Page 1

XL7 OCS QUICK START GUIDE

General Specifications

Required Power (Steady State) 170mA @ 24VDC

Heater Option

Required Power (Inrush) 7A for < 1ms @ 24VDC, DC switched

Primary Power Range 10 - 30VDC

Typical Power Backlight 100% 4.848W @ 24VDC

Power Backlight @ 50% 3.792W @ 24VDC

Power Backlight OFF 3.408W @ 24VDC

Relative Humidity 5 to 95% non-condensing

Clock Accuracy

Surrounding Air Temp

Storage Temp -20°C to +60°C

Weight 2 lbs (907g)

Altitude Up to 2000m

Rated Pollution Degree

Certifications

(UL/CE)

250mA @ 24VDC with heater operation

*Heater Option (Model # plus “-22)

+ / - 20 ppm maximum at 25°C

(+/- 1 min/month)

-10°C to +60°C (-22 Heater Option

Range is -40°C to +60°C)

Evaluated for Pollution Degree 2

Rating

North America: https://hornerautomation.com/

certifications/

Europe: http://www.hornerautomation.eu+

1. Touchscreen

2. Function Keys

3. MJ1: RS232/ MJ2: 1/2 duplex RS485

4. Dip Switches

5. MJ3: RS-232/485 Serial Port

6. CAN1 Port

7. PWR: 10-30VDC In

8. Audio In & Out Ports

9. USB 2.0 “A”: Flash Drive

10. LAN 1 & 2 Ports

11. CAN2 Port

12. USB mini “B”: Programming

13. microSD: Data Storage

XL7 Overview

NOTE: See Precaution #15 on page 4 about USB and grounding.

3

1

2

4

5

6

7

page 1 of 4

Indianapolis, USA | Cork, Ireland | Calgary, Canada | Bangalore, India | Oakleigh, Australia | Tianjin, China | Esteio, Brazil

Please visit our website for a complete listing and to learn more about certified Horner Automation products.

This document is the property of Horner Automation Group, and is subject to change.

