Page 1

MAN0845-04-EN Specifications / Installation

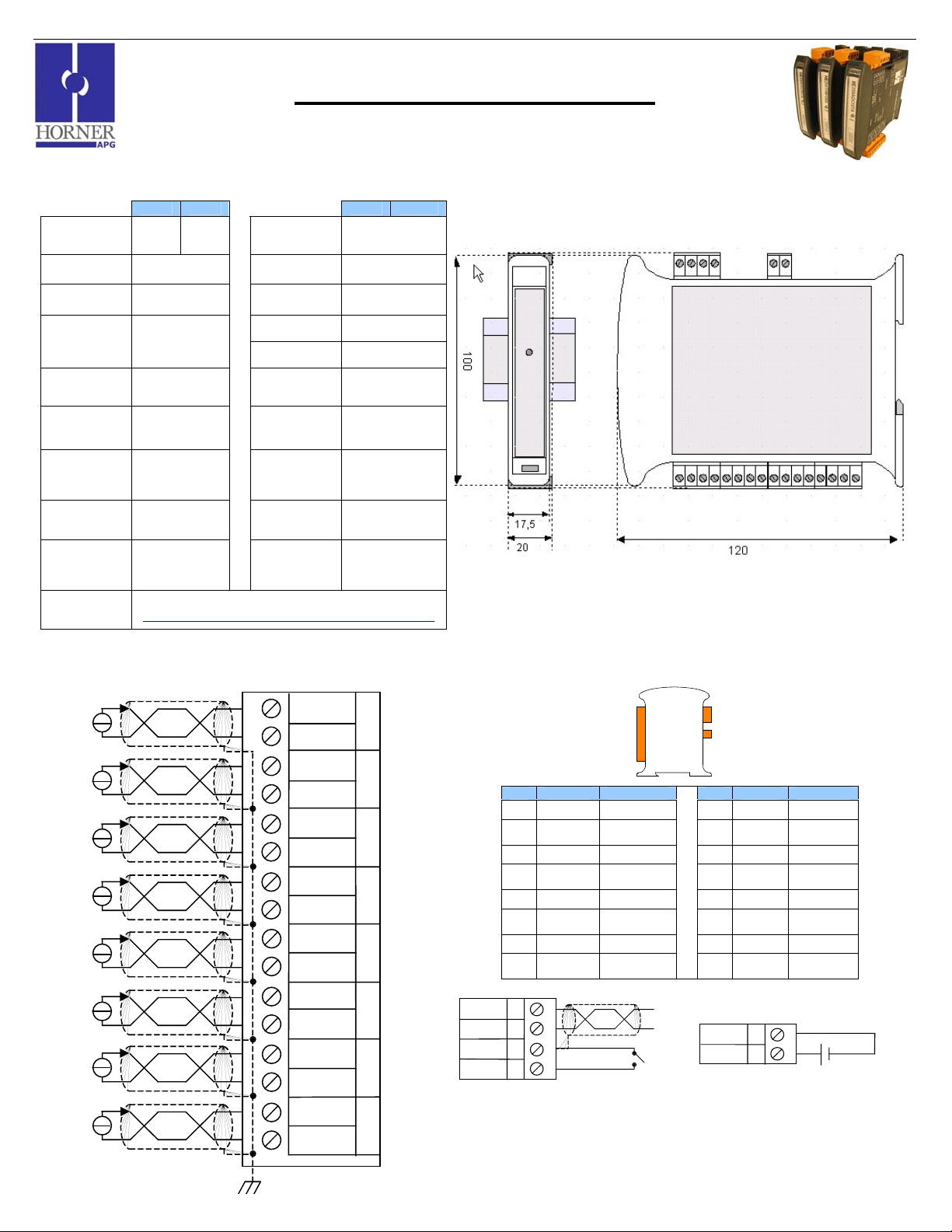

1 Specifications

ADC120 ADC220 ADC120 ADC220

Number of

Channels

Input Ranges +/-20mA Terminal Type

Resolution 16-Bit Storage Temp.

Input Impedance <50 Ohms

Linearity +/-0.1%

External Power

Supply Voltage

Required Power

(Steady State)

Required Power

(Inrush)

Isolation

CE & UL

Compliance

4 8

10-30Vdc Weight 150g (6 oz.)

