Page 1

MAN0577-03-En

HE800DNM650 & HE800DNS600

DeviceNet Modules

User Manual for

HE800DNM650/HEDNM650 &

HE800DNS600/HEDNS600

DeviceNet

Master and Slave SmartStack™ Modules

Page 1 of 98

EO 09-0009

Page 2

MAN0577-03-En

HE800DNM650 & HE800DNS600

DeviceNet Modules

PREFACE

This manual explains how to use the Horner APG HSyCon software product.

Copyright © 2001 Horner APG, LLC., 640 North Sherman Drive, Indianapolis, Indiana 46201-3899. All rights

reserved. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form by any means, electronic,

mechanical, magnetic, optical, chemical, manual or otherwise, without the prior agreement and written

permission of Horner APG, LLC.

Information in this document is subject to change without notice and does not represent a commitment on

the part of Horner APG, LLC.

Windows 95, Windows 98, and Windows NT are registered trademarks of Microsoft

Corporation.

DeviceNet is a trademark of Open DeviceNet Vendors Association (ODVA).

Profibus is a trademark of Siemens.

Cscape, CsCAN, and SmartStack are trademarks of Horner APG, LLC.

For user manual updates and technical support contact :

Horner APG

Technical Support (317) 916-4274 Technical Support +353-21-4321266

web-site www.horner-apg.com. web-site www.horner-apg.com

(USA) Horner APG (Europe)

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Horner APG, LLC. ("HE-APG") warrants to the original purchaser that the Operator Station manufactured by HE is free from defects

in material and workmanship under normal use and service. The obligation of HE-APG under this warranty shall be limited to the

repair or exchange of any part or parts which may prove defective under normal use and service within two (2) years from the date

of manufacture or eighteen (18) months from the date of installation by the original purchaser whichever occurs first, such defect to

be disclosed to the satisfaction of HE-APG after examination by HE-APG of the allegedly defective part or parts. THIS WARRANTY

IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR USE AND OF ALL OTHER OBLIGATIONS OR LIABILITIES AND HE-APG NEITHER

ASSUMES, NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR HE-APG, ANY OTHER LIABILITY IN CONNECTION

WITH THE SALE OF THE Operator Station. THIS WARRANTY SHALL NOT APPLY TO THE Operator Station OR ANY PART

THEREOF WHICH HAS BEEN SUBJECT TO ACCIDENT, NEGLIGENCE, ALTERATION, ABUSE, OR MISUSE. HE MAKES NO

WARRANTY WHATSOEVER IN RESPECT TO ACCESSORIES OR PARTS NOT SUPPLIED BY HE. THE TERM "ORIGINAL

PURCHASER", AS USED IN THIS WARRANTY, SHALL BE DEEMED TO MEAN THAT PERSON FOR WHOM THE Operator

Station IS ORIGINALLY INSTALLED. THIS WARRANTY SHALL APPLY ONLY WITHIN THE BOUNDARIES OF THE

CONTINENTAL UNITED STATES.

In no event, whether as a result of breach of contract, warranty, tort (including negligence) or otherwise, shall HE-APG or its

suppliers be liable of any special, consequential, incidental or penal damages including, but not limited to, loss of profit or revenues,

loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of substitute

products, facilities, services or replacement power, down time costs, or claims of original purchaser's customers for such damages.

Page 2 of 98

EO 09-0009

Page 3

MAN0577-03-En

HE800DNM650 & HE800DNS600

DeviceNet Modules

List of Revisions

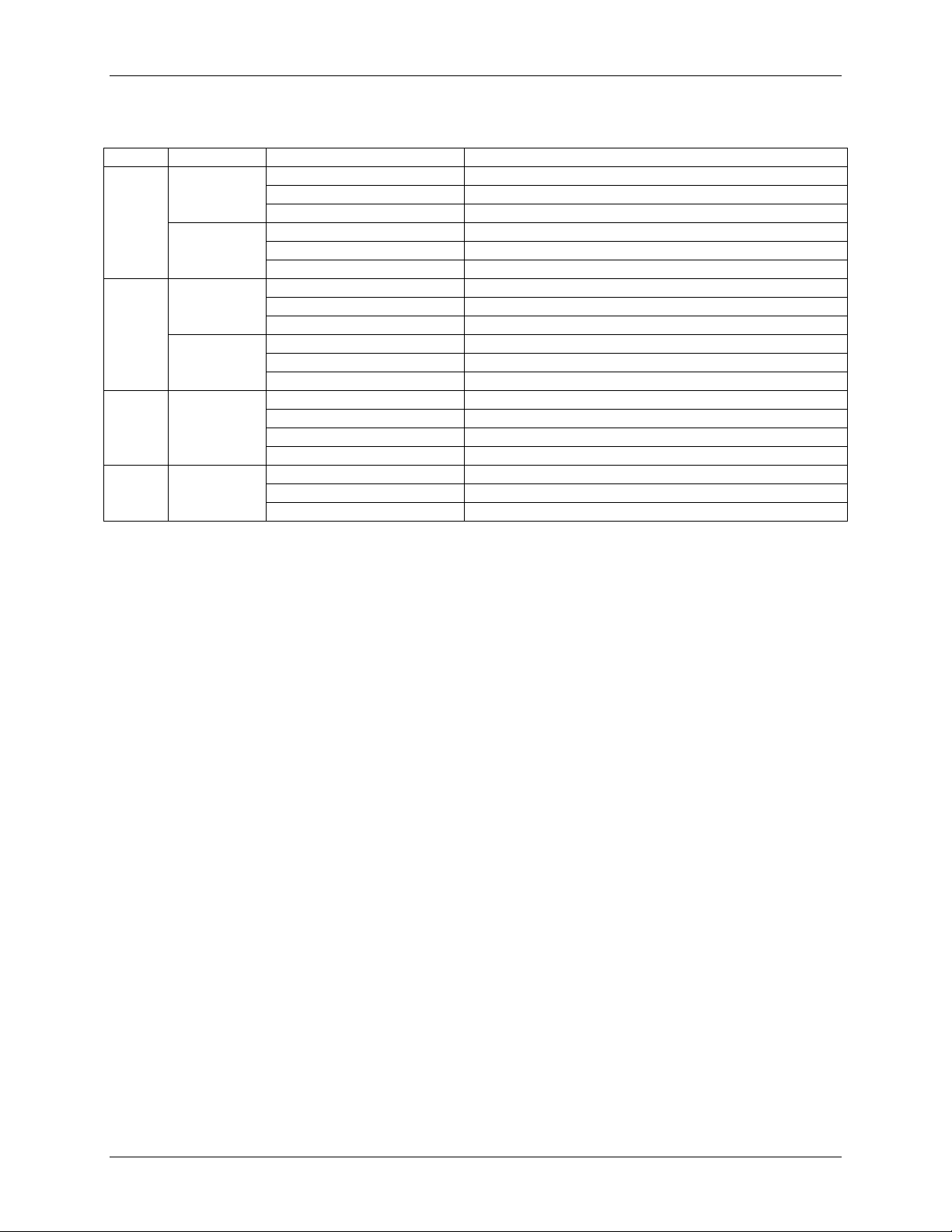

Index Date Version Chapter Revision

21-May-04 01 All Initial Release

18-Mar-07 02 3 Added Cscape Configuration Section

10-Jul-08 03 9 Added Explicit Messaging chapter

Page 3 of 98

EO 09-0009

Page 4

MAN0577-03-En

HE800DNM650 & HE800DNS600

DeviceNet Modules

TABLE OF CONTENTS

PREFACE ..................................................................................................................................................... 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY ............................................................................. 2

CHAPTER 1: INTRODUCTION .................................................................................................................... 7

1.1 Scope ........................................................................................................................................... 7

1.2 Introduction ................................................................................................................................... 7

1.3 Installing and Removing a SmartStack Module ........................................................................... 8

1.4 Installing SmartStack Modules ..................................................................................................... 8

1.5 Removing SmartStack Modules ................................................................................................... 8

1.6 Status LED definitions .................................................................................................................. 9

1.7 Main Functions ............................................................................................................................. 9

CHAPTER 2: INSTALLATION .................................................................................................................... 10

2.1 System Requirments .................................................................................................................. 10

2.2 System Installation ..................................................................................................................... 10

2.3 Installation of the System Configurator HSyCon ........................................................................ 11

CHAPTER 3: GETTING STARTED – CSCAPE CONFIGURATION .......................................................... 15

3.1 Scope ......................................................................................................................................... 15

3.2 Configuring Cscape. ................................................................................................................... 15

3.3 Configuring a SmartStack DeviceNet Master with any DeviceNet Slave .................................. 19

3.4 Configuring a SmartStack DeviceNet Slave with any DeviceNet Master .................................. 19

3.5 Configuring a Horner DeviceNet Master with a Horner DeviceNet Slave .................................. 21

CHAPTER 4: CONFIGURATION OF DEVICENET WITH HSYCON ......................................................... 22

4.1 Setting up the DEVICENET Configuration ................................................................................. 22

4.2 EDS Files (Electronic Data Sheet Files) Introduction ................................................................ 22

4.3 EDS Files and HSyCon .............................................................................................................. 23

4.4 Insert Master .............................................................................................................................. 23

4.5 Insert Device (Slave) .................................................................................................................. 24

4.6 Replace Slave ............................................................................................................................ 25

4.7 Device Configuration .................................................................................................................. 25

4.8 MAC ID (Device network address) ............................................................................................. 26

4.9 Actual chosen IO Connection ..................................................................................................... 27

4.10 Connection Object Instance Attributes ....................................................................................... 28

4.11 UCMM Check ............................................................................................................................. 28

4.12 Fragmented Timeout .................................................................................................................. 28

4.13 Parameter Data .......................................................................................................................... 28

4.14 Process Data Configuration ....................................................................................................... 30

CHAPTER 5: SETTINGS ............................................................................................................................ 32

5.1 Device Assignment .................................................................................................................... 32

5.2 COM Serial Driver ...................................................................................................................... 32

5.3 Bus Parameter ........................................................................................................................... 34

5.4 DeviceNet Master ....................................................................................................................... 34

5.5 Device (Slave) ............................................................................................................................ 38

5.6 Project Information ..................................................................................................................... 39

5.7 Path ............................................................................................................................................ 39

5.8 Language ................................................................................................................................... 39

5.9 Start Options .............................................................................................................................. 40

CHAPTER 6: ONLINE FUNCTIONS .......................................................................................................... 42

6.1. Introduction ................................................................................................................................. 42

6.2. Online to the Module .................................................................................................................. 42

6.3. Downloading the Configuration .................................................................................................. 42

6.4. Firmware Download ................................................................................................................... 43

6.5. Firmware / Reset ........................................................................................................................ 43

6.6. Device Info ................................................................................................................................. 44

Page 4 of 98

EO 09-0009

Page 5

MAN0577-03-En

HE800DNM650 & HE800DNS600

DeviceNet Modules

6.7. Automatic Network Scan ............................................................................................................ 45

6.8. Start/Stop Communication ......................................................................................................... 48

6.9. Diagnostic Functions .................................................................................................................. 48

6.10. Live List ...................................................................................................................................... 49

6.11. Change MAC-ID ......................................................................................................................... 49

6.12. Debug Mode ............................................................................................................................... 49

6.13. The Debug Window .................................................................................................................... 50

6.14. Device Diagnostic ...................................................................................................................... 50

6.15. Global State Field ....................................................................................................................... 52

6.16. Device Diagnostic ...................................................................................................................... 54

6.17. Extended Device Diagnostic ...................................................................................................... 55

6.18. Extended Device Diagnostic Master .......................................................................................... 55

6.19. Extended Device Diagnostic Device (Slave) .............................................................................. 56

6.20. User Data Transfer ..................................................................................................................... 56

6.21. I/O Monitor .................................................................................................................................. 57

6.22. I/O Watch ................................................................................................................................... 57

6.23. DeviceNet Services .................................................................................................................... 59

6.24. Get Device Attribute ................................................................................................................... 59

6.25. Set Device Attribute ................................................................................................................... 60

6.26. Change MAC-ID ......................................................................................................................... 60

6.27. Message Monitor ........................................................................................................................ 61

6.28. Message Monitor for testing explicit messaging of DeviceNet .................................................. 62

CHAPTER 7: FILE, PRINT, EXPORT, EDIT AND VIEW ........................................................................... 63

7.1. File 63

7.1.1. Open .............................................................................................................................................. 63

7.1.2. Save and Save As ......................................................................................................................... 63

7.1.3. Close .............................................................................................................................................. 63

7.2. Print ................................................................................................................................................... 63

7.3. Export Functions ............................................................................................................................... 64

7.3.1. DBM Export .................................................................................................................................... 64

7.3.2. CSV Export .................................................................................................................................... 64

7.3.2.1. DataType Code ........................................................................................................................... 65

7.3.2.2. DataPosition Code ...................................................................................................................... 65

7.4. Edit 66

7.4.1. Delete ............................................................................................................................................. 67

7.4.1. Replace .......................................................................................................................................... 67

7.5. View of the Configuration .................................................................................................................. 67

7.5.1. Device Table .................................................................................................................................. 67

7.5.2. Address Table ................................................................................................................................ 67

7.6. View Menu HSyCon .......................................................................................................................... 68

7.6.1. Logical Network View ..................................................................................................................... 68

7.6.2. Toolbars ......................................................................................................................................... 68

7.6.3. Status Bar ...................................................................................................................................... 68

CHAPTER 8: ERROR NUMBERS .............................................................................................................. 69

8.1. CIF Device Driver (Dual-port memory) Error Numbers (-1-49) .................................................. 69

8.2. CIF Serial Driver Error Numbers (-20 .. -71) .............................................................................. 73

8.3. RCS Error Numbers (4 .. 93) ...................................................................................................... 75

8.4. Database Access Error Numbers (100 .. 130) ........................................................................... 77

8.5. Online Data Manager Error Numbers (1000 .. 1018) ................................................................. 78

8.6. Message Handler Error Numbers (2010 .. 2027) ....................................................................... 78

