Page 1

MAN0951-02 12 May 2011 PAGE 1

HE-579ACM300

Information is subject to change without notice.

The SmartBlock ACM300 is a Power and Energy Monitor that is easy to setup, and provides a variety of

advanced features, including:

• 3-phase Power Monitoring with three

current (0-5A CTs) and voltage inputs

(480V, direct connect or PTs).

• CsCAN CAN network connection

provides a fast flexible communication

path.

• SmartBlock package allows convenient

mounting close to the source to be

monitored

• On board relay allows load shedding,

alarming or other local switching.

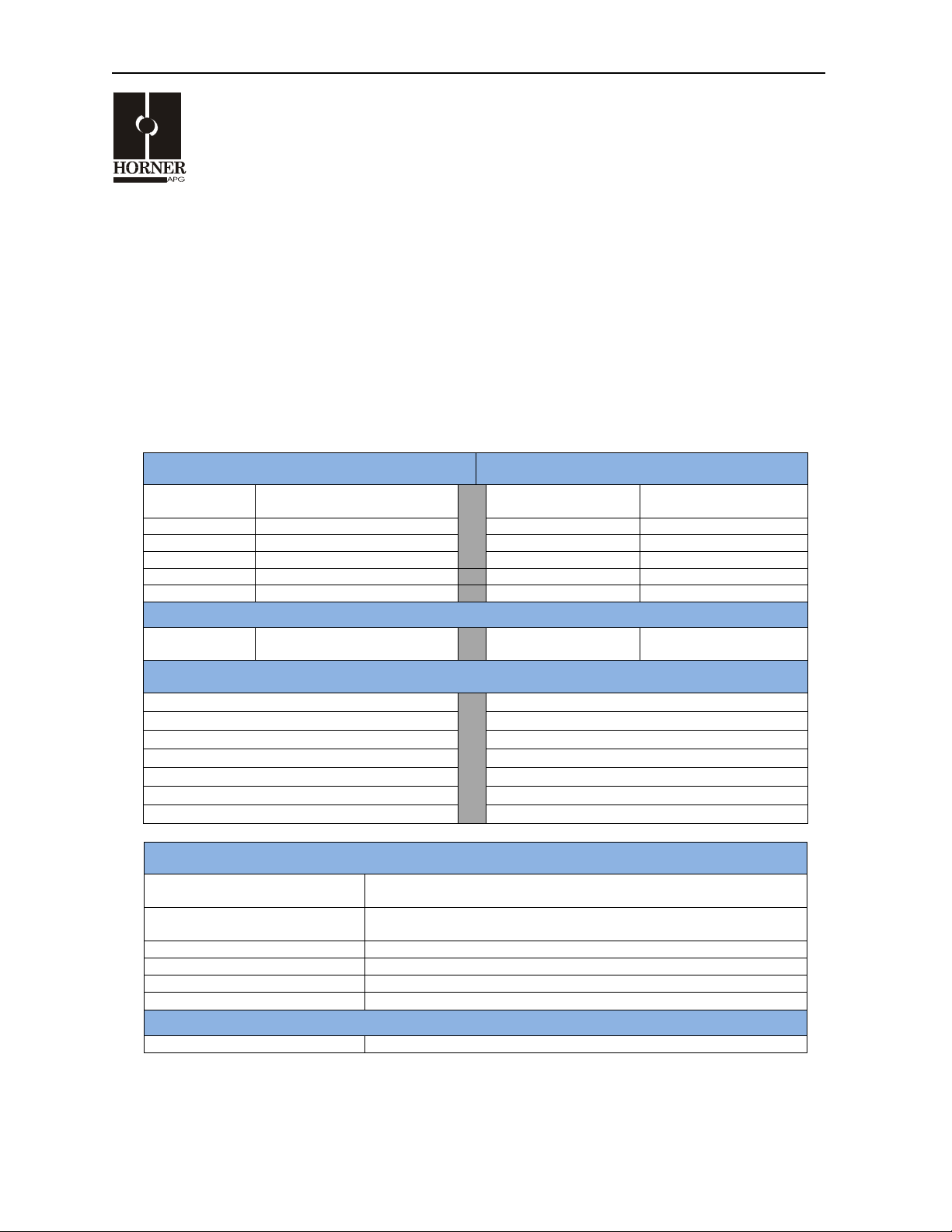

1 SPECIFICATIONS

CURRENT INPUTS

VOLTAGE INPUTS

Conversion

True RMS

78.1K samples/sec

Conversion

True RMS

CT Input

5A Secondary

PT Input (or direct)