30mA @ 24Vdc,

typical

Negligible

2000Vac for 60

seconds

(Input/Power &

Input/Serial)

See Compliance Table at

http://www.heapg.com/Pages/TechSupport/ProductCert.html

20mA Analog Input Module

Conversion Time

(PLC Update

Rate)

Operating Temp.

Relative Humidity

Dimensions

WxHxD

Communications

Factory Default

Communications

Parameters

Supported

Modbus

Commands

HE359ADC120 / HE359ADC220

Determined by

Communications

5 to 90% Non-

17.5mm x 100mm x

0.69” x 3.94” x 4.72”

38400 baud, N, 8, 1,

Default Modbus ID 1

1,2,3,4,5,6,8,15,16

SmartMod

16-Bit Resolution

w/OCS

Screw Type,

Removable

-40° to 85°

Celsius

-10° to 60°

Celsius

condensing

120mm

Modbus/RTU

(binary)

RS-485 half

duplex

no h/s

2 Wiring – I/O

+

+

+

+

+

+

+

+

__________________________________________________________________________________________________________________________________________________________________

5/8/2009 Page 1 of 2 ECN # 950

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

I+

GNA

I+

GNA

I+

GNA

I+

GNA

I+

GNA

I+

GNA

I+

GNA

I+

GNA

IN

0

IN

1

IN

2

IN

3

IN

4

IN

5

IN

6

IN

7

Notes:

Both ends of the RS-485 network should be terminated with a 100ohm, 1/4W, 1% resistor. Many OCS

controllers feature dip switches or jumpers which enable appropriate termination if the OCS is located on

a network end.

