Page 1

User Manual for

MiniOCS, MiniRCS,

and SmartStix

Mini Hardware

Fourth Edition

15 March 2003

MAN0305-04

Page 2

Page 3

PREFACE 15 MAR 2003 PAGE 3

MAN0305-04

PREFACE

This manual explains how to use MiniOCS / MiniRCS / SmartStix.

Copyright (C) 2003 Hor ner APG, LLC., 640 North Sherman Drive Indianapolis, Indiana 46201. All rights

reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form by any means, electronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without the prior agreement and written

permission of Horner APG, Inc.

All software described in this document or media is also copyrighted material subject to the terms and

conditions of the Horner Software License Agreement.

Information in this document is subject to change without notice and does not represent a commitment on

the part of Horner APG.

Cscape, SmartStix, and CsCAN are trademarks of Horner APG.

DeviceNet is a trademark of the Open DeviceNet Vendor Association (OVDA), Inc.

Ethernet is a trademark of the Xerox Corporation.

For user manual updates, contact Horner APG Technical Support

Division, at (317) 916- 4274 or visit our website at www.heapg.com.

Page 4

PAGE 4 15 MAR 2003 PREFACE

MAN0305-04

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG,LLC. ("HE-APG") warrants to the original purchaser that the MiniOCS/RCS/SmartStix manufactured by

HE-APG is free from defects in material and workmanship under normal use and service. The obligation of HE-APG

under this warranty shall be limited to the repair or exchange of any part or parts which may prove defective under

normal use and service within two (2) years from the date of manufacture or eighteen (18) months from the date of

installation by the original purchaser whichever occurs first, such defect to be disclosed to the satisfaction of HE-APG

after examination by HE-APG of the allegedly defective part or parts. THIS WARRANTY IS EXPRESSLY IN LIEU

OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR USE AND OF ALL OTHER OBLIGATIONS OR LIABILITIES AND HEAPG NEITHER ASSUMES, NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR HE-APG, ANY OTHER

LIABILITY IN CONNECTION WITH THE SALE OF THIS MiniOCS/RCS/SmartStix. THIS WARRANTY SHALL NOT

APPLY TO THIS MiniOCS/RCS/SmartStix OR ANY PART THEREOF WHICH HAS BEEN SUBJECT TO

ACCIDENT, NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. HE-APG MAKES NO WARRANTY

WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT SUPPLIED BY HE-APG. THE TERM

"ORIGINAL PURCHASER", AS USED IN THIS WARRANTY, SHALL BE DEEMED TO MEAN THAT PERSON FOR

WHOM THE MiniOCS/RCS/SmartStix IS ORIGINALLY INSTALLED. THIS WARRANTY SHALL APPLY ONLY

WITHIN THE BOUNDARIES OF THE CONTINENTAL UNITED STATES.

In no event, whether as a result of breach of contract, warranty, tort (including negligence) or otherwise, shall HEAPG or its suppliers be liable of any special, consequential, incidental or penal damages including, but not limited to,

loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated equipment,

cost of capital, cost of substitute products, facilities, services or replacement power, down time costs, or claims of

original purchaser's customers for such damages.

To obtain warranty service, return the product to your distributor with a description of the problem, proof of

purchase, post paid, insured and in a suitable package.

ABOUT PROGRAMMING EXAMPLES

Any example programs and program segments in this manual or provided on accompanying diskettes are included

solely for illustrative purposes. Due to the many variables and requirements associated with any particular

installation, Horner APG cannot assume responsibility or liability for actual use based on the examples and diagrams.

It is the sole responsibility of the system designer utilizing the MiniOCS/RCS/SmartStix to appropriately design the

end system, to appropriately integrate the MiniOCS/RCS/SmartStix and to make safety provisions for the end

equipment as is usual and customary in industrial applications as defined in any codes or standards which apply.

Note: The programming examples shown in this manual are for illustrative

purposes only. Proper machine operation is the sole responsibility of the

system integrator.

Page 5

PREFACE 15 MAR 2003 PAGE 5

MAN0305-04

REVISIONS TO THIS MANUAL

This version (MAN0305 -04) of the Mini Hardware Manual contains the following revisions, additions, and

deletions:

1. Removed Mini data sheets from the back of this manual and moved them into a new manual.

Revised Section 1.5: Additional References.

2. Revised Section 1.1. to include the SmartStix product line.

3. Added Chapter 6: SmartStix.

Page 6

PAGE 6 15 MAR 2003 PREFACE

MAN0305-04

Page 7

PREFACE 15 MAR 2003 PAGE 7

MAN0305-04

Table of Contents

CHAPTER 1 : INTRODU CTION..........................................................................................................9

1.1 Scope...................................................................................................................................9

1.2 MiniOCS and MiniRCS Product Description ............................................................................9

1.2.1 Functions and Features...................................................................................................9

1.2.2 Cscape Software.......................................................................................................... 10

1.2.3 MiniOCS / MiniRCS Specifications ................................................................................. 11

1.3 MiniOCS / MiniRCS Resources ............................................................................................ 12

1.3.1 Overview...................................................................................................................... 12

1.3.2 Resource Definitions ..................................................................................................... 13

1.4 MiniOCS / MiniRCS Models ................................................................................................. 17

1.5 Additional References.......................................................................................................... 18

1.6 Technical Support ............................................................................................................... 18

CHAPTER 2 : INSTALLATION .........................................................................................................19

2.1 MiniOCS Mounting Requirements .........................................................................................19

2.1.1 MiniOCS Mounting Procedures (Installed in a Panel Door).............................................. 19

2.1.2 MiniOCS Dimensions and Panel Cut -outs......................................................................19

2.1.3 MiniOCS Mounting Orientation ...................................................................................... 21

2.2 MiniRCS Mounting Requirements ......................................................................................... 22

2.2.1 MiniRCS Mounting Procedures (Installed in a Panel Box) ................................................22

2.2.2 MiniRCS Dimensions and Panel Cut -outs......................................................................22

2.2.3 MiniRCS Mounting Orientation .......................................................................................23

2.3 Factors Affecting Panel Layout Design and Clearances ......................................................... 23

2.3.1 Panel Layout Design and Clearance Checklist:............................................................... 25

2.4 Ports, Connectors, and Wiring.............................................................................................. 26

2.4.1 Power, Network, and Programming Ports....................................................................... 26

2.4.2 Primary Power Port....................................................................................................... 26

2.3.3 CAN Network / DeviceNet Network Port and Wiring........................................................ 27

2.3.4 RS-232 Programming Port and Wiring ........................................................................... 30

2.3.5 Modem Setup............................................................................................................... 31

2.5 Selecting DeviceNet Network (Firmware Update Wizard)....................................................... 33

2.6 MiniOCS / MiniRCS LEDs .................................................................................................... 33

2.7 Mini Battery Replacement .................................................................................................... 35

CHAPTER 3 : SYSTEM MENU.........................................................................................................37

3.1 General............................................................................................................................... 37

3.2 Navigating Through the System Menu .................................................................................. 37

3.3 Editing System Menu Screen Fields ......................................................................................37

3.4 Remote Screen / Keypad (Using Remote Text Terminal and Status Bar) .................................38

3.5 Initial System Menu Screens and Self-Test ........................................................................... 38

3.6 Entering the System Menu ................................................................................................... 38

CHAPTER 4 : KEYPAD AND SCREEN............................................................................................. 45

4.1 Remote Screen and Keypad Capability .................................................................................45

4.1.1 Remote Text Terminal ................................................................................................... 45

4.1.2 Cscape Status Bar........................................................................................................ 45

4.1.3 Establishing Communications using the Remote Text Terminal........................................ 46

4.2 Keypad Description ............................................................................................................. 46

4.3 Operation............................................................................................................................ 47

4.4 User Screens ...................................................................................................................... 48

4.4.1 Cursor Types ................................................................................................................48

CHAPTER 5 : MINI CONFIGURATION .............................................................................................49

5.1 General............................................................................................................................... 49

5.2 Preliminary Configuration Procedures ................................................................................... 49

Page 8

PAGE 8 15 MAR 2003 PREFACE

MAN0305-04

CHAPTER 6 : SMARTSTIX..............................................................................................................53

6.1 General............................................................................................................................... 53

6.2 SmartStix I/O Introduction .................................................................................................... 53

6.3 SmartStix I/O Modules ......................................................................................................... 53

BASIC SMARTSTIX PROGRAMMING ........................................................................................... 54

6.4 Using GET and PUT ............................................................................................................54

6.4.1 Get Remote I/O Function Block ..................................................................................... 54

6.4.2 Get Remote Parameter Description:............................................................................... 54

6.4.3 Put Remote I/O Function Block ......................................................................................55

6.4.4 Put Remote Parameter Description: ............................................................................... 56

6.5 SmartStix I/O Default Operation ........................................................................................... 56

ADVANCED SMARTSTIX PROGRAMMING ...................................................................................57

6.6 SmartStix I/O Module Device Classes................................................................................... 57

6.7 SmartStix I/O Module Consumed (Received) Directed Data ................................................... 58

6.8 Consumed Directed Data Power -Up Initialization...................................................................59

6.9 SmartStix I/O Module Produced (Transmitted) Global Data.................................................... 60

6.10 Produced Global Data Power-Up Initialization ....................................................................60

6.11 SmartStix I/O Module LED Indicators ................................................................................ 61

6.11.1 Diagnostic LED Indicators ............................................................................................. 61

6.11.2 Status LED Indicators ................................................................................................... 61

6.12 SmartStix I/O Module Network ID...................................................................................... 61

Page 9

CH.1 15 MAR 2003 PAGE 9

MAN0305-04

CHAPTER 1: INTRODUCTION

1.1 Scope

The Mini Hardware User Manual provides information about the following products:

a. MiniOCS (HE500OCSxxx)

MiniRCS (HE500RCSxxx)

The specifications, installation, and configuration procedures of the Operator Control Station (OCS) and

the Remote Control Station (RCS) are covered in detail in this user manual. Information is also provided

for the use of the products in CsCAN and DeviceNet Networks.

Note: Mini data sheets are now located in their own manual. (Refer to Additional References on page

18).

b. SmartStix Modules for CsCAN Networks (HE550xxxxxx).

SmartStix is a family of remote products for the OCS. This manual covers programming information for

SmartStix used in CsCAN networks.

Figure 1.1 - Front View of MiniOCS (Shown on Door in Panel Box)

1.2 MiniOCS and MiniRCS Product Description

1.2.1 Functions and Features

The MiniOCS provides controller, I/O, operator interface, and optional networking capabilities in one unit.

The MiniRCS has the same functionality as the MiniOCS except that it does not have local operator

interface capabilities. Both the MiniRCS and the MiniOCS support a remote operator interface through a

PC connected to the Mini unit’s built-in network or serial port. The remote operator interface (Remote

Text Terminal) is particularly useful when using the MiniRCS, which does not have a physical front panel

screen or keypad.

The MiniOCS is mounted in a panel door; the MiniRCS is designed for backplate mounting. Both the

MiniOCS and the MiniRCS can be used in CsCAN or DeviceNet networks. To use the MiniRCS in a

DeviceNet network, a DeviceNet file can be downloaded from Cscape’s Firmware Update Wizard.

Page 10

PAGE 10 15 MAR 2003 CH.1

MAN305-04

A variety of MiniOCS / MiniRCS models are available. Each model comes equipped with one factory

installed I/O board. Models of the MiniOCS / MiniRCS, which vary according to the type of I/O board

installed, are available in non-network and network versions. Network versions contain an additional

connector allowing connectivity to networks.

MiniOCS / MiniRCS devices have Serial and CAN (Controller Area Network) communication abilities.

The units contain a standard 9-pin RS -232 port for programming/debugging, monitoring and network

administration from an IBM -compatible PC. MiniOCS / MiniRCS models, which have built-in networking

capabilities, use CsCAN (pronouned “Sea-scan”) protocol and standard CAN network hardware. CANbased network hardware is used in the controllers because of CAN’s automatic error detection, ease of

configuration, low-cost of design and implementation and ability to operate in harsh environments. The

MiniOCS / MiniRCS can also be used in DeviceNet networks. Networking abilities are built-in to the

MiniOCS / MiniRCS and require no external or additional modules. When several MiniOCS / MiniRCS

units are networked together to ac hieve a specific purpose, the system acts like a large parallelprocessing controller.

