Page 1

MAN0925-02-EN Specifications / Installation

________________________________________________________________________________________________________________________________________

6/1/11 Page 1 of 5 # 1018

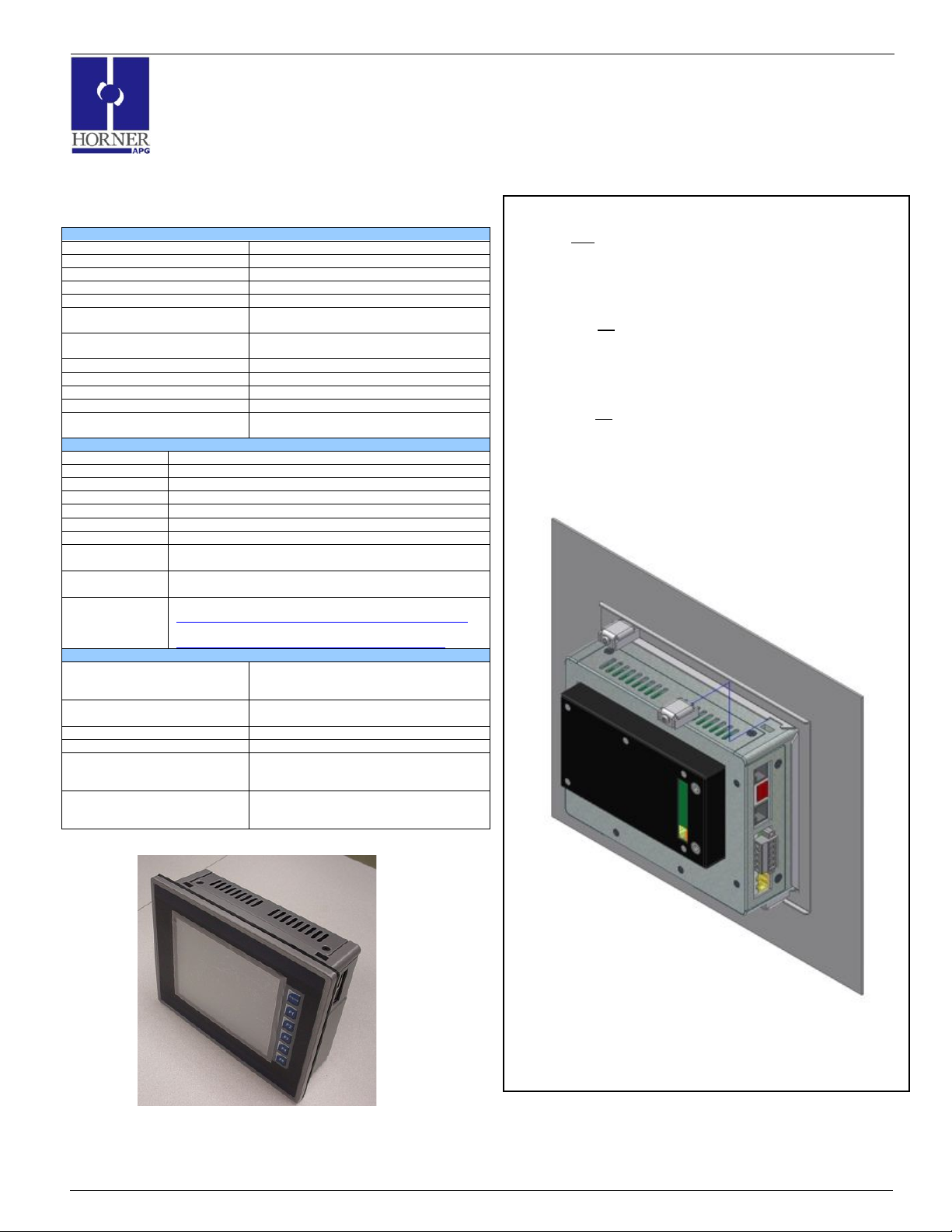

1. Specifications

Table 1 - RX371 Specifications

Display Type (LCD with Backlight)