480V Secondary

Burden

0.2VA

Burden

2.0Mohm

Range

1 to 150% of CT Primary

Input Range

40 to 600Vac

Full Scale

150% of CT Primary

Full Scale

600Vac

Accuracy

<1% of Full Scale

Accuracy

Better than 1% full scale

RELAY OUTPUT (Form C)

Current

1A max at 30Vdc

0.5A max at 125Vac

Contact Voltage

30Vdc, Max

125Vac, Max

MEASURED DATA VALUES

Phase A RMS voltage (Va)

Watts (W)

Phase B RMS voltage (Vb)

Power Factor (PF)

Phase C RMS voltage (Vc)

Volt-Amps (VA)

Phase A RMS current (Ia)

Volt-Amps Reactive (VAR)

Phase B RMS current (Ib)

Kilowatt Hour (KWhr)

Phase C RMS current (Ic)

Voltage Peak (Vpeak)

Frequency (Hz)

Current Peak (Ipeak)

GENERAL SPECIFICATIONS

Required Power (Steady State)

40mA @ 24VDC

Required Power

(Inrush)

14A for 50uSec

Primary Power Range

10-30VDC

Operating Temperature

0 to +60 C

Relative Humidity

5 to 95%, Non-condensing

Measurement Rating

CAT III Max 600V

CONNECTIVITY

CAN Port

Horner CsCAN Peer-to-Peer

SmartBlock Power and Energy Monitor

HE-579ACM300

Page 2

PAGE 2 12 May 2011 MAN0951-02

HE-559ACM300

Information is subject to change without notice.

