Page 1

User Manual for

Profibus DP

HE800PBM650/HEPBM650 &

HE800PBS600/HEPBS600

Master and Slave SmartStack Modules

PAGE 1 of 97

EO 09-0009

Page 2

Preface MAN0575-04-EN

Profibus Modules User Manual

PREFACE

Copyright © 2001 Horner APG, LLC. 640 North Sherman Drive, Indianapolis, Indiana 46201-3899. All

rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language or computer language, in any form by any means,

electronic, mechanical, magnetic, optical, chemical, manual or otherwise, without the prior agreement

and written permission of Horner APG, LLC.

Information in this document is subject to change without notice and does not represent a

commitment on the part of Horner APG, LLC.

Windows 95, Windows 98, Windows NT, windows 2000 and XP are registered

trademarks of Microsoft Corporation.

DeviceNet is a trademark of Open DeviceNet Vendors Association (ODVA).

Profibus is a trademark of Siemens.

Cscape, CsCAN, and SmartStack are trademarks of Horner APG, LLC.

For user manual updates and technical support contact:

Horner APG

Technical Support (317) 916-4274 Technical Support +353-21-4321266

Web site www.horner-apg.com. Web-site www.horner-apg.com

(USA) Horner APG (Europe)

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG, LLC. ("HE-APG") warrants to the original purchaser that the Operator Station manufactured by HE is free from

defects in material and workmanship under normal use and service. The obligation of HE-APG under this warranty shall be

limited to the repair or exchange of any part or parts which may prove defective under normal use and service within two (2)

years from the date of manufacture or eighteen (18) months from the date of installation by the original purchaser whichever

occurs first, such defect to be disclosed to the satisfaction of HE-APG after examination by HE-APG of the allegedly defective

part or parts. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR USE AND OF ALL OTHER OBLIGATIONS OR

LIABILITIES AND HE-APG NEITHER ASSUMES, NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR HE-APG,

ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF THE Operator Station. THIS WARRANTY SHALL NOT

APPLY TO THE Operator Station OR ANY PART THEREOF, WHICH HAS BEEN SUBJECT TO ACCIDENT, NEGLIGENCE,

ALTERATION, ABUSE, OR MISUSE. HE MAKES NO WARRANTY WHATSOEVER IN RESPECT TO ACCESSORIES OR

PARTS NOT SUPPLIED BY HE. THE TERM "ORIGINAL PURCHASER", AS USED IN THIS WARRANTY, SHALL BE

DEEMED TO MEAN THAT PERSON FOR WHOM THE Operator Station IS ORIGINALLY INSTALLED. THIS WARRANTY

SHALL APPLY ONLY WITHIN THE BOUNDARIES OF THE CONTINENTAL UNITED STATES.

In no event, whether as a result of breach of contract, warranty, tort (including negligence) or otherwise, shall HE-APG or its

suppliers be liable of any special, consequential, incidental or penal damages including, but not limited to, loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, down time costs, or claims of original purchaser's customers for

such damages.

PAGE 2 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 3

Preface MAN0575-04-EN

Profibus Modules User Manual

List of Revisions

Index Date Version Chapter Revision

20-Feb-03 01 All Initial release.

9-Nov-04 02 All Rev. 2

16-Oct-06 03 All Added Cscape configuration section 3.2

10-Jun-09 04 Added Interface details.

PAGE 3 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 4

Preface MAN0575-04-EN

Profibus Modules User Manual

TABLE OF CONTENTS

PREFACE ..................................................................................................................................................... 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY ............................................................................. 2

CHAPTER 1: INTRODUCTION .................................................................................................................... 6

1.1 Scope ........................................................................................................................................... 6

1.2 Introduction ................................................................................................................................... 6

1.3 Installing and Removing a SmartStack Module ........................................................................... 7

1.4 Main Functions ............................................................................................................................. 8

CHAPTER 2: SOFTWARE INSTALLATION INSTRUCTIONS ..................................................................... 9

2.1 System Requirements .................................................................................................................. 9

2.2 System Installation ....................................................................................................................... 9

CHAPTER 3: GETTING STARTED – CSCAPE CONFIGURATION .......................................................... 11

3.1 Scope ......................................................................................................................................... 11

3.2 Configuring Cscape. ................................................................................................................... 11

3.3 Configuration of a SmartStack Profibus DP Master to any Profibus DP Slave ......................... 15

3.4 Configuration of a SmartStack Profibus DP Slave to any Profibus DP Master ......................... 16

3.5 Configuration of a SmartStack DPV1 Master to any DPV1 Slave ............................................. 17

3.6 Configuration a SmartStack Profibus DPV1 Slave to any Profibus DPV1 Master ..................... 18

3.7 Verifying a Project ...................................................................................................................... 19

CHAPTER 4: CONFIGURATION OF PROFIBUS WITH HSYCON ........................................................... 21

4.1 Setting up the PROFIBUS Configuration ................................................................................... 21

4.2 GSD Files ................................................................................................................................... 21

4.3 Master ........................................................................................................................................ 22

4.4 Master Configuration .................................................................................................................. 23

4.5 PROFIBUS-DP Auto Configuration ............................................................................................ 24

4.6 Replace Master .......................................................................................................................... 24

4.7 Insert DP Slave .......................................................................................................................... 25

4.8 Slave Configuration .................................................................................................................... 26

4.9 Inserting Predefined Device – PDD ........................................................................................... 28

4.10 Replace Slave ............................................................................................................................ 29

CHAPTER 5: SETTINGS ............................................................................................................................ 32

5.1 Device Assignment .................................................................................................................... 32

5.2 Bus Parameters ......................................................................................................................... 32

5.3 Setting the Bus Parameters and Profiles ................................................................................... 33

5.4 Description of the Individual Parameters ................................................................................... 34

5.5 Rules .......................................................................................................................................... 36

CHAPTER 6: DP MASTER ......................................................................................................................... 39

6.1 Master Settings .......................................................................................................................... 39

6.2 Group Membership .................................................................................................................... 40

CHAPTER 7: DP SLAVE ............................................................................................................................ 42

7.1 Slave Settings ............................................................................................................................ 42

7.2 Parameter Data .......................................................................................................................... 44

7.3 DPV1 Parameter ........................................................................................................................ 45

7.4 Project Information ..................................................................................................................... 46

7.5 Path ............................................................................................................................................ 47

7.6 Language ................................................................................................................................... 47

7.7 Start Options .............................................................................................................................. 47

CHAPTER 8: ONLINE FUNCTIONS .......................................................................................................... 49

8.1 Downloading the Configuration .................................................................................................. 49

8.2 Firmware Download ................................................................................................................... 49

8.3 Firmware / Reset ........................................................................................................................ 50

8.4 Device Info ................................................................................................................................. 50

8.5 Automatic Network Scan ............................................................................................................ 51

8.6 Assign Slave ............................................................................................................................... 53

8.7 Assign Module ............................................................................................................................ 54

8.8 Slave with Station Address 126 ................................................................................................. 55

PAGE 4 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 5

Preface MAN0575-04-EN

Profibus Modules User Manual

8.9 Start/Stop Communication ......................................................................................................... 56

CHAPTER 9 : DIAGNOSTIC FUNCTIONS ................................................................................................ 58

9.1 Live List ...................................................................................................................................... 58

9.2 Debug Mode (PROFIBUS-DP) ................................................................................................... 58

9.3 PROFIBUS DP Device Diagnostic ............................................................................................. 59

9.4 Compare Configuration .............................................................................................................. 64

9.5 Extended DP Slave Diagnostic .................................................................................................. 65

9.6 Global State Field ....................................................................................................................... 66

9.7 Extended Device Diagnostic ...................................................................................................... 67

9.8 I/O Monitor .................................................................................................................................. 68

9.9 I/O Watch ................................................................................................................................... 68

CHAPTER 10: PROFIBUS SERVICES ...................................................................................................... 71

10.1 Setting the Slave Address .......................................................................................................... 71

10.2 Message Monitor ........................................................................................................................ 72

10.3 Message Monitor for Testing of DPV1 (Master) ......................................................................... 73

10.4 Message Monitor for Testing of DPV1 (at Slave) ....................................................................... 74

CHAPTER 11: FILE, PRINT, EXPORT, EDIT AND VIEW ......................................................................... 77

11.1 File Open .................................................................................................................................... 77

11.2 File Save and Save As ............................................................................................................... 77

11.3 File Close ................................................................................................................................... 77

11.4 Print ............................................................................................................................................ 77

11.5 DBM Export ................................................................................................................................ 78

11.6 CSV Export ................................................................................................................................. 78

11.7 PDD Export ................................................................................................................................ 81

11.8 Cut, Copy and Paste (Master) .................................................................................................... 82

11.9 Cut, Copy and Paste (Slave) ...................................................................................................... 83

11.10 Delete ......................................................................................................................................... 84

11.11 Replace ...................................................................................................................................... 84

11.12 View the Configuration ............................................................................................................... 85

11.13 Device Table .............................................................................................................................. 85

11.14 Address Table ............................................................................................................................ 86

11.15 Address Overview ...................................................................................................................... 87

11.16 Byte information Window ........................................................................................................... 87

CHAPTER 12: TOOLS ................................................................................................................................ 88

12.1 GSD Viewer ................................................................................................................................ 88

CHAPTER 13: ERROR CODES ................................................................................................................. 89

13.1 Serial Driver Error Numbers (-20… -71) .................................................................................... 89

13.2 Database Access Error Numbers (100 .. 130) ........................................................................... 90

13.3 Online Data Manager Error Numbers ........................................................................................ 91

13.4 Message Handler Error Numbers (2010….,2017) .................................................................... 92

13.5 Driver Functions Error Numbers (2501…,2512) ........................................................................ 93

13.6 Online Data Manager Subfunctions Error Numbers (8001…,8035) .......................................... 93

13.7 Data Base Functions Error Numbers (4000 .. 4098).................................................................. 94

PAGE 5 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 6

Introduction MAN0575-04-EN

Profibus DP Modules User Manual

CHAPTER 1: INTRODUCTION

1.1 Scope

This manual shows how to connect and configure the Profibus Master or Slave Smartstack Modules.

HSyCon, is an easy-to-use ‘ Windows’-based configuration package for use with the SmartStack

COM range of fieldbus modules and Cscape or Cbreeze a windows based configuration package for

use with the OCS/ TIU product range. The software user’s guide is contained in this manual.

A basic level of understanding of Microsoft Windows technology and operation is assumed. The

manual assumes that the user is familiar with Windows 95, Windows 98, Windows NT, Windows

2000 or XP.

1.2 Introduction

The Smartstack Fieldbus module range require only three stages to become operational, these are:

1. Physical installation and connection.

2. Configuration of the fieldbus interface.

3. Configuration of Cscape / Cbreeze to map the fieldbus data.

The system is comprised of two separate software functions; the fieldbus interface software running

independently in the COM module and the OCS/TIU firmware running in the main module. Data and

commands are exchanged via a dual port ram interface. The configuration of the COM module is via

the RS232 serial port on the module. For correct operation, the number of registers assigned in the

OCS must match the number required by the Master or Slave module configuration.

The Smartstack module should be configured with the OCS/TIU first as otherwise it

will be held in reset and cannot be configured.

PAGE 6 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 7

Introduction MAN0575-04-EN

Profibus DP Modules User Manual

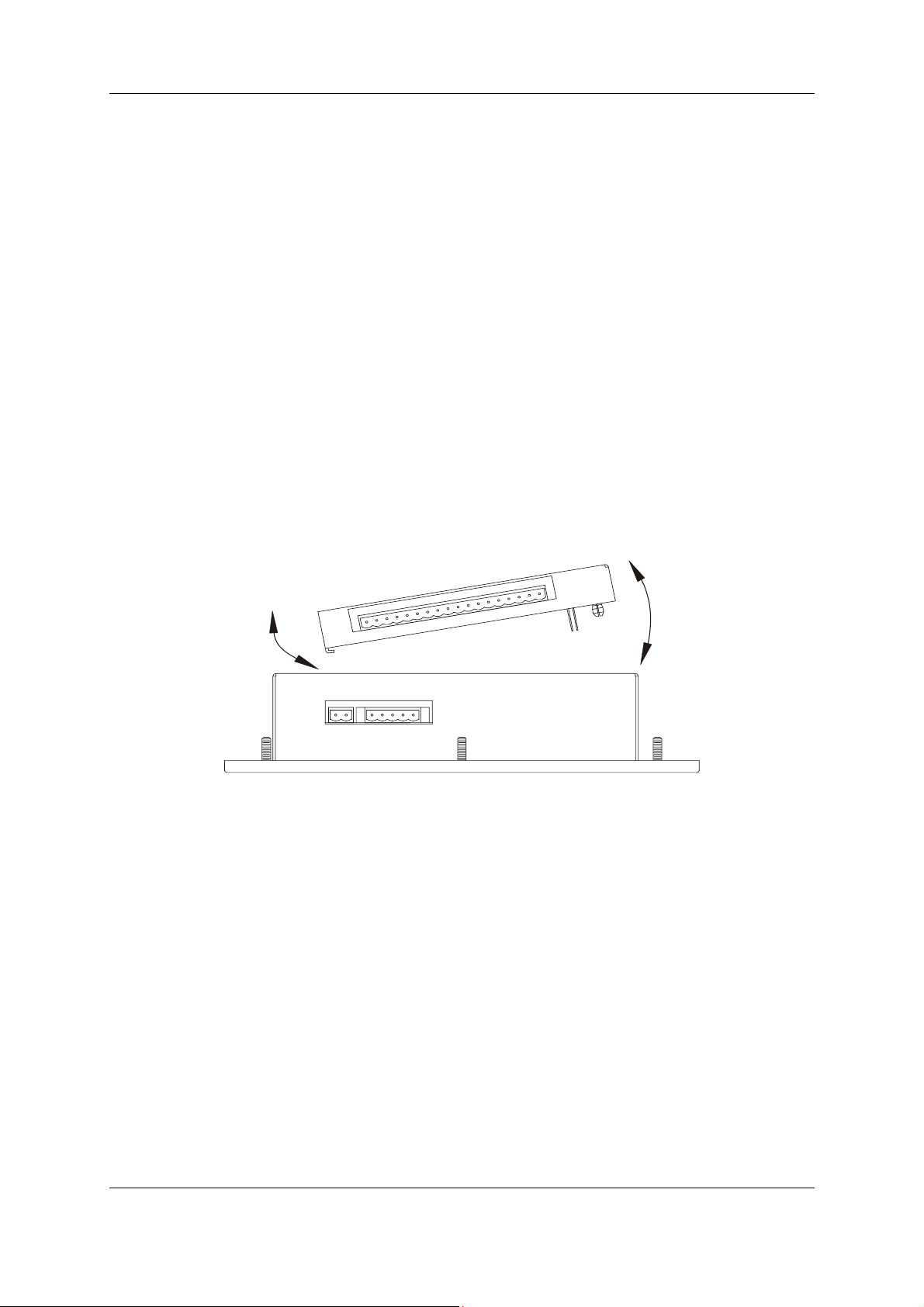

1.3 Installing and Removing a SmartStack Module

The following section describes how to install and remove a SmartStack Module.