5.7” QVGA TFT

Display Size

5.7”

Display Brightness

700 nits

Display Screen Dimensions

320 x 240

Display Memory

2.75MB

Display Life

Minimum 40000 hours (50% brightness, 25

deg C)

User Keys

5 user-defined Function keys and a System

key

Screens supported

1023

Colors

32768

Primary power

10 – 30 VDC

Steady state current

0.8A @ 24 VDC, 2A @ 10 VDC

Inrush current

30 A for 1 ms @ 24 VDC – DC Switched

2.5 A for 4 ms @ 24 VDC - AC Switched

Product Descriptions

Height

5.964” (151.49mm)

Width

7.682” (195.12mm)

Depth

2.425” (61.60mm)

Serial Ports

RS232 & RS485. Software Selectable

Terminal Type

Screw Type, 5mm removable

Weight

54 oz (1.53kg)

Portable Memory

Micro SD card slot

Temperature &

Humidity

–30°C to +60°C & 5 to 95% Non-condensing

(Storage & Operating)

Clock Accuracy

+/- 35 ppm maximum at 25° C

(+/- 1.53 Minutes per Month)

CE

UL

USA:

http://www.heapg.com/Pages/TechSupport/ProductCert.html

EUROPE:

http://www.horner-apg.com/en/support/certification.aspx

Connectivity

Smart Stack Modules

Provides a wide variety of I/O options for the

QX. Requires little space and are easy to

install.

SmartStix Modules

It is a family of remote I/O products for the

QX.

Serial Ports

2 Serial Ports – RS232 & RS485

Ethernet

Ethernet (10/100 Mbps)

USB

USB networking port for communication with

PC’s, programming of controller, flash drive

connectivity

Removable Media

Removable Media for up to 2 GB (gigabytes)

of storage of programs, data logging or screen

captures

RX371 Models:

HE-RX371 / HERX371C101

RX371

2. Installation

1. Prior to mounting, observe requirements for the panel layout design

and spacing/clearances in the OCS RX371 Manual (MAN0924).

2. Cut the host panel.

3. Insert the OCS through the panel cutout (from the front). The

gasket material needs to be between the host panel and the OCS

Caution: Do not force the OCS into the panel cutout. An incorrectly

sized panel cutout can damage the touch screen.

4. Install and tighten the mounting clips (provided with the OCS) until

the gasket material forms a tight seal.

Caution: Do not over-tighten. Over-tightening damages the case

5. Connect cables as needed such as communications, programming,

power and CsCAN cables to the ports using the provided

connectors.

6. Begin configuration procedures.

Page 2

MAN0925-02-EN Specifications / Installation

________________________________________________________________________________________________________________________________________