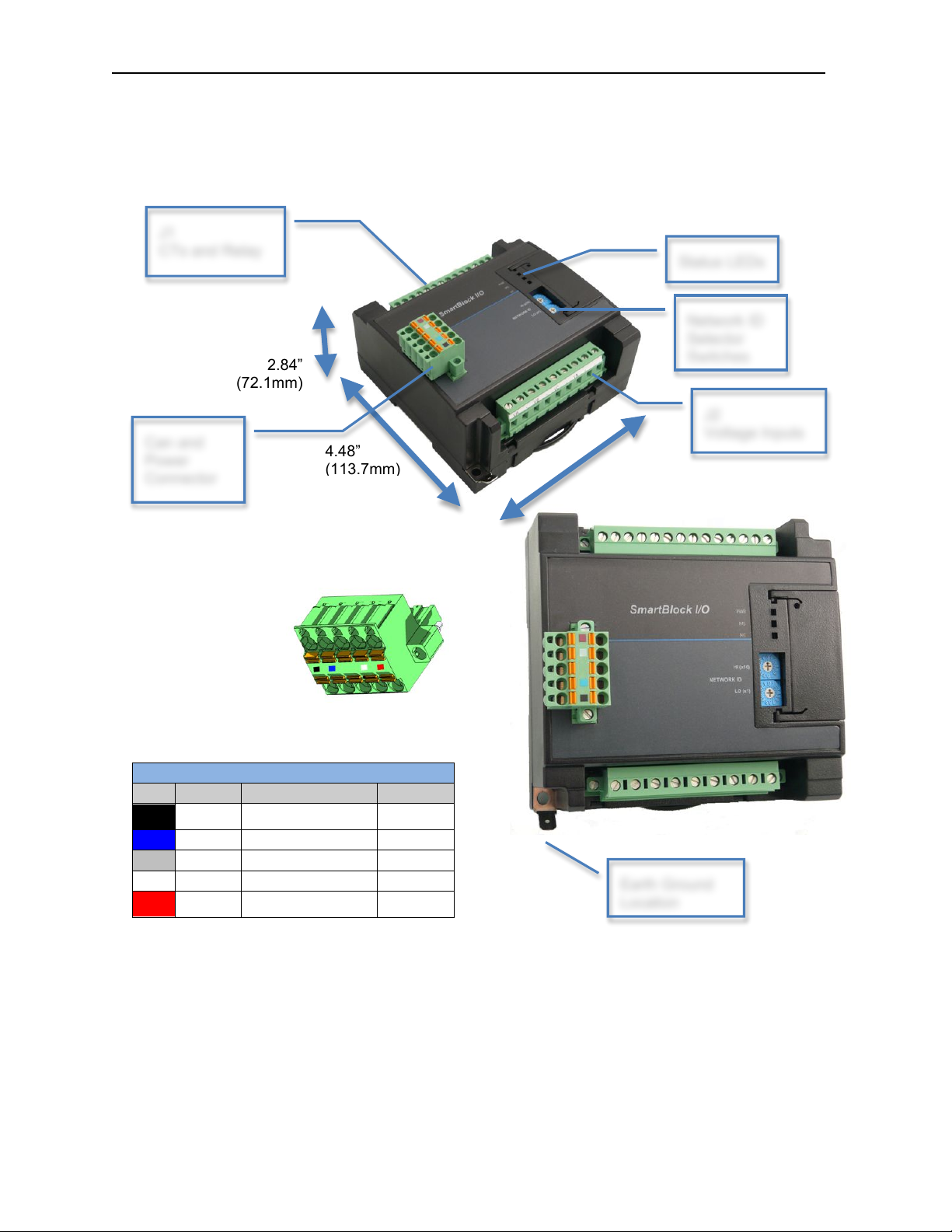

2 DIMENSIONS AND INSTALLATION

Network, Power and Grounding:

A single 5 pin connector is used to make both a network connection and power input. A quality class 2

power supply should be used for this product. If the power is run with the network cable, care must be

taken such that the voltage does not drop below the lower supply limit on longer runs.

A quality protective earth ground is required for safe and proper operation. The best protective earth

ground is achieved by screwing the lower left grounding location into a grounded back plate. Alternately

a protective earth ground can be connected to the spade lug.

Please see Horner manual MAN0799 for details on CAN wiring.

CAN Network & Power Port Pin Assignments

Pin

Signal

Signal Description

Direction

1

V-

CAN and Device

Ground - Black

!

2

CN_L

CAN Data Low - Blue

In/Out

3

SHLD

Shield Ground - None

!

4

CN_H

CAN Data High - White

In/Out

5

V+

Positive DC Voltage

Input (10-30VDC) - Red

!

4.56”

(115.8mm)

4.48”

(113.7mm)

2.16”

(54.8mm)

With connector

2.84”

(72.1mm)

CAN Network & Power

Connector

Torque rating 4.5 – 7 Lb-In

(0.50 – 0.78 N-m)

J1

CTs and Relay

J2

Voltage Inputs

Can and

Power

Connector

Network ID

Selector

Status LEDs

Earth Ground

Location

Page 3

MAN0951-02 12 May 2011 PAGE 3

HE-579ACM300

Information is subject to change without notice.