Caution: To function properly and avoid possible damage, do not install more than four

Smart Stack Modules per OCS, RCS, NX, QX, FOX base/hub or TIU.

Do not attempt to install or remove a SmartStack module with the units powered on.

Installing SmartStack Modules

10 Hook the tabs. Each SmartStack Module has two tabs that fit into slots located on the OCS,

RCS, FOX base or TIU. (The slots on the OCS are located on the back cover.)

11 Press the SmartStack Module into the “locked” position, making sure to align the SmartStack

Module fasteners or clip with the SmartStack receptacles on the main housing.

Removing SmartStack Modules

1. In the case of a metal Smartstack module using a flathead screwdriver, lever up the end of the

SmartStack Module (opposite end to tabs) and swing the module out. In the case of a plastic

Smartstack module press the button in the end of the module and swing the module out.

2. Lift out the tabs of the module.

Figure 1.1 – Installing a SmartStack Module in an OCS

PAGE 7 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 8

Introduction MAN0575-04-EN

Profibus DP Modules User Manual

1.4 Main Functions

The main functions of the HsyCon System Configurator are:

• Configuration of the complete Fieldbus range with one package.

• Standardised configuration files – allows use of protocol specific standardised configuration files.

• Diagnostic tool – upon configuration download the software may be switched into diagnostic

mode.

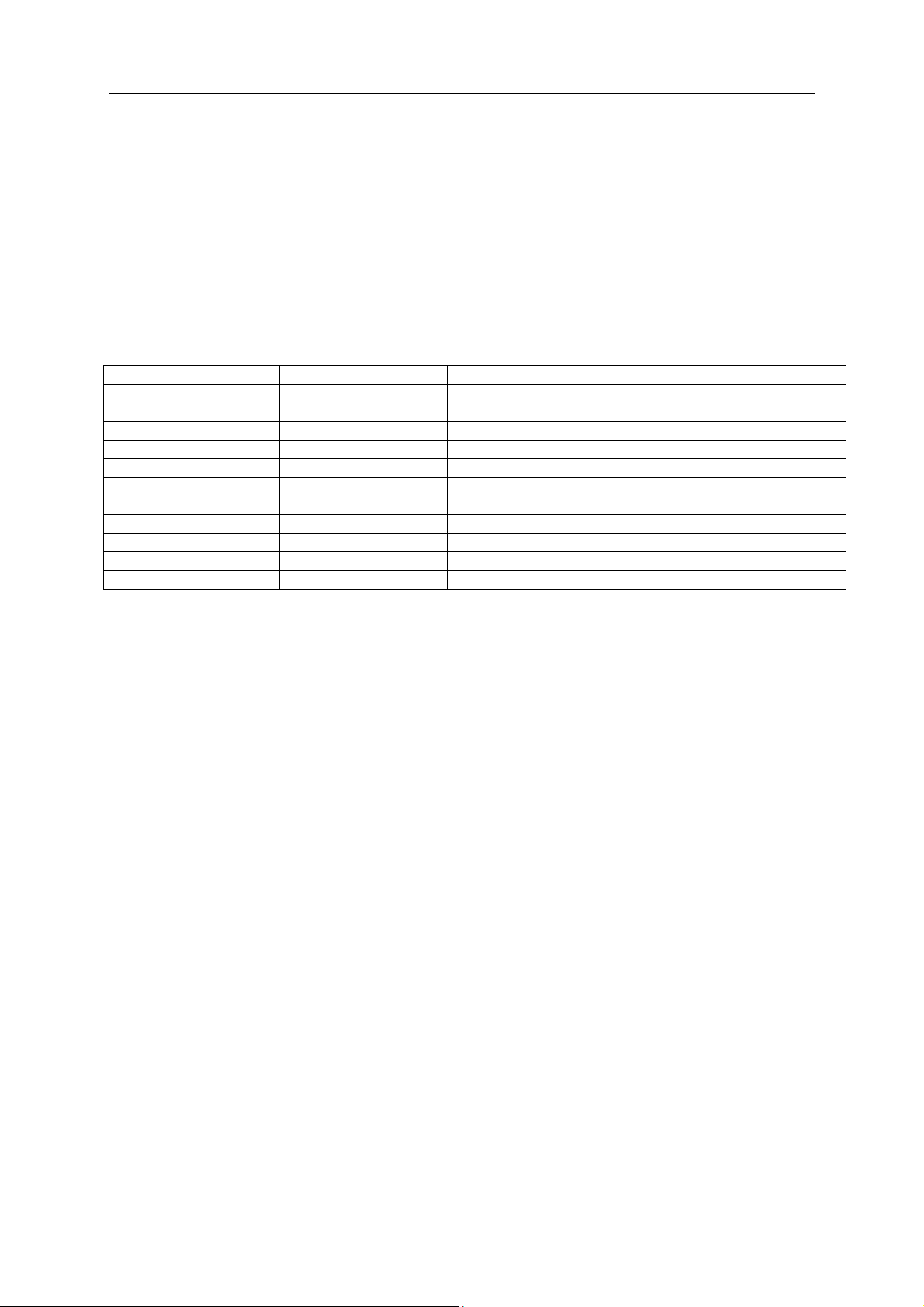

Signal LED Colour State Definition

RDY Yellow On COM Ready

Cyclical flashing Bootstrap loader active

Non cyclical flashing Hardware or system error.

Off Hardware error.

RUN Green On Communication running.

Non cyclical flashing Parameter error.

Off Communications stopped.

ERR Red On Error on communications line.

Off No error.

STA Yellow On Master: Hold Token. Slave: Data Exchange

Off Master: No Hold Token. Slave: No Data Exchange

Figure 1.1

Figure 1.1 shows the onboard LED Status definitions for the PBM650/PBS600

PAGE 8 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 9

Installation MAN0575-04-EN

Profibus Modules User Manual

CHAPTER 2: SOFTWARE INSTALLATION INSTRUCTIONS

2.1 System Requirements

PC with 486-, Pentium processor or higher.

Windows 95/98/ME, Windows NT/2000/XP.

Free disk space: 30 - 80 Mbytes.

CD ROM drive.

RAM: min. 16 Mbytes.

Graphic resolution: min. 800 x 600 pixel.

Windows 95: Service Pack 1 or higher.

Windows NT: Service Pack 3 or higher.

Keyboard and Mouse.

2.2 System Installation

It is recommended that all application programs on the system be closed before installation begins.

Change to the Hscon/SYCON directory on the disk and start set-up

Note: Administrator privileges are required on Windows NT/2000/XP systems for installation!

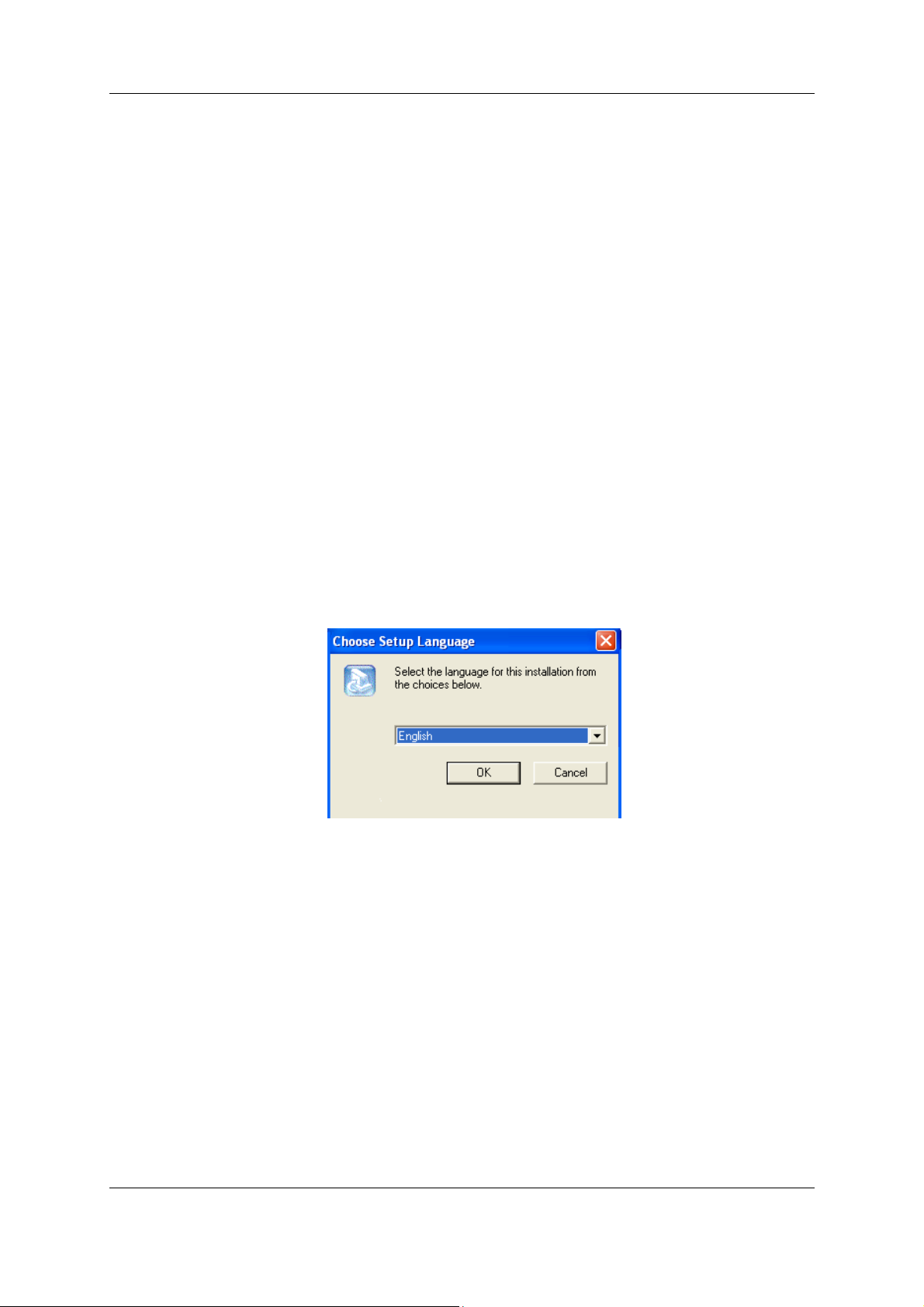

Select the required language version for installation.

Figure 2.1 – language selection

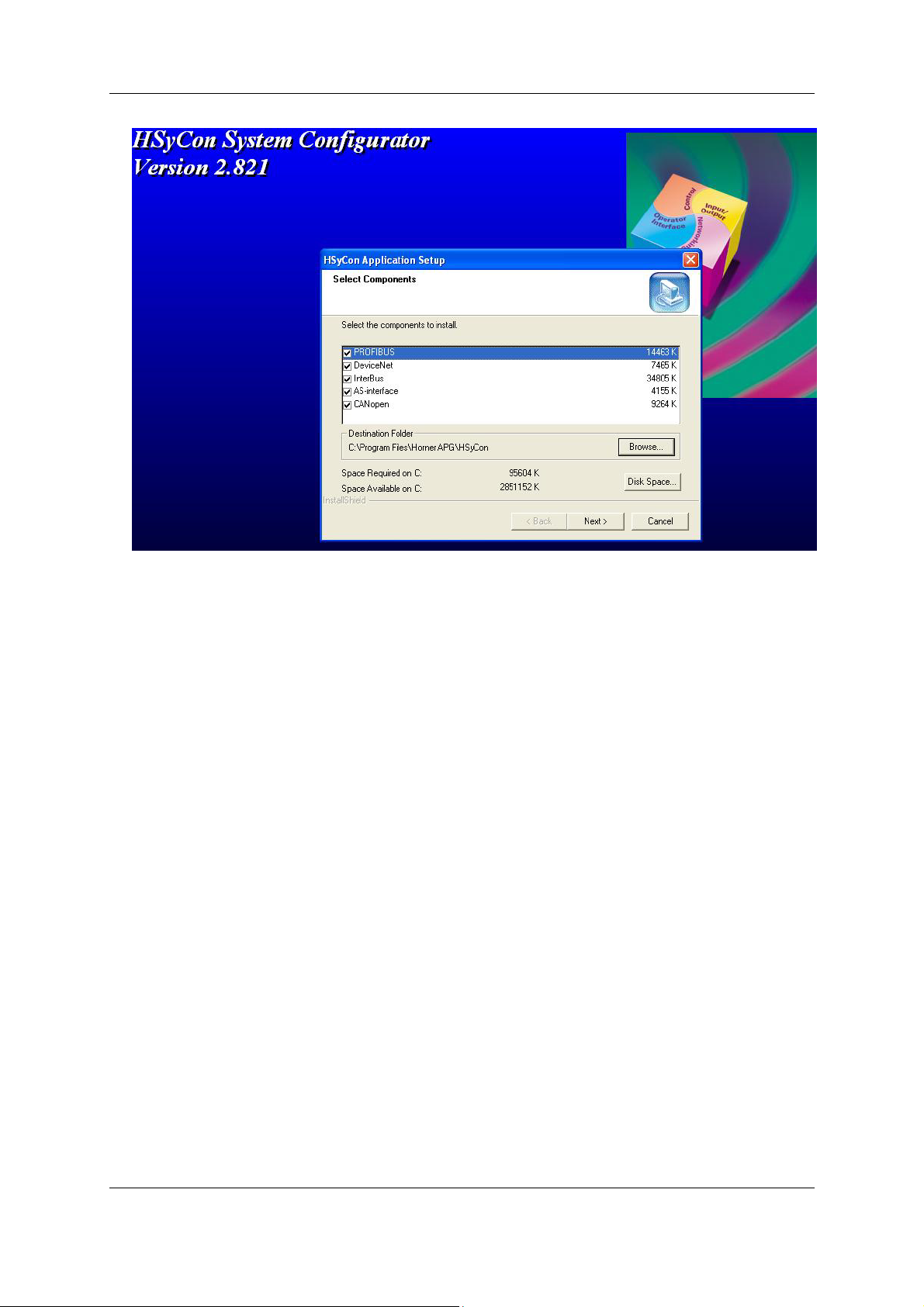

Select the desired Fieldbus components to install. Click Next and the required components will be

installed in the chosen destination folder.