6/1/11 Page 2 of 5 # 1018

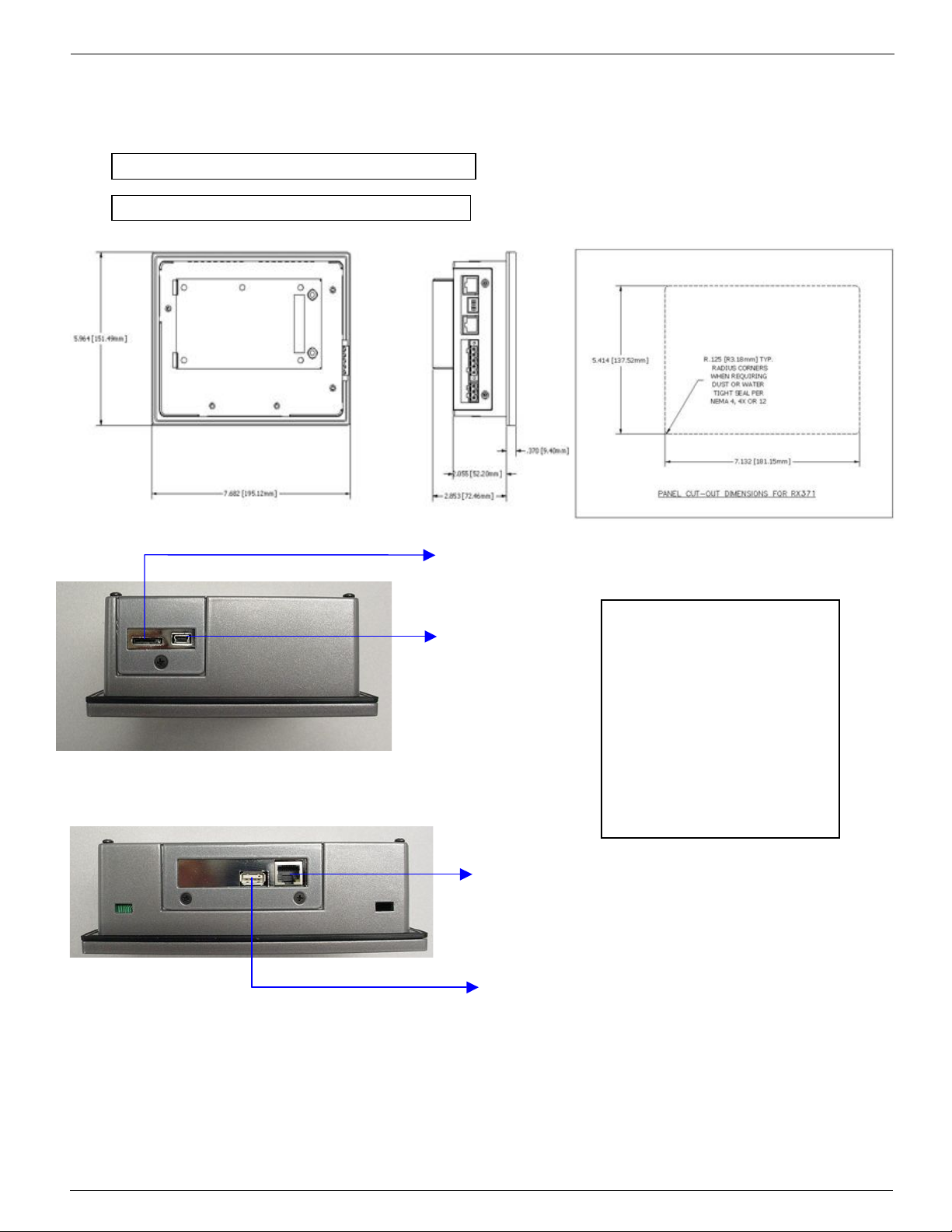

3. Panel Cut out and dimensions

Refer to the RX371 User Manual (MAN0924) for panel box information and a handy checklist of requirements.

4. Ports and Connectors

Note: The tolerance to meet NEMA standards is ± 0.005” (0.1 mm).

Note: Max. Panel thickness: 5 mm

Ethernet

USB A

USBA: For flash drive connectivity

USBB: For network communication and

programming of OCS

Removable Memory: Uses Removable

Memory for data logging, screen captures,

program loading and recipes. Horner Part

No.: HE-MC1

Serial Communications: MJ1/MJ2: (RS-

232 / RS-485) Use for Cscape programming

and Application-Defined Communications.

Ethernet: Used for Cscape programming

and Application-Defined Communications.

Removable Media

USB B

Page 3

MAN0925-02-EN Specifications / Installation

________________________________________________________________________________________________________________________________________

6/1/11 Page 3 of 5 # 1018

4.1 Serial Communications:

MJ1: (RS-232 / RS-485) Use for Cscape programming and

Application-Defined Communications.

MJ2: (RS-232 / RS-485) Use for Application-Defined

Communications.

