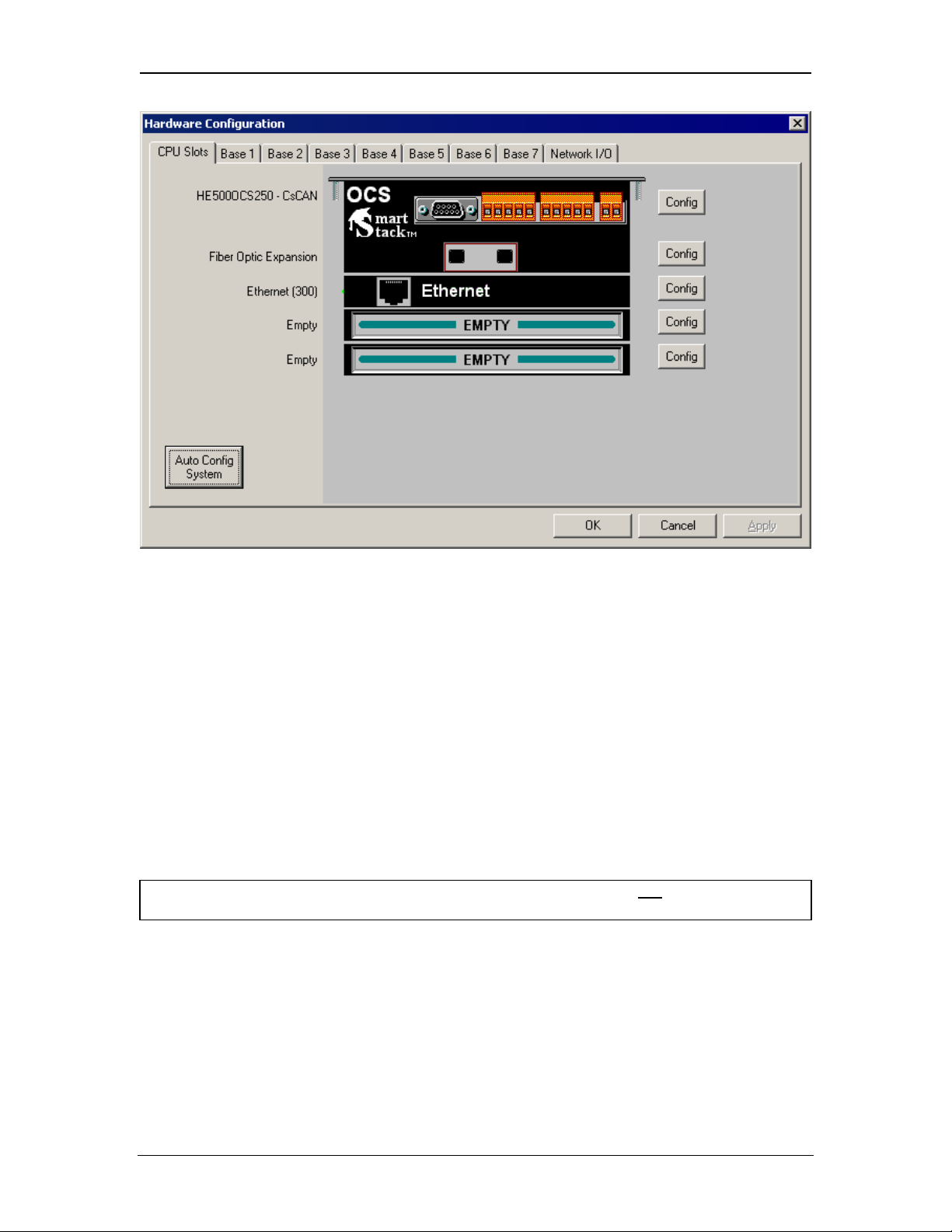

Figure 3.2 shows a typical I/O Configuration dialog for other OCS Models, in which the

Ethernet Module is a user-installable option. For these models, step 3 must be performed

to configure the Ethernet Module into a SmartStack I/O slot.

.

,

Figure 3-1 – Hardware Configuration Dialog – OCS Models With Built-In Ethernet

11/30/2009 Page 15 of 98 # 958

Page 16

CH.3 SUP0740-07

Figure 3-2– Hardware Configuration Dialog – OCS Models With User-Installable Ethernet

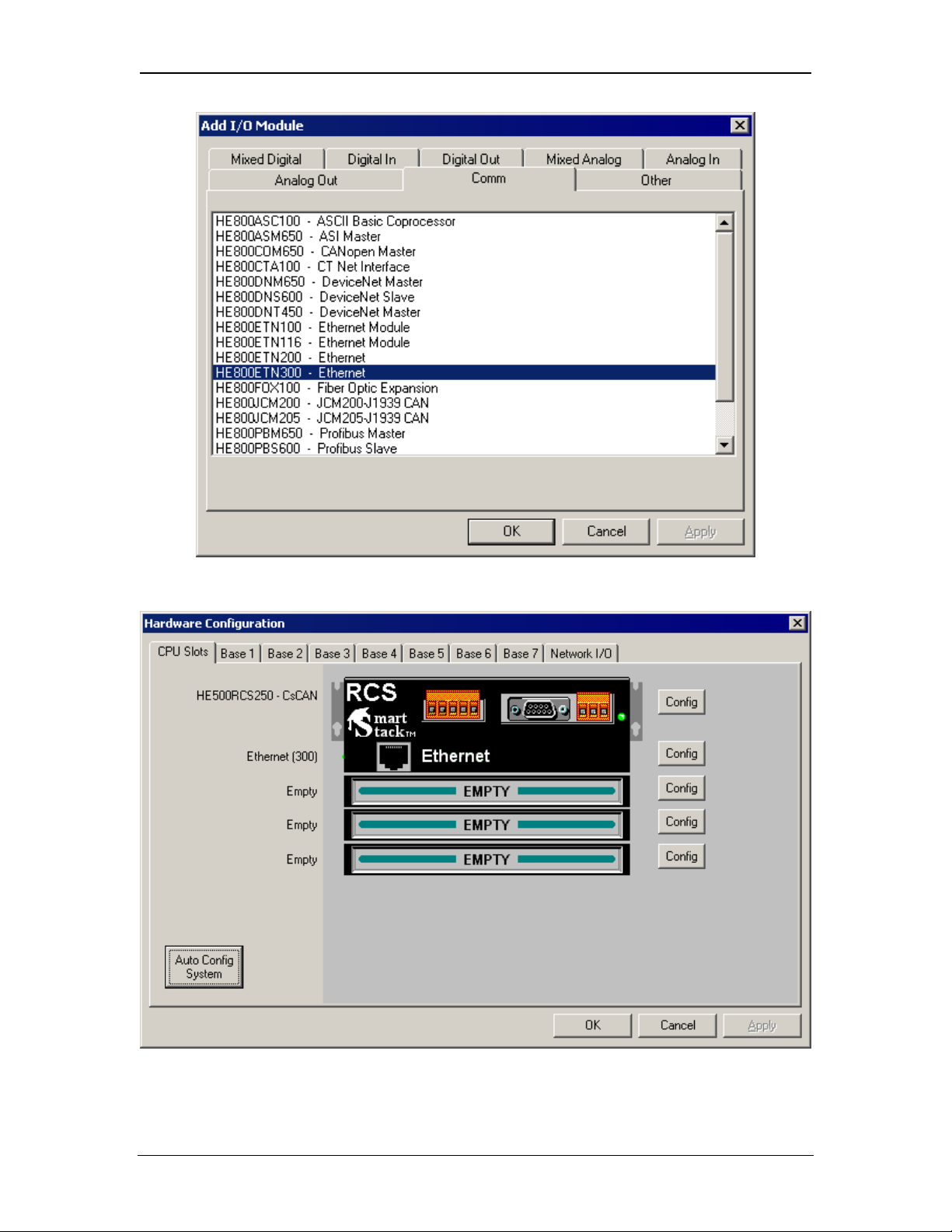

3. To configure a user-installable Ethernet Module into a SmartStack I/O slot, do the following:

a. Referring to Figure 3.2 above, click on the Config button to the right of the desired I/O

slot, which will open the Add I/O Module dialog, as shown in Figure 3.3.

b. Click the Comm tab and select the desired HE800ETNxxx item from the list.

c. Click OK. The Ethernet Module is now configured into an I/O slot, as shown in Figure 3.4.