The installation program copies the program files, GSD or EDS files and Bitmaps to the PC. Finally,

the following files are entered in the system Registry.

System Dynamic Link Library’s (DLL’s)

The application

PAGE 9 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 10

Installation MAN0575-04-EN

Profibus Modules User Manual

Figure 2.2 – Component Selection

PAGE 10 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 11

Getting Started MAN0575-04-EN

Profibus Modules User Manual

CHAPTER 3: GETTING STARTED – CSCAPE CONFIGURATION

3.1 Scope

This chapter describes the procedure for configuring the DP Master and slaves. This includes

configuring the Cscape section, loading GSD files, saving, downloading and assigning I/O.

3.2 Configuring Cscape.

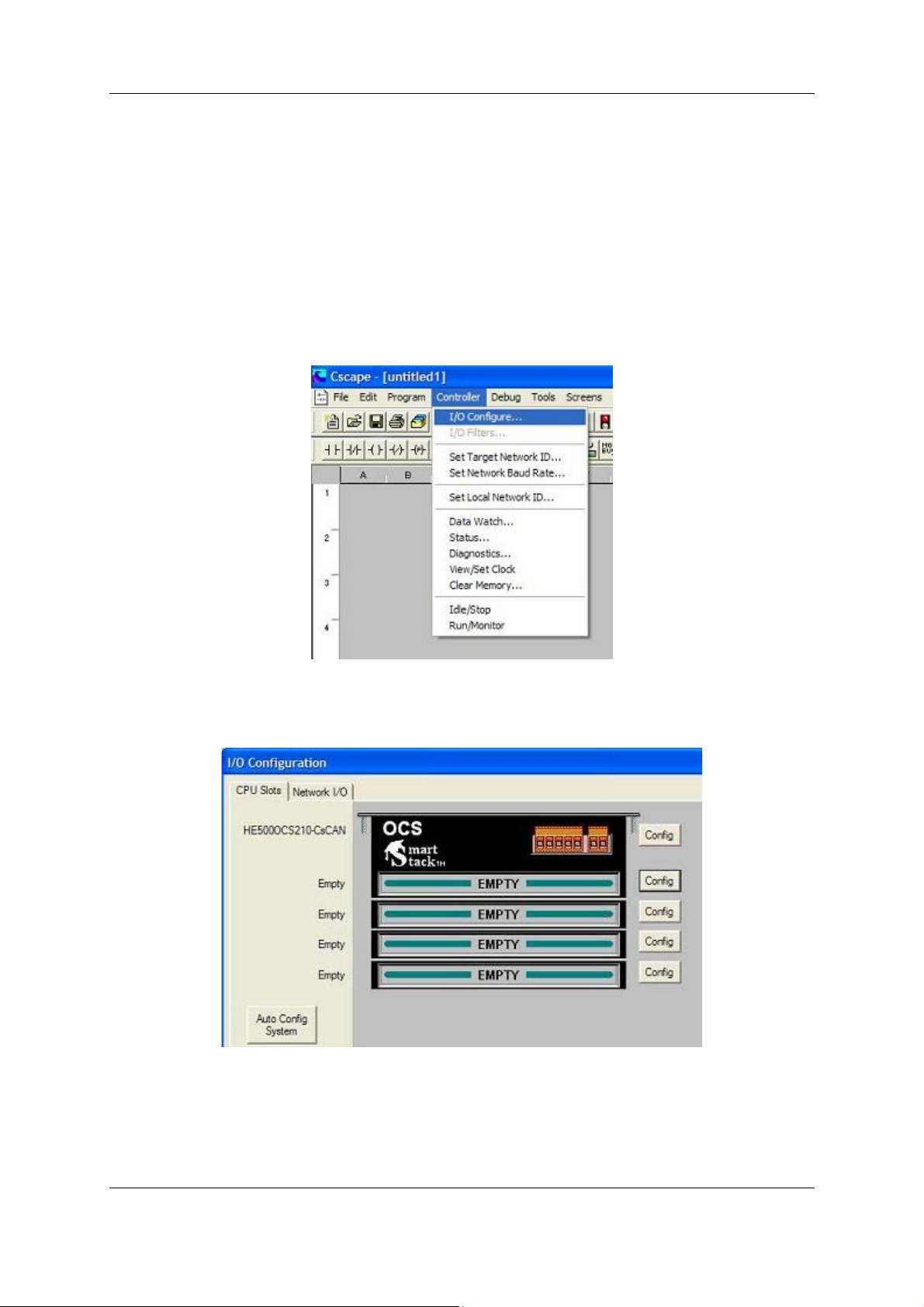

The following describes the steps involved to setup Cscape. Attach the communications module to

the appropriate OCS unit. Open Cscape. All I/O is setup through the I/O Configure Menu in Cscape:

Figure 3.1

The following window is displayed. Select the CONFIG button adjacent to the first empty slot (nearest

the main unit).

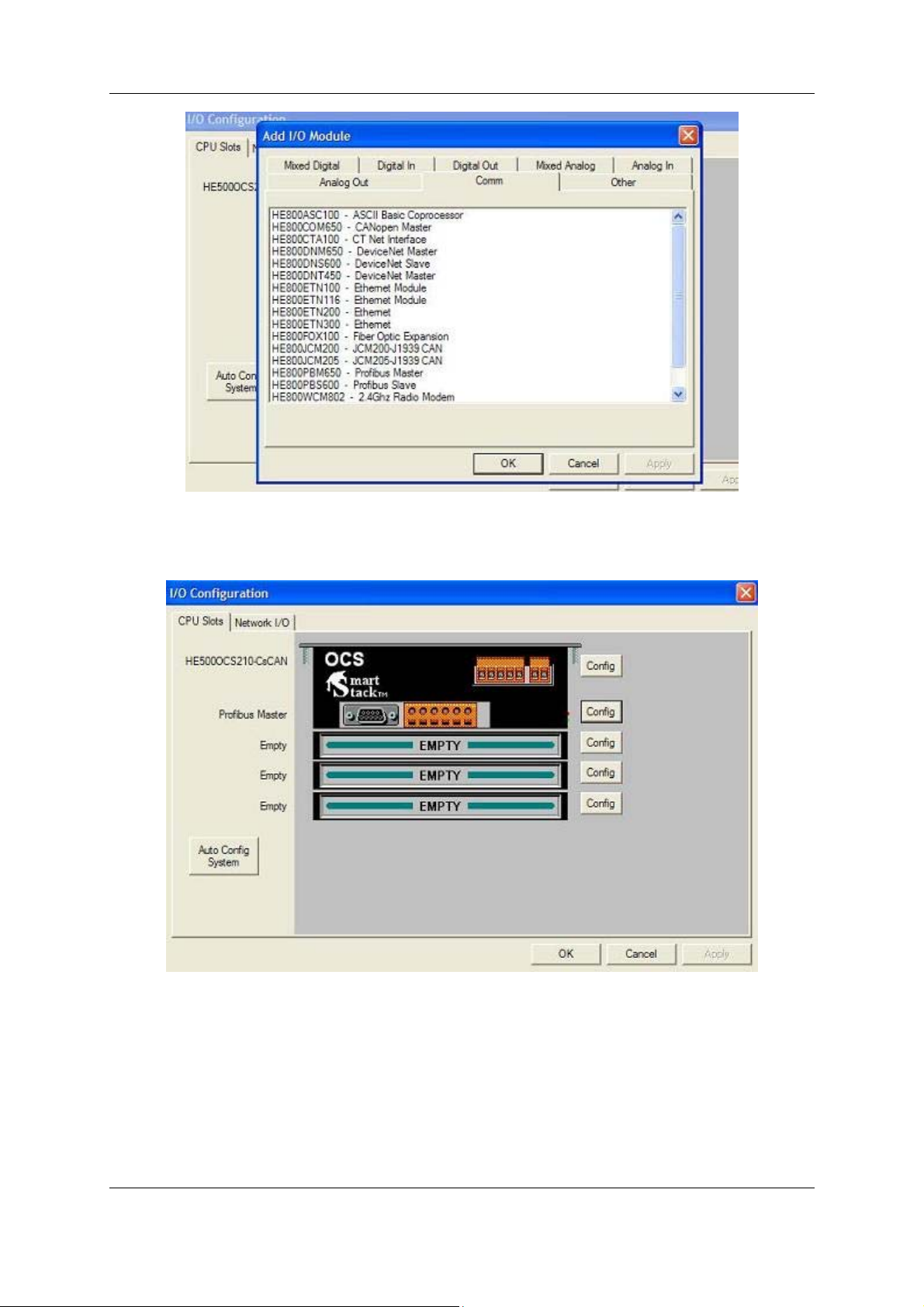

Figure 3.2

Select the COMM Tab. From here select the appropriate Profibus Module and click OK.

PAGE 11 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 12

Getting Started MAN0575-04-EN

Profibus Modules User Manual

Figure 3.3

The selected module is now visibly attached to the main unit and can be configured.

Figure 3.4

Select the CONFIG button adjacent to the module. Then select the MODULE SETUP tab.

PAGE 12 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 13

Getting Started MAN0575-04-EN

Profibus Modules User Manual

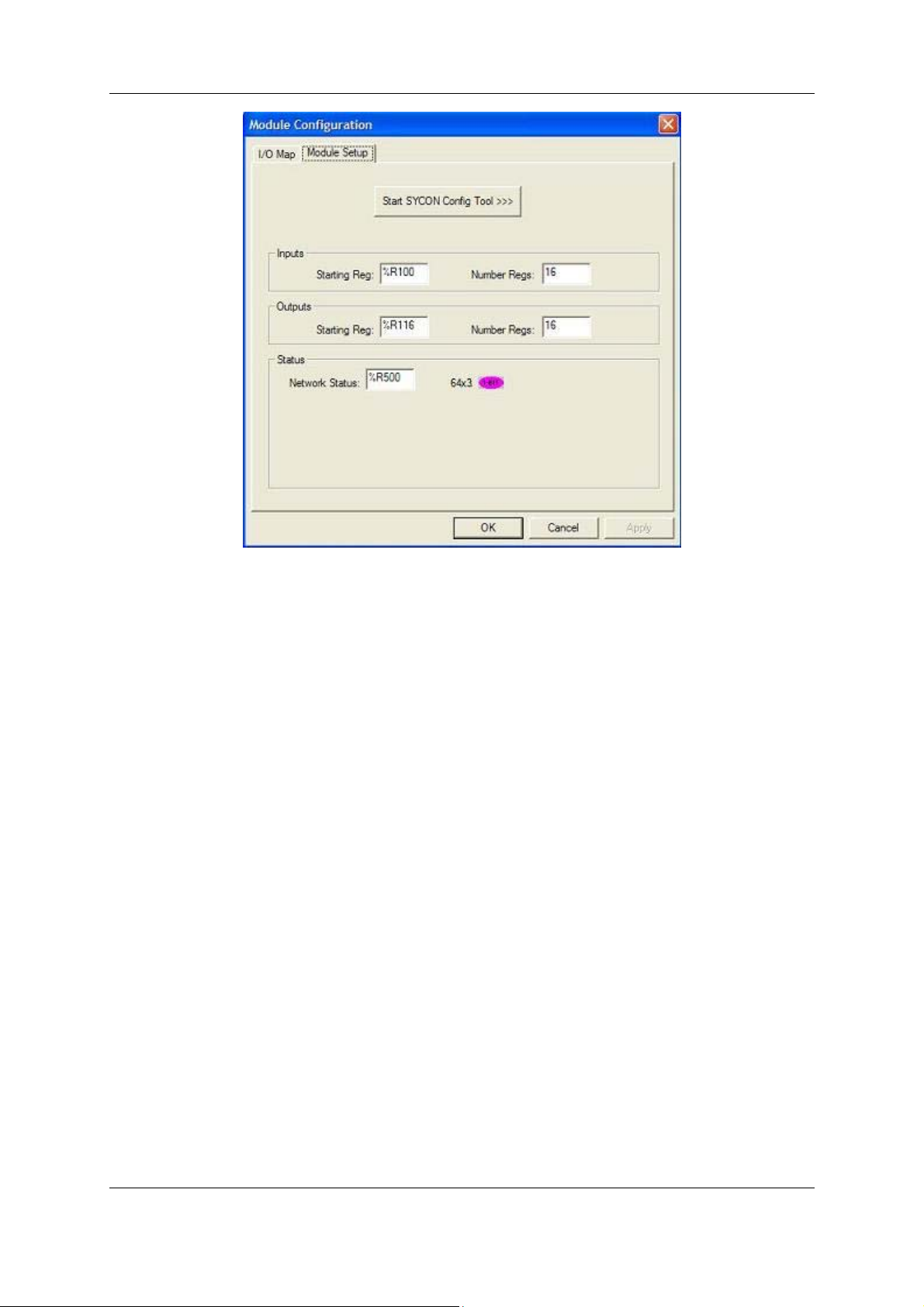

Figure 3.5

Configure the Inputs and Outputs.