The MiniOCS / MiniRCS have standard features consisting of the following:

• 24 VDC powered • Integrated Bezel

• One Internal I/O Module • Real-Time Clock

• RS-232 Programming Port • Flash Memory for easy field upgrades

1.2.2 Cscape Software

Cscape Software (pronounced “Sea -scape”) is used with the MiniOCS / MiniRCS, OCS, and RCS

products. (The part number for Cscape is HE500OSW232.) Cscape stands for Control Station Central

Application Programming Environment. The Windows -based software package is easy to use and aids in

the integration of a CAN-based Distributed Control System. The program is used for configuring

controllers and I/O Modules. Cscape is also used for programming MiniOCS / MiniRCS ladder logic,

programming user displays for the MiniOCS, configuring the network for global digital and analog data,

setting system-wide security and monitoring controllers in the system. Provided there is one serial

connection to one node on the network (i.e., CsCAN Network), the operator has control over the entire

system. The operator can upload, download, monitor and debug to any node on the network.

Page 11

CH.1 15 MAR 2003 PAGE 11

MAN0305-04

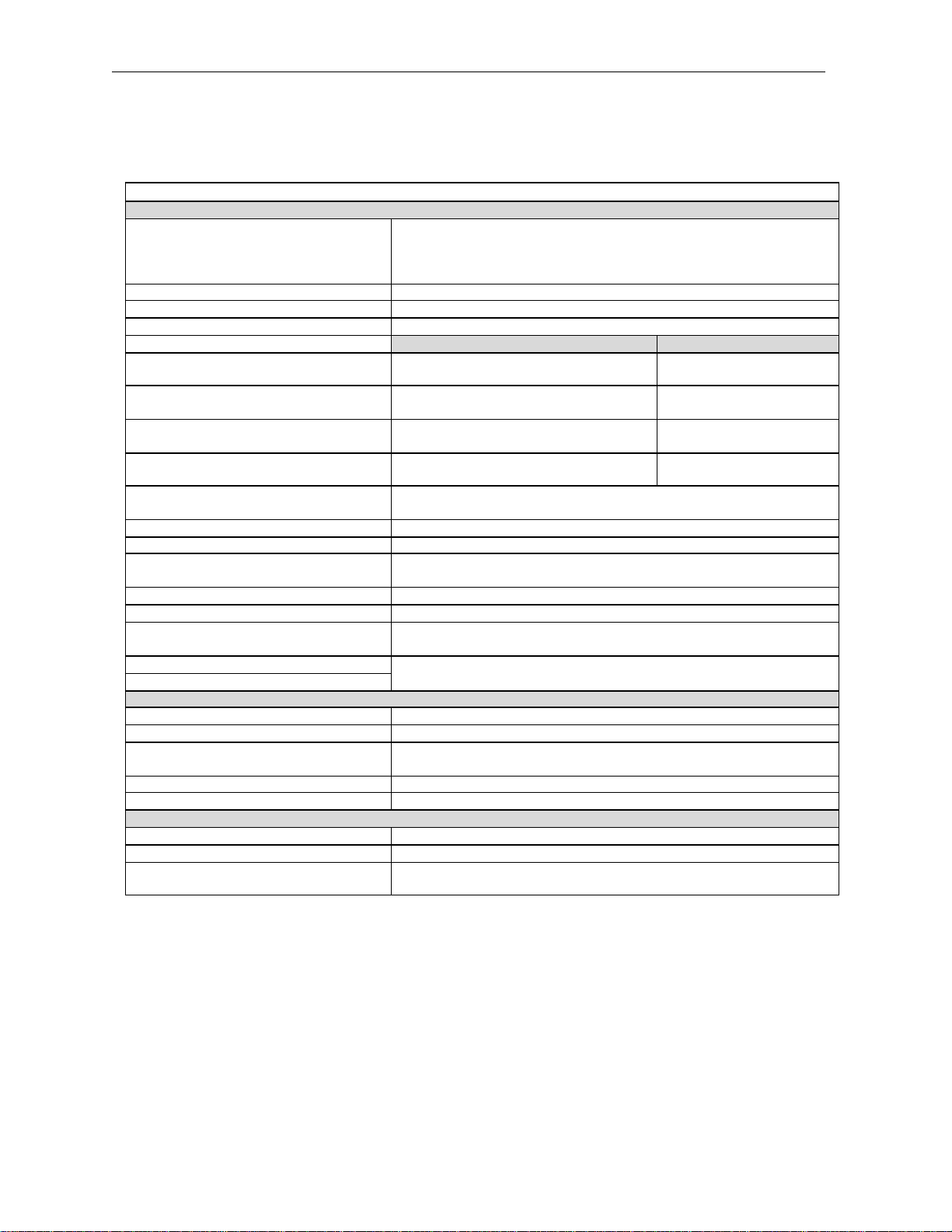

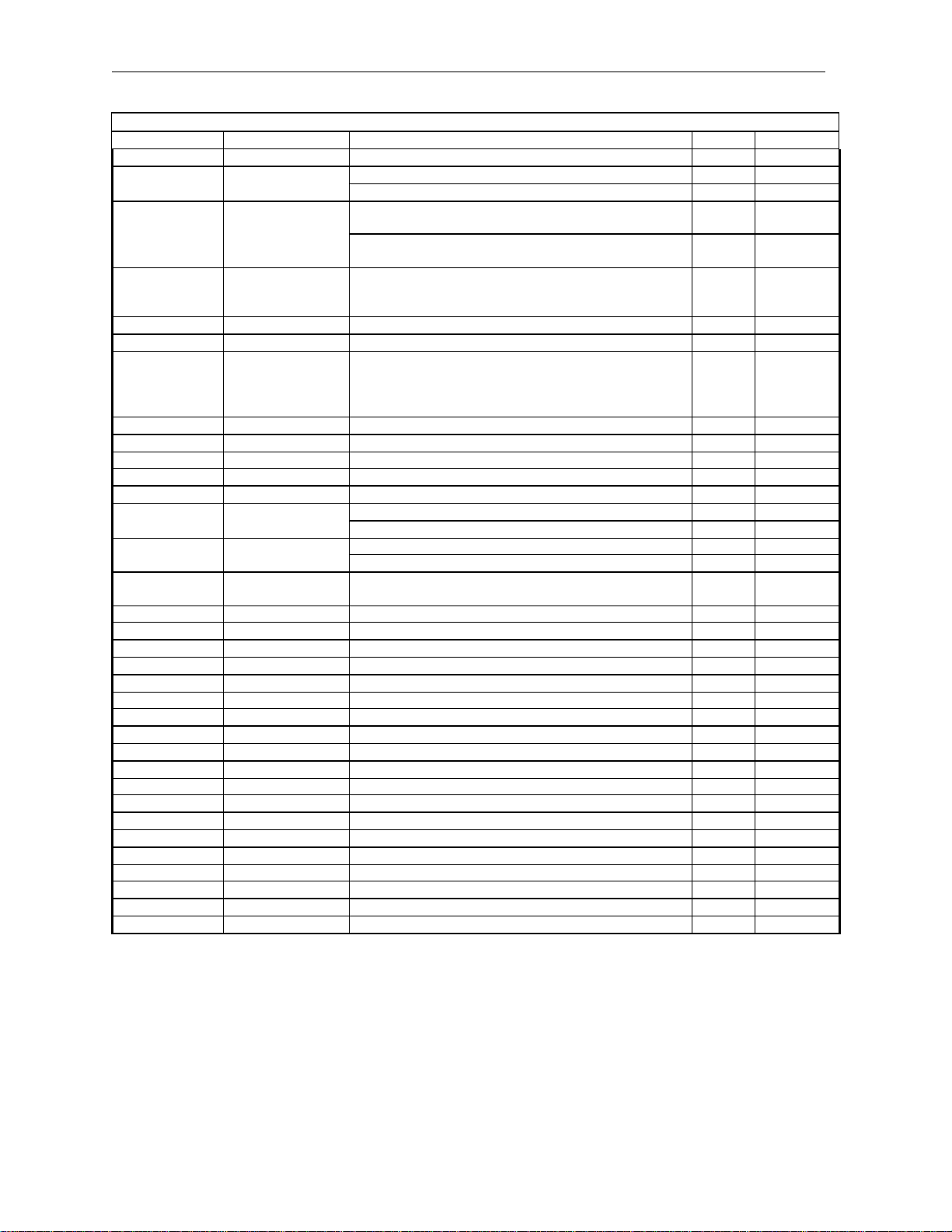

1.2.3 MiniOCS / MiniRCS Specifications

TBD = To Be Determined

Table 1.1 – Physical Specifications

MiniOCS and MiniRCS

Operating Temperature*

Humidity 5% to 95% non-condensing

NEMA Rating NEMA 4X

Primary Power Range 10-30VDC

Mini OCS Mini RCS

Maxim um Power Draw (Non-network

Version)

Maximum Power Draw (Network

Version)

Maximum Inrush Current ((Nonnetwork Version)

Maximum Inrush Current (Network

Version)

Ladder Execution

Typical Execution Speed

CAN Power Range 12 – 25 VDC

CAN Power Current 75mA maximum

Serial Standard 9 pin RS-232 for programming, monitoring, and network

CAN CsCAN Network / DeviceNet

Input / Output One factory -installed I/O board per model

Keypad 10 user-programmable keys + , Esc, Enter and 4 direction keys

UL

CE

MiniOCS

Height 4.4” (111.76mm)

Width 7” (177.80)

Mounting Depth 2.25” (57.15)

User Keys (MiniOCS Only) 17

Display (MiniOCS only) 2x20 LCD w/backlight; 3.2mm w x 5.55mm h characters

MiniRCS

Height 4.13” (104.78mm)

Width 5.83” (147.98mm)

Mounting Depth 1.83” (46.48mm)

(* Although the MiniOCS / MiniRCS withstands the temperature range of 0°C

to +60°C, such temperatures can decrease the life of the display. The

recommended rating is 0°C to +50°C.)

200mA max. @ 24VDC

200mA max. @ 24VDC

900mA max. @ 24VDC for 1mS

900mA max. @ 24VDC for 1mS

2.0ms. per 1K of Boolean logic.

administration from a IBM compatible PC

Faceplate made of Marnot XL Polyester by Tekra.