Note: Normally, a user-installed Ethernet Module occupies the first I/O slot on the back of the

OCS or RCS unit. The only exception to this rule occurs if a FOX100 Module is also

installed. In this case, the FOX100 Module occupies the first I/O slot, and the Ethernet

Module is installed into the second I/O slot.

Caution: For proper functioning and to avoid possible damage, do not install more than

four SmartStack Modules on the back of an OCS or RCS controller.

11/30/2009 Page 16 of 98 # 958

Page 17

SUP0740-07 CH.3

Figure 3.3– Add I/O Module Dialog – Comm Tab and Ethernet Module Selected

Figure 3.4– Hardware Configuration Dialog – User-Installed Ethernet Module

11/30/2009 Page 17 of 98 # 958

Page 18

CH.3 SUP0740-07

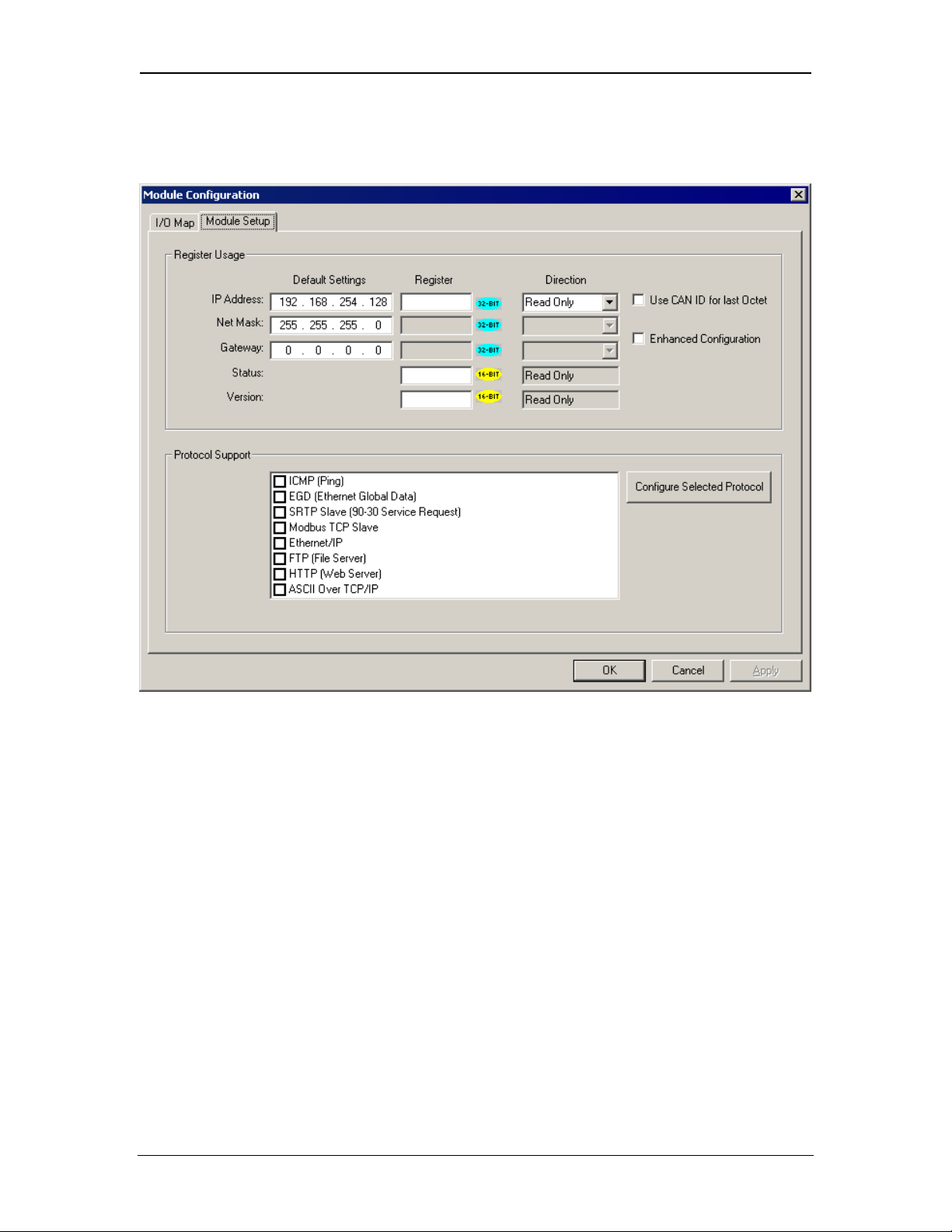

4. Now it is time to configure the Ethernet Module as appropriate for the application. Referring to

Figure 3.1 or 3.4 above, click the Config button to the right of the Ethernet Module, and then

select the Module Setup tab, revealing the Ethernet Module Configuration dialog (Figure 3.5).

Figure 3.5– Ethernet Module Configuration Dialog - Module Setup Tab Selected

5. Configure the Ethernet Module parameters as follows:

It has two parts 1. Register Usage and 2. Protocol Support

Register Usage:

i. IP Address: Enter the static IP Address for the Ethernet Module being configured.

Note: IP Addresses are entered as four numbers, each ranging from 0 to 255. These

four numbers are called octets and they are always separated by decimal points.

ii. Net Mask: Enter the Net Mask (sometimes called Subnet Mask) being used by all

nodes on the local network. Typical local networks use Class C IP Addresses, in

which case the low octet (rightmost number) is used to uniquely identify each node

on the local network. In this case, the default Net Mask value of 255.255.255.0

should be used.

iii. Gateway: Enter the IP Address of a Gateway Server on the local network that allows

for communication outside of the local network. To prevent the Ethernet Module from

communicating outside the local network, set the Default Gateway IP Address to

0.0.0.0 (the default setting).

11/30/2009 Page 18 of 98 # 958

Page 19

SUP0740-07 CH.3

iv. Status Register: Enter an OCS Register reference (such as %R100) to indicate

which 16-bit OCS register will have the Ethernet Status word written to it. Table 3.1

shows how this register value is formatted and explains the meaning of each bit in

the Status Word.

Table 3.1 - Ethernet Status Word Register Format

High Byte Low Byte

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit

16

15

14

13

12

11

10

1

0 0 Dup Spd 0 Rx Tx Link TCP Connections

Status Bit(s) Status Indication

Status Values

Minimum Maximum

0 Reserved Always 0

Dup Link Duplex (Auto-Negotiated)

0 = Half

Duplex

1 = Full

Duplex

Spd Link Speed (Auto-Negotiated) 0 = 10 Mbps 1 = 100 Mbps

Rx Receive State 0 = Inactive 1 = Active

Tx Transmit State 0 = Inactive 1 = Active

Link Link State 0 = Down 1 = Up

Total Number of Active TCP Connections

TCP Connections

(CsCAN, SRTP, Modbus, EIP, FTP,

0 40

HTTP)

v. Version Register: Enter an OCS Register reference (such as %R101) to indicate

which 16-bit OCS register will have the Ethernet Firmware Version written to it. The

value stored in the Version Register is: (Ethernet Firmware Version * 100). For

example, for Ethernet Firmware Version 4.30, the Version register will contain 430.