NOTE:

INPUTS: means data coming FROM the Network VIA the PBM/PBS Module to the OCS Registers.

OUTPUTS: means data going TO the NETWORK VIA the PBM/PBS Module from the OCS Registers.

In Figure 3.5 above, For both Inputs and Outputs, 16 %R registers are used. The OCS %R registers

are retentive, general purpose, 16 bit registers.

It is VERY important that the number of registers used for both Inputs and Outputs in Cscape

is identical to the number setup in the Hsycon software when setting up the PBM650 and

PBS600 modules. See Figure 3.6 below.

PAGE 13 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 14

Getting Started MAN0575-04-EN

Profibus Modules User Manual

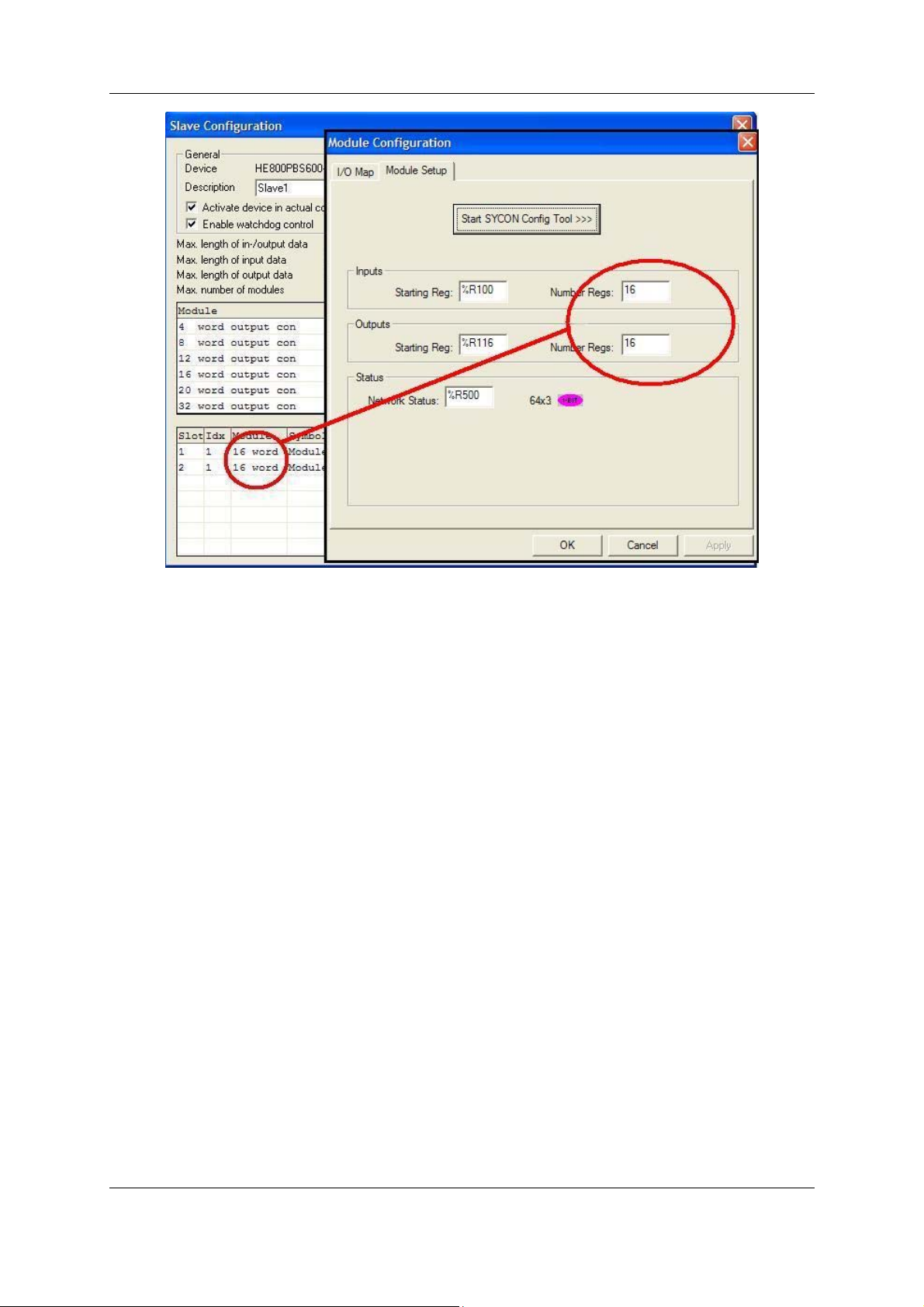

Figure 3.6

The Network Status is a block of registers 64 bits x 3 tables give status’ of each slave station.

Table 1 indicates the the configured state of the corresponding slave.

1 or On means the Slave is configured in the Master

0 or Off means the Slave is not configured in the Master

Table 2 indicates the state of each slave.

1 or On means the Slave and Master are exchanging their I/O data.

0 or Off means the Slave and Master are not exchanging their I/O data.

Table 3 indicates the diagnostic bit of each slave. (Can only be viewed in Hsycon)

1 or On means the latest received slave diagnostic data are available in the

internal diagnostic buffer.

0 or Off means since the last diagnostic buffer read access of the host, no

values were changed in this buffer.

PAGE 14 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 15

Getting Started MAN0575-04-EN

Profibus Modules User Manual

3.3 Configuration of a SmartStack Profibus DP Master to any Profibus DP Slave

The following describes the steps to configure a SmartStack Profibus DP Master to any Profibus DP

Slave:

Action Menu in the System Configurator

Create a new project

•

Copy GSD file of the DP Slave, if the Slave is not in the

•

selection list. Horner module GSD’s loaded by default.

Choose Horner DP Master and provide bus address

•

Choose DP Slave and provide bus address

•

Assign the input and output modules (*1)

•

Assign the offset addresses

•

Assign the DP Slave Parameter data, if the Slave needs

•

Parameter data

Set the bus parameter Mark the Master (left Mouse click), then

•

Set device assignment if no automatic assignment has

•

occurred

Save project

•

Download to the Master. Mark the Master (left Mouse click), then

•

Download to the Slave (if a Horner DP Slave). Mark the Slave (left Mouse click), then

•

Live List Mark the Master (left Mouse click), then

•

Start Debugger Mark the Master (left Mouse click), then

•

Device diagnostic Mark the Slave (left Mouse click), then

•

Stop Debugger

•

Global Diagnostic Mark the Master (left Mouse click), then

•

Transfer user data:

•

Write output, read input

File > New > PROFIBUS

File > Copy GSD

Insert > Master

Insert > Slave

Mark the Slave (left Mouse click), then

Settings > Slave Configuration

Mark the Slave (left Mouse click), then

Settings > Parameter Data

Settings > Bus Parameters

Mark the Master (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Download

Online > Live List

Online > Start Debug Mode

Online > Device Diagnostic

Online > Stop Debug Mode

Online > Global State Field

Mark the Master (left Mouse click), then

Online > I/O Monitor

Figure 3.2. Steps for Configuration of a SmartStack Profibus DP Master to any Profibus DP

Slave

Note (*1): The Offset addresses assigned in the Slave configuration are always related to the DP

Master.

PAGE 15 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 16

Getting Started MAN0575-04-EN

Profibus Modules User Manual

3.4 Configuration of a SmartStack Profibus DP Slave to any Profibus DP Master

The following table describes the steps to configure a SmartStack DP Slave to any DP Master:

Action Menu in the System Configurator

Create a new project

•

Choose Horner DP Master and provide bus address (*1) Insert > Master

•

Choose Horner DP Slave and provide bus address

•

Assign the input and output modules (*2)

•

Set device assignment if no automatic assignment has

•

occurred

Save project

•

Download Mark the Slave (left Mouse click), then

•

Configuration diagnostic Mark the Slave (left Mouse click), then

•

Configuration diagnostic Mark the Slave (left Mouse click), then

•

Transfer user data:

•

Write output, read input

File > New > PROFIBUS

Insert > Slave

Mark the Slave (left Mouse click), then

Settings > Slave Configuration

Mark the Slave (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Extended Device Diagnostic >

SPC3CTRL Slave Config

Online > Extended Device Diagnostic >

SPC3CTRL Master Config

Mark the Slave (left Mouse click), then

Online > I/O Monitor

Figure 3.3. Steps for Configuration of a SmartStack Profibus DP Slave to any Profibus DP

Master

Note (*1): Insert a SmartStack DP Master. This Master is a placeholder and it is not necessary to

match the connected Master.

Note (*2): The Offset addresses assigned in the Slave configuration are always related to the DP

Master.

PAGE 16 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 17

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

Getting Started MAN0575-04-EN

Profibus Modules User Manual

3.5 Configuration of a SmartStack DPV1 Master to any DPV1 Slave

The following describes the steps to configure a SmartStack Profibus DPV1 Master to any Profibus

DPV1 Slave :

Action Menu in the System Configurator

Create a new project

•

Choose Horner DPV1 Master and

•

provide bus address

Choose Horner DPV1 Slave and provide

•

bus address

Set DPV1 parameter Mark the Slave (left Mouse click), then

•

Set DPV1 buffer size (if connecting to

•

Horner DPV1 Slave.

Set the bus parameter Mark the Master (left Mouse click), then

•

Set device assignment for the Master if

•

no automatic assignment has occurred

Set device assignment for the Slave if no

•

automatic assignment has occurred (if

connecting to a Horner Slave).

Save project

•

Download to the Master Mark the Master (left Mouse click), then

•

Download to the Slave Mark the Slave (left Mouse click), then

•

Live List Mark the Master (left Mouse click), then

•

Transfer user data:

•

Read and write data

File > New > PROFIBUS

Insert > Master

Insert > Slave

Settings > Slave Configuration

DPV1 Parameter data

Mark the Slave (left Mouse click), then

Settings > Slave Settings

Settings > Bus Parameters

Mark the Master (left Mouse click), then

Settings > Device Assignment

Mark the Slave (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Download

Online > Live List

Mark the Master (left Mouse click), then

Online > Message Monitor

Mark the Slave (left Mouse click), then

Online > Message Monitor

Table 1: Steps for Configuration of Profibus DPV1 Master to any Profibus DPV1 Slave.

Note (*1): If connecting to anything other than a Horner Slave then see the Slave manual for

configuration help.

PAGE 17 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 18

1

2

3

4

5

6

7

8

9

Getting Started MAN0575-04-EN

Profibus Modules User Manual

3.6 Configuration a SmartStack Profibus DPV1 Slave to any Profibus DPV1 Master

The following table describes the steps to configure a SmartStack Profibus DPV1 Slave to any

Profibus DPV1 Master:

Action Menu in the System Configurator

Create a new project

•

Choose Horner DPV1 Master and provide bus address

•

(*1)

Choose Horner DPV1 Slave and provide bus address

•

Set DPV1 parameter Mark the Slave (left Mouse click), then

•

Set DPV1 buffer size Mark the Slave (left Mouse click), then

•

Set device assignment if no automatic assignment has

•

occurred

Save project

•

Download Mark the Slave (left Mouse click), then

•

Transfer user data:

•

Read and write data

File > New > PROFIBUS

Insert > Master

Insert > Slave

Settings > Slave Configuration

DPV1 Parameter data

Settings > Slave Settings

Mark the Slave (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Mark the Slave (left Mouse click), then

Online > Message Monitor

Figure 3.5. Steps for Configuration a SmartStack Profibus DPV1 Slave to any Profibus DPV1

Master

Note (*1): Insert a SmartStack Profibus DPV1 Master. This Master is a placeholder and it is not

necessary to match the connected Master.

PAGE 18 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 19

1

2

3

4

5

6

7

8

Getting Started MAN0575-04-EN

Profibus Modules User Manual

3.7 Verifying a Project

The following describes the steps to configure a SmartStack Profibus DP Master as a class 2 Master:

Action Menu in the System Configurator

Create a new project

•

Choose Horner DP Master and provide bus address

•

Set the bus parameter Mark the Master (left Mouse click), then

•

Set device assignment if no automatic assignment has

•

occurred

Save project

•

Download Mark the Master (left Mouse click), then

•

Live List Mark the Master (left Mouse click), then

•

Call DP class 2 function Mark the Hilscher Master (left Mouse click), then

•

File > New > PROFIBUS

Insert > Master

Settings > Bus Parameters

Mark the Master (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Live List

Online > Message Monitor

Table 3.6: Steps for Configuration as a Class 2 Master.

Note (*1): The functions for Profibus DP class 2 are activated by messages or by the application

program.