Please refer to Compliance Table located at

http://www.heapg.com/Support/compliance.htm

(approximately 2.75” [69.85] including Ground Screw extension)

(approximately 2.33” [59.18] including Ground Screw extension)

0°C to +50°C*

To Be Determined

To Be Determined

To Be Determined

To Be Determined

Page 12

PAGE 12 15 MAR 2003 CH.1

MAN305-04

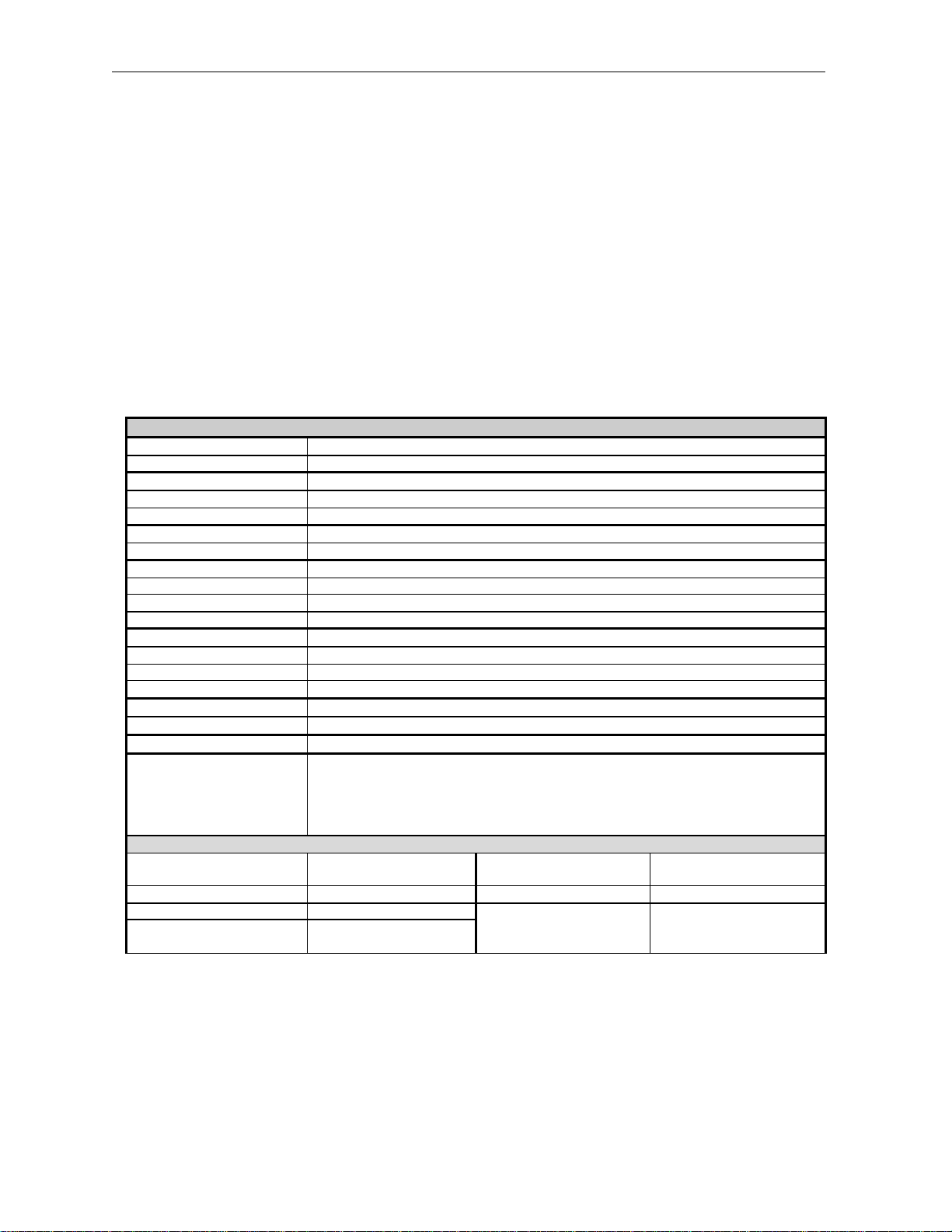

1.3 MiniOCS / MiniRCS Resources

1.3.1 Overview

This section defines the resource limits that a programmer needs to know when writing a program using

the MiniOCS / MiniRCS.

A MiniOCS / MiniRCS combine local I/O (analog and digital), networking, and controller, into a single

product. The MiniOCS also provides an operator interface (display and keypad). The controller portion of

the MiniOCS / MiniRCS is programmed in ladder logic via the Windows -based Cscape (Control Station

Central Application Programming Environment) package. Each MiniOCS / MiniRCS provide a set of

resources for use by the ladder logic control program as indicated in Table 1.2. The table shows the

resources available in MiniOCS / MiniRCS products. Note that although each register type inherently

consists of either 1-bit or 16-bit registers, all registers can be accessed via User Screens and/or Ladder

Code as 1, 8, 16 or 32-bit values or as ASCII character strings.

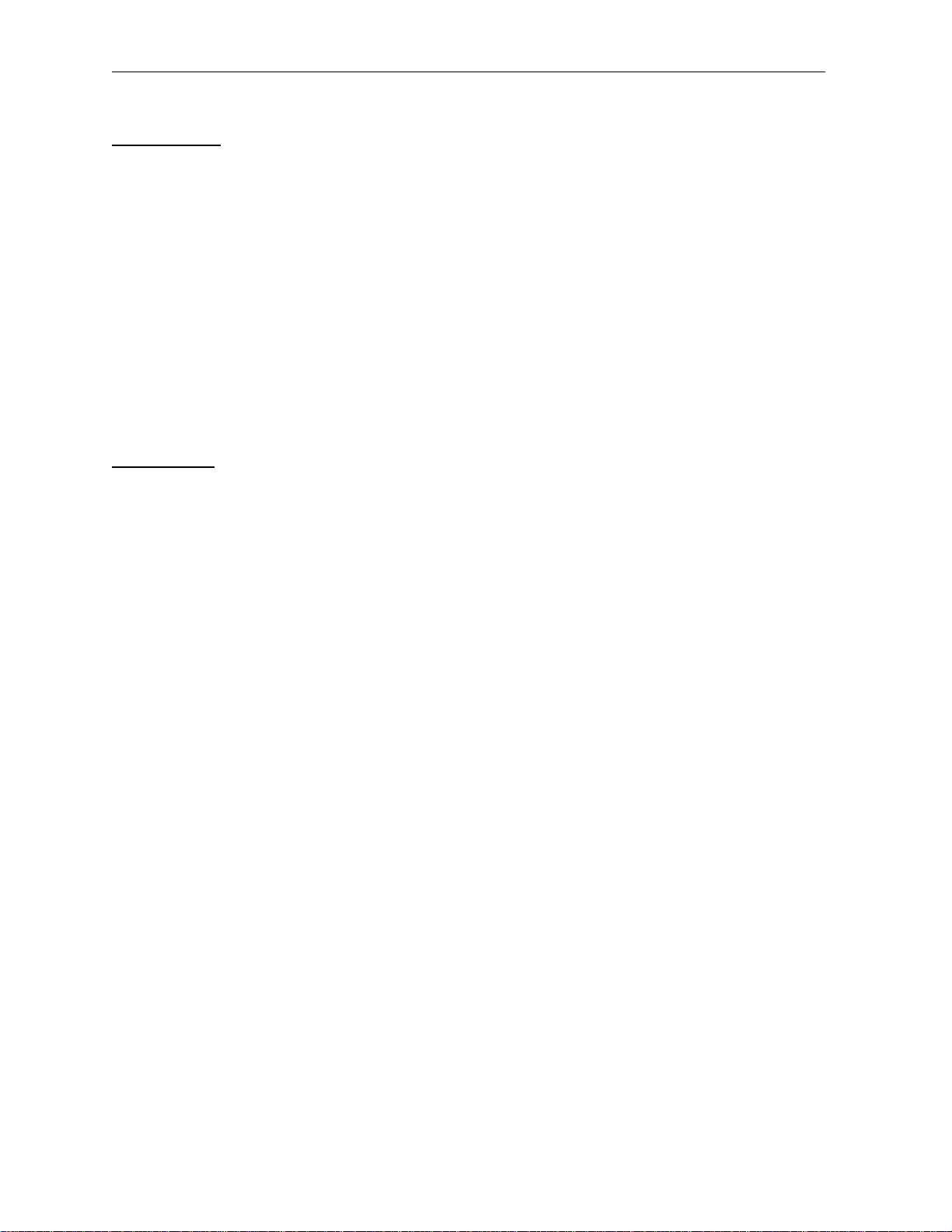

Table 1.2 - MiniOCS/MiniRCS Resource Limits

%S Registers 8

%SR Registers 192

%T Registers 2048

%M Registers 2048

%R Registers 2048

%K Registers 10

%D Registers 200

%I Registers 2048

%Q Registers 2048

%AI Registers 512

%AQ Registers 512

%IG Registers 0 / 64 / 0

%QG Registers 0 / 64 / 0

%AIG Registers 0 / 32 / 16

%AQG Regi sters 0 / 32 / 16

Network Port

Controllers Per Network 0 / 253 / 64

SmartStack I/O Modules 1 Slot

The faceplate is made of Marnot XL Polyester by Tekra. The material is

Keypad

Local MiniOCS Display / Remote Text Terminal for MiniRCS and MiniOCS

Display

Screen Memory 64K Items Per Text Table 20

User Screens 200

Data Fields Per

User Screen

resistant to most corrosive substances found in industrial environments. The

material also holds up well in most industrial conditions. If used outdoors, the

materials can yellow or crack.

2x20 Characters

(Text LCD)

10

None / CsCAN / DeviceNet

16 Keys (Membrane)

Text Tables 200

Ladder Code 64K

Page 13

CH.1 15 MAR 2003 PAGE 13

MAN0305-04

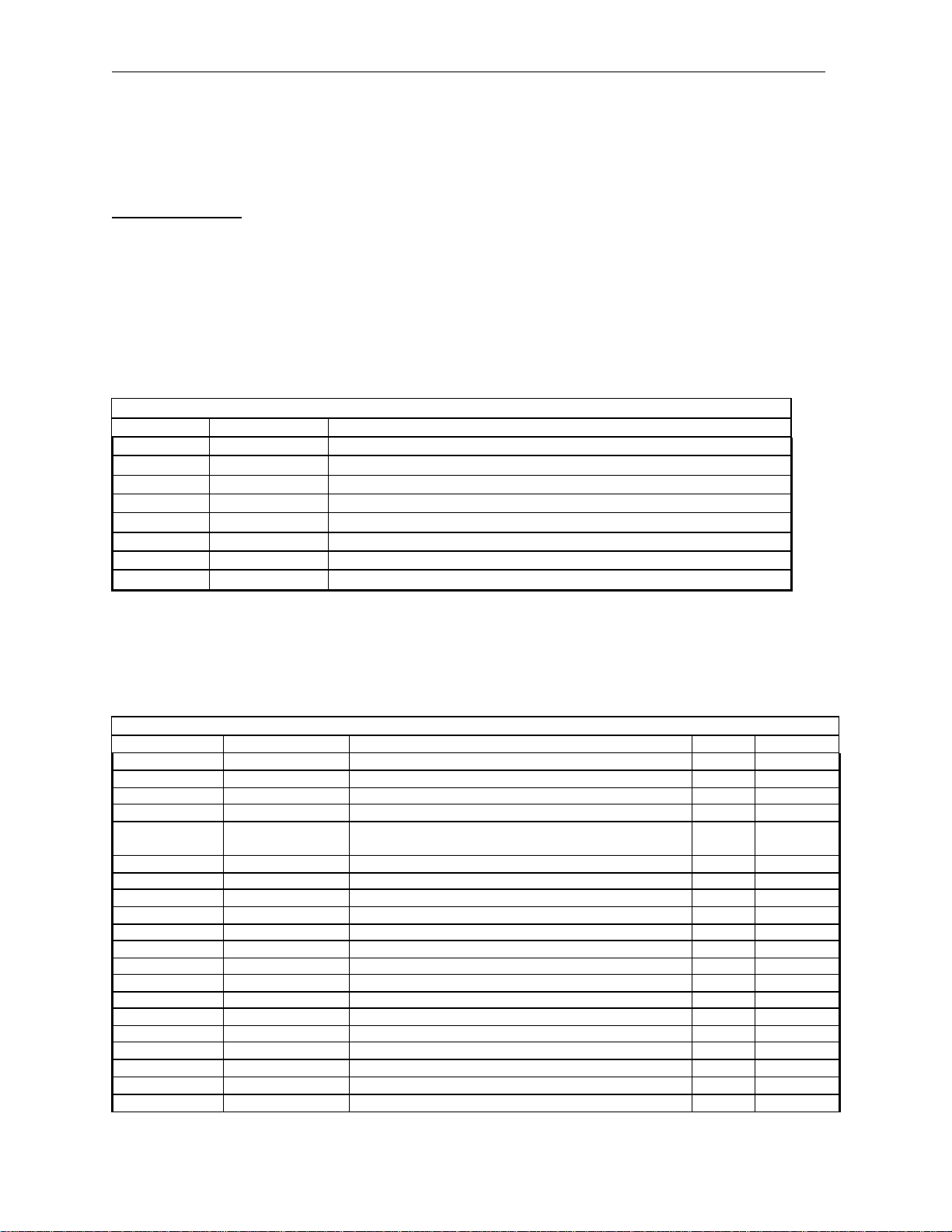

1.3.2 Resource Definitions

This section defines the resources listed in Table 1.2.