8.7. Driver Functions Error Numbers (2501 .. 2512) ......................................................................... 79

8.8. Online Data Manager Subfunctions Error Numbers (8001 .. 8035) ........................................... 79

8.9. Data Base Functions Error Numbers (4000 .. 4199).................................................................. 80

8.10. Converting Functions Error Numbers (5001 .. 5008) ................................................................. 84

CHAPTER 9: EXPLICIT MESSAGING USING DNM650 .......................................................................... 85

9.1 General ....................................................................................................................................... 85

Page 5 of 98

EO 09-0009

Page 6

MAN0577-03-En

HE800DNM650 & HE800DNS600

DeviceNet Modules

9.2 Building Explicit Messages ......................................................................................................... 85

9.3 How to Interpret Explicit Response Messages .......................................................................... 86

9.4 Explicit Message Errors ............................................................................................................. 87

APPENDIX: ................................................................................................................................................. 88

A. EXTENDED DEVICE DIAGNOSTIC MASTER ................................................................................ 88

A.1. PLC_TASK Common Variables ................................................................................................. 88

A.2. DNM_TASK Common Variables ................................................................................................ 88

A.3. DNM_TASK Device Running States .......................................................................................... 90

A.4. DNM_Task Global State Field .................................................................................................... 90

A.5. DNM_Task Communication Error .............................................................................................. 90

A.6. DNM_Task Receive Queue ....................................................................................................... 91

A.7. DNM_Task Transmit Queue ...................................................................................................... 91

A.8. DNM_Task DeviceNet Command Counters .............................................................................. 92

A.9. DNM_Task Timeout Counter ..................................................................................................... 93

A.10. DNM_Task Init Counter .............................................................................................................. 93

B. EXTENDED DEVICE DIAGNOSTIC DEVICE (SLAVE) .................................................................. 94

B.1. PLC_Task Common Variables (Device) .................................................................................... 94

B.2. DNS_Task Common Variables .................................................................................................. 95

B.3. DNS_TASK Receive Queue (Device) ........................................................................................ 96

B.4. DNS_TASK Transmit Queue (Device) ....................................................................................... 97

Page 6 of 98

EO 09-0009

Page 7

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

CHAPTER 1: INTRODUCTION

1.1 Scope

This manual shows how to connect and configure the DeviceNet Master or Slave Smartstack Modules.

HSyCon, a Windows-based software package, is an easy-to-use configuration package for use with the

SmartStack COM range of fieldbus modules and Cscape or Cbreeze, a Windows™ based package for

use with the OCS/ TIU ranges. The software user’s guide is contained in this manual.

A basic level of understanding of Microsoft Windows™ technology and operation is assumed. The

manual assumes that the user is familiar with Windows 95, Windows 98, Windows NT, Win 2000 or XP.

1.2 Introduction

The Fieldbus Smartstack module range require only three stages to get them operational, these are:

1. Physical installation and connection.

2. Configuration of the fieldbus interface.

3. Configuration of Cscape / Cbreeze to map the fieldbus data.

The system is comprised of two separate software software functions, the fieldbus interface software

running independently in the COM module and the OCS/TIU firmware running in the main module. Data

and commands are exchanged via a dual port ram interface. The configuration of the COM module is via

the RS232 serial port on the module. For correct operation the number of registers assigned in the OCS

must match the number required by the Master or Slave module configuration.

The Smartstack module should be configured with the OCS/TIU software first as otherwise it will be held

in reset and cannot be configured.

Page 7 of 98

EO 09-0009

Page 8

DeviceNet Modules

MAN0577-03-en

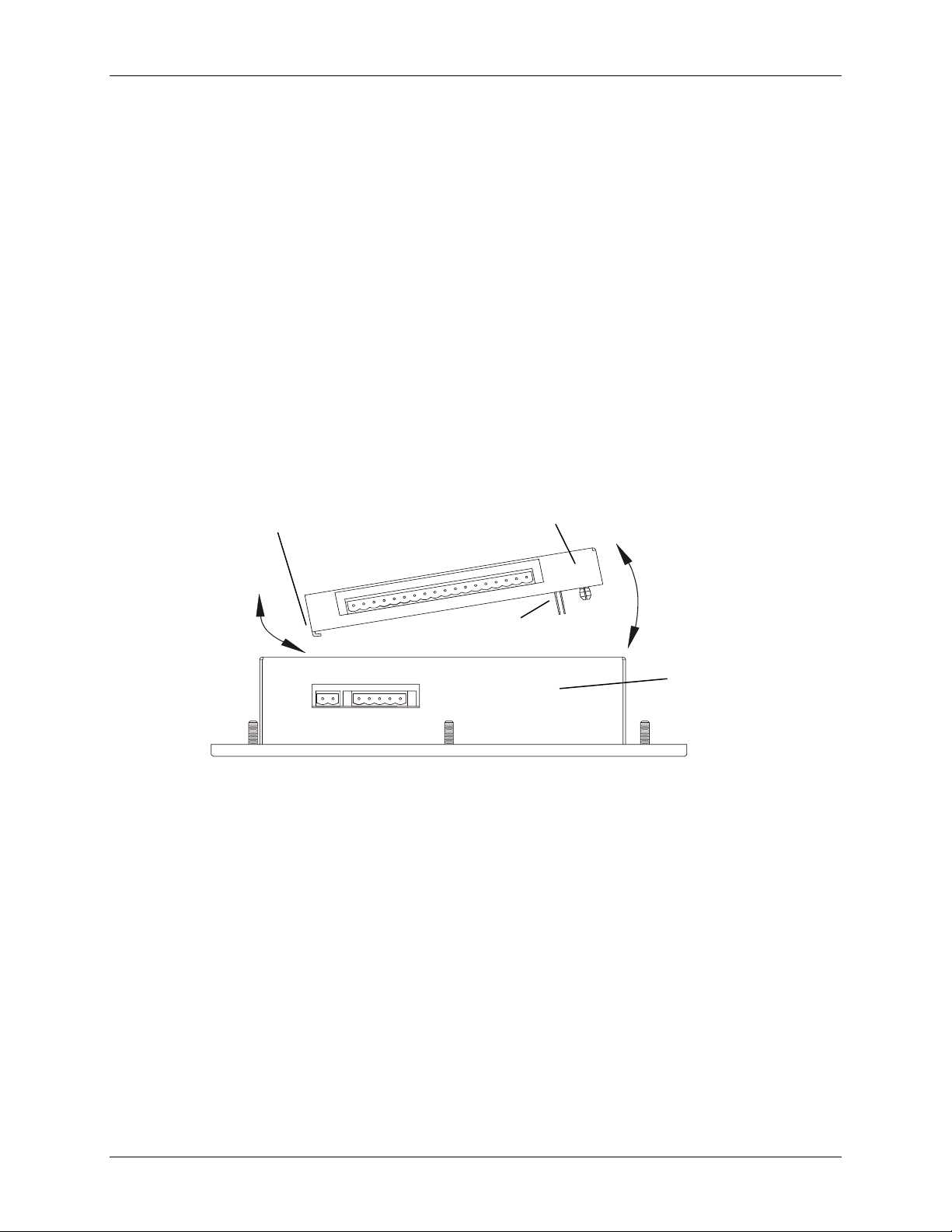

1.3 Installing and Removing a SmartStack Module

The following section describes how to install and remove a SmartStack Module.

Caution: To function properly and avoid possible damage, do not install more than four

SmartStack Modules per OCS or RCS.

Do not attempt to install or remove a SmartStack module with the units powered on.

1.4 Installing SmartStack Modules

1. Hook the tabs. Each SmartStack Module has two tabs that fit into slots located on the OCS.

(The slots on the OCS are located on the back cover.)

2. Press the SmartStack Module into the “locked” position, making sure to align the SmartStack

Module fasteners with the SmartStack receptacles on the OCS.

1.5 Removing SmartStack Modules

1. Using a flathead screwdriver, lever up the end of the SmartStack Module (opposite end to tabs) and

swing the module out.

2. Lift out the tabs of the module.

SmartStack Tab

Figure 2.1 – Installing a SmartStack Module in an OCS

HE800DNM650 & HE800DNS600

Fastener

Mating Pins

OCS Back Cover

Page 8 of 98

EO 09-0009

Page 9

DeviceNet Modules

MAN0577-03-en

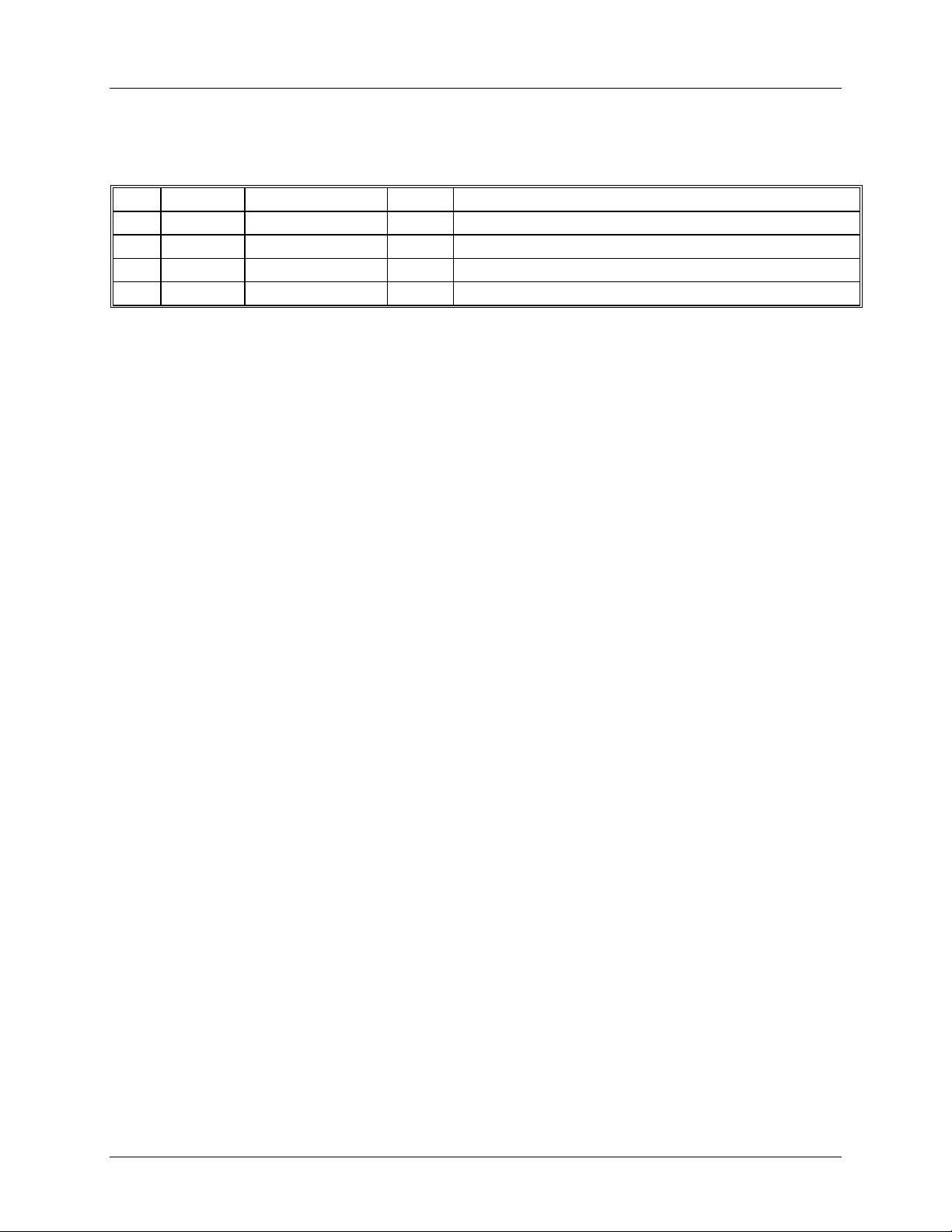

1.6 Status LED definitions

Signal LED Colour State Definition

NET RED

ON Critical Link Failure

Flashing Connection Time out

OFF Device Not Powered

GREEN

ON ON-LINE Link OK

Flashing ON-LINE, Not connected

OFF Device Not Powered

MOD RED

ON Unrecoverable Fault

FLASHING Minor Fault

OFF No Power

GREEN

ON Normal Operation

FLASHING Configuration Failure

OFF No Power

RDY YELLOW

ON COM ready

FLASHING CYCLIC Bootstrap Loader Active

FLASHING NON CYCLIC Hardware or System Error

OFF Hardware Error

RUN GREEN

ON Communication Running

FLASHING NON CYCLIC Parameter Error

OFF Communication Stopped

Status Signals of the DNM650 and DNS600

1.7 Main Functions

The main functions of the DEVICENET System Configurator are:

• Universal Fieldbus Configurator - Configuration of the complete Fieldbus range with one package.

• Documents Fieldbus system - detailed documentation of the Fieldbus network may be printed.

• Standardised configuration files – allows use of protocol specific standardised configuration files.

• Diagnostic tool – upon configuration download the software may be switched into diagnostic mode.

HE800DNM650 & HE800DNS600

Page 9 of 98

EO 09-0009

Page 10

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

CHAPTER 2: INSTALLATION

2.1 System Requirments

• PC with 486-, Pentium processor or higher.

• Windows 95/98/ME, Windows NT/2000/XP.

• Free disk space: 30 - 80 Mbyte.

• CD ROM drive.

• RAM: min. 16 Mbyte.

• Graphic resolution: min. 800 x 600 pixel.

• Windows 95: Service Pack 1 or higher.

• Windows NT: Service Pack 3 or higher.

• Keyboard and Mouse.

2.2 System Installation

It is recommended that all application programs on the system are closed before installation begins.