Pin # ADC120 ADC220 Pin # ADC120 ADC220

1 INPUT 0+ INPUT 0+ 9 COM INPUT 4+

2

3 INPUT 1+ INPUT 1+ 11 INPUT 5+

4 12 INPUT 0

5 INPUT 2+ INPUT 2+ 13 INPUT 1 INPUT 6+

7 INPUT 3+ INPUT 3+ 15 INPUT 3 INPUT 7+

8

A

D-

B

D+

C

GND

D

INIT

Wiring RS-485

Dimensions in inches are 0.69”W x 3.95”H x 4.72”D

Note: Number of I/O terminal connections vary from model to model

RS-485

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

I/O

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

DC IN

10 N.O.

14 6 INPUT 2

16 COM

VV+

Wiring DC IN

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

ANALOG

COMMON

I

J

10-30Vdc

Page 2

MAN0845-04-EN Specifications / Installation

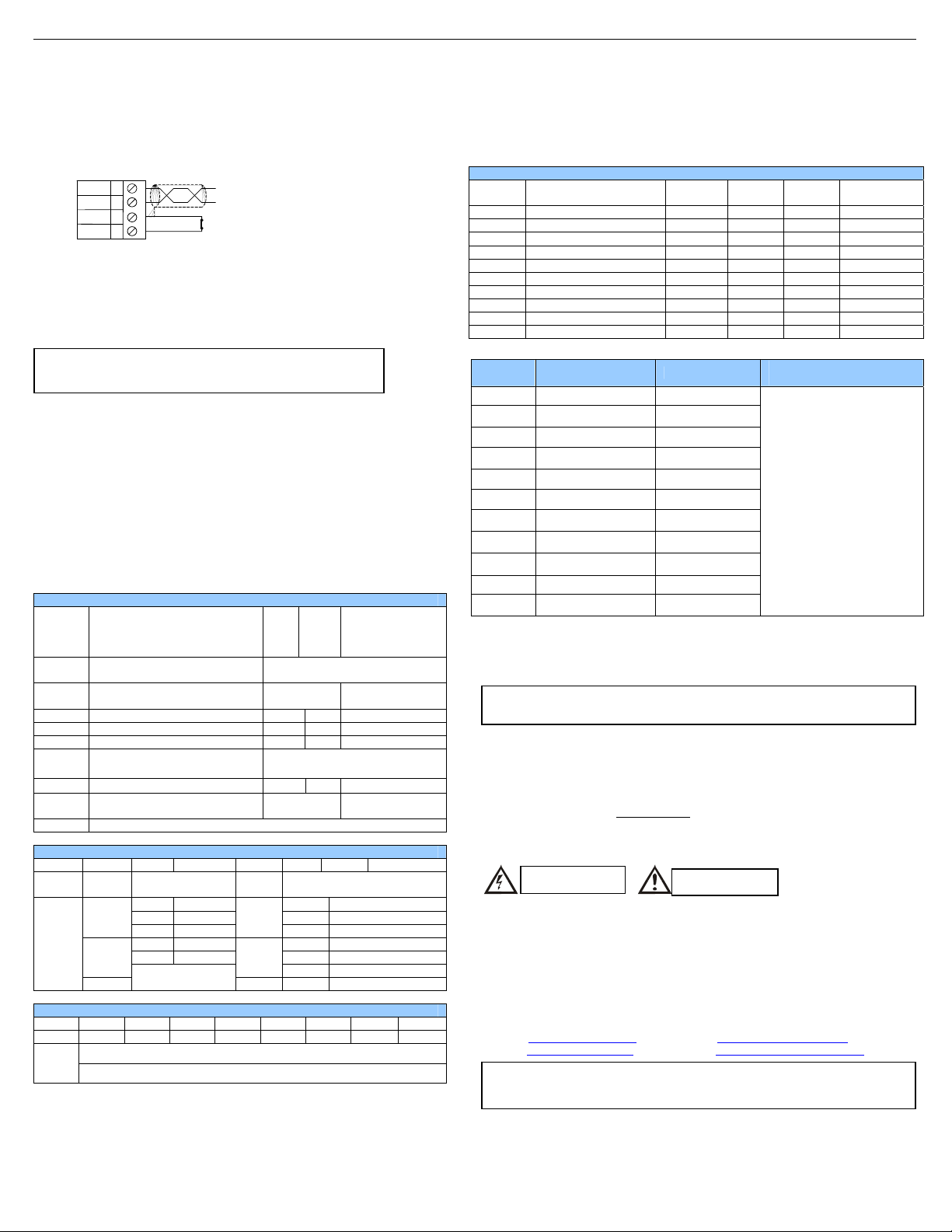

3 Init Default Setup

Communication parameters will be set to INIT default after performing the procedure:

1. Install jumper between INIT and GND terminals of the RS-485 port.

2. Apply power to Smartmod unit.

3. Read parameter words to see current parameters.

4. Write changes if necessary.

The INIT Default RS485 Settings Are:

Modbus ID = 1

Baud rate = 9600

Parity = None

Stop Bits = 1

Data Bits = 8

No handshake

Note: There are 2 types of default settings possible:

1. Factory default as described in section 1 (Specifications)

2. Default after INIT as described in section 3 (INIT Default Setup)

4 Configuration DATA

SmartMod Configuration settings are mapped into Modbus Register space. This

configuration data may be modified with any Modbus/RTU Master device. For

convenience, Horner APG has developed a variety of Cscape application files which

allow an OCS (Xle, NX, LX, QX) to act as a SmartMod configurator. Initial

configuration of SmartMod module should be done on an individual basis, since all

modules come from the factory with a default Modbus ID of 1. Once each module on

the network has its own unique Modbus ID, further configuration adjustments can be

made with the entire network powered.

All configuration parameters listed below (except 40012 Channel Enable) are stored

in EPROM. That means they should not be constantly rewritten.

Modbu

s

Regist

er

40001-

40005

40006 Communications Parameters See Table

40007 Modbus ID 1 255 1

40008 Rx/Tx Delay (in 2mS steps) 0 255 0mS

40009 Watchdog Timer (in 0.5s steps) 0 255 10 (5s)

40010 Modbus Coil Data

40011 Input Type 6 6 6 (+/-20mA)

40012 Channel Enable See Table

40013 Reserved

Bits 7-15 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Unused Mode Parity

Bit 8-15 Bit 7 Bit 6 Bi t 5 Bit 4 Bit 3 Bit 2 Bi t 1 Bit 0

Unused Input 1 Input 1 Input 1 Input 1 Input 1 Input 1 Input 1 Input 1

A

D-

B

D+

C

GND

D

INIT

Configuration Parameters – Registers 40001 through 40013

Description Min Max Default

Reserved

38.4kbaud, N, 8, 1,

RTU Mode

Not Configuration Data – See I/O

Data

255 (Channels 1-

8 enabled)