Built-in I/O

8 9 10

13

12

11

MAN1195-02-EN

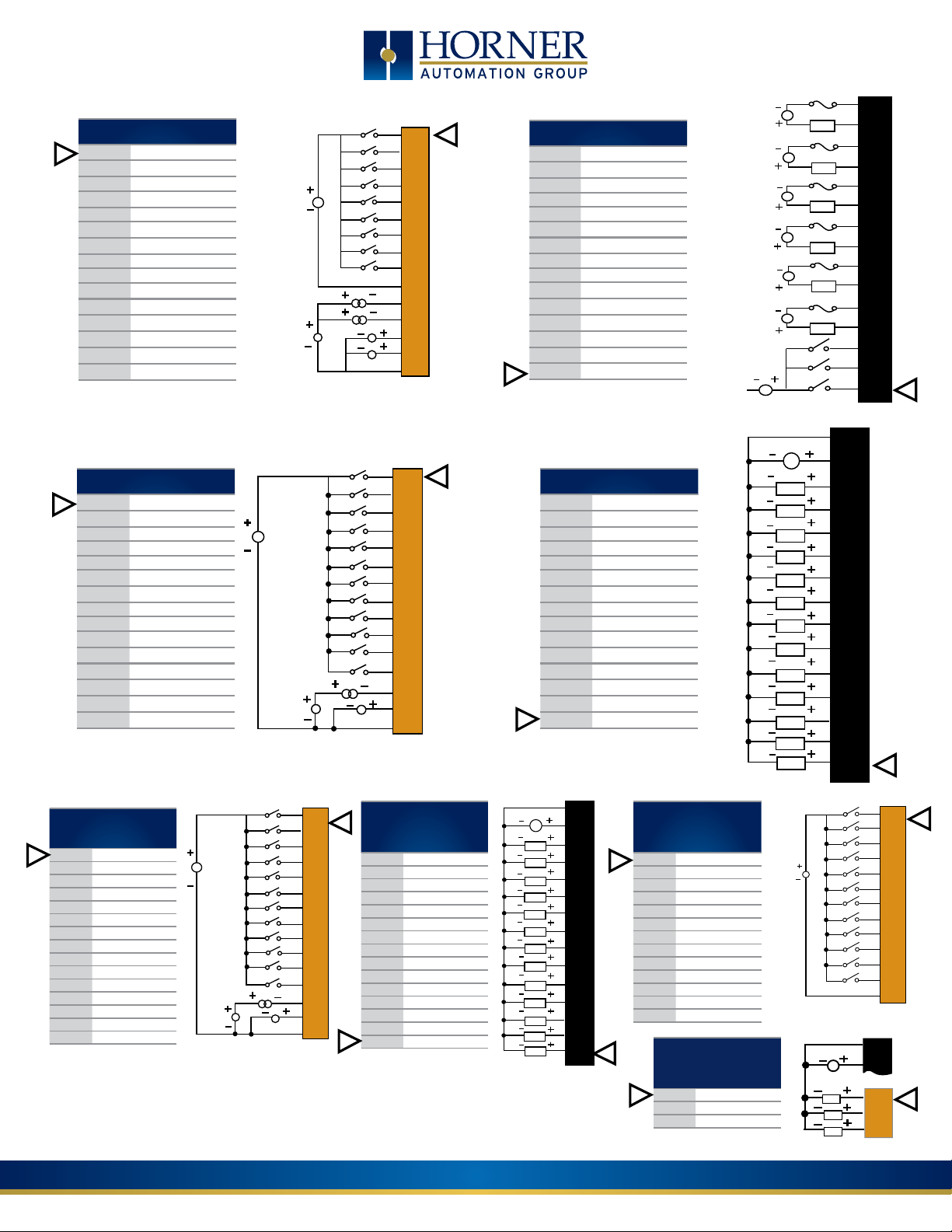

Page 2

J1 (Orange)