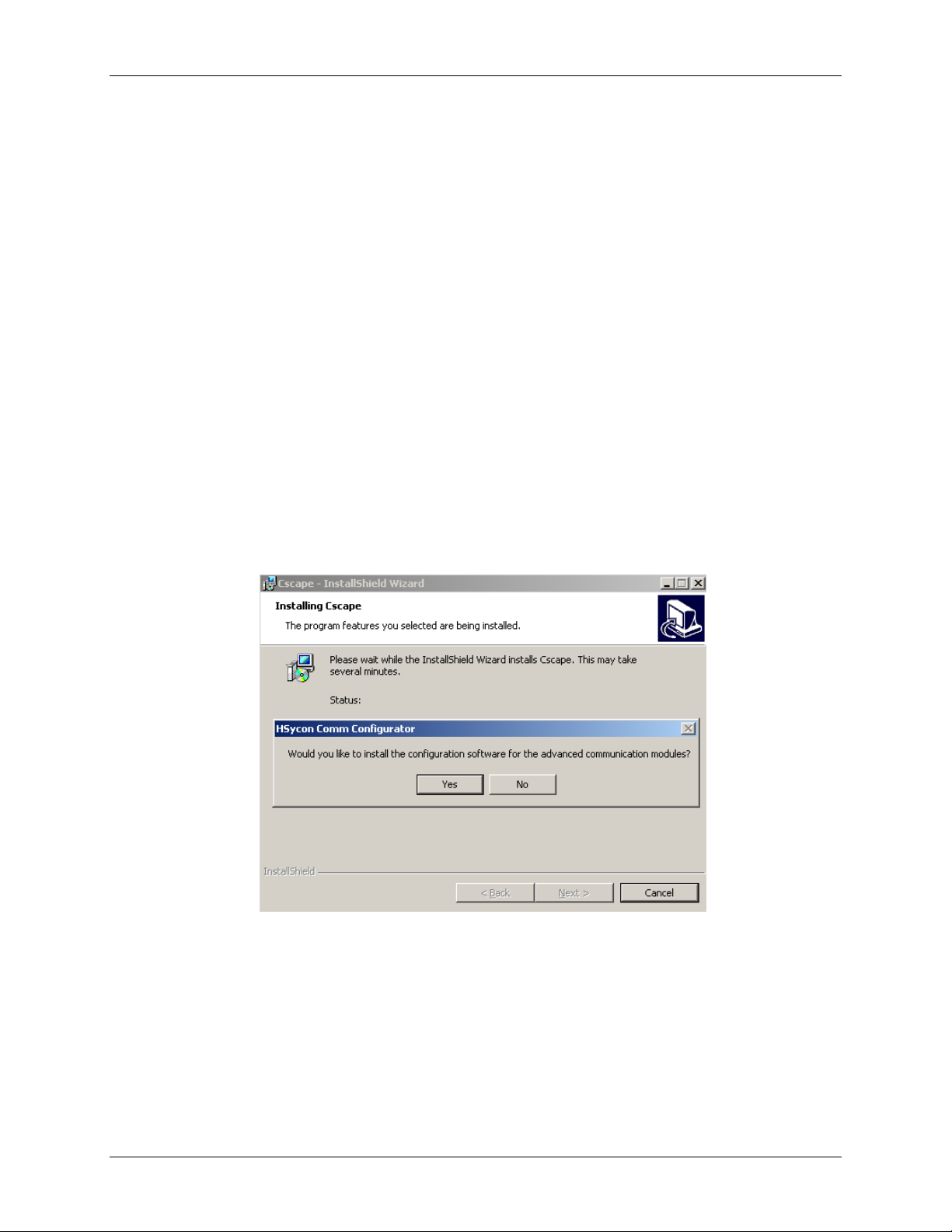

Insert the Cscape CD in the local CD ROM drive. The HSycon installation program will start automatically

when installation of Cscape is complete (see Fig 2.1)

Fig 2.1

Note: Administrator privileges are required on Windows NT/2000/XP systems for installation.

The installation program asks for the components to install. Answer these questions with Yes or No. Tick

‘No’ for the OPC Server function, it is not included with this installation pack.

Page 10 of 98

EO 09-0009

Page 11

DeviceNet Modules

MAN0577-03-en

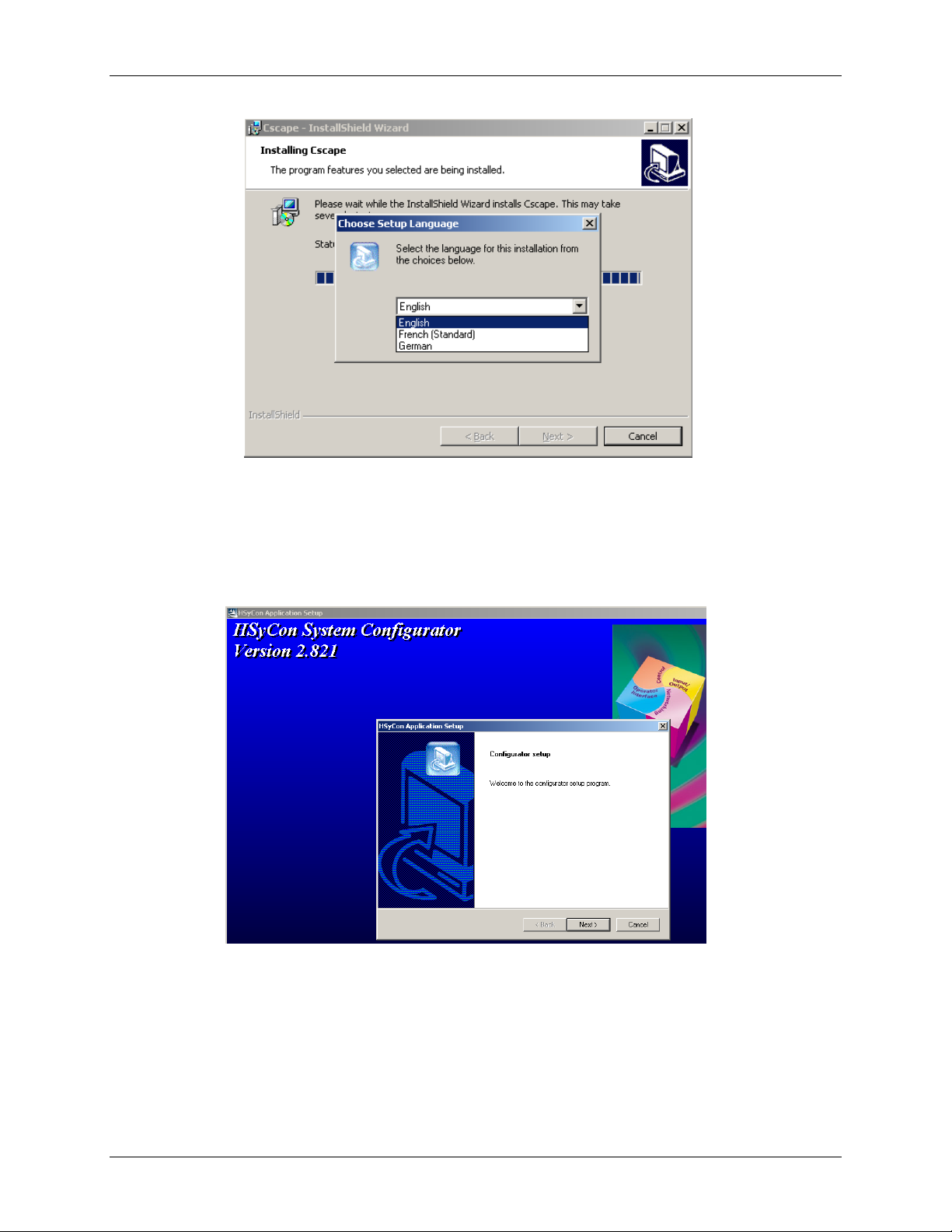

2.3 Installation of the System Configurator HSyCon

Follow the instructions of the installation program by selecting the Language, Fieldbus system to be

installed and answer all the questions with OK or NEXT.

HE800DNM650 & HE800DNS600

Fig 2.2

Fig 2.3

The installation program copies the program files, GSD or EDS files and Bitmaps to the PC.

Page 11 of 98

EO 09-0009

Page 12

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

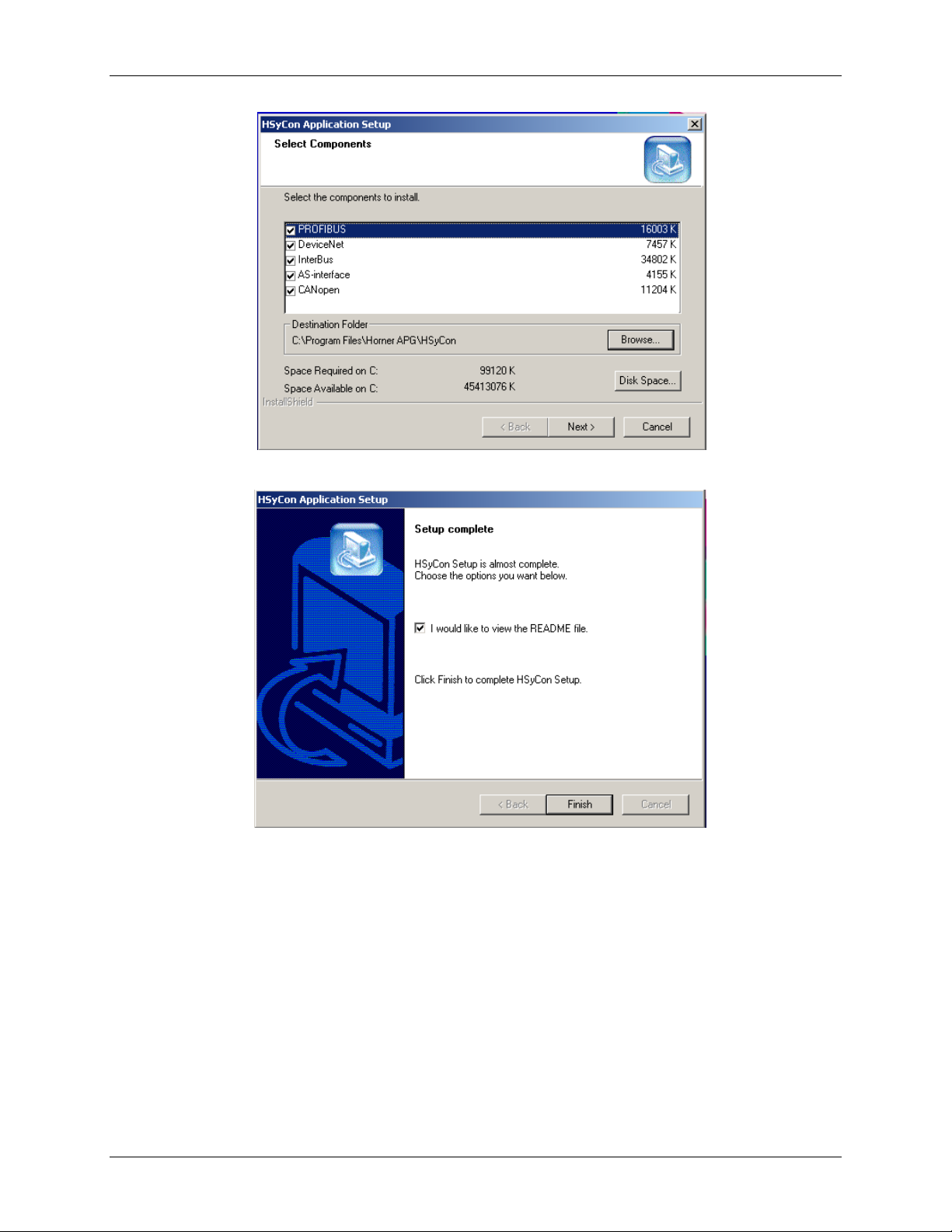

Fig 2.4

Fig 2.5

Finally the following files are entered in the system Registry.

• System DLLs

• The application

Page 12 of 98

EO 09-0009

Page 13

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

NOTES

Page 13 of 98

EO 09-0009

Page 14

Page 15

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

CHAPTER 3: GETTING STARTED – CSCAPE CONFIGURATION

3.1 Scope

This chapter describes the procedures for configuring the DeviceNet Master and slaves. This includes

loading EDS files, saving, downloading and assigning I/O.