Pin

MJ1 Pins

MJ2 Pins

Signal

Direction

Signal

Direction

8

TXD

OUT

TXD

OUT

7

RXD

IN

RXD

IN

6

0 V

Ground

0 V

Ground

5*

+5 60mA

OUT

+5 60mA

OUT

4

RTS

OUT

TX-

OUT

3

CTS

IN

TX+

OUT

2

RX- / TX-

IN / OUT

RX-

IN

1

RX+ / TX+

IN / OUT

RX+

IN

1

8

Pin

MJ2 Pins

Signal

Direction

8

TXD

OUT

7

RXD

IN

6

0 V

Ground

5*

+5 60mA

OUT

4

TX-

OUT

3

TX+

OUT

2

TX-/RX-

IN/OUT

1

TX+/RX+

IN/OUT

1

8

MJ2 Half Duplex Mode

* +5V 60mA Max

Pin

MJ2 Pins

Signal

Direction

8

TXD

OUT

7

RXD

IN

6

0 V

Ground

5*

+5 60mA

OUT

4

TX-

OUT

3

TX+

OUT

2

RX-

IN

1

RX+

IN

1

8

MJ2 Full Duplex Mode

* +5V 60mA Max

Smart Stack Connector

DIP Switches

MJ2

MJ1

CAN

Power

USB A

Ethernet

Page 4

MAN0925-02-EN Specifications / Installation

________________________________________________________________________________________________________________________________________

6/1/11 Page 4 of 5 # 1018

4.2 Ethernet Port

Table 3 - Ethernet Port

Speeds

10 BaseT Ethernet (10-Mbps)

100 BaseTx Fast Ethernet (100-Mbps)

Modes

Half or Full Duplex

Auto - Negotiation

Both 10/100-Mbps and Half/Full Duplex

Connector Type

Shielded RJ-45

Cable Type (Recommended)

CAT5 (or better) UTP

Port

Auto MDI/MDI-X

4.3 External DIP Switch settings

4.4 CAN Network Port and wiring 4.5 Power port and wiring

Table 2 - Ports and Functions

Functions

Port 1 (MJ1)

Port 2 (MJ2)

RS-232

!

!

Hardware Handshaking

!

X

Programming

!

X

Ladder function controlled

!

!

Serial Downloadable

Protocols

!

!

RS 485 Half duplex

!

!

RS485 Full duplex

X

!

NET 1 Port Pin Assignments

Pin

Signal

Signal Description

Direction

1

V-

CAN Ground

-

2

CN_L

CAN Data Low

In/Out

3

SHLD

Shield Ground

-

4

CN_H

CAN Data High

In/Out

5

NC

No Connect

-

Primary Power Port Pins

Pin

Signal

Description

1

Ground

Frame Ground

2

V-

Input Power Supply Ground

3

V+

Input Power Supply Voltage

As seen when looking at the side of the RX371 unit:

The DIP Switches are used for

termination of the RS-485 ports. The

RX371 is shipped un-terminated.

To terminate, select one of the DIP

Switches and configure it based

upon the option that is desired.

MJ1

On

Off

On

Off

On

Off

MJ2

SW1 –

ON enables MJ2 RS485 port termination (121 ohms)

OFF disables MJ2 RS485 port termination.

SW2 & SW3 –

ON places MJ2 RS485 port in half-duplex mode.

OFF places MJ2 RS485 port in full-duplex mode.

SW4 –

ON enables MJ1 RS485 port termination (121 ohms)

OFF disables MJ1 RS485 port termination.

CAN Connector

Use the CAN Connector when

using CsCAN network.

Torque rating 4.5 – 7 Lb-In

(0.50 – 0.78 N-m)

Power Connector

Power Up:

Connect to Earth Ground.

Apply 10 - 30 VDC.

Screen lights up.

Torque rating 4.5 – 7 Lb-In

(0.50 – 0.78 N-m)

Page 5

MAN0925-02-EN Specifications / Installation

________________________________________________________________________________________________________________________________________

6/1/11 Page 5 of 5 # 1018

5. Safety

When found on the product, the following symbols specify:

Warning: Electrical

Shock Hazard.