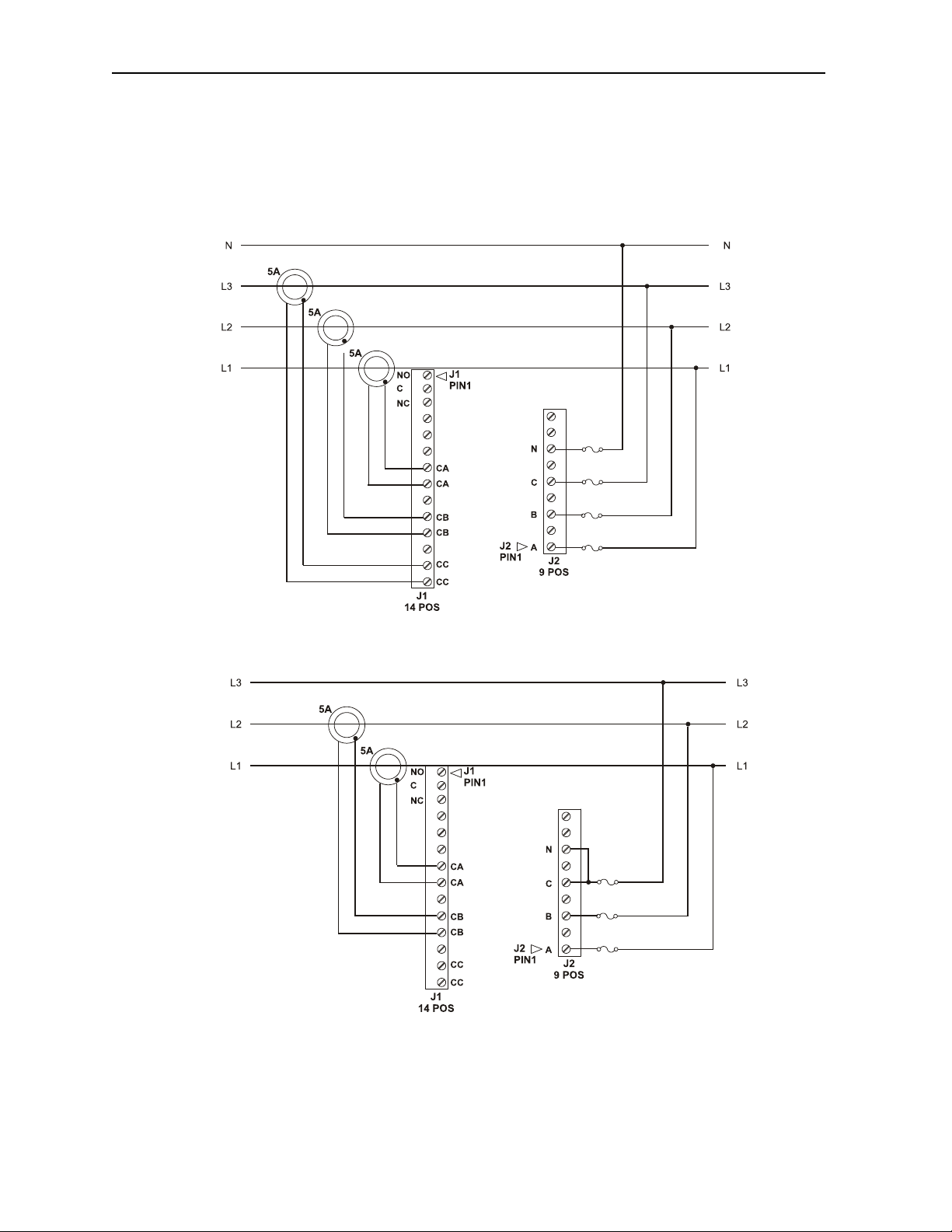

3 WIRING

4-wire Wye or 4-wire Delta

3-wire Delta

Page 4

PAGE 4 12 May 2011 MAN0951-02

HE-559ACM300

Information is subject to change without notice.

4 NETWORK DATA

Consumed Digital Data – This data is sent from the controller to the SmartBlock. For typical

applications the I/O configuration setup in Cscape will automatically populate this data. For more

advanced applications you may use NetPut functions to write this data. Please see the advanced

programming guide MAN0880 for more details.

Bit

Description

1

Q1 default

2

Q1 override

Upon module stop / timeout, if Q1 override is true, Q1 is set to Q1 default, otherwise the Q1

value is held. This override / hold polarity is consistent with OCS / Cscape usage but the

reverse of the legacy analog hold / override polarity in word 5.

3

Frequency Source, Set for phase B, Clear for phase A or C

4

Frequency Source, Set for phase C, Clear for phase A or B

If Clear

Always accumulate Watt-Hours

5

If Set

Do not accumulate Watt-Hours if load is under 0.005% of full scale to avoid meter

creep due to slight zero errors

6

Set to report period instead of frequency in AI13 / AI14

17

Relay output, set to ON to close N.O. and open N.C contacts.

23

Set to ON to clear KWhr, set to OFF to re-enable KWhr accumulator

24

Set to ON to clear Status flags, set to OFF to re-enable Status flags

Produced Digital Data – This data is sent from the SmartBlock to the controller. Normally this data is

mapped into specific registers in the I/O configuration in Cscape. For advanced applications NetGet

functions can be used to obtain this data. Since this data is broadcast to all controllers on the network

additional controllers can use NetGet functions to obtain this data as well.

Bit

Name

Description

I1

AEHF

Watt-Hour accumulator half full.

I2

REHF

VAR-Hour accumulator half full

I3

VAEHF

VA-Hour accumulator half

I4

SAGA

Voltage sag on Phase A

I5

SAGB

Voltage sag on Phase B

I6

SAGC

Voltage sag on Phase C

I7

ZXTOA

Zero Cross timeout on Phase A

I8

ZXTOB

Zero Cross timeout on Phase B

I9

ZXTOC

Zero Cross timeout on Phase C

I10

ZXA

Zero Cross detected on Phase A

I11

ZXB

Zero Cross detected on Phase B

I12

ZXC

Zero Cross detected on Phase C

I13

LENERGY

Reserved

I14

RESET

5V supply rail under 4 volts

I15

PKV

Peak voltage level exceeded

I16

PKI

Peak current level exceeded

I17

WFSM

Reserved

I18

REVPAP

Sign changed occurred in Watt calculation

I19

REVPRP

Sign changed occurred in VAR calculation

I20

SEQERR

A-B-C Rotation

Page 5

MAN0951-02 12 May 2011 PAGE 5

HE-579ACM300

Information is subject to change without notice.