System Registers

System Registers (%S and %SR) are used to store general OCS or RCS status information. This

information is used internally, and is also available to the operator via the System Menu, using the Control

Station’s display and keypad. The System Registers are also available for User Screens and can be

accessed by Ladder Code.

a. %S Registers

%S Registers are 1-bit memory loc ations, containing system status information, implemented as shown in

Table 1.3:

Table 1.3 - %S Registers

Register Name Description

%S1 FST_SCN On during first scan after entering RUN mode

%S2 NET_OK On if Network is functioning properly

%S3 T_10MS On for 5 mS; Off for 5 mS

%S4 T_100MS On for 50 mS; Off for 50 mS

%S5 T_SEC On for 500 mS; Off for 500 mS

%S6 IO_OK On if SmartStack I/O is configured properly

%S7 ALW_ON Always On

%S8 ALW_OFF Always Off

b. %SR Registers

%SR Registers are 16-bit memory locations, containing system status information, implemented as

shown in Table 3. Note: Where 2 %SRs are combined to make a 32-bit value, the lower numbered %SR

is the low word, while the higher numbered %SR is the high word.

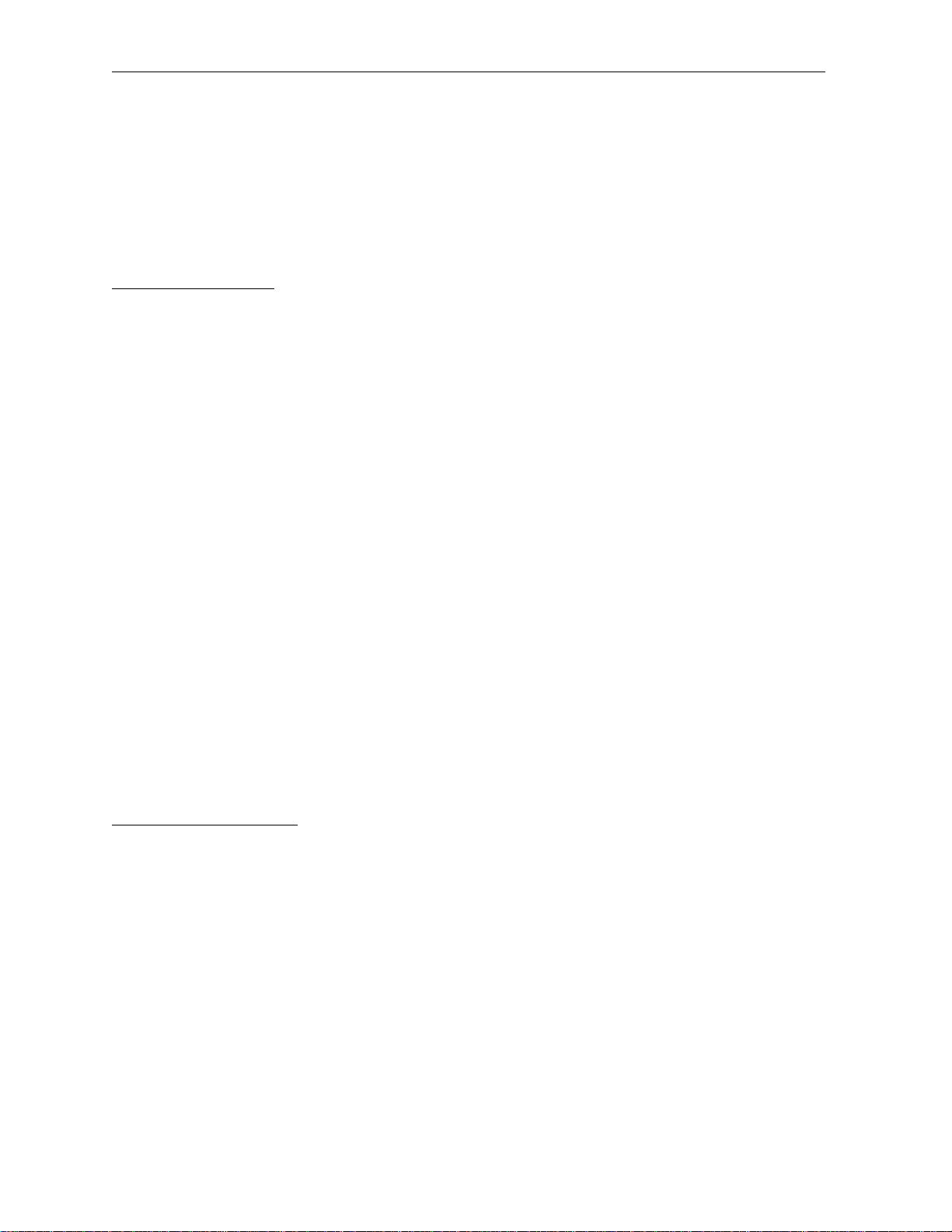

Table 1.4 - % SR Registers

Register Name Description Min Max

%SR1 USER_SCR Current User Screen Number (0=none) 0 200

%SR2 ALRM_SCR Current Alarm Screen Number (0=none) 0 200

%SR3 SYS_SCR Current System Screen Number (0=none) 0 11

%SR4 SELF_TEST Bit-Mapped Self -Test Result 0 65535

%SR5 CS_MODE

%SR6 SCAN_RATE Average Scan Rate (in tenths of mS) - 1000

%SR7 MIN_RATE Minimum Scan Rate (in tenths of mS) - 1000

%SR8 MAX_RATE Maximum Scan Rate (in tenths of mS) - 1000

%SR9-10 EDIT_BUF Data Field Edit Buffer 0 232-1

%SR11-12 LADDER_SIZE Ladder Code Size 2 64K

%SR13-14 UTXT_SIZE User Text Screen Table Size 4 64K

%SR15-16 Reserved - - %SR17-18 IO_SIZE I/O Configuration Table Size 16 64K

%SR19-20 NET_SIZE Network Configuration Table Size 34 32K

%SR21-22 SD_SIZE Security Data Table Size - %SR23 LADDER_CRC Ladder Code CRC 0 65535

%SR24 UTXT_CRC User Text Screen Table CRC 0 65535

%SR25 Reserved - - %SR26 IO_CRC I/O Configuration Table CRC 0 65535

%SR27 NET_CRC Network Configuration Table CRC 0 65535

Control Station Mode

(0=Idle, 1=Do I/O, 2=Run)

0 2

Page 14

PAGE 14 15 MAR 2003 CH.1

MAN305-04

Table 1.4 - % SR Registers

Register Name Description Min Max

%SR28 SD_CRC Security Data Table CRC 0 65535

%SR29 NET_ID

%SR30 NET_BAUD

%SR31 NET_MODE

%SR32 LCD_CONT LCD Display Contrast Setting 0 255

%SR33 FKEY_MODE Function Key Mode (0=Momentary; 1=Toggle) 0 1

%SR34 SERIAL_PROT

%SR35-36 SERIAL_NUM This Station’s 32-bit Serial Number 0 232-1

%SR37 MODEL_NUM This Station’s Binary Model Number 0 65535

%SR38 ENG_REV Main CPU Engine Firmware Rev Number x 100 0000 9999

%SR39 BIOS_REV Main CPU BIOS Firmware Rev Number x 100 0000 9999

%SR40 FPGA_REV FPGA Image Rev Number x 10 000 255

%SR41 LCD_COLS

%SR42 LCD_ROWS

%SR43 KEY_TYPE

%SR44 RTC_SEC Real-Time-Clock Second 0 59

%SR45 RTC_MIN Real-Time-Clock Minute 0 59

%SR46 RTC_HOUR Real-Time-Clock Hour 0 23

%SR47 RTC_DATE Real-Time-Clock Date 1 31

%SR48 RTC_MON Real-Time-Clock Month 1 12

%SR49 RTC_YEAR Real-Time-Clock Year 1996 2095

%SR50 RTC_DAY Real-Time-Clock Day (1=Sunday) 1 7

%SR51 NET_CNT Network Error Count 0 65535

%SR52 WDOG_CNT Watchdog-Tripped Error Count 0 65535

%SR53-54 BAD_LADDER Bad Ladder Code Error Index 0 65534

%SR55 F_SELF_TEST Filtered Bit -Mapped Self-Test Result 0 65535

%SR56 LAST_KEY Key Code of Last Key Press or Release 0 255

%SR57 BAK_LITE LCD Backlight On/Off Switch (0=Off; 1=On) 0 1

%SR58 USER_LEDS User LED Control / Status 0 65535

%SR59 S_ENG_REV Slave CPU Engine Firmware Rev Number x 100 0000 9999

%SR60 S_BIOS_REV Slave CPU BIOS Firmware Rev Number x 100 0000 9999

%SR61 NUM_IDS This Station’s Number of Network IDs (CsCAN) 1 253

This Station’s Number of Network IDs (DeviceNet) 1 1

%SR62-192 Reserved - - -

This Station’s Primary Network ID (CsCAN) 1 253

This Station’s Primary Network ID (DeviceNet) 0 63

Network Baud Rate (CsCAN)

(0=125KB; 1=250KB; 2=500KB; 3=1MB)

Network Baud Rate (DeviceNet)

(0=125KB; 1=250KB; 2=500KB)

Network Mode

(0=Network Not Required; 1=Network Required;

2=Reserved; 3=Network Required and Optimized)

RS232 Serial Protocol Mode

(0=Firmware Update (RISM); 1=CsCAN; 2=Generic

(Ladder- Controlled); 3=Modbus RTU; 4=Modbus

ASCII)

LCD Text Display Number of Columns 20 20

LCD Graphics Display Number of Columns 240 240

LCD Text Display Number of Rows 2 4

LCD Graphics Display Number of Rows 128 128

Keypad Type

(0=16 Keys; 1=17 Keys; 2=32 Keys; 3=36 Keys)

0 3

0 2

0 3

0 4

0 3

Page 15

CH.1 15 MAR 2003 PAGE 15

MAN0305-04

User Registers

User Registers (%T, %M and %R) are used to store application-specific Mini data. This data can be

accessed via User Screens and/or by Ladder Code.

a. %T Register

A %T Register is a non -retentive 1-bit memory location, used to store application-specific state

information.

b. %M Registers

A %M Register is a retentive 1-bit memory location, used to store application-specific state information.

c. %R Registers

A %R Register is a retentive 16 -bit memory location, used to store application-specific values.

HMI Registers

HMI Registers (%K and %D) give the user access to the OCS or RCS keypad and display.

The MiniOCS has a membrane keypad and text-based LCD display, allowing the operator to enter and

display general and application -specific information. This same information can be entered and displayed

for the MiniRCS (and MiniOCS if desired) via a remote PC using Cscape’s Remote Display Terminal

function.

a. %K Registers

A %K Register is a non -retentive 1-bit memory location (contact), used to store the state of a function key

on the Control Station’s keypad. If the function keys are set for momentary mode, a function key’s

associated %K register will be ON as long as the function key is pressed. If the function keys are set for

toggle mode, a function key’s associated %K register will toggle each time the function key is pressed.

b. %D Registers

A %D Register is a non-retentive 1-bit memory location (coil), which can be turned ON by Ladder Code to

cause the corresponding User or Alarm Screen to be displayed.

c. User Screens

A User Screen is a combination of fixed text or graphics, along with variable Data Fields (called Graphics

Objects in the MINIOCS), which together fill the LCD display screen. These screens are defined via

Cscape di alogs and are then downloaded and stored into the Control Station’s Flash memory. User

Screens can be selected for display by operator entries on the keypad, or by Ladder Code.

d. Data Fields

A Data Field is an area on a User Screen where variable data is displayed and edited. The source data

for a Data Field can be any of the Control Station’s Register resources as defined above. The field size

and display format is programmable via Cscape dialogs.