PAGE 19 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 20

Page 21

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

CHAPTER 4: CONFIGURATION OF PROFIBUS WITH HSYCON

4.1 Setting up the PROFIBUS Configuration

To create a new configuration, choose the File > New menu. This will offer a selection list of fieldbus

systems. Choose PROFIBUS. If only the PROFIBUS fieldbus system is installed, the configuration

window will open directly. The name of the configuration file can be allocated when the configuration

is finished or with File > Save As.

4.2 GSD Files

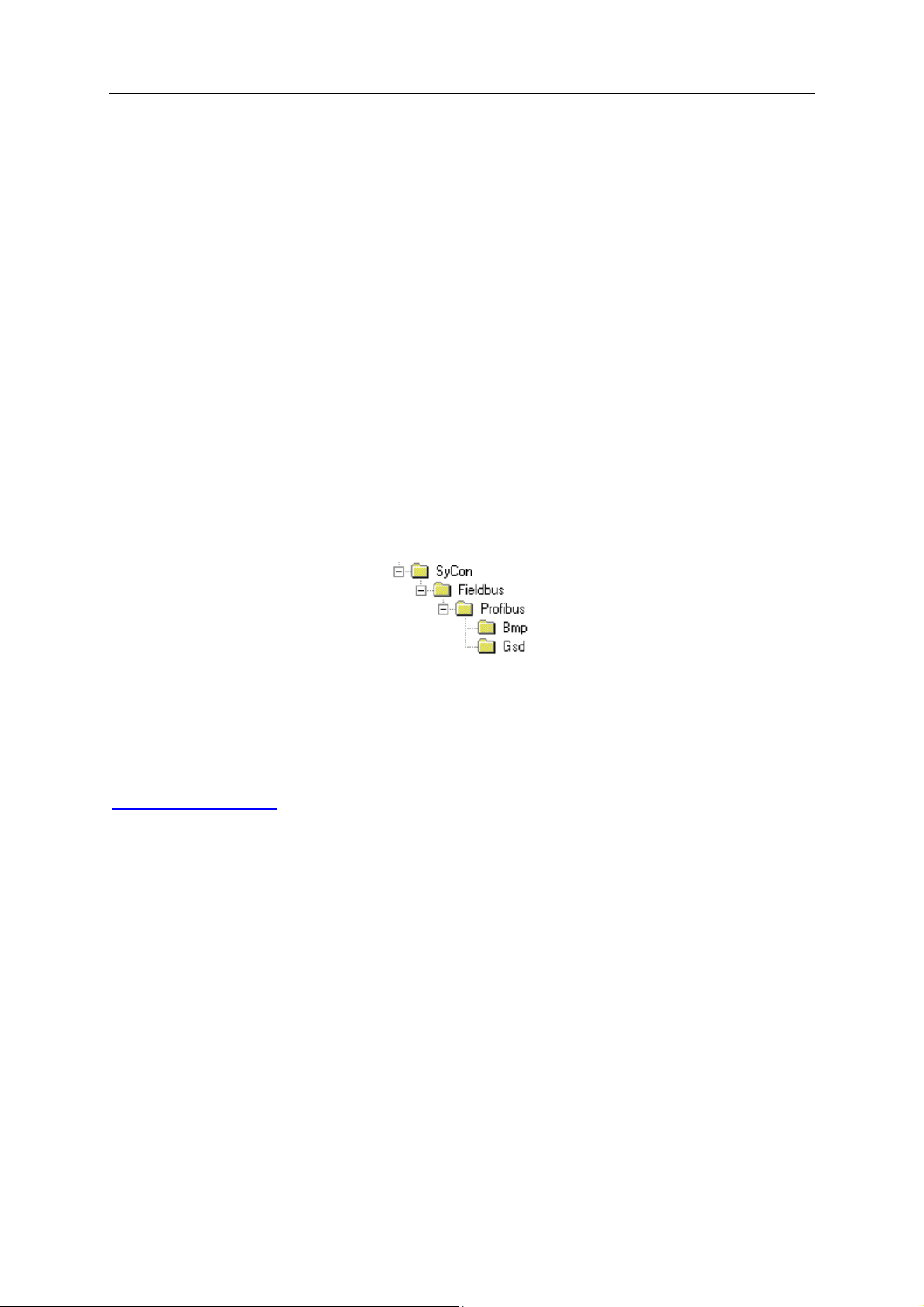

GSD (Electronic data sheet of a device) files contain and describe the functions and characteristics of

PROFIBUS devices. The abbreviation GSD means 'Gerätestammdaten' (Device Base Files). All the

available GSD files together form the device database.

When the program is started, the System Configurator automatically retrieves all of the GSD files

stored in the GSD directory. The device names are placed into an internal list. During configuration,

the device-specific data is retrieved directly from the GSD files.

If a DP Slave device does not appear in the selection list, the required GSD file can be copied into the

GSD directory with File > Copy GSD. Another way is to copy the GSD file into the SyCon GSD

directory using Windows Explorer and then retrieve the GSD files into the GSD directory with

Settings > Path and OK.

The GSD files can be viewed with the Tools > GSD Viewer menu.

.

Figure 4.2: GSD files and bitmaps directory

SmartStack Devices: The GSD files for the SmartStack devices are included and installed.

Other Devices: The respective device manufacturer provides the GSD files for other devices.

The GSD files of many vendors are available on the PROFIBUS user organisation home page.

http://www.profibus.com

Note: GSD files are only used for PROFIBUS-DP.

The GSD directory is adjustable. In order to alter the directory from a previous setting in another

directory, use the Settings > Path menu. All GSD files must be placed in this directory.

PAGE 21 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 22

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

4.3 Master

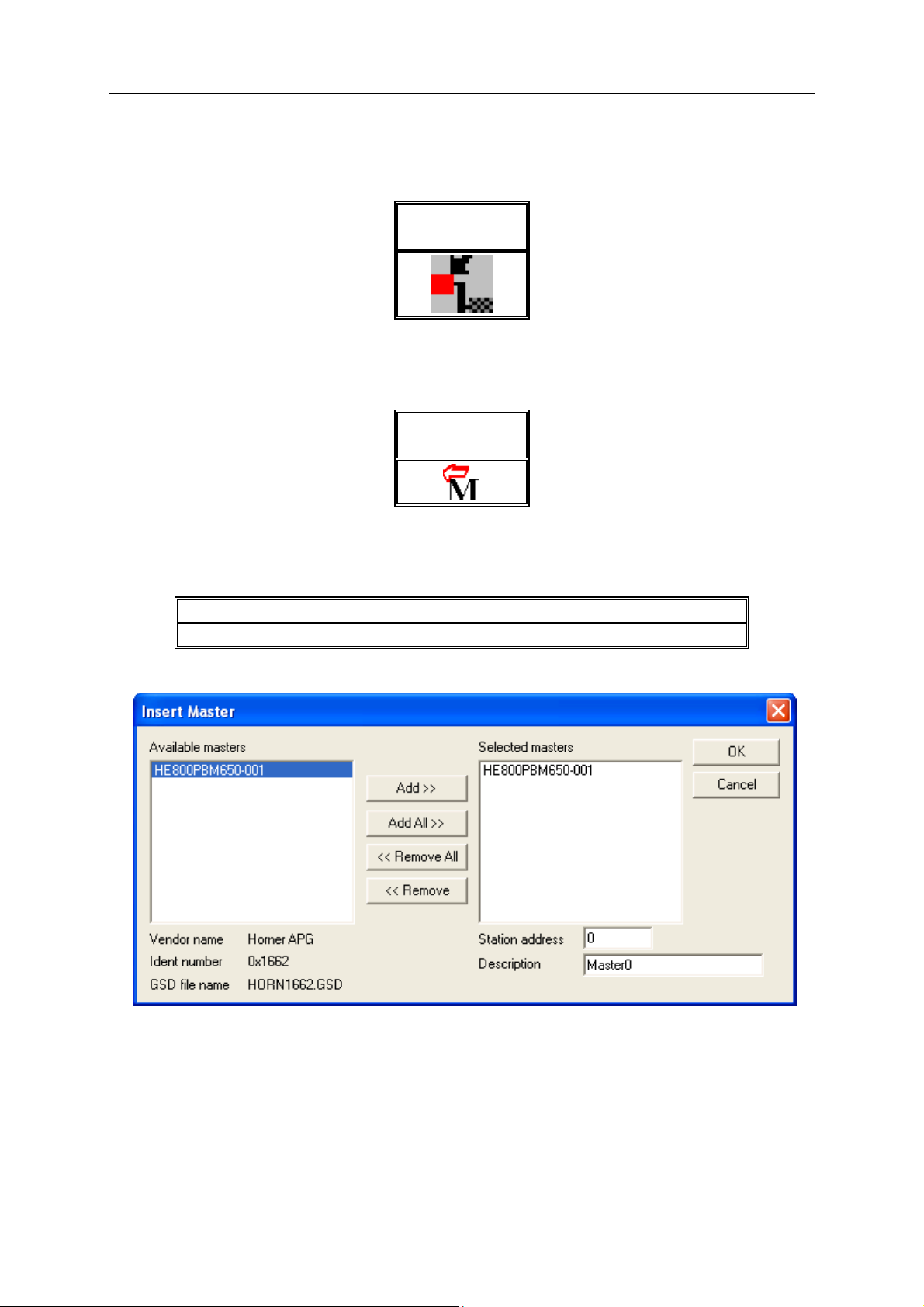

In order to insert a (SmartStack) Master into the configuration, choose the Insert > Master menu, this

will open the selection window, or click on the symbol:

Symbol

Insert > Master

Table 2: Symbol Insert > Master

The mouse pointer automatically changes into the Insert Master pointer.

Mouse pointer

Insert Master

Table 3: Mouse pointer insert Master

Click on the position where the Master is to be inserted. The dialog box, from which one or more

Masters can be chosen, opens. The following types of Masters may be selected:

PROFIBUS Combi Master (PROFIBUS-FMS and PROFIBUS-DP) PB

PROFIBUS-DP Master DPM

Table 4: Selectable Master types

Figure 1: Insert > Master

In this window select the required Master by clicking on it in the Available Masters list and then click

the Add button to put the Master to Selected Masters. With OK confirm the selection and the Master

will be insert. This example shows a HE800PBM650-001 that is inserted with the Station address 0

and the Master0. Note for SmartStack masters only COMDPM and COMPB are valid.

PAGE 22 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 23

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

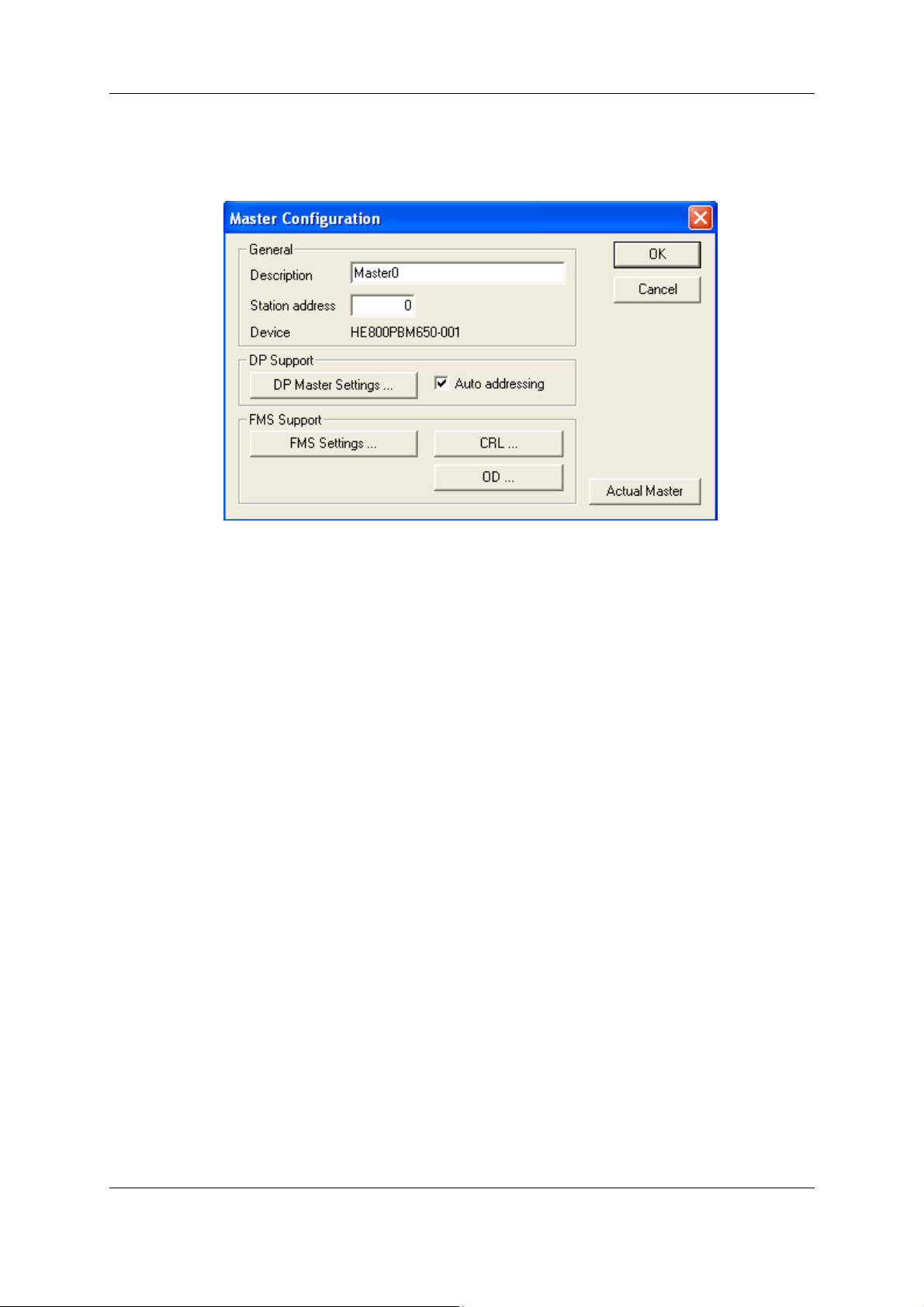

4.4 Master Configuration

The Master-specific configuration is carried out in the following window. Set the focus on the Master

(left mouse click) and then select the Settings > Master Configuration menu or double click on the

symbol of the Master to be configured, the following window will open.