Consumed Analog Data – This data is sent from the controller to the SmartBlock. For typical

applications the I/O configuration setup in Cscape will automatically populate this data. For more

advanced applications you may use NetPut functions to write this data. Please see the advanced

programming guide MAN0880 for more details.

Word

Description

Details

Word 1 / 2

REAL

PT A Ratio

Word 3 / 4

REAL

PT B Ratio

Word 5 / 6

REAL

PT C Ratio

Voltage Input Ratio

For example 120 to 480 step up enter 0.25

for 7200 to 480 step down enter 15

Word 7 / 8

REAL

CT A Ratio

Word 9 / 10

REAL

CT B Ratio

Word 11 / 12

REAL

CT C Ratio

Current Input Ratio

For example for 5A:100A CT enter 20

Word 13 / 14

REAL

CT A Phase Shift

Word 15 / 16

REAL

CT B Phase Shift

Word 17 / 18

REAL

CT C Phase Shift

Phase correction for CTs Enter in degrees

Min of -1.63° Lag, Max of +3.32 Lead

Word 19 / 20

REAL

Zero Cross Timeout

Seconds for zero cross alarm – max 2.5

Word 21 / 22

REAL

RMS Sag Voltage Level

Voltage Sag level in volts

Word 23

UINT

Sag Half Cycles

Number of half cycles before alarm

Word 24

UINT

Peak Level Half Cycles

Number of half cycles before alarm

Word 25 / 26

REAL

Voltage Peak Level

Voltage level for peak alarm

Word 27 / 28

REAL

Current Peak Level

Current level for peak alarm

Produced Analog Data – This data is sent from the SmartBlock to the controller. Normally this data is

mapped into specific registers in the I/O configuration in Cscape. For advanced applications NetGet

functions can be used to obtain this data. Since this data is broadcast to all controllers on the network

additional controllers can use NetGet functions to obtain this data as well.

Word

Function

Word 1 / 2

REAL

Phase A RMS Voltage

Word 3 / 4

REAL

Phase B RMS Voltage

Word 5 / 6

REAL

Phase C RMS Voltage

Word 7 / 8

REAL

Phase A RMS Current

Word 9 / 10

REAL

Phase B RMS Current

Word 11 / 12

REAL

Phase C RMS Current

Word 13 / 14

REAL

Frequency

Word 15 / 16

REAL

Watts

Word 17 / 18

REAL

PF Power Factor

Word 19 / 20

REAL

VA Volt-Amps

Word 21 / 22

REAL

VAR Volt-Amps Reactive

Word 23 / 24

REAL

KWhr

Word 25 / 26

REAL

Voltage Peak

Word 27 / 28

REAL

Current Peak

Page 6

PAGE 6 12 May 2011 MAN0951-02

HE-559ACM300

Information is subject to change without notice.

5 INSTALLATION / SAFETY

Warning: Remove power from the SmartBlock, CAN port, and any peripheral equipment

connected to this local system before adding or replacing this or any module.

Use the following wire type or equivalent:

• Belden 8917

• 16 AWG or larger

When found on the product, the following symbols specify:

WARNING: This unit should be located so that it is not accessible without the use of a tool.

WARNING: If this device is used in a way not specified by the manufacturer the safety provided

may be impaired.

WARNING: To avoid the risk of electric shock or burns, always connect the safety (or earth)

ground before making any other connections.

WARNING: To reduce the risk of fire, electrical shock, or physical injury it is strongly

recommended to fuse the voltage measurement inputs. Be sure to locate fuses as close to the

source as possible.

WARNING: Replace fuse with the same type and rating to provide protection against risk of fire

and shock hazards.

WARNING: In the event of repeated failure, do not replace the fuse again as a repeated failure

indicates a defective condition that will not clear by replacing the fuse.

WARNING: Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this

equipment. Read and understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in severe bodily injury or loss

of life.

Warning: Consult user documentation.

Warning: Electrical Shock Hazard.

Note: Protective Earth Ground. Must be

connected to the system protective earth

ground for proper and safe operation

Page 7

MAN0951-02 12 May 2011 PAGE 7

HE-579ACM300

Information is subject to change without notice.

6 TECHNICAL SUPPORT

For assistance and manual up-dates, contact Technical Support at the following locations:

North America:

(317) 916-4274

www.heapg.com

Europe:

(+) 353-21-4321-266

www.horner-apg.com

Loading...

Loading...