Page 16

PAGE 16 15 MAR 2003 CH.1

MAN305-04

e. Text Tables

A Text Table is a list of Text Items, which can be used in a Data Field, to display descriptive words and

phrases to describe the value of a Register, instead of displaying numeric values. A simple example of

this, would allow the strings “OFF” and “ON” to be displayed, instead of 0 and 1, to describe the state of

the %I4 digital input. The maximum number of Text Tables and Text Items per Text Table is shown in

Table 1, but the number can be further limited by overall User Screen memory usage.

Physical I/O Registers

Physical I/O Registers (%I, %Q, %AI and %AQ) give the user access to the Physical I/O Module

data. This data can be accessed via User Screens and/or by Ladder Code.

a. %I Registers

A %I Register is a 1-bit memory location, which is normally used to store the state of one of the digital

inputs associated with a Physical I/O module. When used in this way, %I registers are non -retentive. All

extra %I registers, which are not associated with physical inputs, are retentive, and can be used just like

%M registers.

b. %Q Registers

A %Q Register is a non-retentive 1-bit memory location, which is normally used to store the state of one

of the digital outputs associated with a Physical I/O module.

c. %AI Registers

A %AI Register is a 16 -bit memory location, which is normally used to store the value of one of analog

inputs associated with a Physical I/O module. When used in this way, %AI registers are non -retentive.

All extra %AI registers, which are not associated with physical inputs, are retentive, and can be used just

like %R registers.

d. %AQ Registers

A %AQ Register is a non-retentive 16-bit memory location, which is normally used to store the value of

one of the analog outputs associated with a Physical I/O module.

Global Data I/O Registers

Global Data I/O Registers (%IG, %QG, %AIG and %AQG) give the user access to the Network Port’s

Global I/O data. This data can be accessed via User Screens and/or by Ladder Code.

a. %IG Registers

A %IG Register is a retentive 1-bit memory location, which is normally used to store a global digital state

obtained from another Control Station on the network.

b. %QG Registers

A %QG Register is a retentive 1-bit memory location, which is normally used to store a digital state to be

sent as global data to the other Control Stations on the network.

Page 17

CH.1 15 MAR 2003 PAGE 17

MAN0305-04

c. %AIG Registers

A %AIG Register is a retentive 16-bit memory location, which is normally used to store a global analog

value obtained from another Control Station on the network.

d. %AQG Registers

A %AQG Register is a retentive 16 -bit memory location, which is normally used to store an analog value

to be sent as global data to the other Control Stations on the network.

e. Network Port

The CsCAN Network is based on the Bosch Control Area Network (CAN), and implements the CsCAN

Protocol which is designed to take maximum advantage of the global data broadcasting capability of

CAN. Using this network protocol, up to 64 Control Stations can be linked without repeaters, and up to

253 Control Stations can be linked by using 3 repeaters. For more information regarding CsCAN

Protocol, refer to the CsCAN Protocol Specification document.

DeviceNet is an “open” higher layer protocol, which is supported by products from multiple vendors. In an

OCS or RCS, DeviceNet can be loaded as a replacement for the CsCAN Protocol Message Layer, and as

a result, the OCS or RCS becomes a DeviceNet Slave device. Note that the Mini still implements the

CsCAN Protocol Command Layer with respect to the RS -232 programming port. For more information

regarding DeviceNet Protocol, contact the DeviceNet governing body (ODVA).

Ladder Code

The Ladder Code, stores ladder instructions generated by Cscape. This Ladder Code is downloaded and

stored into the Control Station’s Flash memory, to be executed each controller scan, when the controller

is in RUN mode.

1.4 MiniOCS / MiniRCS Models

Because there are several models of MiniOCS / MiniRCS models available, the MiniOCS / MiniRCS can

be used in a wide range of applications. The MiniOCS consists of an Operator Control Station, and the

MiniRCS consists of a Remote Control Station. Each model comes equipped with one factory installed

I/O board. The models vary according to the type of I/O board installed and are available in non-network

and network versions. Network versions contain an additional connector allowin g connectivity to CAN

networks. Refer to Additional References on page 18 to locate model-specific information for each Mini.

Page 18

PAGE 18 15 MAR 2003 CH.1

MAN305-04

1.5 Additional References

For further information regarding products covered in this manual, refer to the following references:

a. Mini I/O (MAN0581) – Contains a collection of individual data sheets covering model-specific

information.

b. DeviceNet Implementation Using Control Station Modules (SUP0326) - Covers the

implementation of Control Station products in a DeviceNet network.

c. Cscape Reference Manual (MAN0313) – Contains topics specifically selected to assist you

through the programming process.

1.6 Technical Support

For user manual updates, contact Technical Services at the following locations:

North America:

(317) 916 -4274

www.heapg.com

Europe:

(+) 353-21-4321-266

www.horner-apg.com

Page 19

CH.2 15 MAR 2003 PAGE 19

3 3/16

MAN0305-04

CHAPTER 2: INSTALLATION

2.1 MiniOCS Mounting Requirements

2.1.1 MiniOCS Mounting Procedures (Installed in a Panel Door)

The MiniOCS is designed for permanent panel mounting. To install the MiniOCS, follow the instructions

below.

1. Prior to mounting the MiniOCS, observe requirements for the panel layout design and adequate

clearances. A checklist is provided on page 25.

2. Cut the host panel as described in the Figure 2.1 - Figure 2.6.

Warning: Make sure the power and network connectors are removed from the MiniOCS.

3. Insert the MiniOCS through the panel cutout (from the front). The gasket material needs to lie

between the host panel and the MiniOCS panel.

4. Install and tighten the mounting clips (provided with the MiniOCS) until the gasket material forms a

tight seal. (See Figure 2.7.)

Caution: Do not over-tighten. Over-tightening can potentially damage the case.

5. Connect the communications, programming, and power cables to the MiniOCS ports using the

provided connectors.

6. Begin configuration procedures for the MiniOCS models.

2.1.2 MiniOCS Dimensions and Panel Cut -outs

80.96mm

Programming Port

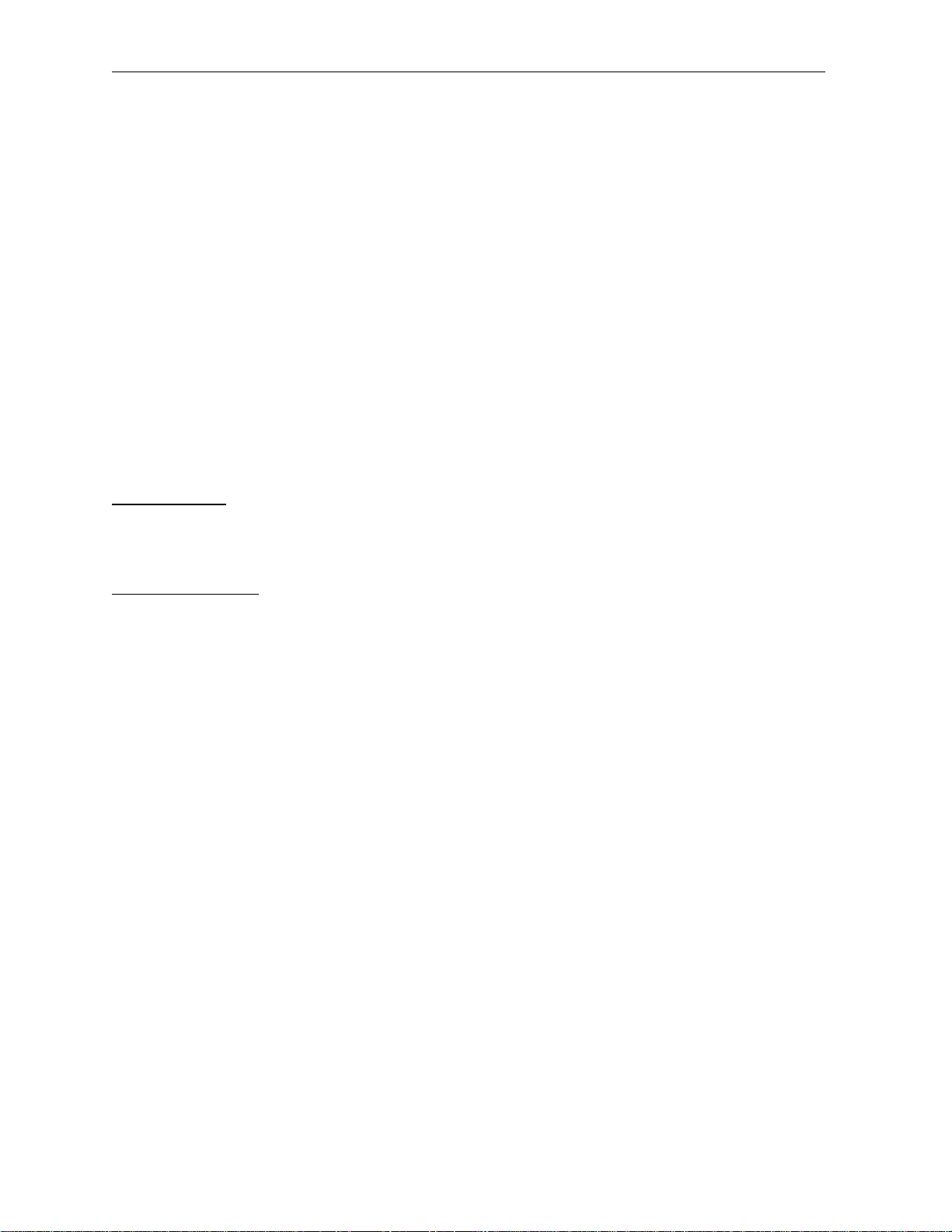

Figure 2.1 –Right-end View Network Model Figure 2.2 - Left-end View Network Model

Network Port

Power Port

Page 20

PAGE 20 15 MAR 2003 CH.2

3 3/16

2 1/4

5 13/16

MAN0305-04

Programming Port

80.96mm

Power Port

Figure 2.3 - Right -end View (Non-Network Model) Figure 2.4 - Left-end View (Non-Network Model)

I/O Port

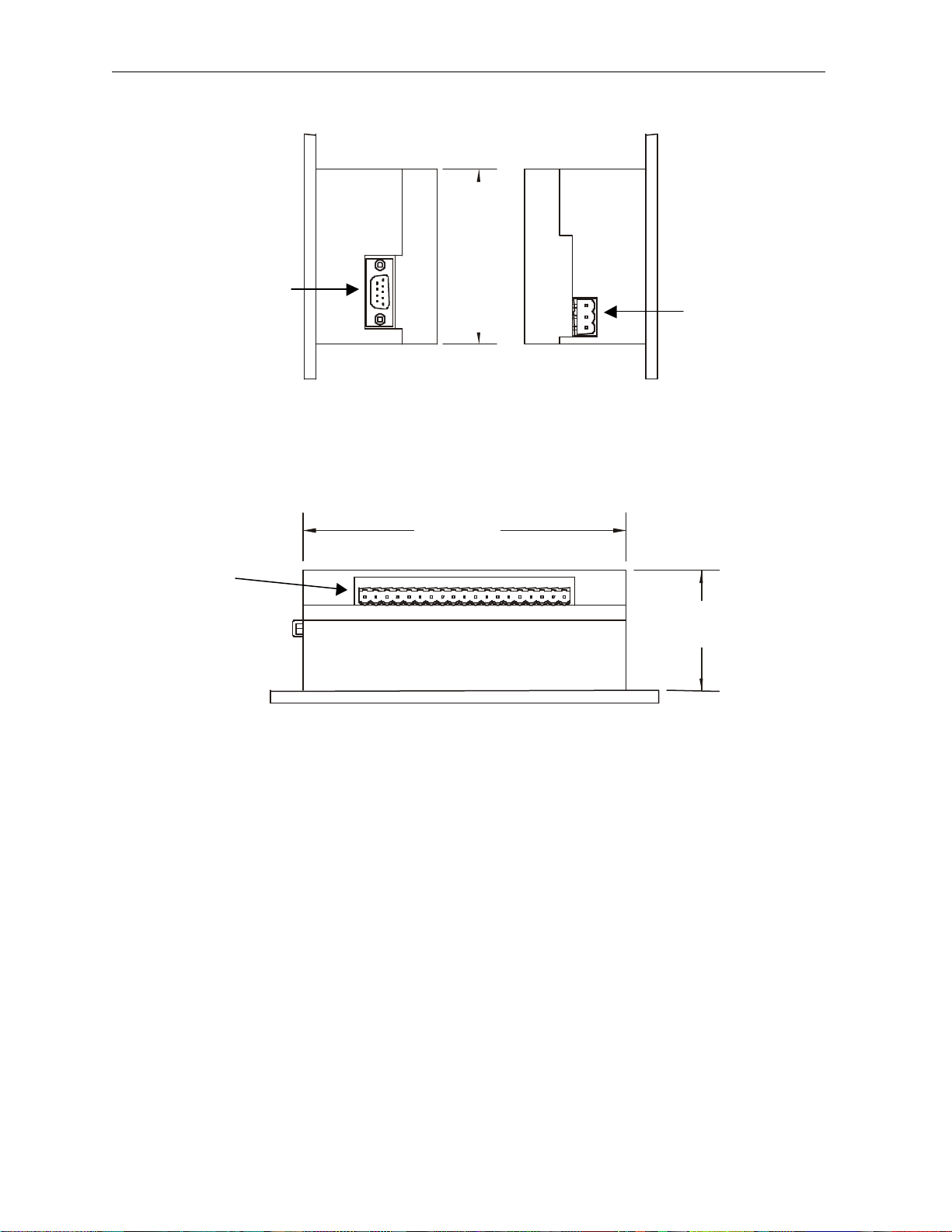

147.64mm

57.15mm

Figure 2.5 – Bottom View

Page 21

CH.2 15 MAR 2003 PAGE 21

3 11/32

6

MAN0305-04

84.93mm

152.40

Figure 2.6 – Panel Cut-out (MiniOCS)