Figure 2: Settings > Master Configuration

The following can be set in this Master Configuration window:

• A (symbolic) Description of the Master

• The Station address of the Master

• Selection of the Master as the Actual Master (for example as the download target)

The following parameters may be set for PROFIBUS-DP:

• Open the DP Master Settings window

• Activate or deactivate the automatic addressing (Auto addressing) for this DP Master.

PAGE 23 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 24

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

4.5 PROFIBUS-DP Auto Configuration

The Auto Configuration can be used to configure a Slave. The parameter data cannot be retrieved

from a PROFIBUS-DP Slave. Thus, if the Slave requires parameter data, it must be provided by the

user. The following is the procedure for Auto Configuration:

Action Menu in the System Configurator

Create a new project

•

Copy GSD file of the DP Slave, if the Slave is not in the

•

selection list

Choose Horner DP Master and provide bus address

•

Choose DP Slave and provide bus address

•

Set the bus parameter Mark the Master (left Mouse click), then

•

Set device assignment if no automatic assignment has

•

occurred

File > New > PROFIBUS

File > Copy GSD

Insert > Master

Insert > Slave

Settings > Bus Parameters

Mark the Master (left Mouse click), then

Settings > Device Assignment

Save project

•

Download Mark the Master (left Mouse click), then

•

Live List Mark the Master (left Mouse click), then

•

Start Debugger Mark the Master (left Mouse click), then

•

Device diagnostic Mark the Slave (left Mouse click), then

•

Compare Configuration

•

Automatic configuration

•

Stop Debugger

•

Save project

•

Download Mark the Master (left Mouse click), then

•

Start Debugger Mark the Master (left Mouse click), then

•

Device diagnostic Mark the Slave (left Mouse click), then

•

Stop Debugger

•

File > Save

Online > Download

Online > Live List

Online > Start Debug Mode

Online > Device Diagnostic

Compare Configuration

Automatic Configuration

Online > Stop Debug Mode

File > Save

Online > Download

Online > Start Debug Mode

Online > Device Diagnostic

Online > Stop Debug Mode

Transfer user data:

•

Write output, read input

Mark the Master (left Mouse click), then

Online > I/O Monitor

Figure 4.5. Auto Configuration (PROFIBUS-DP)

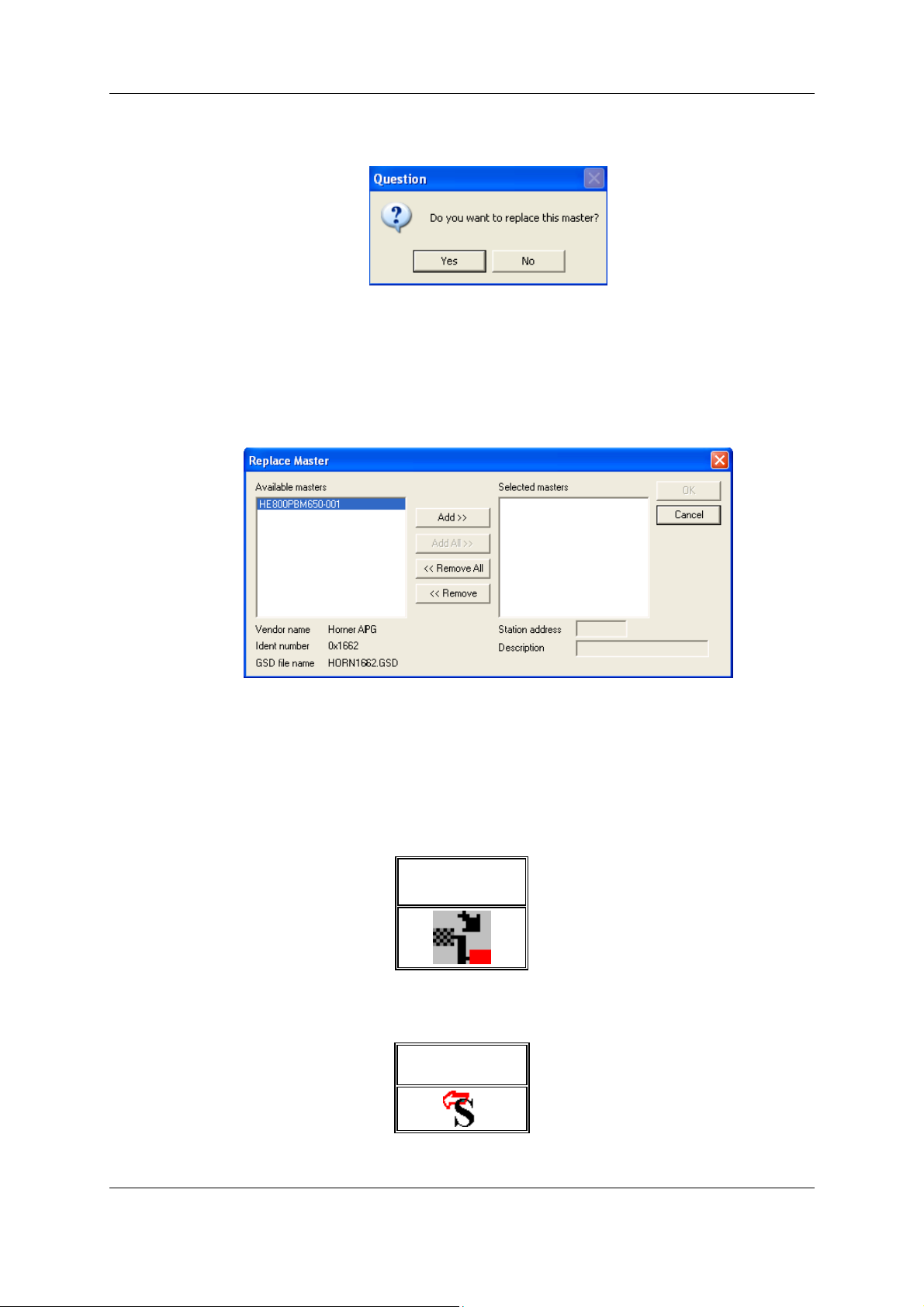

4.6 Replace Master

If a Master already exists in the configuration and should be replaced for another Master, first set the

focus on the Master (left mouse click on the Master) and then choose the menu Edit > Replace or

PAGE 24 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 25

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

Right mouse click on the Master and select Replace. In the newly opened window, the question

appears asking if the Master should be replaced.

Figure 3: Security question replace Master

Click the Yes button, a new window opens. Replace the Master for the required one.

Figure 4: Edit > Replace Master

Select the required Master by clicking on it in the Available Masters list. Click the Add button to put

the Master in the Selected Masters list. Confirm the selection by with OK and the Master will be

replaced.

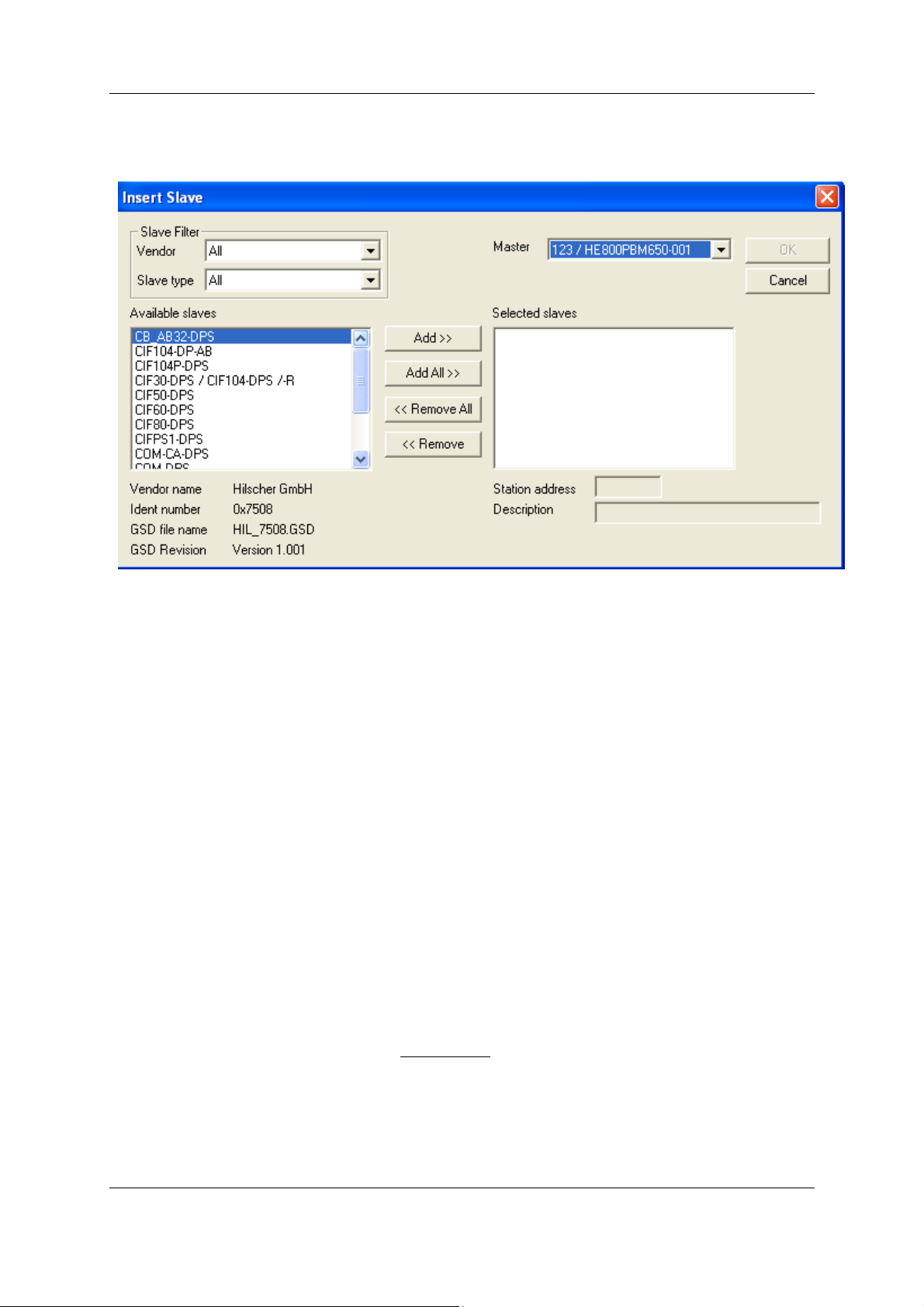

4.7 Insert DP Slave

To insert a PROFIBUS-DP Slave into the configuration, choose the Insert > Slave menu to open the

selection window, or click on the symbol:

Symbol

Insert > Slave

Table 5: Symbol Insert > Slave

The mouse pointer automatically changes to the Insert Slave pointer:

Mouse pointer

insert Slave

Table 6: Mouse pointer insert Slave

PAGE 25 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 26

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

Click on the position where the Slave is to be inserted. The dialog box, from which one or more

Slaves can be selected, opens:

Figure 5: Insert > Slave

The list on the left displays all the available Slave devices whose GSD files have been put in the GSD

directory. A filter can be used to limit the selection list to Slave type and Vendor (manufacturer).

Further information on a Slave is shown below the selection list (Available Slaves) when it is selected

(a mouse click). The Slave appears in the list Selected Slaves with a double click or with the Add

button.

All devices in the right-hand list are assigned to the current Master that is also shown in this window.

If the Slaves in the right-hand list are chosen, one after the other (a mouse click), then every Slave

can be allocated a Station address as well as a name in the Description field.

For every Slave accepted into the right-hand list, the station address count is automatically raised by

one but can be overwritten by the user in the Station address field.

Note: It is permissible to choose a Slave several times. However, each Slave must possess its own

(unique) station address in order to distinguish it on the network.

4.8 Slave Configuration

First click on the symbol of the Slave with the left mouse button and then choose the Settings >

Slave Configuration menu or open the Slave configuration window by double clicking on the

PROFIBUS-DP Slave device.

The Slave-specific configuration is carried out in this window. Here, the modules and their addresses

are allocated in the process data memory in the Master

. Note that the address must agree with that in

the PC application program.

Note 1: The information of the offset addresses refers to the addressing of the data in the Master!

The address information does not refer to the addressing of the data in the Slave! The Slave

organises its own data addressing.

PAGE 26 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 27

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

Note 2: With the SmartStack Slave, the input or output data at the bus are taken directly into the

Dual-port memory. The offset addresses refer to the Master.

There are two types of Slaves. A simple Slave has a fixed data length. The data length of a

modular Slave is configurable. A modular Slave can be understood as a combination of a simple

Slave with a Station address.