Digital & Analog In

I1 IN1

I2 IN2

I3 IN3

I4 IN4

I5 IN5

I6 IN6

I7 IN7

I8 IN8

H1 HSC1 / IN9

0V Common

A1 Analog IN1

A2 Analog IN2

A3 Analog IN3

A4 Analog IN4

0V Common

MODEL 2: 2 DC In, 6 Relay Out, 4 – 12-bit Analog In

J2 (Black) Relay Out /

Digital In

C6 Relay 6 COM

R6 Relay 6 NO

C5 Relay 5 COM

R5 Relay 5 NO

C4 Relay 4 COM

R4 Relay 4 NO

C3 Relay 3 COM

R3 Relay 3 NO

C2 Relay 2 COM

R2 Relay 2 NO

C1 Relay 1 COM

R1 Relay 1 NO

H4 HSC4 / IN12

H3 HSC3 / IN11

H2 HSC2 / IN10

12-24VDC

LOOP PWR

20mA

0-10VDC

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

OV

0V on J1

230VAC

or

25VDC

230VAC

or

25VDC

230VAC

or

25VDC

230VAC

or

25VDC

230VAC

or

25VDC

230VAC

or

25VDC

12-24VDC

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

J1 (Orange) Digital &

Analog In

I1 IN1

I2 IN2

I3 IN3

I4 IN4

I5 IN5

I6 IN6

I7 IN7

I8 IN8

H1 HSC1 / IN9

H2 HSC2 / IN10

H3 HSC3 / IN11

H4 HSC4 / IN12

A1 Analog IN1

A2 Analog IN2

0V Common

J1 (Orange) Name

Digital & Analog In

I1 IN1

I2 IN2

I3 IN3

I4 IN4

I5 IN5

I6 IN6

I7 IN7

I8 IN8

H1 HSC1 / IN9

H2 HSC2 / IN10

H3 HSC3 / IN11

H4 HSC4 / IN12

A1 Analog IN1

A2 Analog IN2

0V Common

MODEL 3: 12 DC In, 12 DC Out, 2 – 12-bit Analog In

J2 (Black) Positive Logic

Digital Out

0V Common

V+ V+

NC No Connect

Q12 OUT 12

Q11 OUT 11

Q10 OUT 10

Q9 OUT 9

Q8 OUT 8

Q7 OUT 7

Q6 OUT 6

Q5 OUT 5

Q4 OUT 4

Q3 OUT 3

Q2 OUT 2 / PWM 2

Q1 OUT 1 / PWM 1

12-24VDC

20mA

LOOP

PWR

0-10VDC

I1

I2

I3

I4

I5

I6

I7

I8

H1

H2

H3

H4

A1

A2

OV

10 - 30VDC

MODEL 4: 24 DC In, 16 DC Out, 2 – 12-bit Analog In

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

OV

V+

Q13

Q12

Q11

Q10

Q9

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

J3 (Orange) Name

Positive Logic

Digital In

I13 IN13

I14 IN14

I15 IN15

I16 IN16

I17 IN17

I18 IN18

I19 IN19

I20 IN20

I21 IN21

I22 IN22

I23 IN23

I24 IN24

0V Common

J4 (Orange) Name

Positive Logic

Digital Out

Q16 OUT16

Q15 OUT15

Q14 OUT14

12-24VDC

10 - 30VDC

12-24VDC

LOOP

PWR

20mA

0-10VDC

I2

I3

I4

I5

I6

I7

I8

H1

H2

H3

H4

A1

A2

OV

I1

J2 (Black) Name

Positive Logic

Digital Out

0V Common

V+ V+

NC OUT 13

Q12 OUT 12

Q11 OUT 11

Q10 OUT 10

Q9 OUT 9

Q8 OUT 8

Q7 OUT 7

Q6 OUT 6

Q5 OUT 5

Q4 OUT 4

Q3 OUT 3

Q2 OUT 2 / PWM 2

Q1 OUT 1 / PWM 1

page 2 of 4

Indianapolis, USA | Cork, Ireland | Calgary, Canada | Bangalore, India | Oakleigh, Australia | Tianjin, China | Esteio, Brazil

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

10 - 30VDC

LOAD

LOAD

LOAD

OV

V+

Q13

Q12

Q11

Q10

Q9

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

I13

I14

I15

I16

I17

I18

I19

I20

I21

I22

I23

I24

0V

J2

0V

V+

J4

Q16

Q15

Q14

Please visit our website for a complete listing and to learn more about certified Horner Automation products.

This document is the property of Horner Automation Group, and is subject to change.

MAN1195-02-EN

Page 3

MODEL 5: 2 DC In, 12 DC Out, 2 – 14/16-bit Analog In (mA/V/Tc/mV/RTD),

2 – 12-bit Analog Out

J1 (Orange) - Positive

Logic - Digital In

I1 IN1

I2 IN2

I3 IN3

I4 IN4

I5 IN5

I6 IN6

I7 IN7

I8 IN8

H1 HSC1 / IN9

H2 HSC2 / IN10

H3 HSC3 / IN11

H4 HSC4 / IN12

NC No Connect

NC No Connect

0V Common

12-24VDC

H2

H3

H4

NC

NC

0V

I1

I2

I3

I4

I5

I6

I7

I8

HI

J2 (Black) Positive Logic

- Digital Outputs

0V Common

V+* Output Power

NC No Connect

Q12 OUT12

Q11 OUT11

Q10 OUT10

Q9 OUT9

Q8 OUT8

Q7 OUT7

10 - 30VDC

Q6 OUT6

Q5 OUT5

Q4 OUT4

Q3 OUT3

Q2 OUT2 / PWM2

Q1 OUT1 / PWM1

OV

V+

NC

Q12

LOAD

Q11

LOAD

Q10

LOAD

Q9

LOAD

Q8

LOAD

Q7

LOAD

Q6

LOAD

Q5

LOAD

Q4

LOAD

Q3

LOAD

Q2

LOAD

Q1

LOAD

J3 (Orange) Name

TC (1+) or RTD (1+)

T1+

or 100 mV (1+)

TC (1-) or RTD (1-)

T1-

or 100 mV (1-)

TC (2+) or RTD (2+)

T2+

or 100 mV (2+)

TC (2-) or RTD (2-)

T2-

or 100 mV (2-)

AQ1 10V or 20mA OUT (1)

AQ2 10V or 20mA OUT (2)

0V Common

MA1 0-20mA IN (1)

V1 0-10V IN (1)

0V Common

MA2 0-20mA IN (2)

V2 0-10V IN (2)

0V Common

See MAN1172 for Model 5 wiring details.