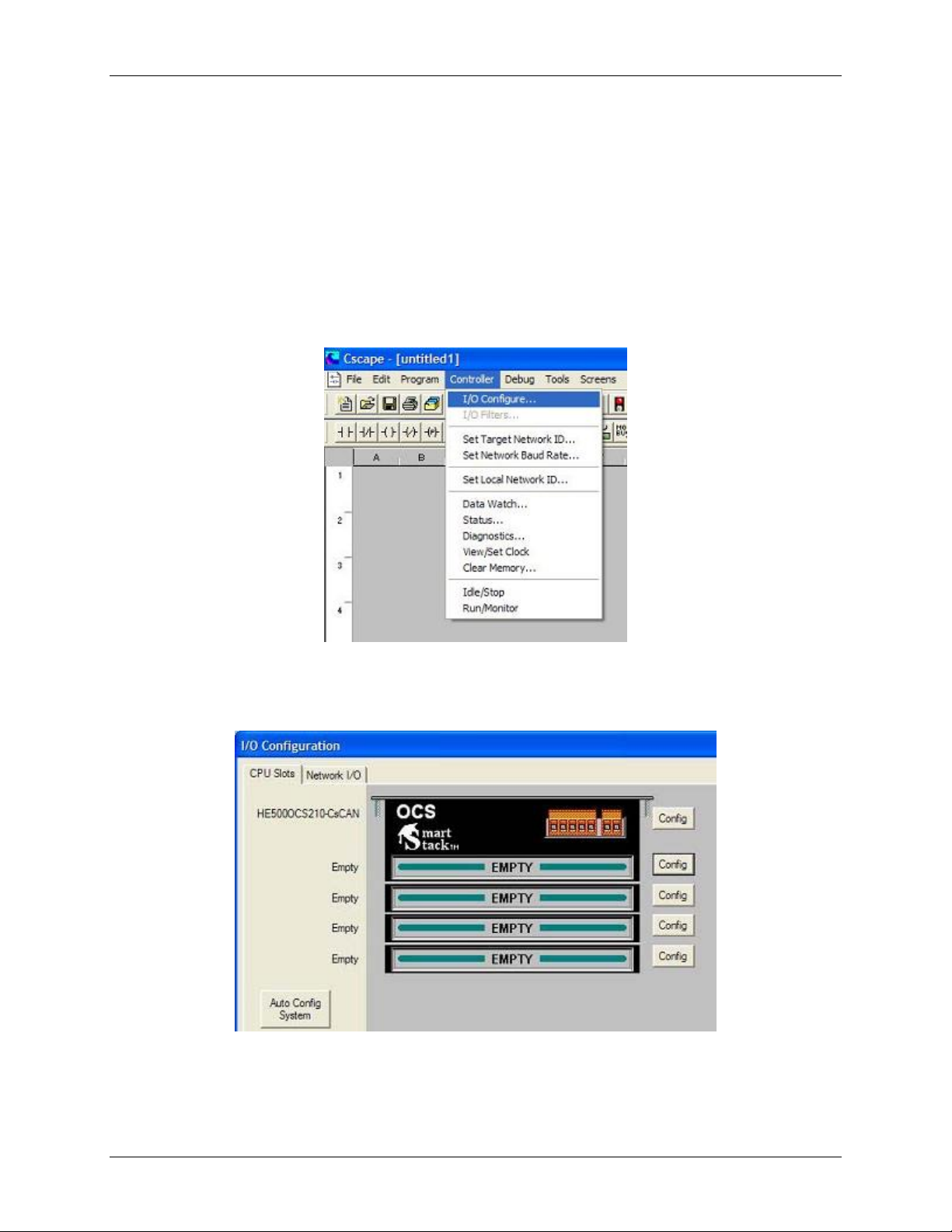

3.2 Configuring Cscape.

The following describes the steps involved to setup Cscape. Attach the communications module to the

appropriate OCS unit. Open Cscape. All I/O is setup through the I/O Configure Menu in Cscape:

Figure 3.1

The following window is displayed. Select the CONFIG button adjacent to the first empty slot (nearest the

main unit).

Figure 3.2

Page 15 of 98

EO 09-0009

Page 16

DeviceNet Modules

MAN0577-03-en

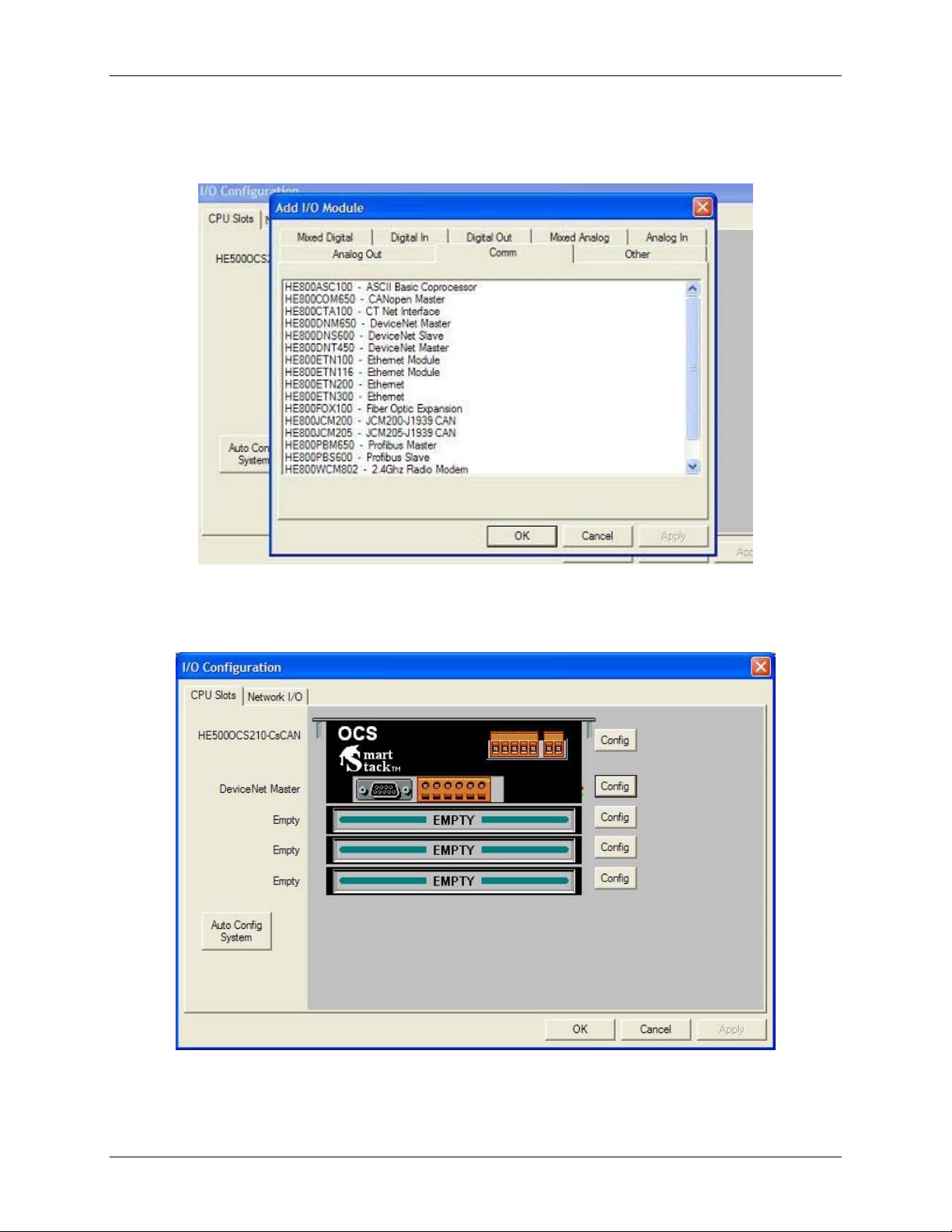

Select the COMM Tab. From here select the appropriate DeviceNet Module and click OK.

HE800DNM650 & HE800DNS600

Figure 3.3

The selected module is now visibly attached to the main unit and can be configured.

Figure 3.4

Page 16 of 98

EO 09-0009

Page 17

DeviceNet Modules

MAN0577-03-en

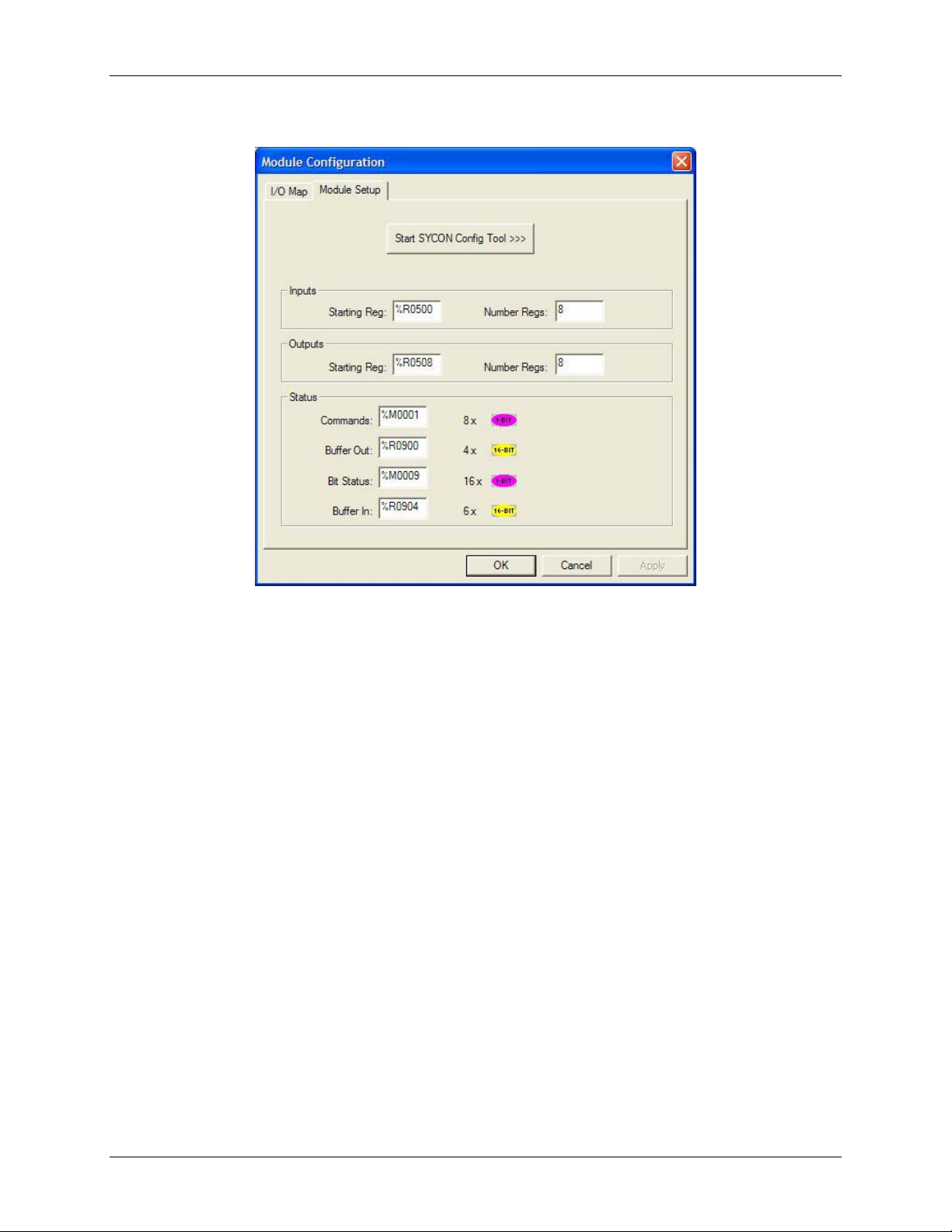

Select the CONFIG button adjacent to the module. Then select the MODULE SETUP tab.

HE800DNM650 & HE800DNS600

Figure 3.5

Configure the Inputs and Outputs.

NOTE:

INPUTS: means data coming FROM the Network VIA the DNM/DNS Module to the OCS Registers.

OUTPUTS: means data going TO the NETWORK VIA the DNM/DNS Module from the OCS Registers.

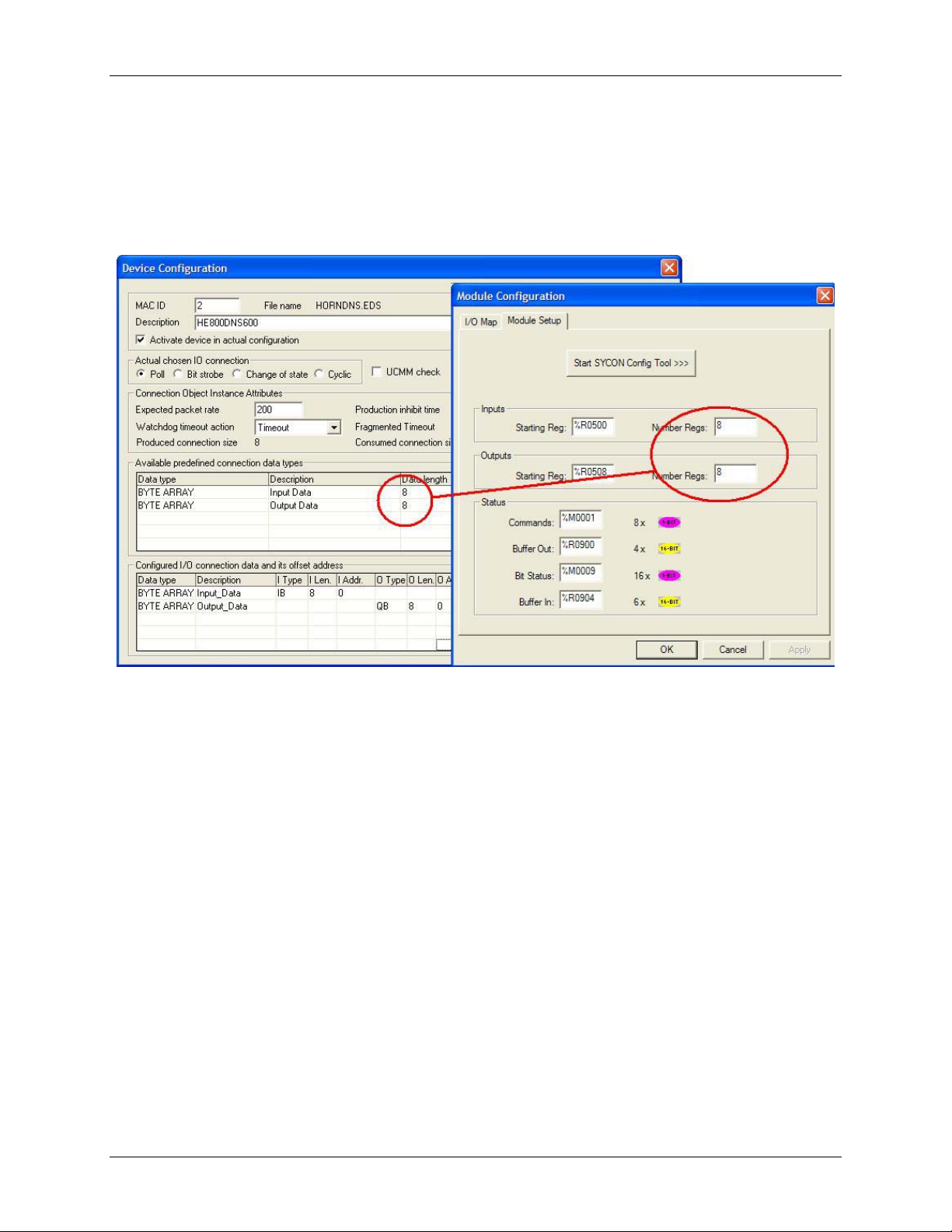

In Figure 3.5 above, For both Inputs and Outputs, 8 %R registers are used. The OCS %R registers are

retentive, general purpose, 16 bit registers.