Warning: Consult

user documentation.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D

or Non-hazardous locations only

WARNING – EXPLOSION HAZARD – Do not disconnect equipment unless

power has been switched off or the area is known to be non-hazardous.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DECONNECTOR

L'EQUIPMENT, COUPER LE COURANT OU S'ASSURER QUE

L'EMPLACEMENT EST DESIGNE NON DANGEREUX.

WARNING: To avoid the risk of electric shock or burns, always connect the

safety (or earth) ground before making any other connections.

WARNING: To reduce the risk of fire, electrical shock, or physical injury it is

strongly recommended to fuse the voltage measurement inputs. Be sure to

locate fuses as close to the source as possible.

WARNING: Replace fuse with the same type and rating to provide protection

against risk of fire and shock hazards.

WARNING: In the event of repeated failure, do not replace the fuse again as a

repeated failure indicates a defective condition that will not clear by replacing

the fuse.

WARNING – EXPLOSION HAZARD – Substitution of components may impair

suitability for Class I, Division 2

AVERTISSEMENT - RISQUE D'EXPLOSION - LA SUBSTITUTION DE

COMPOSANTS PEUT RENDRE CE MATERIAL INACCEPTABLE POUR LES

EMPLACEMENTS DE CLASSE 1, DIVISION 2

WARNING - The USB parts are for operational maintenance only. Do not leave

permanently connected unless area is known to be non-hazardous.

WARNING – EXPLOSION HAZARD - BATTERIES MUST ONLY BE

CHANGED IN AN AREA KNOWN TO BE NON-HAZARDOUS

AVERTISSEMENT - RISQUE D'EXPLOSION - AFIN D'EVITER TOUT

RISQUE D'EXPLOSION, S'ASSURER QUE L'EMPLACEMENT EST DESIGNE

NON DANGEREUX AVANT DE CHANGER LA BATTERIE

WARNING - Battery May Explode If Mistreated. Do Not Recharge, Disassemble

or Dispose Of In Fire

WARNING: Only qualified electrical personnel familiar with the construction

and operation of this equipment and the hazards involved should install, adjust,

operate, or service this equipment. Read and understand this manual and other

applicable manuals in their entirety before proceeding. Failure to observe this

precaution could result in severe bodily injury or loss of life.

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

Radiated Emission Compliance: For compliance requirement, a ferrite

(Horner P/N FBD006 supplied with the unit) needs to be placed on the AC/DC

line with one loop.

" All applicable codes and standards need to be followed in the installation of this

product.

" Adhere to the following safety precautions whenever any type of connection is

made to the module:

# Connect the safety (earth) ground on the power connector first before making

any other connections.

# When connecting to electric circuits or pulse-initiating equipment, open their

related breakers.

# Do not make connections to live power lines.

# Make connections to the module first; then connect to the circuit to be

monitored.

# Route power wires in a safe manner in accordance with good practice and local

codes.

# Wear proper personal protective equipment including safety glasses and

insulated gloves when making connections to power circuits.

# Ensure hands, shoes, and floors are dry before making any connection to a

power line.

# Make sure the unit is turned OFF before making connection to terminals.

# Make sure all circuits are de-energized before making connections.

# Before each use, inspect all cables for breaks or cracks in the insulation.

Replace immediately if defective.

• Use Copper Conductors in Field Wiring Only, 60/75° C

6. Technical Support

For assistance and Manual updates, contact Technical Support at the following

locations:

North America:

Tel: 317-916-4274

Fax: 317-639-4279

Web: www.heapg.com

Email: techsppt@heapg.com

Europe:

Tel: +353-21-4321-266

Fax: +353-21-4321-826

Web: www.horner-apg.com

Email: techsupport@horner-apg.com

No part of this publication may be reproduced without the prior agreement and

written permission of Horner APG, Inc. Information in this document is subject to

change without notice.

Loading...

Loading...