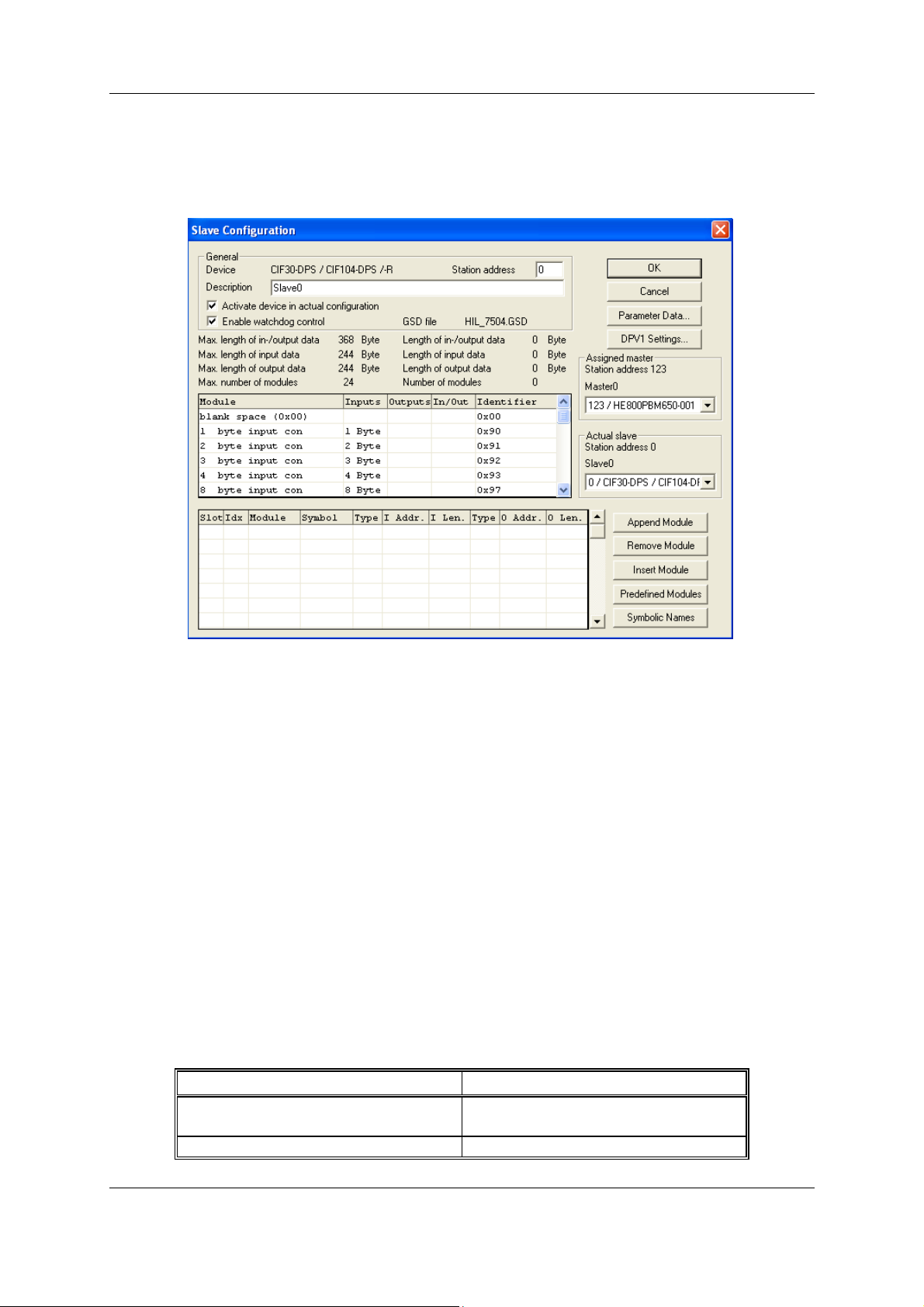

Figure 6: Settings > Slave Configuration

The selection list (upper list) shows all possible modules of the Slave. In the case of a simple Slave,

one module is shown and this is automatically copied into the configuration list (lower list). In the case

of a modular Slave, the user must select the required modules and transfer these by means of a

double click or transfer it using the Append Module button into the configuration list (lower list).

If a module consists of several sub-modules, then each sub-module is shown in the configuration list

(lower list) in a separate row. This is displayed by the number in the Slot column. The Index column

shows a sequential number for sub-modules.

For configuration of the modules (selection of the modules) of a Slave, proceed as follows:

Transfer all the required modules from the selection list (upper list) into the configuration list (lower

list). The sequence of the modules in the configuration list (lower list) is important and must be in

agreement with the Slave. Typically, the sequence follows the actual physical sequence. There are

Slaves to which this rule does not apply and where first analogue modules and then digital modules

must be entered, independent of their actual sequence.

In the configuration list (lower list) allocate the address of each module to the process depiction

memory. The address is entered separately in the Type and Addr columns for Inputs and Outputs.

The I/O addresses can be allocated by the user or can be automatically assigned by SyCon. For this

purpose Auto addressing must be activated or deactivated in the Master Configuration window:

Auto addressing activated Auto addressing deactivated

Auto addressing

(by SyCon)

The addresses will be allocated beginning

Manually addressing

(by the user)

The address 0 is shown in the I Addr or O

PAGE 27 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 28

Addr

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

with 0 and incremented in accordance with

the entry sequence of the Slaves before

downloading and can be viewed and

checked in the View > Address Table.

and must be overwritten by the user.

Table 7: Auto addressing activated / deactivated

Depending on the Addressing mode, which can be set in the DP Master Settings, the addresses

are either Byte or Word addresses. The DP Slaves utilise the Watchdog Control setting in order to

detect communication errors to the assigned DP Master. When the DP Slave finds an interruption of

an already operational communication, defined by a Watchdog time, then the Slave carries out an

independent Reset and places the outputs into the secure condition.

Caution: When the monitoring by means of the Watchdog Control has been deactivated, it is

possible that the outputs are not reset by the Slave, even though the communication has been

interrupted.

If Activate Device in the Current Configuration is selected, the process memory for this Slave is

occupied in the Master and data is exchanged. If this setting is switched off, the process memory for

this Slave is occupied in the Master and no data is exchanged.

4.9 Inserting Predefined Device – PDD

In order to insert predefined devices, choose Insert > PDD. This function is used for simple copying

or re-using already configured devices. Before this function can be used, a PDD Export must be

carried out as described in section PDD Export.

Figure 7: Inserting predefined device – PDD (1)

Select the PDD file and then Open. The following window appears:

PAGE 28 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 29

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

Figure 8: Inserting predefined device – PDD (2)

Select the device or devices of the Found predefined devices (left-hand side), pull this over to the

Selected predefined devices (right-hand side) and release the left mouse button (drag and drop).

The following picture will appear:

Figure 9: Inserting predefined device – PDD (3)

The figure shows a device with the description PC_Slave consisting of two modules with the

description Module1 and Module2. Choose Ok in order to insert the device into the configuration.

The station address of the device can be altered subsequently.

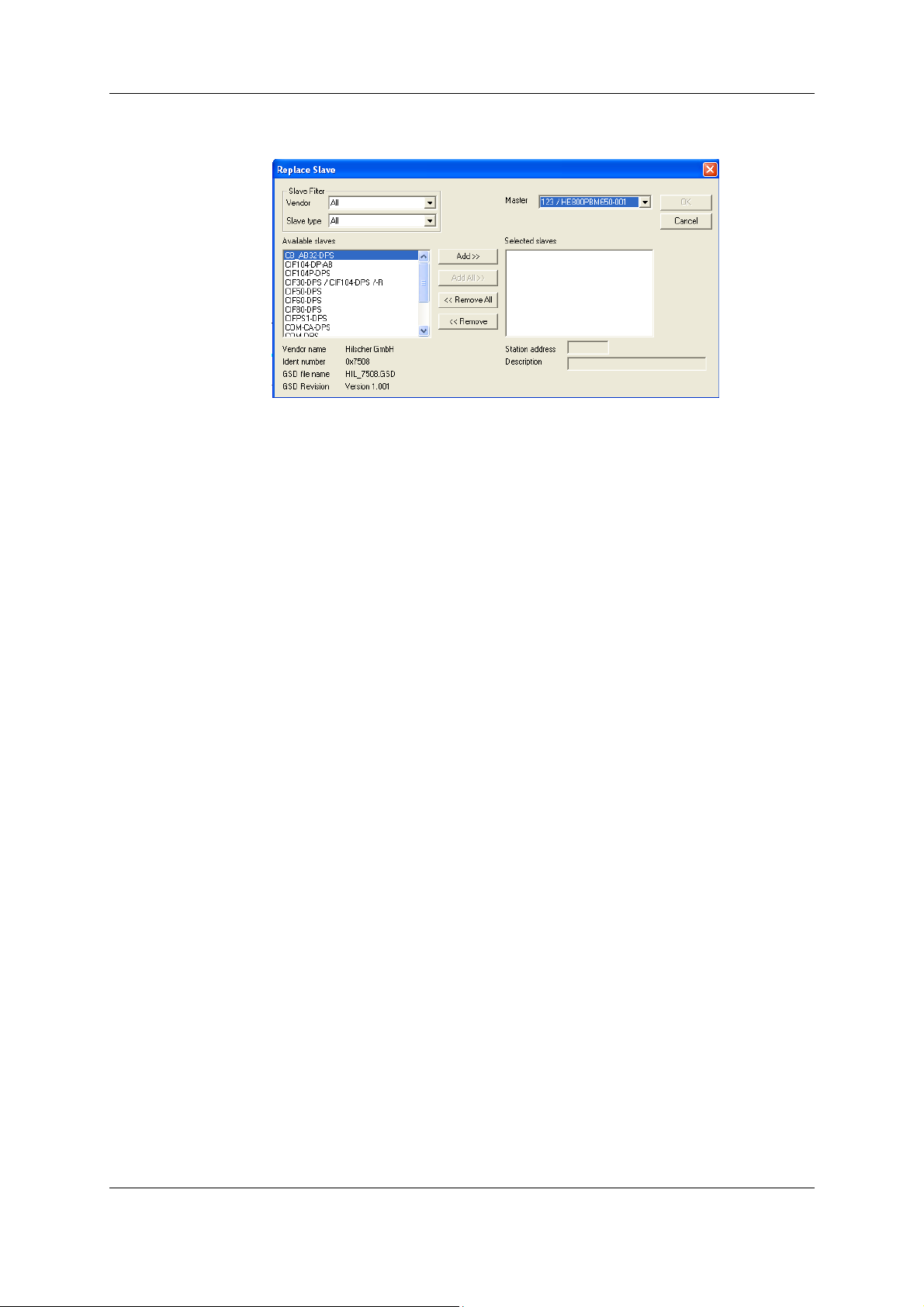

4.10 Replace Slave

If a Slave already exists in the configuration and should be replaced with another Slave, first set the

focus on the Slave (left mouse click at the Slave) and then choose the menu Edit > Replace or right

click the on the Slave and select Replace. In the new window, the question appears asking if the

Slave should be replaced.

Figure 10: Security question replace Slave

PAGE 29 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 30

Profibus configuration MAN0575-04-EN

Profibus Modules User Manual

Click the Yes button a new window opens, allowing the replacement of the current Slave with another

one.

Figure 11: Edit > Replace Slave

In this window, select the required Slave by clicking on it in the Available Slaves list. Clicking the

Add button puts the Slave in the list Selected Slaves. With OK confirm the selection and the Slave

will be replaced.

PAGE 30 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 31

Page 32

Setings MAN0575-04-EN

Profibus Modules User Manual

CHAPTER 5: SETTINGS

5.1 Device Assignment

The Device Assignment setting determines how the System Configurator communicates with the device. This

is set in the device arrangement via the menu Settings > Device Assignment. The following possibilities are

available:

------------------------------------- CIF Serial Driver -------------------------------------

Figure 12: Driver selection – CIF Serial Driver

CIF Serial Driver:

CIF Serial Driver: The HSystem Configurator communicates with the SmartStack device over a serial

connection. The serial interface of the PC must be connected via a cable (straight) with the diagnostic

interface of the SmartStack device. The cable is standard straight through Programming cable.

Choose the CIF Serial Driver and then OK, in order to select the CIF Serial Driver. The connection must first

be established using the relevant COM port checkbox. The ports available will depend upon the number of

ports installed in the PC. and free.

The System Configurator sends a request to the corresponding COM interface and polls the Firmware of the

device. A display of the Firmware will indicate when a device is connected. In the event that no device is

connected a Timeout error (-51) appears.

Figure 13: CIF Serial Driver – Device Assignment

The error number –20 indicates that this COM interface is not available or already in use.

5.2 Bus Parameters

The Bus Parameters are the foundations of a functioning data exchange. This section contains information

for setting the Bus Parameters as well as the descriptions of the individual parameters.

Basic Rule: The Bus Parameters must be set the same

for all devices. The Station Address, on the other

hand, must be different from device to device.

PAGE 32 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 33

Setings MAN0575-04-EN

Profibus Modules User Manual

For PROFIBUS Master devices (PROFIBUS-DP):

The Bus Parameters are set.

Most of the PROFIBUS-DP Slave devices

Recognize the Baud rate automatically and adapt to it. This is especially the case when the ASIC SPC3 is

used.

There are also PROFIBUS-DP Slave devices, in which the Bus Parameters must be set by the user.

5.3 Setting the Bus Parameters and Profiles

The Baud rate can be set in the Settings > Bus Parameters menu. Furthermore, the optimising or profile

can be selected.

Figure 14: Settings > Bus Parameters

The Bus Parameters may be viewed with the Settings > Bus Parameters menu and may be edited by

clicking on the Edit button. The Bus Parameters may or may not be edited depending upon the optimising or

profile selected. The optimising standard provides each Baud rate with default Bus Parameters for

PROFIBUS-DP systems. By changing the settings in the Optimising field from Standard to User defined,

all Bus Parameters may be edited.

Figure 15: Editing Bus Parameters

Caution: Changing the Bus Parameters can cause communication interruptions.

PAGE 33 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 34

Setings MAN0575-04-EN

Profibus Modules User Manual

Note: The offline Bus Parameters are displayed. The Bus Parameters are only accepted by the device upon

download of the configuration.

The Baud rate must be set to be the same for all devices on the bus. The result of changing the Baud rate is

that all other parameters must be re-calculated. The System Configurator tests whether the Baud rate is

supported by all configured PROFIBUS-DP Slave devices based on entries in the GSD files. If the System

Configurator recognizes at least one device that does not support the selected Baud rate, then an error

message will appear.