Figure 2.7 – MiniOCS Mounted in Panel Box using Mounting Clips.

2.1.3 MiniOCS Mounting Orientation

The bases of the MiniOCS model needs to be mounted with the proper orientation.

Figure 2.8 - Orientation of MiniOCS (Shown in Panel Box)

NOTE: There are NO orientation restrictions on the MiniOCS. However, the above orientation provides

for optimum readability of the screen and ease of use of the keypad.

Page 22

PAGE 22 15 MAR 2003 CH.2

001RCS001

MOUNTING HOLES FOR

MAN0305-04

2.2 MiniRCS Mounting Requirements

2.2.1 MiniRCS Mounting Procedures (Installed in a Panel Box)

The MiniRCS is designed for permanent installation in a panel box. To install the MiniRCS in a panel

box, use the instructions that follow:

1. Prior to mounting the MiniRCS, observe requir ements for the panel layout design and adequate

clearances. A checklist is provided on page 25.

2. Drill holes as described in the Figure 2.9.

Warning: Make sure the power and network connectors are removed from the MiniRCS.

3. Install and tighten washers and nuts. Do not over -tighten.

4. Connect the communications and power cables to the MiniRCS ports using the provided connectors.

5. Begin configuration procedures for the MiniRCS models.

2.2.2 MiniRCS Dimensions and Panel Cut -outs

#6 OR M3.5 HARDWARE

4 PLCS.

4.13

(104.78mm)

3.75

(95.25mm)

0.19

[4.78mm]

0.91 [23.19mm] 4.00 [101.60mm]

1.83 [46.48mm]

5.83 [147.98mm]

Figure 2.9 – MiniRCS Dimensions / Mounting Holes and MiniRCS Side View

Page 23

CH.2 15 MAR 2003 PAGE 23

Note: Consider the length

Ground

Warning: It is important to follow the requirements of the panel manufacturer and to follow

MAN0305-04

2.2.3 MiniRCS Mounting Orientation

There are NO orientation restrictions on the MiniRCS. However, the orientation shown provides for the

ease of use of the keypad.

2.3 Factors Affecting Panel Layout Design and Clearances

The designer of a panel layout needs to assess the requirements of a particular system and to consider

the following des ign factors . A convenient checklist is provided on page 25.

of the Ground Screw extension

when determining clearances.

applicable electrical codes and standards.

strap

Figure 2.10 – Back view of MiniOCS (Shown On Panel Door)

Page 24

PAGE 24 15 MAR 2003 CH.2

Warning: Be sure to meet the ground requirements of the panel manufacturer and also meet

Warning: To provide maximum noise immunity and to insure minimum EMI radiation, the V-

rth ground at the power supply.

The user must ensure that the power supply selected is compatible with this method

MAN0305-04

a. Clearance / Adequate Space

Install devices to allow sufficient clearance to open and close the panel door. Note that the MiniOCS is

mounted on a panel door and the MiniRCS is mounted in a panel box.

Table 2.1 – Minimum Clearance Requirements for Panel Box and Door

Minimum Distance between base of device and sides of

cabinet

Minimum Distance between base of device and wiring ducts

If more than one device installed in panel box (or on door):

Minimum Distance between bases of each device

When door is closed:

Minimum distance between device and closed door

(Be sure to allow enough depth for MiniOCS / MiniRCS Model

and Ground Screw Extension.)

b. Grounding

Panel box : The panel box needs to be properly connected to earth ground to provide a good common

ground reference.

Panel door: Tie a low impedance ground strap between the panel box and the panel door to ensure that

they have the same ground reference (Figure 2.10).

Devices in panel box and on the panel box door:

Use the mounting hardware provided with the device, which includes mounting clips.

c. Temperature / Ventilation

Ensure that the panel layout design allows for adequate ventilation and maintains the specified ambient

temperature range. Consider the impact on the design of the panel layout if operating at the extreme

ends of the ambient temperature range. For example, if it is determined that a cooling device is required,

allow adequate space and clearances for the device in the panel box or on the panel door.

applicable electrical codes and standards.

signal (DC power return) need to be connected to ea

of grounding.

2 inches (50.80mm)

1.5 inches (38.10mm)

4 inches between bases of each

device (101.60mm)

2 inches (50.80mm)

Page 25

CH.2 15 MAR 2003 PAGE 25

Warning: To provide maximum noise immunity and to insure minimum EMI radiation, the V-

MAN0305-04

d. Orientation

Observe guidelines for proper orientation of the bases when mounting the MiniOCS / MiniRCS (page 25).

Proper orientation helps to ensure a good connection when MiniOCS / MiniRCS models are installed into

the devices.

e. Noise

Consider the impact on the panel layout design and clearance requirements if noise supression devices

are needed. Be sure to maintain an adequate distance between the MiniOCS / MiniRCS and noisy

devices such as relays, motor starters, etc.

Note: Do not route power and signal wires in the same conduit.

2.3.1 Panel Layout Design and Clearance Checklist:

The following list provides highlights of panel layout design factors.

____Meets the electrical code and applicable standards for proper grounding, etc.?

____Meets the panel manufacturer’s requirements for grounding, etc.?

____Is the panel box properly connected to earth ground? Is the panel door properly grounded? Has the

appropriate procedure been followed to properly ground the devices in the panel box and on the

panel door? (See page 25.)

____Are minimum clearance requirements met? (See Table 2.1.) Can the panel door be easily opened

and closed? Is there adequate space between device bases as well as the sides of the panel and

wiring ducts?

____Is the panel box deep enough to accommodate the MiniOCS / MiniRCS. (Be sure to consider the

Ground Screw extension.)

____Are the device bases oriented correctly? (See page 25.) The MiniOCS / MiniRCS devices are

mounted on the door of a panel box.

____Is there adequate ventilation? Is the ambient temperature range maintained? Are cooling or heating

devices required?

____Are noise suppression devices or isolation transformers be required? Is there adequate distance

between the base of the MiniOCS / MiniRCS and noisy devices such as relays or motor starters?

Ensure that power and signal wires are not routed in the same conduit.

____Are there other requirements that impact the particular system, which need to be considered?

signal (DC power return) need to be connected to earth ground at the power supply. The user must

ensure that the power supply selected is compatible with this method of grounding.

Page 26

PAGE 26 15 MAR 2003 CH.2

Warning: To provide maximum noise immunity and to insure minimum EMI radiation, the V-signal

DC Power

MINI

Frame

MAN0305-04

2.4 Ports, Connectors, and Wiring

2.4.1 Power, Network, and Programming Ports

The MiniOCS / MiniRCS Power, Network, and Programming Ports are shown in Figure 2.11 - Figure 2.12.

for both the network and non-network versions of the MiniOCS / MiniRCS. The MiniOCS / MiniRCS I/O

Module receptacle is located on the bottom.

2.4.2 Primary Power Port

Table 2.2 – Primary Power Port Pins

Pin Signal Description

1

Frame Ground

2 V+ Input power supply voltage

3 V- Input power supply ground

PIN 1

PIN 2

PIN 3

PIN 1

PIN 2

PIN 3

Figure 2.11 - Power Connector Figure 2.12 - As viewed looking at

(Primary Power Port) the Mini

(Front and Side Views Shown)

Note: Power Supply Voltage Range is from 10 -30 VDC.

(DC power return) need to be connected to earth ground at the power supply. The user must ensure

that the power supply selected is compatible with this method of grounding.

Supply

+ -

(Earth)

Ground

Connect DC V - to earth ground at the power supply.

Figure 2.13 - Grounding

Page 27

CH.2 15 MAR 2003 PAGE 27

MAN0305-04

2.3.3 CAN Network / DeviceNet Network Port and Wiring

Table 2.3 – CAN Port Pins

Pin Signal Description

1 V- Power 2 CN_L Signal 3 SHLD Shield

4 CN_H Signal +

5 V+ Power +

Figure 2.14 – Network Connector Figure 2.15 – As viewed looking

(CAN Port) at the Mini

1 2 3 4 5

V+

CN_H

SHLD

CN_L

V-

1 2 3 4 5

V-

SHLD

CN_L

V+

CN_H

Page 28

PAGE 28 15 MAR 2003 CH.2

12-25VDC

MAN0305-04

V-

CN_L

SHIELD

CN_H

V+

V-

CN_L

SHIELD

CN_H

V+

V-

CN_L

SHIELD

CN_H

V+

V-

CN_L

SHIELD

CN_H

121

Ω

121

Ω

+

12-25VDC

-

CN_LV-SHIELD121Ω

V+

CN_H

CN_LV-SHIELD

V+

CN_H

CN_LV-SHIELD

V+

CN_H

CN_LV-SHIELD

BLU

BLK

RED

RED

WHT

SHIELD

-

+

BLK

BLK

BLU

BLU

WHT

WHT

RED

RED

SHIELD

BLK

BLK

BLU

BLU

WHT

WHT

RED

RED

SHIELD

121Ω

BLU

BLK

Figure 2.16 – CAN Wiring

Note: To optimize CAN network reliability in electrically noisy environments, the CAN power

supply needs to be isolated (dedicated) from the primary power.

a. CAN Wiring Rul es (See Figure 2.16.)

1. Wire the CAN network in a daisy-chained fashion such that there are exactly two physical end -

points on the network.

2. The two nodes at the physical end -points need to have 121 ohm 1% terminating resistors

connected across the CN_L and CN_H terminals.

3. Use data conductors (CN_L and CN_H) that are 24 AWG shielded twisted pair for “thin cable” and

22 AWG shielded twisted pair for “thick cable.” They must also have 120-ohm characteristic

impedance. In typical industrial environments, use a Belden wire #3084A (“thin”). Use #3082A

(“thick”) for network cable lengths greater than 100 meters environments where noise is a concern.

Place data conductors (CN_L and CN_H) into a twisted pair together.

4. Use powe r conductors (V- and V+) that are 18 AWG twisted-pair for “thin cable” and 15 AWG

twisted-pair for “thick cable.” Place power conductors (V - and V+) into a twisted pair together.

5. If local codes require the local CAN power supply to be earth grounded, connect the V- power

conductor to a good earth ground at one place only on the network, preferably at a physical

endpoint. If multiple power supplies are used, only one power supply must have V- connected to

earth ground. The remaining power supplies need to be isolated.