Register 40006 (Communications Parameters) Bit Definition

0 =

ASCII

Mode

1 =

RTU

Mode

Data

Bits

Value Meaning Value Meaning

0 Mark 0 1200 baud

1 Even

2 Odd 2 4800 baud

3 Space 3 9600 baud

0 = 7

Data

Bits

1 = 8

Data

Bits

5-7 38400 baud

Baud Rate

1 2400 baud

4 19200 baud

Register 40012 (Channel Enable) Bit Definition

0 = Disable Input

1= Enable Input

5 Input/Output DATA

SmartMod Analog I/O utilizes both Modbus Registers (40001-40030) and Coils (1-11). It is

possible to access all data using Registers only, because the Coils can be accessed through

Register 40010.

The following tables lists all Modbus I/O data available.

I/O Register Data (Registers 40014-40022)

Modbus

Register

Description Access

Minimum Maximum Units

40010 Mirror of Coil Data Read/Write n/a n/a n/a

40014 Cold Junction Temperature Read-only -1000 6000 0.01 degrees C

40015 Input 0 Read-only -20000 +20000 1µA (0.001mA)

40016 Input 1 Read-only -20000 +20000 1µA (0.001mA)

40017 Input 2 Read-only -20000 +20000 1µA (0.001mA)

40018 Input 3 Read-only -20000 +20000 1µA (0.001mA)

40019 Input 4 Read-only -20000 +20000 1µA (0.001mA)

40020 Input 5 Read-only -20000 +20000 1µA (0.001mA)

40021 Input 6 Read-only -20000 +20000 1µA (0.001mA)

40022 Input 7 Read-only -20000 +20000 1µA (0.001mA)

Modbus

Coil

Description Access

Watchdog Event & Power-

up Event Operation

00001 Open Detect Input 0 Read/Write

00002 Open Detect Input 1 Read/Write

00003

Open Detect Input 2 Read/Write

00004 Open Detect Input 3 Read/Write

00005 Open Detect Input 4 Read/Write

00006 Open Detect Input 5 Read/Write

00007 Open Detect Input 6 Read/Write

00008 Open Detect Input 7 Read/Write

00009 Watchdog Enabled Read/Write

00010 Watchdog Event Read/Write

If Coil 9 (Watchdog Enabled)

is set, Coil 10 (Watchdog

Event) will set if the Watchdog

Timeout value is exceeded.

The Watchdog Timeout value

is set in Register 40009.

When set, Coil 10 can be

reset by the controller when

normal communications

resumes.

The Power-up Event (Coil 11)

is set every time the power is

applied. It can be cleared by

the controller if desired.

00011 Power-up Event Read/Write

6 Installation / safety

Warning: Remove power from the OCS controller, CAN port, and any peripheral

equipment connected to this local system before adding or replacing this or any

module.

a. All applicable codes and standards should be followed in the installation of this product.

b. Shielded, twisted-pair wiring should be used for best performance.

c. Shields may be terminated at the module terminal strip.

d. In severe applications, shields should be tied directly to the ground block within the panel.

e. Use the following wire type or equivalent: Belden 8441.

For detailed installation and a

minimum clearances, refer to the hardware manual of the controller you are using.

When found on the product, the following symbols specify:

handy checklist that covers panel box layout requirements and

Warning: Electrical

Shock Hazard.

Warning: Consult

user documentation.

7 Technical Support

Technical Support at the following locations:

North America:

Tel: 317 916-4274

Fax: 317 639-4279

Web:

http://www.heapg.com

Email: techsppt@heapg.com

No part of this publication may be reproduced without the prior agreement and written

permission of Horner APG, Inc. Information in this document is subject to change

without notice.

Europe:

Tel: +353-21-4321266

Fax: +353-21-4321826

Web:

http://www.horner-apg.com

Email: tech.support@horner-apg.com

__________________________________________________________________________________________________________________________________________________________________

5/8/2009 Page 2 of 2 ECN # 950

Loading...

Loading...