The highest station address is the highest bus address up to which a Master searches for another Master

on the bus in order to pass on the Token. This station address must on no account be smaller than the

Master station address.

For PROFIBUS-DP, the field Access monitoring time is used for the entry of the monitoring time of the

Slave. If the time chosen for this is too short for a low Baud rate, then it is possible that the Slaves will set

their outlets to zero. If the time chosen is too long, it is possible that if an interruption occurs, the Slaves will

take a long time to set their outlets to zero.

For PROFIBUS-DP, the Auto Clear setting is provided for global error handling. The DP Master monitors the

user data exchange (Data Exchange) to all DP Slaves by means of a timer. If no data exchange occurs to at

least one DP Slave, or an existing data exchange takes place after the expiration of a monitoring time, and the

Auto clear mode option is ON, then the Master leaves the Data Exchange and sets the outlets of all

assigned DP Slaves into a secure condition.

5.4 Description of the Individual Parameters

All times for the Bus, parameters are given in Bit times.

The Bit time t

is the result of the reciprocal of the Baud rate:

Bit

t

= 1 / Baud rate (Baud rate in Bit/s)

Bit

The conversion from milliseconds into a Bit time is shown in the following formula:

Bit time = Time [milliseconds] * Baud rate,

Formula 2: Conversion into Bit time t

The Bus parameters and their meanings:

Baud rate

Transfer speed: number of Bits per second.

Baud rate Bit time (t

9,6 kBaud 104,2 us 1200 m

19,2 kBaud 52,1 us 1200 m

93,75 kBaud 10,7 us 1200 m

187,5 kBaud 5,3 us 1000 m

500 kBaud 2 us 400 m

1,5 Mbaud 666,7 ns 200 m

3 Mbaud 333,3 ns 100 m

6 Mbaud 166,7 ns 100 m

12 Mbaud 83,3 ns 100 m

Formula 1: Bit time t

Max cable length (type

)

Bit

Bit

Bit

A)

Table 8: Baud rates, Bit times and cable lengths

Note: The maximum cable length is dependent on the Baud rate.

PAGE 34 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 35

Setings MAN0575-04-EN

Minimum Station Delay of Responders (min T

Profibus Modules User Manual

)

SDR

This is the shortest time period that must elapse before a remote recipient (Responder) may send an

acknowledgement of a received query telegram. The shortest time period between receipt of the last Bit

of a telegram to the sending of the first Bit of the following telegram.

Value range: 1 .. 65535

Maximum Station Delay of Responders (max T

SDR

)

This is the longest time period that must elapse before a Sender (Requestor) may send a further query

telegram. Greatest time period between receipt of the last Bit of a telegram to the sending of the first Bit

of the following telegram.

The Sender (Requestor, Master) must wait at least for this time period upon sending an unacknowledged

telegram (e.g. Broadcast only) before a new telegram is sent.

Value range: 1 .. 65535

Slot Time (T

)

SL

'Wait for receipt' – monitoring time of the Senders (Requestor) of telegram for the acknowledgement of the

recipient (Responder). After expiration, a retry occurs in accordance with the value of 'Max. telegram

retries'.

Value range: 52 .. 65535

Quiet Time (T

QUI

)

This is the time delay that occurs for modulators (Modulator-trip time) and Repeaters (Repeater-switch

time) for the change over from sending to receiving.

Value range: 0 .. 255

Setup Time (T

SET

)

Minimum period “reaction time” between the receipt of an acknowledgement to the sending of a new

query telegram (Reaction) by the Sender (Requestor).

Value range: 1 .. 255

Target Rotation Time (T

TR

)

Pre-set nominal Token cycling time within the Sender authorization (Token) will cycle around the ring.

How much time the Master still has available for sending data telegrams to the Slaves is dependent on

the difference between the nominal and the actual token cycling time.

Value range: 1 .. 16.777.215

GAP Update Factor (G)

Factor for determining after how many Token cycles an added participant is accepted into the Token ring.

After expiry of the time period G*T

, the Station searches to see whether a further participant wishes to

TR

be accepted into the logical ring.

Value range: 1 .. 100

Max number of telegram retries (Max_Retry_Limit)

Maximum number of repeats in order to reach a Station.

Value range: 1 .. 8

Highest Station Address (HSA)

Station address of the highest active (Master) Station.

Value range: 2 .. 126

Further, there are:

Ready time (T

RDY

)

This is the time period, after the Master has sent out a query, during which it must be ready for the

respective acknowledgement or answer.

PAGE 35 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 36

Setings MAN0575-04-EN

Synchronization time (T

SYN

)

Profibus Modules User Manual

This is the minimum time that must be available to each device as a rest condition before it is allowed to

accept the start of a query. It is defined at 33 Bit times.

The following parameters are applicable only for PROFIBUS-DP:

Data Control Time (Data_Control_Time)

This parameter defines the time within the Data_Transfer_List is updated at least once. After the

expiration of this period, the Master (class 1) reports its operating condition automatically via the

Global_Control command.

Value range: 1 .. 65535 (time basis 10ms)

Min Slave Interval (Min_Slave_Interval)

This parameter defines the minimum time period between two Slave list cycles. The maximum value that

the active Stations require is always given.

Value range: 1 .. 65535 (time basis 100us).

Access Monitoring (T

Access monitoring T

)

WD

at the Slave ensures that when an interruption of the DP Master occurs, the

WD

outlets are placed in a secure condition after this time period.

Poll Timeout (Poll_Timeout)

This parameter defines the maximum time period in a Master-Master relationship within which the

answer must be fetched by the Requestor.

Value range: 1 .. 65535 (time basis 1ms).

T

and T

ID1

ID2

This is the time that the Sender spends at idle after the receipt of the last Bit of a telegram on the Bus,

until the first Bit of a new telegram is sent on the Bus.

Depending on the type of the telegram:

T

starts after the Initiator has received an acknowledgement, answer or a Token telegram.

ID1

T

= max (T

ID1

+ 2 * T

QUI

+ 2 + T

SET

SYN

min T

SDR

). (*)

T

starts after the Initiator has sent a telegram that is not acknowledged.

ID2

These times cannot be set directly, they result from the given calculations.

(*) Depending on the ASIC and Baud rate utilized, the T

values due to the ASIC software.

5.5 Rules

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

T

= max (T

ID2

For min T

0 < min T

For T

T

QUI

QUI

< T

, T

RDY

+ 2 * T

QUI

, max T

SDR

< max T

SDR

SDR

Formula 5: Min T

and min T

RDY

< min T

SDR

.

Formula 3: T

+ 2 + T

SET

Formula 4: T

ID1

SYN

ID2

max T

and T

ID1

). (*)

SDR

can take on somewhat different

ID2

and TSL the following rule applies:

< TSL

SDR

, Max T

SDR

the following rule applies:

SDR

PAGE 36 of 97

SDR

and T

SL

EO 09-0009

Page 37

Setings MAN0575-04-EN

Profibus Modules User Manual

Formula 6: T

QUI

, T

RDY

and min T

SDR

For access monitoring (T

) and Target Rotation Time (TTR):

WD

TWD > TTR

Formula 7: TWD and T

For the Data_Control_Time the following rule applies:

Data_Control_Time > 6 * TWD

Formula 8: Data_Control_Time

If the devices used have different values for min T

greatest of these values is used for all devices.

Min T

)

N

= max (min T

SDR

SDR device 1

Formula 9: Min T

Example: If for device 1 the value for min T

200, for device 2 the values 75 and for device 3 the value 125,

SDR

then the value of 200 must be used for all devices.

The same applies also for the Bus parameters max T

, min T

, TSL, T

SDR

TR

SDR device 2

SDR

, T

QUI

SDR

, ..., min T

and TTR.

SET

then the

SDR device

PAGE 37 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 38

Page 39

DP Master MAN0575-04-EN

Profibus Modules User Manual

CHAPTER 6: DP MASTER

6.1 Master Settings

To enter the DP Master settings, choose the Settings > Master Settings or click with the right mouse

button on the corresponding Master symbol and select Master Settings from the list that opens. The

DP Master Settings are also available in the Master Configuration window.

The DP Master settings contain parameters that determine the behaviour of the Master device as well

as the user interface. These settings are only valid for Horner devices and are included in the

download of the configuration.

Figure 16: DP Master Settings

Startup behaviour after system initialisation

When Automatic release of the communication by the device has been set, the Master device

starts to exchange data on the Bus once initialisation is complete. When Controlled release of

communication by the application program has been set, the application program must activate

the data exchange on the Bus.

User program monitoring

The Watchdog time determines how long the device waits for a triggering of the software Watchdog

by the application program until it sets the outputs of the Slave devices to zero. This function must be

activated by the user program and does not start automatically. The value must be set to zero on

current Horner modules.

Addressing mode

The addressing mode of the process data image determines how the addresses (Offsets) of the

process data are interpreted. Either of the addressing modes Byte addresses or Word

addresses are possible.

Storage format (word module)

PAGE 39 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 40

DP Master MAN0575-04-EN

Profibus Modules User Manual

The storage format determines how the data words are laid down in the process image. For the

Word data type it is possible to choose high/low (big Endian) value Byte or low/high value Byte

(little Endian).

Handshake of the process data

These various types are used for setting the handshake of the process data of the Master. The

choice of used type is important for the correct data exchange between the application program

and the device. The chosen handshake of the process data must be supported by the application

program. For all Horner modules select the buffered, host controlled handshake.

Hardware parameter

This parameter displays the size of the dual-port memory. The value enlarges or reduces the

permissible address area for the process data addresses.

For the Horner Profibus master the size of the dual-port memory is 8K.

For the Horner DP Slave the size of the dual-port memory is 2K.

6.2 Group Membership

After the Master has been assigned, the Slaves can be assigned to up to eight different groups.

These groups can then be assigned here. Choose the Settings > Group membership menu.

Choose the group that is to support the DP-Freeze and DP-Sync commands.

Figure 17: Settings > Group Membership (1)

In the Group Membership, the Slaves can be assigned to the groups with the desired characteristics.

The table shows all configured Slave devices from the main editor window. Here it is possible to

select which of up to eight possible groups the Slave is assigned. The selected group membership is

transferred to the Slaves during their start-up sequence. The group membership acts as a filter for

the Sync and Freeze global commands. These are output as Broadcast telegrams in order to

synchronize the input and output data of several Slaves. Only those Slaves in whose group these

commands have been released react to it.

PAGE 40 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 41

DP Master MAN0575-04-EN

Profibus Modules User Manual

Figure 18: Settings > Group Membership (2)

PAGE 41 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 42

DP Slave MAN0575-04-EN

Profibus Modules User Manual

CHAPTER 7: DP SLAVE

7.1 Slave Settings

The DP Slave Settings contain parameters that define the behaviour of the device at the user

interface, which do not belong to the DP configuration. This menu point is applicable only to Horner

devices. These settings are transferred with the download of the DP configuration to the device. In

order to open the DP Slave settings menu, first choose the Slave by clicking on it and then open the

window in the Settings > DP Slave Settings menu.

Figure 19: DP Slave Settings

Handshake of the process data

These various functions select the Handshake of the process data of the Slave. The selection of

the function is important for the correct data exchange between the application and the device.

Select ‘Buffered Host Controlled’ for all Horner Slave modules.

Configuration mode

If the Slave device is to use the parameters of the configuration that is downloaded from SyCon

then the Configuration by SYstem CONfigurator mode must be selected for the Configuration

mode. If the DP configuration is written online from an application into the Dual-port memory,

then the Configuration by Application mode must be selected.

PAGE 42 of 97

© Horner APG.This drawing is the property of Horner APG. And shall not be disclosed or reproduced except as specifically authorised.

EO 09-0009

Page 43

DP Slave MAN0575-04-EN

Profibus Modules User Manual

User program monitoring

The Watchdog time determines how long the device will wait for an application triggering until it

resets all outputs to zero. For current firmware versions, this must be set to zero.

Start-up behaviour after system initialisation

When Automatic release of the communication by the device has been chosen, then the

Slave is ready to communicate with the Master. When Controlled release of the

communication by the application program has been chosen, then the user must release the

communication by means of a defined release procedure. The current firmware version expects

the ‘Automatic release’ option to be chosen.

Configuration data

For Standard, the configuration of the Slave is compared with that from CHK_CFG_TELEGRAM

from the Master.

For Forced by CHK_CFG_TELEGRAM, the configuration of the Slave is transferred from the

Master to the Slave with the CHK_CFG_TELEGRAM. The normal (default) is ‘Standard’.

DPV1 Parameter

Class 1 Buffer length: This setting defines the size of the buffer for DPV1 class 1 services in the

DP Slave. The length determines the maximum data count that can be transferred in a DPV1

class 1 telegram. From the buffer size set here, 4 Bytes are reserved for the transfer of the DPV1

administration data and these are not available for transfer of user data.

Valid values for the length of class 1 buffer are in the range of 4 .. 244. Alterations of the size of

the buffer can only be set in the Slave configuration dialog, if the DPV1 services for the Slave

have been activated.

Class 2 Buffer length: The length of the DPV1 class 2 buffer that is to be established must be

defined in this field. Similar to the configuration of the class 1 buffer, here, 4 Bytes of the given

buffer length are reserved for the transfer of the DPV1 administration data. The maximum

transferable user data count is reduced by these 4 Bytes. Values in the range 48 .. 244 can be

defined for the DPV1 class 2 buffer lengths. If the value 0 is entered, then the DP Slave lays

down no DPV1 class 2 buffer. In this case, the DPV1 class 2 services of the Slave are not

available.

Note: Please note that the settings of the class 1 and class 2 buffer lengths influence the usable