For the Status and Version registers (if configured), the Direction settings are always

Read Only

vi. Use CAN ID for last Octet: The Use CAN ID for last Octet checkbox does not

affect Net Mask, Gateway, Status or Version configuration. If the checkbox is

checked then it behaves as follows:

A. If the IP Address Direction combo box is Read / Write, the Use CAN ID for last

Octet checkbox will be unchecked and grayed.

B. If the IP Address Direction combo box is empty or Read Only, the Use CAN ID

for last Octet checkbox will be ungrayed, and can then be unchecked or

checked.

C. If the Use CAN ID for last Octet checkbox is checked, the unit’s 8-bit CAN

Network ID replaces the last (rightmost) octet of the Default IP Address, and the

combined result will be the unit’s IP Address. In this case, if the IP Address

Register edit box contains a valid OCS register, the indicated register will be

loaded with the combined IP Address.

vii. Enhanced Configuration

To perform Enhanced Configuration, first check the Enhanced Configuration

checkbox. In this case, IP Address, Net Mask, Gateway, Status and Version can

all be optionally

assigned to OCS registers. By default, the register edit boxes are

empty indicating that no registers are assigned.

11/30/2009 Page 19 of 98 # 958

Page 20

CH.3 SUP0740-07

As with the IP Address register (described in the Standard Configuration section

below), Net Mask and Gateway register Directions can be set to Read Only or Read

/ Write

With Cscape 8.2 onwards, the ETN Module Configuration dialog has been enhanced

to support the following:

1. More easily expanded Protocol Support list for current and future

protocols.

2. Optional Enhanced Configuration:

a. Allows Net Mask and Gateway to be optionally read from or written

to OCS registers.

b. Allows all

OCS register assignments to be optional instead of

mandatory.

Ethernet Module Configuration Dialog Rules

The following rules describe how the new Ethernet Module Configuration Dialog is to

be used:

I. The Enhanced Configuration checkbox will be unchecked and grayed if

configuring an ETN100 or ETN116 Module.

II. If the Enhanced Configuration checkbox is checked, Cscape will display an

error message and will abort an I/O Configuration download if:

A. Configuring an ETN200 or ETN300 Module with ETN Firmware < 4.35,

B. Configuring an OCS, QX or NX with Engine Firmware < 11.91.

III. If the Enhanced Configuration checkbox is unchecked, the dialog maintains

backward compatibility as follows:

A. The Net Mask and Gateway Register edit boxes will be empty and

grayed.

B. The Net Mask and Gateway Direction combo boxes will be empty and

grayed.

C. All other dialog objects function the same as in the Cscape 8.0b dialog,

except as follows:

1. The new IP Address Direction combo box replaces the old Get IP

from IP Addr Register checkbox. A Direction of Read Only, is

equivalent to unchecked and a Direction of Read / Write is equivalent

to checked.

2. The new Protocol Support area contains a protocol list box showing

the protocols supported by the platform being configured. Each

protocol in the list box has a checkbox in front of it that can be checked

to enable the protocol. The single Config Selected Protocol button

applies to the protocol that is currently highlighted in the list box.

Standard Configuration

To perform Standard Configuration, simply leave the Enhanced Configuration

checkbox unchecked.

In this case, Net Mask and Gateway cannot

Address, Status and Version must

be assigned to OCS registers.

be assigned to OCS registers, while IP

11/30/2009 Page 20 of 98 # 958

Page 21

SUP0740-07 CH.3

Note that the assigned IP Address register’s Direction can set to Read only or Read

/ Write.

If the register is Read only, the Default IP Address becomes the unit’s IP Address and

is loaded into the assigned register, where it can be read by the application. (Note: In

this case, the low octet of the IP Address can be replaced with the unit’s CAN Network

ID, by checking the Use CAN ID for last Octet checkbox.)

If the register is Read / Write, the application should write an IP Address to the

assigned register, and this value will then be the unit’s IP Address. (In this case, the

Default IP Address is used only if communication is lost during an I/O configuration

download; otherwise the Default IP Address is ignored.)

Protocol Support:

The Protocol Support area contains a list of all the protocols supported by the platform being

configured. To activate a protocol, check its checkbox.

For protocols that require additional configuration, click on a listed protocol to select it and then

click the Configure Selected Protocol button. This will open a new dialog with configuration

options for the selected protocol (Detailed configuration of the protocols is explained in the

corresponding chapters below).

6. Click OK to accept the new Ethernet Module configuration.

3.2 Ethernet Module IP Address

The Ethernet Module obtains its IP Address in one of three different ways, depending on how the

Use CAN ID for last Octet, Enhanced Configuration & IP Address direction checkboxes

(Figure 3.5) are configured, as described in the following three se ctions.

3.2.1 Static IP Address

Use CAN ID for last Octet

IP Address Direction (Read Only)

In this mode, the Ethernet Module’s IP Address comes from the IP Address parameter only, and

does not

use the CAN Network ID for the low octet and does not use IP Address Register to

obtain an IP Address from an OCS register. In this case the Ethernet Module writes the static IP

Address to the 32-bit OCS register indicated by the IP Address Register parameter.

3.2.2 Static IP Address with CAN ID

9 Use CAN ID for last Octet

IP Address Direction (Read Only)

In this mode, the Ethernet Module’s IP Address comes from a combination of the IP Address

parameter and the OCS/RCS CAN Network ID. The most significant (leftmost) three octets of the

IP Address come from the IP Address parameter. The least significant (rightmost) octet of the IP

Address is taken from the OCS (or RCS) CAN Network ID. In this case the Ethernet Module

writes the adjusted IP Address to the 32-bit OCS register indicated by the IP Address Register

parameter.

11/30/2009 Page 21 of 98 # 958

Page 22

CH.3 SUP0740-07

3.2.3 IP Address from OCS Register

Use CAN ID for last Octet

9 IP Address Direction (Read / Write)

In this mode, the Ethernet Module’s IP Address comes from an OCS register. The IP Address

Register parameter indicates which 32-bit OCS registers to read the IP Address from. The static

IP Address parameter is not

used in this situation, except to set the Default IP Address in non-

volatile memory.

Note: Every time an I/O configuration is successfully downloaded to an OCS with an Ethernet

Module, the static IP Address, Net Mask and Default Gateway parameters are stored in

non-volatile memory. In the event of a future unsuccessful I/O configuration download, the

Ethernet Module will communicate using these 3 stored parameters. This is done in an

effort to minimize potential loss of communication, which would require direct on-site

intervention to correct.

11/30/2009 Page 22 of 98 # 958

Page 23

SUP0740-07 CH.4

CHAPTER 4: CSCAN OVER ETHERNET PROTOCOL

4.1 CsCAN over Ethernet Overview

This chapter describes CsCAN TCP Server Communication protocol, also known as CsCAN over

Ethernet protocol.

CsCAN over Ethernet protocol allows a CsCAN Host Programming Tool, such as Cscape, to

access an OCS unit, as though it were connected directly to the OCS programming serial port.

4.2 CsCAN over Ethernet Configuration

The Ethernet Module requires no

protocol. Only the general Ethernet Module Configuration previously described in Chapter 3 is

required. As long as the Ethernet Module has been assigned an IP Address and Net Mask, it will

automatically respond to CsCAN over Ethernet messages sent to it by a PC running Cscape.