Page 17 of 98

EO 09-0009

Page 18

DeviceNet Modules

MAN0577-03-en

It is VERY important that the number of registers used for both Inputs and Outputs in Cscape is

identical to the number setup in the Hsycon software when setting up the DNM650 and DNS600

modules. See Figure 3.6 below.

HE800DNM650 & HE800DNS600

Figure 3.6

Page 18 of 98

EO 09-0009

Page 19

DeviceNet Modules

MAN0577-03-en

3.3 Configuring a SmartStack DeviceNet Master with any DeviceNet Slave

Table 4 below describes the steps to configure a Horner Smartstack DeviceNet Master to any DeviceNet

Device (Slave).

Action Menu in the System Configurator

Create a new project

•

Copy EDS file of the DeviceNet device (Slave), if the

•

device is not in the selection list.

Choose Horner DeviceNet Master and provide MAC ID.

•

Choose DeviceNet device and provide MAC ID address

•

Assign the input and output modules (*1)

•

Assign the offset addresses

•

Assign the Device Parameter data, if the Device needs

•

Parameter data

Set the Bus parameter Mark the Master (left Mouse click), then

•

Set device assignment if no automatic assignment has

•

occurred

Save project

•

Download Mark the Master (left Mouse click), then

•

Live list Mark the Master (left Mouse click), then

•

Start Debugger Mark the Master (left Mouse click), then

•

Device diagnostic Mark the Slave (left Mouse click), then

•

Stop Debugger

•

Global Diagnostic Mark the Master (left Mouse click), then

•

Transfer user data:

•

Write output, read input

HE800DNM650 & HE800DNS600

File > New > DeviceNet

File > Copy EDS

Insert > Master

Insert > Device

Mark the Device (left Mouse click), then

Settings > Device Configuration

Mark the Device (left Mouse click), then

Settings > Device Configuration >

Parameter Data

Settings > Bus Parameters

Mark the Master (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Live List

Online > Start Debug Mode

Online > Device Diagnostic

Online > Stop Debug Mode

Online > Global State Field

Mark the Master (left Mouse click), then

Online > I/O Monitor

Table 4: Steps to Configure DNM650 with any DeviceNet Slave.

Note (*1): The Offset addresses assigned in the Slave configuration are always related to the Master.

3.4 Configuring a SmartStack DeviceNet Slave with any DeviceNet Master

Table 5 below describes the steps to configure a Horner DeviceNet Slave to any DeviceNet Master as it is

typical for many cases.

Action Menu in the System Configurator

Page 19 of 98

EO 09-0009

Page 20

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Create a new project

•

Choose DeviceNet Master (*1) and provide MAC ID

•

address

Choose Horner DeviceNet device (Slave) and

•

provide Mac address

Assign the input and output modules (*2)

•

Set device assignment if no automatic assignment

•

has occurred

Save project

•

Download Mark the Slave (left Mouse click), then

•

Device diagnostic Mark the Slave (left Mouse click), then

•

Transfer user data:

•

Write output, read input

File > New > DeviceNet

Insert > Master

Insert > Device

Mark the Device (left Mouse click), then

Settings > Device Configuration

Mark the Device (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Device Diagnostic

Mark the Device (left Mouse click), then

Online > I/O Monitor

Table 5: Steps to configure a DNS600 with any DeviceNet Master.

Note (*1): Insert a Horner SmartStack DeviceNet Master (HE800DNM650). This Master is a place holder

and it is not necessary to match the connected Master.

Note (*2): The Offset addresses assigned in the Slave configuration are always related to the DeviceNet

Master.

Page 20 of 98

EO 09-0009

Page 21

DeviceNet Modules

MAN0577-03-en

3.5 Configuring a Horner DeviceNet Master with a Horner DeviceNet Slave

Table 6 below describes the steps to configure a SmartStack DeviceNet Master to a Smartstack

DeviceNet slave :

Action Menu in the System Configurator

Create a new project

•

Choose Horner DeviceNet Master and provide MAC ID address

•

Choose Horner DeviceNet Device (Slave) and provide MAC ID

•

address

Assign the input and output modules Mark the Device (left Mouse click), then

•

Assign the offset addresses (*1)

•

Set the Bus parameter Mark the Master (left Mouse click), then

•

Set device assignment for the Master if no automatic assignment

•

has occurred

Set device assignment for the Device (Slave) if no automatic

•

assignment has occurred

Save project

•

Download to the Master Mark the Master (left Mouse click), then

•

Download to the Device (Slave) Mark the Device (left Mouse click), then

•

Live list Mark the Master (left Mouse click), then

•

Start Debugger Mark the Master (left Mouse click), then

•

Device diagnostic Mark the Device (left Mouse click), then

•

Stop Debugger

•

Global Diagnostic Mark the Master (left Mouse click), then

•

Transfer user data:

•

Write output, read input

HE800DNM650 & HE800DNS600

File > New > DeviceNet

Insert > Master

Insert > Device

Settings > Device Configuration

Settings > Bus Parameters

Mark the Master (left Mouse click), then

Settings > Device Assignment

Mark the Device (left Mouse click), then

Settings > Device Assignment

File > Save

Online > Download

Online > Download

Online > Live List

Online > Start Debug Mode

Online > Device Diagnostic

Online > Stop Debug Mode

Online > Global State Field

Mark the Master (left Mouse click), then

Online > I/O Monitor

Table 6: Steps to configure a DNM650 with DNS600’s.

Note (*1): The Offset addresses assigned in the Slave configuration are always related to the DeviceNet

Master.

Page 21 of 98

EO 09-0009

Page 22

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

CHAPTER 4: CONFIGURATION OF DEVICENET WITH HSYCON

4.1 Setting up the DEVICENET Configuration

To create a new configuration, choose the File > New menu. This will offer a selection list of fieldbus

systems. Choose DEVICENET. If only the DeviceNet fieldbus system is installed, the configuration

window will open directly. The name of the configuration file can be allocated when the configuration is

finished or with File > Save As.

4.2 EDS Files (Electronic Data Sheet Files) Introduction

An Electronic Data Sheet (EDS) provides information necessary to access and alter the configurable

parameters of a device. An Electronic Data Sheet (EDS) is an external file that contains information

about configurable attributes for the device, including object addresses of each parameter.

The application objects in a device represent the destination addresses for configuration data. These

addresses are encoded in the EDS. The figure below shows a general block diagram of a sample EDS.

EDS

General Device

Information

Device Parameter 1

Standard Device Profile

Device Parameter X

Standard Device Profile

Vendor-Specific

Device Parameter 1

Vendor-Specific

Device Parameter X

Optional

Figure 1: General block diagram of an EDS file

Page 22 of 98

EO 09-0009

Page 23

DeviceNet Modules

MAN0577-03-en

4.3 EDS Files and HSyCon

When HSyCon is started, it automatically retrieves all the EDS files stored in the EDS directory. The

device names are placed in an internal list. During the configuration, the device-specific data is retrieved

directly from the EDS files.

If a DeviceNet device does not appear in the selection list (Insert Master or Insert Device), the required

EDS file may be copied into the EDS directory with File > Copy EDS. Another method is to copy the

EDS file into the HSyCon EDS directory with Windows Explorer and then access the EDS files in the EDS

directory with Settings > Path and OK.

Horner devices: The EDS files for Horner devices are included and already installed.

Other devices: The respective device manufacturer provides the EDS files for other devices.

The EDS files of some vendors are available on the DeviceNet homepage http://www.odva.org

or visit the homepage of the manufacturer.

The EDS directory is adjustable. In order to alter the directory from a previous setting in another

directory, use the menu Settings > Path. All EDS files must be placed in this directory.

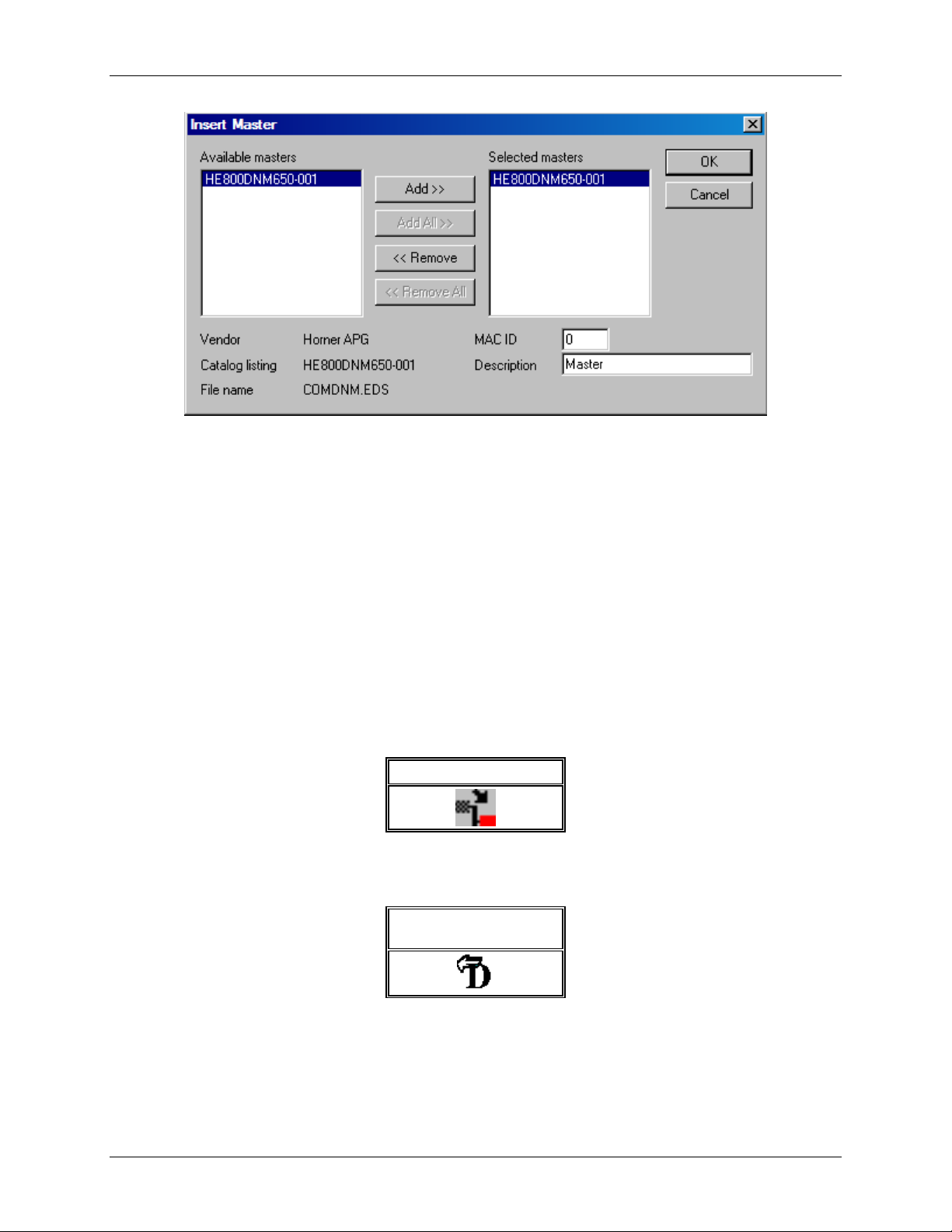

4.4 Insert Master

To insert a Master into the configuration, choose the Insert > Master menu, this will open the selection

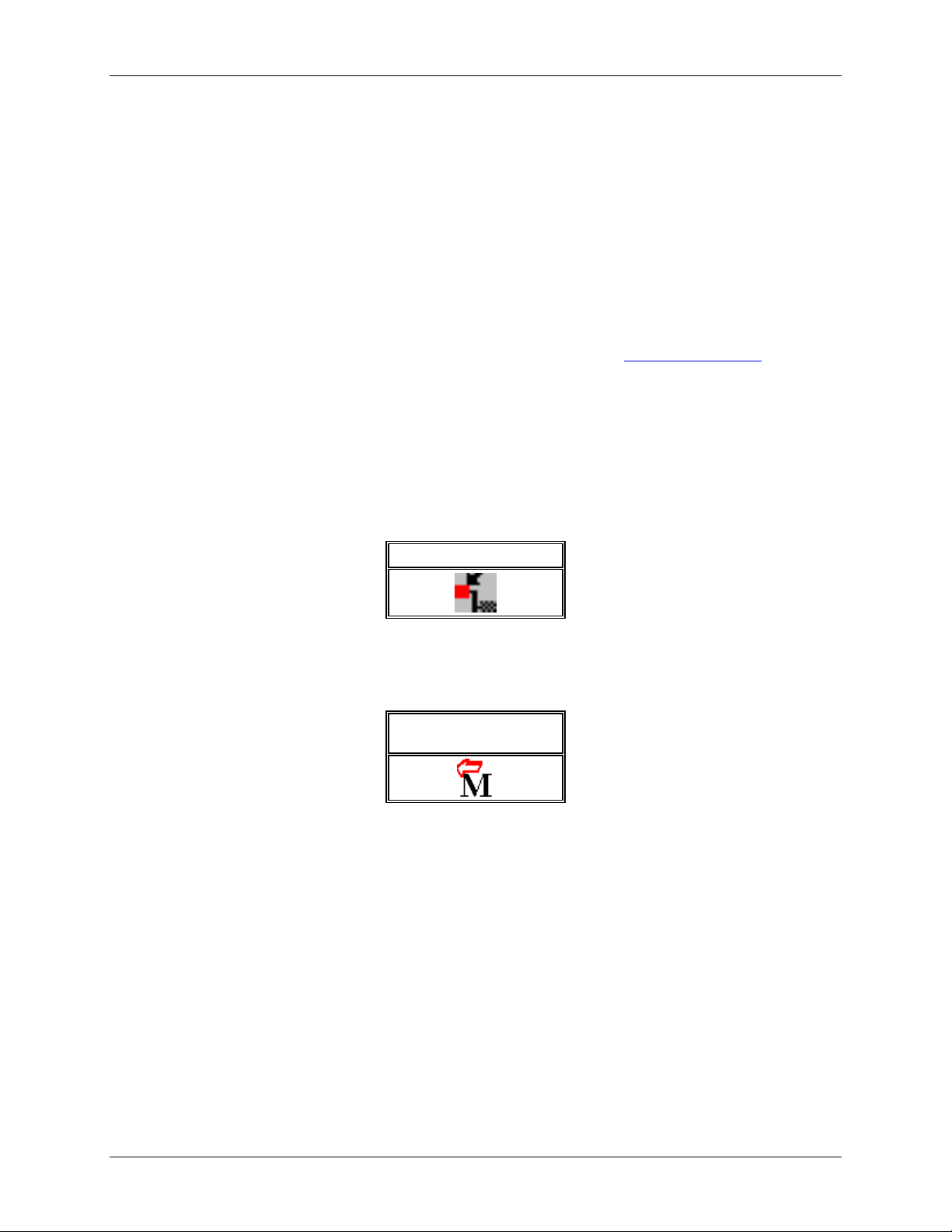

window, or click on the symbol :

HE800DNM650 & HE800DNS600

Insert > Master Symbol

Figure 1: Symbol Insert > Master

The mouse pointer automatically changes to the Insert Master pointer.