MODEL 6: 2 DC In, 12 DC Out, 6 – 14/17-bit Analog In (mA/V/TC/mV/RTD),

4 – 12-bit Analog Out

I1

H1

H2

H3

H4

0V

A1A

A1B

A1C

N/C

A2A

A2B

A2C

N/C

I2

I3

I4

I5

I6

I7

I8

J2 (Black/Green) Name

V3 V OUT 3*

V2 V OUT 2*

V1 V OUT 1*

mA4 mA OUT 4*

J2A

mA3 mA OUT 3*

mA2 mA OUT 2*

mA1 mA OUT 1*

Q1 OUT 1 / PWM1

Q2 OUT 1 / PWM2

Q3 OUT 3

Q4 OUT 4

Q5 OUT 5

Q6 OUT 6

Q7 OUT 7

Q8 OUT 8

J2B

Q9 OUT 9

Q10 OUT 10

Q11 OUT 11

Q12 OUT 12

V+ V External+

0V Common

V3

V2

V1

mA4

mA3

mA2

mA1

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

Q10

Q11

Q12

V+

0V

0-10V Out

+

LOAD

0-10V Out

+

LOAD

0-20mA Out

+

LOAD

0-20mA Out

+

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

LOAD

-

-

-

-

J1 (Orange/Green) Name

I1 IN1

I2 IN2

I3 IN3

I4 IN4

I5 IN5

I6 IN6

J1A

I7 IN7

I8 IN8

H1 HSC1 / V IN9

H2 HSC2 / V IN10

H3 HSC3 / V IN11

H4 HSC4 / V IN12

0V Common

A1A Univ. AI 1 Pin 1

A1B Univ. AI 1 Pin 2

A1C Univ. AI 1 Pin 3

J1B

NC No Connect

A2A Univ. AI 2 Pin 1

A2B Univ. AI 2 Pin 2

A2C Univ. AI 2 Pin 3

NC No Connect

12-24VDC

20mA

Transmitter

T/C

NOTE: * Both mA & V outputs are active

J3 (Orange/Green) Name

NC No Connection

A3A Univ. AI 3 Pin 1

A3B Univ. AI 3 Pin 2

A3C Univ. AI 3 Pin 3

Univ.

NC No Connection

AI

A4A Univ. AI 4 Pin 1

A4B Univ. AI 4 Pin 2

A4C Univ. AI 4 Pin 3

NC No Connection

A5A Univ. AI 5 Pin 1

A5B Univ. AI 5 Pin 2

A5C Univ. AI 5 Pin 3

NC No Connection

Univ.

A6A Univ. AI 6 Pin 1

AI

A6B Univ. AI 6 Pin 2

A6C Univ. AI 6 Pin 3

0V Common

V4 V OUT 4*

20mA

Transmitter

RTD

T/C

N/C

A3A

A3B

V

A3C

N/C

A4A

A4B

A4C

N/C

A5A

A5B

A5C

N/C

A6A

A6B

A6C

0V

V4

Indianapolis, USA | Cork, Ireland | Calgary, Canada | Bangalore, India | Oakleigh, Australia | Tianjin, China | Esteio, Brazil

Please visit our website for a complete listing and to learn more about certified Horner Automation products.

This document is the property of Horner Automation Group, and is subject to change.

for each output channel, however, only

the configured output type is calibrated

(maximum 4 channels simultaneously).

page 3 of 4

ALL MODELS:

Power Wiring Connector

Primary Power Range: 10-30VDC

MAN1195-02-EN

Page 4

Dimensions

5.66”

(143.76mm)

8.27”

(210.06mm)

1.73”

(43.94mm)

Panel Cut-Out

5.165”

(131.2mm)

7.468”

(189.7mm)

Installation Procedure

• The XL7 utilizes a clip installation method to ensure a robust and

watertight seal to the enclosure. Please follow the steps below for

the proper installation and operation of the unit.

• This equipment is suitable for Class I, Division 2, Groups A, B, C and

D or non-hazardous locations only.

• Digital outputs shall be supplied from the same source as the

operator control station.

• Jumpers on connector JP1 shall not be removed or replaced while

the circuit is live unless the area is known to be free of ignitable

concentrations of flammable gases or vapors.

The XL7 utilizes a clip installation method to ensure a robust and

watertight seal to the enclosure. Please follow the steps below for the

proper installation and operation of the unit.

1. Carefully locate an appropriate place to mount the XL7. Be sure to

leave enough room at the top of the unit for insertion and removal

of the microSD™ card.

2. Carefully cut the host panel per the diagram, creating a 131.2mm x

189.7mm +/-0.1 mm opening into which the XL7 may be installed.

If the opening is too large, water may leak into the enclosure,

potentially damaging the unit. If the opening is too small, the OCS

may not fit through the hole without damage.

3. Remove any burrs and or sharp edges and ensure the panel is not

warped in the cutting process.

4. Remove all Removable Terminals from the XL7. Insert the XL7

through the panel cutout (from the front). The gasket must be

between the host panel and the XL7.

5. Install and tighten the four mounting clips (provided in the box)

until the gasket forms a tight seal

NOTE: Max torque is 0.8 to 1.13Nm, or 7 to 10 in-lbs.