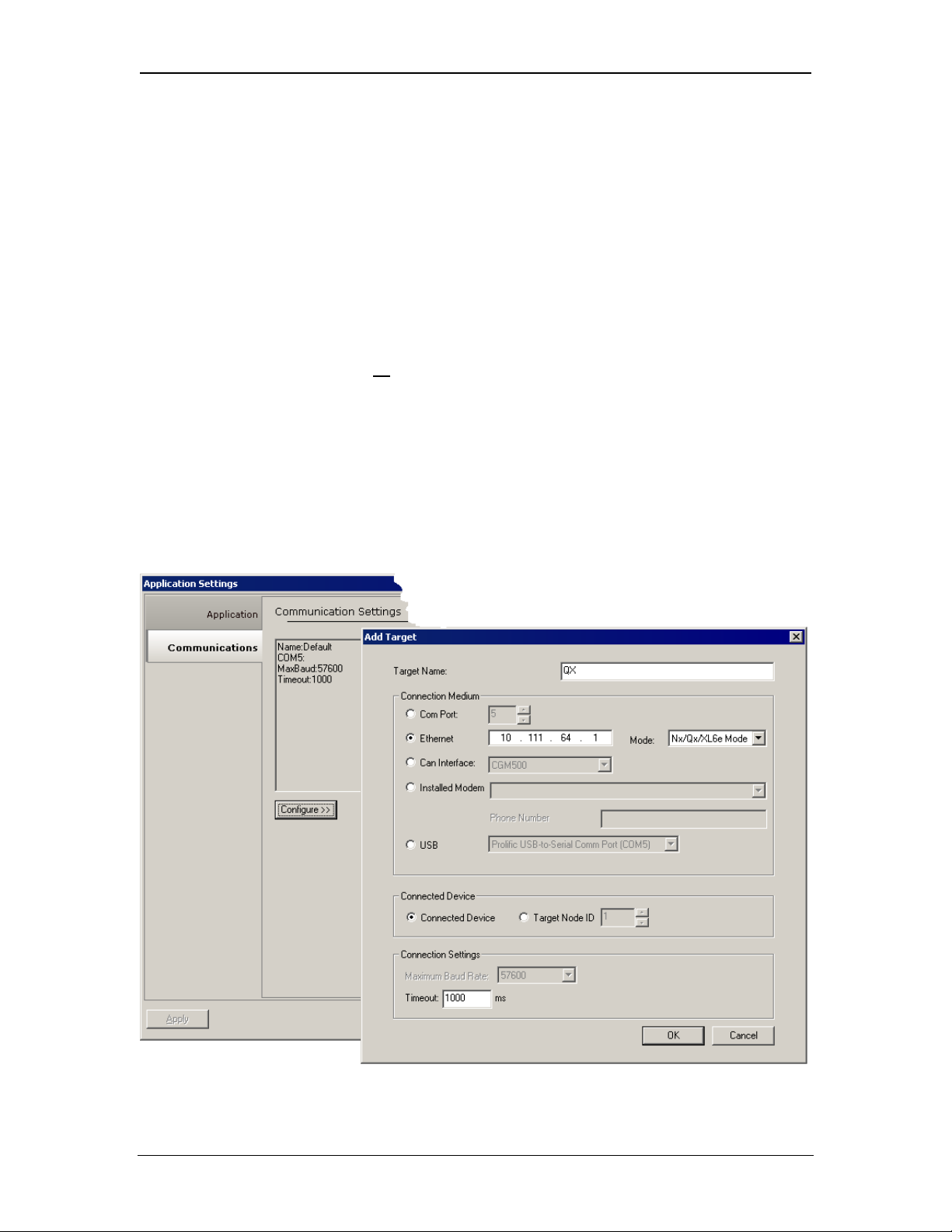

To connect Cscape to an OCS unit’s Ethernet Module, using CsCAN over Ethernet protocol,

perform the following two steps:

1. On the main Cscape screen, select the Tools menu > Application Settings >

Communications and then click on Configure button to display Add Target dialog

(Figure 6.1).

protocol-specific configuration for CsCAN over Ethernet

Figure 4.1– Program Options Dialog – Communications Port Tab and Ethernet Selected

11/30/2009 Page 23 of 98 # 958

Page 24

CH.4 SUP0740-07

2. Select the Ethernet from the Connection Medium list, and then set the Target IP Address

and Timeout parameters as follows:

Target IP Address: Enter the IP Address previously assigned to the target Ethernet Module.

Please refer to Chapter 3 regarding how to assign an IP Address to an Ethernet Module.

Timeout: Enter a number between 1000 and 65,000 (in milliseconds) for the maximum expected

network round-trip communication time. This value determines how long Cscape will wait for a

response after it sends a CsCAN over Ethernet protocol command to the Ethernet Module.

Note: For most local network applications, the default Timeout value of 1000 is sufficient.

However, there are some network considerations, which may require the Timeout

value to be increased to facilitate reliable communication. This includes heavily loaded

networks, complex networks with multiple levels of routers and switches, and Internet

communication.

Also, because CsCAN communication is affected by ladder code scan rate, the

Timeout value may have to be further increased to compensate for applications with

very slow scan rates.

4.3 CsCAN over Ethernet Operation

As stated previously, the Ethernet Module allows a CsCAN Host Programming Tool, such as

Cscape, to use CsCAN over Ethernet to perform all standard supervisory control, monitoring and

programming functions with the OCS, as though it were connected directly to the OCS

programming serial port.

These standard supervisory functions include the Ethernet Module’s ability to handle passthrough communication with the CsCAN Nodes attached to the OCS CAN port. This feature is

known as CsCAN single-point programming. For example, referring back to Figure 1.1 (page

Figure 1.1– Example of an Ethernet Network) the PC (running Cscape) can use OCS #1’s

ETN200 Module as a gateway, to easily access all of the CsCAN Nodes on OCS #1’s CsCAN

network.

4.4 CsCAN over Ethernet Downloading Precautions

When downloading a new Ethernet configuration to a target OCS, using CsCAN over Ethernet

protocol, extra care should be taken.

In particular, when downloading I/O and Network Configuration, the Ethernet Module

configuration is also downloaded, which has the potential to change the target device’s IP

Address, or it could even remove the Ethernet Module configuration entirely, resulting in loss of

communication and a failed download.

For this reason, when the Cscape user modifies the I/O Configuration, and then starts to