Insert Master Mouse

Pointer

Figure 2: Mousepointer insert Master

Click on the position where the Master should be inserted. The dialog box from which one or more

Masters can be chosen opens. The following types of Masters may be selected:

Page 23 of 98

EO 09-0009

Page 24

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Figure 3: Selectable Master types

Select a Master device from the Available Masters list by clicking on it. By clicking the Add button the

Master is shown in the list Selected Masters. Click the OK button, the Master will be inserted at the top

of the configuration.

This example shows an HE500DNM650-001. The Master gets the description Master at first. This may

be changed in the Description field. The MAC ID of the Master may also be changed here.

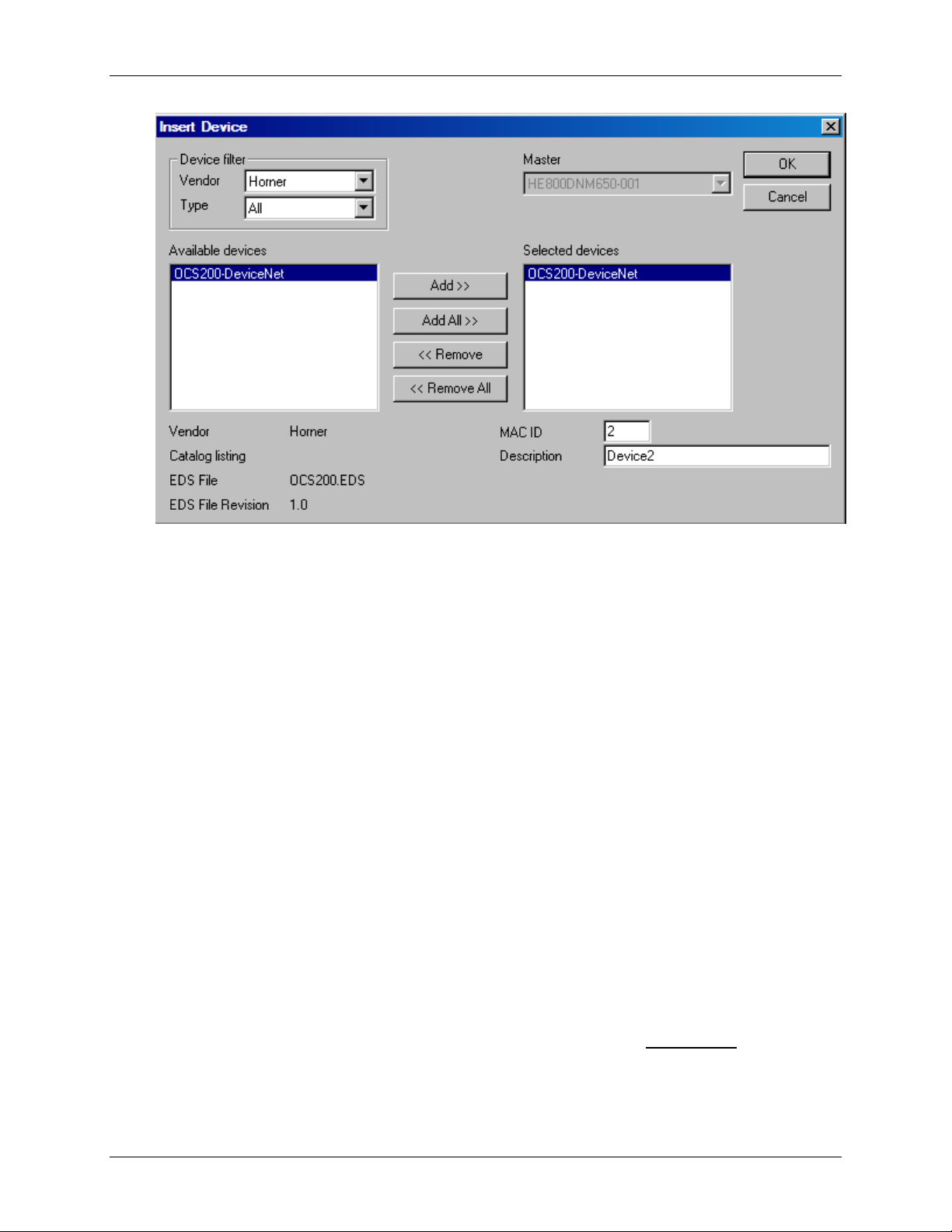

4.5 Insert Device (Slave)

To insert a DeviceNet Slave in the configuration select the Insert > Device menu to open the selection

window or click on the following Icon:

Insert > Device Symbol

Table 4: Insert > Device Symbol

The mouse cursor changes automatically to the insert device cursor.

Insert Device Mouse

Pointer

Table 5: Insert Device Mouse Pointer

Click on the position at which the new device should be inserted. A dialogue box appears from which one

or more devices may be chosen.

Page 24 of 98

EO 09-0009

Page 25

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Figure 2: Insert > Device (Slave)

The list on the left displays all the Slave devices whose EDS files have been put in the EDS directory. A

filter may be used to limit the selection list of the manufacturer. Further information on a Slave is shown

below the selection list (Available devices) when it is selected (one mouse click). Apart from the vendor

name and the description especially the ID-Code, the I/O-Code, the file name and the file revision are

given. The Slave appears on the right-hand list with a mouse click or with the Add button.

All devices in the right-hand list are assigned to the current insert point that is also shown in this window.

If the Slaves in the right-hand list are chosen one after the other (a mouse click), then every Slave can be

assigned a name in the Description field.

With each new selected device in the right list the MAC ID is incremented by one but it can be changed

by the user in the field MAC ID.

Note: It is possible to select the same device more than once, however, each device must have a unique

MAC ID to distinguish it in the network.

4.6 Replace Slave

To replace an existing Slave device first mark the device to be replaced. Then proceed as described in

the section 4.5 Replace Master.

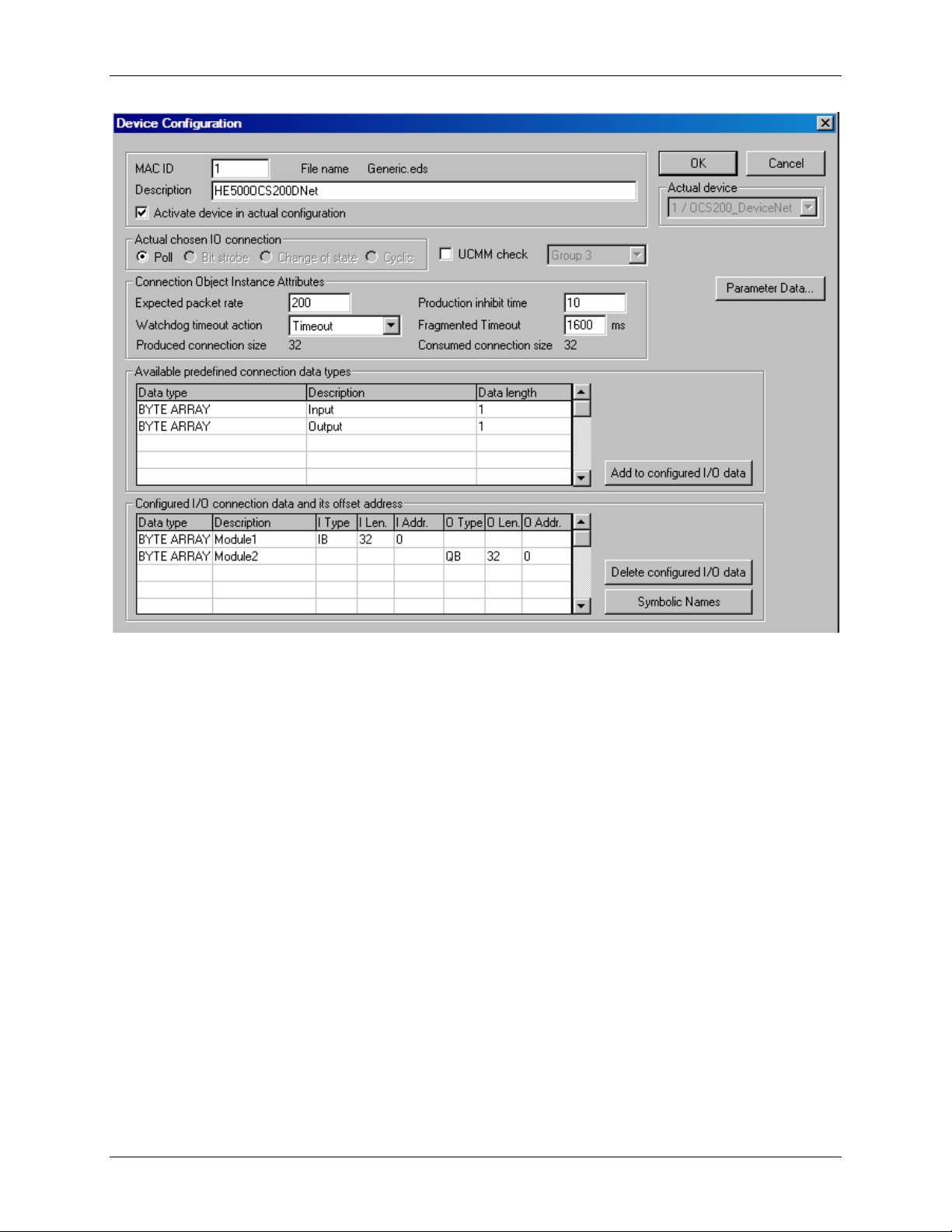

4.7 Device Configuration

To enter the Device Configuration set the focus on the device (left mouse click) and select the menu

Settings > Device Configuration or set the focus on the device (left mouse click) and use the right

mouse button at the device or simply double-click on the device.

The device’s I/O are assigned to logical addresses in the process data image of the Master

configuration. Note that the device offsets set here will be used in the application to read inputs and write

outputs.

in the device

Page 25 of 98

EO 09-0009

Page 26

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Figure 3: Settings > Device Configuration

Note 1: The offset addresses set in this window are for the addressing of the input data and output data

in the Master. These address settings (offsets) are not the settings in the DeviceNet device (Slave). The

DeviceNet device (Slave) organizes its data itself.

Note 2: The input data and the output data from the bus are transferred directly to the dual-port memory

in the DeviceNet Slave. These offset addresses are related to the Master.

The File Name displayed is the EDS file for the device.

The Description and MAC ID fields display the entries made during the selection phase of the Slave

device. Both entries can be set/changed here.

The checkbox Activate Device in actual configuration decides, whether the Master tries to establish

the communication with the Node or not. If a Node is physically not present in the network but will be

present in future then the checkbox should not be checked. This suppresses unnecessary requests by

the Master to devices that do not exist, but the device insertion reserves process data in the process data

image of the Master.

4.8 MAC ID (Device network address)

The network address of a device serves to distinguish itself on a DeviceNet fieldbus system from any

other device or Slave on this network. This should be a unique number for each device. A valid MAC-ID

address is within a range of 0 to 63 and can be re-entered and changed in the MAC-ID box in the Device

Configuration Dialog.

Page 26 of 98

EO 09-0009

Page 27

DeviceNet Modules

MAN0577-03-en

4.9 Actual chosen IO Connection

DeviceNet allows several kinds of I/O connections between devices. Please note that a device does not

have to support all types of IO connections.

The different connections types are :

• Polled I/O Connection - One poll command from the Master sends a number of output data to a

single, specific device (point-to-point). The device receives (consumes) the poll command and

processes the output data. If it has input data configured for this poll connection it reacts by sending

(producing) back a number of input data and/or status information to the Master. Before a polled I/O

connection is initiated by the Master, it reads the Consumed and Produced Connection Size of the

data from the Slave first and compares each value with the internally configured one. If the Master

detects differences the connection cannot be established. Sending a poll command can happen at

any time the Master wants to and has timer or event dependencies. A device has to respond if it has

consumed and understood the poll command request of the Master, even if it has no input data.

Otherwise the Master will report a timeout error. Polling data to many devices has the disadvantage

that the network traffic rate is very high and most data which is transferred has not changed since the

last transmission. Furthermore the higher the bus load more communication errors can occur if the

bus is disturbed by external influences.