6. Reinstall the XL7 I/O Removable Terminal Blocks. Connect

communications cables to the serial port, USB ports, Ethernet port,

and CAN port as required.

page 4 of 4

Indianapolis, USA | Cork, Ireland | Calgary, Canada | Bangalore, India | Oakleigh, Australia | Tianjin, China | Esteio, Brazil

Precautions

All applicable codes and standards need to be followed in the installation of

this product. Adhere to the following safety precautions whenever any type of

connection is made to the module:

1. Connect the safety (earth) ground on the power connector first before making

any other connections.

2. When connecting to the electric circuits or pulse-initiating equipment, open

their related breakers.

3. Do NOT make connection to live power lines.

4. Make connections to the module first; then connect to the circuit to be

monitored.

5. Route power wires in a safe manner in accordance with good practice and local

codes.

6. Wear proper personal protective equipment including safety glasses and

insulated gloves when making connections to power circuits.

7. Ensure hands, shoes, and floor are dry before making any connection to a

power line.

8. Make sure the unit is turned OFF before making connection to terminals.

9. Make sure all circuits are de-energized before making connections.

10. Before each use, inspect all cables for breaks or cracks in the insulation.

Replace immediately if defective.

11. Use copper conductors in Field Wiring only, 60/75°C.

12. Do not disconnect while circuit is live unless area is known to be non-hazardous.

13. Do not remove or replace jumpers or connectors while circuit is live unless the

area is known to be free of ignitable concentrations of flammable gases or

vapors.

14. Use caution when making connections to the controller to protect against static

discharge. Special care must be taken when replacing the battery or inserting or

adjusting I/O or communication boards.

15. Use caution when connecting controllers to PCs via serial or USB. PCs,

especially laptops may use “floating power supplies” that are ungrounded.

This could cause a damaging voltage potential between the laptop and

controller. Ensure the controller and laptop are grounded for maximum

protection. Consider using a USB isolator due to voltage potential differences as

a preventative measure.

16. Failure to follow these guidelines can damage the controller and/or other

devices.

Hazardous Location Notice

Power, input and output (I/O) wiring must be in accordance with Class 1, Division

2 wiring methods [Article 501-4(b) of the National Electrical Code, NFPA 70] for

installations in the U.S. or as specified in Section 18-1J2 of the Canadian Electrical

Code for installations within Canada and in accordance with the authority having

jurisdiction.

1. THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A B C D or

NON-HAZARDOUS LOCATIONS ONLY.

2. WARNING – EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS I, DIVISION 2.

AVERTISSEMENT - RISQUE D’EXPLOSION LA SUBSTITUTION DECOMPOSANTS

PEUT RENDRECE MATE RIEL INACCEPTABLE POUR LES EMPLACEMENTS DE

CLASSE I, DIVISION 2

3. WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS

POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-

HAZARDOUS AND FREE OF IGNITABLE CONCENTRATIONS.

ATTENTION - RISQUE D’EXPLOSION - NE DECONNECTEZ PAS L’EQUIPEMENT

A MOINS DE L’AVOIR MIS HORS TENSION OU QUE LA ZONE EST CONNUE NON-

DANGEUREUSE ET NE CONTIENT PAS DE CONCENTRATIONS INFLAMMABLES.

4. WARNING - EXPLOSION HAZARD - BATTERIES MUST ONLY BE CHARGED IN AN

AREA KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D’EXPLOSION - LES PILES NE DOIVENT ÊTRE CHARGÉES

QUE DANS UN ENDROIT DE DANGER NON DANGEREUX.

5. WARNING - Battery may explode if mistreated. Do not recharge, disassemble, or

dispose of in fire.

AVERTISSEMENT - La batterie peut exploser si elle est maltraitée. Ne pas recharger,

démonter ou jeter au feu.

FCC Compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference

2. This device must accept any interference received, including interference

that may cause undesired operation

Technical Support

For further details, please refer to the Datasheets, MAN1112 – MAN1117. For assistance

and manual updates, contact Technical Support at the following locations:

North America Europe

+1 (317) 916-4274 +353 (21) 4321-266

www.hornerautomation.com www.hornerautomation.eu

techsppt@heapg.com technical.support@horner-apg.com

Please visit our website for a complete listing and to learn more about certified Horner Automation products.

This document is the property of Horner Automation Group, and is subject to change.

MAN1195-02-EN

Loading...

Loading...