V+

V+

CN_H

RED

WHT

Page 29

CH.2 15 MAR 2003 PAGE 29

MAN0305-04

6. For a section of cable between two nodes, the cable shield is connected to the cable shield input at

one end of the cable only.

7. A CAN network (without repeaters) is limited to 64 nodes (with 63 cable segments) with a maximum

combined cable length of 1500 ft. at 125KBaud.

8. Up to four CAN network segments, which adhere to the above rules, may be connected together

using three CAN repeaters. In this manner, a CAN network may be extended to 253 nodes with a

total cable distance of 6000 ft. at 125KBaud.

b. CsCAN or DeviceNet Cable

The 5-wire, multi-conductor copper cable used in CsCAN or DeviceNet network include:

1. Two wires used as a transmission line for network communications.

2. Two wires used to transmit network power.

3. One conductor used as an electromagnetic shield.

Cabling is available in a variety of current-carrying capacities. On a CsCAN or DeviceNet fieldbus, every

device must, at least, power its network transceivers from the network power supply. Some devices draw

all of their power from the network supply.

In CsCAN or DeviceNet, thick and thin cable is used as indicated:

1. Thick cable: Use for long distances and more power. Usually used for Trunk cable.

2. Thin cable: Use for shorter distances. Usually used for drop cables or where cable flexibility is

needed.

Table 2.4 - CsCAN / DeviceNet Cable Specifications

Thick Cable –

general specifications

(e.g., Belden 3082A)

Thin Cable –

general specifications

(e.g., Belden 3084A)

Network Topology Bus with limited branching (truckline / dropline)

Redundancy Not Supported

Network Power for Node

devices

Allowed Nodes (Bridging

excluded)

Data Packet Size 0-8 bytes with allowance for message fragmentation

Duplicate Address Detection Addresses verified at power-up

Error Detection / Correction CRC – retransmission of message if validity not acknowledged by

Two twisted shielded pairs –Common axis with drain wire in center.

One signal pair (#18), blue/white; One power power pair (#15) black/red.

Separate aluminized mylar shields around power pair and signal pair.

Overall foil/braid shield with drain wire (#18), bare*. High Speed (Vp=75% min),

low loss, low distortion, data pair (to keep propagation delays to a minimum).

8 amp maximum current capacity. PVC insulation on power pair. Industrial

temperature range. High flexibility.

Two twisted shielded pairs –Common axis with drain wire in center.

One signal pair (#24), blue/white; One power power pair (#22) black/red.

Separate aluminized mylar shields around power pair and signal pair.

Overall foil/braid shield with drain wire (#22), bare*. High Speed (Vp=75% min),

low loss, low distortion, data pair (to keep propagation delays to a minimum).

3 amp maximum current capacity. PVC insulation on pow er pair. Industrial

temperature range. High flexibility

Nominal 24 VDC ±4%

64 nodes

recipient.

* The drain wire connects shields within the cable and serves as a means to terminate the shield into the

connector.

Page 30

PAGE 30 15 MAR 2003 CH.2

MAN0305-04

c. Bus Length

Several factors affect the maximum length of the bus including the accumulated length of drop lines,

cable type, transfer rate and the number of drop lines. Although a branch is limited to one network per

drop, it can have multiple ports. A branch can not exceed 6 meters.

Table 2.5 - CAN Network Baudrate vs. Total Cable Length

Note: The following values apply to both CsCAN or DeviceNetworks except as indicated.

Thick Cable: Network Data Rate Maximum Total Cable Length

1Mbit / sec. (Does not apply to DeviceNet.) 40m (131 feet)

500Kbit / sec. 100m (328 feet)

250Kbit / sec. 200m (656 feet)

125Kbit / sec. 500m (1,640 feet)

Thin Cable Maximum Total Cable Length

Maximum bus length is independent of network data rate. Maximum bus length is 100m.

Note: Network baud rates above 250Kbit/sec are not recommended for the MiniOCS /

MiniRCS . The potential for a high rate of network messages can cause an unacceptable

increase in the ladder scan rate.

d. Bus Power and Grounding

When using CsCAN or DeviceNet:

1. A power supply of 24VDC (±4%) at 16A maximum is required for use in a CsCAN / DeviceNet network

2. With thick cable, a single network segment can have a maximum of 8A. To do this, the power supply

needs to be located in the center of two network segments.

3. Thin cable has maximum of 3A.

4. To ground the cable shield, connect to pin 3 as shown in Figure 2.16.

5. If local codes require the local CAN power supply to be earth grounded, connect the V- power

conductor to a good earth ground at one place only on the network, preferably at a physical endpoint.

If multiple power supplies are used, only one power supply must have V- connected to earth ground.

The remaining power supplies need to be isolated.

2.3.4 RS-232 Programming Port and Wiring

Table 2.6 – RS -232 Port Pins

Pin Signal Description Direction

1 DCD Always high Out

2 RXD Received Data Out

3 TXD Transmitted Data In

4 DTR Data Terminal Ready In

5 GND Ground 6 DSR Data Set Ready Out

7 RTS Request to Send In

8 CTS Clear to Send Out

9 RI Ring Indicate Out

Pin 1

Pin 9

Figure 2.17 – RS -232 Port

Page 31

CH.2 15 MAR 2003 PAGE 31

15.24 METERS MAX

Telephone

Telephone

MAN0305-04

a. RS-232 Communications Wiring

The MiniOCS / MiniRCS features an RS -232 port (Programming/Debug) for connection to a personal

computer. This port is used for the purposes of MiniOCS / MiniRCS programming, configuring,

monitoring, and debugging. This port can also be used for general ladder logic controlled serial

communications to printers, modems, terminals, etc. When ladder has control of this port, it is not

available for programming or debugging. The wiring diagram for the RS -232 ports is shown in Figure

2.18Figure 2.18. For connection between the MiniOCS / MiniRCS and the PC, the use of a shielded,

multiple conductor wire with a maximum length of 15.24 meters (50 feet) enables proper performance.

Note: A shorter cable can be required when used for high-speed MiniOCS / MiniRCS firmware updating.

OCS RS -232

DCD 1

RXD 2

TXD 3

DTR 4

GND 5

DSR 6

RTS 7

CTS 8

RI 9

DB9

MALE

SHIELDED MULTI CONDUCTOR

(50 FEET MAX)

9-PIN PC COM

1 DCD

2 RXD

3 TXD

4 DTR

5 GND

6 DSR

7 RTS

8 CTS

9 RI

DB9

FEMALE

Figure 2.18 – MiniOCS / RCS to PC Wiring

2.3.5 Modem Setup

A modem can be used for remote communications between a computer (using Cscape Software) and the

MiniOCS / MiniRCS. The modem must operate at 9600 baud or higher.

PC

Modem

Modem

System

System

Figure 2.19 – Modem Setup

Mini

Page 32

PAGE 32 15 MAR 2003 CH.2

Warning: Damage can result if the CD and RI lines are connected to each other or to any other signal

Warning: To connect a modem to the MiniOCS / MiniRCS the controller to modem cable must be

9-PIN 25- PIN

MAN0305-04

a. Setup

Setup the modems to match the default serial port characteristics of the MiniOCS / MiniRCS.

9600 baud

8 data bits

No parity

1 stop bit

disable error checking

disable compression

b. Cable Wiring

Note: If the mo dem has a DB25 connector, a 9-to-25-pin adapter may need to be supplied.

The grayed connections are used only if hardware handshaking between the controller and modem

is required.

The wire type used in not overly critical except where the length of the cable must be between 30 and 50

feet (10 to 15 meters). In all cases, the cable must be shielded multi-conductor with conductors of at

least 20 gauge. The length of the cable must be as short as possible, and in no case, longer than 50 feet

(15 meters).

The modem must be located as close as possible to the OCS, preferably less than one meter. However,

EIA-232 specifications allow for cable runs up to 50 feet (15 meters). If cable lengths longer than 30 feet

(10 meters) are required, a special low capacitance cable must be used.

on the connector or through the cable to the other unit.

constructed or purchased. Using a Null Modem cable can cause damage to the MiniOCS / MiniRCS,

modem or both.

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

N/C

N/C

N/C N/C

Figure 2.20 – Modem Wiring

MODEM OCS

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

Page 33

CH.2 15 MAR 2003 PAGE 33

MAN0305-04

c. Recommended Modem

Selection of a telephone modem for use with the OCS is highly dependent on environment . For a

relatively benign, low-noise environment, an off-the-shelf external modem like a U.S. Robotics Sportster

Modem can work well. For a more industrial environment, however, it is appropriate to use a telephone

modem designed for that environment. Manufacturers such as Datalinc and Sixnet have models, which

have been known to work in more harsh environments, at a higher cost. If a modem is used, which is not

appropriate for the environment, there may be little that can be done to correct the situation other than

change to a more appropriate model.

For detailed inform ation regarding the use of modems with Control Station Products, contact Technical

Support. (See page 18.) You can also find specific application information (cabling, modem commands,

etc.) in the Cscape Help file as well.

2.5 Selecting DeviceNet Network (Firmware Update Wizard)

To use the OCS in a DeviceNet network, use Cscape’s Firmware Update Wizard. Select File, Firmware

Update Wizard from the pull-down menu. The following screen appears.

Figure 2.21 – Using Firmware Update Wizard

Select the product type (MiniOCS or MiniRCS) using the pull-down menu and click on the circle next to

the desired network. Press OK. On the next screen, press Send. Firmware is now updated.

2.6 MiniOCS / MiniRCS LEDs

The following LED information is provided for the MiniOCS / MiniRCS.

Table 2.7 - LEDs

LED MiniOCS / MiniRCS

RUN

OK

• OFF indicates OCS is in IDLE/STOP mode.

• Flashing indicates DO / IO mode or RUN with no ladder program.

• ON indicates ladder code running.

• OFF indicates one or more self -tests failed.

• ON indicates all self -tests passed.

• FLASHING indicates all self -tests passed and one or more I/O points is

currently forced.

Page 34

PAGE 34 15 MAR 2003 CH.2

001RCS002

MAN0305-04

MiniOCS LED status is indicated on the physical unit as shown in the following figure.

OK

RUN

Esc

1 2 3 4 5

QZ ABC DEF GHI JKL

F1 F2

6

F6

7

MNO PRS TUV WXY

F7 F8 F9 F 10

F3

8 9 0

F4 F5

+/-

System

Enter

Figure 2.22 – MiniOCS LEDs

The MiniRCS LEDs are also viewed by looking at the physical unit. They are not viewable from a remote

screen.

mini

OCS/RCS

OPERATOR CONTROL STATION

COM

PORT

OK

RUN

SHIELD

NETWORK

V+

CAN_H

CAN_L

V-

INPUT

POWER

9-30VDC

Figure 2.23 – MiniRCS L EDs (I/O Connections Not Shown)

Page 35

CH.2 15 MAR 2003 PAGE 35

Warning: Disposal of lithium batteries must be done in accordance with federal, state, and local

Warning: Do not make subs titutions for the battery. Be sure to only use the authorized part number

MAN0305-04

2.7 Mini Battery Replacement

The following instructions apply to the MiniOCS and MiniRCS.

1. Disconnect power from the unit.

2. Remove ground screw (item #1) from back of unit.

3. Remove back cover (item #2) by carefully pressing in on one corner locking tab and lifting back

cover to disengage the locking tab. Repeat this for all four corners.

4. Unscrew the grounding spacer (item #3) using a ¼” Hex nut driver.

5. Gently lift up and remove the I/O board (item #4) from the three snap top fasteners on the CPU

board.

6. Once the CPU board is exposed locate the battery (item #5, U7). Remove the battery by prying

up slightly on each end until it lifts free. Dispose of the battery.

regulations. Be sure to consult with the appropriate regulatory agencies before disposing batteries. In

addition, do not re-charge, disassemble, heat or incinerate lithium batteries.

7. Replace the battery with HE500BAT005 noting the polarity tab at one end of the battery. Use

care when replacing the battery that this tab is located in the right direction. Use only the authorized

battery part number.

to replace the battery.