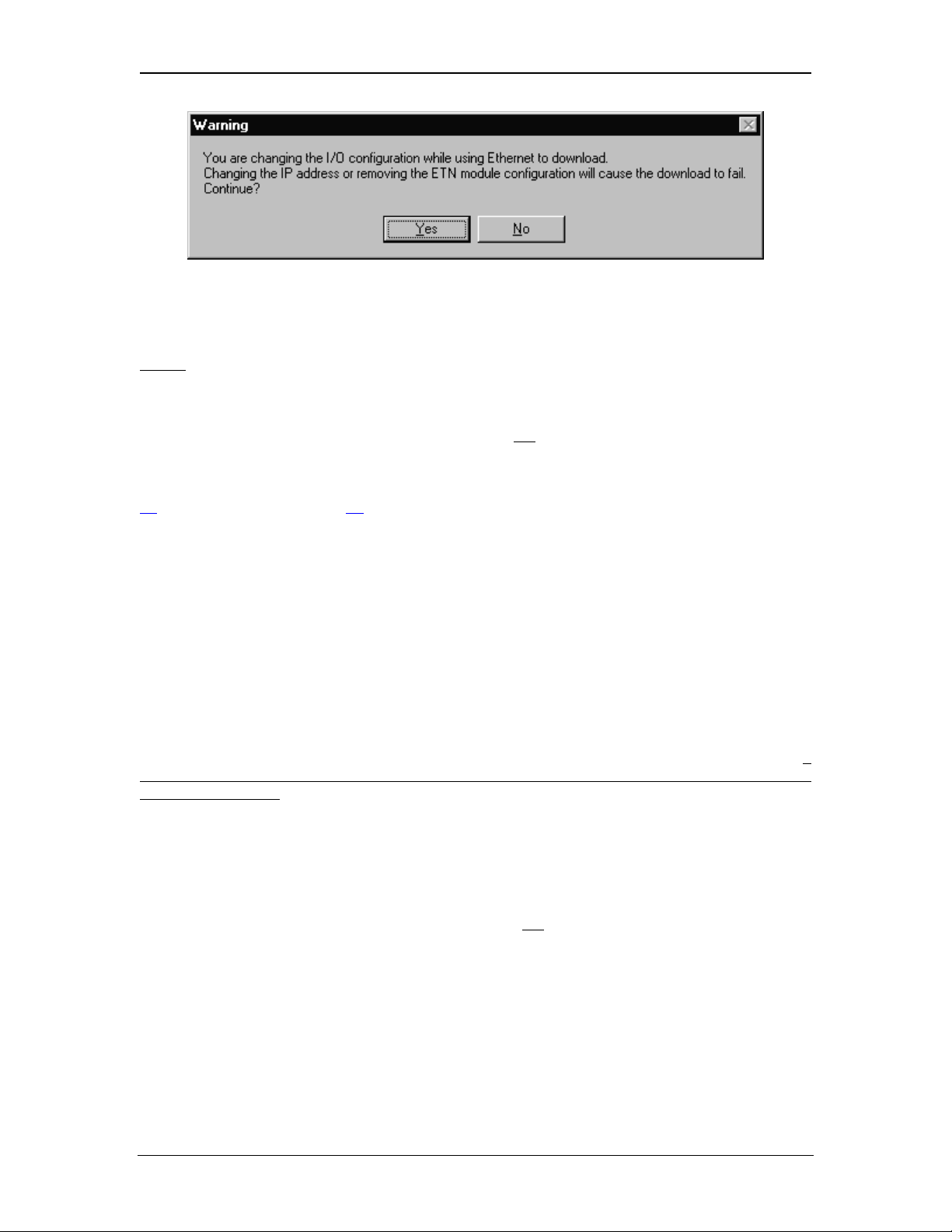

download it using CsCAN over Ethernet, Cscape issues a warning message, as shown in Figure

4.2.

11/30/2009 Page 24 of 98 # 958

Page 25

SUP0740-07 CH.4

Figure 4.2 – I/O Configuration Download Warning

4.4.1 How to Prevent Losing Communication

using CsCAN over Ethernet to download a new I/O Configuration, to an OCS with an

Before

Ethernet Module installed, the application programmer should:

1. Make sure the new I/O Configuration contains an Ethernet Module configuration.

2. Make sure the new Ethernet configuration will not

change the IP Address.

Refer to Chapter 3 on how to check and/or correct Ethernet Module configuration and pay

particular attention to step 5 of the Ethernet Module configuration process in Section 3.1 (page

18), and to Section 3.2 (page 21), which explains in detail how the Ethernet Module obtains an IP

Address.

If the new Ethernet configuration specifies Static IP Address (Section 3.2.1 [page

the IP Address parameter (Figure 3.5 [page

18]) matches Cscape’s Target IP Address (Figure

21]), make sure

4.1).

If the new Ethernet configuration specifies Static IP Address with CAN ID (Section 3.2.2 [page

21]), make sure the IP Address, which will be built from the combination of the IP Address

parameter (Figure 3.5 [page

18]) and the OCS/RCS CAN Network ID, matches Cscape’s Target

IP Address (Figure 4.1).

If the new Ethernet configuration specifies IP Address from OCS Register (Section 3.2.3 [page

22]), make sure the OCS register indicated by the IP Addr Register parameter (Figure 3.5 [page

18]) contains an IP Address, and that it matches Cscape’s Target IP Address (Figure 4.1). If

necessary, use Cscape’s Data Watch facility to set the OCS register to the correct IP Address

before downloading.

4.4.2 How to Recover from Lost Communication

If the Ethernet Module’s IP Address changes as a result of using CsCAN over Ethernet to

download a new user program, activity will halt at the end of the I/O Configuration download, and

communication between Cscape and the target OCS will

be lost. Then, after several seconds,

Cscape will display a Communication Timeout error.

If this happens, it is possible to recover Cscape communication with the target OCS, as follows:

1. Referring to Chapter 3 (especially Section 3.2 [page

21]) and to Section 4.4.1, determine

the Ethernet Module’s new IP Address, by using Cscape to re-examine the I/O

Configuration just downloaded.

2. Referring to Figure 4.1, change Cscape’s Target IP Address to match the Ethernet

Module’s new IP Address.

3. Try performing the download again.

11/30/2009 Page 25 of 98 # 958

Page 26

CH.4 SUP0740-07

4. If this does not succeed, try changing Cscape’s Target IP Address (Figure 4.1) to match

the static IP Address parameter (even if it is grayed out).

5. If all else fails, connect a PC running Cscape directly to the target OCS unit’s

programming serial port, repeat the download, and then use Data Watch to examine the

register indicated by the IP Addr Register parameter (Figure 3.5 [page

the Ethernet Module’s new IP Address.

Note: If the application programmer wants to use CsCAN over Ethernet to intentionally change

an Ethernet Module’s IP Address, do this by (1) starting the download, (2) waiting for

Cscape to timeout and (3) performing steps 1, 2 and 3 of the recovery process, as

described above.

4.5 CsCAN over Ethernet Security

To prevent the use of CsCAN over Ethernet protocol to gain unauthorized access to an OCS or

RCS, Cscape Programming Software and OCS Ethernet Firmware have the ability to passwordprotect CsCAN over Ethernet communication. To implement CsCAN over Ethernet Security, use

Cscape Programming Software, to perform the following nine steps:

1. Open the user program previously created for the target OCS or RCS controller.

18]), to discover

2. IF THE USER PROGRAM HAS ALREADY BEEN SET UP WITH SECURITY

PASSWORDS, FIRST LOG-IN AS THE ADMINISTRATOR. TO DO THIS, SELECT THE

TOOLS MENU AND ITS SECURITY SUB-MENU, CLICK LOG-IN, ENTER THE

ADMINISTRATOR PASSWORD, AND THEN CLICK OK. CSCAPE WILL THEN

ACKNOWLEDGE THE ADMINISTRATOR LOG-IN; CLICK OK AGAIN

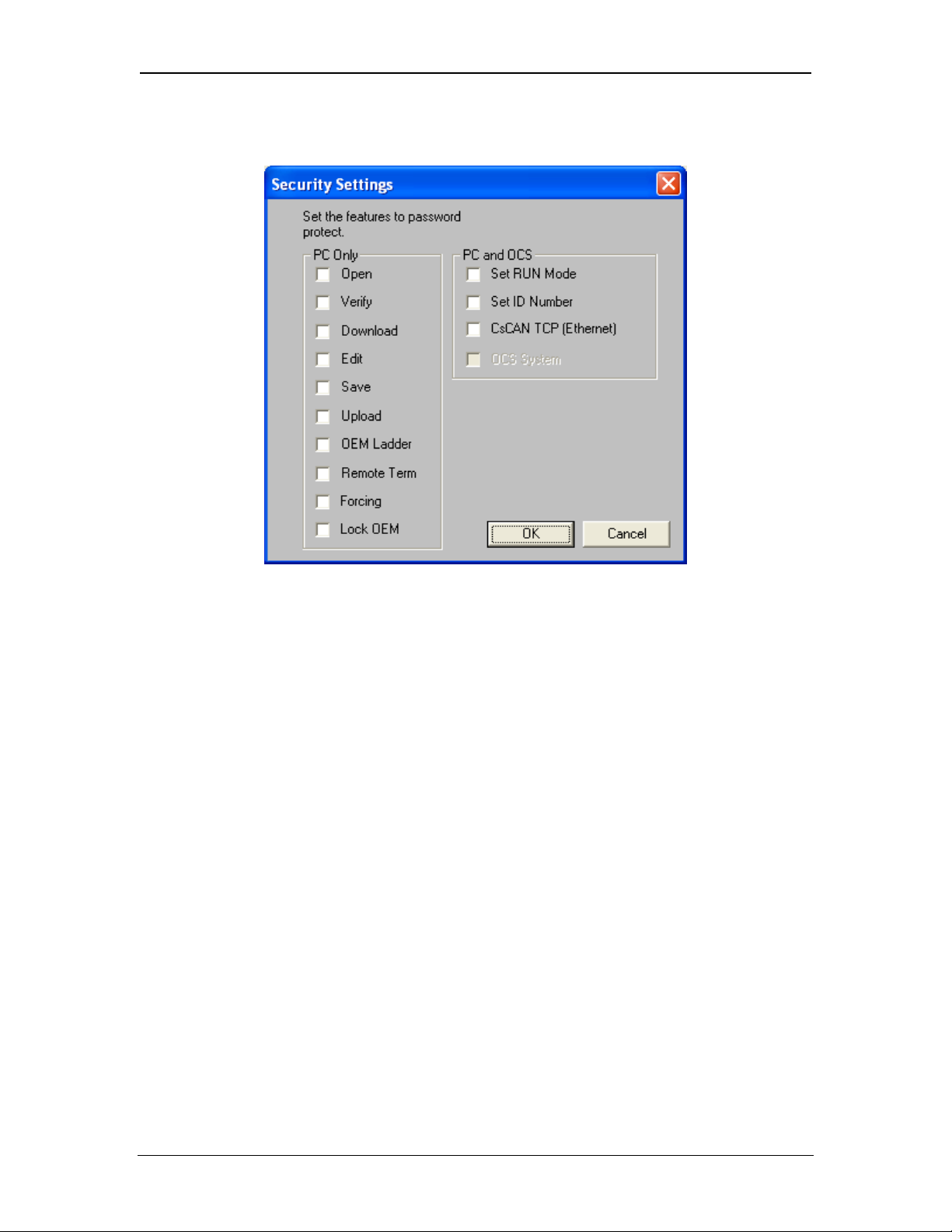

3. On the main Cscape screen, select the Tools menu and its Security sub-menu, and then

click Change Passwords, to open the Security Passwords dialog, as shown in Figure 4.3.

.

Figure 4.3 – Security Passwords Dialog

4. Click on the View Passwords button to view the Administrator and User passwords.

5. Change passwords and user names as desired for the application. Note that passwords are

numeric values between 1 and 999,999, while the user names can be any text from 1 to 15

characters long.

11/30/2009 Page 26 of 98 # 958

Page 27

SUP0740-07 CH.4

6. Click on the Items to Protect Setup button to open the Administrator’s Security Settings

dialog, as shown in Figure 4.4.

Figure 4.4– Administrator’s Security Settings Dialog

7. To password-protect CsCAN over Ethernet protocol, make sure the CsCAN TCP (Ethernet)

checkbox is checked in the Administrator’s Security Settings dialog, as shown in Figure 4.4.

Then click OK.

8. The Administrator password is always authorized for all protected features. If desired, one or

more of the user passwords can also be authorized for CsCAN over Ethernet communication.

To do this, refer to Figure 4.3 and click one of the User Permissions Setup buttons to open

that user’s Security Settings dialog, which will be similar to Figure 4.4. Then check the

CsCAN TCP (Ethernet) checkbox and click OK.

9. After downloading the user program to the target OCS or RCS, both Cscape and the OCS (or

RCS) controller will enforce the new password security for CsCAN over Ethernet protocol.

11/30/2009 Page 27 of 98 # 958

Page 28

CH.4 SUP0740-07

NOTES

11/30/2009 Page 28 of 98 # 958

Page 29

SUP0740-07 CH.5

CHAPTER 5: INTERNET CONTROL MESSAGE PROTOCOL (ICMP)

5.1 ICMP Overview

ICMP is used for diagnostic purposes only, to determine if another device exists on the Ethernet

network.

Using ICMP, the Ethernet Module sends Ping Echo Requests to another device, and expects the

other device to answer with Ping Echo Responses. The Ethernet Module measures the round-trip

time of each Ping Echo Request / Response exchange and puts the result (in milliseconds) into

an OCS register.

In addition, when the Ethernet Module receives a Ping Echo Request from another device, it

answers with a Ping Echo Response.

Note: Although ICMP supports other network diagnostics, the Ethernet Module only supports

Ping.

5.2 ICMP Configuration

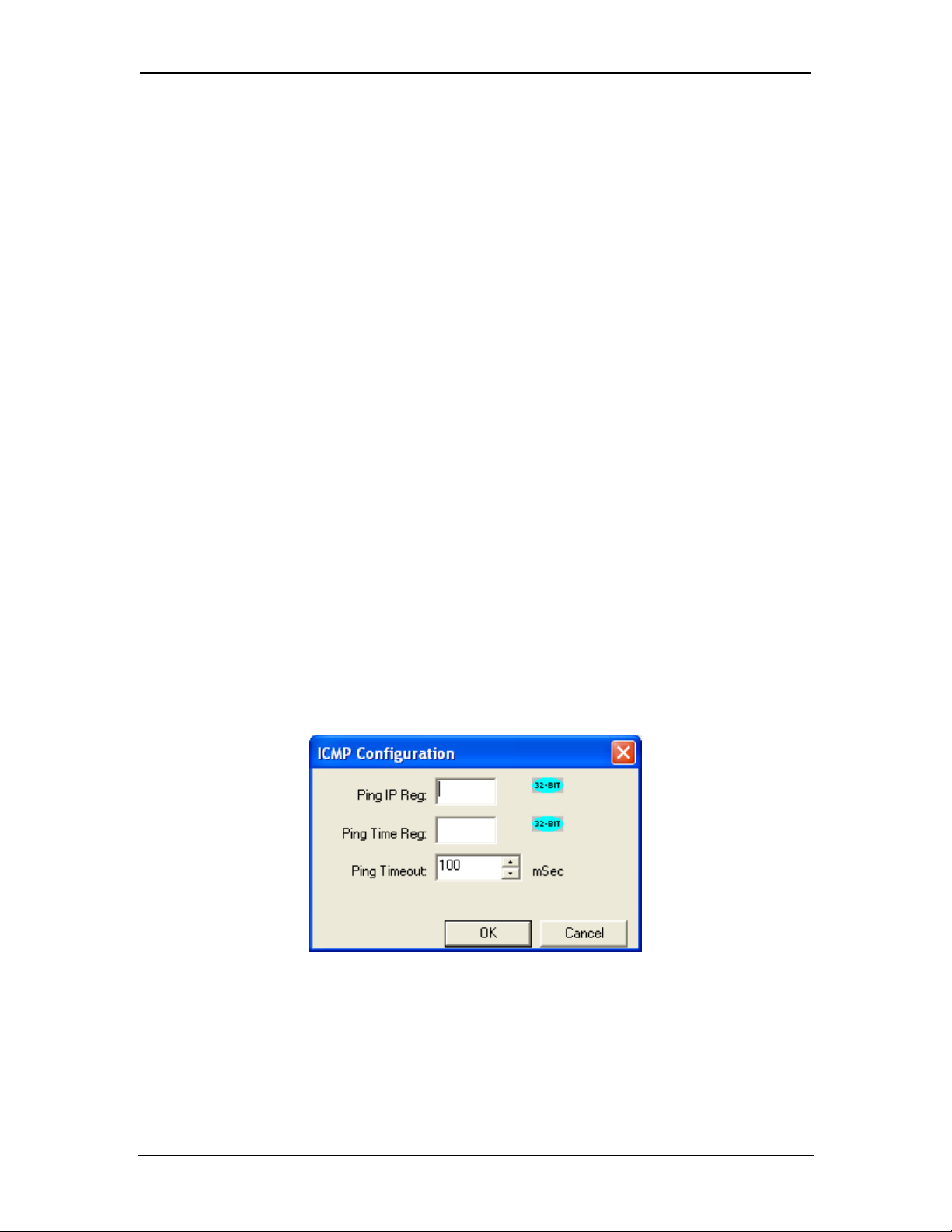

If ICMP protocol will be used in the application, ICMP Configuration must be performed, in

addition to the general Ethernet Module Configuration previously described in Chapter 3. To

configure ICMP protocol, use Cscape Programming Software to perform the following five steps:

1. Open the Ethernet Module Configuration dialog (Figure 3.5 [page

Chapter 3.

2. Enable ICMP by checking the ICMP (Ping) checkbox in the Module Configuration dialog

(Figure 3.5).

3. Click on the Config button next to the ICMP (Pin g) checkbox to open the ICMP Configuration

dialog (Figure 5.1).

18]), as described in

Figure 5.1– ICMP Configuration Dialog

4. Set up the ICMP Configuration parameters as follows:

Ping IP Reg: Enter an OCS Register reference (such as %R200) to indicate which 32-bit

OCS register will be read to obtain the IP Address of the network device to send Ping Echo

Requests to.

11/30/2009 Page 29 of 98 # 958

Page 30

CH.5 SUP0740-07

Ping Time Reg: Enter an OCS Register reference (such as %R202) to indicate which 32-bit

OCS register will be written with the Ping Echo Request / Response round-trip time (in

milliseconds).

Ping Timeout: Enter a number between 100 and 100,000 for how often (in milliseconds) the

Ethernet Module should send Ping Echo Requests.

5. Click OK to accept the new ICMP Configuration.

5.3 ICMP Operation

To start Ping Echo Requests, use Ladder Code, User Screens or Cscape Data Watch to write an

IP Address to the OCS register indicated by Ping IP Reg. To check the resulting Ping Echo

Response times, read the OCS register indicated by Ping Time Reg. If the round-trip time

exceeds the configured Ping Timeout (or if there is no response at all), the reported response

time will be -1.

To stop Ping Echo Requests, write 0.0.0.0 to the OCS register indicated by Ping IP Reg.

Note that ICMP protocol is active even when the OCS is not

OCS is not

in RUN mode, User Screens and Cscape Data Watch can still be used to control and

in RUN mode. Therefore, when the

monitor ICMP Pinging.

11/30/2009 Page 30 of 98 # 958

Page 31

SUP0740-07 CH.6

CHAPTER 6: ETHERNET GLOBAL DATA PROTOCOL (EGD)

6.1 EGD Overview

Ethernet Global Data (EGD) protocol is a GE Fanuc Automation protocol, which is designed for

simple, efficient data exchanges between peer devices on a network.

EGD protocol communicates using the UDP transport layer. Although this method of data transfer

is very efficient, it has no specific way to detect and recover lost data packets. However, since all

EGD data transfers are periodic, lost data packets will be repeated when their user-configured

time periods expire.

Caution: EGD protocol is not

critical data, which can’t withstand being delayed as described above.

Each device on an EGD network can be configured as a Producer, as a Consumer, or both. A

Producer is a device that transmits Exchanges (blocks of data) to one or more Consumers. A

Consumer is a device that receives Exchanges from one or more Producers.

A Producer can transmit Exchanges directly to a specific Consumer, by sending them to the

Consumer’s IP Address (using Unicast IP Addressing). A Producer can also transmit Exchanges

to a Group of Consumers, by sending them to a Group ID (using Multicast IP Addressing). See

Section 2.3.2 (page

An Ethernet Module supports up to 127 concurrent Exchanges, each of which can be either a

Producer or a Consumer of data.

12) for more details regarding Unicast and Multicast IP Addressing.

intended for one-shot event notification or for applications with

6.2 EGD Terminology

Before configuring an Ethernet Module for EGD protocol, it is essential that the application

programmer understand the key EGD terms, which are shown in Table 6.1.

Table 6.1 – EGD Terminology

Term Definition

Exchange

Exchange Number

Producer An EGD network device configured to transmit one or more Exchanges

Consumer An EGD network device configured to receive one or more Exchanges

Produced Exchange

Consumed Exchange

Group

Group ID A number (1 to 32), which is used to identify a Group of Consumers

Production Period

Update Timeout

A block of data sent by a Producer and received by one or more

Consumers

A number (1 to 16,383), which along with the IP Address of the Producer,

is used to uniquely identify an Exchange on an EGD network

A block of data that a Producer sends to a Consumer or to a Group of

Consumers

A block of data that a Consumer or Group of Consumers receives from a

Producer

One or more Consumers that are configured to receive Exchanges,

which have been sent by a Producer to a specific Group ID

A value (in milliseconds) that specifies how often a Produced Exchange

is transmitted to the network

A value (in milliseconds) that specifies how long a Consumer will wait to

receive an Exchange, before considering it late. (Note: As rule of thumb,

a Consumed Exchange’s Update Timeout is normally set to at least twice

the corresponding Produced Exchange’s Production Period, plus 10

milliseconds.)

11/30/2009 Page 31 of 98 # 958

Page 32

CH.6 SUP0740-07

6.3 EGD Configuration

If EGD protocol will be used in the application, EGD Configuration must be performed, in addition

to the general Ethernet Module Configuration previously described in Chapter 3. To configure

EGD protocol, use Cscape Programming Software to perform the following six steps:

1. Open the Ethernet Module Configuration dialog (Figure 3.5 [page

18]) as described in

Chapter 3.

2. Enable EGD by checking the EGD (Ethernet Global Data) checkbox in the Module

Configuration dialog (Figure 3.5).

3. Click on the Config button next to the EGD (Ethernet Global Data) checkbox to open the

Ethernet Global Data Configuration dialog (Figure 6.1 or Figure 6.2).

Note: The Ethernet Global Data Configuration dialog allows EGD Produced and Consumed

Exchanges to be configured. To configure Produced Exchanges, select the Produced

Exchanges tab (Figure 6.1); to configure Consumed Exchanges, select the Consumed

Exchanges tab (Figure 6.2)

Figure 6.1– Ethernet Global Data (EGD) Configuration Dialog – Produced Exchange Tab

Selected

11/30/2009 Page 32 of 98 # 958

Page 33

SUP0740-07 CH.6

Figure 6.2 – Ethernet Global Data (EGD) Configuration Dialog – Consumed Exchange Tab

Selected

4. Follow the steps in Section 6.4 to configure Produced Exchanges, as necessary for the

application.

5. Follow the steps in Section 6.5 to configure Consumed Exchanges, as necessary for the

application.

6. Click OK to accept the new EGD Configuration.

6.4 EGD Produced Exchange Configuration

To configure EGD Produced Exchanges, open the Ethernet Global Data Configuration dialog

(Figure 6.1) as described in Section 6.3, and select the Produced Exchanges tab, where:

1. In the upper window, one or more Produced Exchanges can be created (Section 6.4.1).

2. In the lower window, I/O Blocks can be defined for each Produced Exchange (Section 6.4.2).

When creating a Produced Exchange, the application programmer selects an Exchange Number

for it, determines whether the Exchange will be sent to a specific Consumer or to a Group of

Consumers, chooses which Consumer or Group of Consumers will receive the Exchange, and

sets how often the Exchange will be sent to the EGD network.