HE800DNM650 & HE800DNS600

I/O connection

Poll

Bit Strobe

Change of State

Cyclic

Table 6: Overview I/O Connections

• Bit Strobe I/O Connection - Bit strobe command and response messages rapidly move small

amounts of I/O data between the Master device and one/some/all Slave devices. The bit strobe

message contains a bit string of 64 bits of output data, one output bit per possible device. Each bit is

assigned to one device address in the network. This service has broadcast functionality that means

more than one Slave device can be addressed by one command. Because all addressed Slave

devices get this command at the same time, this command is normally used to synchronize data

transfer to several Slave devices. A Slave device can take its corresponding output bit as a real

output information to give it to the peripheral connections (e.g. an LED) and/or use the bit as a trigger

to send back its input data with a poll response message. The data that can be send back from each

Slave after a bit strobe command was received is limited to 8 bytes in length. Bit strobe connections

reduce the bus loading.

• Change of State/Cyclic I/O Connection - The Master device sends a number of output data to a

single, specific device (point-to-point). Data production is triggered by either a determined changed

value in the output data or the cyclic timer expiration. Depending on how the Slave behaviour is

configured, the Slave can send back an acknowledge message, containing a number of input data

and/or status information. The Slave device sends a number of input data to the Master, if the data is

either changed or the cyclic timer has expired. The Master itself can acknowledge this message with

output data if configured.

• Change of state only production of data hold down the bus load as small as possible, while data than

can be transmitted as fast as possible by each device because bus conflicts are less possible. High

performance data transmission can be achieved with comparatively low baud rates.

Page 27 of 98

EO 09-0009

Page 28

DeviceNet Modules

MAN0577-03-en

4.10 Connection Object Instance Attributes

The Production Inhibit Time, one for each connection, configures the minimum delay time between new

data production in multiples of a millisecond. The timer is reloaded each time new data production

through the established connection occurs. While the timer is running the device suppresses new data

production until the timer has expired. This method prevents that the device is overloaded with to fast

incoming requests.

The value 0 defines no inhibit time and data production can and will be done as fast as possible. If in

polled mode for example a Production Inhibit Time of 1000dec is configured, then the poll request

message to the device will be sent every second.

The Expected Packet Rate, one for each connection, is always transferred to the device before starting

and doing the I/O transfer . The value is used by the device later to reload its 'Transmission Trigger' and

'Watchdog Timer'. The 'Transmission Trigger Timer' is used in a 'cyclic' I/O connection to control the time

when the data shall be produced. Expiration of this timer then is an indication that the associated

connection must transmit the corresponding I/O message. In 'change of state' connections the timer is

used to avoid the watchdog timeout in this connection, when a production has not occurred since the

timer was activated or reloaded.

Note: the Production Inhibit Time is verified against the Expected Packet Rate. If the Expected Packet

Rate value is unequal zero, but less than the Production Inhibit Time value, then an error window is

opened when pressing the OK button or changing to a wrong value.

The Watchdog Timeout Action defines the device behaviour when the watchdog timer in the device

expires. The following values are defined and their functionality is closer described in the DeviceNet

specification.

• Transition to Timed Out: The connection transitions to the Timed Out state and remains in this state

until it is Reset or Deleted.

HE800DNM650 & HE800DNS600

• Auto Delete: The connection class automatically deletes the connection if it experiences an

Inactivity/Watchdog timeout.

• Auto Reset: The connection remains in the established state and immediately restarts the

Inactivity/Watchdog timer.

4.11 UCMM Check

The UCMM Check box is used for modules that require the use of UCMM messaging format. Class

1,2,and 3 are supported. Check the documentation for the Slave device to identify if this box must be

checked.

4.12 Fragmented Timeout

If a transmission of I/O data or explicit message is greater than 8 bytes in length, it must be transmitted

on DeviceNet in a fragmented manner. The maximum time the Master will wait until a Slave has to

respond during the fragmented transmissions is the fragmented timeout.

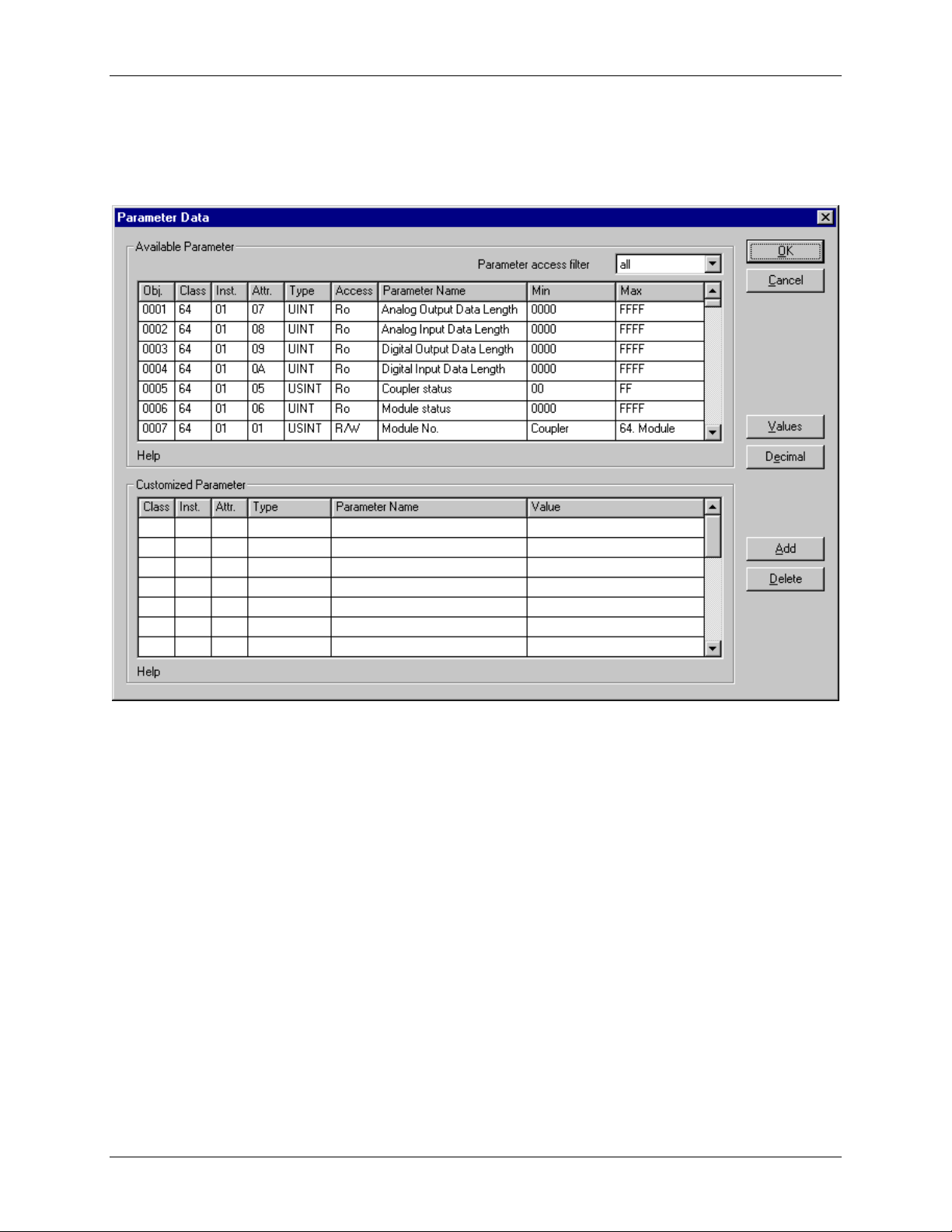

4.13 Parameter Data

The button Parameter Data can be selected in the Device Configuration window to edit the parameter

data.

If default parameters are configured in the EDS file for this Node, they are inserted automatically when

the menu is chosen the first time.

Page 28 of 98

EO 09-0009

Page 29

DeviceNet Modules

MAN0577-03-en

Some of devices need some further parameterisation data, to change for example a measurement

limitation or a value range. These data is Node specific and their functionality can not be explained at this

point.

The explanation can be normally found in the corresponding Node manual.

This window below shows an example of parameter data of a device.

HE800DNM650 & HE800DNS600

Figure 4: Settings > Device Configuration > Parameter Data

Two tables are available: one table with all available parameters and one table for customized

parameters. These parameters can be selected from the available parameters to that table.

Page 29 of 98

EO 09-0009

Page 30

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

4.14 Process Data Configuration

• Fixed I/O data transferred

DeviceNet handles I/O data transparent as a byte string without defining any data type in the

transferred data. To be operative it defines only the number of bytes in consumed and produced

direction that shall be transferred across a connection, nothing else. But HSyCon and the firmware

now allows to assign modular each byte or a bunch of bytes of the transparent string to different data

types. A list of the supported data types of the connection can be found in the middle table of the

window called

The following data types are supported:

• Bit, Byte, Word, Dword, Byte Array

If the data type Byte Array is chosen the number of bytes that shall be reserved for this data type can

be entered in the Data Count column in the lower table. Any other data type has its fixed length that

can not be changed. The data types are distinguished in process output and process input data in the

view of the Master device.

A double-click on a predefined data type or a click in the Add to configured I/O data button will

insert the chosen data type in the lower table called Configured I/O connection data. This table

contains all data that shall be really transferred across the connection. HSyCon will add separately

the number of used bytes of each configured I/O data and forms the values Consumed and

Produced Connection Size automatically. Both values indicates the sum of bytes which shall be

sent by the Master as outputs (Consumed by the device) and received by the Master as inputs

(Produced by the device).

Available Predefined Connection Data Types.

• Assigning the process data offset addresses

The I/O offset addresses of each placed data type in the connection data table can be freely

configured in a range of 0 to 3583 or they are set automatically by HSyCon. To enable or disable free

configuration use the flag Auto Addressing in the menu Settings - Auto Addressing. If enabled

HSyCon will place all configured I/O data, without spaces in physical order one after another based

on the rising MAC-ID order. This is done during the download procedure. The assigned addresses

can be checked then in the overview Address Table of the menu View. If the addresses are entered

manually the default address 0 in the input address respectively the output address must be

overwritten. Depending on the Addressing mode in the DNM Master Settings the addresses are

byte addresses or word addresses. This is described in the chapter Addressing mode.

Page 30 of 98

EO 09-0009

Page 31

DeviceNet Modules

MAN0577-03-en

In case of manual addressing (that means auto addressing is deactivated) the configuration window looks

like:

HE800DNM650 & HE800DNS600

Figure 5: Settings > Device Configuration

In the column I Addr and O Addr, the addresses where to locate the data in the process image must be

assigned. Remember that these addresses correspond to the application on the HOST side.

If a device is deactivated in the actual configuration the device is shown like this:

Activating or deactivating a device in a configuration can be very useful for devices that don't exist in the

real physical network. The I/O offset addresses will be reserved or simply a symbolic 'missing device'

waiting to be inserted as long the device is not connected.

Page 31 of 98

EO 09-0009

Page 32

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

CHAPTER 5: SETTINGS

5.1 Device Assignment

The Device Assignment setting determines how the System Configurator communicates with the device.

This is set in the device arrangement via the menu Settings > Device Assignment. The following

possibilities are available:

CIF Device Driver CIF Serial Driver CIF TCP/IP Driver

CIF Device Driver:

• Not supported do not choose this driver.

CIF Serial Driver:

• CIF Serial Driver: The HSycon Configurator communicates with the SmartStack device over a serial

connection. In this case a COM interface of the PC must be connected via a cable (straight) with the

diagnostic interface of the SmartStack device. The cable is standard Horner Programming cable.

CIF TCP/IP Driver:

• Not supported. Do not choose this driver.

5.2 COM Serial Driver

The serial driver supports COM1 to COM 4, in order to communicate via the diagnostic interface with the

device. The Device is selected via Settings > Device Assignment.

Figure 6: Driver selection > CIF Serial Driver

Choose the CIF Serial Driver and then OK, in order to select the CIF Serial Driver.

Page 32 of 98

EO 09-0009

Page 33

DeviceNet Modules

MAN0577-03-en

The connection must first be established using the switching surface Connect COM1, Connect COM2,

Connect COM3 or Connect COM4. They can be used depending on which COM interfaces are installed

and free on the PC.

The System Configurator sends a request to the corresponding COM interface and polls the Firmware of

the device. A display of the Firmware will indicate when a device is connected. In the other case, a

Timeout error (-51) appears, which will state that no device is connected.

HE800DNM650 & HE800DNS600

Figure 7: CIF Serial Driver > Device Assignment

The error number –20 indicates that this COM interface is not available or free.

Figure 8: CIF Serial Driver > Device Assignment

Page 33 of 98

EO 09-0009

Page 34

DeviceNet Modules

MAN0577-03-en

5.3 Bus Parameter

In the menu Settings > Bus Parameter the basic settings for the DeviceNet network must be done.

Mainly, this concerns the determination of the Baudrate. The DeviceNet board supports the baudrates

125kbit/s, 250kbit/s and 500kbit/s. Normally DeviceNet components use the autobaud detection to get the

baudrate automatically. Furthermore, the MAC ID for the Master can be assigned in the Bus Parameter

window.

The Auto Clear mode feature defines the behaviour of the Master if the communication breaks down or

is interrupted to a Node. If the flag Auto clear mode ON is activated, then the Master will also stop the

communication to all further Nodes which were still responding and active. If the flag Auto clear mode is

not activated, then a lost communication contact to one Node has no influence on the communication

channel of the still present ones. For all the error effected Nodes the Master remains in the state to try the

reestablishment of the communication again.

5.4 DeviceNet Master

5.4.1. DeviceNet Master Settings

To enter the DeviceNet Master settings set the focus on the Master (left mouse click) and select the menu

Settings > Master Settings or set the focus on the Master (left mouse click) and use the right mouse

button at the DeviceNet Master device or simply doubleclick on the DeviceNet Master device.

The DeviceNet Master settings contain parameters which define the behaviour of the device on its user

interface which is not a part of the DeviceNet configuration directly. This menu is only valid for Horner

devices, and is downloaded with the DeviceNet configuration.

HE800DNM650 & HE800DNS600

Figure 9: Settings > Bus Parameters

Page 34 of 98

EO 09-0009

Page 35

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Figure 10: Settings > Master Settings

• Startup behaviour after system initialization

If Automatic release of the communication by the device is selected, the Master starts with the

data transfer on the bus when initialisation is finished. If Controlled release of the communication

by the application program is selected, the user has to start the data transfer on the bus, by a

defined release procedure.