8. Reassemble the Mini unit by first replacing the I/O board then replacing the ¼” hex spacer. It is

recommended that Loctite 222MS Threadlocker or an equivalent be applied to the male threads of item

#xx before reassembling. Line up the back cover with ground hole over the ground spacer and press back

in place. Make sure all four locking tabs of the back cover snap into place. Reconnect the ground wire.

Follow the instructions in the units’ manual for powering up the Mini and restoring it to operation.

5

4

2

3

1

OR

Figure 2.24 – Battery Replacement

Page 36

PAGE 36 15 MAR 2003 CH.2

MAN0305-04

NOTES

Page 37

CH.3 15 MAR 2003 PAGE 37

MAN0305-04

CHAPTER 3: SYSTEM MENU

3.1 General

Chapter Three describes the System Menu for the MiniOCS / MiniRCS.

The System Menu is used to access and edit information using the MiniOCS front panel or using the

Remote Text Terminal , which is a feature available in both the MiniOCS and the MiniRCS. The Remote

Text Terminal is particularly useful when using the MiniRCS, because the MiniRCS does not have a

physical front panel display screen or keypad. For more information, see page 45.

The following list contains examples of parameters that can be set using the System Menu:

• Network ID

• Network Baud

• RS232 Mode

• Time/Date

• LCD contrast

• Fkeys mode

3.2 Navigating Through the System Menu

Prior to configuration, it is important to know how to navigate through the System Menu using the

following guidelines.

1. Pressing the ↑ and ↓ keys scroll up or down through the menu options.

2. Pressing the Enter key selects the system screen that the indicator arrow is pointing to.

3. Once in a system screen, press ESC (if not currently modifying a field) to return to the main

System Menu.

3.3 Editing System Menu Screen Fields

Prior to configuration, it is important to know how to edit the System Menu screen fields using the

following guidelines.

1. Some fields in the system screens are editable; others are not editable. The MiniOCS / MiniRCS

model indicates an editable field with a solid cursor (_) under the first character in the field.

2. To change a value in an editable field, press the Enter key to select edit mode. The MiniOCS /

MiniRCS model indicates edit mode by displaying a flashing block curs or.

3. In edit mode, the fields require one of the following methods for modifying the value. Refer to the

field description to determine which method to use.

• Enumerated entry - use ↑ and ↓ keys to select appropriate value.

• Numeric entry - use Numeric keys or ↑ and ↓ keys on the appropriate digit.

• Bar graph entry - use ← and → keys to adjust value.

4. After the value is correctly entered, press the Enter key to accept the value.

5. Should the user not wish to accept the value before the Enter key is pressed, the ESC key may

be pressed instead. This action restores the original value to the display. The MiniOCS /

MiniRCS model also immediately exits edit mode; however, the Text models remains in edit

mode with the original value and requires the Enter key to be pressed to exit.

Page 38

PAGE 38 15 MAR 2003 CH.3

MAN0305-04

3.4 Remote Screen / Keypad (Using Remote Text Terminal and Status Bar)

The MiniRCS has the same functionality as the MiniOCS except that it does not have a local operator

screen and keypad. However, the MiniRCS (as well as the MiniOCS) supports a remote operator screen

and keypad through a PC connected to the Mini unit’s built-in network or serial port. If desired, the

remote operator interface and keypad can be displayed (using Cscape software) by pressing Screens,

Remote Text Terminal . A virtual display screen and keypad appear that are similar to that of the

MiniOCS, and the user can navigate through the system menu, make selections, and edit fields using a

mouse. In addition, the Cscape Status Bar can be used as a tool to ensure that communications are

properly established. For more information on the Remote Test Terminal and the Cscape Status

Bar feature, see page 45.

3.5 Initial System Menu Screens and Self-Test

Note: The examples in this chapter depict the MiniOCS, but the information also applies to the MiniRCS

when using the Remote Text Terminal screen. (Refer to Section 3.4.)

1. After turning on the power to the Mini, the following screen appears which indicates the product

name and the network it is connected to. It also indicates that the Self-Test is running.

(This screen does not appear when using the Remote Text Terminal.)

a. If the Self-Test passes, the following screen appears:

b. If the Self-Test fails, see View OCS(RCS) Diags (page 41.)

3.6 Entering the System Menu

a. To enter the System Menu on the MiniOCS using the local keypad, press both the ↑ and ↓ keys

at the same time. Notice that the two keys are surrounded by a white outline and the word

“System” on the silkscreen of the keypad.

b. If using the MiniRCS, refer to Section 4.1 (starting on page 45) to use the Remote Text Terminal

to create a virtual keypad and screen. Be sure to follow the procedures to establish and verify

proper communications (page 46). After doing so, the following menu options can be accessed

by clicking the specified key in the display representation using a mouse.

MiniOCS – CsCAN

Self-Test Running

** Self-Test **

**** Passed ****

Page 39

CH.3 15 MAR 2003 PAGE 39

MAN0305-04

3.7 System Menu Option Screens

In addition to providing access to the MiniOCS / MiniRCS, configuration parameters, the System Menu

also provides power-up and runtime status. For brevity, both configuration and status fields are covered

in this section

There are up to ten different menu options, which include the following:

• Set Network ID

• Set Network Baud

• Set Contrast

• View OCS(RCS) Status

• View OCS(RCS) Diags

• View I/O LEDs

• View OCS(RCS) Model

• Set Fkeys Mode

• Set RS232 Mode.

• Set Time/Date

• Set Network ID

This screen contains two fields. The first field cont ains the current network status. The second field

contains the current Network ID of the model. The second field is numerically editable and is used to

configure the Network ID.

Each unit on the network needs a unique ID number. The correct ID number should be entered here

before physically attaching the unit to the network.

Cscan model: [ 1 - 253 ]

DeviceNet model: [ 0 - 63 ]

Note: If the Network ID setting is changed, the unit stops executing the ladder code (for up to 1 second)

while the network is re-tested. If the “Network OK?” status changes from “Yes” to “No,” the new Network

ID is a duplicate, and another ID needs to be selected.

• Set Network Baud

This screen contains an editable enumerated field allowing the user to select the current baud rate of the

network.

Cscan model: [125K, 250K, 500K, 1M]

DeviceNet model: [125K, 250K, 500K]

Note: All devices on the network must be at the same baud rate. A device configured for the wrong

baud rate may shut down the network entirely.

• Set Contrast

This menu contains an editable bar graph entry allowing the user to set the contrast of the LCD display.

Page 40

PAGE 40 15 MAR 2003 CH.3

MAN0305-04

• View OCS (RCS) Status

This screen contains both a single enumerated editable field that sets the MiniOCS / MiniRCS scan mode

and status fields that display information about the internal state of the MiniOCS/ MiniRCS. Pressing the

↑ and ↓ keys scrolls through the different items. Pressing Esc returns to the System Menu.

Parameter Description

OCS Mode Displays the current scanning mode (Idle, Run, DoIO). In Idle mode, the I/O is

not scanned and the OCS ladder program does not execute. The green “RUN”

LED is OFF. In Run mode, the ladder program executes and the green “RUN”

LED illuminates. DoIO mode is similar to Run mode, except the ladder logic is

not solved. When the OCS is in DoIO mode, the user is able to exercise all of

the I/O from Cscape, without interference from the ladder program. In this mode

the green “RUN” LED flashes. This feature is a valuable troubleshooting tool.

Scan-Rate Shows the number of milliseconds for the scan. The scan-rate is the sum of the

time required to execute the following items:

a. Scan inputs

b. Solve logic

c. Write outputs

d. Handle network communications

e. Handle host communications request

f. Process data for operator interface

OCS Net Use Shows the percentage of the network used by the Mini.

All Net Use Shows the percentage of the network used by all devices on the network.

Ladder Size Shows the number of bytes used by the ladder program.

Config Size Shows the number of bytes used by the I/O configuration

Text Size Shows the number of bytes used by the text screens

Firmware Rev Shows the execution engine firmware version.

BIOS Rev Shows the BIOS firmware revision.

FPGA Rev Shows the FPGA Image version.

Self-Test Shows if the power-up self-test passed or failed by displaying Ok or Fault.

Page 41

CH.3 15 MAR 2003 PAGE 41

MAN0305-04

• View OCS(RCS) Diags

This screen displays a list of self-test diagnostics results (no editable fields). Each item describes a test

and shows a result of Ok if the test passed or Fault/Warn if an error was found while running the test.

Fault indications will prevent the loaded application from running. Warn(ing) indications allow the

application to run but inform the user that a condition exists that needs correction.

System BIOS - This test checks for a valid BIOS portion of the controller firmware.

Ok The loaded BIOS firmware is valid

Fault The loaded BIOS is invalid.

(Engine) Firmware - This test validates the controller firmware.

Ok The firmware is valid.

Fault The controller firmware is invalid.

User Program - This tests for a valid user program and configuration data.

Ok The user program and confi guration is valid.

Fault The user program and/or configuration are not valid.

System RAM - This test checks the functionality of the controller RAM at power up.

Ok The RAM is functioning correctly.

Fault The RAM is not functioning correctly.

Logic Error - This test checks for problems with the user program while running.

Ok No errors have been encountered while running a user program.

Fault Indicates the user program contained an instruction that was invalid or unsupported.

W-Dog Trips - This test checks for resets caused by hardware faults, power brownouts or large amounts

of electrical interference.

0 No unintentional resets have occurred.

xx Indicates a fault with xx showing the number of occurrences.

Net Errors - This test checks for abnormal network operations while running. (Network models only.)

0 No network errors were counted

xx Indicate serious networking problems exist, xx indicates the number of occurrences.

Network State - This test checks that the network sub-system is powered and operating correctly.

(Network models only.)

Ok The network system is receiving power and has determined other devices are

communicating on the network.

Warn Power is not being applied to the network or no other devices were found to be

communicating on the network.

Network ID - This test checks that the network ID is valid. (Network models only.)

Ok The network ID is valid.

Warn The network ID is not valid for the selected protocol.

Dup Net ID - This test checks for duplicate IDs on a network. (Network models only.)

Ok This controller's ID was not found to be a duplicate.

Warn Another controller on the network was found with the same ID as this controller.

Page 42

PAGE 42 15 MAR 2003 CH.3

MAN0305-04

DeviceNet In - (DeviceNet model only.)

Ok DeviceNet master is maintaining a polled connection and not sending IDLE.

Warn The DeviceNet master is no longer maintaining a polled connection or sending IDLE.

(IDLE is a network state in which ‘some’ masters maintain a polled connection but sends

zero data if an associated PLC controller is in IDLE mode. Refer to Master

documentation for more information.)

Clock Error - This test checks that the real time clock contains valid data.

Ok The real time clock contains valid data.

Warn Indicates invalid data in the real time clock.

I/O System - This test checks that the configured (downloaded) model number matches the physical

I/O module installed in the controller.

Ok The configured model number matches the installed I/O module.

Warn Indicates the configured model number does not match the installed I/O module.

(See View OCS(RCS) Model system screen for more information.)

• View I/O LEDs

The View I/O LEDs simulate the LEDs and show the statuses of the first 16 %I and first 16 %Q registers.

• View OCS(RCS) Model

The View OCS(RCS) Model screen allows the user to view the MiniOCS / MiniRCS model number.

When viewing the model number, the following status screens are possible. Note the term OCSxxx (or

RCSxxx) refers to the MiniOCS (or Mini RCS) model number such as OCS082 (or RCS082).

a. If the Mini model number is not configured and no I/O module is installed, the message

" I/O: Empty” is displayed.

b. If the Mini model number is not configured but has an I/O module installed, the message

"+Mini OCSxxx (or RCSxx)" is displayed.

c. If the Mini model number is configured but no I/O module is installed, the message

"-I/O Missing" is displayed.

d. If the configured Mini model number does not match the installed I/O module, the message

"?Mini OCSxxx (or RCSxx)" is displayed.

e. If the installed I/O module is not supported by the Mini firmware, the message

“*Unsupported” is displayed. The module is either defective or an Engine firmware upgrade is

required to support the module.

f. If the installed I/O module has erroneous or outdated firmware in it, the message