11/30/2009 Page 33 of 98 # 958

Page 34

CH.6 SUP0740-07

When defining I/O Blocks for a Produced Exchange, the application programmer selects what

type and how much information will be associated with the Exchange. For Produced Exchanges,

there are two types of I/O Blocks to choose from: Data and Status. Table 6.2 shows these I/O

Block Types along with their definitions:

Table 6.2 – Produced Exchange I/O Block Type Definitions

Type Definition

Data Block

Status Block

Block of consecutive OCS registers to be sent periodically to the EGD

network

16-bit OCS register to be written with the Produced Exchange’s Status

Word

When defining Data Blocks for a Produced Exchange, the maximum total OCS register data the

Exchange can send to the EGD network is 1400 bytes. This means that up to a total of 700 16-bit

registers (%R, %AI, AQ, etc.), or 11,200 1-bit registers (%M, %T, %I, %Q, etc.), or a combination

thereof can be defined for a Produced Exchange.

Note: The Ethernet Module allows a total of up to 256 Data Blocks to be defined for all Produced

Exchanges combined. This means that if 127 Produced Exchanges are configured, each

can have an average of about 2 Data Blocks defined.

When a Status Block is defined for a Produced Exchange, exactly 2 bytes of register data are

written with the Produced Exchange’s Status Word. See Section 6.7 for general information

regarding EGD Status Words, and Section 6.7.1 for specific information regarding EGD Produced

Exchange Status Words.

Note: The Ethernet Module maintains just one 16-bit status word for each Produced Exchange.

For this reason, there is never

any need to define more than one Status Block for a given

Produced Exchange.

6.4.1 Creating EGD Produced Exchanges

To create EGD Produced Exchanges, perform the following six steps:

1. In the Ethernet Global Data Configuration dialog (Figure 6.1), click on the Add Exch button to

open the Add / Edit Produced Exchange dialog (Figure 6.3).

Figure 6.3– Add / Edit Produced Exchange Dialog – IP Address Selected

2. Configure the Produced Exchange parameters as follows:

11/30/2009 Page 34 of 98 # 958

Page 35

SUP0740-07 CH.6

Exchange Number: Enter a number between 1 and 16,383, which will be used to identify the

Exchange to be sent.

IP Address Radio Button: Select this option if the Exchange will be sent to a specific

Consumer. (This will cause the next edit box to be for entering IP Address, instead of Group

ID.)

Group ID Radio Button: Select this option if the Exchange will be sent to a Group of

Consumers. (This will cause the next edit box to be for entering Group ID, instead of IP

Address.)

IP Address Edit Box: If the IP Address radio button was selected, enter the IP Address of

the specific Consumer that will receive the Produced Exchange.

Group ID Edit Box: If the Group ID radio button was selected, enter the Group ID number (1

to 32) of the Group of Consumers that will receive the Produced Exchange.

Production Period: Enter a number (in milliseconds) for how often the Produced Exchange

will be sent to the EGD network.

3. Click OK to accept the new Produced Exchange configuration, which will be now be

displayed in the upper window of the Ethernet Global Data Configuration dialog (Figure 6.1).

4. To add another Produced Exchange to the list, click on the Add Exch button again.

5. To edit or delete a Produced Exchange, highlight it in the upper window of the Ethernet

Global Data Configuration dialog (Figure 6.1), and then click on the Edit Exch button or the

Delete Exch button.

6. To quickly change the IP Address in multiple Produced Exchanges, click on the Replace

Addr button. This will open a dialog to allow the user to search and replace the IP Address

parameter, in all Produced Exchanges simultaneously.

6.4.2 Defining EGD Produced Exchange I/O Blocks

After creating a Produced Exchange (Section 6.4.1), one or more I/O Blocks should be defined

for it. An I/O Block specifies what type and how much information will be associated with the

Produced Exchange.

To define I/O Blocks for a Produced Exchange, perform the following six steps:

1. In the upper window of the Ethernet Global Data Configuration dialog (Figure 6.1), highlight

one of the Produced Exchanges, and then click the Add Range button to open the Add I/O

Range to Exchange dialog (Figure 6.4).

11/30/2009 Page 35 of 98 # 958

Page 36

CH.6 SUP0740-07

Figure 6.4– Add I/O Range to Exchange Dialog

2. Configure the I/O Block parameters as follows:

Type: Select Data Type to define a block of OCS registers, which the Produced Exchange

will periodically read and send to the EGD network. Select Status Type to define a 16-bit

OCS register, which will be written with the Produced Exchange’s Status Word.

Address: Enter an OCS Register reference (such as %R1000), for the first OCS register, in

a block of OCS registers, that will be periodically read and sent (Data Type), or for a 16-bit

OCS register that will be written with status information (Status Type).

Number of Registers: If Data Type was selected, enter the number of registers to be

periodically read and sent. If Status Type was selected, this edit box changes to Number of

Bytes, and always has a fixed value of 2.

3. Click OK to accept the Produced Exchange’s new I/O Block, which will be now be displayed

in the lower window of the Ethernet Global Data Configuration dialog (Figure 6.1).

Note: The OCS registers, specified in Data Block definitions, are sent to the EGD network in

top-to-bottom order, as they appear in the lower window of the Ethernet Global Data

Configuration dialog (Figure 6.1).

4. To add another I/O Block, click the Add Range button again and repeat steps 2 and 3. The

new I/O Block will appear at the end of the list.

5. To insert an I/O Block into the middle of the list, highlight one of the I/O Block items in the list

and then click on the Insert Range button. In this case, the new I/O Block will be inserted just

before the highlighted I/O Block.

6. To edit or delete an I/O Block in the list, highlight it and then click on the Edit Range or

Delete Range button.

6.5 EGD Consumed Exchange Configuration

To configure EGD Consumed Exchanges, open the Ethernet Global Data Configuration dialog

(Figure 6.2) as described in Section 6.3, and select the Consumed Exchanges tab, where:

1. In the upper window, one or more Consumed Exchanges can be created (Section 6.5.1).

2. In the lower window, I/O Blocks can be defined for each Consumed Exchange (Section

6.5.2).

11/30/2009 Page 36 of 98 # 958

Page 37

SUP0740-07 CH.6

When creating a Consumed Exchange, the application programmer selects an Exchange Number

for it, determines whether to receive the Exchange as a single Consumer or as a member of a

Group of Consumers, chooses which Producer to receive the Exchange from, and sets how often

to expect the Exchange to be received.

When defining I/O Blocks for a Consumed Exchange, the application programmer selects what

type and how much information will be associated with the Exchange. For Consumed Exchanges,

there are five types of I/O Blocks to choose from: Data, Status, Timestamp, OCS Timestamp,

and Filler. Table 6.3 shows these I/O Block Types along with their definitions:

Table 6.3 – Consumed Exchange I/O Block Type Definitions

Type Definition

Data Block Block of consecutive OCS registers to be written with received data

Status Block

Timestamp Block

OCS Timestamp Block

16-bit OCS register to be written with the Consumed Exchange’s

status word

8-byte binary timestamp indicating when the Producer sampled the

data

14-byte OCS-format timestamp indicating when the Producer sampled

the data

Filler Block Specifies a block of received data to ignore (skips unwanted data)

When defining Data Blocks for a Consumed Exchange, the maximum total OCS register data the

Exchange can receive from the EGD network is 1400 bytes. This means that up to a total of 700

16-bit registers (%R, %AI, AQ, etc.), or 11,200 1-bit registers (%M, %T, %I, %Q, etc.), or a