Note: The HE800DNM650 must be set to Automatic release of the communication by the

device

• User program monitoring

The watchdog time appointed defines how long the device will wait for a user trigger of the software

watchdog if started once, until it resets all outputs of the device to zero. This procedure must be

activated by the user application and is not started automatically.

Note: This is not a special DeviceNet function. Watchdog Time must be set to 0 for

HE800DNM650

• Addressing mode

The addressing mode of the process data defines, how to interpret the addresses of the process

image. Possibilities are Byte addresses or Word addresses. See details next page.

• Storage format (word module)

The storage format fixes the format, how the data is placed and interpreted in the process images.

For the data type word the Little Endian format and Big Endian format can be selected.

Page 35 of 98

EO 09-0009

Page 36

DeviceNet Modules

MAN0577-03-en

• Handshake of the process data

With these different modes the handshake of the process data is selected for the Master. The

selection of this mode is important for the correct data exchange between the application and the

device. Please refer to the tool kit or the device driver manual for the detailed description of these

modes. If foreign user programs or drivers are used, like S5 for Windows for example, refer to the

delivered manual to choose the right mode.

HE800DNM650 & HE800DNS600

NOTE: For HE800DNM650, this must be set to Buffered, host controlled

• Hardware parameter

With this parameter, the size of the dual-port memory of the hardware is selected. The parameter will

enlarge or reduce the possible value ranges for the I/O offsets.

5.4.2. Auto Addressing

With this Check Box it is possible to force the System Configurator to allocate the process data addresses

in physical order itself or to enable the manual address configuration. Please see also Process Data

Configuration on page 27.

5.4.2. Addressing Mode

The addresses in the configuration of the Nodes define the starting point of the data in the process

depiction. This can work in a Word or Byte oriented method by means of the Addressing mode

parameter.

Addresses Meaning

Byte addresses

Word addresses

The process depiction has a Byte structure and each Byte has its own

address.

The process depiction has a Word structure and each Word has its

own address.

Table 7: Addressing Mode

This has nothing to do with the physical size of the Dual-port memory – this is always Byte-oriented!

When the application makes a Word access, it is automatically divided by the PC into two sequential Byte

accesses.

Page 36 of 98

EO 09-0009

Page 37

DeviceNet Modules

MAN0577-03-en

The following table shows the different storing of the various data types in the Byte- or Word-oriented

process image:

IEC

address

in Byte

mode

QB 0 QB 0 0 0000 0000

QB 1 1 0000 0000

QB 2 QB1 2 1110 0010

QB 3 3 0000 0000

QB 4

QB 5

QW 6 QW3

IEC

address

in Word

mode

QB2

Offset

address

in the

Dualport

memory

4

5

6

7

HE800DNM650 & HE800DNS600

Data in

the

Process

image

1111 1000

0000 0111

1111 1111

0100 0100

Output to an I/O module

Output of QB2 / QB1 to a single Byte module:

D7 D6 D5 D4 D3 D2 D1 D0

1 1 1 0 0 0 1 0

Output of two Bytes beginning from QB4 / QB2 to a module that

is defined as a Byte module with the data count 2

(no differentiation between the two memory formats as the data

are of Byte type):

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1

Output of QW6 / QW3 in the data format lower/higher value

Byte:

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

0 1 0 0 0 1 0 0 0 1 1 1 1 1 1 1

Table 8: Example for data in the process data image

Page 37 of 98

EO 09-0009

Page 38

DeviceNet Modules

MAN0577-03-en

The following table is meant to clarify the method of addressing:

Byte Addressing Word Addressing

Byte 0 IB 0 IW 0 Word 0 IB 0 IW 0

Byte 1 IB 1 -

Byte 2 IB 2 IW 2 Word 1 IB 1 IW 1

Byte 3 IB 3 -

Byte 4 IB 4 IW 4 Word 2 IB 2 IW 2

Byte 5 IB 5 -

Figure 11: Image of the method of addressing for input

Byte Addressing Word Addressing

Byte 0 QB 0 QW 0 Word 0 QB 0 QW 0

Byte 1 QB 1 -

Byte 2 QB 2 QW 2 Word 1 QB 1 QW 1

Byte 3 QB 3 -

Byte 4 QB 4 QW 4 Word 2 QB 2 QW 2

Byte 5 QB 5 -

HE800DNM650 & HE800DNS600

Figure 12: Image of the method of addressing for output

5.5 Device (Slave)

5.5.1. Device Configuration

To call up the menu Device Configuration, set the focus at the device (left mouse click) and select the

menu Settings > Device Configuration

or

make a doubleclick on the device icon will open the Device Configuration window. The section Device

Configuration on page 25 describes the configuration.

Page 38 of 98

EO 09-0009

Page 39

DeviceNet Modules

MAN0577-03-en

5.6 Project Information

When a project is created, the project information can be typed into the Settings > Project Information

menu. This entry can then be read when this menu is called up.

Figure 13: Settings > Project Information

Click the OK button to save the Project Information.

5.7 Path

In the menu Settings > Path the path directory of the EDS files is shown (EDS File directory). The default

value is:

C:\Program Files\HornerAPG\HSyCon\Fieldbus\DEVNet\EDS

The path for Project directory defines the path where the project specific files are stored.

HE800DNM650 & HE800DNS600

Figure 14: Settings > Path

Click the OK button to read in all EDS files.

5.8 Language

Choose the Settings > Language menu and the following window opens:

Figure 15: Settings > Language

Page 39 of 98

EO 09-0009

Page 40

DeviceNet Modules

MAN0577-03-en

The language of the System Configurator can be set. Select the desired language and confirm the entry

with the OK button.

A message appears that the System Configurator must be started again in order to activate the selected

language. Please carry this out.

After restarting the System Configurator, the language will have changed to the one selected.

Note: Up to now not all languages are available for all fieldbuses!

5.9 Start Options

After activating the Settings > Start Options menu point in the network mode (the network mode can be

changed by choosing Window > Logical Network View) , the following dialog will appear.

Here it is possible to set the various starting options or modes. Some are of importance only for the OPCServer operation.

The important ones are given below.

HE800DNM650 & HE800DNS600

Figure 16: Settings > Start Options

• Simulation mode ON/OFF

Only valid for the OPC Server.

• Start HSyCon hidden if started via OPC

Only valid for the OPC Server.

• Start HSyCon next time with last Configuration

When this is selected the last saved configuration in the HSyCon is automatically loaded when the

HSyCon is started again.

Page 40 of 98

EO 09-0009

Page 41

DeviceNet Modules

MAN0577-03-en

• Logic Network View visible

When this is selected possibility of diverting to the network mode without having to install the HSyCon

with OPC. It is also possible to use the Watch List from the network mode.

• Fast start ON/OFF

Only valid for the OPC Server.

• TAG tracing ON/OFF

Only valid for the OPC Server.

• OPC tracing ON/OFF

Only valid for the OPC Server.

• Start with multiple configurations

If this option is selected HSyCon can be started with up to four configurations simultaneously. The

paths are shown in the window and they are changeable there.

HE800DNM650 & HE800DNS600

Figure 17: Settings > Start Options

Page 41 of 98

EO 09-0009

Page 42

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

CHAPTER 6: ONLINE FUNCTIONS

6.1. Introduction

In this section all the functions that directly affect the Horner DeviceNet Modules are described, e.g.

HE800DNS600 and HE800DNM650.

Note: This will permit interruption of Devicenet communication and outputs can be switched ON or OFF.

6.2. Online to the Module

First, the desired device must be chosen for downloading by a left mouse click on the symbol of the

device.

6.3. Downloading the Configuration

In order to release the configuration and network access, a transfer (Download) to the DNM/DNS devices

must be carried out on the Online > Download menu. A warning will appear that the communication on

the DeviceNet will be interrupted. This warning must be confirmed.

Figure 18: Security question before Download

Attention: The download overwrites the configuration in the device and the communication with the

connected devices is interrupted.

Figure 19: Online > Download

Page 42 of 98

EO 09-0009

Page 43

DeviceNet Modules

MAN0577-03-en

Before the download is executed, the configuration is tested by the Configurator. The most common

cause of error is overlapping of addresses in the process data image. This can be checked by calling up

the address table with the View > Address Table menu point.

If the issue of addresses in the process data image should be carried out automatically, then the Auto

Addressing button in the Master Configuration window must be activated.

The configuration is transferred into the selected device and stored there in FLASH memory in a zero

voltage manner so that the configuration is available when the voltage supply is switched off and on

again.

After the download, the device carries out an internal restart and begins with the communication if in

DeviceNet Master Settings the Automatic Release of Communication by the Device menu point has

been set.

6.4. Firmware Download

If a Firmware download is to be carried out, proceed as follows: first the desired device for Firmware

downloading must be chosen in that the symbol of the device is selected with a left mouse click. Then,

call up the Online > Firmware Download menu. Select the new Firmware and retrieve it with Download

into the device. The Firmware is now retrieved.

HE800DNM650 & HE800DNS600

Figure 20: Online > Firmware Download

6.5. Firmware / Reset

First the desired device must be chosen with a left mouse click on the symbol of the device. Then the

Online > Firmware / Reset menu must be called up and the name and the version of the Firmware are

displayed.

Page 43 of 98

EO 09-0009

Page 44

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Figure 21: Online > Firmware / Reset

Click the button Reset to reset the device.

6.6. Device Info

First the desired device must be chosen with a left mouse click on the symbol of the device. Then select

the Online > Device Info menu in order to obtain further information on the selected device.

The manufacturer date, the device number and the serial number of the device is retrieved and shown.

Figure 22: Online > Device Info

Page 44 of 98

EO 09-0009

Page 45

DeviceNet Modules

MAN0577-03-en

6.7. Automatic Network Scan

After the Master device is configured, it is possible to scan the DeviceNet network for other devices

(automatic network scan). This allows a very fast configuration, and detailed parameters for these devices

can be changed later.

To start an automatic network scan, please proceed as followed:

1. Create a new project: Select the menu File > New and DeviceNet.

2. Select a Master: The Master is selected with the menu Insert > Master

3. Click on Settings > Bus parameters and select the baudrate and the MAC ID from the Master

(explained in section

4. Select Online > Download to load these settings into the DeviceNet Master.

5. Save: With the menu File > Save the so far set settings are saved.

6. Click on the Master and choose Online > Automatic Network Scan

Bus Parameter on page 34)

HE800DNM650 & HE800DNS600

Figure 23: Online > Automatic Network Scan (Security question)

Page 45 of 98

EO 09-0009

Page 46

DeviceNet Modules

MAN0577-03-en

HE800DNM650 & HE800DNS600

Figure 24: Online > Automatic Network Scan (during scan)

The network scan will take approx. 30 seconds. The network scan is still in progress and could not be

interrupted until the status, shown in the field “Current Status”, is “Ready!”. When the scan is done, the

devices found can be seen at the corresponding MAC ID address in the table.

The master reads the following objects from the DeviceNet device (Slave) during the scan:

Element Class.Instance.Attribute

Device Name 1.1.7

Poll Size Produced 5.2.7

Poll Size Consumed 5.2.8

BitStr. Size Produced 5.3.7

BitStr. Size Consumed 5.3.8

Cyc/COS. Size Produced 5.4.7

Cyc/COS. Size Consumed 5.4.8

Table 9: Readed Classes.Instance.Attribute during the network scan

Page 46 of 98

EO 09-0009

Page 47

DeviceNet Modules

MAN0577-03-en

Example:

HE800DNM650 & HE800DNS600

Figure 25: Online > Automatic Network Scan (after scan)

In our example in the figure above the automatic network scan detected a Horner device at MAC ID 1.

Here is an explanation of the different columns:

Variable Meaning

Supported functions

Device Name Name of the device, result from network scan

Poll Size Produced Number of data for poll connection (input)

Poll Size Consumed Number of data for poll connection (output)

BitStr. Size Produced Number of data for bit strobe connection (input)

BitStr. Size Consumed Number of data for bit strobe connection (output)

Cyc/COS. Size Produced Number of data for cyclic/COS connection (input)

Cyc/COS. Size Consumed Number of data for cyclic/COS connection (output)

Chosen Config

Functions supported by the device, could be polled, bit strobe

or cyclic/change of state (see explanation in Actual chosen IO

Connection page 27)

Configuration chosen by the user, could be Change of State,

Cyclic, Polling, Bit strobed or explicit only and depends on the

functions supported by the device. Click on the cell to change

the configuration.

Table 10: Meaning of the columns in the automatic network scan

A double click on the first or second column of the corresponding row of the device shows information of

the device

Page 47 of 98

EO 09-0009

Page 48

DeviceNet Modules

MAN0577-03-en

Figure 26: Information on a device in the automatic scan window

If this configuration is the required one, click on Automatic Configuration and select Yes when

prompted. Afterwards the Automatic Configuration Window can be closed by clicking on Close. If the

devices that were found in the configuration are not required, just click Close.

To manually insert the devices, please go on with section Insert Device (Slave) on page 24.

6.8. Start/Stop Communication

First the desired Master must be chosen with a left mouse click on the symbol of the Master. The

communication between the DeviceNet Master and the DeviceNet Slaves can be manually started or

stopped. In order to do this select the Online > Communication start or Online > Communication stop

menu.

6.9. Diagnostic Functions

The following table shows Diagnostic Functions and their using for

• Horner DeviceNet Master devices

HE800DNM650 & HE800DNS600

• Horner DeviceNet Slaves

Diagnostic Functions Using

Live List

Debug Mode

Global State Field

Extended Device Diagnostic

Usable for Horner

DeviceNet Masters

devices

Detects, which devices

are connected to the

Horner DeviceNet Master

Detects, to which

DeviceNet Slaves the

Master has a connection

State information of the

Horner DeviceNet Master

Statistic information and

state information from the

Horner DeviceNet device

Yes

Yes

Yes

Yes Yes